Automated Concrete Bridge Deck Inspection Using Unmanned Aerial System (UAS)-Collected Data: A Machine Learning (ML) Approach

Abstract

1. Introduction

- •

- It reduces the overall time and the cost of inspection.

- •

- It reduces traffic control during the time of inspection.

- •

- It provides easy access to areas of the bridge that are difficult to reach, such as tall piers.

- •

- Most importantly, it provides safety for the inspection crew by reducing the need for interaction with hazardous environments and working in the tight and confined spaces of snooper trucks and roadside areas.

2. Literature Review

2.1. Automated Bridge Inspection

Automated Data Collection

- It reduces the overall time and the cost of inspection.

- It reduces traffic control during the time of inspection.

- It provides easy access to areas of the bridge that are difficult to reach, such as tall piers.

- Most importantly, it provides safety for the inspection crew by removing the need for interaction with hazardous environments and working in the tight and confined space of the snooper trucks.

2.2. Machine Learning for Automated UAS Data Analysis

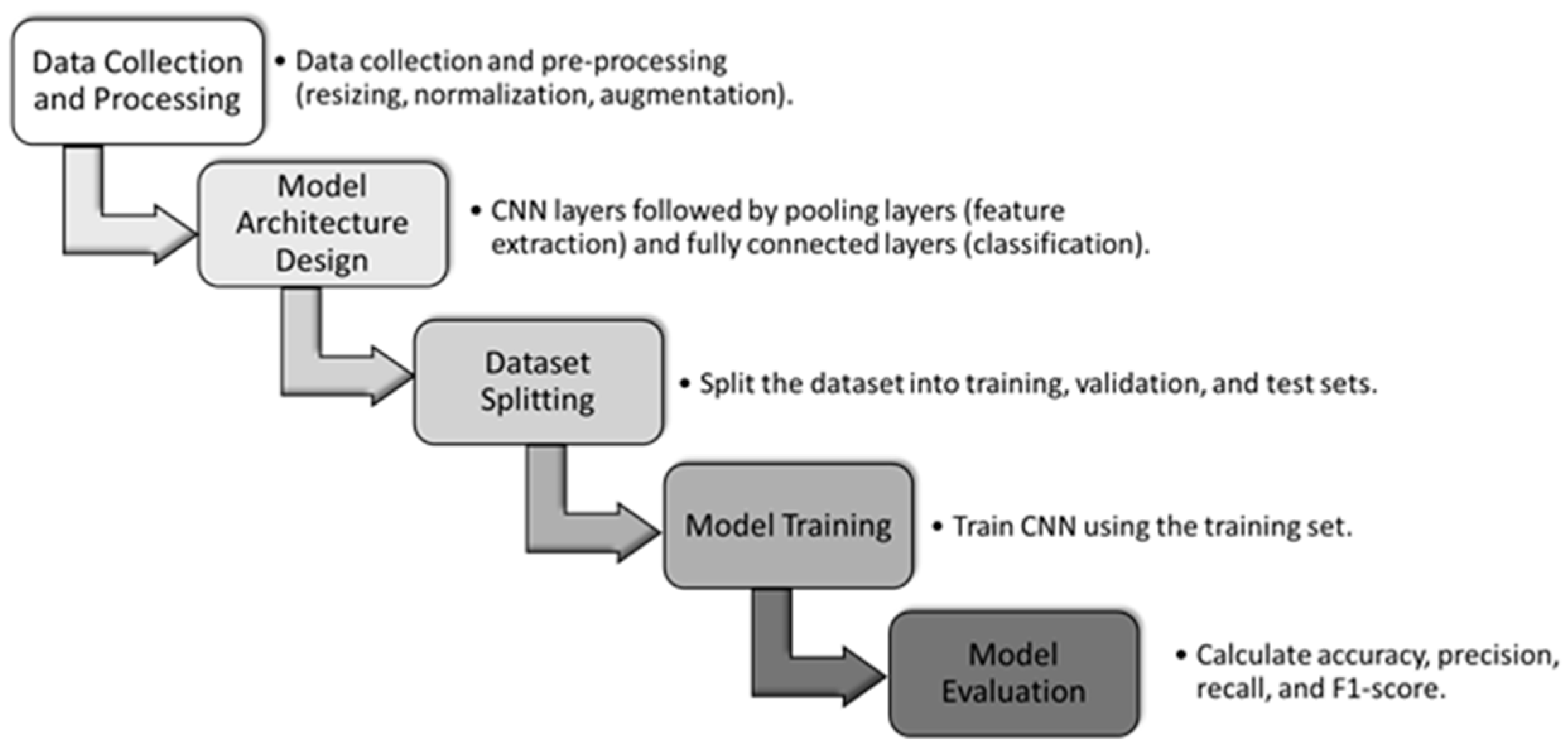

3. Materials and Methods

- •

- Data collection: As the first step, the UAS collects images of the bridge deck surface as raw data.

- •

- Data processing: The raw data are then processed automatically by labeling the features of the data to create positive (damaged) and negative (undamaged) datasets.

- •

- Data analysis: CNN and ViT algorithms are developed, and the labeled data are deployed in these models to identify and localize damage on the bridge deck.

- •

- Model evaluation and results: The final step assesses the performance of the model after it is trained on specific datasets, focusing on its ability to predict and classify data accurately. The evaluation encompasses various metrics such as training loss, validation loss, model accuracy, and validation accuracy, which help gauge the model’s efficiency and reliability.

3.1. Data Collection

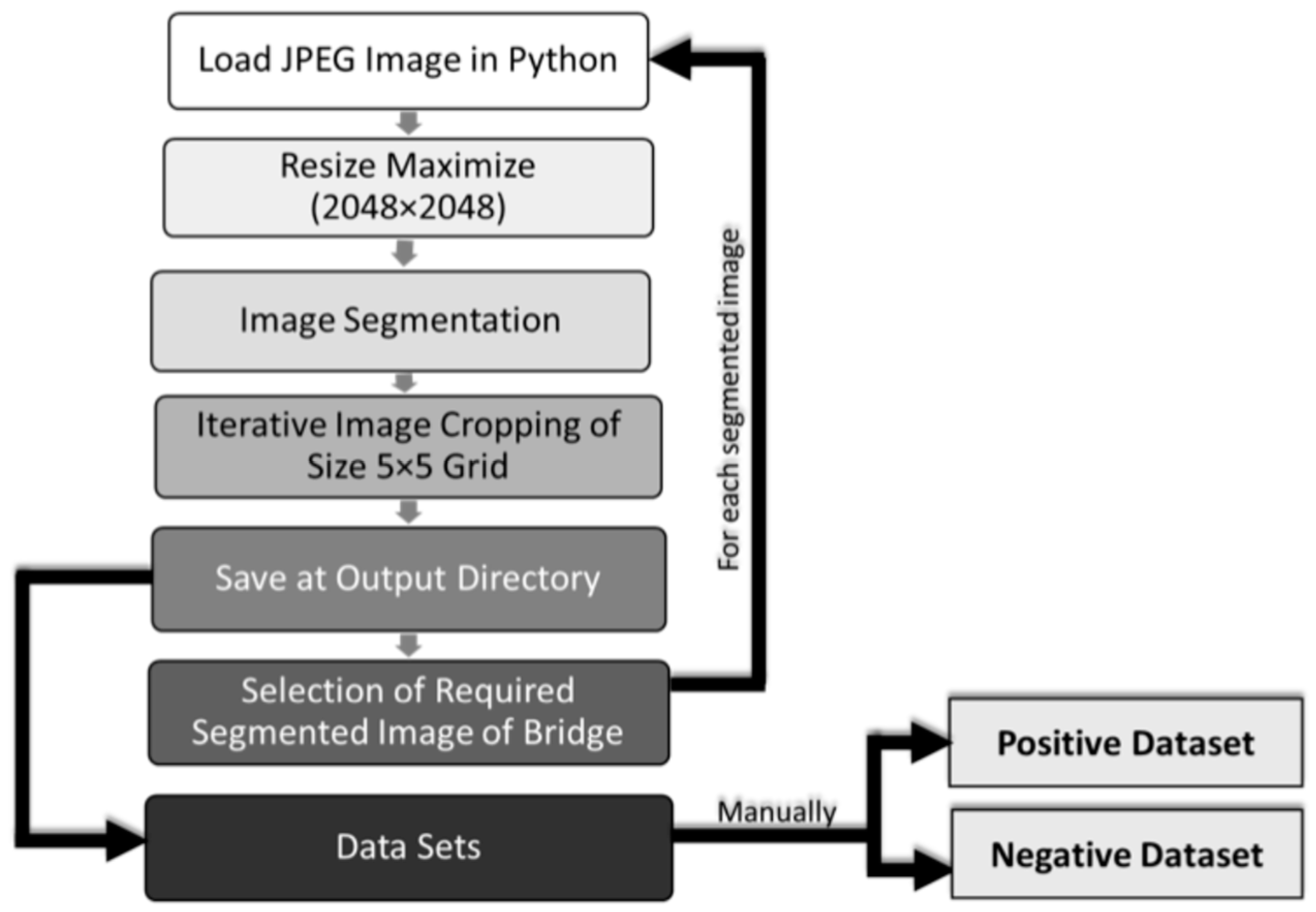

3.2. Data Processing

3.3. Data Analysis

3.3.1. Data Analysis Using CNN

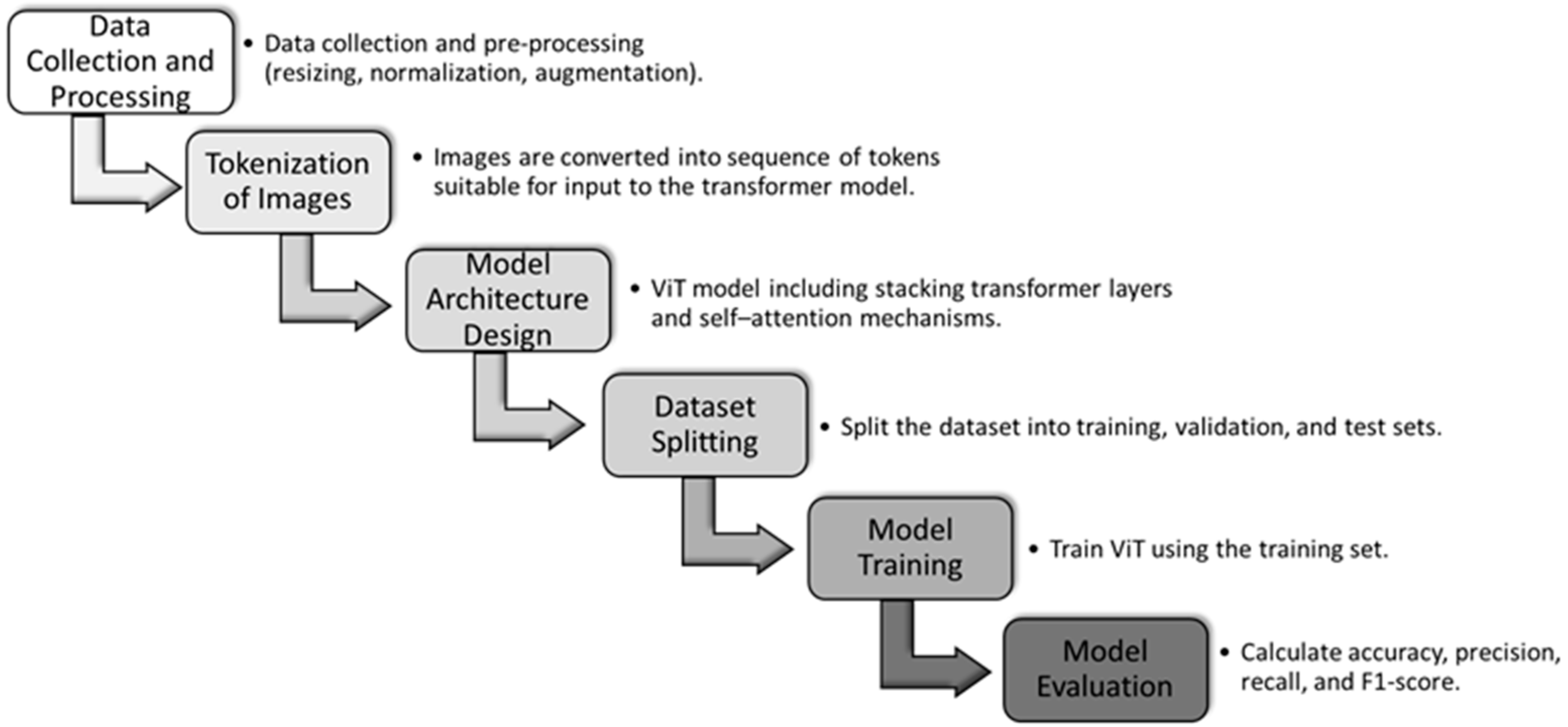

3.3.2. Data Analysis Using ViT

3.4. Model Evaluation and Results

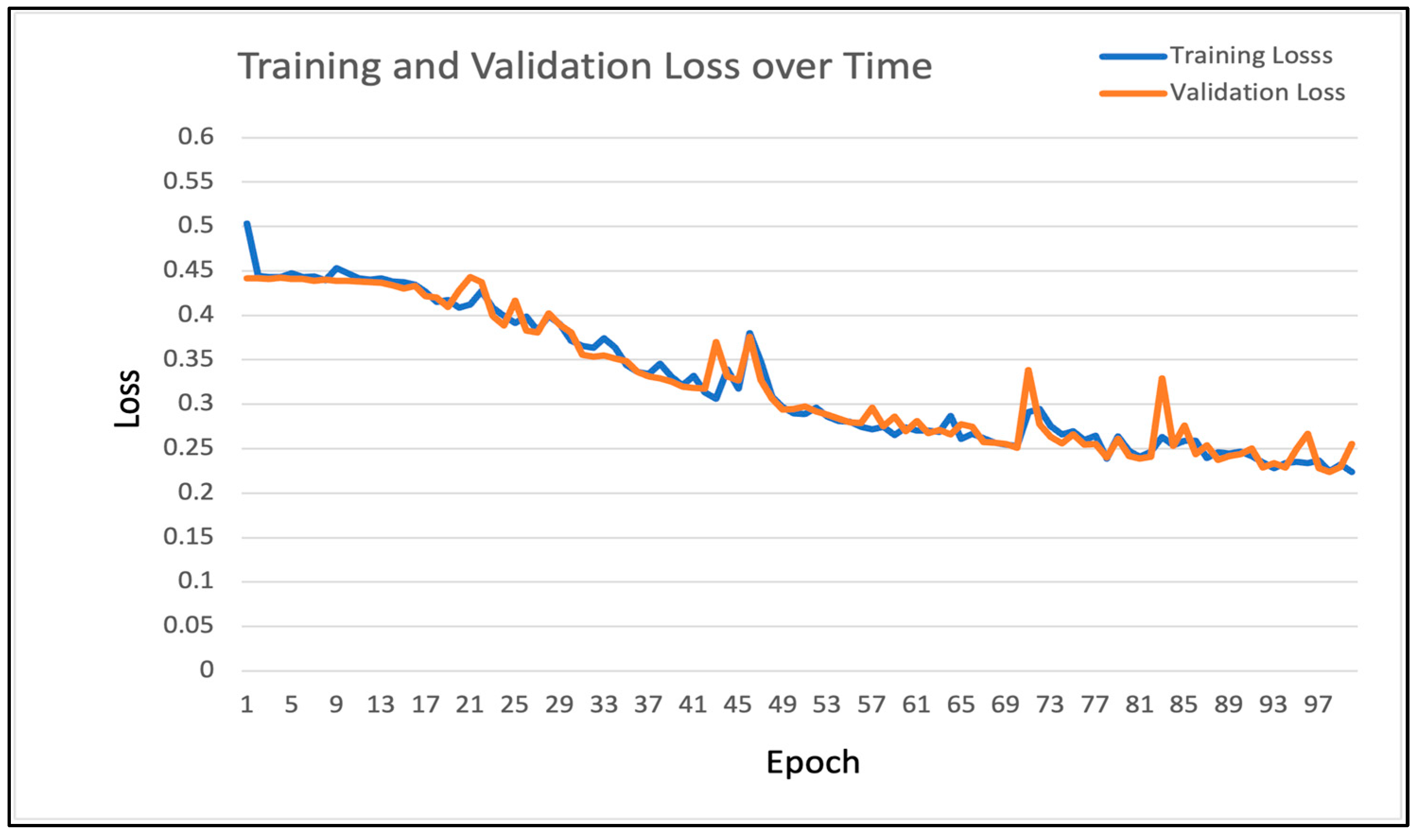

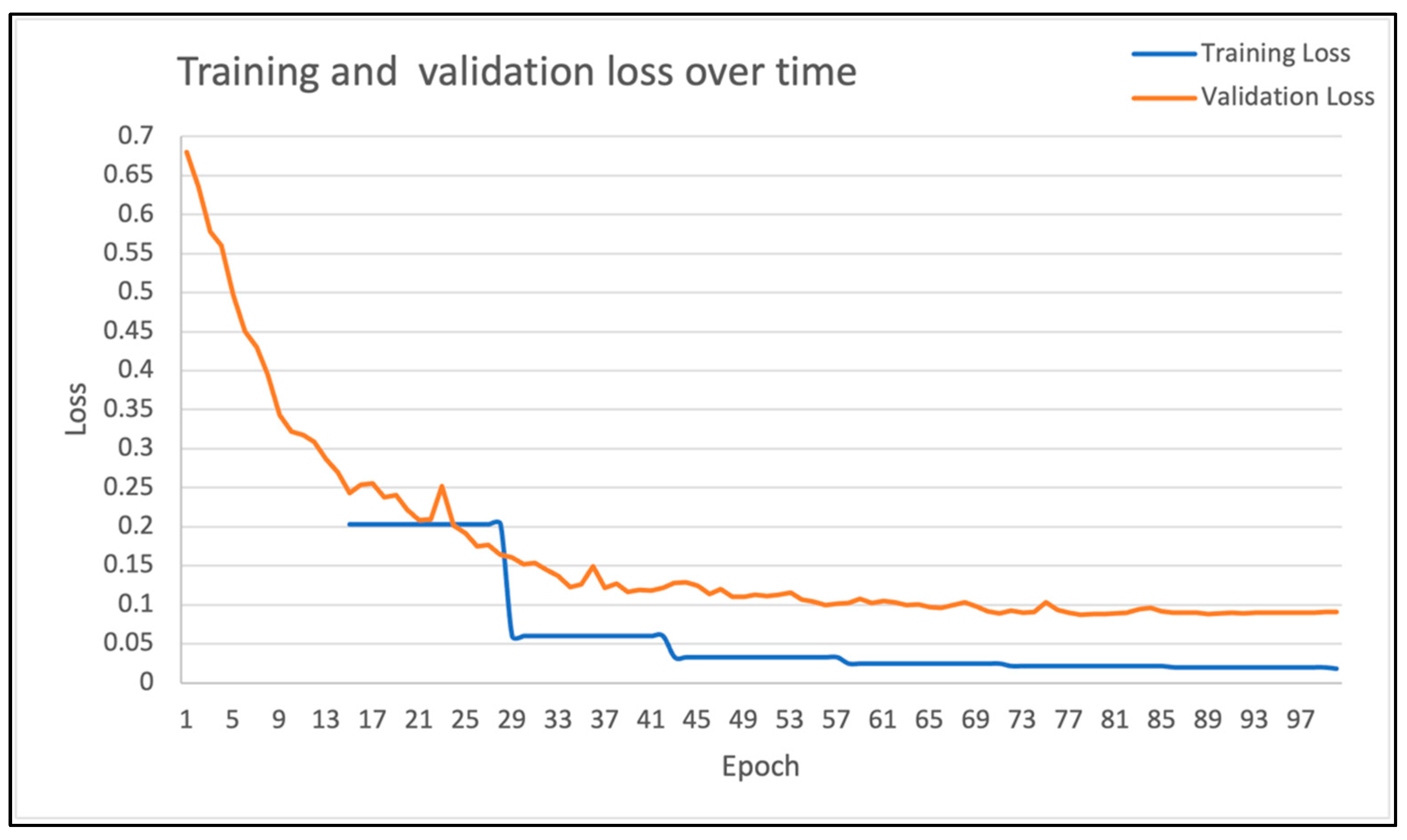

3.4.1. Training Loss

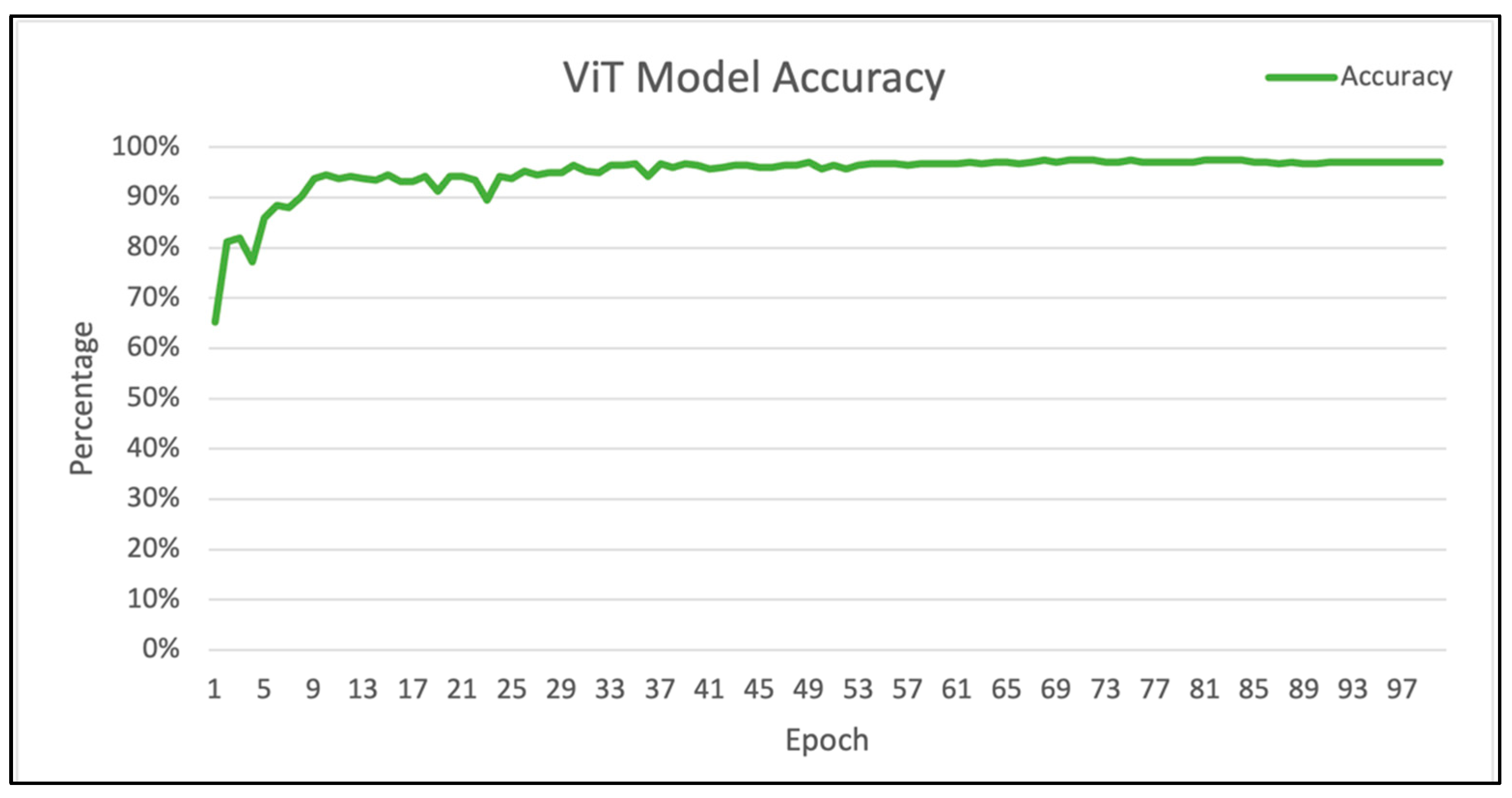

3.4.2. Model Accuracy

3.4.3. Validation Loss

3.4.4. Validation Accuracy

3.4.5. Epoch

3.4.6. Precision

3.4.7. Recall

3.4.8. F1 Score

3.4.9. Macro Avg

3.4.10. Weighted Avg

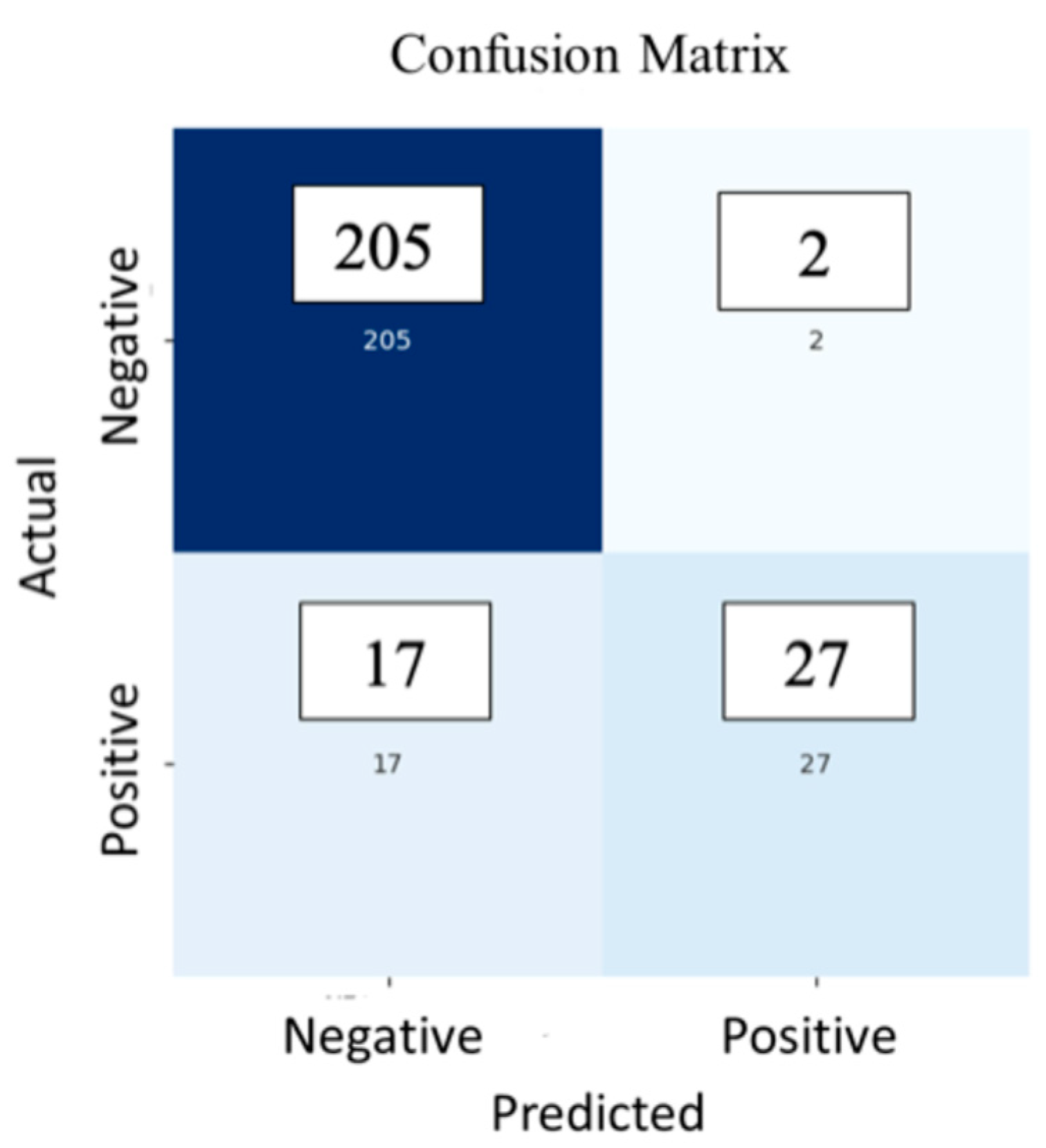

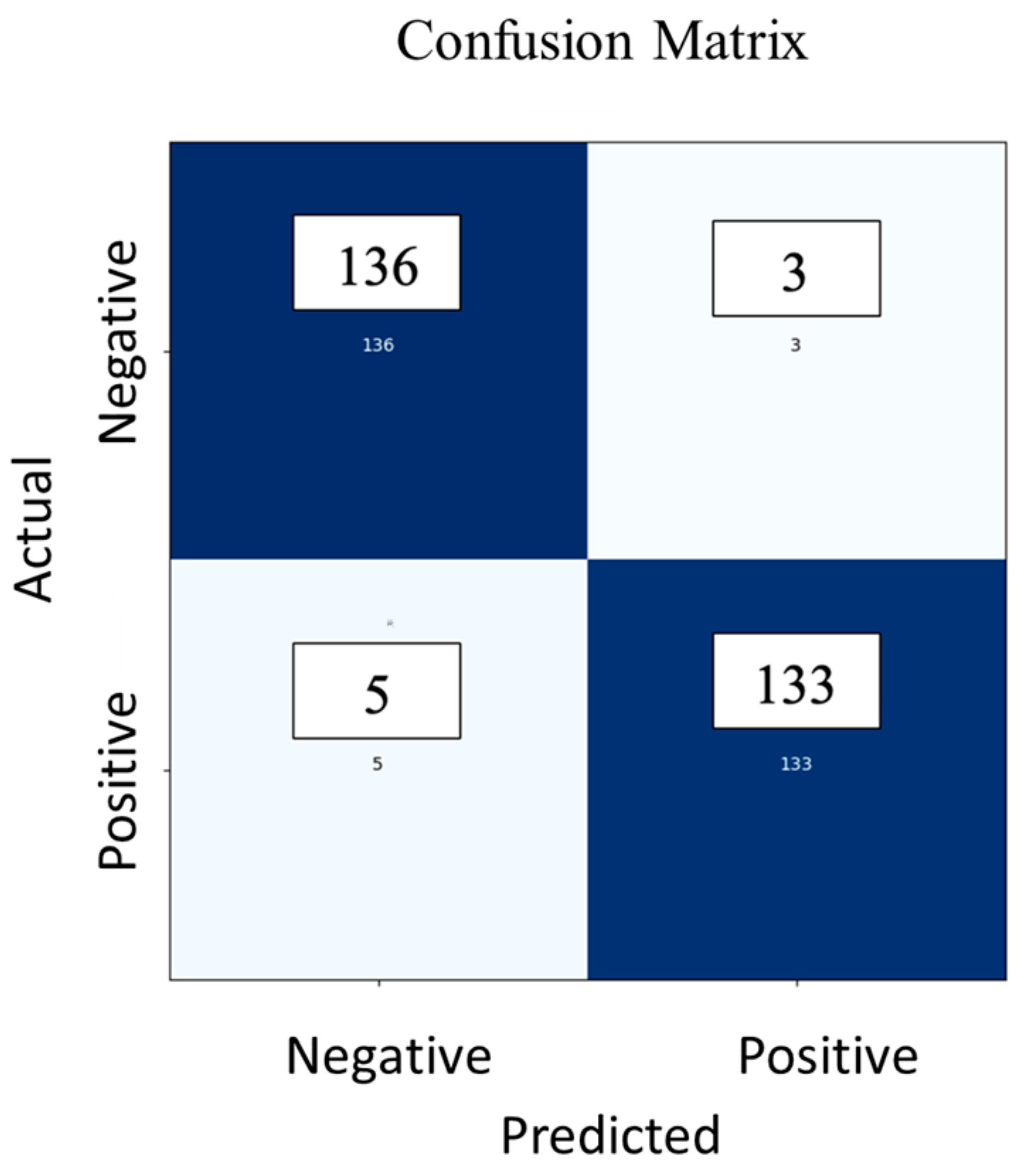

3.4.11. Confusion Matrix

- •

- True positive (TP): It is the number of cases in the positive class that the model properly predicts to be positive.

- •

- False positive (FP): It is the number of cases in the negative class that model incorrectly predicts to be positive.

- •

- True negative (TN): It is the number of cases in the negative class that the model properly predicts to be negative.

- •

- False negative (FN): It is the number of cases in the positive class that model incorrectly predicts to be negative.

4. Illustrative Experiment

4.1. Data Collection

4.1.1. Nikon D810

4.1.2. DJI Phantom 3A

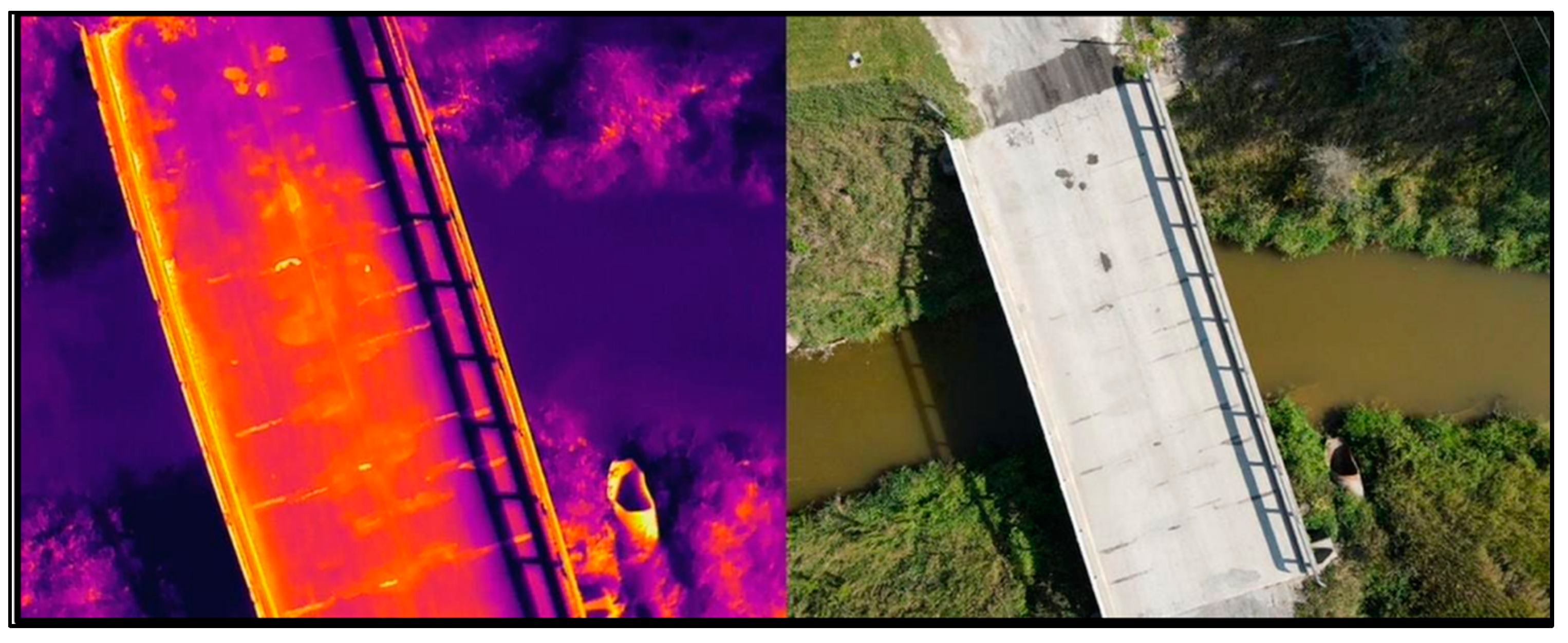

4.1.3. DJI M2EA

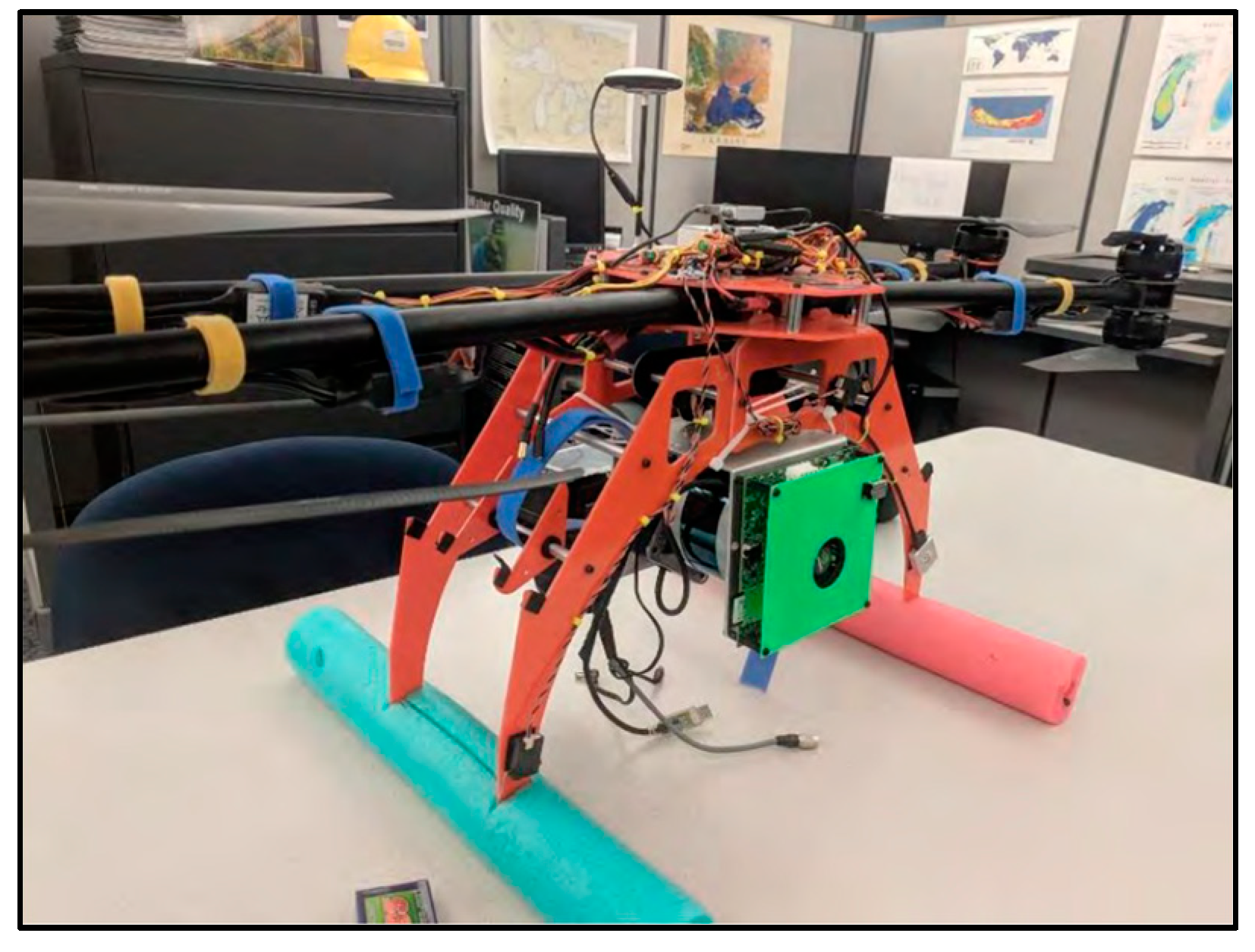

4.1.4. Bergen Quad-8

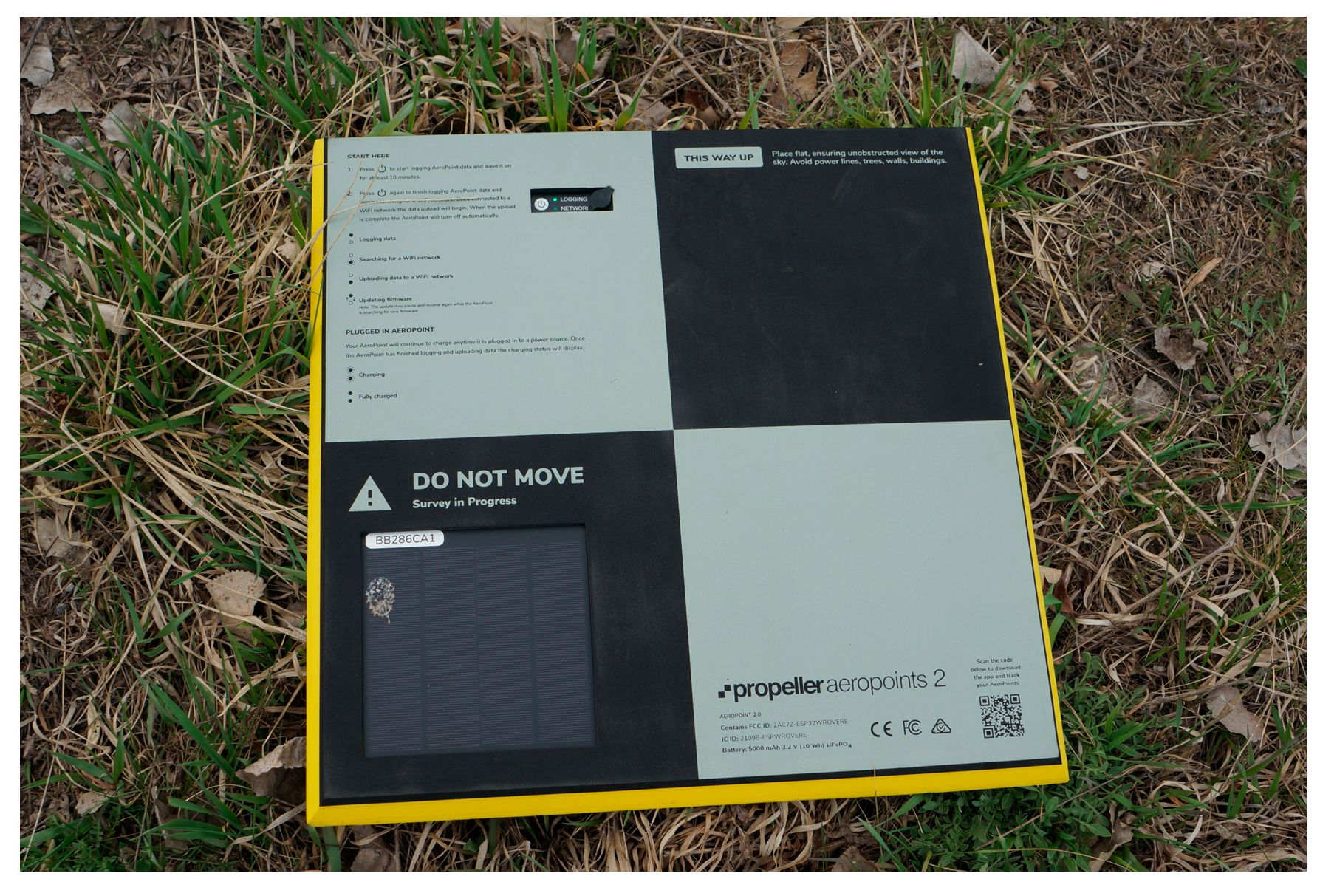

4.1.5. Ground Control Points with GPS

4.2. Data Processing

4.3. Data Analysis

4.4. Model Evaluation and Results

4.4.1. CNN Model Evaluation and Results

4.4.2. ViT Model Evaluation and results

5. Discussion

5.1. Limitations

5.2. Future Scope

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Weseman, W.A. The Recording and Coding Guide for the Structure Inventory and Appraisal of the Nation’s Bridges; United States Department of Transportation, Ed.; Federal Highway Administration: Washington, DC, USA, 1995; Volume 119.

- Li, T.; Alipour, M.; Harris, D.K. Mapping textual descriptions to condition ratings to assist bridge inspection and condition assessment using hierarchical attention. Autom. Constr. 2021, 129, 103801. [Google Scholar] [CrossRef]

- American Society of Civil Engineers, America’s Infrastructure. 2017. Available online: https://www.infrastructurereportcard.org/wp-content/uploads/2016/10/2017-Infrastructure-Report-Card.pdf (accessed on 1 September 2023).

- American Road & Transportation Builders Association, 2020 ARTBA Bridge Report. 2020. Available online: https://www.artbabridgereport.org (accessed on 9 December 2023).

- Azari, H.; O’shea, D.; Campbell, J. Application of unmanned aerial systems for bridge inspection. Transp. Res. Rec. 2022, 2676, 401–407. [Google Scholar] [CrossRef]

- Zhou, Z.-H. Machine Learning; Springer Nature: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Kim, I.-H.; Jeon, H.; Baek, S.-C.; Hong, W.-H.; Jung, H.-J. Application of crack identification techniques for an aging concrete bridge inspection using an unmanned aerial vehicle. Sensors 2018, 18, 1881. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Coopmans, C.; Maguire, M. Deep learning neural networks for sUAS-assisted structural inspections: Feasibility and application. In Proceedings of the 2018 International Conference on Unmanned AIRCRAFT Systems (ICUAS), Dallas, TX, USA, 12–15 June 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 874–882. [Google Scholar]

- Nguyen, D.-C.; Nguyen, T.-Q.; Jin, R.; Jeon, C.-H.; Shim, C.-S. BIM-based mixed-reality application for bridge inspection and maintenance. Constr. Innov. 2022, 22, 487–503. [Google Scholar] [CrossRef]

- Choi, Y.; Choi, Y.; Cho, J.-S.; Kim, D.; Kong, J. Utilization and Verification of Imaging Technology in Smart Bridge Inspection System: An Application Study. Sustainability 2023, 15, 1509. [Google Scholar] [CrossRef]

- Kim, R.C. Local Assistance Procedures Manual Exhibit 11-B Bridges and Structures. 2022. Available online: https://dot.ca.gov/programs/engineering-services/manuals (accessed on 1 June 2023).

- USDOT; Federal Highway Administration (FHWA). 2022-09512; 2022. Available online: https://www.govinfo.gov/content/pkg/FR-2022-05-06/pdf/2022-09512.pdf (accessed on 1 September 2023).

- Kušar, M. Bridge inspection quality improvement using standard inspection methods. In Proceedings of the Joint COST TU1402—COST TU1406—IABSE WC1 Workshop: The Value of Structural Health Monitoring for the Reliable Bridge Management, Zagreb, Croatia, 2–3 March 2017; Available online: https://www.grad.unizg.hr/_download/repository/BSHM2017_3.7.pdf (accessed on 1 September 2023).

- Lovelace, B. Improving the Quality of Bridge Inspections Using Unmanned Aircraft Systems (UAS). 2018. Available online: https://transportation.org/uas-aam/wp-content/uploads/sites/80/2023/05/201826.pdf (accessed on 1 June 2023).

- Ganapuram, S.; Adams, M.; Patnaik, A. Ohio Department of Transportation, Office of Research and Development: Columbus, OH, USA, 2012. Available online: https://rosap.ntl.bts.gov/view/dot/24222 (accessed on 1 September 2023).

- Sen, S.; Bricka, S. Data Collection Technologies—Past, Present, and Future. 2013. Available online: https://books.google.co.in/books?hl=en&lr=&id=uIwWBAAAQBAJ&oi=fnd&pg=PA295&dq=related:UnIrl330L7cJ:scholar.google.com/&ots=FuRxiamYqU&sig=0DEG09a9BCfzw3Nz7Qydp4BNrG4&redir_esc=y#v=onepage&q&f=false (accessed on 1 September 2023).

- Tang, P.; Akinci, B.; Garrett, J.H. Laser Scanning for Bridge Inspection and Management. In IABSE Symposium Report, International Association for Bridge and Structural Engineering; 2007; pp. 17–24. Available online: https://www.researchgate.net/profile/Pingbo-Tang/publication/233686297_Laser_Scanning_for_Bridge_Inspection_and_Management/links/543edbc50cf2e76f02244798/Laser-Scanning-for-Bridge-Inspection-and-Management.pdf (accessed on 1 September 2023).

- Badanes, B. Ohio Department of Transportation, Eyes in the Sky. 2022. Available online: https://www.transportation.ohio.gov/about-us/stories/march-winter-spring-2022/eyes-in-the-sky (accessed on 1 June 2023).

- Hiasa, S.; Karaaslan, E.; Shattenkirk, W.; Mildner, C.; Catbas, F.N. Bridge inspection and condition assessment using image-based technologies with UAVs. In Structures Congress 2018; American Society of Civil Engineers: Reston, VA, USA, 2018; pp. 217–228. [Google Scholar]

- Seo, J.; Jeong, E.; Wacker, J.P. Machine learning approach to visual bridge inspection with drones. In Structures Congress 2022; American Society of Civil Engineers: Reston, VA, USA, 2022; pp. 160–169. [Google Scholar]

- Ali, L.; Aljassmi, H.; Parambil, M.M.A.; Swavaf, M.; AlAmeri, M.; Alnajjar, F. Crack Detection and Localization in Stone Floor Tiles using Vision Transformer approach. In Proceedings of the International Symposium on Automation and Robotics in Construction, Chennai, India, 5–7 July 2023; IAARC Publications: Waterloo, ON, Canada, 2023; pp. 699–705. [Google Scholar]

- Chun, P.; Yamane, T.; Maemura, Y. A deep learning-based image captioning method to automatically generate comprehensive explanations of bridge damage. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 1387–1401. [Google Scholar] [CrossRef]

- Zhang, G.-Q.; Wang, B.; Li, J.; Xu, Y.-L. The application of deep learning in bridge health monitoring: A literature review. Adv. Bridge Eng. 2022, 3, 22. [Google Scholar] [CrossRef]

- Jáuregui, D.V.; Tian, Y.; Jiang, R. Photogrammetry applications in routine bridge inspection and historic bridge documentation. Transp. Res. Rec. 2006, 1958, 24–32. [Google Scholar] [CrossRef]

- Adhikari, R.S.; Moselhi, O.; Bagchi, A. Image-based retrieval of concrete crack properties for bridge inspection. Autom. Constr. 2014, 39, 180–194. [Google Scholar] [CrossRef]

- Song, L.; Sun, H.; Liu, J.; Yu, Z.; Cui, C. Automatic segmentation and quantification of global cracks in concrete structures based on deep learning. Measurement 2022, 199, 111550. [Google Scholar] [CrossRef]

- Zhang, C.; Wan, L.; Wan, R.-Q.; Yu, J.; Li, R. Automated fatigue crack detection in steel box girder of bridges based on ensemble deep neural network. Measurement 2022, 202, 111805. [Google Scholar] [CrossRef]

- Ayele, Y.Z.; Aliyari, M.; Griffiths, D.; Droguett, E.L. Automatic crack segmentation for UAV-assisted bridge inspection. Energies 2020, 13, 6250. [Google Scholar] [CrossRef]

- Zollini, S.; Alicandro, M.; Dominici, D.; Quaresima, R.; Giallonardo, M. UAV photogrammetry for concrete bridge inspection using object-based image analysis (OBIA). Remote Sens. 2020, 12, 3180. [Google Scholar] [CrossRef]

- Potenza, F.; Rinaldi, C.; Ottaviano, E.; Gattulli, V. A robotics and computer-aided procedure for defect evaluation in bridge inspection. J. Civ. Struct. Health Monit. 2020, 10, 471–484. [Google Scholar] [CrossRef]

- Wang, W.; Su, C. Automatic concrete crack segmentation model based on transformer. Autom. Constr. 2022, 139, 104275. [Google Scholar] [CrossRef]

- Xiao, S.; Shang, K.; Lin, K.; Wu, Q.; Gu, H.; Zhang, Z. Pavement crack detection with hybrid-window attentive vision transformers. Int. J. Appl. Earth Obs. Geoinf. 2023, 116, 103172. [Google Scholar] [CrossRef]

- Reghukumar, A.; Anbarasi, L.J.; Prassanna, J.; Manikandan, R.; Al-Turjman, F. Vision based seg-mentation and classification of cracks using deep neural networks. Int. J. Uncertain. Fuzziness Knowl.-Based Syst. 2021, 29, 141–156. [Google Scholar] [CrossRef]

- Escobar-Wolf, R.; Oommen, T.; Brooks, C.N.; Dobson, R.J.; Ahlborn, T.M. Unmanned aerial vehicle (UAV)-based assessment of concrete bridge deck delamination using thermal and visible camera sensors: A preliminary analysis. Res. Nondestruct. Eval. 2018, 29, 183–198. [Google Scholar] [CrossRef]

- Wolf, T.; Debut, L.; Sanh, V.; Chaumond, J.; Delangue, C.; Moi, A.; Cistac, P.; Rault, T.; Louf, R.; Funtowicz, M.; et al. Transformers: State-of-the-art natural language processing. In Proceedings of the 2020 Conference on Empirical Methods in Natural Language Processing: System Demonstrations, Online, 16–20 November 2020; pp. 38–45. [Google Scholar]

- Brooks, C.; Dobson, R.; Banach, D.; Oommen, T.; Zhang, K.; Mukherjee, A.; Havens, T.; Ahborn, T.; Escobar-Wolf, R.; Bhat, C.; et al. Implementation of Unmanned Aerial Vehicles (UAVs) for Assessment of Transportation Infrastructure-Phase II; Michigan Technological University: Houghton, MI, USA, 2018. [Google Scholar]

- Brooks, C.; Cook, C.; Dobson, R.; Oommen, T.; Zhang, K.; Mukherjee, A.; Samsami, R.; Semenchuk, A.; Lovelace, B.; Hung, V.; et al. ntegration of Unmanned Aerial Systems Data Collection into Day-to-Day Usage for Transportation Infrastructure—A Phase III Project. Michigan Department of Transportation Research Administration Report No. 1713. 2022. Available online: https://rosap.ntl.bts.gov/view/dot/62974 (accessed on 1 June 2023).

| No. | Paper | Title | Methodology | Output |

|---|---|---|---|---|

| 1 | Seo et al., 2022 [14]. | Machine Learning Approach to Visual Bridge Inspection with Drones | CNN is used as a machine learning algorithm. Damage assessment is conducted using semantic segmentation software (ImageJ 2022). | Identification of different types of damage such as cracking, weathering, and spalling (chipping, flaking, or breaking off of small fragments from the surface). |

| 2 | Nguyen et al., 2022 [9]. | BIM-based mixed-reality application for bridge inspection and maintenance | BIM-based model named Heronbridge for bridge inspection based on Microsoft HoloLens. | Inspection information improved in the interpretation, visualization, and visual interpretation of 3D models. |

| 3 | Dorafshan et al., 2018 [8]. | Deep Learning Neural Networks for sUAS-Assisted Structural Inspections: Feasibility and Application | Deep learning CNN for concrete deck inspection. Autonomous image classification and object detection and calculation of learning parameters through thousands to millions of iterations. | A CNN algorithm using Alex net architecture and ResNet to improve network evaluation. |

| 4 | Chun et al., 2022 [22]. | A deep learning-based image captioning method to automatically generate comprehensive explanations of bridge damage | Deep learning model to generate texts for the condition of bridges. | Generation of explanatory texts for 1000 new bridge images. |

| 5 | Zhang et al., 2022 [23]. | The application of deep learning in bridge health monitoring: a literature review | Deep learning based on deep neural networks for structural health monitoring (vibration- and vision-based). | A review of bridge health monitoring and damage detection techniques. |

| 6 | Kim et al., 2018 [7]. | Application of Crack Identification Techniques for an Aging Concrete Bridge Inspection Using an Unmanned Aerial Vehicle | Commercial software, Pix4D mapper 2022, for 3D model generation. AutoCAD 2017 to convert spatial information into digital information by using. | Three-dimensional point cloud of bridge. RCNN algorithm. |

| 7 | Choi et al., 2023 [10]. | Utilization and Verification of Imaging Technology in Smart Bridge Inspection System: An Application Study | Image processing and machine learning data algorithms. | Three-dimensional external inspection map. VR assisted in illustrating inspection details. Inspection cost was reduced by 19%. |

| 8 | Azari et al., 2022 [5]. | Application of Unmanned Aerial Systems for Bridge Inspection | UAS and LiDAR (light detection and imaging) to capture HD images. Use of geospatial software programs and CAD to create 3D model of bridges. | Cost, time, and labor effectiveness are reported. |

| 9 | Li et al., 2021 [2]. | Mapping textual descriptions to condition ratings to assist bridge inspection and condition assessment using hierarchical attention | Hierarchical architecture recurrent neural network (GRU-based sequence encoder) with an attention mechanism. | Condition rating and quality control of bridges. |

| 10 | Hiasa et al., 2018 [19]. | Bridge Inspection and Condition Assessment Using Image-Based Technologies with UAVs | Infrared thermography inspection to detect subsurface defects such as delamination and voids. High-definition (HD) imaging technologies to detect surface defects such as cracks. | Crack size is assessed according to several manuals or standards. |

| 11 | David V et al. [24]. | Photogrammetry applications in routine bridge inspection and historic bridge documentation | Photogrammetry techniques to assess bridge geometry. PhotoModeler 2006 software was used to process the images for measurement. | Photogrammetry techniques provide sufficient accuracy. |

| 12 | Adhikari et al., 2014 [25]. | Image-based retrieval of concrete crack properties for bridge inspection | Integrated model based on digital image processing to identify crack quantification, change detection, neural networks, and 3D visualization. | Fourier transform of digital images and integrated model is used to detect crack length and change detection. |

| 13 | Song et al., 2022 [26]. | Automatic segmentation and quantification of global cracks in concrete structures based on deep learning. | Methods of close-range scanning and shooting to obtain HD panoramas of the surface of concrete. | Identification and quantification of cracks and calculation of crack width with 3.87% accuracy. |

| 14 | Zang et al., 2022 [27]. | Automated fatigue crack detection in steel box girder of bridges based on ensemble deep neural network | Sub-networks (detection classifiers) to differentiate cracks on images; segmentation sub-network to obtain pixel level crack details. | Crack segmentation. |

| 15 | Ayele et al., 2020 [28]. | Automatic Crack Segmentation for UAV-Assisted Bridge Inspection | Mask RCNN. Three-dimensional construction of bridge geometry and damage identification. | Detection, locating, and quantification of cracks and fractures on the bridge. |

| 16 | Zollini et al., 2020 [29]. | UAV Photogrammetry for Concrete Bridge Inspection Using Object-Based Image Analysis (OBIA) | Object-Based Image Analysis (OBIA). | Concrete structure inspection model. |

| 17 | Potenza et al., 2020 [30]. | A robotics and computer-aided procedure for defect evaluation in bridge inspection | Color-based image processing algorithm and software DEEP (Defect Detection by Enhanced image processing). | Defect extension evaluation. |

| 18 | Wang et al., 2022 [31]. | Automatic concrete crack segmentation model based on transformer | Novel SegCrack model for pixel-level crack segmentation using a hierarchically structured transformer. | Pixel-level crack segmentation. |

| 19 | Xiao et al., 2023 [32]. | Pavement crack detection with hybrid-window attentive vision transformers | Vision Transformers. | Pavement crack detection. |

| 20 | Reghukumar et al., 2021 [33]. | Vision based segmentation and classification of cracks using deep neural networks | Deep Neural Networks. | Crack classification. |

| 21 | Ali et al., 2023 [21]. | Crack detection and localization in stone floor tiles using vision transformation approach. | Vision Transformation. | Crack detection and localization. |

| 22 | Escobar-Wolf et al., 2018 [34] | Close-range photogrammetry and thermal sensing | Edge detection techniques. | Delamination and spall detection. |

| Epoch Number | Loss | Accuracy | Validation Loss | Validation Accuracy |

|---|---|---|---|---|

| 1 | 0.5195 | 0.8269 | 0.4505 | 0.8291 |

| 50 | 0.3037 | 0.8825 | 0.3022 | 0.8632 |

| 98 | 0.2247 | 0.9209 | 0.2447 | 0.8974 |

| 100 | 0.2282 | 0.9145 | 0.2302 | 0.9145 |

| Precision | Recall | F1 Score | Support | |

|---|---|---|---|---|

| Negative | 0.92 | 0.99 | 0.95 | 207 |

| Positive | 0.93 | 0.61 | 0.74 | 44 |

| Accuracy | 0.92 | 251 | ||

| Macro avg | 0.92 | 0.80 | 0.84 | 251 |

| Weighted avg | 0.92 | 0.87 | 0.94 | 251 |

| Epoch Number | Training Loss | Validation Loss | Accuracy |

|---|---|---|---|

| 1 | No log | 0.68 | 0.65 |

| 15 | 0.20 | 0.24 | 0.94 |

| 50 | 0.03 | 0.11 | 0.95 |

| 68 | 0.02 | 0.10 | 0.97 |

| 100 | 0.01 | 0.09 | 0.97 |

| Precision | Recall | F1 Score | Support | |

|---|---|---|---|---|

| Negative | 0.97 | 0.96 | 0.97 | 139 |

| Positive | 0.96 | 0.97 | 0.97 | 138 |

| Accuracy | 0.97 | 277 | ||

| Macro avg | 0.97 | 0.97 | 0.97 | 277 |

| Weighted avg | 0.97 | 0.97 | 0.97 | 277 |

| Model Factors | CNN Model | ViT Model |

|---|---|---|

| Model Accuracy | 0.92 | 0.97 |

| Negative Precision | 0.92 | 0.97 |

| Positive precision | 0.93 | 0.96 |

| Negative Recall | 0.99 | 0.96 |

| Positive Recall | 0.61 | 0.97 |

| Negative F1 Score | 0.95 | 0.97 |

| Positive F1 Score | 0.74 | 0.97 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokhrel, R.; Samsami, R.; Elmi, S.; Brooks, C.N. Automated Concrete Bridge Deck Inspection Using Unmanned Aerial System (UAS)-Collected Data: A Machine Learning (ML) Approach. Eng 2024, 5, 1937-1960. https://doi.org/10.3390/eng5030103

Pokhrel R, Samsami R, Elmi S, Brooks CN. Automated Concrete Bridge Deck Inspection Using Unmanned Aerial System (UAS)-Collected Data: A Machine Learning (ML) Approach. Eng. 2024; 5(3):1937-1960. https://doi.org/10.3390/eng5030103

Chicago/Turabian StylePokhrel, Rojal, Reihaneh Samsami, Sayda Elmi, and Colin N. Brooks. 2024. "Automated Concrete Bridge Deck Inspection Using Unmanned Aerial System (UAS)-Collected Data: A Machine Learning (ML) Approach" Eng 5, no. 3: 1937-1960. https://doi.org/10.3390/eng5030103

APA StylePokhrel, R., Samsami, R., Elmi, S., & Brooks, C. N. (2024). Automated Concrete Bridge Deck Inspection Using Unmanned Aerial System (UAS)-Collected Data: A Machine Learning (ML) Approach. Eng, 5(3), 1937-1960. https://doi.org/10.3390/eng5030103