An Investigation into Current Sand Control Testing Practices for Steam Assisted Gravity Drainage Production Wells

Abstract

:1. Introduction

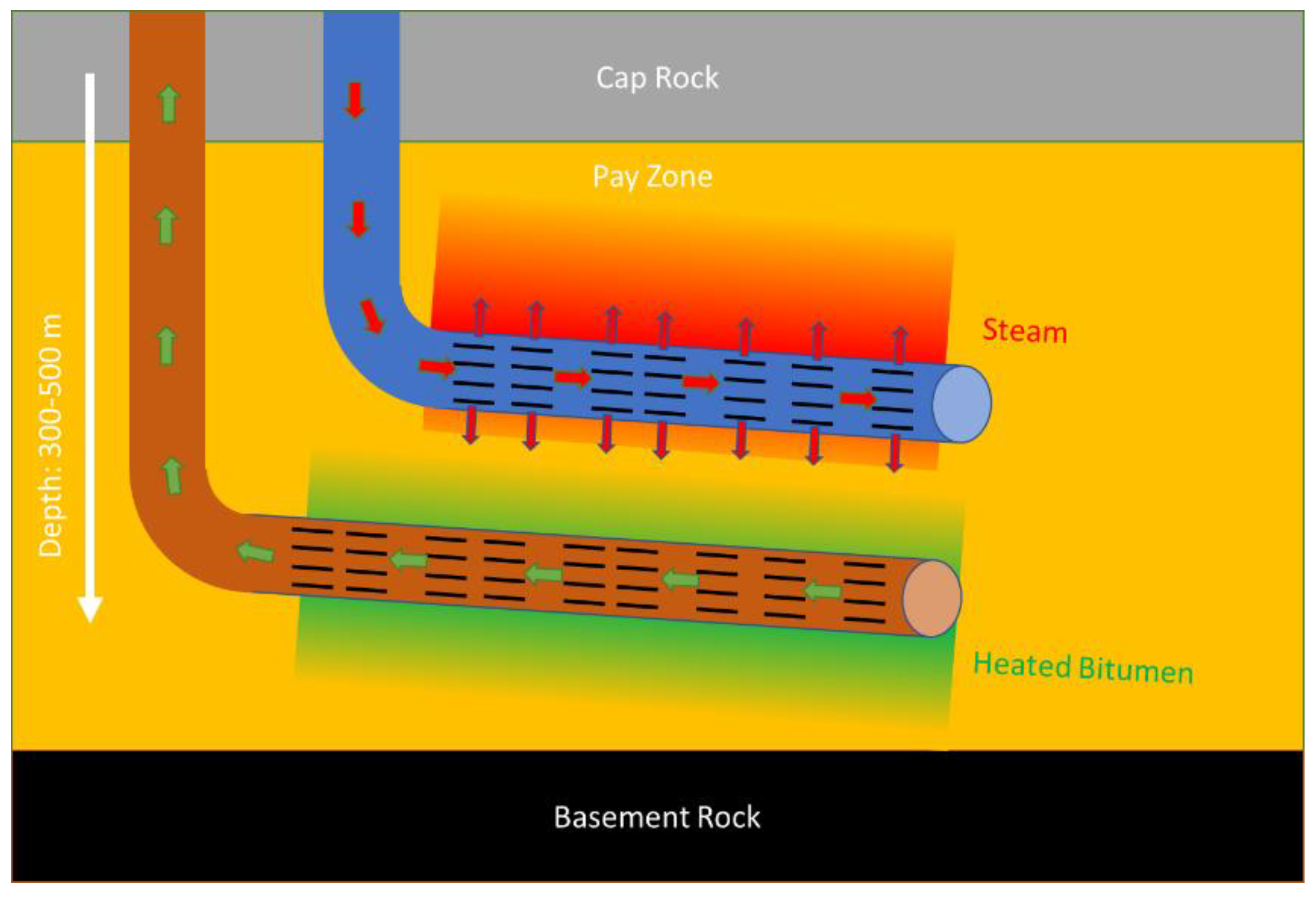

1.1. Background

1.2. Existing Testing Setups

1.3. Essential Factors in SCD Design

2. Experimental Design

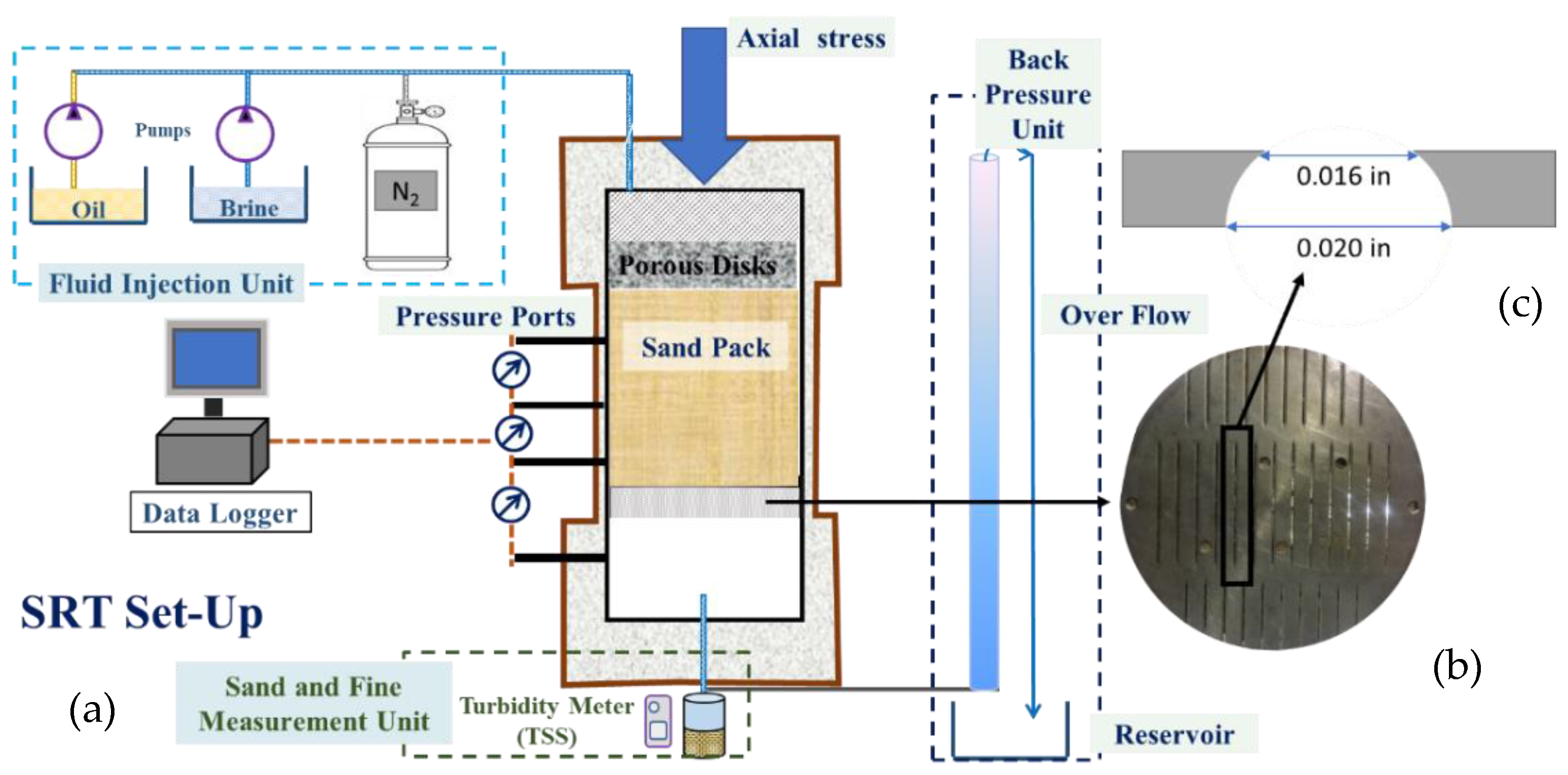

2.1. Experimental Setup

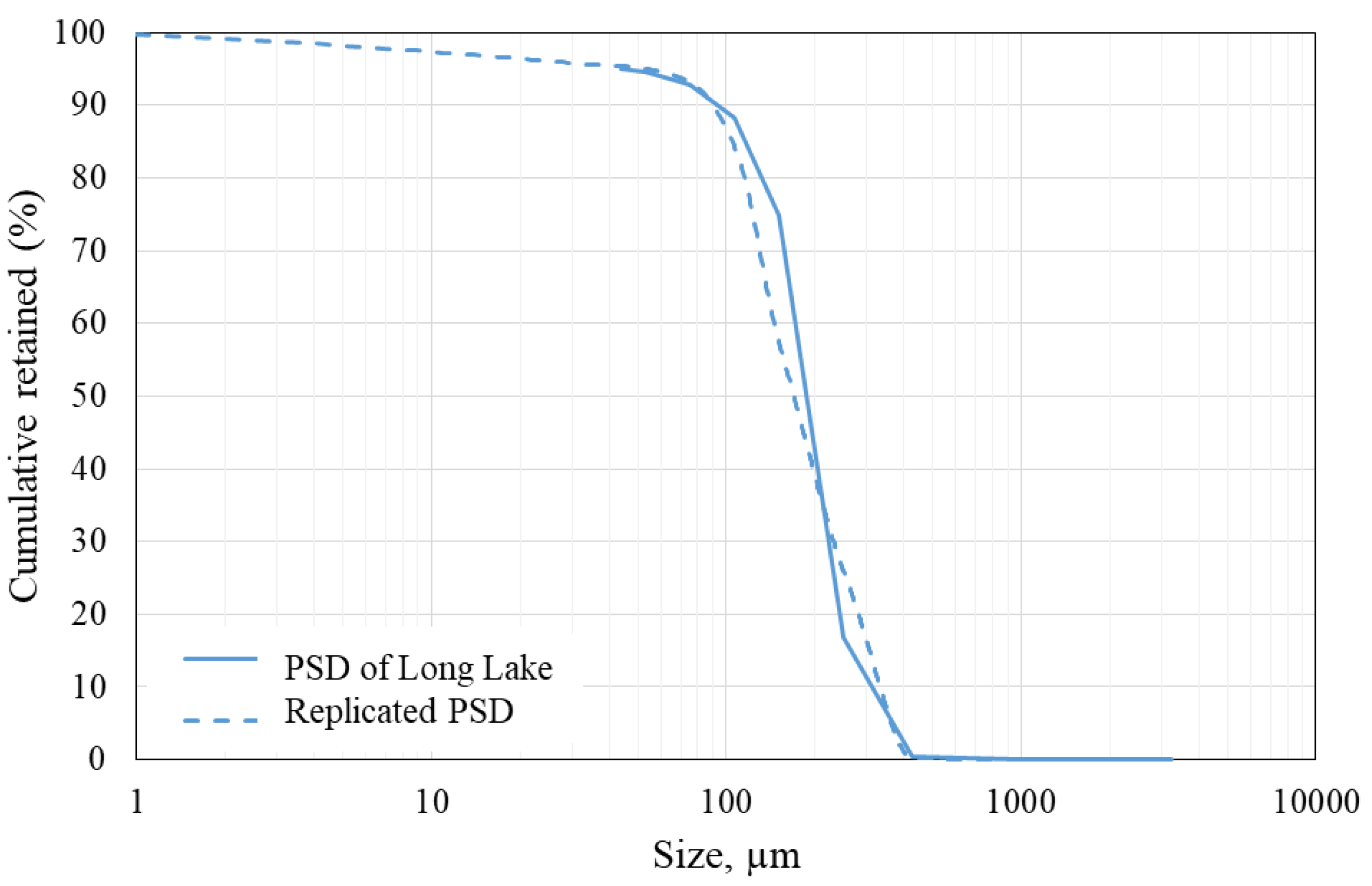

2.2. Sand Pack Material Preparation

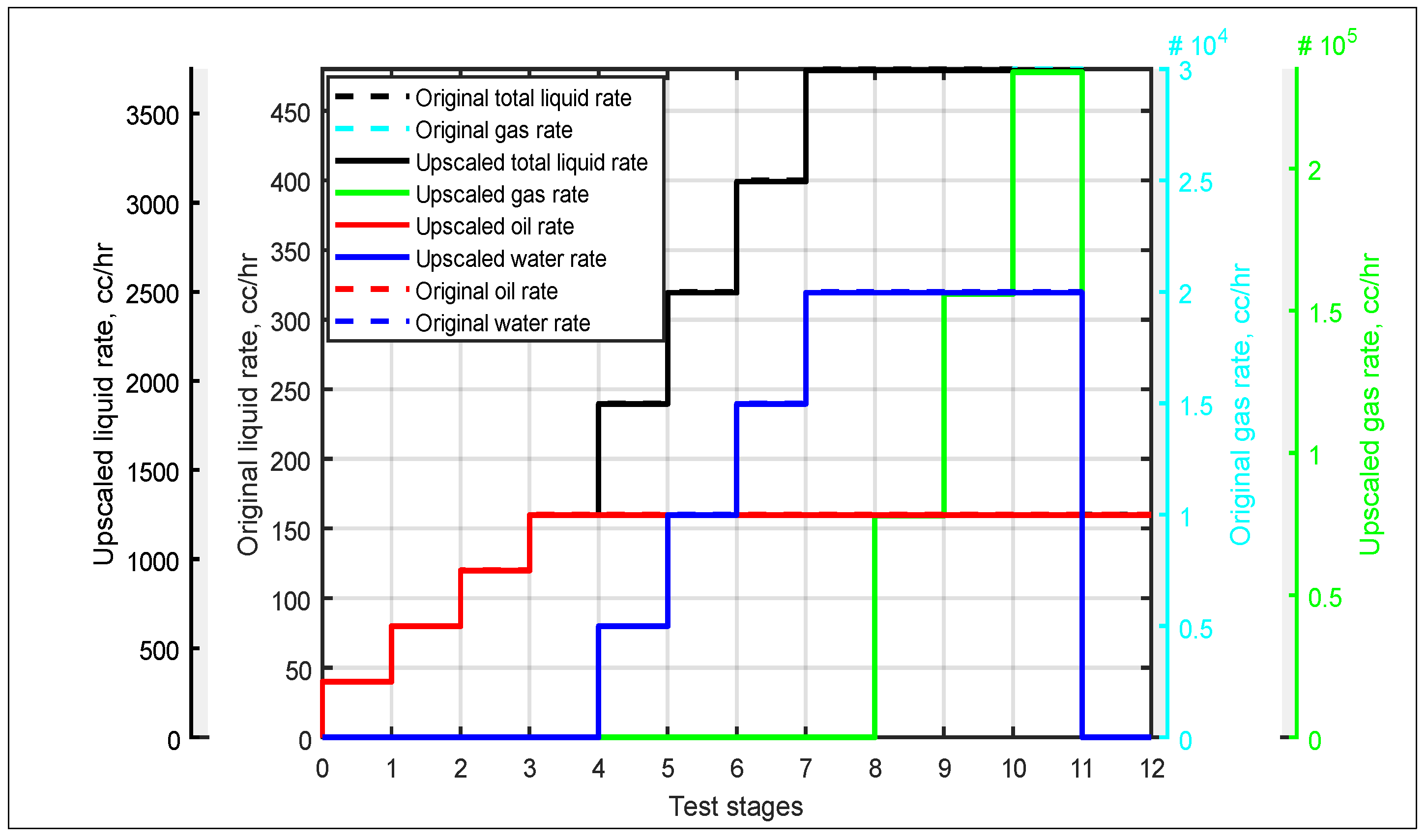

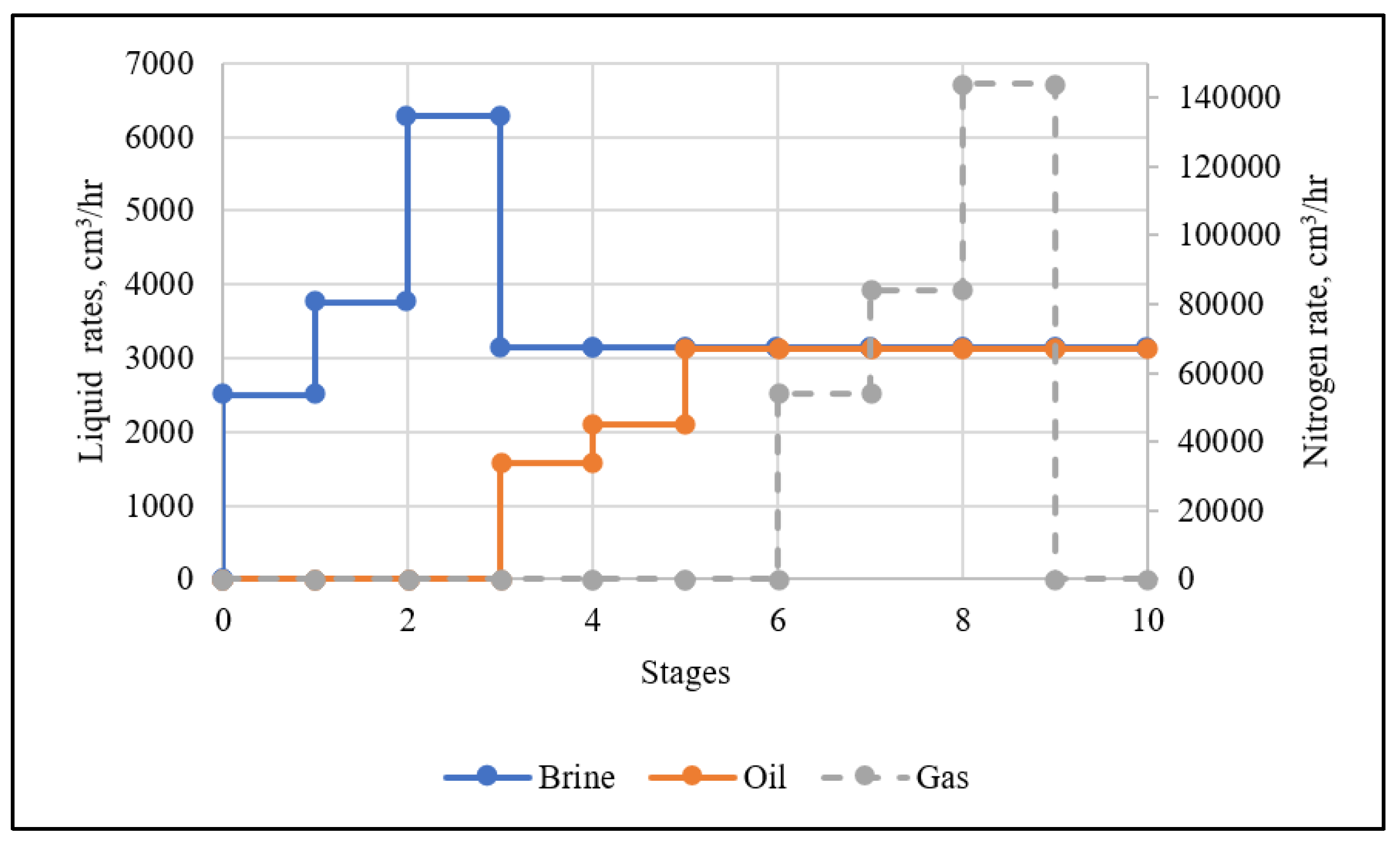

2.3. Testing Matrix

3. Results and Discussions

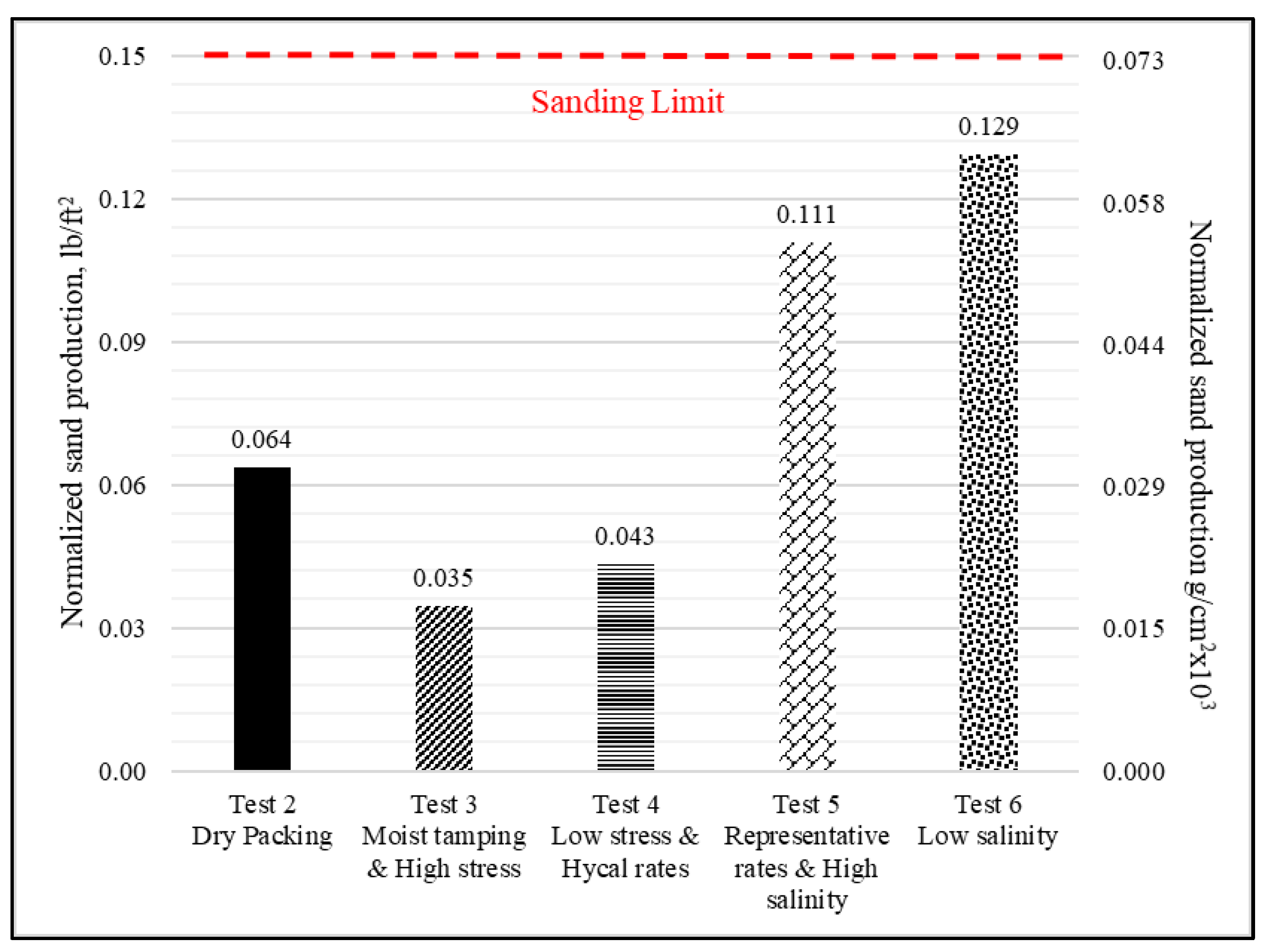

3.1. Replication Test

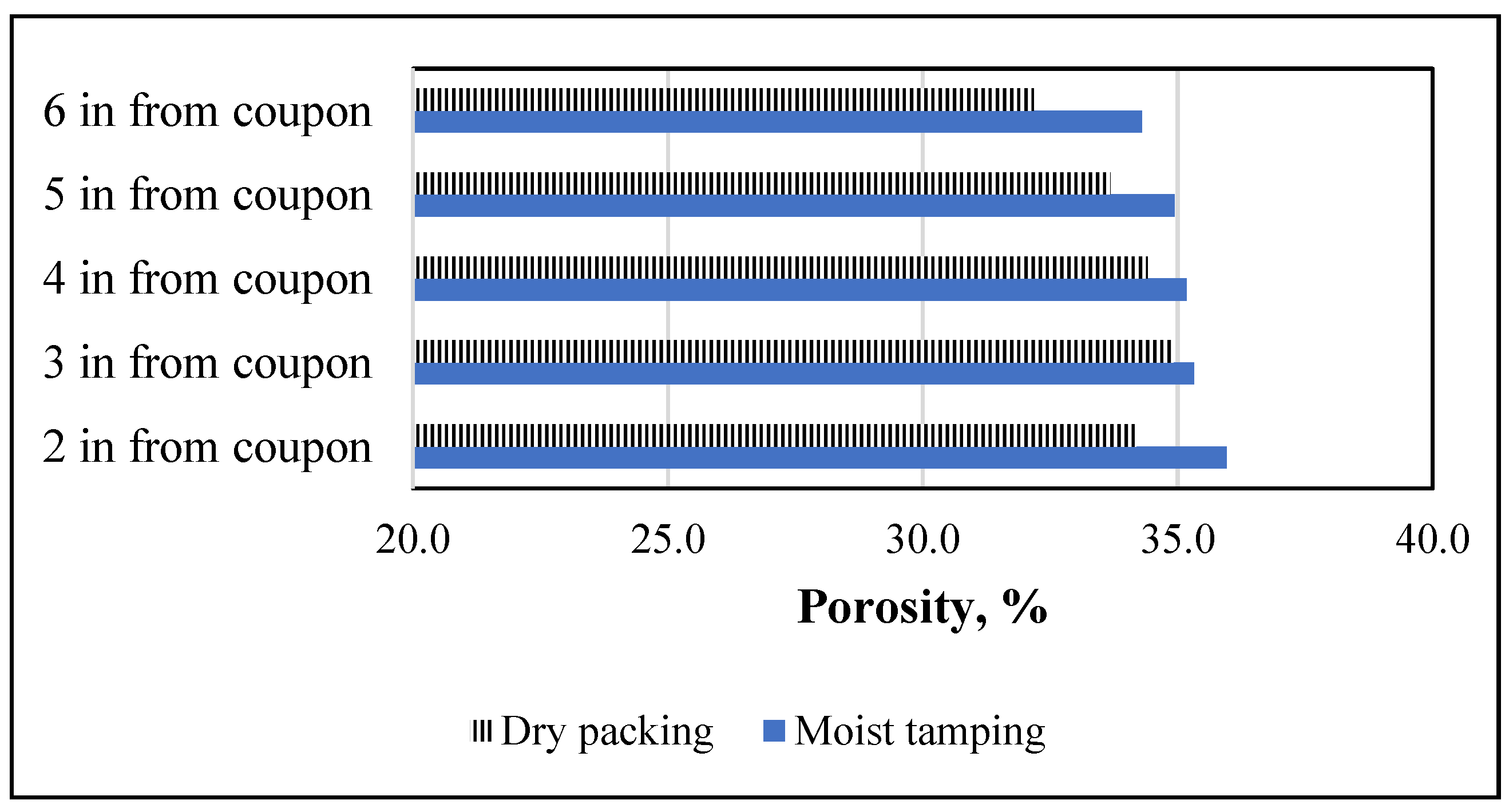

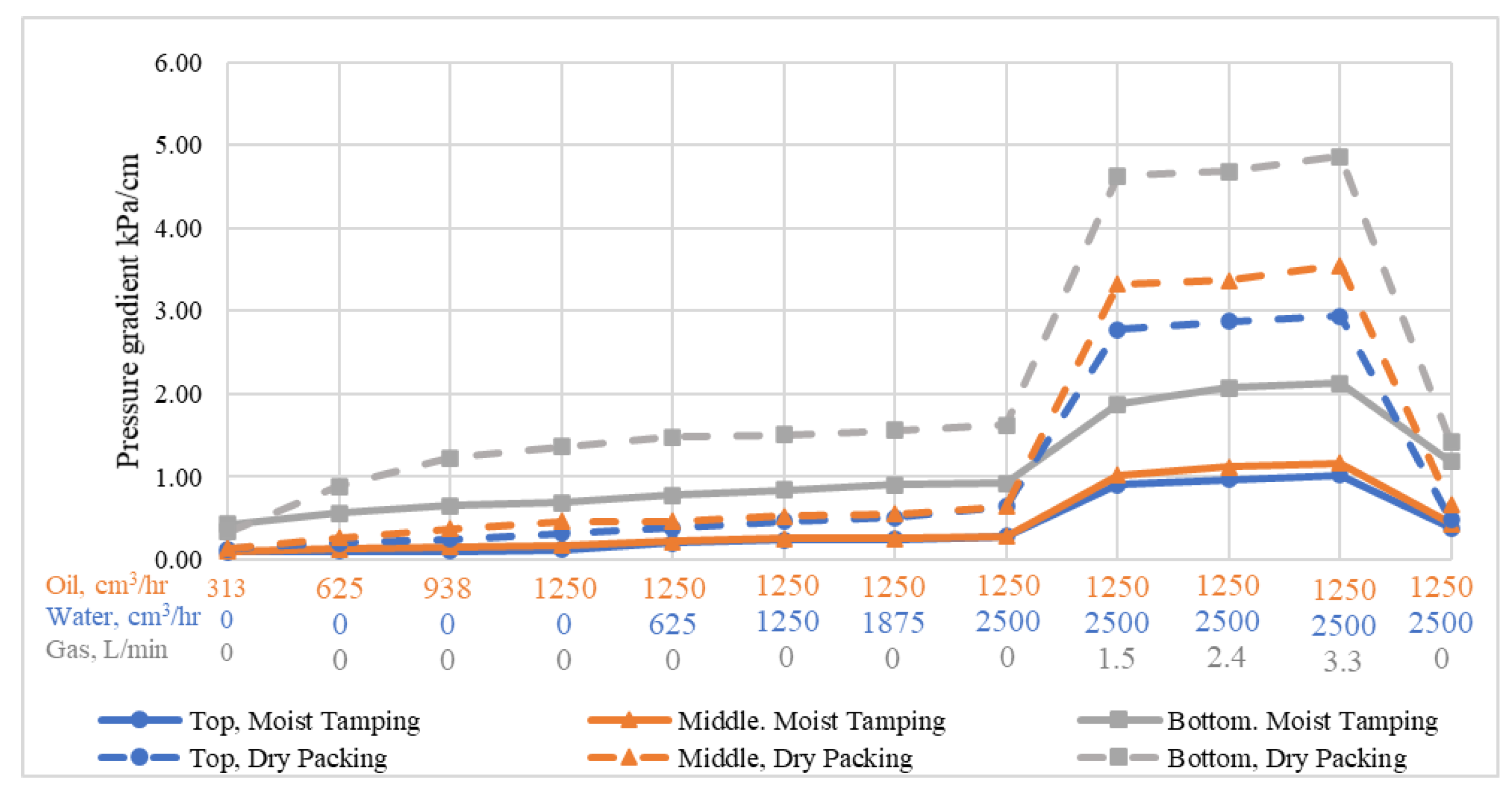

3.2. Effect of Packing Technique

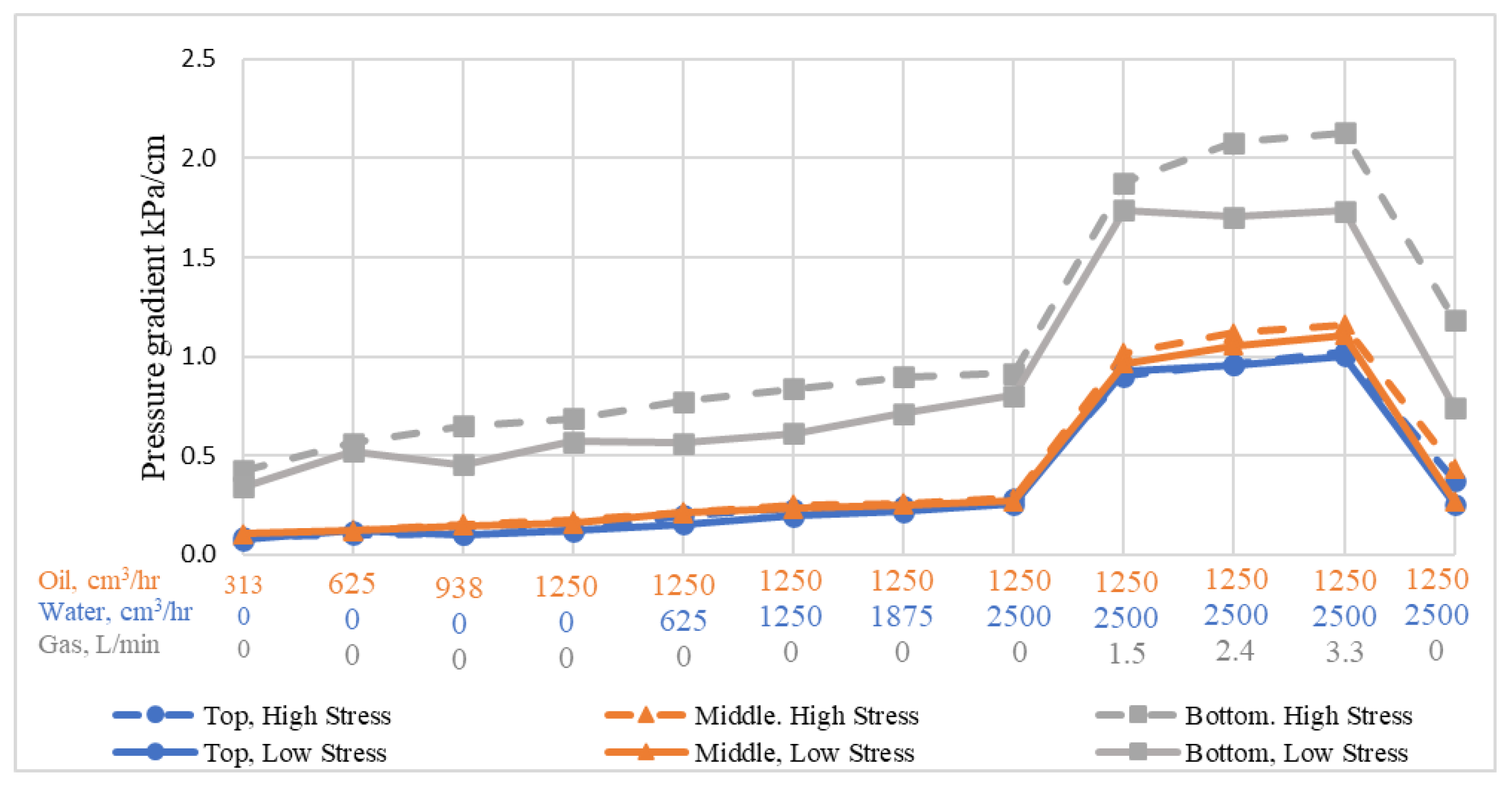

3.3. Effect of Stress Magnitude

3.4. Effect of Fluid Flow Rates

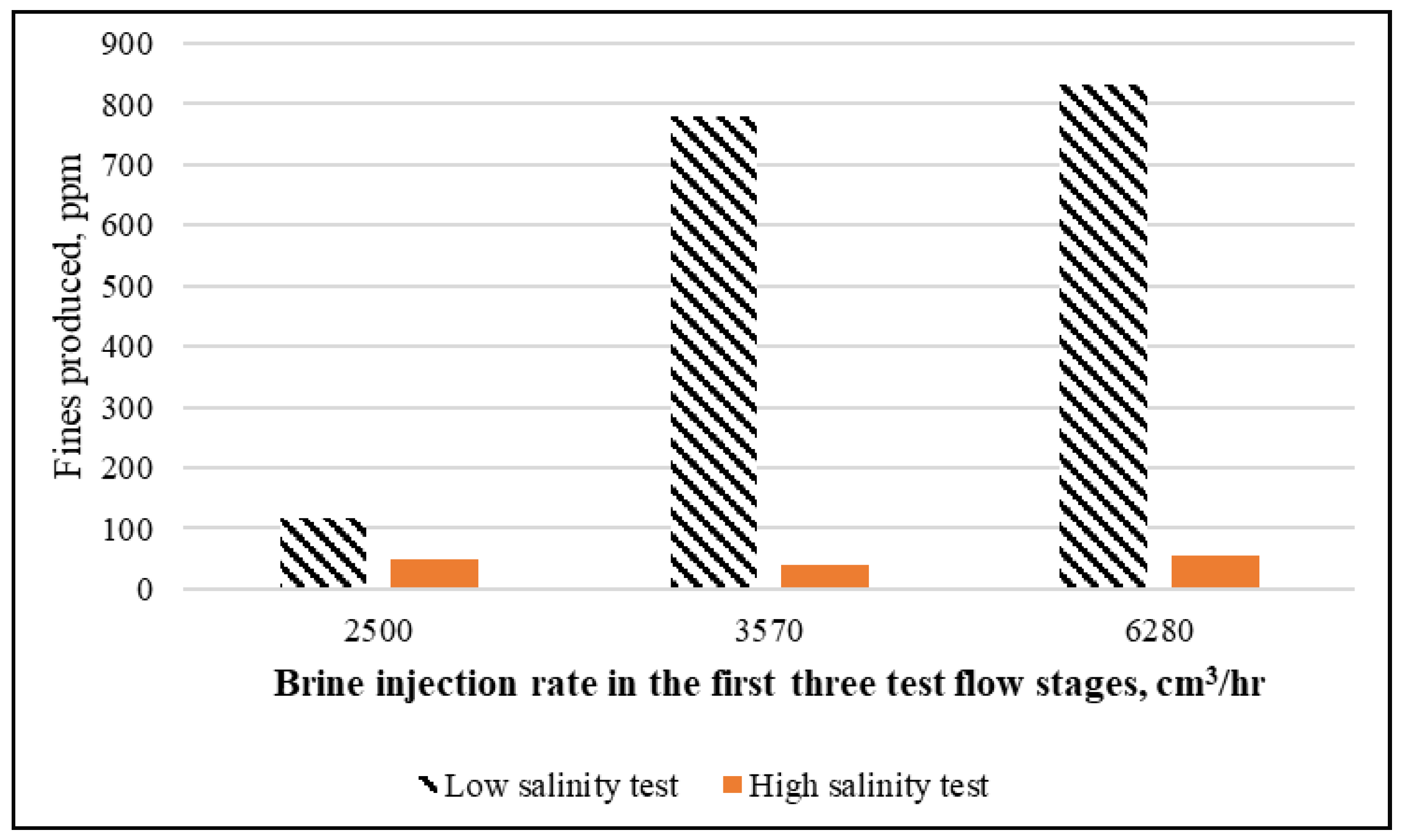

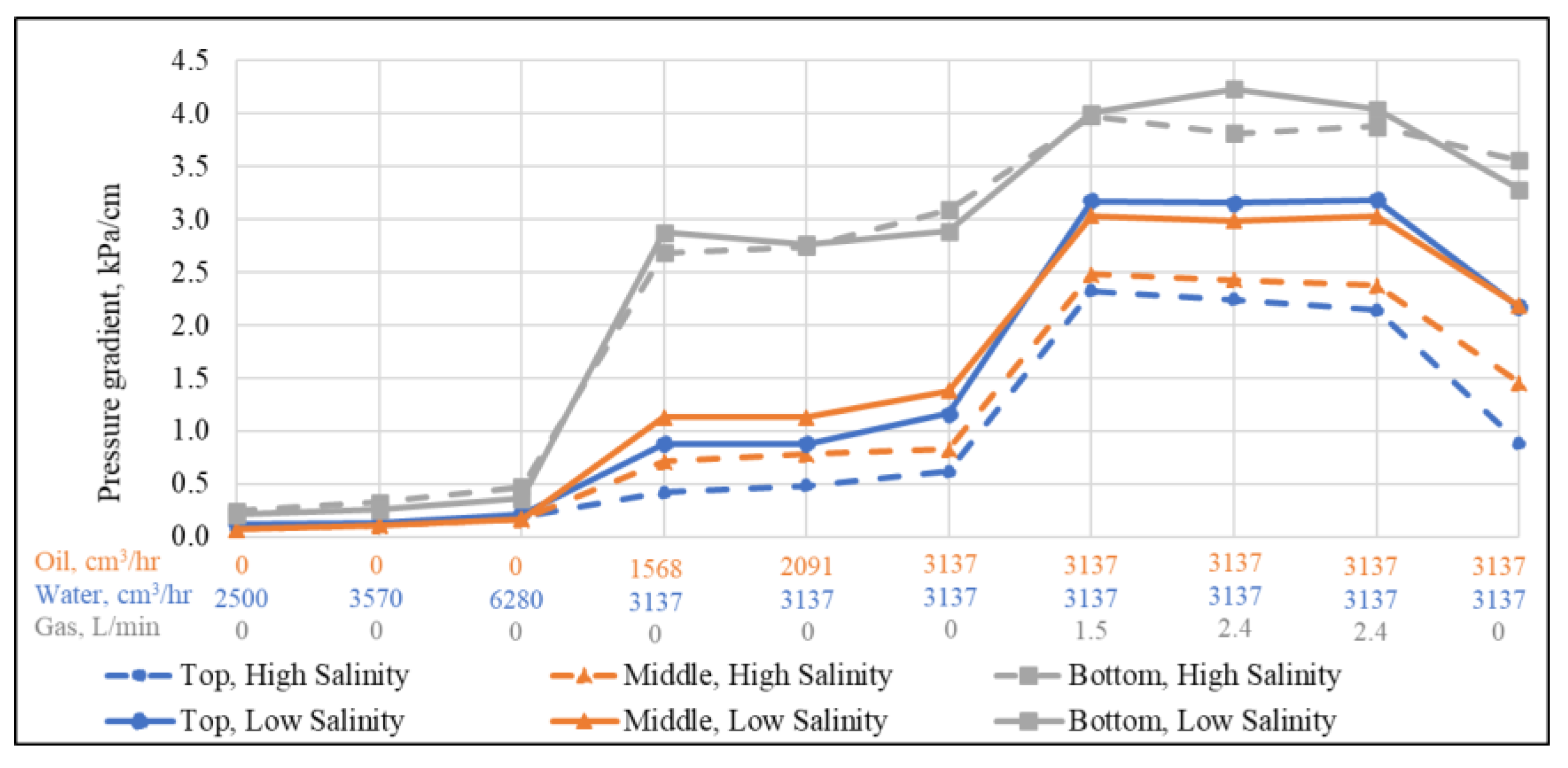

3.5. Effect of Brine Salinity

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Acronyms

| CSC | Critical Salt Concentration |

| Ppm | Part Per Million |

| PSD | Particle Size Distribution |

| SAGD | Steam Assisted Gravity Drainage |

| SCD | Sand Control Devices |

| SCT | Scaled Completion Test |

| SL | Slotted Liner |

| SRT | Sand Retention Test |

| UC | Uniformity Coefficient |

| WWS | Wire-Wrapped Screen |

References

- Gates, I.D.; Leskiw, C. Impact of steam trap control on performance of steam-assisted gravity drainage. J. Pet. Sci. Eng. 2010, 75, 215–222. [Google Scholar] [CrossRef]

- Shen, J. Enhanced Oil Recovery Field Case Studies, 1st ed.; Gulf Professional Publishing: Oxford, UK, 2013; pp. 413–445. [Google Scholar]

- Devere-Bennett, N. Using Pre-Pack Sand-Retention Tests (SRT’s) to Narrow Down Liner/Screen Sizing in SAGD Wells. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 23 November 2015. [Google Scholar]

- Bennion, D.B.; Gupta, S.; Gittins, S.; Hollies, D. Protocols for Slotted Liner Design for Optimum SAGD Operation. J. Can. Pet. Technol. 2009, 48, 21–26. [Google Scholar] [CrossRef]

- Xie, J. Slotted Liner Design Optimization for Sand Control in SAGD Wells. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 23 November 2015. [Google Scholar]

- Zhang, Z. An Advanced Sand Control Technology for Heavy Oil Reservoirs. Master’s Thesis, University of Calgary, Calgary, AB, Canada, 2017. [Google Scholar]

- Montero, J.D.; Chissonde, S.; Kotb, O.; Wang, C.; Roostaei, M.; Nouri, A.; Mahmoudi, M.; Fattahpour, V. A Critical Review of Sand Control Evaluation Testing for SAGD Applications. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 13–14 March 2018. [Google Scholar]

- Coberly, C.J. Selection of Screen Openings for Unconsolidated Sands. In Proceedings of the Drilling and Production Practice, New York, NY, USA, 1 January 1937. [Google Scholar]

- Underdown, D.R.; Dickerson, R.; Vaughan, W. The Nominal Sand-Control Screen: A Critical Evaluation of Screen Performance. SPE Drill. Complet. 2001, 16, 252–260. [Google Scholar] [CrossRef]

- Gillespie, G.; Deem, C.K.; Malbrel, C. Screen Selection for Sand Control Based on Laboratory Tests. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Brisbane, Australia, 16 October 2000. [Google Scholar]

- Hodge, R.M.; Burton, R.C.; Constien, V.; Skidmore, V. An Evaluation Method for Screen-Only and Gravel-Pack Completions. In Proceedings of the International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 20 February 2002. [Google Scholar]

- Constien, V.G.; Skidmore, V. Standalone Screen Selection Using Performance Master Curves. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2006. [Google Scholar]

- Chanpura, R.A.; Hodge, R.M.; Andrews, J.S.; Toffanin, E.P.; Moen, T.; Parlar, M. A Review of Screen Selection for Standalone Applications and a New Methodology. SPE Drill. Complet. 2011, 26, 84–95. [Google Scholar] [CrossRef]

- Ballard, T.J.; Beare, S.P. An Investigation of Sand Retention Testing With a View To Developing Better Guidelines for Screen Selection. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2012. [Google Scholar]

- Markestad, P.; Christie, O.; Espedal, A.; Rorvik, O. Selection of Screen Slot Width to Prevent Plugging and Sand Production. In Proceedings of the SPE Formation Damage Control Symposium, Lafayette, LA, USA, 14 February 1996. [Google Scholar]

- Ballard, T.; Beare, S. Media Sizing for Premium sand Screens: Dutch Twill Weaves. In Proceedings of the SPE European Formation Damage Conference, The Hague, The Netherlands, 13 May 2003. [Google Scholar]

- Ballard, T.; Beare, S. Sand Retention Testing: The More You Do, the Worse It Gets. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2006. [Google Scholar]

- Williams, C.F.; Richard, B.M.; Horner, D. A New Sizing Criterion for Conformable and Nonconformable Sand Screens Based on Uniform Pore Structures. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 15 February 2006. [Google Scholar]

- Romanova, U.G.; Gillespie, G.; Sladic, J.; Ma, T.; Solvoll, T.A.; Andrews, J.S. A Comparative Study of Wire Wrapped Screens vs. Slotted Liners for Steam-Assisted Gravity Drainage Operations. In Proceedings of the World Heavy Oil Congress, New Orleans, LA, USA, 5–7 March 2014. [Google Scholar]

- Romanova, U.G.; Piwowar, M.; Ma, T. Sand Control for Unconsolidated Heavy Oil Reservoirs: A Laboratory Test Protocol and Recent Field Observations. In Proceedings of the International Symposium of the Society of Core Analysts, St. John’s, NL, Canada, 16–21 August 2015. [Google Scholar]

- O’Hara, M. Thermal Operations in the McMurray: An Approach To Sand Control. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 23 November 2015. [Google Scholar]

- Mahmoudi, M. New Sand Control Design Criteria and Evaluation Testing for Steam-Assisted Gravity Drainage (SAGD) Wellbores. Ph.D. Thesis, University of Alberta, Edmonton, AB, Canada, 2016. [Google Scholar]

- Anderson, M. SAGD Sand Control: Large Scale Testing Results. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 15 February 2017. [Google Scholar]

- Wang, C.; Pang, Y.; Montero, J.; Haftani, M.; Fattahpour, V.; Mahmoudi, M.; Nouri, A. Impact of Anisotropic Stresses on the Slotted Liners Performance in Steam Assisted Gravity Drainage Process. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 27 November 2018. [Google Scholar]

- Fattahpour, V.; Mahmoudi, M.; Wang, C.; Kotb, O.; Roostaei, M.; Nouri, A.; Fermaniuk, B.; Sauve, A.; Sutton, C. Comparative Study on the Performance of Different Stand-Alone Sand Control Screens in Thermal Wells. In Proceedings of the SPE International Conference and Exhibition on Formation Damage Control, Lafayette, LA, USA, 7 February 2018. [Google Scholar]

- Fattahpour, V.; Azadbakht, S.; Mahmoudi, M.; Guo, Y.; Nouri, A.; Leitch, M. Effect of Near Wellbore Effective Stress on the Performance of Slotted Liner Completions in SAGD Operations. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 28 November 2016. [Google Scholar]

- Bennion, D.B.; Gupta, S.; Gittins, S.; Hollies, D. Protocols for Slotted Liner Design for Optimum SAGD Operation. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 17 June 2008. [Google Scholar]

- Selig, E.; Ladd, R.S. Preparing Test Specimens Using Undercompaction. Geotech. Test. J. 1978, 1, 16. [Google Scholar] [CrossRef]

- Guo, Y.; Roostaei, M.; Nouri, A.; Fattahpour, V.; Mahmoudi, M.; Jung, H. Effect of stress build-up around standalone screens on the screen performance in SAGD wells. J. Pet. Sci. Eng. 2018, 171, 325–339. [Google Scholar] [CrossRef]

- Haftani, M.; Kotb, O.; Nguyen, P.H.; Wang, C.; Salimi, M.; Nouri, A. A Novel sand control testing facility to evaluate the impact of radial flow regime on screen performance and its verification. J. Pet. Sci. Eng. 2020, 195, 107903. [Google Scholar] [CrossRef]

- Fermaniuk, B. Sand Control in Steam-Assisted Gravity Drainage (SAGD) Wellbores and Process of Slotted Liner Design and Process. Master’s Thesis, University of Calgary, Calgary, AB, Canada, 2013. [Google Scholar]

- Mahmoudi, M.; Nejadi, S.; Roostaei, M.; Olsen, J.; Fattahpour, V.; Lange, C.F.; Zhu, D.; Fermaniuk, B.; Nouri, A. Design Optimization of Slotted Liner Completions in Horizontal Wells: An Analytical Skin Factor Model Verified by Computational Fluid Dynamics and Experimental Sand Retention Tests. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 28 November 2017. [Google Scholar]

- Tiffin, D.L.; King, G.E.; Larese, R.E.; Britt, L.K. New Criteria for Gravel and Screen Selection for Sand Control. In Proceedings of the SPE International Symposium on Formation Damage Control, Lafayette, LA, USA, 18 February 1998. [Google Scholar]

- Price-Smith, C.; Parlar, M.; Bennett, C.; Gilchrist, J.M.; Pitoni, E.; Burton, R.C.; Hodge, R.M.; Troncoso, J.; Ali, S.A.; Dickerson, R. Design Methodology for Selection of Horizontal Open-Hole Sand-Control Completions Supported by field Case Histories. SPE Drill. Completion 2003, 18, 235–255. [Google Scholar] [CrossRef]

- Rogers, E.B. Sand Control in Oil and Gas Wells. Oil Gas J. 1971, 54–60. [Google Scholar]

- Suman, G.O.; Ellis, R.C.; Snyder, R.E. Sand Control Handbook, 2nd ed.; Gulf Publishing Company, Book Division: Houston, TX, USA, 1983. [Google Scholar]

- Wang, C.; Pang, Y.; Mahmoudi, M.; Haftani, M.; Salimi, M.; Fattahpour, V.; Nouri, A. A Set of Graphical Design criteria for Slotted Liners in SteamAssisted Gravity Drainage Production Wells. J. Pet. Sci. Eng. 2020, 185, 106608. [Google Scholar] [CrossRef]

- Stein, N.; Odeh, A.; Jones, L. Estimating Maximum Sand-Free Production Rates From Friable Sands for Different Well Completion Geometries. J. Pet. Technol. 1974, 26, 1156–1158. [Google Scholar] [CrossRef]

- Spronk, E.M.; Doan, L.T.; Matsuno, Y.; Harschnitz, B. SAGD Liner Evaluation and Liner Test Design for JACOS Hangingstone SAGD Development. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 9 June 2015. [Google Scholar]

- Khilar, K.C. Fogler, H.S. Migration of Fines in Porous Media; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1998; p. 12. [Google Scholar]

- Mahmoudi, M.; Fattahpour, V.; Nouri, A.; Leitch, M. An Experimental Investigation of the Effect of pH and Salinity on Sand Control Performance for Heavy Oil Thermal Production. In Proceedings of the SPE Canada Heavy Oil Technical Conference, Calgary, AB, Canada, 7 June 2016. [Google Scholar]

- Haftani, M.; Wang, C.; Pallares, J.D.M.; Mahmoudi, M.; Fattahpour, V.; Nouri, A. An Investigation into the Effect of Brine Salinity on Fines Migration in SAGD Operations. In Proceedings of the SPE Western Regional Meeting, San Jose, CA, USA, 22 April 2019. [Google Scholar]

- Kia, S.; Fogler, H.; Reed, M. Effect of pH on colloidally induced fines migration. J. Colloid Interface Sci. 1987, 118, 158–168. [Google Scholar] [CrossRef]

- Khilar, K.; Fogler, H. The existence of a critical salt concentration for particle release. J. Colloid Interface Sci. 1984, 101, 214–224. [Google Scholar] [CrossRef] [Green Version]

- Clearly, M.P.; Melvan, J.J.; Kohlhaas, C.A. The Effect of Confining Stress and Fluid Properties on Arch Stability in Unconsolidated Sands. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 23 September 1979. [Google Scholar]

- Coşkuner, G.; Maini, B. Effect of net confining pressure on formation damage in unconsolidated heavy oil reservoirs. J. Pet. Sci. Eng. 1990, 4, 105–117. [Google Scholar] [CrossRef]

- Pallares, J.D.M.; Wang, C.; Haftani, M.; Nouri, A. Experimental Correlations for the Performance and Aperture Selection of Wire-Wrapped Screens in Steam-Assisted Gravity Drainage Production Wells. SPE Prod. Oper. 2020, 35, 537–548. [Google Scholar] [CrossRef]

- Oda, M. Initial Fabrics and their Relations to Mechanical Properties of Granular Material. Soils Found. 1972, 12, 17–36. [Google Scholar] [CrossRef] [Green Version]

- Arthur, J.R.F.; Menzies, B.K. Inherent anisotropy in a sand. Géotechnique 1972, 22, 115–128. [Google Scholar] [CrossRef]

- Vaid, Y.P.; Sivathayalan, S. Fundamental Factors Affecting Liquefaction Susceptibility of Sands. Can. Geotech. J. 2000, 37, 592–606. [Google Scholar] [CrossRef]

- Miura, S.; Toki, S. A Sample Preparation Method and its Effect on Static and Cyclic Deformation-Strength Properties of Sand. Soils Found. 1982, 22, 61–77. [Google Scholar] [CrossRef] [Green Version]

- Kuerbis, R.; Vaid, Y. Sand Sample Preparation—The Slurry Deposition Method. Soils Found. 1988, 28, 107–118. [Google Scholar] [CrossRef] [Green Version]

- Suits, L.D.; Sheahan, T.; Ueng, T.-S.; Wang, M.-H.; Chen, M.-H.; Chen, C.-H.; Peng, L.-H. A Large Biaxial Shear Box for Shaking Table Test on Saturated Sand. Geotech. Test. J. 2006, 29, 1–8. [Google Scholar] [CrossRef]

- Huang, Y.-H.; Yang, S.-Q.; Hall, M.R.; Zhang, Y.-C. The Effects of NaCl Concentration and Confining Pressure on Mechanical and Acoustic Behaviors of Brine-Saturated Sandstone. Energies 2018, 11, 385. [Google Scholar] [CrossRef] [Green Version]

- Suits, L.D.; Sheahan, T.C.; Bradshaw, A.S.; Baxter, C.D.P. Sample Preparation of Silts for Liquefaction Testing. Geotech. Test. J. 2007, 30, 324–332. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Fattahpour, V.; Nouri, A.; Rasool, S.; Leitch, M. The Effect of Screen Aperture Size on Fines Production and Migration in SAGD Production Wells. In Proceedings of the 2016 World Heavy Oil Congress, Calgary, AB, Canada, 6–9 September 2016. [Google Scholar]

- Mahmoudi, M.; Fattahpour, V.; Nouri, A.; Rasoul, S.; Yao, T.; Baudet, B.A.; Leitch, M.; Soroush, M. Investigation Into the Use of Commercial Sands and Fines to Replicate Oil Sands for Large-Scale Sand Control Testing. In Proceedings of the SPE Thermal Well Integrity and Design Symposium, Banff, AB, Canada, 28 November 2016. [Google Scholar]

- Rhodes, M. Introduction to Particle Technology; John Wiley & Sons Ltd.: Chichester, UK, 2008. [Google Scholar]

- Michaelides, E.; Crowe, C.T.; Schwarzkopf, J.D. Multiphase Flow Handbook; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- CNOOC. Long Lake Kinosis Oil Sands Project Annual Performance Presentation. 2018. Available online: https://static.aer.ca/prd/documents/oilsands/insitu-presentations/2018AthabascaNexenLongLakeSAGD9485.pdf (accessed on 10 August 2021).

- Le Ravalec, M.; Morlot, C.; Marmier, R.; Foulon, D. Heterogeneity Impact on SAGD Process Performance in Mobile Heavy Oil Reservoirs. Oil Gas Sci. Technol.-Rev. L’ifp 2009, 64, 469–476. [Google Scholar] [CrossRef]

- Stone, T.W.; Bailey, W.J. Optimization of Subcool in SAGD Bitumen Processes. In Proceedings of the World Heavy Oil Congress, New Orleans, La, USA, 5–7 March 2014. [Google Scholar]

- Sidahmed, A.K. Optimization of Outflow Control Devices Design in Steam-Assisted Gravity Drainage Models with Wellbore Trajectory Excursions. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2018. [Google Scholar]

- Beshry, M.A.; Krawchuk, P.; Brown, G.A.; Brough, B. Predicting the Flow Distribution on Total E&P Canada’s Joslyn Project Horizontal SAGD Producing Wells Using Permanently Installed Fiber-Optic Monitoring. In Proceedings of the SPE Annual Technical Conference and Exhibition, San Antonio, TX, USA, 24 September 2006. [Google Scholar]

- Brand, S. Results From Acid Stimulation in Lloydminster SAGD Applications. In Proceedings of the SPE International Symposium and Exhibition on Formation Damage Control, Lafayette, LA, USA, 10 February 2010. [Google Scholar]

- Romanova, U.G.; Ma, T. An Investigation of the Plugging Mechanisms in a Slotted Liner from the steam-Assisted Gravity Drainage Operations. In Proceedings of the SPE European Formation Damage Conference & Exhibition, Noordwijk, The Netherlands, 5 June 2013. [Google Scholar]

- Harvey, A.H. Thermodynamic Properties of Water: Tabulation from the IAPWS Formulation 1995 for the Thermodynamic properties of Ordinary Water Substance for General and Scientific Use, NISTIR 5078. United States Department of Commerce, 1995. Available online: https://nvlpubs.nist.gov/nistpubs/Legacy/IR/nistir5078.pdf (accessed on 10 August 2021).

- Guo, Y. Effect of Stress Build-Up around SAGD Wellbores on the Slotted Liner Performance. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2018. [Google Scholar]

- Jafarpour, M.; Rahmati, H.; Azadbakht, S.; Nouri, A.; Chan, D.; Vaziri, H. Determination of mobilized strength properties of degrading sandstone. Soils Found. 2012, 52, 658–667. [Google Scholar] [CrossRef] [Green Version]

- Dahm, K.; Visco, D. Fundamentals of Chemical Engineering Thermodynamics. In Cengage Learning; Cengage: Boston, MA, USA, 2015. [Google Scholar]

| Test No. | SCD Coupon | Flow Rates | Packing Technique | Water Composition | Stress | ||

|---|---|---|---|---|---|---|---|

| Brine | Oil | Nitrogen | |||||

| 1 | WWS 0.006 in/152 µm | Devere-Bennett [3] | Dry packing | 1% NaCl | 350 psi 2413 kPa | ||

| 2 | Slotted Liner RT OFA 2.33%, 0.016 in/ 406 µm | Devere-Bennett [3] rates | Dry packing | 1% NaCl | 350 psi 2413 kPa | ||

| 3 | Slotted Liner RT OFA 2.33%, 0.016 in/406 µm | Devere-Bennett [3] rates | Moist tamping | 1% NaCl | 350 psi 2413 kPa | ||

| 4 | Slotted Liner RT OFA 2.33%, 0.016 in/406 µm | Devere-Bennett [3] rates | Moist tamping | 1% NaCl | 60 psi 413 kPa | ||

| 5 | Slotted Liner RT OFA 2.33%, 0.016 in/406 µm | Representative rates | Moist tamping | 1% NaCl | 60 psi 413 kPa | ||

| 6 | Slotted Liner RT OFA 2.33%, 0.016 in/406 µm | Representative rates | Moist tamping | Field representative ion composition | 60 psi 413 kPa | ||

| Scenarios | Non-Uniform Flow Condition | Plugging Factor | Non-Contributing Liner Sections | Effective Flow Coefficient |

|---|---|---|---|---|

| Favorable condition scenario | 0.8 | 0.5 | 0.8 | 0.32 |

| Non-uniform flow scenario | 0.5 | 0.5 | 0.8 | 0.20 |

| Plugged and non-uniform flow scenario | 0.5 | 0.3 | 0.8 | 0.12 |

| Calculation Parameters | ||

|---|---|---|

| Coupon diameter * | 17.1 | cm |

| Coupon area * | 229.7 (0.023) | cm2 (m2) |

| Average steam injection rate ** | 270 | m3/day |

| Injected water density | 1000 | kg/m3 |

| Mass of injection water | 270,000 | kg/day |

| Well length ** | 0.8 | km |

| Assumed steam quality | 0.5 | - |

| Field Information | ||

|---|---|---|

| Oil rate * | 80 | m3/d |

| Water rate ** | 270 | m3/d |

| Liquid rate | 350 | m3/d |

| Liquid rate | 2201 | bbl/d |

| WOR * | 3.38 | - |

| Length of wells * | 0.80 | Km |

| Oil rate/length | 0.10 | m2/d |

| Water rate/length | 0.34 | m2/d |

| Liquid rate/length | 0.44 | m2/d |

| Oil rate/liner surface area | 0.18 | m/d |

| Water rate/liner surface area | 0.60 | m/d |

| Liquid rate/liner surface area | 0.78 | m/d |

| Liquid rate/liner surface area | 0.46 | bbl/ft2 |

| Scenarios | Effective Flow | Lab Equivalent Oil Rate, cc/h | Lab Equivalent Water Rate, cc/h | Lab Equivalent Liquid Rate, cc/h |

|---|---|---|---|---|

| Perfect SAGD well condition | 1.0 | 171 | 578 | 749 |

| Favorable condition | 0.32 | 535 | 1807 | 2342 |

| Non-uniform flow | 0.20 | 857 | 2891 | 3747 |

| Plugged and non-uniform flow | 0.12 | 1428 | 4818 | 6246 |

| Steam Rate Calculations | ||

|---|---|---|

| Temperature | 210 | °C |

| Pressure | 1600 | kPag |

| Density of steam | 8.42 | kg/m3 |

| Steam viscosity | 0.016 | cp |

| Steam rate | 31,544 | m3/d |

| Length of wells | 0.8 | km |

| Steam rate/length | 39.4 | m3/m |

| Steam rate/surface area | 70.6 | m3/m2 |

| Lab equivalent steam rate | 67,548 | cm3/h |

| Lab equivalent steam rate | 1.1 | L/min |

| Steam quality | 25 | % |

| Good scenario steam rate | 0.9 | L/min |

| Non-uniform scenario steam rate | 1.4 | L/min |

| Plugged and non-uniform scenario steam rate | 2.3 | L/min |

| Description | Unit | Field Data * | Brine Composition | |

|---|---|---|---|---|

| pH | - | 8.04 | N/A | |

| Cations | Sodium (Na) | mg/L | 194 | 3935 |

| Potassium (K) | mg/L | 3.6 | - | |

| Calcium (Ca) | mg/L | 56.7 | - | |

| Magnesium (Mg) | mg/L | 21.4 | - | |

| Anions | Bicarbonate (HCO3) | mg/L | 708 | - |

| Carbonate (CO3) | mg/L | 0.5 | - | |

| Hydroxide (OH) | mg/L | 0.5 | - | |

| Chloride (Cl) | mg/L | 40.4 | 6065 | |

| Sulfate (SO4) | mg/L | 46.1 | - | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kotb, O.; Haftani, M.; Nouri, A. An Investigation into Current Sand Control Testing Practices for Steam Assisted Gravity Drainage Production Wells. Eng 2021, 2, 435-453. https://doi.org/10.3390/eng2040027

Kotb O, Haftani M, Nouri A. An Investigation into Current Sand Control Testing Practices for Steam Assisted Gravity Drainage Production Wells. Eng. 2021; 2(4):435-453. https://doi.org/10.3390/eng2040027

Chicago/Turabian StyleKotb, Omar, Mohammad Haftani, and Alireza Nouri. 2021. "An Investigation into Current Sand Control Testing Practices for Steam Assisted Gravity Drainage Production Wells" Eng 2, no. 4: 435-453. https://doi.org/10.3390/eng2040027

APA StyleKotb, O., Haftani, M., & Nouri, A. (2021). An Investigation into Current Sand Control Testing Practices for Steam Assisted Gravity Drainage Production Wells. Eng, 2(4), 435-453. https://doi.org/10.3390/eng2040027