Influence of the Precoat Layer on the Filtration Properties and Regeneration Quality of Backwashing Filters

Abstract

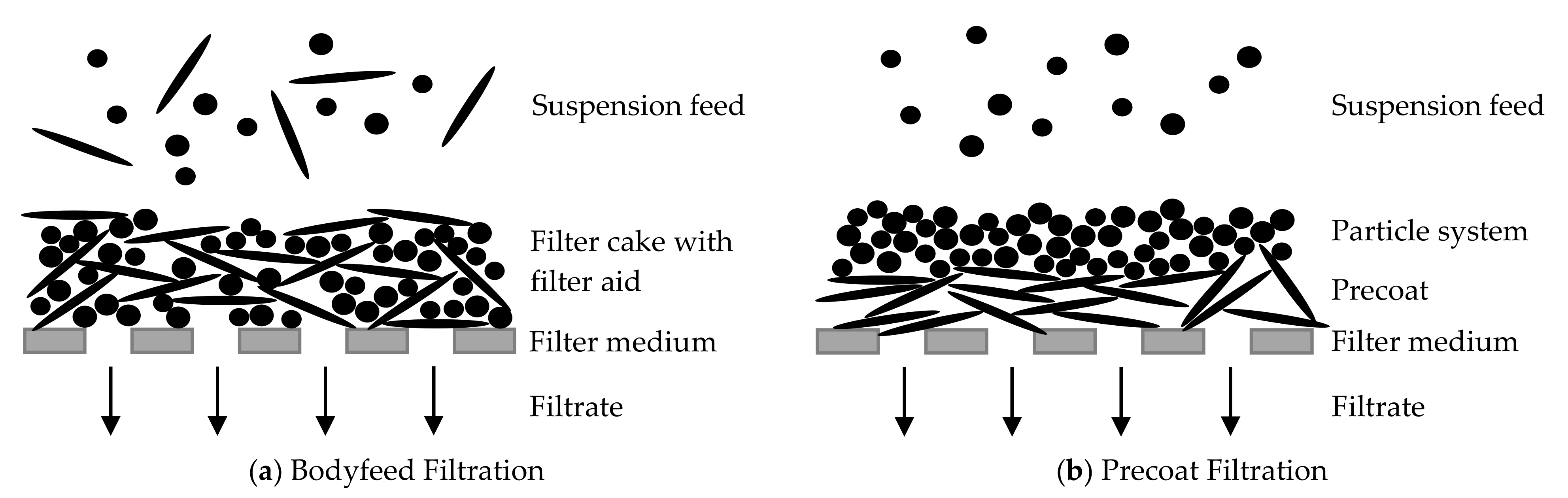

1. Introduction

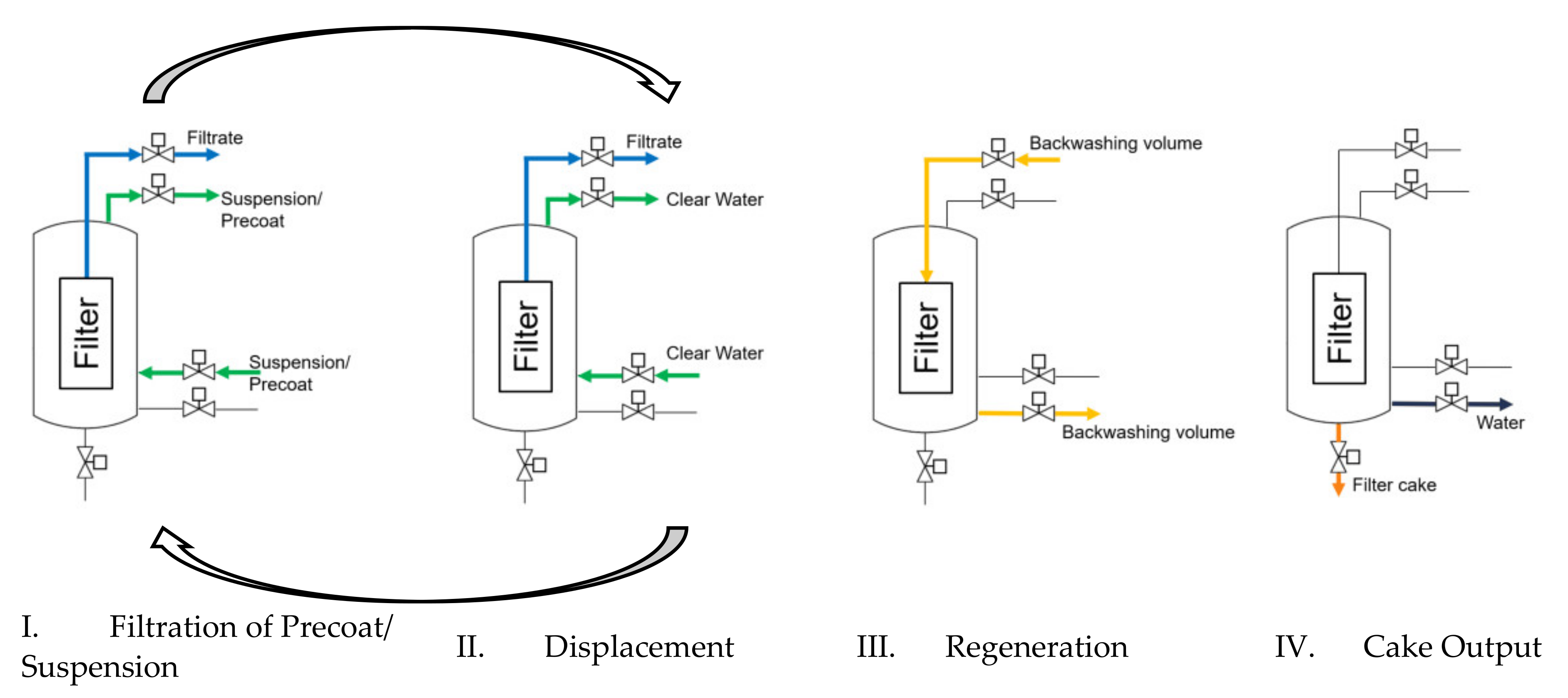

2. Theory

3. Methodology

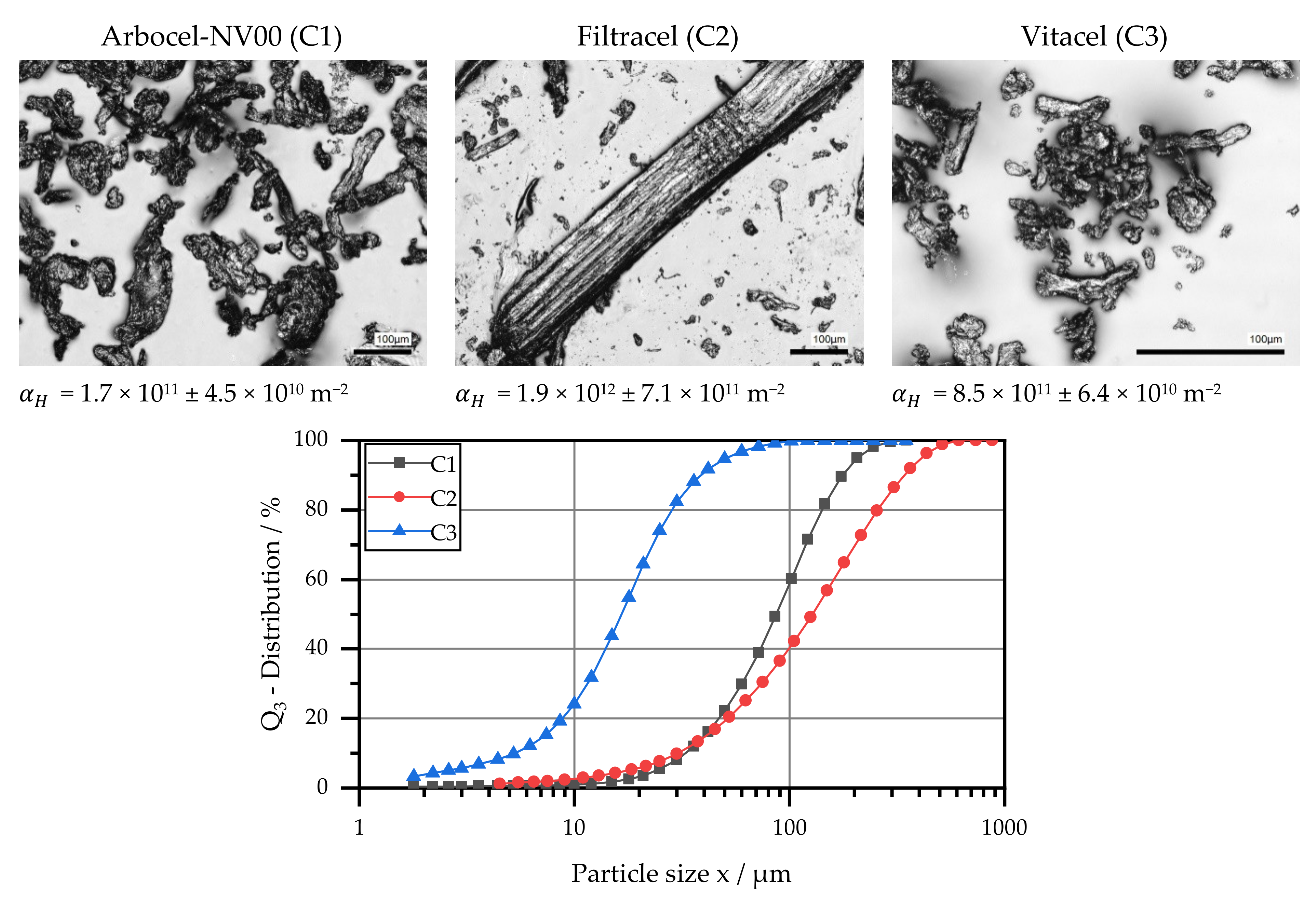

4. Materials

5. Interpretation

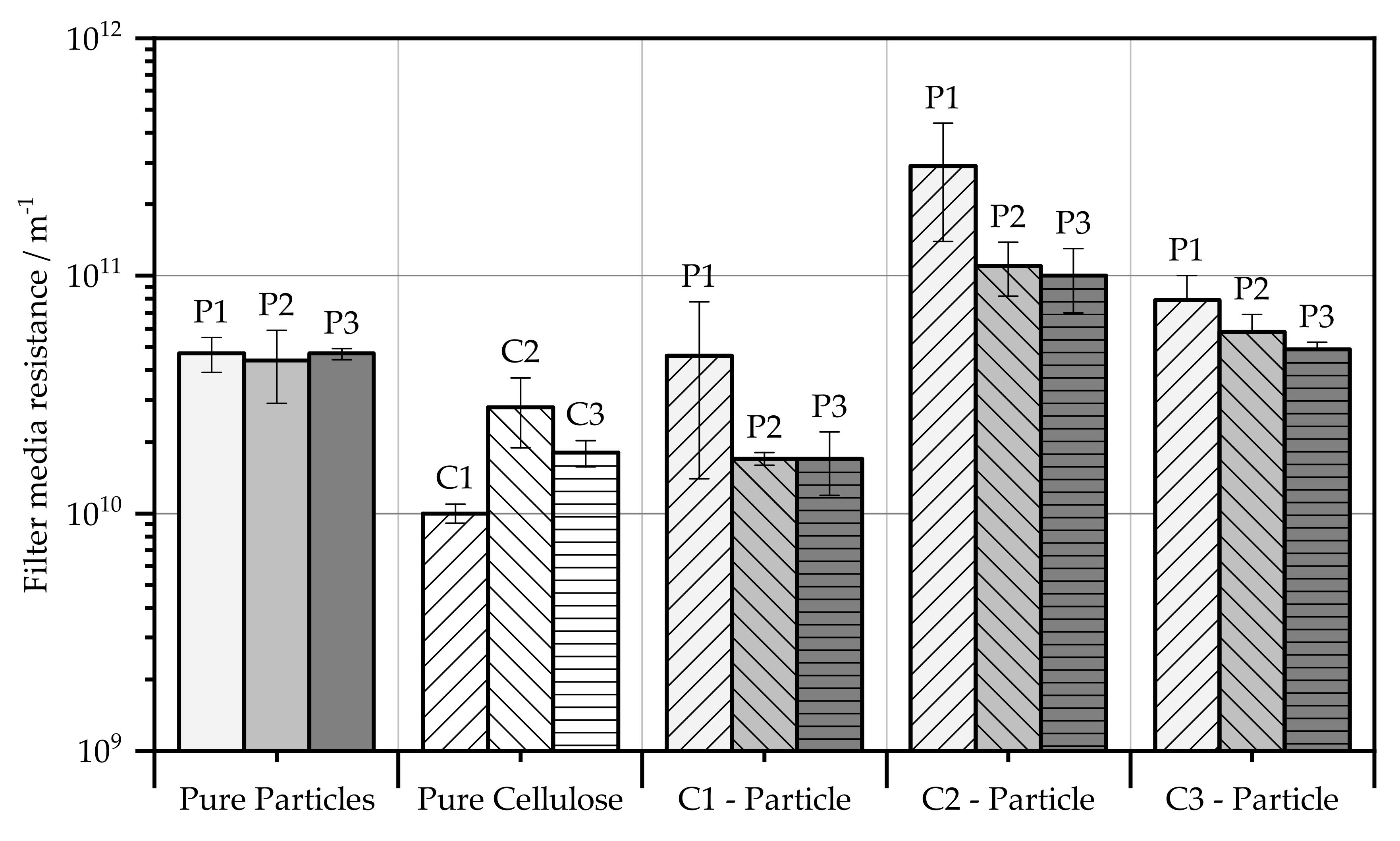

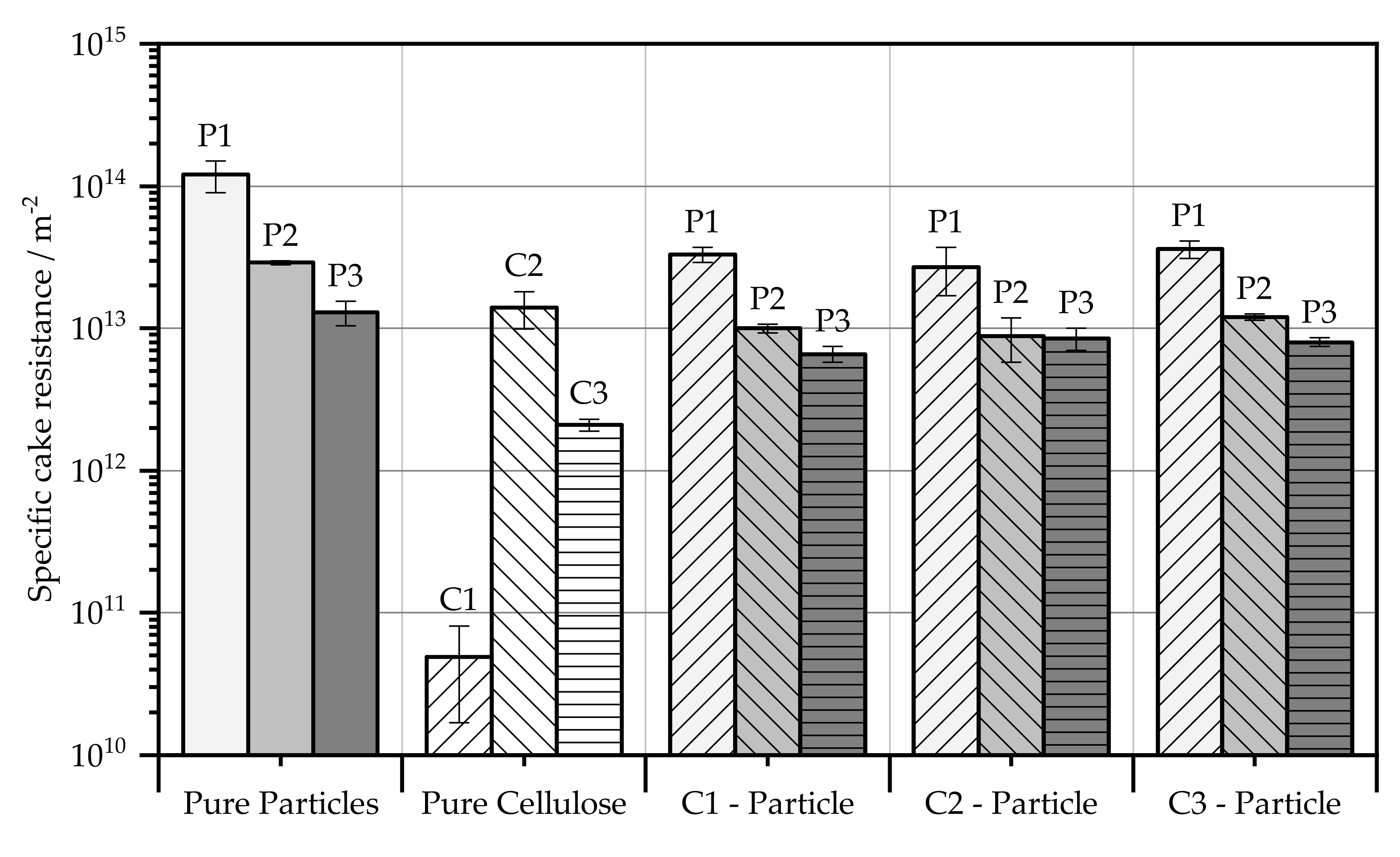

5.1. Influence of a Precoat Layer on the Filter Resistance

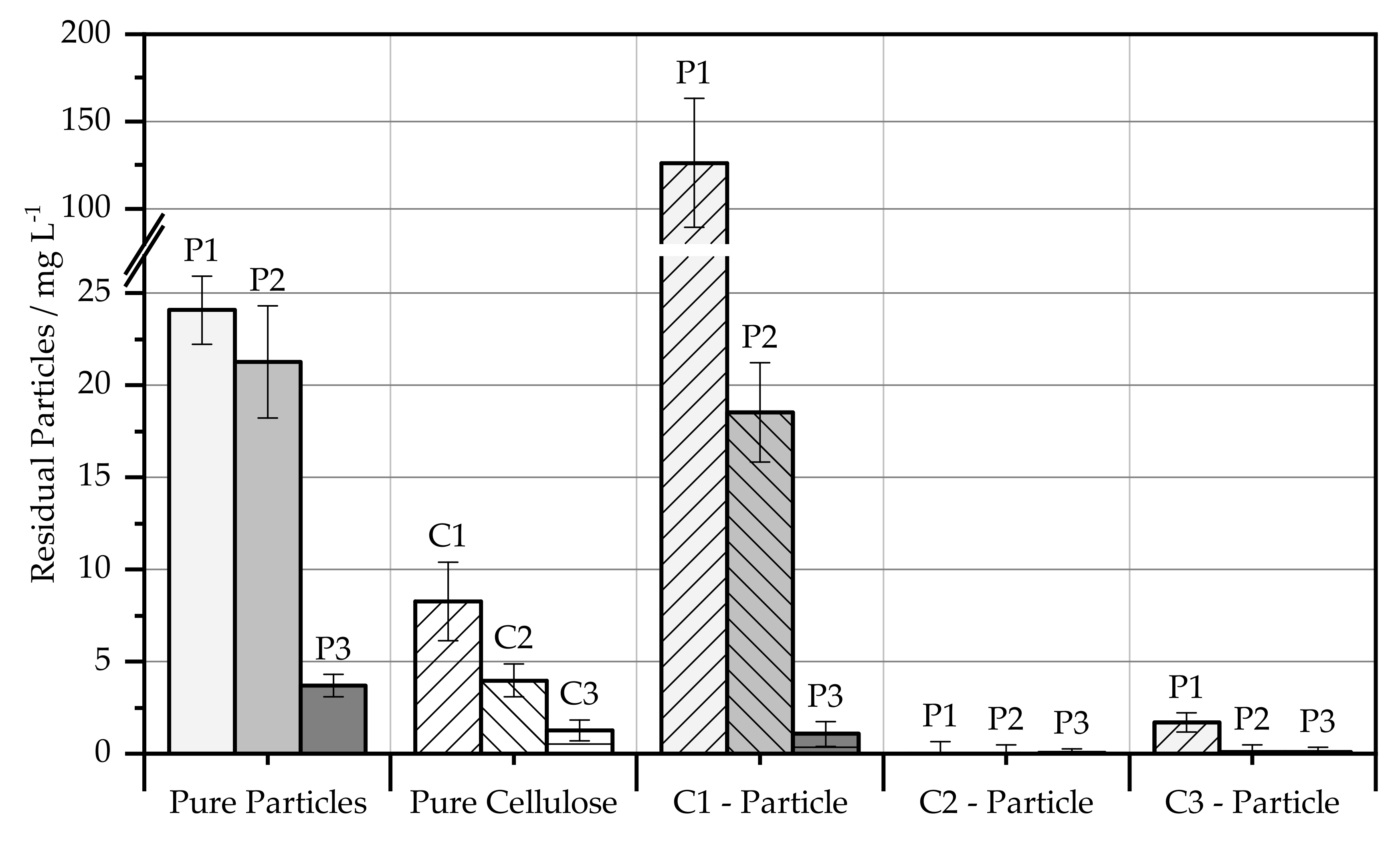

5.2. Influence of Filter Aids on the Turbidity Impact

5.3. Influence of a Precoat Layer on the Backwashing Behavior

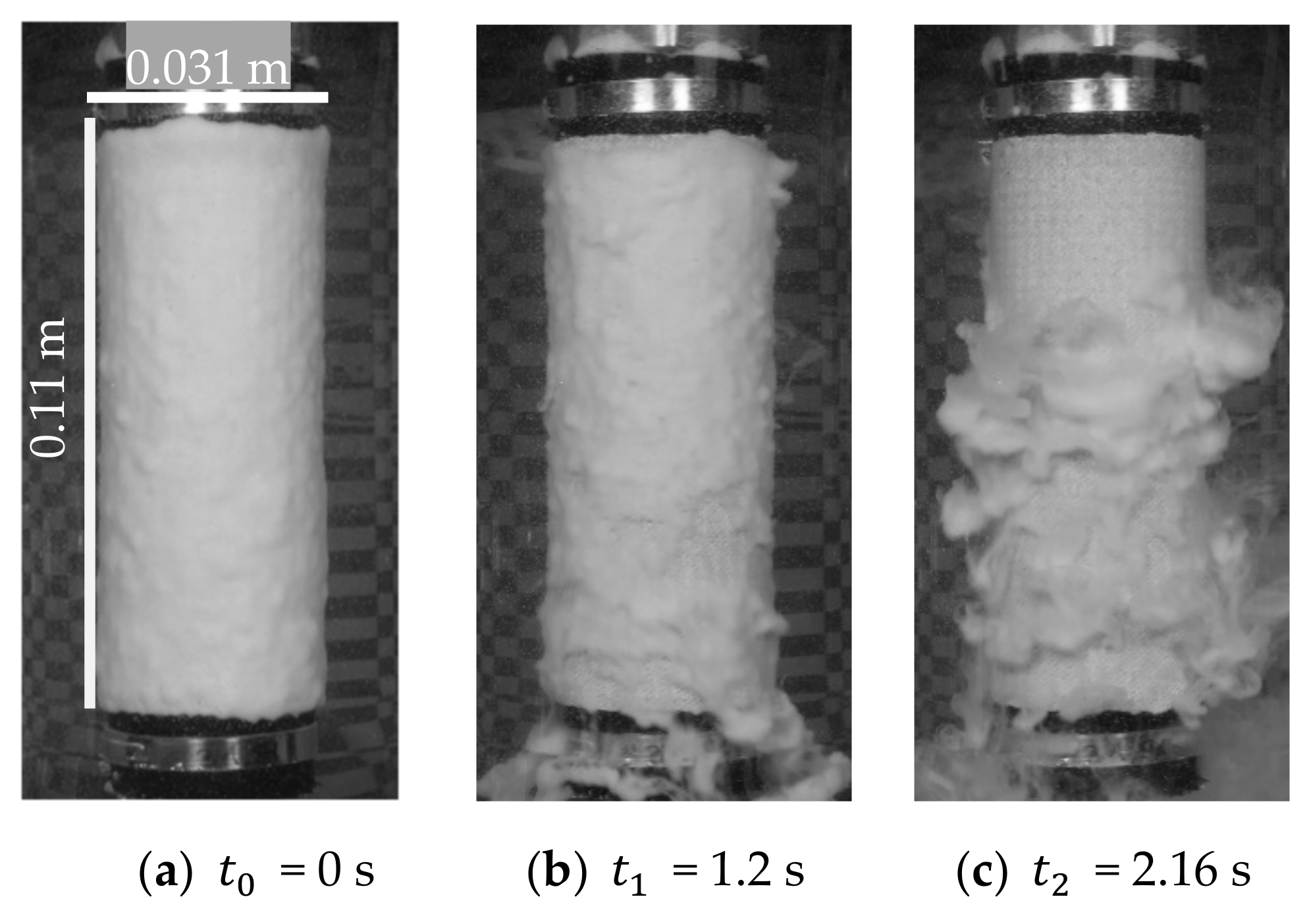

5.3.1. Cleaning Behavior of the Pure Particle Systems

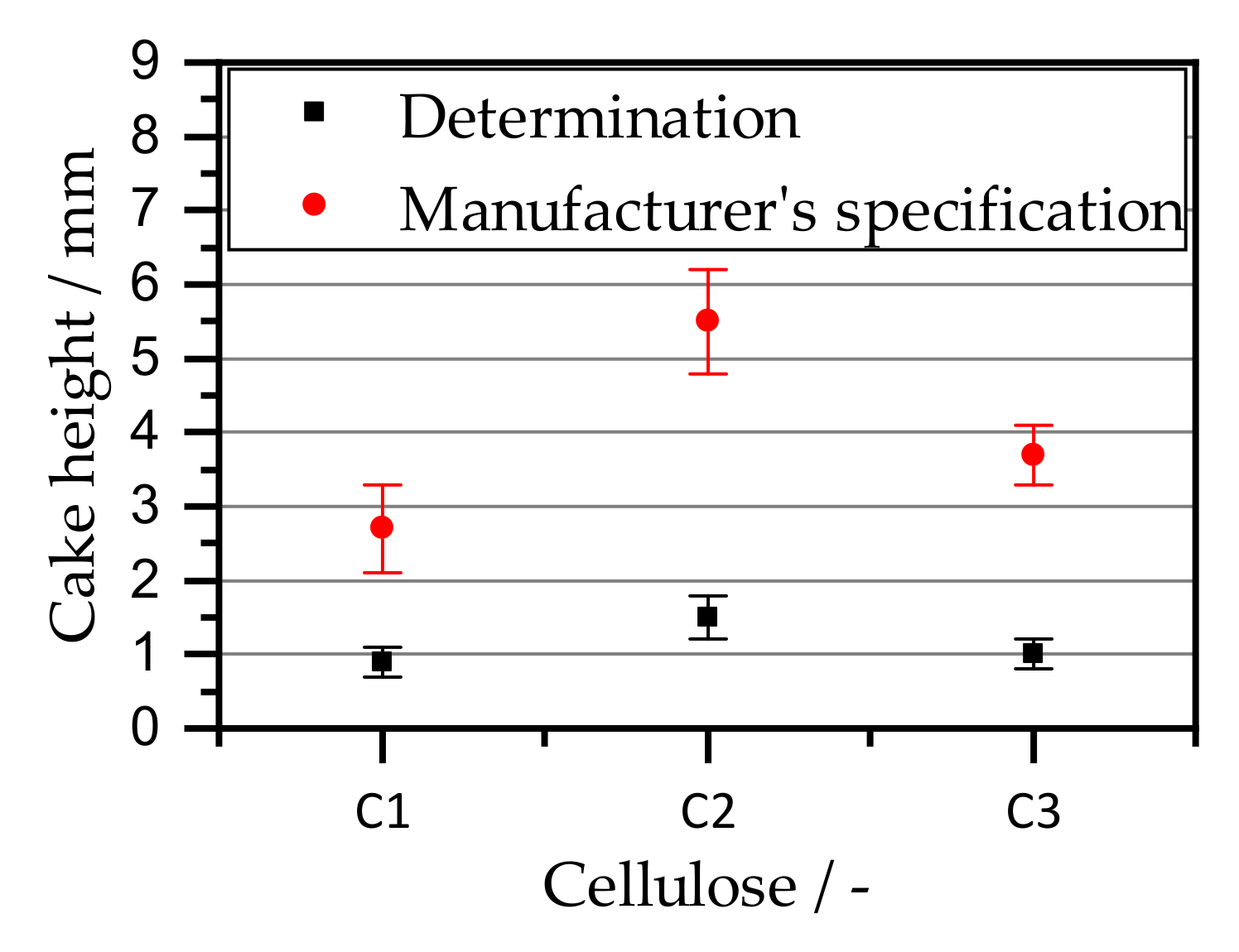

5.3.2. Cleaning Behavior of Pure Cellulose

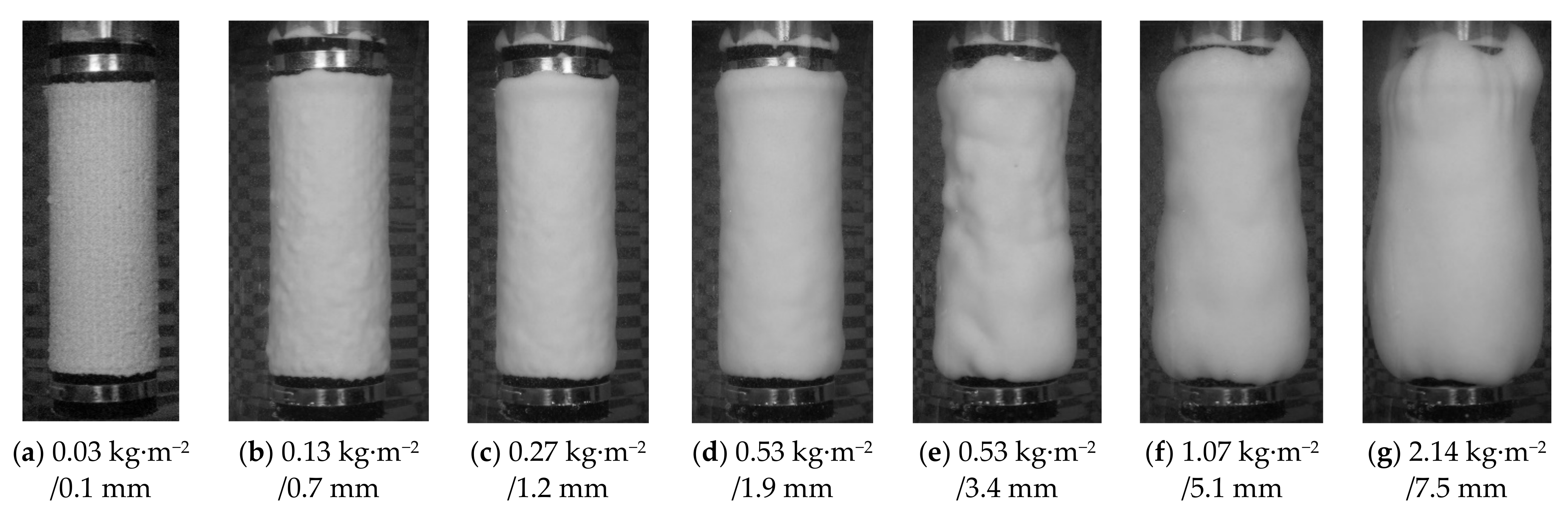

5.3.3. Cleaning Behavior with Additional Precoat Layer

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Symbol | Description | Unit |

| Filter area | m2 | |

| Hydraulic diameter | m | |

| Adhesive force | N | |

| Filter cake height | m | |

| Filter media resistance | m−1 | |

| Filtrate volume | m3 | |

| Filtrate volume flow | m3∙s−1 | |

| Mass/volume modal value | m | |

| Specific filter cake resistance | m−2 | |

| Pressure difference | Pa | |

| Porosity | - | |

| Viscosity of the fluid | Pa∙s |

References

- Purchas, D.B.; Sutherland, K. Handbook of Filter Media, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2002. [Google Scholar]

- Ripperger, S.; Schnitzer, C. Die Barrierewirkung von Geweben Teil 1: Textiltechnische Charakterisierung und Barrieremechanismen. Filtr. Sep. 2005, 19, 110–117. [Google Scholar]

- Schnitzer, C.; Ripperger, S. Die Barrierewirkung von Geweben Teil 2: Experimentelle Methoden zur Bestimmung von Gewebeeigenschaften. Filtr. Sep. 2005, 19, 166–173. [Google Scholar]

- Ripperger, S. Die Barrierewirkung von Geweben Teil 3: Auswahl von Geweben zur Kuchenfiltration. Filtr. Sep. 2005, 19, 284–289. [Google Scholar]

- Ripperger, S. Die Barrierewirkung von Geweben Teil 6: Einfluss des Filtermittels auf die Kuchenfiltration. Filtr. Sep. 2008, 22, 6–9. [Google Scholar]

- Bächle, V.; Morsch, P.; Fränkle, B.; Gleiß, M.; Nirschl, H. Interaction of Particles and Filter Fabric in Ultrafine Filtration. Eng. Adv. Eng. 2021, 2, 9. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 2762: Filtrierbarkeit von Suspensionen Bestimmung des Filterkuchenwiderstands; Verein Deutscher Ingenieure e.V.: Düsseldorf, Germany, 2010. [Google Scholar]

- Morsch, P.; Anlauf, H.; Nirschl, H. The influence of filter cloth on cake discharge performances during backwashing into liquid phase. Sep. Purif. Technol. 2021, 254, 117549. [Google Scholar] [CrossRef]

- Fränkle, B.; Morsch, P.; Nirschl, H. Regeneration assessments of filter fabrics of filter presses in the mining sector. Miner. Eng. 2021, 168, 106922. [Google Scholar] [CrossRef]

- Christensen, M.L.; Klausen, M.M.; Christensen, P.V. Test of precoat filtration technology for treatment of swimming pool water. Water Sci. Technol. 2017, 77, 748–758. [Google Scholar] [CrossRef]

- Morsch, P.; Ginisty, P.; Anlauf, H.; Nirschl, H. Factors influencing backwashing operation in the liquid phase after cake filtration. Chem. Eng. Sci. 2020, 213. [Google Scholar] [CrossRef]

- Hackl, A.; Heidenreich, E.; Hoflinger, W.; Tittel, R. Filterhilfsmittelfiltration. Fortschr. VDI Reihe 3 1993, 348, 1–5. [Google Scholar]

- Heertjes, P.; Zuideveld, P. Clarification of liquids using filter aids Part III. Cake Resistance in surface filtration. Powder Technol. 1978, 19, 45–64. [Google Scholar] [CrossRef]

- Heertjes, P.M.; Zuideveld, P.L. Clarification of liquids using filter aids Part II. Depth filtration. Powder Technol. 1978, 19, 31–43. [Google Scholar] [CrossRef]

- Khirouni, N.; Charvet, A.; Drisket, C.; Ginestet, A.; Thomas, D.; Bémer, D. Precoating for improving the cleaning of filter media clogged with metallic nanoparticles. Process. Saf. Environ. Prot. 2021, 147, 311–319. [Google Scholar] [CrossRef]

- Zeller, A. Substitution der Kieselgur Durch Regenerierbare Zellulosefasern Auf Einem Neuartigen Filtrationssystem Für Brauereien. Ph.D. Thesis, Technische Universität Bergakademie Freiberg, Freiberg, Germany, 2011. [Google Scholar]

- Kain, J. Entwicklung und Verfahrenstechnik Eines Kerzenfiltersystems (Twin-Flow-System ) als Anschwemmfilter. Ph.D. Thesis, Technische Universität München, München, Germany, 2005. [Google Scholar]

- Kuhn, M.; Briesen, H. Dynamic Modeling of Filter-Aid Filtration Including Surface- and Depth-Filtration Effects. Chem. Eng. Technol. 2016, 39, 425–434. [Google Scholar] [CrossRef]

- Rushton, A. Effect of Filter Cloth Structure on Flow Resistance, Bleeding, Blinding and Plant performance. Chem. Eng. 1970, 273, 88–94. [Google Scholar]

- Anlauf, H. Filtermedien zur Kuchenfiltration-Schnittstelle Zwischen Suspension und Apparat. Chem. Ing. Tech. 2007, 79, 1821–1831. [Google Scholar] [CrossRef]

- Tiller, F.M.; Green, T.C. Role of porosity in filtration IX skin effect with highly compressible materials. AIChE J. 1973, 19, 1266–1269. [Google Scholar] [CrossRef]

- Ripperger, S. Optimierung von Rückspülfiltern für Flüssigkeiten. Filtr. Sep. 2008, 22, 68–72. [Google Scholar]

- Morris, K.; Allen, R.W.; Clift, R. Adhesion of Cakes to Filter Media. Filtr. Sep. 1987, 24, 41–45. [Google Scholar]

- Lengweiler, P. Modelling Deposition and Resuspension of Particles on and from Surfaces. Ph.D. Thesis, Swiss Federal Institute of Technology Zürich, Zürich, Switzerland, 2000. [Google Scholar]

- Gruschwitz, F.; Nirschl, H.; Anlauf, H. Optimized backflushing process for fibrous media in engine oil filtration and enhancement by ultrasound. Chem. Eng. Technol. 2013, 36, 467–473. [Google Scholar] [CrossRef]

| Particle | Concentration/kg∙L−1 | Particle Volume/kg∙m−2 | Cake Height/mm | Backwashing Volume/L∙m−2 | Remark |

|---|---|---|---|---|---|

| P1 | 5.71 | 1.07 | 0.7 ± 0.11 | 2.2 ± 0.50 | Complete Discharge |

| P2 | 5.71 | 1.07 | 0.6 ± 0.07 | 0.3 ± 0.01 | |

| P3 | 1.43 | 0.13 | 0.2 ± 0.07 | 0.3 ± 0.03 |

| Particle | Concentration/kg∙L−1 | Particle Volume/kg∙m−2 | Cake Height/mm | Backwashing Volume/L∙m−2 | Remark |

|---|---|---|---|---|---|

| C1–P1 | 22.86 | 2.13 | 1.4 ± 0.4 | 1.40 ± 0.22 | Incomplete discharge |

| C1–P2 | 1.43 | 0.13 | 1.1 ± 0.2 | 1.19 ± 0.10 | Resuspended discharge |

| C1–P3 | 1.43 | 0.13 | 1.2 ± 0.2 | 0.53 ± 0.06 | Complete discharge |

| C2–P1 | 1.43 | 0.13 | 2.0 ± 0.3 | > 5 | No filtration effect |

| C2–P2 | 1.43 | 0.13 | 1.5 ± 0.3 | > 5 | No filtration effect |

| C2–P3 | 1.43 | 0.13 | 1.4 ± 0.4 | 1.55 ± 0.18 | Incomplete good discharge |

| C3–P1 | 1.43 | 0.13 | 0.9 ± 0.3 | 0.76 ± 0.08 | Complete discharge |

| C3–P2 | 1.43 | 0.13 | 0.9 ± 0.1 | 0.23 ± 0.02 | Complete discharge |

| C3–P3 | 1.43 | 0.13 | 0.9 ± 0.2 | 0.24 ± 0.04 | Complete discharge |

| Particle | Concentration/kg∙L−1 | Particle Volume/kg∙m−2 | Cake Height/mm | Backwashing Volume/L∙m−2 | Remark |

|---|---|---|---|---|---|

| C1–P1 | 22.86 | 2.13 | 3.1 ± 0.2 | 1.07 ± 0.10 | Resuspended discharge |

| C2–P1 | 5.71 | 1.07 | 5.3 ± 0.7 | >5 | No filtration effect |

| C3–P1 | 1.43 | 0.13 | 2.9 ± 0.3 | 2.19 ± 0.14 | Complete discharge |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bächle, V.; Morsch, P.; Gleiß, M.; Nirschl, H. Influence of the Precoat Layer on the Filtration Properties and Regeneration Quality of Backwashing Filters. Eng 2021, 2, 181-196. https://doi.org/10.3390/eng2020012

Bächle V, Morsch P, Gleiß M, Nirschl H. Influence of the Precoat Layer on the Filtration Properties and Regeneration Quality of Backwashing Filters. Eng. 2021; 2(2):181-196. https://doi.org/10.3390/eng2020012

Chicago/Turabian StyleBächle, Volker, Patrick Morsch, Marco Gleiß, and Hermann Nirschl. 2021. "Influence of the Precoat Layer on the Filtration Properties and Regeneration Quality of Backwashing Filters" Eng 2, no. 2: 181-196. https://doi.org/10.3390/eng2020012

APA StyleBächle, V., Morsch, P., Gleiß, M., & Nirschl, H. (2021). Influence of the Precoat Layer on the Filtration Properties and Regeneration Quality of Backwashing Filters. Eng, 2(2), 181-196. https://doi.org/10.3390/eng2020012