Abstract

The use of polyester and polyamide fabrics for parachute constructions has a great advantage because, in comparison with classical silk-based parachutes, they are more durable and suitable for absorbing higher mechanical shocks. Because polyester and polyamides are thermoplastics, they are sensitive to sudden increases in temperature due to mechanical shocks and high-speed friction. It is known that the local surface temperature of these parachute fabrics may exceed the melting point of the canopy for a short time period during parachute opening, which would have irreversible effects on parachute functionality and could lead to catastrophic parachute rupture. The main aim of this article is to enhance the surface heat resistance of the parachute fabrics from polyamide and polyester filaments through surface coating combined with super-fine TiO2 particles and silanization. This coating is also selected to increase the frictional heat loss and enhance the mechanical stability of parachute fabrics constructed from polyamide and polyester filaments. The changes in air permeability, bending rigidity, and friction of surface-coated parachute fabrics are evaluated as well. The new method based on laser irradiation by a pulsed laser is used for the prediction of these fabrics’ short-time surface thermal resistance.

1. Introduction

Towards the end of last century, parachutes were manufactured mainly from polyamide (PAD 6,6). This synthetic fiber perfectly replaced traditional silk material due to its strength and softness. However, a problem arose here that did not occur with natural silk, namely heat generated by friction of the material when opening the parachutes. In this phase, the parachute is abruptly pulled out of the containers and the support lines are straightened, which creates great friction between the parachute material and the support lines. Although this friction is only created through impact and the effect lasts a very short time, the material on the parachute is often partially melted and some material degradation is noticeable. Due to the degradation, the parachutes are damaged and there is a risk of the parachute canopy tearing during the jump (meaning after repeated jumps). For these reasons, smoothing treatments began to be used on the materials, which are designed to reduce high friction. Other modifications to parachute materials include calendering, which is performed to reduce the breathability of the material.

The behavior of a parachute during operation is dependent on its aerodynamic forces and stability. These factors are primarily influenced by the geometry and porosity of the parachute canopy.

The structure and design of parachutes is composed of special filament textile fabric for the absorption of shocks, balancing the pressure forces and for a smooth opening during flying and landing. When using the parachute, many rapid processes start with the opening of the parachute and end with vibrations of the open parachute canopy. From the point of view of the thermal exposure of the parachute material, the opening phase of the canopy is crucial, i.e., withdrawing the parachute from the folded state. Here, not only does the material of the parachute canopy rub with the same material but also the canopy material rubs on the ropes. This friction can be located in a relatively small area in adverse cases.

The reduction of the friction coefficient, the increase in the thermal capacity, and the increase of the surface heat resistance of the parachute fabrics can be then used to reduce the damage of the parachutes. It also follows directly from the foregoing that it would also be advantageous to increase the frictional heat loss so that some of the frictional heat released from the system escapes before the parachute fabrics are heated to a critical limit.

The following mechanisms can be applied for the reduction of parachute fabric thermal damage:

- A.

- Reduction of the coefficient of friction of parachute fabrics, for example, by applying layers based on PTFE or silicone [1,2,3,4,5,6,7,8,9,10], which are materials with low coefficients of friction and high thermal stability.

- B.

- Increasing the thermal resistance of parachute fabrics, for example, by applying a thermally resistant layer based on silanization, which is able to protect the fibers against thermal damage.

- C.

- Making it difficult to heat parachute fabrics, e.g., by applying PCM with high specific heat, which consumes the friction energy to melt PCM.

- D.

- Increasing heat dissipation induced by friction, e.g., through macroscopic roughening via the deposition of structures emerging from the surface of parachute fabrics as the deposition of polyolefin structures with low coefficients of friction.

All of these mechanisms can be combined, and the combination of a reduction in the coefficient of friction and an increase in the thermal resistance of the parachute is very promising. This article is focused on the investigation of silanization combined with the creation of TiO2 particles [1,5] for the enhancement of the short-time surface thermal resistance and improvement of mechanical stability of parachute fabrics constructed from polyamide 6,6 and polyester filaments from polyethylene terephthalate having practically the same melting point, 256 °C. The laser irradiation by a pulsed laser is used for the simulation of these fabrics’ short-time surface thermal resistance.

2. Surface Silanization

One of the very promising ways to enhance the thermal resistance of fibrous structures is to use sol-gel technology [1]. Sol-gel technology has been used widely since 1980 in the process of synthesizing superconducting materials, functional ceramic materials, nonlinear optical materials, catalysts, enzyme carriers, porous glass materials, and other materials. The solution, sol or gel, solidifies the metal–organic or inorganic (precursor) compounds to form a sol or gel state and then develops an oxide through heat treatment. The condensation reaction transforms Si-OR- and Si-OH-comprising species to siloxane compounds, which is the basic chemical principle of sol-gel treatment of silica-based materials. Corner sharing connects this to the SiO4 tetrahedra (or RSiO3 tetrahedra in hybrid materials) from the structural point of view. In order to achieve a stable gel, it is essential to maximize the number of siloxane bonds (Si-O-Si) and subsequently minimize the number of silanol (Si-OH) and alkoxo (Si-OR) groups. Sol-gel is a wet treatment process. For sol-gel synthesis, the homogeneous solution is formed by dissolving the precursor in a solvent, which is the foremost step of the reaction (water or organic solvent) irrespective of the raw material, either an inorganic salt or metal alkoxide [4]. The sol-gel method has the advantages of eco-friendly, less chemical utilization, low-temperature treatment, low toxicity to human health, protection of the inherent properties of textile materials, and long-lasting properties of finished fabrics. Some types of sol-gel systems also have bacteriostatic or antibacterial effects. These systems are anatase-modified photoactive TiO2 coatings and sol-gel coatings with colloidal metals or metal compounds embedded in them, such as silver, silver salt, copper compound, zinc, or quaternary ammonium salt. It can be applied to textiles to develop various functional finishes, such as antibacterial, water repellent, superhydrophobic, oil/water separations, flame retardant [5,6,7,8,9,10], multifunctional, and ultraviolet (UV) protection self-cleaning, as well as soil-repellency, photocatalytic, and wear and abrasion resistance [10].

3. Materials and Methods

3.1. Materials

Parachute fabrics of the Ripstop weave made of PES and PAD multifilaments (see Table 1) were supplied by the company Sky Paragliders, Frýdlant nad Ostravicí, Czech Republic.

Table 1.

Tested parachute fabrics.

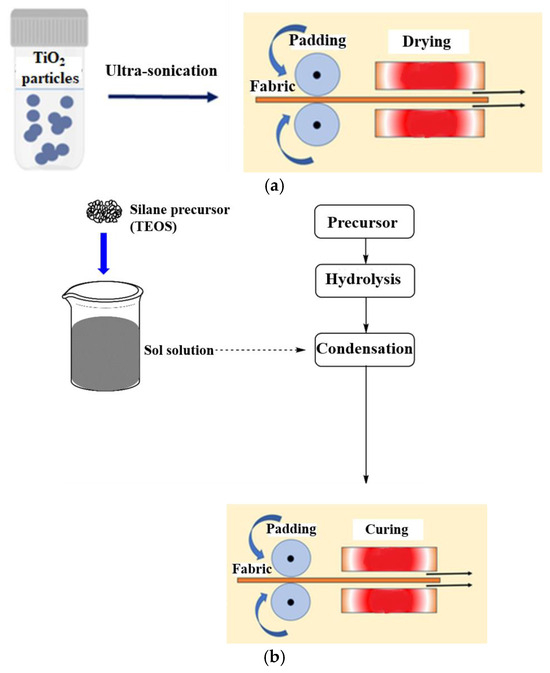

3.2. Preparation of TiO2 and Silanization

The method used for the deposition of TiO2 consists of sonication, padding, and drying. In the first step, nano TiO2 particles were prepared using the ultrasonic acoustic method, and then, direct deposition took place. For this purpose, a system composed of titanium tetraisopropoxide (TTIP), titanium tetrachloride (TTC), and ethylene glycol in ethanol was used. All samples were treated with ultrasonic acoustic waves in an ultrasonic homogenizer system (Bandelin Sonopuls, Merck, Germany) for 60 min for successful synthesis and the deposition of nano TiO2 (pure Anatase). Previous investigations reported that a higher amount of synthesized TiO2 in textiles produces higher photocatalytic and functional properties of the deposited samples. A significant amount of TiO2 (added by the padding of nano TiO2 at a concentration of 1g/L of the water dispersion) was found in all samples. Enhanced mechanical, thermal, and photocatalytic properties were induced and observed in the treated samples compared to the untreated samples.

The developed samples were further silanized using tetraethoxysilane (TEOS) as a precursor and HNO3 as a catalyst. The fabrics were dried in atmospheric conditions and then cured at 110 °C for 10 min. The coated samples are numbered 1-1, 2-1, and 4-1. Figure 1 shows the schematic of the deposition of TiO2 and silanization.

Figure 1.

(a) Deposition of TiO2 and (b) silanization.

3.3. Testing

For a more comprehensive evaluation of the efficiency of surface treatments of parachute textiles, the following characteristics (based on standard or new tests) were selected:

- Surface geometry. Microscopic images of fabric samples were prepared on a Vega Tescan electron microscope.

- Air permeability (reduction of the porosity). Air permeability was measured on the FX3300 air permeability machine with measurements taken at an airflow rate of 1000 Pa and 1500 Pa under standard conditions

- Bending rigidity (force bending). The device TH-7, Inotex, Dvůr Králové, Czech Republic with distance between the clamping and the sensor jaws of 14 mm was used. The range of the measuring force of bending was from 40 to 4000 mN. The output from the device is the value of the bending force, FM [mN]. A sample width of 50 mm and a length of 50 mm were selected. The calculation of bending rigidity is described in the work [11].

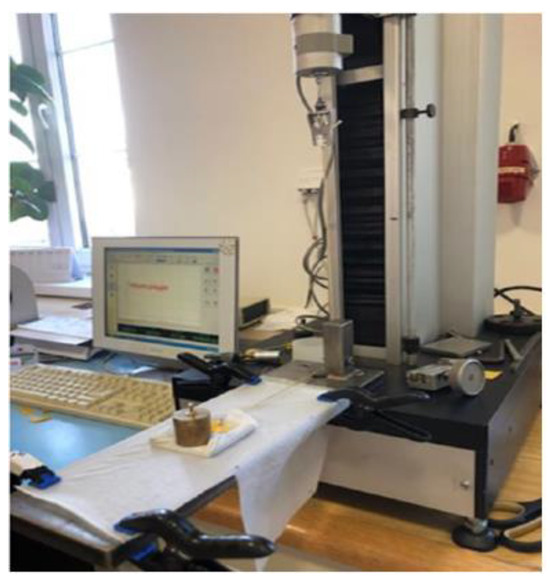

- Friction. Static and kinetic friction coefficients were measured using a flat surface and a dynamic plate on an instrument developed at the Technical University of Liberec with force provided by an Instron, Darmstadt, Germany (see Figure 2). A dynamic plate with a load of 150 g was pulled over the sample in both the warp and weft direction over a distance of 100 mm at a rate of 150 mm/min. This device is shown in Figure 2.

Figure 2. Friction–tensile test arrangement.

Figure 2. Friction–tensile test arrangement.

The coefficient of friction μ was calculated from the known first law of Amontons as

where F is the friction force and N is the normal load that presses the surfaces together.

- 5.

- Short-term irradiation. The original method of laser thermal exposure was implemented. This method enables the accurate dosing of thermal energy into parachute fabrics in an extremely short time. The equipment output is up to 100 W/mm2 (100 MW/m2). The defined transfer of energy occurs in such a short time that heat losses can be neglected, and the effect is similar to the processes of the friction of parachute fabrics. The realization of the test was based on the graded dosing of laser radiation and the search for limited laser exposition power irreversibly damaging the parachute fabrics [12,13,14].

A commercial pulsed CO2 laser engraving machine (GFK Marcatex FLEXI-150, Jeanologia S.L., Valencia, Spain) was used under normal atmospheric conditions (see Figure 3). The average output power was 150/250 watts, the peak output power was 230/400 watts, the working frequency was 50/60 Hz, the wavelength of the laser beam was 10.6 μm, and polarization was linear, with a time mode pulse. The thermal stress was caused by the laser beam using various power setting parameters to achieve different stress conditions. The duty cycle and resolution were fixed for all the treatments, and the pixel time differed for each treatment, as shown in Table 2.

Figure 3.

150 FLEXI MARCATEX laser instrument.

Table 2.

Process parameters of the laser-engraving machine.

The marking time in seconds induced by the laser on the samples was found for the treatment 1 as 0.182 s, for treatment 2 as 0.219 s, and for treatment 3 as 0.25 s. The increase in pixel time tends to increase in the marking time:

- ✓

- treatment 1 used the pixel time of 50 μs

- ✓

- treatment 2 used the pixel time of 70 μs

- ✓

- treatment 3 has used the pixel time of 90 μs

Fabric pieces of a size of 2 cm × 2 cm were subjected to laser treatment under different combinations of resolutions and pixel times. The thermal stress was caused by a laser beam using various power setting parameters to achieve different stress conditions.

4. Results and Discussion

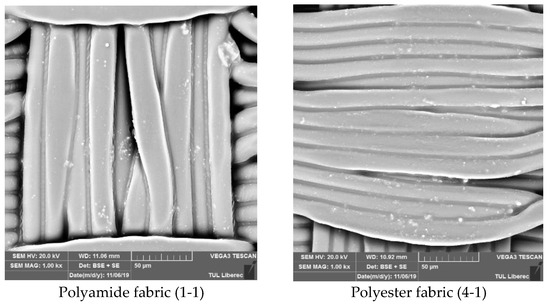

4.1. Surface Characterization

Figure 4 shows SEM images of selected parachute fabric surfaces after treatment with a combination of nano TiO2 and silanization for polyamide samples (1-1) and calendered polyester samples (4-1). Sample 2-1 was used to investigate the influence of treatment with a combination of nano TiO2 and silanization on changes in the polyester material properties, such as air permeability, friction, and bending rigidity. Sample 2-1 is used in the intermediate stage of fabrication.

Figure 4.

Surface of parachute fabrics after treatment with nano TiO2 and silanization.

There is an apparent silane layer, which adheres to adjacent fibrils and partly appears as nano TiO2 particles. It can be seen that the surface of the fabrics is not completely covered by the silane layer so that they remain breathable. The polyamide fabric (1-1) had better coverage and the best performance with TiO2 deposition and the silane layer.

4.2. Air Permeability

The results of air permeability for two pressure drops are shown in Table 3. As indicated in Table 3, sample 1 (polyamide) performed the best with the lowest air permeability. As shown in Table 3, calendering and surface coating decreased the air permeability significantly.

Table 3.

Ninety-five percent confidence interval of the air permeability values.

The work explains in detail the relation between air permeability and the porosity of textile fabrics [15].

Usually, the Dacry linear relationship is used to express the relationship between the relative pressure drop (the ratio of the pressure drops Δp to the fabric thickness) and air permeability. This model was the best from a statistical point of view. Air permeability generally depends on the construction and treatment of the fabric, and therefore, it is necessary to determine it for each parachute textile.

4.3. Bending Rigidity

The average bending forces and bending rigidity of untreated samples (1, 2, 4) and samples with TiO2 and silane coating (1-1, 2-1, 4-1) are given in Table 4. Each sample was measured five times in both warp and weft directions.

Table 4.

Bending properties of selected materials.

It is visible that the bending rigidity of treated samples with TiO2 and silane coating are smaller in comparison with the original materials.

The bending rigidity of fabric depends on the fiber/filament diameter, yarn fineness, number of filaments, the inter-fiber and inter-yarn friction, etc. The friction between individual filaments in a yarn is caused by different mechanisms. The filaments on the outer perimeter of the yarn interact with filaments from other yarns due to the undulation in fabrics. Filaments within the yarns are often entangled because of fiber migration and length differences due to deformations. A fiber sizing is often applied during production to protect the yarn material and/or improve fiber–matrix bonding. Another factor plays a role in the intra- and inter-yarn friction behavior. The effects mentioned above all have an influence on the deflection behavior of yarns based on friction mechanisms.

It is clearly visible that the warp way rigidity is higher than the weft way bending rigidity as the warp yarns are stiffer, and there is a higher sett in the warp direction. The PES samples have higher rigidity as compared to the PAD fabric. It can be due to the inherent higher rigidity of the PES filaments as compared to PA filaments. There is a higher number of filaments in each yarn, thus causing an increase in the yarn bending rigidity. Further, the sett of the PES fabrics is much higher than the PAD fabric. Therefore, the bending stiffness is increased.

4.4. Friction

The static friction forces F0 (coefficients µ0) and the kinetic friction forces Fk (coefficients µk) for the untreated samples (1, 2, 4) and samples with TiO2 and silane coating (1-1, 2-1, 4-1) are shown in Table 5.

Table 5.

Ninety-five percent confidence interval of the friction-tensile values.

Before TiO2 and silane coating, sample 4 (PES) had the lowest static and kinetic friction coefficients in both the warp and weft directions; however, after TiO2 and silane coating, sample 2 (PES) exhibited the lowest static and kinetic friction coefficients in the warp direction and sample 1 (polyamide) in the weft direction.

Sample 1 (polyamide) had a kinetic friction coefficient of 0.11 and 0.060 and a static friction coefficient of 0.17 and 0.140 in the warp and weft directions, respectively. The friction coefficients for sample 1 (polyamide) also differ the least between warp and weft, which can be attributed to the balanced plain weave structure and unbalanced plain weave for samples 2 (PES) and 4 (PES). Sample 4 (PES) was the worst after the TiO2 and silane coating. They had a kinetic friction coefficient of 0.17 and 0.27 and a static friction coefficient of 0.23 and 0.320 in the warp and weft directions, respectively.

4.5. Propagation of Damage During Short-Term Irradiation

The images of the samples were scanned by the laser scanner to obtain a clear picture of the damage caused by the laser beams according to their intensity. In Table 6, the images of the original samples, 1 (polyamide fabric), 2 (grey polyester fabric), and 4 (calendered polyester fabric), treated under three different parameters of the laser instrument are shown.

Table 6.

Images of the untreated samples.

Treatment 1 shows the minor marks in the whole set of samples, but in treatment 2, the mark is strong for polyester fabrics and a minor hole is appearing in the PA fabric (1).

Treatment 3 shows the nearly total destruction of the all samples, so at the 90 μs pixel time, all material was destructed more than 80%.

In Table 7, the images of sample 1 (surface coated polyamide fabric) treated under three different parameters of the laser instrument are shown.

Table 7.

Images of sample 1 (coated polyamide).

Treatment 1 shows the minor marks in the whole set of samples, but in treatment 2, the mark is a little stronger than treatment 1, and a minor hole is appearing.

The images of sample 2 (surface coated polyester fabric) treated under three different parameters of the laser instrument are shown in Table 8.

Table 8.

Images of sample 2 (coated polyester).

Treatment 1 shows the minor holes, but in treatment 2, the destruction of the samples appeared. Treatment 3 shows the complete destruction.

The images of sample 4 (surface coated calendered polyester fabric) treated under three different parameters of the laser instrument are shown in Table 9.

Table 9.

Images of sample 4 (coated calendered polyester).

Treatment 1 shows the minor holes in the whole set of samples, but in treatment 2, the destruction of the samples appeared. Treatment 3 shows the complete destruction.

5. Conclusions

Parachute textile fabrics serve as a primary source for aerodynamic deceleration systems (parachutes) subjected to dynamic fluttering during utilization. The performance of these fibrous structures is often constrained by the fiber, yarn, and fabric properties. Careful and precise design techniques allow for performance gains to approach theoretical limits, but continuing performance demands require the use of new and improved materials and surface treatments.

In general, PA fibers have long been used for the construction of parachute fabrics. PES materials generally have a lower toughness and a lower elongation to break than PAD 6,6. On the other hand, their benefits are dimensional stability and better steady-state flight performance. Their lower elasticity is responsible for higher parachute-opening forces. A new method for the characterization of shock thermal resistance by using a laser is efficient, and conditions of irradiations could be tuned according to different conditions of parachute fabric use.

It was shown that parachute fabrics (especially PAD 66) show better resistance against CO2 laser irradiation, i.e., better thermal resistance. This surface modification does not have serious adverse effects on the bending rigidity and air permeability. Friction properties are negatively influenced by the TiO2-silane coating. Before an application for parachutes, the comprehensive testing of durability under conditions of practical use should be realized. For further studies, it will be beneficial to compare this modification with other techniques, such as treatment with silicon oil or PCM (see Section 1).

Author Contributions

Conceptualization, J.M. and J.W.; methodology, D.K.; validation, J.W., M.V. and J.M.; formal analysis, M.V.; investigation, J.W.; resources, D.K.; data curation, J.M.; writing—original draft preparation, J.M.; writing—review and editing, M.V.; visualization, M.V.; supervision, J.M.; project administration, M.V.; funding acquisition, M.V. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by the project ‘Advanced structures for thermal insulation in extreme conditions’ (Reg. No. 21–32510 M) granted by the Czech Science Foundation (GACR).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

This work is dedicated to Izabella Krucińska from TU Lodz, Poland. She was not only a prominent scientific personality but also our close friend. It is a tribute to her memory.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Periyasamy, A.P.; Venkataraman, M.; Kremenakova, D.; Militky, J.; Zhou, Y. Progress in Sol-Gel Technology for the Coatings of Fabrics. Materials 2020, 13, 1838. [Google Scholar] [CrossRef] [PubMed]

- Colleoni, C.; Donelli, I.; Freddi, G.; Guido, E.; Migani, V.; Rosace, G. A novel sol-gel multi-layer approach for cotton fabric finishing by tetraethoxysilane precursor. Surf. Coat. Technol. 2013, 235, 192–203. [Google Scholar] [CrossRef]

- Guido, E.; Alongi, J.; Colleoni, C.; Di Blasio, A.; Carosio, F.; Verelst, M.; Malucelli, G.; Rosace, G. Thermal stability and flame retardancy of polyester fabrics sol–gel treated in the presence of boehmite nanoparticles. Polym. Degrad. Stab. 2013, 98, 1609–1616. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Sol–gel treatments on cotton fabrics for improving thermal and flame stability: Effect of the structure of the alkoxysilane precursor. Carbohydr. Polym. 2012, 87, 627–635. [Google Scholar] [CrossRef] [PubMed]

- Alongi, J.; Ciobanu, M.; Malucelli, G. Thermal stability, flame retardancy and mechanical properties of cotton fabrics treated with inorganic coatings synthesized through sol–gel processes. Carbohydr. Polym. 2012, 87, 2093–2099. [Google Scholar] [CrossRef]

- Selvakumar, N.; Azhagurajan, A.; Natarajan, T.S.; Khadir, M.M.A. Flame-retardant fabric systems based on electrospun polyamide/boric acid nanocomposite fibers. J. Appl. Polym. Sci. 2012, 126, 614–619. [Google Scholar] [CrossRef]

- Alongi, J.; Ciobanu, M.; Tata, J.; Carosio, F.; Malucelli, G. Thermal stability and flame retardancy of polyester, cotton, and relative blend textile fabrics subjected to sol–gel treatments. J. Appl. Polym. Sci. 2011, 119, 1961–1969. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, C.; Fang, S.; Ji, P.; Wang, H.; Ji, C. Durable flame-retardant and antidroplet finishing of polyester fabrics with flexible polysiloxane and phytic acid through layer-by-layer assembly and sol–gel process. J. Appl. Polym. Sci. 2018, 135, 4641–4644. [Google Scholar] [CrossRef]

- Horrocks, A.R. Flame Retardant Textile Finishes. Text. Finish. 2017, 2017, 69–127. [Google Scholar]

- Brzeziński, S.; Kowalczyk, D.; Borak, B.; Jasiorski, M.; Tracz, A. Nanocoat finishing of polyester/cotton fabrics by the sol-gel method to improve their wear resistance. Fibres Text. East. Eur. 2011, 19, 83–88. [Google Scholar]

- Fridrichová, L. A new method of measuring the bending rigidity of fabrics and its application to the determination of their anisotropy. Text. Res. J. 2013, 83, 883–892. [Google Scholar] [CrossRef]

- Hung, O.; Kan, C.-W. Effect of CO2 Laser Treatment on the Fabric Hand of Cotton and cotton/Polyester Blended Fabric. Polymers 2017, 9, 609–615. [Google Scholar] [CrossRef] [PubMed]

- Yuan, G.X.; Jiang, S.X.K.; Newton, E.; Fan, J.T.; Au, W.M. Fashion Design Using Laser Engraving Technology. In Proceedings of the 8th ISS Symposium-Panel on Transformation, Garmisch-Partenkirchen, Germany, 11–16 September 2011; Volume 1, pp. 65–69. [Google Scholar]

- Štěpánková, M.; Wiener, J.; Dembický, J. Impact of Laser Thermal Stress on Cotton Fabric. Fibres Text. East. Eur. 2010, 18, 70–73. [Google Scholar]

- Militký, J.; Havrdová, M. Porosity and air permeability of composite clean room textiles. Int. J. Cloth. Sci. Technol. 2001, 13, 280–289. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).