Enhancing Dry-Sliding Wear Performance of a Powder-Metallurgy-Processed “Metal Matrix–Carbide” Composite via Laser Surface Modification

Abstract

1. Introduction

2. Materials and Methods

3. Results

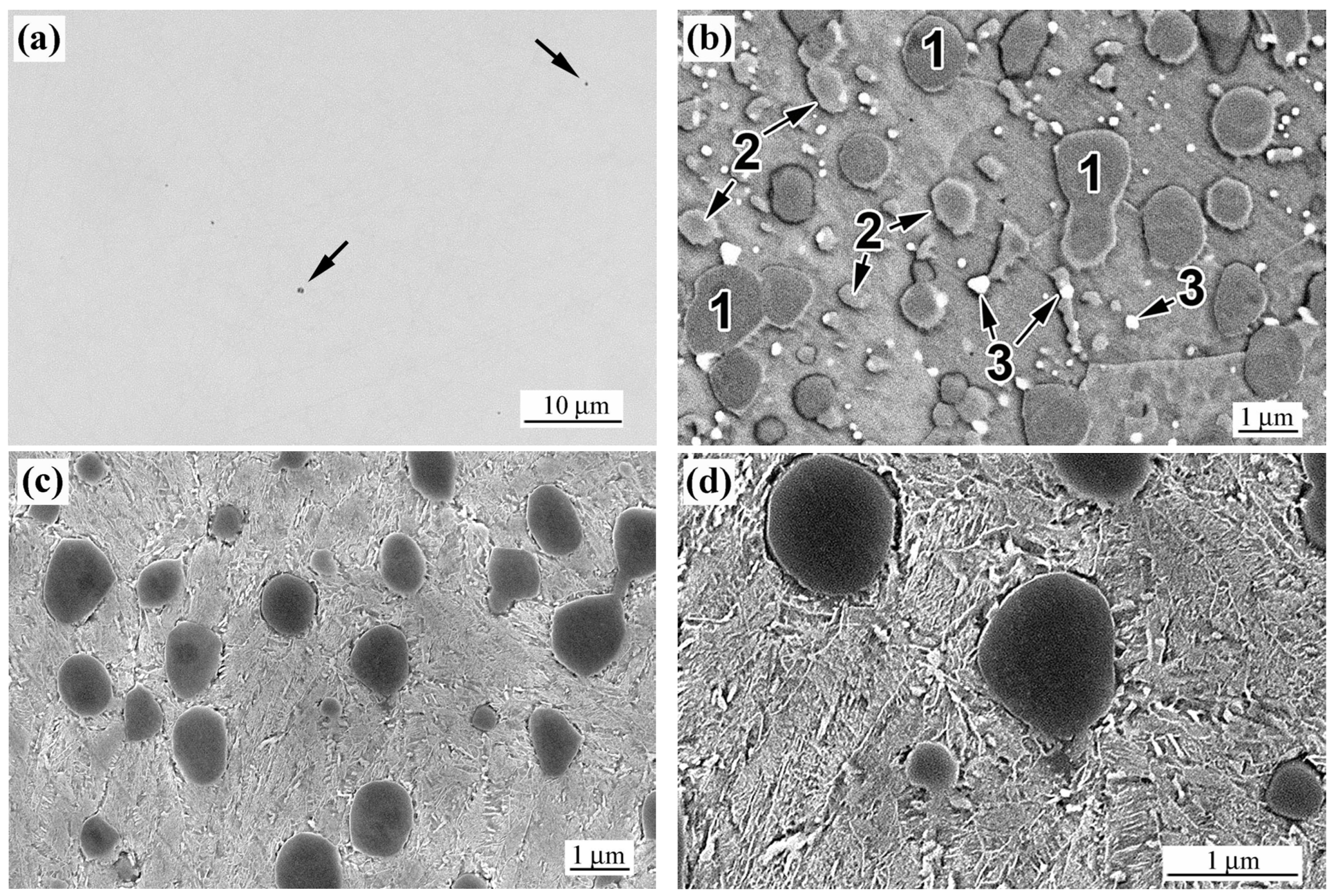

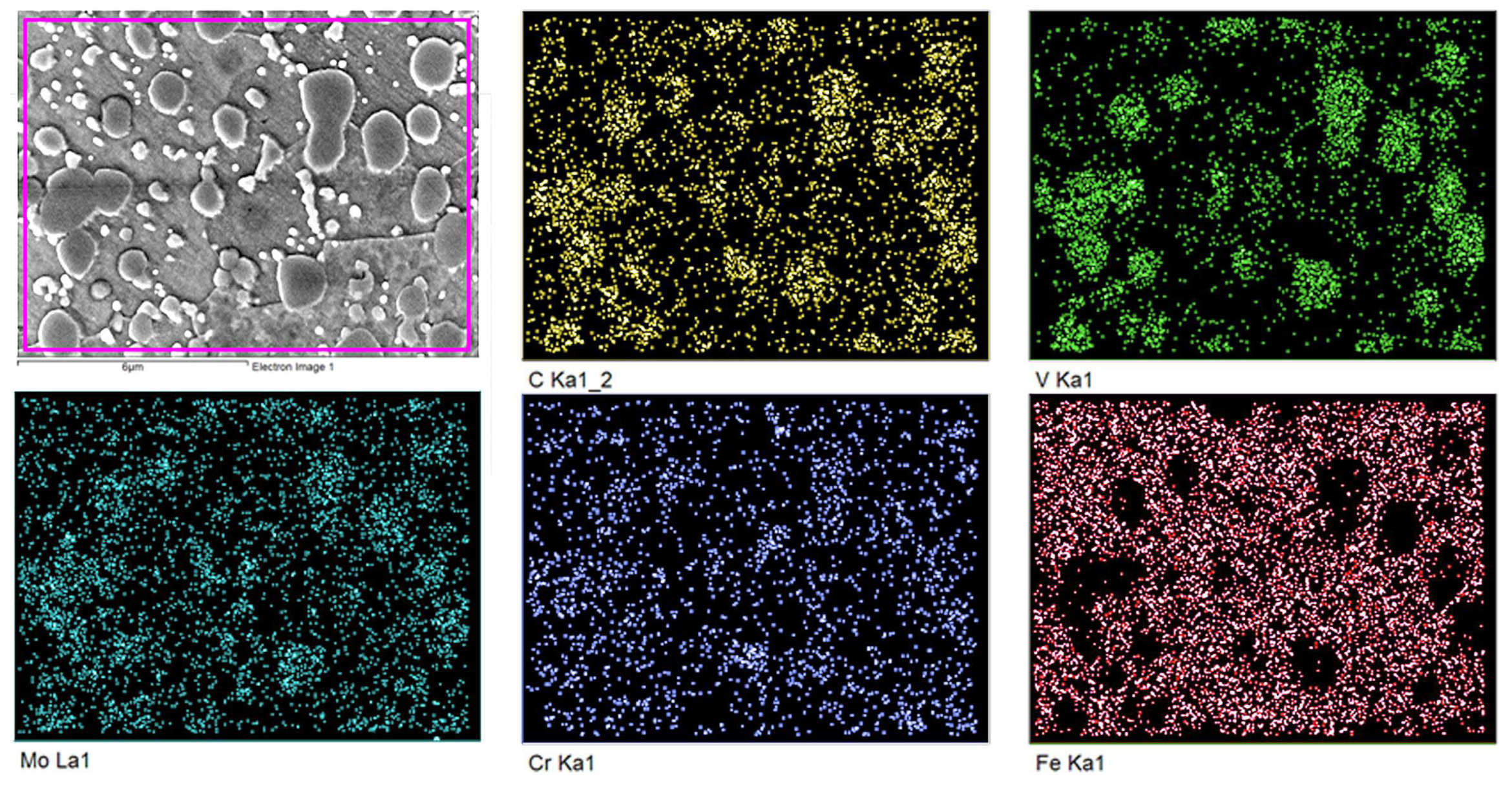

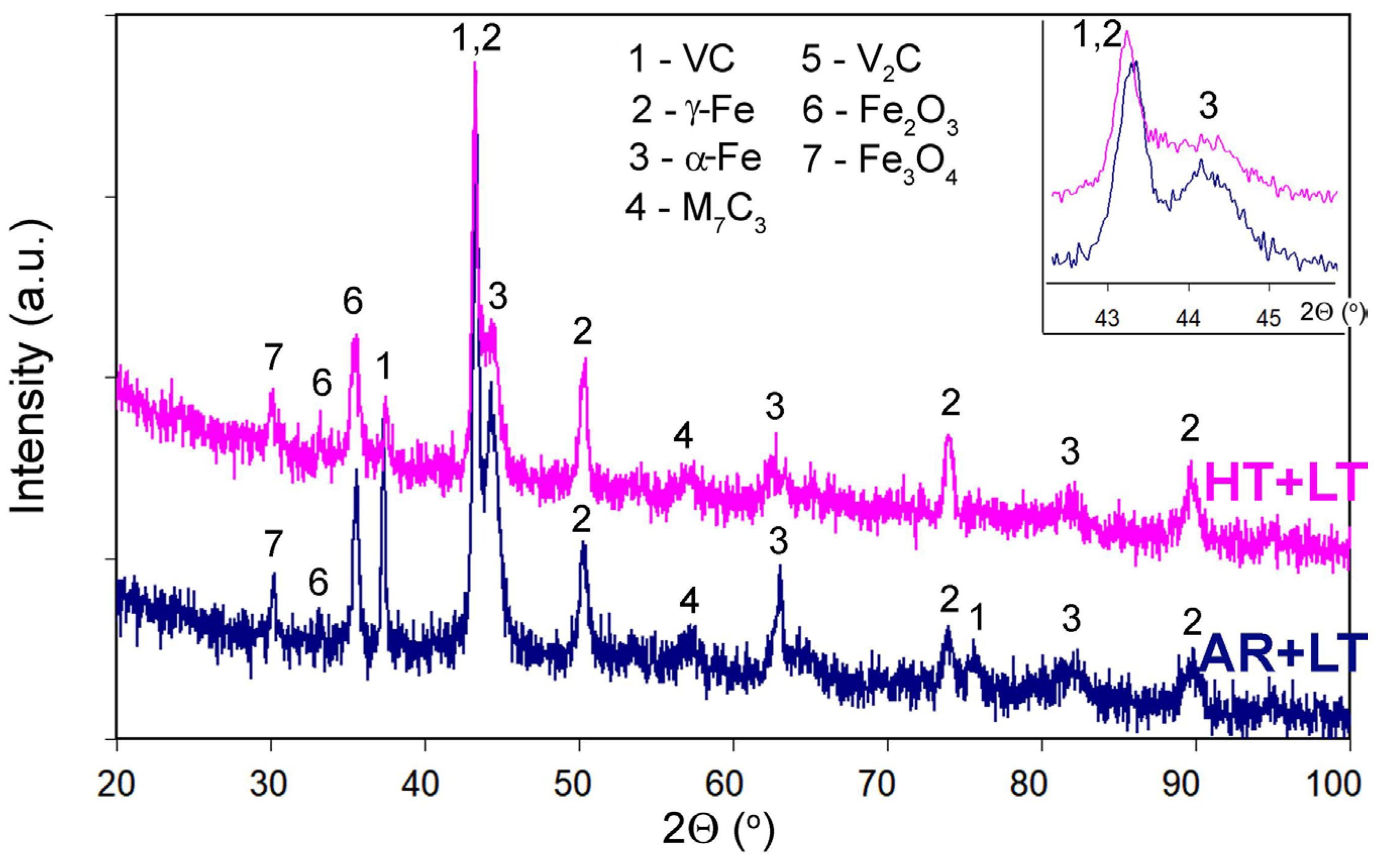

3.1. Phase-Structural State of As-Received and Bulk Heat-Treated Specimens

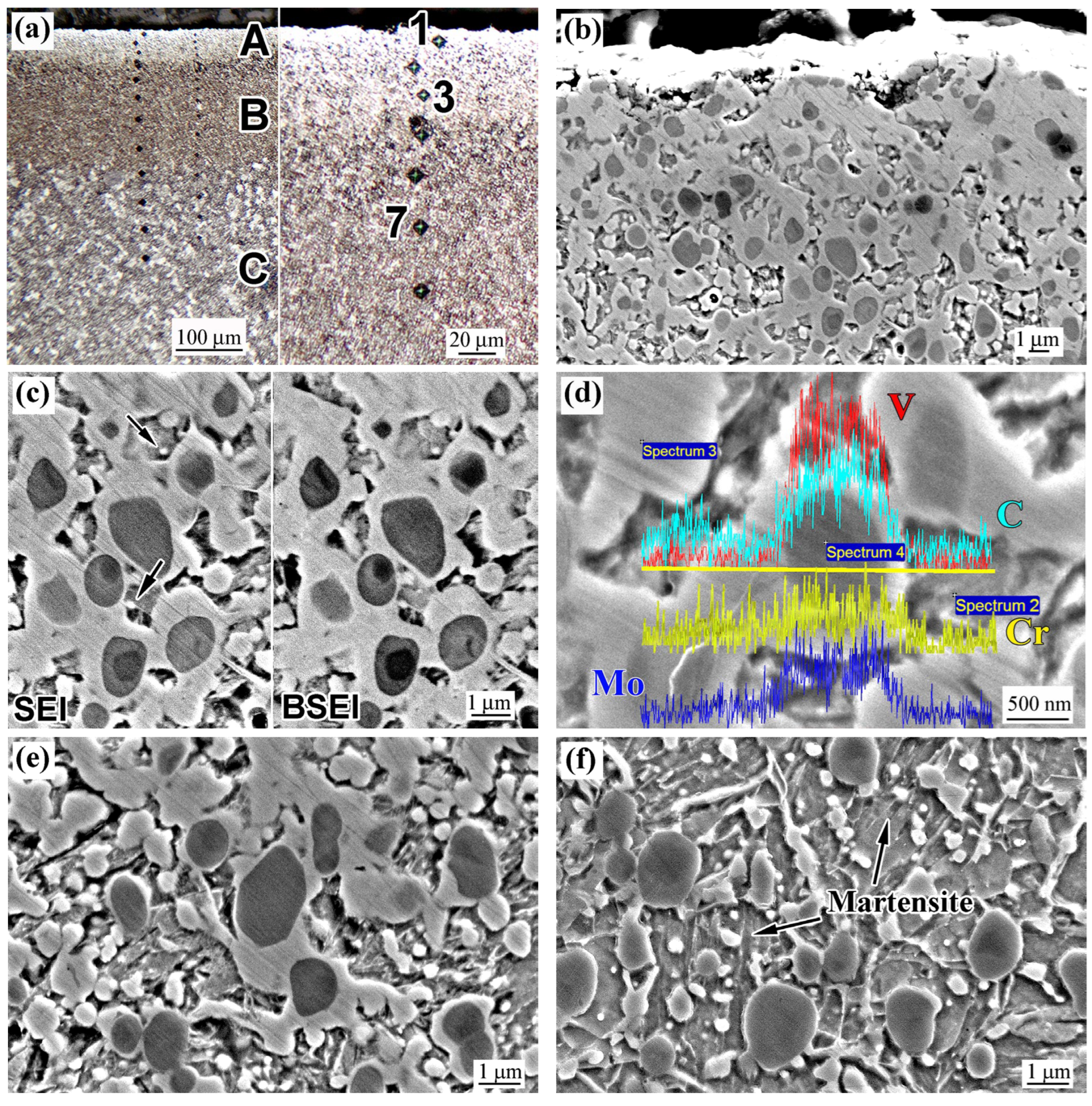

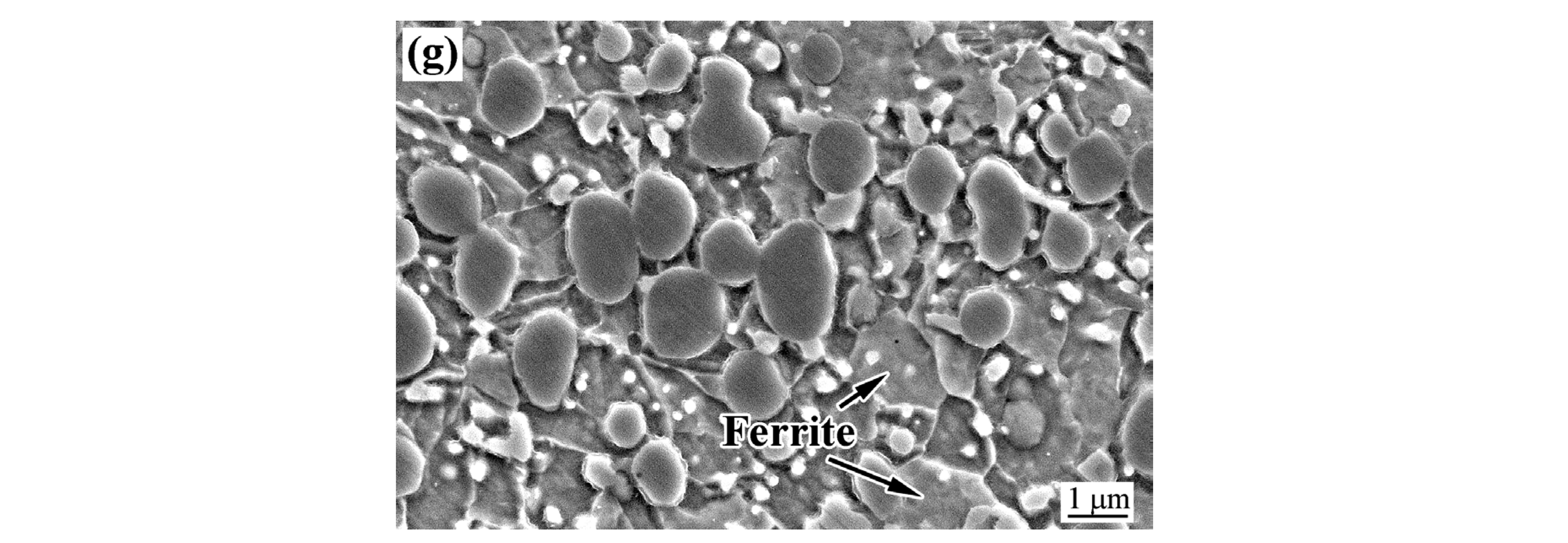

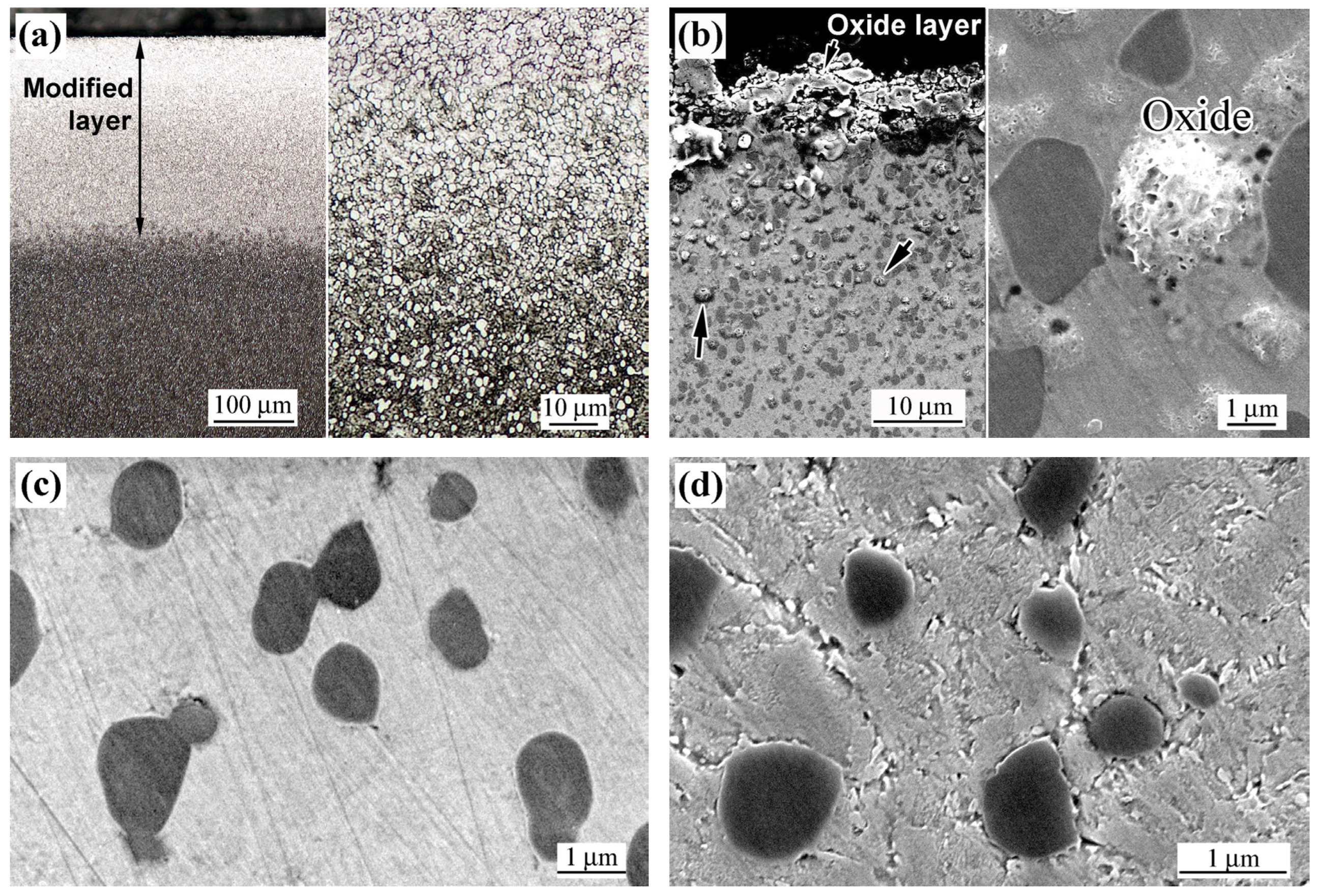

3.2. Laser-Modified Structure

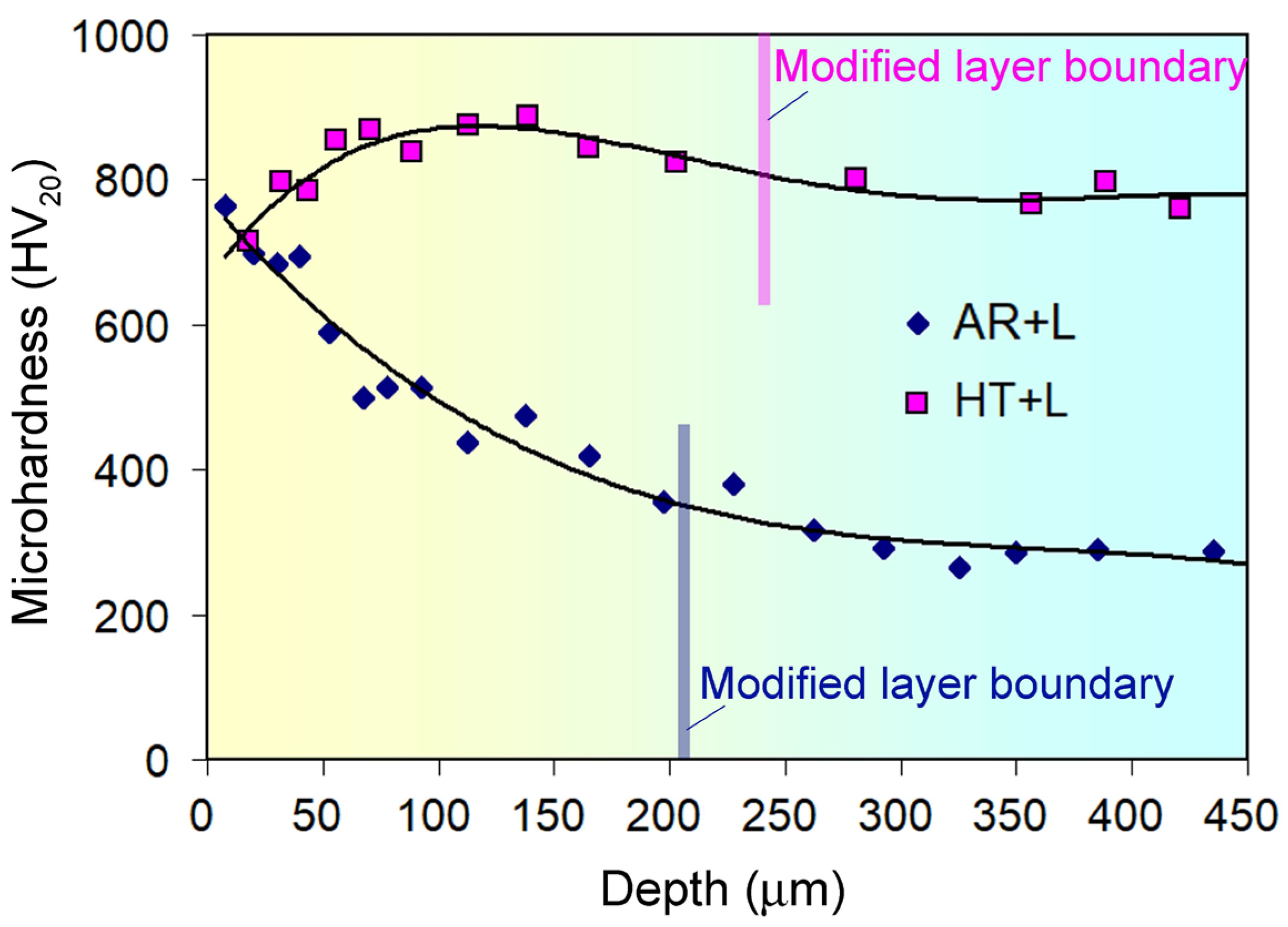

3.3. Microhardness Distribution

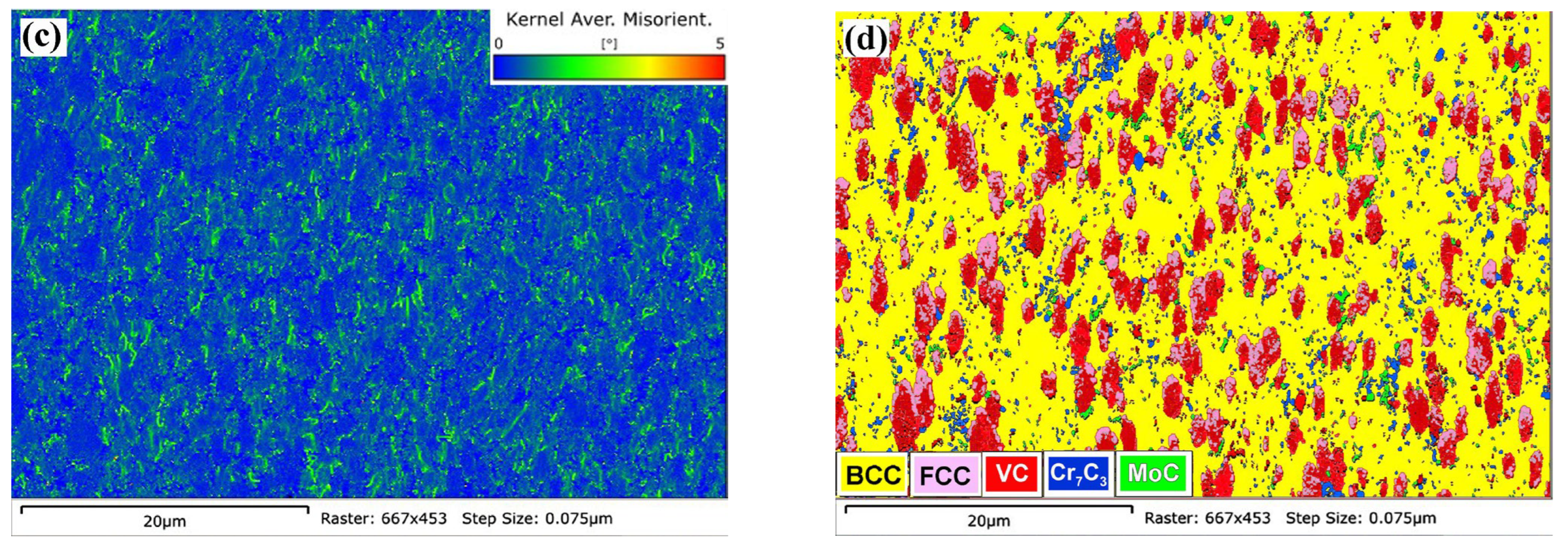

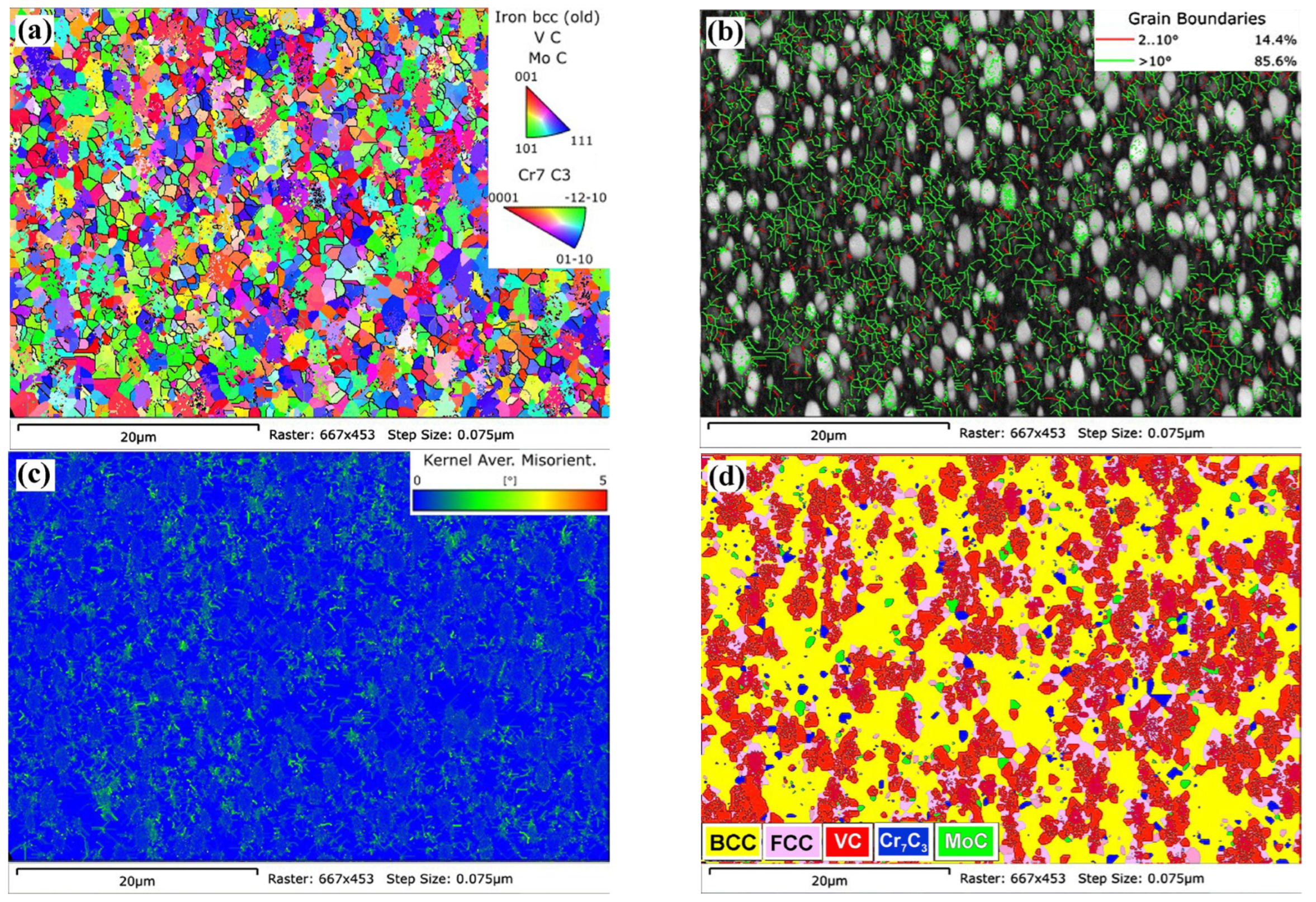

3.4. EBSD Characterisation

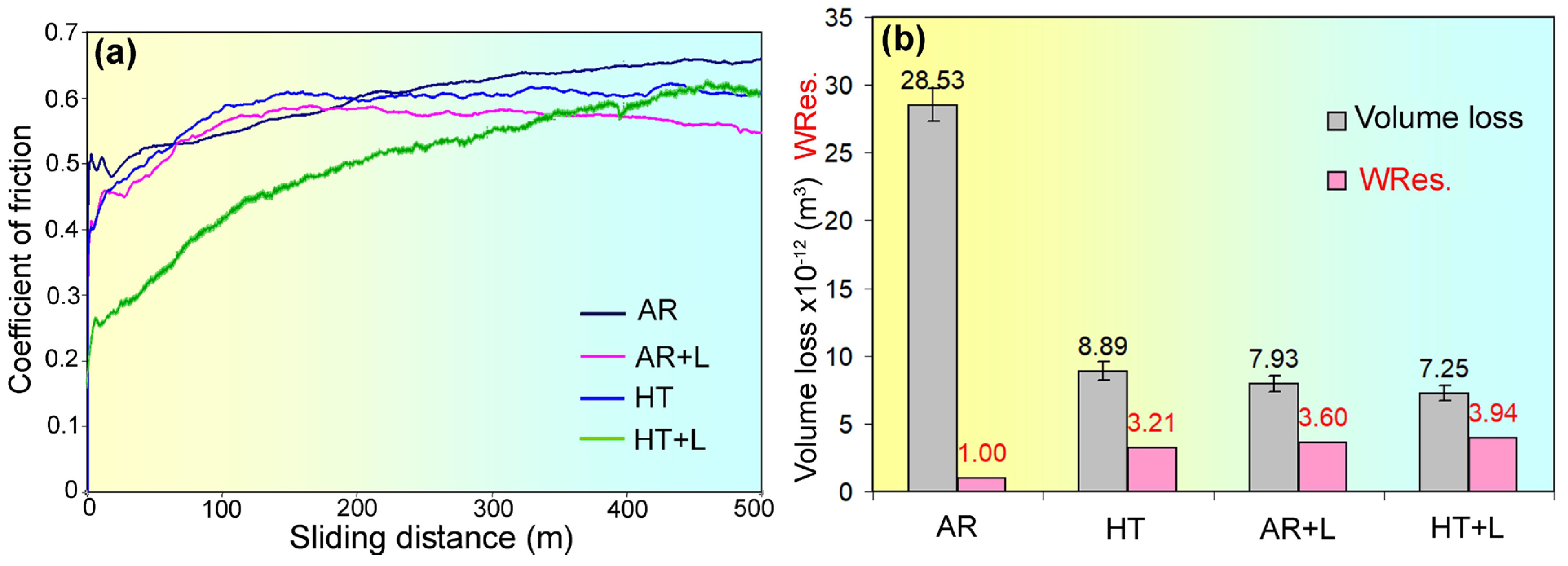

3.5. Wear Properties

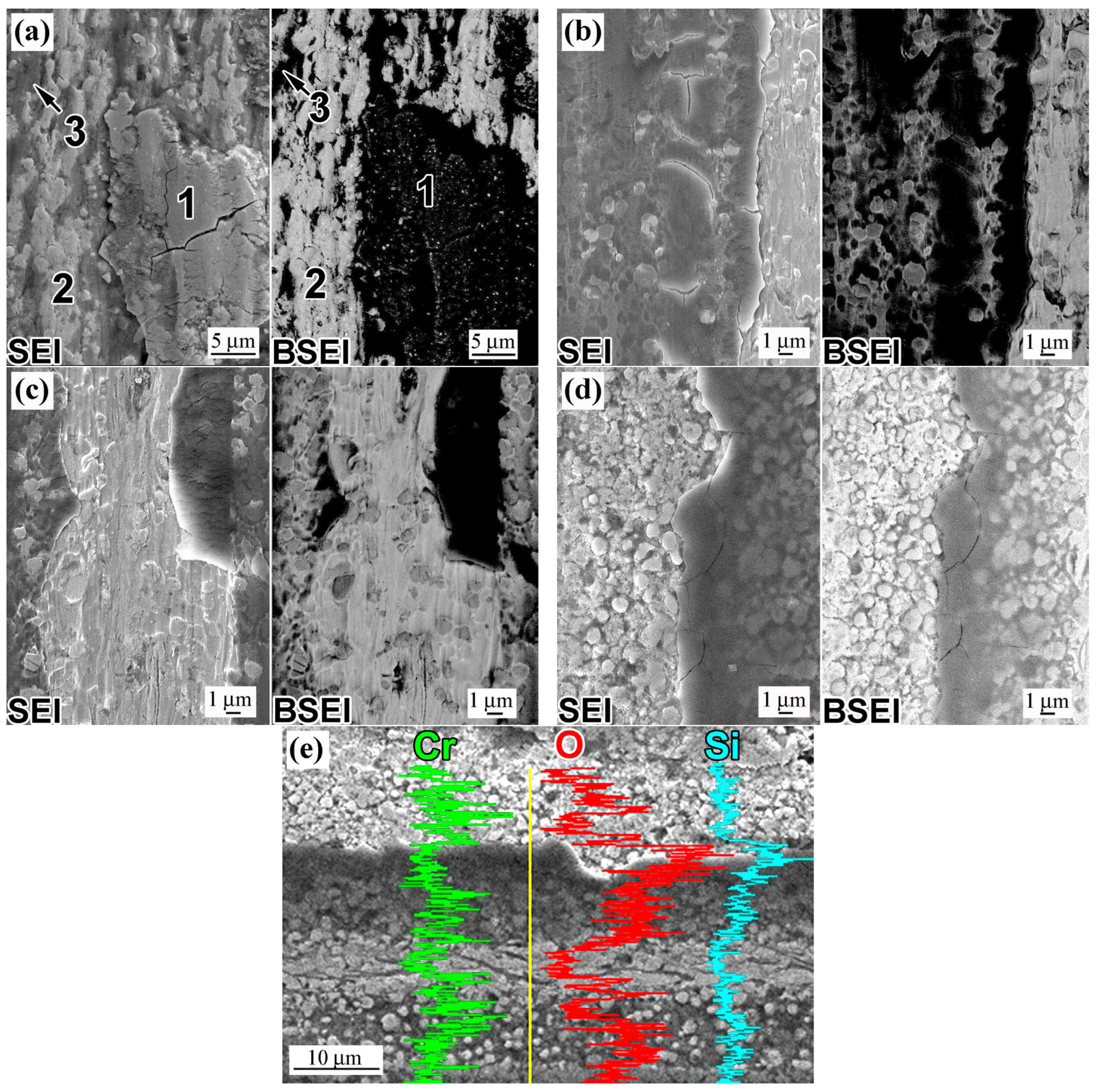

3.6. Worn Surface Characterisation

4. Discussion

Microstructure Evolution

5. Conclusions

- In the as-received condition, K390 steel exhibited a ferritic matrix containing a uniform dispersion of coarse VC carbides and finer M7C3 and M6C/MC carbides, with a total carbide volume fraction of 36.2%, and a retained austenite content of 7.1%. After bulk heat treatment (1 h at 1180 °C followed by quenching and triple 500 °C tempering), the matrix transformed into a fully martensitic structure with a lower amount of carbides and increased retained austenite content (up to 18.3%).

- Non-melting laser surface treatment produced a modified surface layer up to 250 µm thick, composed of acicular martensite, retained austenite, and carbides. In regions where carbides partially dissolved and enriched the matrix with carbon, a homogeneous, structureless phase mixture of nanosized constituents (martensite and retained austenite) formed around the carbides, contributing to enhanced mechanical performance.

- Laser heating induced partial dissolution of fine carbides, resulting in matrix saturation with carbon and alloying elements, which in turn led to an increase in lattice parameters and the volume fraction of retained austenite. Preceding bulk heat treatment promoted more extensive carbide dissolution, enabling deeper carbon enrichment of the matrix. As a result, the retained austenite fraction increased from 7.1% in the as-received state to 38.4% in AR+L and 54.7% in HT+L specimens, with corresponding carbon contents of 1.20 wt.% and 1.44 wt.%, respectively.

- Laser modification led to a substantial microhardness improvement: up to 700–763 HV20 near the surface in AR+L and 855–890 HV20 in deeper zones of HT+L, compared to an average 331.5 HV20 in the as-received state and 777.8 HV20 in the bulk heat-treated condition. This enhancement was attributed to the formation of carbon-enriched martensite, elevated dislocation density (up to 2.6 × 1015 m−2), and ultrafine-crystallite size (as small as 8.3 nm).

- Tribological testing confirmed superior wear resistance in laser-modified specimens, particularly HT+L, which exhibited a 3.94-fold reduction in volume loss and a lower friction coefficient compared to the untreated state. This improvement was attributed to the most favourable wear mechanism—formation and gradual detachment of oxide tribo-layers—occurring without extensive carbide degradation or severe matrix deformation.

- The combined approach of bulk heat treatment followed by non-melting laser surface modification offered clear advantages over laser hardening of the as-received base structure. This method produced a robust, graded microstructure, making it well-suited for demanding tooling applications involving extreme contact loads during cold stamping and forming.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AR | As-received |

| AR+L | As-received with laser processing |

| BSEI | Backscattered electron image |

| EBSD | Electron backscatter diffraction |

| EDX | Energy-dispersive X-ray analysis |

| HAGB | High-angle grain boundary |

| HAZ | Heat-affected zone |

| HT | Bulk heat-treated |

| HT+L | Bulk heat-treated with laser processing |

| KAM | Kernel average misorientation |

| LAGB | Low-angle grain boundary |

| LST | Surface laser treatment |

| OM | Optical microscopy |

| PM | Powder metallurgy |

| RA | Retained austenite |

| SEI | Secondary electron image |

| SEM | Scanning electron microscopy |

| XRD | X-ray diffraction |

References

- Böhler K390 MICROCLEAN. 2024. Available online: https://www.us.bohler.com/en-us/products/k390-microclean/ (accessed on 28 September 2025).

- Czupryński, A. Microstructure and Abrasive Wear Resistance of Metal Matrix Composite Coatings Deposited on Steel Grade AISI 4715 by Powder Plasma Transferred Arc Welding Part 2. Mechanical and Structural Properties of a Nickel-Based Alloy Surface Layer Reinforced with Particles of Tungsten Carbide and Synthetic Metal–Diamond Composite. Materials 2021, 14, 2805. [Google Scholar] [CrossRef]

- Duriagina, Z.A.; Romanyshyn, M.R.; Kulyk, V.V.; Kovbasiuk, T.M.; Trostianchyn, A.M.; Lemishka, I.A. The character of the structure formation of model alloys of the Fe-Cr-(Zr, Zr-B) system synthesized by powder metallurgy. J. Achiev. Mater. Manuf. Eng. 2020, 100, 49. [Google Scholar] [CrossRef]

- Nemec, M.; Jurci, P.; Kosnacova, P.; Kucerova, M. Evaluation of structural isotropy of Cr-V ledeburitic steel made by powder metallurgy of rapidly solidified particles. Kov. Mater. Met. Mater. 2016, 54, 453. [Google Scholar] [CrossRef]

- Tóth, L.; Fábián, R.E.; Pinke, P.; Kovács, T.A.; Nabiałek, M.; Sandu, A.V.; Vizureanu, P. Comparison of the Properties of Cold Work Tool Steels with the Same Hardness but Different Manufacturing Processes The required important properties. Arch. Metall. Mater. 2024, 69, 809. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Shimizu, K.; Cheiliakh, A.P.; Kozarevs’ka, T.V.; Chabak, Y.G.; Hara, H.; Kusumoto, K. Abrasive wear resistance of spheroidal vanadium carbide cast irons. J. Frict. Wear 2013, 34, 466. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Shimizu, K.; Cheiliakh, A.P.; Pastukhova, T.V.; Chabak, Y.G.; Kusumoto, K. Abrasive resistance of metastable V–Cr–Mn–Ni spheroidal carbide cast irons using the factorial design method. Int. J. Miner. Metall. Mater. 2016, 23, 645. [Google Scholar] [CrossRef]

- González-Pociño, A.; Alvarez-Antolin, F.; Peral-Martinez, L.B. Effects of Nitriding and Thermal Processing on Wear and Corrosion Resistance of Vanadis 8 Steel. Coatings 2024, 14, 1066. [Google Scholar] [CrossRef]

- Surekha, K.; Els-Botes, A. Effect of Cryotreatment on Tool Wear Behaviour of Bohler K390 and AISI H13 Tool Steel During Friction Stir Welding of Copper. Trans. Indian. Inst. Met. 2012, 65, 259. [Google Scholar] [CrossRef]

- Trembach, B.; Silchenko, Y.; Balenko, O.; Hlachev, D.; Kulahin, K.; Heiko, H.; Bellorin-Herrera, O.; Khabosha, S.; Zakovorotnyi, O.; Trembach, I. Study of the hardfacing process using self-shielding flux-cored wire with an exothermic addition with a combined oxidizer of the Al-(CuO/Fe2O3) system. Int. J. Adv. Manuf. Technol. 2024, 134, 309. [Google Scholar] [CrossRef]

- Efremenko, B.V.; Shimizu, K.; Espallargas, N.; Efremenko, V.G.; Kusumoto, K.; Chabak, Y.G.; Belik, A.G.; Chigarev, V.V.; Zurnadzhy, V.I. High-temperature solid particle erosion of Cr-Ni-Fe-C arc cladded coatings. Wear 2020, 460–461, 203439. [Google Scholar] [CrossRef]

- Loskutova, T.; Hatala, M.; Pogrebova, I.; Nikitina, N.; Bobina, M.; Radchenko, S.; Kharchenko, N.; Kotlyar, S.; Pavlenko, I.; Ivanov, V. Composition, Structure, and Properties of Ti, Al, Cr, N, C Multilayer Coatings on AISI W1-7 Alloyed Tool Steel. Coatings 2022, 12, 616. [Google Scholar] [CrossRef]

- Lesyk, D.A.; Mordyuk, B.N.; Dzhemelinskyi, V.V.; Voloshko, S.M.; Burmak, A.P. Optimization of Ultrasonic Impact Treatment for Surface Finishing and Hardening of AISI O2 Tool Steel by Experimental Design. J. Mater. Eng. Perform. 2022, 31, 8567. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Fedun, V.I.; Efremenko, V.G.; Pastukhova, T.V.; Efremenko, B.V. Plasma coating formation by the deposition of cathode material eroded through high-current pulsed discharge. Probl. At. Sci. Technol. 2019, 5, 167. [Google Scholar] [CrossRef]

- Vasylyev, M.O.; Mordyuk, B.N.; Voloshko, S.M.; Lesyk, D.A. Microstructure Evolution of the Carbon Steels During Surface Severe Plastic Deformation. Prog. Phys. Met. 2021, 22, 562. [Google Scholar] [CrossRef]

- Łach, Ł. Recent Advances in Laser Surface Hardening: Techniques, Modeling Approaches, and Industrial Applications. Crystals 2024, 14, 726. [Google Scholar] [CrossRef]

- Steen, W.M.; Mazumder, J. Laser Material Processing, 4th ed.; Springer: Berlin/Heidelberg, Germany, 2010. [Google Scholar] [CrossRef]

- Ameri, M.H.; Malek Ghaini, F.; Torkamany, M.J. Investigation into the efficiency of a fiber laser in surface hardening of ICD-5 tool steel. Opt. Laser Technol. 2018, 107, 150. [Google Scholar] [CrossRef]

- Šebek, M.; Falat, L.; Kováč, F.; Petryshynets, I.; Horňak, P.; Girman, V. The Effects of Laser Surface Hardening on Microstructural Characteristics and Wear Resistance of AISI H11 Hot Work Tool Steel. Arch. Metall. Mater. 2017, 62, 1721. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, M.; Ji, S.; Zhang, J.; Fan, H. Numerical simulation and experimental study on laser hardening process of the 42CrMo4 steel. Adv. Mech. Eng. 2021, 13, 16878140211044649. [Google Scholar] [CrossRef]

- Basu, A.; Chakraborty, J.; Shariff, S.M.; Padmanabham, G.; Joshi, S.V.; Sundararajan, G.; Dutta Majumdar, J.; Manna, I. Laser surface hardening of austempered (bainitic) ball bearing steel. Scr. Mater. 2007, 56, 887. [Google Scholar] [CrossRef]

- Maharjan, N.; Zhou, W.; Zhou, Y.; Guan, Y.; Wu, N. Comparative study of laser surface hardening of 50CrMo4 steel using continuous-wave laser and pulsed lasers with ms, ns, ps and fs pulse duration. Surf. Coat. Technol. 2019, 366, 311. [Google Scholar] [CrossRef]

- Dutta Majumdar, J.; Manna, I. Laser processing of materials. Sadhana 2003, 28, 495–562. [Google Scholar] [CrossRef]

- Dinesh Babu, P.; Marimuthu, P. Status of laser transformation hardening of steel and its alloys: A review. Emerg. Mater. Res. 2019, 8, 188. [Google Scholar] [CrossRef]

- Telasang, G.; Majumdar, J.D.; Padmanabham, G.; Tak, M. Wear and corrosion behavior of laser surface engineered AISI H13 hot working tool steel. Surf. Coat. Technol. 2015, 261, 69. [Google Scholar] [CrossRef]

- El-Batahgy, A.; Ahmed, R.; Moussa, A.-R. Laser Surface Hardening of Tool Steels—Experimental and Numerical Analysis. J. Surf. Eng. Mater. Adv. Technol. 2013, 03, 146. [Google Scholar] [CrossRef]

- Wu, J.; Zhou, Z.; Lin, X.; Qiao, H.; Zhao, J.; Ding, W. Improving the wear and corrosion resistance of aeronautical component material by laser shock processing: A Review. Materials 2023, 16, 4124. [Google Scholar] [CrossRef]

- Azevedo, L.; Kashaev, N.; Horstmann, C.; Ventzke, V.; Furtado, C.; Moreira, P.M.G.P.; Tavares, P.J. Fatigue behaviour of laser shock peened AISI D2 tool steel. Int. J. Fatigue 2022, 165, 107226. [Google Scholar] [CrossRef]

- Zhao, K.; Yan, G.; Li, J.; Guo, W.; Gu, J.; Li, C. The Resistance to Wear and Thermal Cracking of Laser Surface Engineered P20 Steel. Coatings 2023, 13, 97. [Google Scholar] [CrossRef]

- Senthil Kumar, P.; Jegadheesan, C.; Somasundaram, P.; Praveen Kumar, S.; Vivek Anand, A.; Singh, A.P.; Jeyaprakash, N. State of art: Review on laser surface hardening of alloy metals. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Zhou, H.; Zhou, H.; Zhao, Z.; Li, K.; Yin, J. Numerical Simulation and Verification of Laser-Polishing Free Surface of S136D Die Steel. Metals 2021, 11, 400. [Google Scholar] [CrossRef]

- Mohajerani, S.; Miller, J.D.; Tutunea-Fatan, O.R.; Bordatchev, E.V. Thermo-physical modelling of track width during laser polishing of H13 tool steel. Procedia Manuf. 2017, 10, 708. [Google Scholar] [CrossRef]

- Dobrzański, L.A.; Piec, M.; Klimpel, A.; Trojanowa, Z. Surface modification of hot work tool steel by high-power diode laser. Int. J. Mach. Tools Manuf. 2007, 47, 773. [Google Scholar] [CrossRef]

- Barka, N.; Amamou, A.; Fakir, R.; Thibeault, P.; Blériot, V.; Feujofack Kemda, B.V. Effects of Laser Hardening Process Parameters on Hardness Profile of 4340 Steel Spline-An Experimental Approach. Coatings 2020, 10, 342. [Google Scholar] [CrossRef]

- Barka, N.; El Ouafi, A. Effects of Laser Hardening Process Parameters on Case Depth of 4340 Steel Cylindrical Specimen—A Statistical Analysis. J. Surf. Eng. Mater. Adv. Technol. 2015, 5, 124. [Google Scholar] [CrossRef]

- Wagh, S.; Bhatt, D.; Menghani, J.; Pardeshi, S.; Deshmukh, B. Experimental investigation and effects of laser hardening process parameters on microhardness of En24 steel. IOP Conf. Ser. Mater. Sci. Eng. 2020, 814, 012003. [Google Scholar] [CrossRef]

- Jurci, P.; Domankova, M.; Hudakova, M.; Ptacinova, J.; Pasak, M.; Palcek, P. Characterization of microstructure and tempering response of conventionally quenched, short- and long-time sub-zero treated PM Vanadis 6 ledeburitic tool steel. Mater. Charact. 2017, 134, 398–415. [Google Scholar] [CrossRef]

- Mussa, A.; Krakhmalev, P.; Selte, A.; Bergström, J. Development of a New PM Tool Steel for Optimization of Cold Working of Advanced High-Strength Steels. Metals 2020, 10, 1326. [Google Scholar] [CrossRef]

- Mahmoudi, B.; Torkamany, M.J.; Sabour Rouh Aghdam, A.; Sabbaghzade, J. Laser surface hardening of AISI 420 stainless steel treated by pulsed Nd:YAG laser. Mater. Des. 2010, 31, 2553. [Google Scholar] [CrossRef]

- Pacella, M.; Butler-Smith, P.W.; Axinte, D.A.; Fay, M.W. The allotropic transformation of polycrystalline cubic boron nitride structures resulting from the thermal effects of pulsed laser ablation. Diam. Relat. Mater. 2015, 59, 62. [Google Scholar] [CrossRef]

- Yang, L.; Deng, Z.; He, B.; Özel, T. An Experimental Investigation on Laser Surface Texturing of AISI D2 Tool Steel using Nanosecond Fiber Laser. Lasers Manuf. Mater. Process. 2021, 8, 140–156. [Google Scholar] [CrossRef]

- Moravčíková, J.; Moravčík, R.; Sahul, M.; Necpal, M. Influence of Laser Texturing and Coating on the Tribological Properties of the Tool Steels Properties. Machines 2024, 12, 311. [Google Scholar] [CrossRef]

- Yasavol, N.; Abdollah-zadeh, A.; Ganjali, M.; Alidokht, S.A. Microstructure and mechanical behavior of pulsed laser surface melted AISI D2 cold work tool steel. Appl. Surf. Sci. 2013, 265, 653. [Google Scholar] [CrossRef]

- Moradiani, A.; Beiranvand, Z.M.; Chandima Ratnayake, R.M.; Aliabadi, A.; Rasoulinia, M. The effect of laser surface melting on the retained austenite and wear properties of AISI D2 tool steel. Optik 2022, 252, 168469. [Google Scholar] [CrossRef]

- Chen, C.; Feng, A.; Liu, B.; Wei, Y.; Song, X. Effect of quench-tempering and laser quenching on the microstructure and properties of high-chromium cast iron. J. Mater. Res. Technol. 2022, 19, 2759. [Google Scholar] [CrossRef]

- Šturm, R.; Štefanikova, M.; Steiner Petrovic, D. Influence of pre-heating on the surface modification of powder-metallurgy processed cold-work tool steel during laser surface melting. Appl. Surf. Sci. 2015, 325, 203. [Google Scholar] [CrossRef]

- Kwok, C.T.; Cheng, F.; Man, H.C. Microstructure and corrosion behavior of laser surface-melted high-speed steels. Surf. Coat. Technol. 2007, 202, 336. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Lekatou, A.G.; Efremenko, B.V.; Chabak, Y.G.; Petryshynets, I.; Margariti, D.; Emmanouilidou, S.; Puchy, V. Laser beam surface modification of additively manufactured Ni-based superalloy: Correlations of microstructure and tribological/corrosion properties. J. Mater. Res. Technol. 2025, 35, 4390. [Google Scholar] [CrossRef]

- Cold Work Tool Steels. Available online: https://www.bohler-edelstahl.com/app/uploads/sites/248/productdb/api/k390-microclean_en_gb.pdf (accessed on 28 September 2025).

- Sun, J.; Yu, H. Microstructure development and mechanical properties of quenching and partitioning (Q&P) steel and an incorporation of hot-dipping galvanization during Q&P process. Mater. Sci. Eng. A 2013, 586, 100–107. [Google Scholar] [CrossRef]

- Zakiev, I.M.; Gogotsi, G.A.; Storchak, M.; Zakiev, V.I. Glass Fracture during Micro-Scratching. Surfaces 2020, 3, 211. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Chabak, Y.G.; Fedun, V.I.; Shimizu, K.; Pastukhova, T.V.; Petryshynets, I.; Zusin, A.M.; Kudinova, E.V.; Efremenko, B.V. Formation mechanism, microstructural features and dry-sliding behaviour of “Bronze/WC carbide” composite synthesised by atmospheric pulsed-plasma deposition. Vacuum 2021, 185, 110031. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Chabak, Y.G.; Shimizu, K.; Golinskyi, M.A.; Lekatou, A.G.; Petryshynets, I.; Efremenko, B.V.; Halfa, H.; Kusumoto, K.; Zurnadzhy, V.I. The novel hybrid concept on designing advanced multi-component cast irons: Effect of boron and titanium (Thermodynamic modelling, microstructure and mechanical property evaluation). Mater. Charact. 2023, 197, 112691. [Google Scholar] [CrossRef]

- Sukhova, O.V. Structure and properties of fe-b-c powders alloyed with cr, v, mo or nb for plasma-sprayed coatings. Probl. At. Sci. Technol. 2020, 128, 77–83. [Google Scholar] [CrossRef]

- Chernega, S.; Loskutova, T.; Yantsevych, K. Influence of Corrosion Component on the Process of a Cavitation-Corrosive Wear of Complex Carbide Coatings on a Base of a Chromium. Metallofiz. Noveishie Tekhnol. 2003, 25, 519. [Google Scholar]

- Efremenko, V.G.; Lekatou, A.G.; Chabak, Y.G.; Efremenko, B.V.; Petryshynets, I.; Zurnadzhy, V.I.; Emmanouilidou, S.; Vojtko, M. Micromechanical, corrosion and wet sliding wear behaviours of Co-28Cr-6Mo alloy: Wrought vs. LPBF. Mater. Today Commun. 2023, 35, 105936. [Google Scholar] [CrossRef]

- Lu, Y.; Yu, H.; Sisson, D.R. The effect of carbon content on the c/a ratio of as-quenched martensite in Fe-C alloys. Mater. Sci. Eng. A 2017, 700, 592–597. [Google Scholar] [CrossRef]

- Hutchinson, B.; Lynch, P.; Kada, S.; Wang, J. The Crystal Structure of As-quenched Fe–C Martensite. ISIJ Int. 2024, 64, 176–183. [Google Scholar] [CrossRef]

- Van Dijk, N.H.; Butt, A.M.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Wright, J.P.; van der Zwaag, S. Thermal stability of retained austenite in TRIP steels studied by synchrotron X-ray diffraction during cooling. Acta Mater. 2005, 53, 5439. [Google Scholar] [CrossRef]

- Mostafa, M.; Mostafa, A.; Abdel-Rahman, M.; Assem, E.E.; Ashour, A.; Badawi, E. XRD peak broadening modelling for Al-alloys characterization compared with Rietveld profile analysis. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Mote, V.; Purushotham, Y.; Dole, B. Williamson-Hall Analysis in Estimation of Lattice Strain in Nanometer-Sized ZnO Particles. J. Theor. Appl. Phys. 2012, 6, 6. [Google Scholar] [CrossRef]

- Sivagami, M.; Asharani, I.V. Phyto-Mediated Ni/NiO NPs and Their Catalytic Applications—A Short Review. Inorg. Chem. Commun. 2022, 145, 110054. [Google Scholar] [CrossRef]

- Gubicza, J. Reliability and Interpretation of the Microstructural Parameters Determined by X-ray Line Profile Analysis for Nanostructured Materials. Eur. Phys. J. Spec. Top. 2022, 231, 4153. [Google Scholar] [CrossRef]

- Dong, Y.; Sun, Z.; Xia, H.; Feng, J.; Du, J.; Fang, W.; Liu, B.; Wang, G.; Li, L.; Zhang, X.; et al. The Influence of Warm Rolling Reduction on Microstructure Evolution, Tensile Deformation Mechanism and Mechanical Properties of an Fe-30Mn-4Si-2Al TRIP/TWIP Steel. Metals 2018, 8, 742. [Google Scholar] [CrossRef]

- Alexiades, V.; Solomon, A.D.; Critical Radius for Nucleation. Oak Ridge National Laboratory Report. ORNL/TM-9931 1986. Available online: https://www.osti.gov/biblio/5762299 (accessed on 28 September 2025).

- Na, S.-J.; Yang, Y.-S. Influence of heating rate on the laser surface hardening of a medium carbon steel. Surf. Coat. Technol. 1988, 34, 319. [Google Scholar] [CrossRef]

- Billaud, G.; El Ouafi, A.; Barka, N.; Omidi, N. Thermal analysis of laser surface hardening of gears—3D simulation and experimental validation. Int. J. Adv. Manuf. Technol. 2025, 137, 2355. [Google Scholar] [CrossRef]

- Senthil Selvan, J.; Subramanian, K.; Nath, A.K. Effect of laser surface hardening on En18 (AISI 5135) steel. J. Mater. Process. Technol 1999, 91, 29. [Google Scholar] [CrossRef]

- Canale, L.C.F.; Albano, L.; Totten, G.E.; Meekisho, L. 12.03—Hardenability of Steel. Compr. Mater. Process. 2014, 12, 39. [Google Scholar] [CrossRef]

- Kozechko, V.A.; Kozechko, V.I. Combined Ultrasonic–Mechanical Treatment. Metallofiz. Noveishie Tekhnol. 2024, 46, 851. [Google Scholar] [CrossRef]

- Macchi, J.; Gaudez, S.; Geandier, G.; Teixeira, J.; Denis, S.; Bonnet, F.; Allain, S.Y.P. Dislocation densities in a low-carbon steel during martensite transformation determined by in situ high energy X-Ray diffraction. Mater. Sci. Eng. A 2021, 800, 140249. [Google Scholar] [CrossRef]

- Kostryzhev, A.; Marenych, O.; Killmore, C.; Pereloma, E. Strengthening mechanisms in thermomechanically processed NbTi-microalloyed steel. Metall. Mater. Trans. A 2015, 46, 3470. [Google Scholar] [CrossRef]

- Huang, M.; Rivera-Díaz-del-Castillo, P.E.J.; Bouaziz, O.; Van der Zwaag, S. Modelling strength and ductility of ultrafine grained BCC and FCC alloys using in reversible thermodynamics. Mater. Sci. Technol. 2009, 25, 833. [Google Scholar] [CrossRef]

- Guo, B.; Fan, L.; Wang, Q.; Fu, Z.; Wang, Q.; Zhang, F. Effect of finish rolling temperature on the microstructure and tensile properties of Nb-Ti microalloyed X90 pipeline steel. Metals 2016, 6, 323. [Google Scholar] [CrossRef]

- Pavlina, E.; Van Tyne, C. Correlation of Yield Strength and Tensile Strength with Hardness for Steels. J. Mater. Eng. Perform. 2008, 17, 888. [Google Scholar] [CrossRef]

- Krbata, M.; Kohutiar, M.; Escherova, J.; Klučiar, P.; Studeny, Z.; Trembach, B.; Beronská, N.; Breznická, A.; Timárová, Ľ. Continuous Cooling Transformation of Tool Steels X153CrMoV12 and 100MnCrW4: Analysis of Microstructure and Hardness Changes. Appl. Mech. 2025, 6, 16. [Google Scholar] [CrossRef]

- Chabak, Y.G.; Efremenko, V.G. Change of Secondary-Carbides’ Nanostate in 14.5% Cr Cast Iron at High-Temperature Heating. Metallofiz. Noveishie Tekhnol. 2012, 34, 1205. [Google Scholar]

- Kulyk, V.; Izonin, I.; Vavrukh, V.; Tkachenko, R.; Duriagina, Z.; Vasyliv, B.; Kováčová, M. Prediction of Hardness, Flexural Strength, and Fracture Toughness of ZrO2 Based Ceramics Using Ensemble Learning Algorithms. Acta Metall. Slovaca 2023, 29, 93. [Google Scholar] [CrossRef]

- Lai, Q.; Chen, Z.; Wei, Y.; Lu, Q.; Ma, Y.; Wang, J.; Fan, G. Towards the understanding of fracture resistance of an ultrahigh-strength martensitic press-hardened steel. J. Mater. Res. Technol. 2023, 27, 1996. [Google Scholar] [CrossRef]

- Niu, Z.M.; Lei, Y.B.; Gao, B.; Sun, Y.T.; Wang, Z.B. Architecting an ultrahard surface layer on maraging steel by a surface thermomechanical approach. J. Mater. Res. Technol. 2025, 36, 2243. [Google Scholar] [CrossRef]

- Efremenko, V.; Shimizu, K.; Pastukhova, T.; Chabak, Y.; Brykov, M.; Kusumoto, K.; Efremenko, A. Three-body abrasive wear behaviour of metastable spheroidal carbide cast irons with different chromium contents. Int. J. Mater. Res. 2018, 109, 147. [Google Scholar] [CrossRef]

- Malinov, L.S.; Malinov, V.L.; Malysheva, I.E.; Burova, D.V. Principle Universality of Obtaining Metastable Austenite in the Alloy and Cast Iron Structure to Increase the Abrasive Wear Resistance. J. Frict. Wear 2022, 43, 185. [Google Scholar] [CrossRef]

- Efremenko, V.G.; Shimizu, K.; Pastukhova, T.V.; Chabak, Y.G.; Kusumoto, K.; Efremenko, A.V. Effect of bulk heat treatment and plasma surface hardening on the microstructure and erosion wear resistance of complex-alloyed cast irons with spheroidal vanadium carbides. J. Frict. Wear 2017, 38, 58. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, T.; Zhang, S. Influence of oxides on the formation of self-lubricating layer and anti-wear performance during sliding. Tribol. Int. 2023, 179, 108188. [Google Scholar] [CrossRef]

| Elements | AR | AR+L | HT+L | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Oxide Film | Deformed Area | “Fresh” Area | Oxide Film | Deformed Area | “Fresh” Area | Oxide Film | Deformed Area | “Fresh” Area | |

| O | 56.8 | 10.6 | 4.7 | 50.1 | 4.1 | 5.0 | 32.9 | 27.2 | 3.4 |

| Si | 5.1 | 1.1 | 1.0 | 6.2 | 1.5 | 1.1 | 8.0 | 6.8 | 1.4 |

| V | 4.3 | 5.2 | 4.4 | 5.1 | 1.8 | 1.5 | 1.7 | 1.5 | 3.4 |

| Cr | 1.8 | 2.3 | 3.0 | 3.3 | 4.8 | 4.1 | 2.3 | 2.9 | 3.8 |

| Mn | 0.3 | 0.9 | 0.2 | 0.2 | 0.2 | 0.2 | 0.6 | 0.6 | 0.4 |

| Mo | 1.0 | 1.2 | 0.8 | 1.3 | 1.0 | 0.3 | 0.7 | 0.8 | 1.2 |

| W | 0.0 | 0.1 | 0.3 | 0.3 | 0.2 | 0.2 | 0.1 | 0.2 | 0.2 |

| Fe | 30.7 | 78.6 | 85.6 | 33.5 | 86.4 | 87.6 | 53.7 | 60.0 | 86.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chabak, Y.; Efremenko, V.; Barma, Y.; Petrišinec, I.; Efremenko, B.; Kromka, F.; Sili, I.; Kovbasiuk, T. Enhancing Dry-Sliding Wear Performance of a Powder-Metallurgy-Processed “Metal Matrix–Carbide” Composite via Laser Surface Modification. Eng 2025, 6, 313. https://doi.org/10.3390/eng6110313

Chabak Y, Efremenko V, Barma Y, Petrišinec I, Efremenko B, Kromka F, Sili I, Kovbasiuk T. Enhancing Dry-Sliding Wear Performance of a Powder-Metallurgy-Processed “Metal Matrix–Carbide” Composite via Laser Surface Modification. Eng. 2025; 6(11):313. https://doi.org/10.3390/eng6110313

Chicago/Turabian StyleChabak, Yuliia, Vasily Efremenko, Yevhen Barma, Ivan Petrišinec, Bohdan Efremenko, František Kromka, Ivan Sili, and Taras Kovbasiuk. 2025. "Enhancing Dry-Sliding Wear Performance of a Powder-Metallurgy-Processed “Metal Matrix–Carbide” Composite via Laser Surface Modification" Eng 6, no. 11: 313. https://doi.org/10.3390/eng6110313

APA StyleChabak, Y., Efremenko, V., Barma, Y., Petrišinec, I., Efremenko, B., Kromka, F., Sili, I., & Kovbasiuk, T. (2025). Enhancing Dry-Sliding Wear Performance of a Powder-Metallurgy-Processed “Metal Matrix–Carbide” Composite via Laser Surface Modification. Eng, 6(11), 313. https://doi.org/10.3390/eng6110313