1. Introduction

To combat climate change, the Australian Government is setting targets to continuously reduce its greenhouse gas (GHG) emissions and reach net zero emissions by 2050 [

1]. The Environmental Protection Agency [

2] has linked climate change with energy by stating that the largest emitter of greenhouse gases into the atmosphere can be traced back to the energy sector. Within the renewable energy sector, encompassing solar, hydroelectricity, geothermal, and wind power, wind is increasingly preferrable for Australian Commonwealth States that seek 82% renewable energy for Australia’s electricity grids by 2030 [

3].

Whilst Australia has some 110 operating wind farms [

4], 4C offshore databases (TGS 2024) show no

offshore turbines as yet, as the sector strives to address the 2021/22 Offshore Electricity Infrastructure Act [

5]. In other words, Australian offshore wind turbine projects are currently at the feasibility and early conceptual design studies stages. To this end, there is need for ongoing whole-cost assessments; the work presented here seeks to fill this gap with a Life Cycle Cost Analysis (LCCA) comparison of the key components for a Western Australia (WA)-based floating offshore wind turbine’s (OWT’s) constituent elements and sub-elements, to be used to assist design decisions. Semi-structured interviews, within a phenomenological qualitative research methodology, help develop and populate a comprehensive LCCA specification-choice guidance tool.

2. Offshore Wind Turbines

Early stages of development find that turbines were traditionally designed and constructed with fixed-bottom foundations, including monopile, tripod, jacket, gravity base, tri-pile, and twisted jacket, the most common being monopile, as they are optimal for shallow water depths less than 20 m. By the end of 2016, around 81% of offshore wind turbines in Europe were monopiles [

6], in which thick-walled steel tubular sections weighing up to 950 t are drilled into the seabed with 40–50% of the length submerged. The typical pile length is 50 m, and the outer diameter is 4 to 6 m [

7].

Later developments utilise emerging floating foundation technologies in order to extend turbines to locations with stronger winds and deeper seabeds. Edwards [

8] argues that farther offshore locales mean bottom-fixed turbines are less feasible and that floating platform OWTs are required, the foundations for which use mooring lines to anchor the floating turbine base to the seabed; Chen [

6] notes such technology significantly expands the potential for offshore wind farms.

Although offshore wind turbines have benefits, they are more capital-intensive than onshore counterparts; depending on sea conditions and distance from the coast, the tower and foundations of offshore wind turbines are 20–300% higher than onshore [

9,

10], with repair costs 5–10 times more, and additional costs incurred from using higher-grade turbine blades that are more suited to corrosion and stronger wind [

11]. Such assertions require further study, thus prompting this work.

2.1. Offshore Wind in Australia

The Australian Ministry for Climate Change and Energy notes six priority areas for offshore wind development: Gippsland (VIC); Hunter (NSW); Southern Ocean (VIC); Illawarra (NSW); Bass Strait (TAS); and the Indian Ocean off Bunbury (WA). These are chosen, respectively, for strong consistent winds, existing infrastructure, electricity transmission capabilities, and seaport linkages [

12]. To facilitate feasibility assessments, however, offshore wind turbine component costings are sparse; whilst a study by Gao [

13] applied an LCCA for exploiting development

zones around South-Eastern Australia, areas such as Western Australia have very limited research into the feasibility of offshore wind components in this unique location. This work fills this gap, with an LCCA model unique to the Bunbury site and related regional zoned developments along the WA Coast.

2.2. Life Cycle Cost Analysis LCCA

Farr’s [

14] guide to engineering cost management systems through the perspective of an LCCA highlight techniques for simulation-based, complex systems costings that build somewhat upon the well-established work by Kirk [

15], which presents a systematic approach for making informed economic decisions for building and construction professionals. Generally, the goal of ensuring true sustainability and life cycle cost requires frameworks that identify all major cost elements; collect data; apply economic models; and address risk management via sensitivity analyses [

16,

17]. LCCA frameworks also exist in the National Standards (AS 4536 & ISO 15686-5), which note that LCCA principles outline a specific purpose and define a scope. The research presented here embraces the above LCCA techniques to model a comprehensive, Western Australian-based, whole-cost analysis of OWT developments by assessing the feasibility and/or conceptual design stages.

2.3. LCCA of Fixed or Floating Offshore Wind Turbines

Traditionally, studies focus upon the cost management of bottom-fixed turbines due to their suitability in shallow waters [

18]; their foundations have lower capital cost compared to floating foundations. However, areas farther offshore with stronger winds and deeper seabeds necessitate floating foundation research, and a levelised cost of energy (LCOE) approach via the LCCA’s floating foundation designs [

8,

10,

19,

20]. For this reason, this study addresses floating offshore turbine components for Australian (contour maps of) offshore wind farm development sites with high site wind speed, recognizing that LCOE has defined metrics and is an accepted means to analyse the life cycle of energy projects [

19,

21,

22,

23,

24], notwithstanding that some [

13] argue that LCOE discounts the benefits to power systems attributed to a particular generation source. LCOE is still widely used.

An OWT LCCA from BVG Associates in conjunction with the Crown Estate and Offshore Renewable Energy Catapult [

10] offers guidance for offshore wind farm whole-cost in the UK, based upon a comparative cost per MW of turbine capacity, assuming a project size of 1 GW, consisting of 100,10 MW turbines located 60 km offshore with 30 m seabed depth. This is due to where the was data sampled: historical UK wind farms sourced by the UK Government Department for Business, Energy and Industry Strategy. Although LCCA principles were noted, there was no alternative components considered, again necessitating the work presented here.

2.4. Alternative OWT Component: LVL vs. Steel

Balasbaneh [

25] studied both the environmental and economic impacts of using LVL as a construction material, with a case study of two different mass timber buildings comparing LVL with Glue Laminated Timber. While these two engineered woods are similar, the study included other materials such as steel connections, gypsum board, and glass wool insulation to maximise its reliability; they found that the total life cycle cost of LVL is lower than the total cumulative cost of steel connections and all other construction components. This highlights a significant cost benefit in using LVL as an alternative construction material. Although LVL has a lower cost overall, extrapolating to

OWT applications, it may be argued that high transportation costs will accrue from offshore delivery, alongside a greater prefabrication front end cost. Whilst LVL turbine blades and tower manufacturers claim lower costs compared to traditional steel and fibreglass [

26,

27], further research into accurate transportation and the prefabrication of larger LVL structures is required for successful adaptation of LVL OWT.

LCCA studies that compare alternatives to OWT components are scarce. Advancements in using LVL as a construction material for OWT towers and blades anecdotally appear to offer cost savings, but there remains a need for an (this) LCCA model for offshore wind turbines, using a real-world priority area identified for development in Australia.

3. Methodology

This work’s semi-structured interviews with three WA OWT experts, compliant with Creswell’s [

28] expectation for a phenomenological life experiences quorum, enhances the development of a cost model populated by collective primary and secondary data. The first iteration of this LCCA model sought a quantitative analysis review, which was subsequently validated. The collected data drew interpretations of an optimisation turbine LCC. Pareto’s 80:20 approach [

29] identified the 20% of components that contribute to 80% of whole-cost; namely, secondary research identified the key life-cost OWT elements of the tower and blades; this work developed its LCCA model to also highlight capital costs, and then compared traditional steel and fibreglass, with the alternative material of LVL for the tower and blades. A sensitivity analysis mitigated changing interest rates’

risk, at a ±1% discount rate change (via the RICS rule of thumb [

30] below and further in

Table 1, Equation (2)), alongside multi-variable analysis of raw material prices, towards a breakeven point analysis of alternatives (Equation (1)). This LCCA methodology modelled Net Present Value calculations of LCOE [

19] for two spec. options (

Table 2), with the discount rate taken as the Risk Premium Discount Rate seen in Equation (2) [

30], such that the sourced WA treasury bond return rate (TB%) and inflation rate (IR%) aligned with a Construction Risk (CR%) rate of risk to equity at 0.5 or 50% (RICS) and combined with an equity return rate (Equity Return%) for offshore wind turbine projects [

31]. This study validated the developed LCCA model by follow-up interview [

32].

CAPEX = Capital Expenditures

OPEX = Operational Expenditures

DeComm = Decommission Costs

n = total number of time periods

t = time period

r = discount rate.

TB% = Australian 30-year Treasury Bond Rate

IR% = Interest Rate (30-year average)

CR% = Construction Risk Rate per Equity

Equity Return% = Average Equity Return Rate for Wind Energy Sector

4. Results

This Life Cycle Cost Analysis model compares the traditional steel and fibreglass specifications, with Wooden OWT specifications, of NPVs with risk sensitivity analyses across a calculated risk premium discount rate within a priority-designated WA case study; final validation of the developed LCCA framework is via an industry experts’ quorum.

4.1. Capital Cost: Wooden OWT & Traditional Steel

The total capital costs include the supply of raw materials, fabrication, and installation.

The tower for a Traditional OWT requires 120 t of steel per MW [

35]. The unit cost of steel is specific to Western Australia [

36]. The baseline capital cost of a circular hollow steel section greater than 89 mm is noted as AUD 9000/t, plus necessary premium OWT structural column steelwork of AUD 3000/t, towards a final rate of AUD 12,000/t.

The amount of LVL required for a wooden tower column is 700 m

3 [

27] of Scandinavian spruce, structural-grade, LVL, WA-equivalent timber.

The epoxy-based surface coating systems for OWT comply with ISO 12944. This three-layer system has a zinc primer, epoxy intermediate coat, and polyurethane topcoat [

37]; it is priced using exterior finishes item(s) [

36] applied to both steel tower and timber tower specs. [

27,

38].

Typical/Traditional OWT fibreglass blades are noted here as IEA Wind Task 37 Blades of 130 m rotor diameter for tower heights of ~150 m [

39].

4.2. Operation, Maintenance, and Residual Costs at a Net Present Value (NPV)

Operation and maintenance (O&M) datasets are sampled and adjusted for WA conditions, from a UK case study’s published cost guides of floating OWT costs per MW turbines for equitable wind turbine parameters [

40]. The local WA Engineers’ forum interviews necessarily adapted cost figures to current WA Bunbury case study locales.

Of note is the 30-year design life, starting with the 2024 calendar year, the sum of the capital cost at year 0, and the addition of yearly O&M costs from the first year of operation until 30th, with decommissioning DeComm minus the salvage cost value of steel on 30th year.

NPV and risk premium discount rates were derived as above [

31,

41], as shown in

Table 1.

The total yearly costs are calculated for both like-for-like specification choices, as per

Table 2, against the discount factor using the above NPV formula (Equation (1)).

Table 2 describes the LCCA capital, operation, maintenance, and residual values.

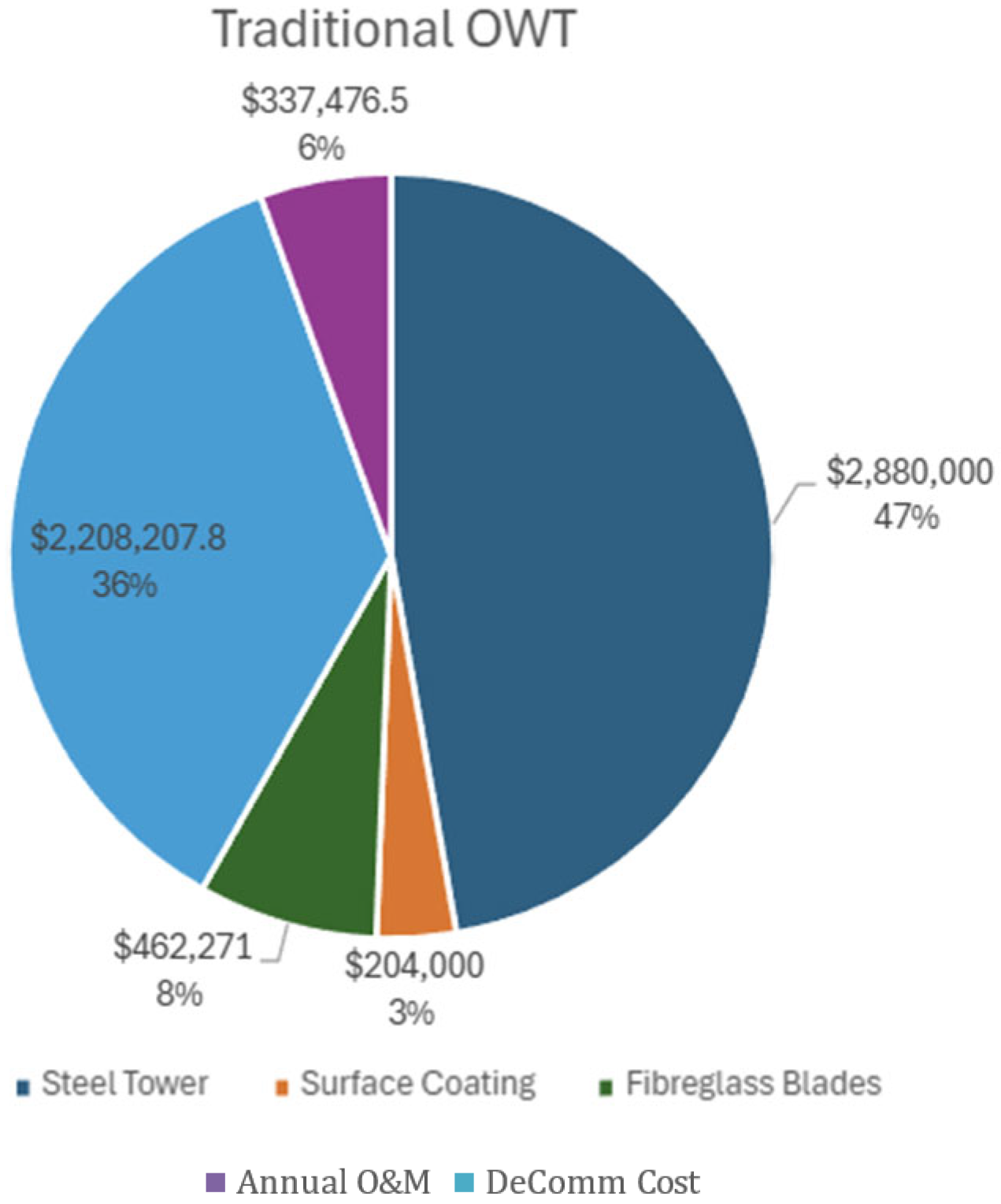

4.3. Summary of LCCA Data

A summary of the life cycle cost analysis (LCCA) is given in

Figure 1 and

Figure 2, in which the NPV calculates alternatives across respective elemental costs. Note the differences in blade and tower costs where timber is 2% greater for the same functional unit.

Although the upfront cost for the LVL timber/wooden blade was lower than a fibreglass blade by 20%, the overall CapEx for the Wooden OWT turned out to be higher than a traditional/steel-and-fibreglass OWT due to the wooden tower/column cost being higher (AUD 97.8k more than a steel tower). A cost saving of 20% per timber blade led to around AUD 93k savings across three blades but does not make up for a timber tower cost disadvantage. Despite a higher CapEx, the Wooden OWT has lower ongoing O&M cost: 5% lower than steel. The Traditional OWT O&M cost for the 30-year life span was pegged at AUD 2.2m, versus the lower Wooden spec. of AUD 2.09m. The DeComm stage introduced another difference in cost for each alternative; namely residual steel-scrap (offset) costs were deemed applicable, whilst the ‘bespoke’ nature of LVL timber components were deemed neither recyclable nor reusable. Thus, the Traditional OWT DeComm costs offset the overall steel total.

The NPV whole-costs of the alternatives were determined across a 30-year design life, such that one Wooden Turbine can provide cost savings of kAUD 30, across equitable comparison units, versus the traditional steel spec. counterpart, over the life cycle. Applying sensitivity analyses of one percentage point alterations, overall had a nominal effect, except in the extreme case of −1% steel price and +1% wood price. For three out of four sensitive scenarios, the Wooden alternative was more cost effective, with savings benefits of AUD 8937 to 30,550 (

Table 3).

Detailed breakdowns, by spec. option, of: CapEx; O&M; and, DeComm salvage values at the end of life are presented below:

Figure 3 shows the direct whole-cost (LCCA) dollar comparison (trad. steel versus. timber).

Figure 4 shows the percentage breakdown of the LCCA across the specification options.

Overall, the Traditional OWT presents a higher life cycle cost than the wooden alternative due to higher O&M, the discount rate and sensitivity analyses notwithstanding. Although, on the one hand, the CapEx and DeComm cost of steel is lower than wood, on the other hand, the O&M of timber is more cost-effective; thus, LVL demonstrates substantial potential for OWT component applications.

5. Conclusions

This study demonstrates that Laminated Veneer Lumber (LVL) components in offshore wind turbines can achieve whole-of-life cost savings of up to AUD 30,400 per megawatt compared to traditional steel–fibreglass systems. Despite marginally higher capital expenditure, mainly due to the cost of LVL towers, the long-term savings are driven by a 5% reduction in operation and maintenance costs. These results are validated across multi-variable sensitivity scenarios and a risk-adjusted discount framework tailored to Western Australia.

A key innovation in this study lies in its hybrid methodology. By integrating a validated Life Cycle Cost Analysis (LCCA) with qualitative insights from industry experts using a phenomenological approach, the research delivers a robust cost-comparison model. This model is the first of its kind to examine LVL-based offshore wind turbine specifications specifically within the Australian context, with a focus on floating turbine design in priority development areas such as Bunbury.

Beyond cost metrics, the findings point to significant environmental and strategic advantages. LVL, as a renewable and carbon-sequestering material, supports Australia’s net-zero targets while offering modular, prefabricated construction potential. The results also highlight broader industry implications: current standards and procurement processes that favour steel-based specifications should be re-evaluated considering emerging engineered timber technologies.

This research not only analyses conventional reliance on steel for offshore wind turbine construction but also explores sustainable innovation in the sector by involving a local case study and practitioner involvement. Future research should explore structural performance modelling of LVL components under marine conditions, life cycle emissions benchmarking, and regulatory alignment to enable widespread adoption. With appropriate policy support and localized supply chain development, LVL-based offshore wind solutions could play a transformative role in Australia’s renewable energy landscape.

Author Contributions

Conceptualization, A.W. and U.H.; Methodology, P.A. and A.W.; Software, P.A.; Validation, P.A.; Formal analysis, P.A., A.W. and U.H.; Investigation, P.A. and A.W.; Resources, U.H.; Data curation, P.A. and A.W.; Writing—original draft, P.A., A.W. and U.H.; Writing—review & editing, A.W. and U.H.; Visualization, P.A.; Supervision, A.W. and U.H.; Project administration, A.W.; Funding acquisition, P.A. and A.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Umair Hasan was employed by the Mobility & Infrastructure AlBurj Engineering Consultants. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- DISR Department of Industry Science and Resources 2024. Future Gas Strategy, Australian Government. Available online: https://www.industry.gov.au/publications/ (accessed on 20 May 2025).

- EPA. Climate Change Impacts on Energy. 2023. Available online: https://www.epa.gov/climateimpacts/climate-change-impacts-energy#:~:text=The%20energy%20sector%20is%20the,Basics%20of%20Climate%20Change%20page (accessed on 10 May 2025).

- ATIC. Australian Success in a Net Zero Future. 2024. Available online: https://international.austrade.gov.au/en/why-australia/go-green-with-australia (accessed on 10 May 2025).

- Aubrey, J. New Report: Vast Majority of Wind Turbines Can Avoid Landfill in Australia Clean Energy Council. 2023. Available online: https://www.cleanenergycouncil.org.au (accessed on 10 May 2025).

- OIR. Legislative Framework. Offshore Infrastructure Regulator. 2024. Available online: https://www.oir.gov.au/ (accessed on 10 May 2025).

- Chen, J.; Kim, M. Review of Recent Offshore Wind Turbine Research and Optimization Methodologies in Their Design. J. Mar. Sci. Eng. 2022, 10, 28. [Google Scholar] [CrossRef]

- Kaiser, M.; Snyder, B. Offshore Wind Energy Installation and Decommissioning Cost Estimation in the U.S. Outer Continental Shelf; TA&R Study 648; Bureau of Ocean Energy Management, Regulation and Enforcement: Herndon, VA, USA, 2010; 340p.

- Edwards, E.C.; Holcombe, A.; Brown, S.; Ransley, E.; Hann, M.; Greaves, D. Evolution of floating offshore wind platforms: A review of at-sea devices. Renew. Sustain. Energy Rev. 2023, 183, 113416. [Google Scholar] [CrossRef]

- MT Collaborative. A Framework for Offshore Wind Energy Development in the United States General Electric; US Department of Energy: Washington, DC, USA, 2005.

- Barooni, M.; Ashuri, T.; Velioglu Sogut, D.; Wood, S.; Ghaderpour Taleghani, S. Floating Offshore Wind Turbines: Current Status and Future Prospects. Energies 2023, 16, 2. [Google Scholar] [CrossRef]

- Zhang, D.; Zhang, X.; He, J.; Chai, Q. Offshore wind energy development in China: Current status and future perspective. Renew. Sustain. Energy Rev. 2011, 15, 4673–4684. [Google Scholar] [CrossRef]

- DCCEW. Australia’s Offshore Wind Areas. Department of Climate Change, Energy, the Environment and Water. Australian Government. 2024. Available online: https://www.dcceew.gov.au/energy/renewable/offshore-wind/areas (accessed on 15 April 2025).

- Gao, Q.; Hayward, J.A.; Sergiienko, N.; Khan, S.S.; Hemer, M.; Ertugrul, N.; Ding, B. Detailed mapping of technical capacities and economics potential of offshore wind energy: A case study in South-eastern Australia. Renew. Sustain. Energy Rev. 2024, 189, 113872. [Google Scholar] [CrossRef]

- Farr, J.; Isaac, J. Engineering Economics of Life Cycle Cost Analysis, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Kirk, S.; Dell’Isola, A. Life Cycle Costing for Design Professionals, 2nd ed.; McGraw-Hill: New York, NY, USA, 1995. [Google Scholar]

- Hasan, U.; Whyte, A.; Al Jassmi, H.; Hasan, A. Lifecycle Cost Analysis of Recycled Asphalt Pavements: Determining Cost of Recycled Materials for an Urban Highway Section. CivilEng 2022, 3, 316–331. [Google Scholar] [CrossRef]

- Hasan, U.; Whyte, A.; AlJassmi, H. Critical review and methodological issues in integrated life-cycle analysis on road networks. J. Clean. Prod. 2019, 206, 541–558. [Google Scholar] [CrossRef]

- Abdelhady, S.; Shaban, A. Assessment of levelized cost of electricity of offshore wind energy in Egypt. Wind. Eng. 2017, 41, 160–173. [Google Scholar] [CrossRef]

- Martinez, A.; Iglesias, G. Mapping of the levelised cost of energy for floating offshore wind in the European Atlantic. Renew. Sustain. Energy Rev. 2022, 154, 111889. [Google Scholar] [CrossRef]

- McMorland, J.; Collu, M.; McMillan, D.; Carroll, J. Operation and maintenance for floating wind turbines: A review. Renew. Sustain. Energy Rev. 2022, 163, 112499. [Google Scholar] [CrossRef]

- Myhr, A.; Bjerkseter, C.; Ågotnes, A.; Nygaard, T.A. Levelised cost of energy for offshore floating wind turbines in a life cycle perspective. Renew. Energy 2014, 66, 714–728. [Google Scholar] [CrossRef]

- Liang, Y.; Ma, Y.; Wang, H.; Mesbahi, A.; Jeong, B.; Zhou, P. Levelised cost of energy analysis for offshore wind farms—A case study of the New York State development. Ocean. Eng. 2021, 239, 109923. [Google Scholar] [CrossRef]

- Li, C.T.; Peng, H.; Sun, J. Life cycle cost analysis of wind power considering stochastic uncertainties. Energy 2014, 75, 411–418. Available online: https://www.sciencedirect.com/science/article/pii/S0360544214009293 (accessed on 10 May 2025). [CrossRef]

- Li, Q.; Duan, H.; Xie, M.; Kang, P.; Ma, Y.; Zhong, R.; Gao, T.; Zhong, W.; Wen, B.; Bai, F.; et al. Life cycle assessment and life cycle cost analysis of a 40 MW wind farm with consideration of the infrastructure. Renew. Sustain. Energy Rev. 2021, 138, 110499. [Google Scholar] [CrossRef]

- Balasbaneh, A.T.; Sher, W.; Yeoh, D.; Yasin, M.N. Economic and environmental life cycle perspectives on two engineered wood products: Comparison of LVL and GLT construction materials. Environ. Sci. Pollut. Res. 2023, 30, 26964–26981. [Google Scholar] [CrossRef] [PubMed]

- Voodin Blade Technology. Blades: The Benefits of Wooden Turbine Blades. Available online: https://voodin-blades.com/ (accessed on 10 May 2025).

- Modvion. The Product–Tower Potential. 2022. Available online: https://modvion.com/the-product/ (accessed on 10 May 2025).

- Creswell, J.W.; Creswell, J.D. Research Design: Qualitative, Quantitative, and Mixed Methods Approaches, 5th ed.; SAGE: Los Angeles, CA, USA, 2018. [Google Scholar]

- Hardy, M. Pareto’s Law. Math. Intell. 2010, 32, 38–43. [Google Scholar] [CrossRef]

- RICS. Discounted Cash Flow Valuations; Royal Institution of Chartered Surveysors: London, UK, 2023. [Google Scholar]

- Zhao, W.; Han, Y.; Niu, D. Analysis of economic benefit of wind power based on system dynamics. AIP Conf. Proc. 2018, 1955, 040077. [Google Scholar] [CrossRef]

- Yin, R. Case Study Research Design and Methods, 5th ed.; Sage: Thousand Oaks, CA, USA, 2014; 282p, ISBN 978-1-4522-4256-9. [Google Scholar]

- WGB. Australia 30 Years Bond—Historical Data. World Government Bonds. 2024. Available online: https://www.worldgovernmentbonds.com/bond-historical-data/australia/30-years/ (accessed on 10 May 2025).

- ABS. 70 Years of Inflation in Australia; Australian Bureau of Statistics, Ed.; ABS: Canberra, Australia, 2018.

- Barnard, M. How Much Steel Will All Those Wind Turbines & Solar Panels Need, & Can We Make It? CleanTechnica. 2022. Available online: https://cleantechnica.com/2023/03/27/how-much-steel-will-all-those-wind-turbines-solar-panels-need (accessed on 10 May 2025).

- Rawlinsons Quantity Surveyors and Construction Cost Consultants. Rawlinsons Construction Cost Guide 2024, 32th ed.; Rawlinsons Construction Cost Guide Series; Rawlinsons Publishing: Perth, Australia, 2024. [Google Scholar]

- Juhl, M.; Hauschild, M.Z.; Dam-Johansen, K. Sustainability of corrosion protection for offshore wind turbine towers. Prog. Org. Coat. 2024, 186, 107998. [Google Scholar] [CrossRef]

- USGS. What Materials Are Used to Make Wind Turbines? U.S. Department of the Interior, Ed.; U.S. Geological Survey: Reston, VA, USA, 2022.

- Bortolotti, P.; Berry, D.; Murray, R.; Gaertner, E.; Jenne, D.; Damiani, R.; Barter, G.; Dykes, K. A Detailed Wind Turbine Blade Cost Model; NREL/TP-5000-73585; National Renewable Energy Laboratory: Golden, CO, USA, 2019. Available online: https://www.nrel.gov/docs/fy19osti/73585.pdf (accessed on 10 May 2025).

- BVG. Guide to an Offshore Wind Farm; The Crown Estate and the Offshore Renewable Energy Catapult: Glasgow, UK; BVG Associates: Swindon, UK, 2019. [Google Scholar]

- Australian Bureau of Statistics. Data Sources. Commonwealth of Australia. 2024. Available online: https://www.abs.gov.au/statistics/understanding-statistics/statistical-terms-and-concepts/data-sources (accessed on 24 May 2025).

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).