Hygrothermal Aging of Glass Fiber-Reinforced Benzoxazine Composites

Abstract

1. Introduction

2. Materials and Methods

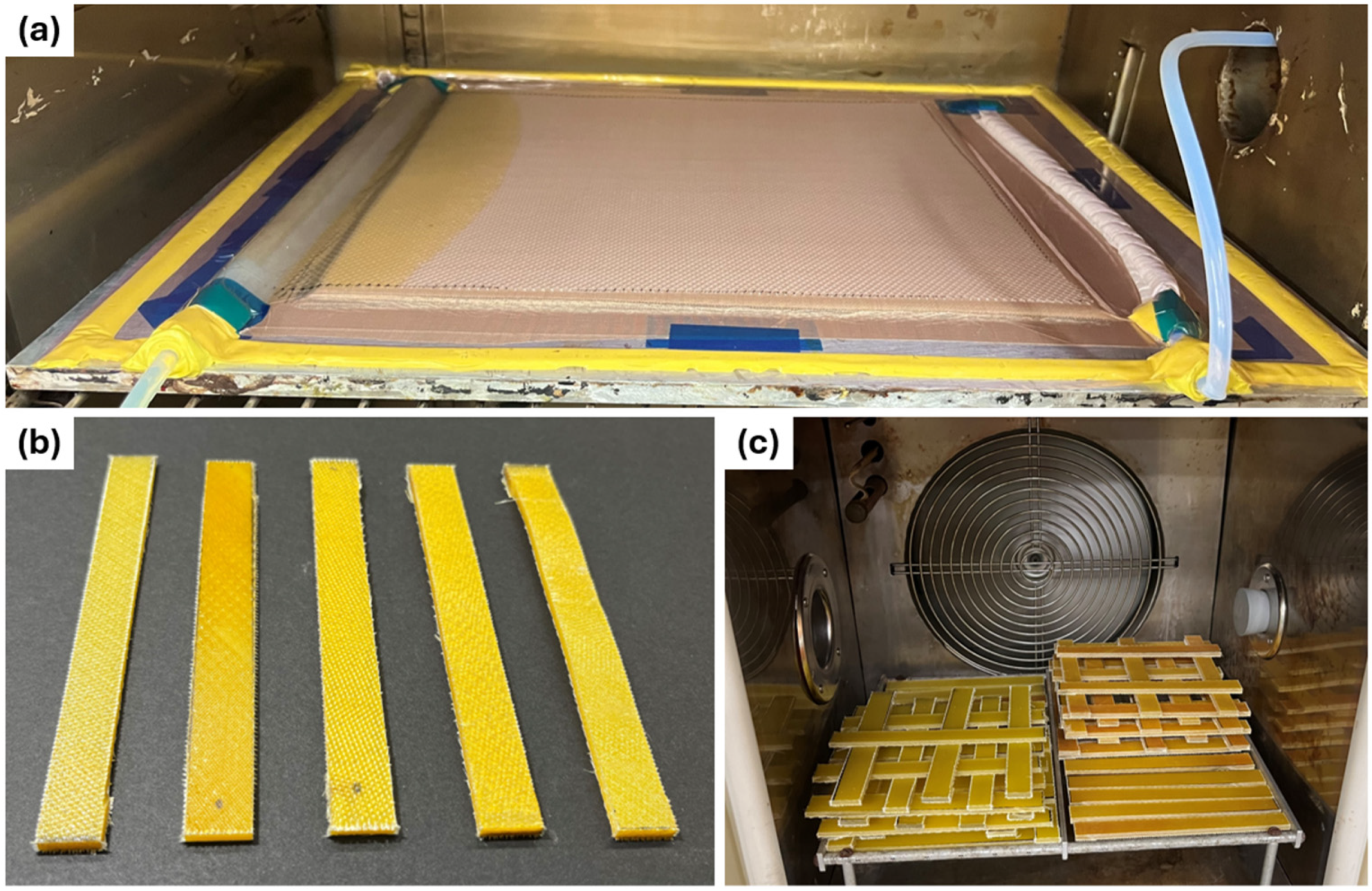

2.1. Composite Fabrication and Hygrothermal Aging

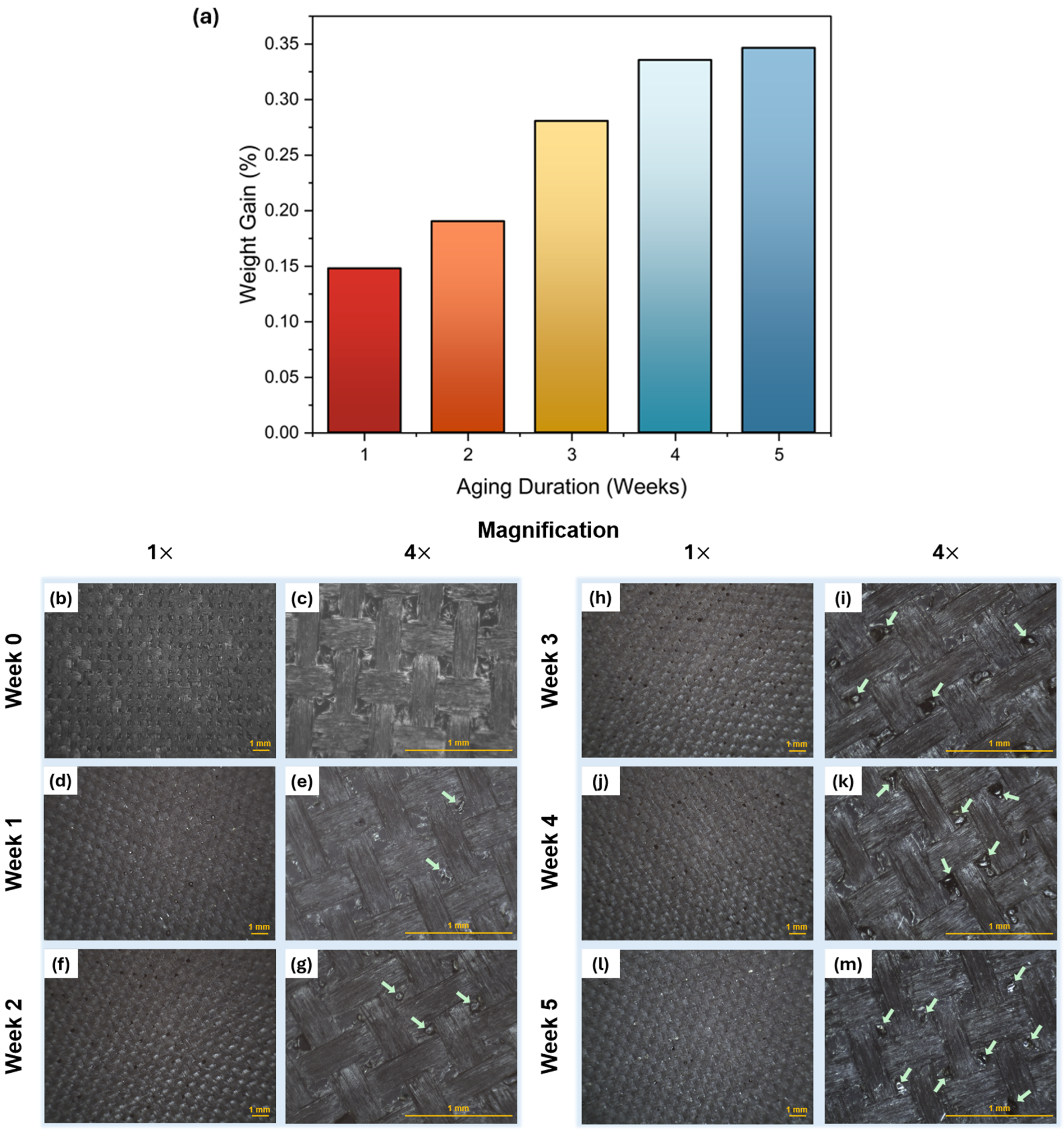

2.2. Weight Change and Optical Microscopy

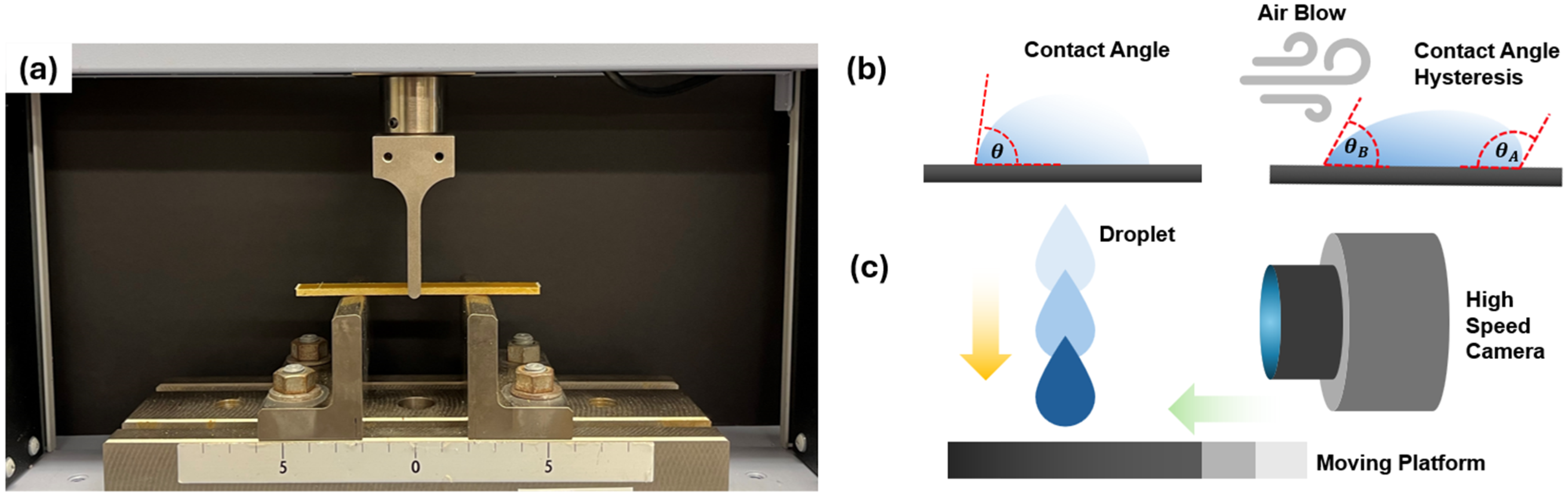

2.3. Characterization of Flexural Properties

2.4. Characterization of Contact Angle, Contact Angle Hysteresis, and Droplet Impact Dynamics

3. Results and Discussion

3.1. Weight Change

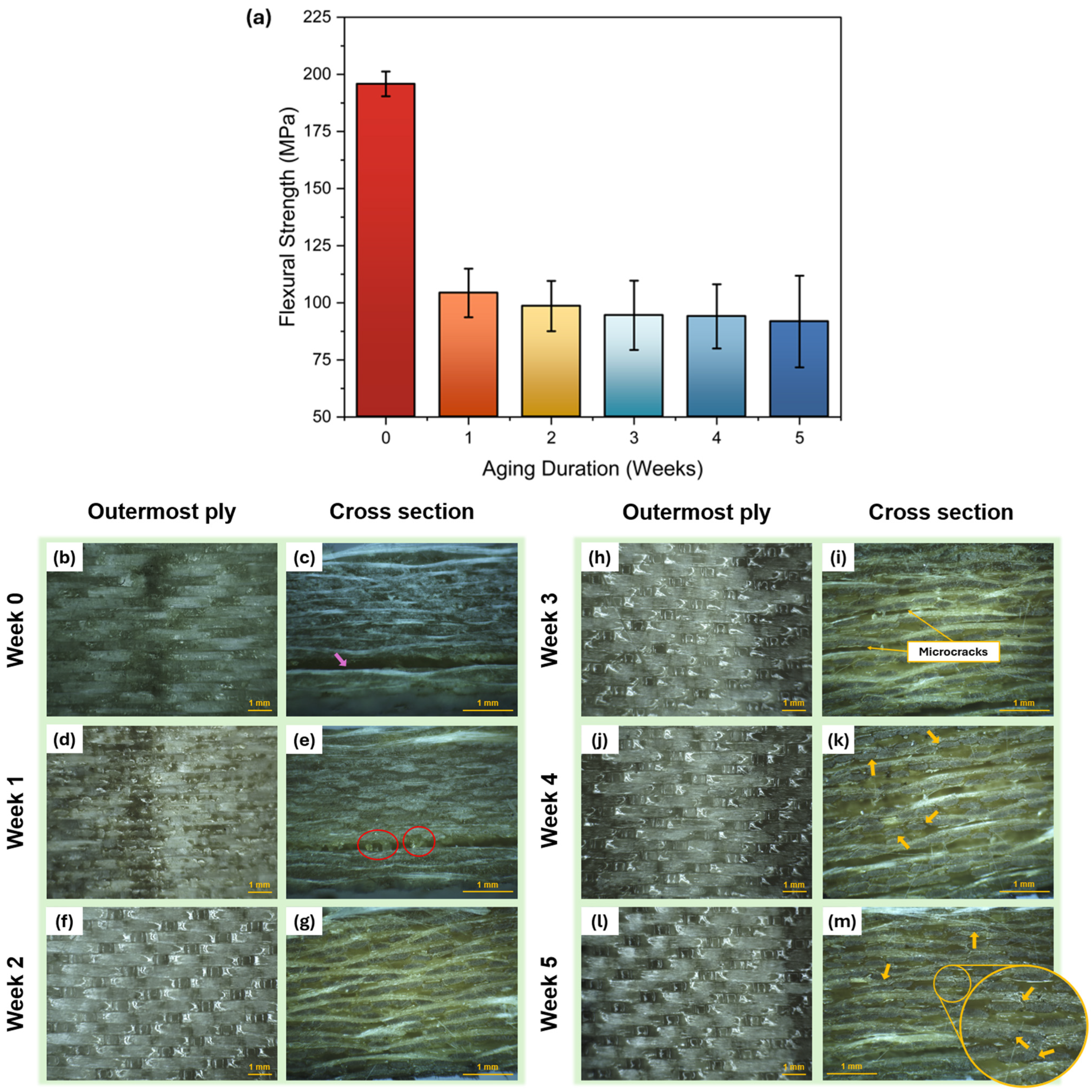

3.2. Flexural Strength

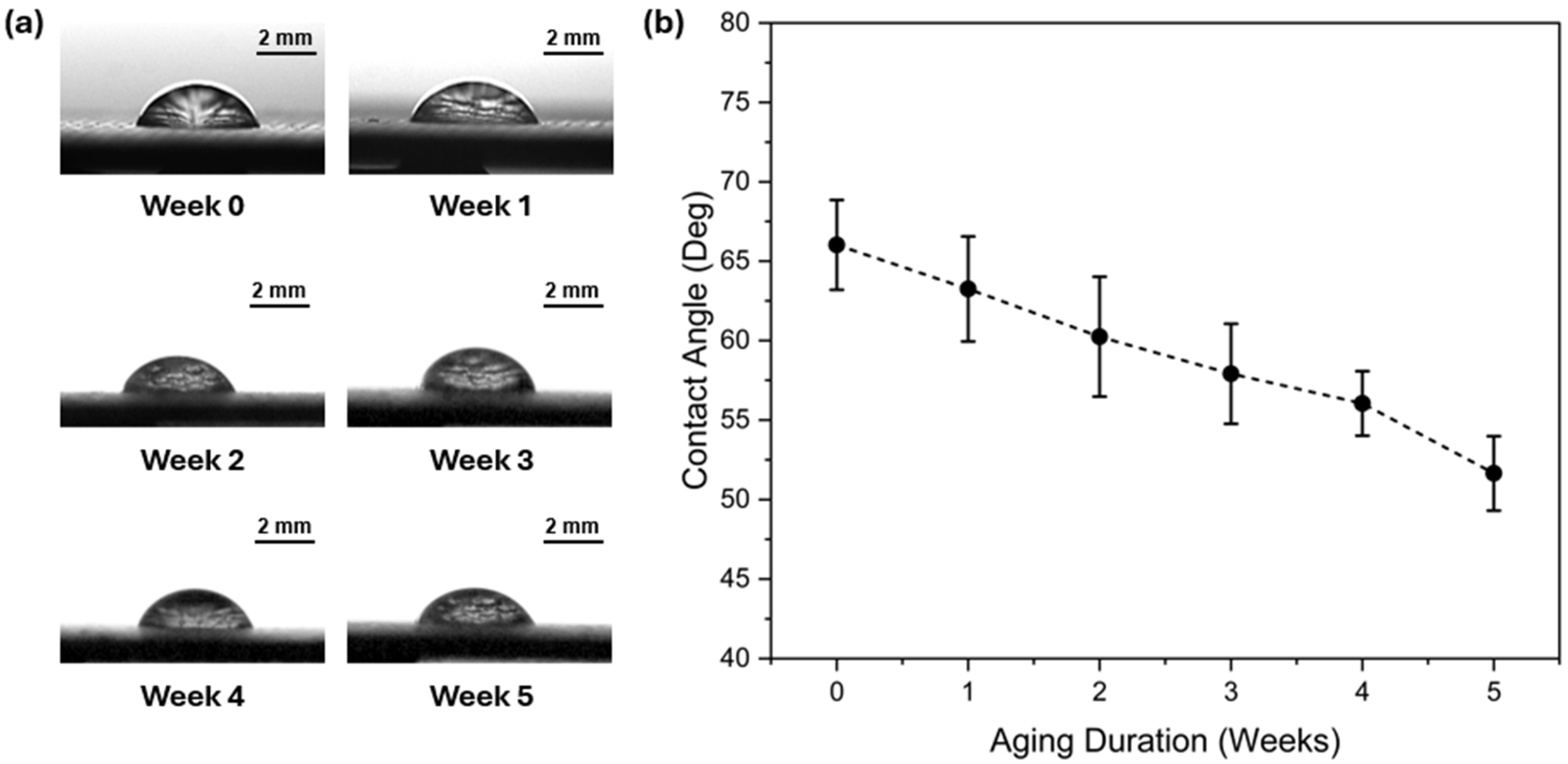

3.3. Contact Angle

3.4. Contact Angle Hysteresis

3.5. Static Droplet Impact

3.6. Dynamic Droplet Impact

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sukur, E.F.; Elmas, S.; Seyyednourani, M.; Eskizeybek, V.; Yildiz, M.; Sas, H.S. Effects of Meso- and Micro-Scale Defects on Hygrothermal Aging Behavior of Glass Fiber Reinforced Composites. Polym. Compos. 2022, 43, 8396–8408. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass Fiber-Reinforced Polymer Composites—A Review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Hussnain, S.M.; Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Choudhry, R.S.; Hussain, M.Z. Hygrothermal Effects on the Durability of Resin-Infused Thermoplastic E-Glass Fiber-Reinforced Composites in Marine Environment. Polym. Compos. 2024, 45, 13901–13923. [Google Scholar] [CrossRef]

- Jubsilp, C.; Mora, P.; Bielawski, C.W.; Lu, Z.; Rimdusit, S. Thermosetting Matrix Based Glass and Carbon Fiber Composites. In Fibre Reinforced Composites: Constituents, Compatibility, Perspectives and Applications; Woodhead Publishing: Sawston, UK, 2021; pp. 341–403. ISBN 9780128210918. [Google Scholar]

- Liu, T.Q.; Liu, X.; Feng, P. A Comprehensive Review on Mechanical Properties of Pultruded FRP Composites Subjected to Long-Term Environmental Effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Liao, D.; Gu, T.; Liu, J.; Chen, S.; Zhao, F.; Len, S.; Dou, J.; Qian, X.; Wang, J. Degradation Behavior and Ageing Mechanism of E-Glass Fiber Reinforced Epoxy Resin Composite Pipes under Accelerated Thermal Ageing Conditions. Compos. Part B Eng. 2024, 270, 111131. [Google Scholar] [CrossRef]

- Gupta, A.K.; Kiran, R.; Zafar, S.; Pathak, H. Effect of Hygrothermal Ageing on the Mechanical Properties of Glass Fiber Reinforced Polymer Composite: Experimental and Numerical Approaches. Mater. Today Commun. 2024, 41, 111060. [Google Scholar] [CrossRef]

- Wang, P.; Ke, L.-Y.-W.; Wu, H.-L.; Leung, C.K.Y. Hygrothermal Aging Effect on the Water Diffusion in Glass Fiber Reinforced Polymer (GFRP) Composite: Experimental Study and Numerical Simulation. Compos. Sci. Technol. 2022, 230, 109762. [Google Scholar] [CrossRef]

- Kajorncheappunngam, S.; Gupta, R.K.; GangaRao, H.V.S. Effect of Aging Environment on Degradation of Glass-Reinforced Epoxy. J. Compos. Constr. 2002, 6, 61–69. [Google Scholar] [CrossRef]

- Heinrick, M.; Crawford, B.; Milani, A.S. Degradation of Fibreglass Composites under Natural Weathering Conditions. MOJ Polym. Sci. 2017, 1, 18–24. [Google Scholar] [CrossRef][Green Version]

- Akil, H.M.; Santulli, C.; Sarasini, F.; Tirillò, J.; Valente, T. Environmental Effects on the Mechanical Behaviour of Pultruded Jute/Glass Fibre-Reinforced Polyester Hybrid Composites. Compos. Sci. Technol. 2014, 94, 62–70. [Google Scholar] [CrossRef]

- Zhuang, X.; Ma, J.; Dan, Y.; Jiang, L.; Huang, Y. Hydrothermal Aging of Carbon Fiber Reinforced Epoxy Composites with Different Interface Structures. Polym. Degrad. Stab. 2023, 212, 110352. [Google Scholar] [CrossRef]

- Guo, R.; Xian, G.; Li, C.; Hong, B.; Huang, X.; Xin, M.; Huang, S. Water Uptake and Interfacial Shear Strength of Carbon/Glass Fiber Hybrid Composite Rods under Hygrothermal Environments: Effects of Hybrid Modes. Polym. Degrad. Stab. 2021, 193, 109723. [Google Scholar] [CrossRef]

- Wang, K.; Chen, Y.; Long, H.; Baghani, M.; Rao, Y.; Peng, Y. Hygrothermal Aging Effects on the Mechanical Properties of 3D Printed Composites with Different Stacking Sequence of Continuous Glass Fiber Layers. Polym. Test. 2021, 100, 107242. [Google Scholar] [CrossRef]

- Angrizani, C.C.; de Oliveira, B.F.; Lorandi, N.P.; Ornaghi, H.L.; Amico, S.C. Combined Hygrothermal Aging and Mechanical Loading Effect on Unidirectional Glass/Epoxy Composites. Polym. Polym. Compos. 2022, 30, 09673911221095261. [Google Scholar] [CrossRef]

- Wang, Y.; Meng, Z.; Zhu, W.; Wan, B.; Han, B.; Cai, G.; Yin, X.; Bai, Y. Hygrothermal Aging Behavior and Aging Mechanism of Carbon Nanofibers/Epoxy Composites. Constr. Build. Mater. 2021, 294, 123538. [Google Scholar] [CrossRef]

- Wang, P.; Ke, L.-Y.-W.; Wu, H.-L.; Leung, C.K.Y.; Li, W.-W. Hygrothermal Aging Effects on the Diffusion-Degradation Process of GFRP Composite: Experimental Study and Numerical Simulation. Constr. Build. Mater. 2023, 379, 131075. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Ding, H.; Wang, H.; Bi, Y. Effect of Hygrothermal Aging on Compression Behavior of CFRP Material with Different Layups. Compos. Part B Eng. 2024, 270, 111134. [Google Scholar] [CrossRef]

- Kimura, H.; Matsumoto, A.; Ohtsuka, K. Glass Fiber-Reinforced Composite Based on Benzoxazine Resin. J. Appl. Polym. Sci. 2009, 114, 1256–1263. [Google Scholar] [CrossRef]

- Ghosh, N.N.; Kiskan, B.; Yagci, Y. Polybenzoxazines-New High Performance Thermosetting Resins: Synthesis and Properties. Prog. Polym. Sci. 2007, 32, 1344–1391. [Google Scholar] [CrossRef]

- Moghtadernejad, S.; Barjasteh, E.; Johnson, Z.; Stolpe, T.; Banuelos, J. Effect of Thermo-Oxidative Aging on Surface Characteristics of Benzoxazine and Epoxy Copolymer. J. Appl. Polym. Sci. 2021, 138, 50211. [Google Scholar] [CrossRef]

- Narongdej, P.; Hanson, J.; Barjasteh, E.; Moghtadernejad, S. Liquid-Solid Interaction to Evaluate Thermal Aging Effects on Carbon Fiber-Reinforced Composites. Fluids 2024, 9, 100. [Google Scholar] [CrossRef]

- Narongdej, P.; Gomez, R.; Tseng, D.; Barjasteh, E.; Moghtadernejad, S. Characterization of Mechanical Properties and Surface Wettability of Epoxy Resin/Benzoxazine Composites in a Simulated Acid Rain Environment. Coatings 2024, 14, 1279. [Google Scholar] [CrossRef]

- Narongdej, P.; Reddy, T.; Barjasteh, E. Effect of Nonwoven Interlayer Melting Temperature and Matrix Toughness on Mode I and Mode II Fracture Toughness of Carbon Fiber/Benzoxazine Composites. J. Compos. Mater. 2023, 57, 2389–2404. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D5229; Standard Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- Butt, H.J.; Liu, J.; Koynov, K.; Straub, B.; Hinduja, C.; Roismann, I.; Berger, R.; Li, X.; Vollmer, D.; Steffen, W.; et al. Contact Angle Hysteresis. Curr. Opin. Colloid Interface Sci. 2022, 59, 101574. [Google Scholar] [CrossRef]

- Nishizaki, I.; Meiarashi, S. Long-Term Deterioration of GFRP in Water and Moist Environment. J. Compos. Constr. 2002, 6, 21–27. [Google Scholar] [CrossRef]

- Bone, J.E.; Sims, G.D.; Maxwell, A.S.; Frenz, S.; Ogin, S.L.; Foreman, C.; Dorey, R.A. On the Relationship between Moisture Uptake and Mechanical Property Changes in a Carbon Fibre/Epoxy Composite. J. Compos. Mater. 2022, 56, 2189–2199. [Google Scholar] [CrossRef]

- Hsu, C.-S.; Hwang, P.Y. The Water Uptake, Thermal and Mechanical Properties, and Aging Resistance to Thermo-Oxidation of Phenylboronic Acid-Modified Benzoxazine-Glass Fiber Composites. J. Appl. Polym. Sci. 2022, 139, 52135. [Google Scholar] [CrossRef]

- Nash, N.H.; Young, T.M.; Stanley, W.F. The Reversibility of Mode-I and -II Interlaminar Fracture Toughness after Hydrothermal Aging of Carbon/Benzoxazine Composites with a Thermoplastic Toughening Interlayer. Compos. Struct. 2016, 152, 558–567. [Google Scholar] [CrossRef]

- Bel Haj Frej, H.; Léger, R.; Perrin, D.; Ienny, P. A Novel Thermoplastic Composite for Marine Applications: Comparison of the Effects of Aging on Mechanical Properties and Diffusion Mechanisms. Appl. Compos. Mater. 2021, 28, 899–922. [Google Scholar] [CrossRef]

- Bel Haj Frej, H.; Léger, R.; Perrin, D.; Ienny, P. Effect of Aging Temperature on a Thermoset-like Novel Acrylic Thermoplastic Composite for Marine Vessels. J. Compos. Mater. 2021, 55, 2673–2691. [Google Scholar] [CrossRef]

- Kwon, T.W.; Lee, K.H.; Seo, Y.M.; Jang, J.; Ha, M.Y. Dynamic Wetting Behaviors of Water Droplets on Surfaces with Dual Structures at the Nanoscale. Int. J. Multiph. Flow 2020, 129, 103352. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Narongdej, P.; Tseng, D.; Gomez, R.; Barjasteh, E.; Moghtadernejad, S. Hygrothermal Aging of Glass Fiber-Reinforced Benzoxazine Composites. Eng 2025, 6, 60. https://doi.org/10.3390/eng6030060

Narongdej P, Tseng D, Gomez R, Barjasteh E, Moghtadernejad S. Hygrothermal Aging of Glass Fiber-Reinforced Benzoxazine Composites. Eng. 2025; 6(3):60. https://doi.org/10.3390/eng6030060

Chicago/Turabian StyleNarongdej, Poom, Daniel Tseng, Riley Gomez, Ehsan Barjasteh, and Sara Moghtadernejad. 2025. "Hygrothermal Aging of Glass Fiber-Reinforced Benzoxazine Composites" Eng 6, no. 3: 60. https://doi.org/10.3390/eng6030060

APA StyleNarongdej, P., Tseng, D., Gomez, R., Barjasteh, E., & Moghtadernejad, S. (2025). Hygrothermal Aging of Glass Fiber-Reinforced Benzoxazine Composites. Eng, 6(3), 60. https://doi.org/10.3390/eng6030060