Abstract

Flooding is one of the climatic change consequences that has become a dangerous threat to many coastal cities. Pervious concrete is considered a solution to decrease rainwater runoff and mitigate flood effects, as it allows water to percolate through the ground and prevent possible damage. Using waste products as aggregates in pervious concrete not only exploits waste materials and makes it valuable but also reduces the amount of this waste ending in the landfill or harming the environment, and it decreases the demand for natural resources. Infiltration rate test and compressive strength tests were conducted to investigate the effect of using waste plastic and/or recycled rubber as concrete coarse aggregates with different ratios (5%, 10%, 15%, 20%, and 25%) on the pervious concrete. The results showed that increasing the waste materials in concrete decreased the compressive strength for all ratios while increased the infiltration rate values.

1. Introduction

The biggest problem facing the world now is the climate emergency, and it has been ignored for decades. Professor Raymond Pierrehumbert’s words stress the crucial situation: “Let’s get this on the table right away, without mincing words. With regard to the climate crisis, yes, it’s time to panic. We are in deep trouble.” [1] Ice melts by billions of tonnes and this leads to a rise in the sea levels all over the world (sea levels are rising about three millimetres a year); as a result, many coastal cities will be partially or totally underwater between 2030 and 2040 [2,3]. Rainforests burned at a record rate and estimates showed that about 20% of the oxygen produced by the Earth’s land comes from the Amazon rainforest. Moreover, climatic emergency is one of the main reasons of flood risk [4]; it could concentrate the hydrological cycle, which causes more intense rainfall, leading to increased frequency and severity of floods. (In the UK, the rainfall in 2015 broke records, receiving 341 mm within one day, breaking the 2009 record of 316.4 mm). Floods not only caused structural damage in roads, sewage treatment plants, and energy supplies, but they also caused economic losses—for example, flood damage costs the UK £1.3 billion every year [5].

Pervious concrete could mitigate flood runoff effects. A pervious or porous concrete is capable of capturing water on the surface and then allowing it to infiltrate into the subgrade layer and groundwater, which is one of the best storm water management systems [6]. The main difference between the traditional concrete and the pervious concrete mixes is eliminating or using a small fraction of fine aggregate which is responsible for the high porosity and void ratio. The strength of pervious concrete is affected by various factors (strength mainly depends on the bonding between cementitious paste and aggregate particles) including the cement content, water-to-cement ratio, type and level of compaction, and the quality and the gradation of used aggregates. The key factor of optimization of pervious concrete mix design is the balance between the strength and permeability [7,8]. The porosity of concrete is the reason for its permeability; the higher the porosity, the higher permeability which is defined by the infiltration rate test [9]. However, increasing the porosity of the mixture negatively affect the compressive strength of concrete [10]. Despite the benefits of pervious concrete, the clogging issue represents an important limitation for pervious concrete from a hydrologic perspective—for example, silt, clay-sized materials, algae, and plant roots, which block the pores created in the previous concrete leading to a reduction on the voids ratio and, consequently, the permeability of the concrete. Clogging also reduces the effective service life and impedes the widespread application of pervious concrete [11,12].

On the other hand, the Earth is running out of natural resources. One way to overcome this issue is recycling the waste materials into existing industries to replace the natural resources. Waste plastic and recycled rubber are considered the most abundant waste materials generated globally. Waste plastic increases from only two million tonnes annually in 1950 to about 381 million tonnes in 2015, and account for 12% of the world total municipal waste annually in 2016 [13,14]. In 2005, about 10 billion rubber tires were generated worldwide. In the US, four million tonnes of waste tires are generated every year [15]. The problem is that these wastes can potentially take over a hundred years to break down when deposited in landfill sites [16]. Another serious issue is that the plastic and rubber wastes end up getting dumped in the globe’s oceans. Polluting oceans can have catastrophic effects on marine life and ecosystems, all of which are essential for a balanced and functioning planet [17]. However, we can lessen the negative effect of that waste by incorporating it in various industries.

Many researchers have studied various types of waste materials to be used as an alternative to natural aggregates in concrete. For example, recycled aggregate from demolished concrete [18,19,20], recycled rubber tires [21,22,23], post-consumer glass [24,25], steel slag by-products [26,27,28,29], and recycled waste plastic [30,31,32,33,34,35,36,37,38]. Using waste plastic aggregate on concrete has been evaluated in many studied. Rahim, N.L. et al. replaced the coarse aggregate with high-density polyethylene (HDPE) by 10%, 20% and 30%, and the results showed that increasing the waste plastic replacement decrease the compressive strength by 6%, 19%, and 35%, respectively [39]. Azad A. Mohammed et al. studied the effect of using plastic waste from PVC waste sheets to partially replace coarse aggregate or fine aggregate up to 85%. The results indicated a significant decrease in the compressive strength from 41.5 to 16.4 MPa for 85% fine aggregate replacement and from 41.5 to 8.3 MPa for 85% coarse aggregate replacement [35]. For all studies, it was reported that using waste plastic aggregates decreased the compressive strength of the manufacturing concrete [40,41,42,43,44,45]. The relation between the increasing of infiltration rate and the decreasing of compressive was also reported.

Researchers also studied the effect of using recycled rubber on the properties of concrete. Sanjeev Kumar et al. studied various sizes of discarded tyre rubber (from powder to 4 mm) as aggregates replacement at different levels (from 2.5% to 20%) with different water-to-cement (W/C) ratios. Compressive strength for all mixes decreased with the addition of discarded rubber; with replacing 20% of rubber, the values declined from 33, 30, and 26.5 N/mm2 to 20, 20, and 17 N/mm2 with 0.40, 0.45, and 0.50 W/C, respectively [46]. Hanbing Liu et al. used two types of waste crumb rubber as coarse and fine aggregates with four replacement levels (2%, 4%, 6%, and 8%), and the compressive strength results at 8% replacement decreased by 34% with coarse aggregate replacement, while with fine aggregate, it was 11%. A slight decrease in the permeability coefficient was also reported [47]. Eshmaiel Ganjian et al. replaced the coarse aggregate with scrap tyre rubber by 5%, 7.5%, and 10%. The strength lost 21% by replacing 10% of scrap rubber, while the permeability increased by 150% [48].

The main purpose of this study was to investigate the effect of using waste plastic and/or recycled rubber as a coarse aggregate replacement on the compressive strength and permeability of pervious concrete.

2. Materials and Methods

2.1. Material

Ordinary Portland cement was used in this study while satisfying ASTM C150 [49] requirements (Table 1 shows the chemical composition of cement). Natural sand was used as a fine aggregate. Clean crushed dolomite was used as a coarse aggregate, waste plastic (WP) was used after it had been shredded, and recycled rubber (RR) was used with different sizes as shown in Figure 1. Table 2 shows the properties of natural aggregate and waste plastic used in the mixes.

Table 1.

Chemical composition of cement.

Figure 1.

Recycled tire rubber, crushed dolomite, and waste plastic aggregates.

Table 2.

Physical properties of sand, crushed dolomite, waste plastic, and recycled rubber.

2.2. Mix Design, Preparation of Samples, and Curing

Absolute volume method was used to calculate the mix design. 15 mixes were prepared with various replacement of gravel by waste plastic and/or recycled tire rubber aggregates (5%, 10%, 15%, 20%, and 25%) by weight to investigate the effect of waste aggregates on the pervious concrete properties (compressive strength and permeability). Table 2 showed the components details of mixes. The control mix was prepared with natural coarse aggregates to act as a reference mix.

Concrete components were weighed out and put into plastic bags ready to be added to the mix. Cement and sand were mixed dry for 3 min, then water was gradually added. The coarse aggregates (gravel, waste plastic, and/or recycled rubber) were added and mixed until the desired consistency was reached. The mix was then added to the moulds in three stages; each time, the sample was consolidated using a tampering rod. Samples were left to sit for 72 h; then, they were demoulded and cured in water at the room temperature until the test date as shown in Figure 2. The cement, sand, and water content were the same for all mixes. Table 3 shows the mixture’s constituents for each mix.

Figure 2.

(a) Hardened sample before being demoulded. (b) Curing samples in water.

Table 3.

Mixtures components for each mix (kg/m3).

2.3. Testing

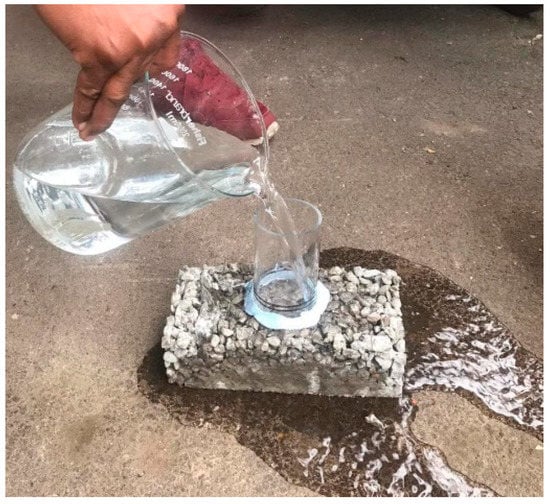

21 × 11 × 6 cm cubes were used to determine the compressive strength in accordance with ASTM C39 test [50], while for measuring the permeability of the pervious concrete, the infiltration rate test was conducted in accordance with ASTM C1701 [51]. The tests used an infiltrometer with a single ring under a constant water head and pre-wetting with 3.60 kg of water. The amount of water used in the actual infiltration test depended on the pre-wetting time. 18.0 kg of water were used in the case of the pre-wetting time under 30 s, while 3.6 kg were used if the time was above 30 s. Figure 3 shows the infiltration rate test. The following formula is used to calculate the infiltration rate:

where I = infiltration rate (mm/s), K = constant, 4.583 × 109 in SI units, M = mass of the water (kg). D2 = inside diameter of the perimeter (mm), and t = time for the body of water to infiltrate the pervious concrete (PC) sample (second).

Figure 3.

Infiltration rate test.

3. Results and Discussion

3.1. Infiltration Rate

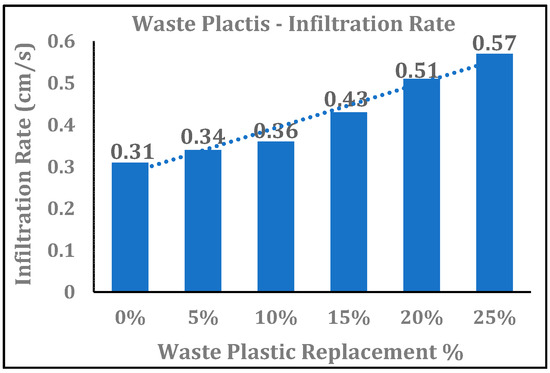

Table 4 represents the values of infiltration rate test for each mix. The results showed a significant increase in the infiltration rate, as the value jumped from 0.31 cm/s to 0.57 cm/s with 25% waste plastic replacement, which is about 84% higher than the control mix. Increasing the percentage of replacement of coarse aggregate with plastic waste in concrete increases the permeability as shown in Figure 4. This could be attributed to the shape and the smooth surface of waste plastic aggregate, which creates a continuous pathway between pores and increases porosity. Additionally, the insufficient compaction due to the low density of plastic waste causes more pores [52].

Table 4.

Infiltration rate results for waste plastic aggregates replacement.

Figure 4.

Infiltration rate of pervious concrete with different ratios of waste plastic aggregates (5%, 10%, 15%, 20%, and 25%).

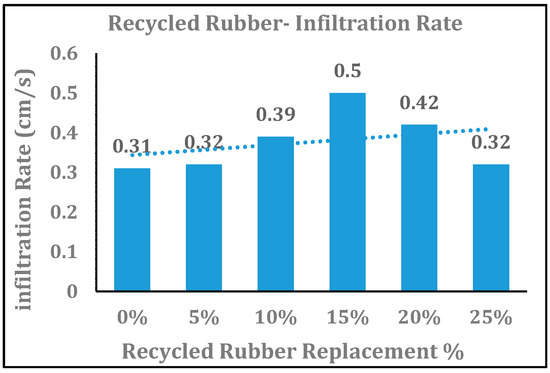

The infiltration rate values for concrete using recycled rubber as a coarse aggregate were illustrated in Table 5. An increasing trend was observed at all level of replacement. The value increased to reach its peak at 15% replacement from 0.31 cm/s to 0.50 cm/s with a 61% increase from the control mix. However, increasing the replacement above 15% led to a decrease in infiltration rate (0.32 cm/s with 25% replacement). Overall, using recycled rubber as coarse aggregates increased the permeability of concrete mixes as shown in Figure 5. This could be due to the weak pond between recycled rubber aggregate and cement matrix, and the associated micro cracks which lead to interfacial gap voids. The non-absorbent nature of the rubber surface and the difference in modulus of elasticity between cement paste and rubber aggregates plays a vital role in the pond on interfacial transition zone [53]. The author suggests that the decrease occurred when replacement exceeded 15% could be attributed to the accumulation of the cement paste creating impermeable spots as shown in Figure 6. This could affect the permeability of the pervious concrete as Suleiman, M. T. et al. reported [54].

Table 5.

Infiltration rate results for recycled rubber aggregates replacement.

Figure 5.

Infiltration rate of pervious concrete with different ratios of recycled rubber aggregates (5%, 10%, 15%, 20%, and 25%).

Figure 6.

Pervious concrete with 25% recycled rubber aggregates after being cured.

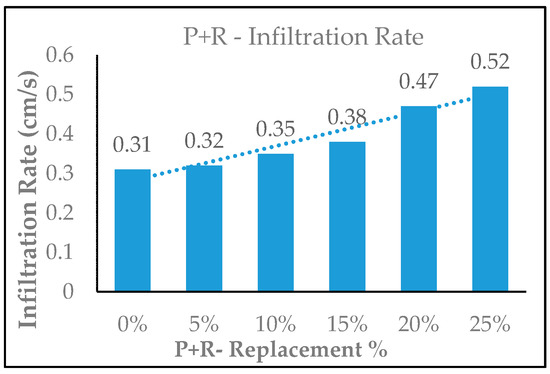

Table 6 showed the infiltration rate values for concrete blended with both waste plastic and recycled rubber as a coarse aggregate. Results showed a linear relationship between the replacement percentage and the permeability, as increasing the waste aggregates increased the permeability of the pervious concrete mixes and this trend aligned with the previously reported trends. Figure 7 indicates that permeability increased by 68% with 25% waste aggregates replacement.

Table 6.

Infiltration rate results for waste plastic and recycled rubber aggregates replacement.

Figure 7.

Infiltration rate of pervious concrete blended with different ratios of waste plastic and recycled rubber aggregates (5%, 10%, 15%, 20%, and 25%).

3.2. Compressive Strength

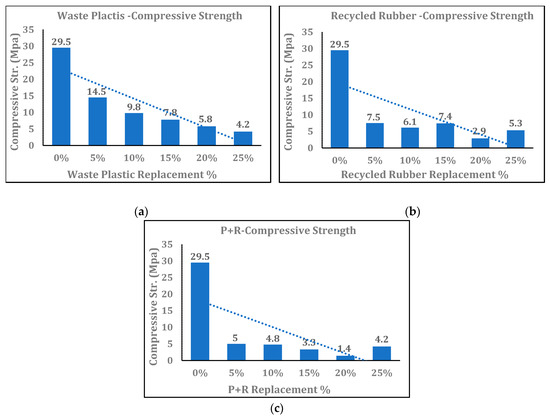

The compressive strength results for concrete with waste plastic aggregates are represented in Figure 8a. The results showed that increasing the percentage of waste plastic decreased the compressive strength significantly. The concrete mix lost about 50% of its strength only after replacing 5% of coarse aggregate with waste plastic (the strength dropped from 29.5 to 14.5 MPa) while increasing the replacement to 25% led to over 85% loss in the compressive strength (4.2 MPa with 25% replacement). These results agree with what other researchers reported [35,36,41,55,56]. This decrease could be due to the weak pond between the plastic aggregate and the cement paste since the plastic has a smooth surface which weakens the interfacial transition zone [37,39]. Moreover, plastic is a kind of hydrophobic material (which makes it water-repelling) and this may limit the water required for cement hydration from entering through the structure [44].

Figure 8.

Compressive strength of pervious concrete with different ratios of aggregates replacement (5%, 10%, 15%, 20%, and 25%). (a) Waste plastic, (b) recycled rubber, and (c) plastic and rubber.

Figure 8b shows the compressive strength of pervious concrete containing recycled rubber aggregates as coarse aggregates. A dramatic decrease was observed when replacing the natural coarse aggregate with recycled rubber by 5% as the strength dropped from 29.5 MPa to 7.5 MPa (the mixture lost about 74% compared with control mix). The least value was obtained with 20% replacement by 2.9 MPa. The lack of adhesion between recycled rubber aggregates and the cement matrix weakens the bonding between them and cause a reduction on the compressive strength [47]. It was also suggested that the specific gravity of the recycled rubber aggregates is lower than the cement paste which accelerates the propagation of cracks around the rubber particles and consequently the failure of the samples. These are in addition to the hydrophobic characteristics of rubber particles which negatively affected the cement hydration process and weakened the concrete [46].

Figure 8c illustrates the compressive strength of pervious concrete blended with both waste plastic and recycled rubber aggregates with equal percentages. The same declined trend was observed as a value reached 4.2 MPa with 25% replacement. The lowest compressive strength was obtained with 20% replacement of natural aggregates by around 95% loss in the strength (from 29.5 MPa to 1.4 MPa).

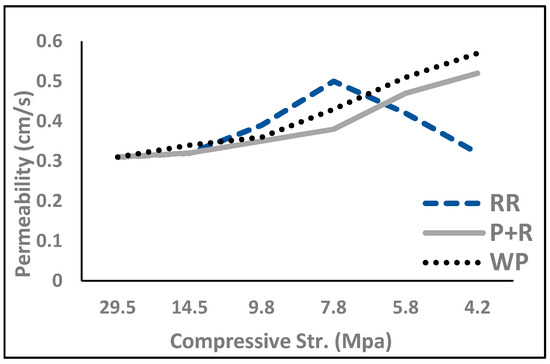

Figure 9 clarifies the relation between the permeability and the compressive strength. It was obvious that the permeability of concrete tended to decrease with the increase in the compressive strength [57]. L. G. Li et al. reported that the main two factors affecting the permeability of concrete are the size of aggregate, which determined the amount of voids in the aggregate and, consequently, the packing density of the aggregate and the type of compaction [58].

Figure 9.

The relation between compressive strength and permeability of pervious concrete with different waste material replacement.

4. Conclusions

In this research study, the effect of replacement of a natural coarse aggregate with waste plastic and/or recycled rubber (5%, 10%, 15%, 20%, and 25%) was studied on the compressive strength and permeability of pervious concrete, and the following conclusions were made:

- Using waste plastic and/or recycled rubber as concrete aggregates significantly decreases the compressive strength of concrete for all level of replacement. 85% 82%, and 85% of compressive strength was lost with 25% replacement with waste plastic, recycled rubber, and a combination of both, respectively.

- The permeability of concrete contains waste plastic and/or recycled rubber increased with the increase of the replacement level. Replacing 25% of natural coarse aggregates with waste plastic, recycled rubber, and a combination of both increases the permeability values by 83%, 3%, and 68%, respectively.

Author Contributions

Methodology, S.A.; investigation, L.C.; writing—original draft preparation, R.B.; writing—review and editing, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Pierrehumbert, R. There is no Plan B for dealing with the climate crisis. Bull. At. Sci. 2019, 75, 215–221. [Google Scholar] [CrossRef]

- Kushner, J. The Life and Death of Great Cities in the Time of Climate Change. J. Comp. Urban Law Policy 2020, 4, 133–217. [Google Scholar]

- Saintilan, N.; Khan, N.S.; Ashe, E.; Kelleway, J.J.; Rogers, K.; Woodroffe, C.D.; Horton, B.P. Thresholds of mangrove survival under rapid sea level rise. Science 2020, 368, 1118–1121. [Google Scholar] [CrossRef]

- O’Donnell, E.C.; Thorne, C.R. Drivers of future urban flood risk. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2020, 378, 20190216. [Google Scholar] [CrossRef]

- Available online: https://eciu.net/analysis/briefings/climate-impacts/flood-risk-and-the-uk (accessed on 22 October 2020).

- Imran, H.; Akib, S.; Karim, M.R. Permeable pavement and stormwater management systems: A review. Environ. Technol. 2013, 34, 2649–2656. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M. Investigating the effect of mixture design parameters on pervious concrete by statistical modelling. Constr. Build. Mater. 2013, 38, 147–154. [Google Scholar] [CrossRef]

- Sonebi, M.; Bassuoni, M.; Yahia, A. Pervious Concrete: Mix Design, Properties and Applications. RILEM Tech. Lett. 2016, 1, 109. [Google Scholar] [CrossRef]

- Ahmed, T.; Hoque, S. Study on pervious concrete pavement mix designs. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Kedah, Malaysia, 2020; Volume 476, p. 012062. [Google Scholar]

- Mahalingam, R.; Mahalingam, S.V. Analysis of pervious concrete properties. Građevinar 2016, 68, 493–501. [Google Scholar]

- Kia, A.; Wong, H.S.; Cheeseman, C.R. Clogging in permeable concrete: A review. J. Environ. Manag. 2017, 193, 221–233. [Google Scholar] [CrossRef]

- Coughlin, J.P.; Campbell, C.D.; Mays, D.C. Infiltration and Clogging by Sand and Clay in a Pervious Concrete Pavement System. J. Hydrol. Eng. 2012, 17, 68–73. [Google Scholar] [CrossRef]

- Available online: https://ourworldindata.org/plastic-pollution (accessed on 22 October 2020).

- Available online: http://datatopics.worldbank.org/what-a-waste/tackling_increasing_plastic_waste.html (accessed on 22 October 2020).

- Li, Y.; Zhang, S.; Wang, R.; Dang, F. Potential use of waste tire rubber as aggregate in cement concrete—A comprehensive review. Constr. Build. Mater. 2019, 225, 1183–1201. [Google Scholar] [CrossRef]

- LeBlanc, R. How Long does It Take Garbage to Decompose? The Balance. 2017. Available online: www.thebalance.Com/how-long-does-it-take-garbage-to-decompose-2878033 (accessed on 22 October 2020).

- Stafford, R.; Jones, P.J. Viewpoint—Ocean plastic pollution: A convenient but distracting truth? Mar. Policy 2019, 103, 187–191. [Google Scholar] [CrossRef]

- Hansen, T.C. (Ed.) Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Evangelista, L.; De Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.; Kohail, M.; Nasr, E.-S.A. Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Abdelmonem, A.; El-Feky, M.; Nasr, E.-S.A.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660. [Google Scholar] [CrossRef]

- Sofi, A. Effect of waste tyre rubber on mechanical and durability properties of concrete – A review. Ain Shams Eng. J. 2018, 9, 2691–2700. [Google Scholar] [CrossRef]

- Park, J.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Jin, W.; Meyer, C.; Baxter, S. “Glascrete”-Concrete with Glass Aggregate. ACI Mater. J. 2000, 97, 208–213. [Google Scholar]

- Chunlin, L.; Kunpeng, Z.; Depeng, C. Possibility of Concrete Prepared with Steel Slag as Fine and Coarse Aggregates: A Preliminary Study. Procedia Eng. 2011, 24, 412–416. [Google Scholar] [CrossRef]

- Nadeem, M.; Pofale, A.D. Utilization of Industrial Waste Slag as Aggregate in Concrete Applications by Adopting Taguchi’s Approach for Optimization. Open J. Civ. Eng. 2012, 2, 96–105. [Google Scholar] [CrossRef]

- Chinnaraju, K.; Ramkumar, V.R.; Lineesh, K.; Nithya, S.; Sathish, V. Study on concrete using steel slag as coarse aggregate replacement and ecosand as fine aggregate replacement. IJREAT Int. J. Res. Eng. Adv. Technol. 2013, 1, 65–69. [Google Scholar]

- El-Tair, A.M.; Bakheet, R.; El-Feky, M.S.; Kohail, M.; Akib, S. Utilization of Water-Cooled and Air-Cooled Slag Aggregate in Concrete: A Solution to the Secular Economy. Eng. Adv. Eng. 2020, 1, 48–59. [Google Scholar] [CrossRef]

- Jeevitha, B.; Urs, N. Study on Mechanical Properties of Cement Concrete for Partial Replacement of Coarse Aggregate by Shredded Plastic and Cement by Fly Ash and Metakaolin. In Sustainable Construction and Building Materials; Springer: Singapore, 2019; pp. 177–187. [Google Scholar]

- Hama, S.M.; Hilal, N.N. Fresh properties of concrete containing plastic aggregate. In Use of Recycled Plastics in Eco-efficient Concrete; Woodhead Publishing: Cambridge, UK, 2019; pp. 85–114. [Google Scholar]

- Mohammed, A. Mechanical strength of concrete with PVC aggregates. In Use of Recycled Plastics in Eco-efficient Concrete; Woodhead Publishing: Cambridge, UK, 2019; pp. 115–135. [Google Scholar]

- Koide, H.; Tomon, M.; Sasaki, T. Investigation of the use of waste plastic as an aggregate for lightweight concrete. In Challenges of Concrete Construction: Volume 5, Sustainable Concrete Construction, Proceedings of the International Conference held at the University of Dundee, Scotland, UK, 9–11 September 2002; Thomas Telford Publishing: London, UK, 2002; Volume 5, pp. 177–185. [Google Scholar]

- Saikia, N.; De Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Mohammed, A.A.; Mohammed, I.I.; Mohammed, S.A. Some properties of concrete with plastic aggregate derived from shredded PVC sheets. Constr. Build. Mater. 2019, 201, 232–245. [Google Scholar] [CrossRef]

- Jaivignesh, B.; Sofi, A. Study on Mechanical Properties of Concrete Using Plastic Waste as an Aggregate. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Thanjavur, India, 2017; Volume 80, p. 012016. [Google Scholar]

- Khalil, W.I.; Mahdi, H.M. Some properties of sustainable concrete with mixed plastic waste aggregate. IOP Conf. Series Mater. Sci. Eng. 2020, 737, 012073. [Google Scholar] [CrossRef]

- Krasna, W.A.; Noor, R.; Ramadani, D.D. Utilization of Plastic Waste Polyethylene Terephthalate (Pet) as a Coarse Aggregate Alternative in Paving Block. In Proceedings of the MATEC Web of Conferences, Banjarmasin, Indonesia, 11–12 October 2018; EDP Sciences: Les Ulis, France, 2019; Volume 280, p. 04007. [Google Scholar]

- Rahim, N.L.; Sallehuddin, S.; Ibrahim, N.M.; Amat, R.C.; Ab Jalil, M.F. Use of Plastic Waste (High Density Polyethylene) in Concrete Mixture as Aggregate Replacement. Adv. Mater. Res. 2013, 701, 265–269. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Marzouk, O.Y.; Dheilly, R.; Quéneudéc, M. Valorization of post-consumer waste plastic in cementitious concrete composites. Waste Manag. 2007, 27, 310–318. [Google Scholar] [CrossRef]

- Kou, S.; Lee, G.; Poon, C.; Lai, W. Properties of lightweight aggregate concrete prepared with PVC granules derived from scraped PVC pipes. Waste Manag. 2009, 29, 621–628. [Google Scholar] [CrossRef]

- Panyakapo, P.; Panyakapo, M. Reuse of thermosetting plastic waste for lightweight concrete. Waste Manag. 2008, 28, 1581–1588. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Kumar, S.; Gupta, R.C.; Thomas, B.S.; Mehra, P.; Charytonowicz, J. Aggregate Replacement and Its Usefulness in Cement Concrete for Sustainable Development—A Study on Rubber, Jarosite and Sandstone Aggregates. In Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2016; Volume 493, pp. 13–25. [Google Scholar]

- Liu, H.; Luo, G.; Gong, Y.; Wei, H. Mechanical Properties, Permeability, and Freeze–Thaw Resistance of Pervious Concrete Modified by Waste Crumb Rubbers. Appl. Sci. 2018, 8, 1843. [Google Scholar] [CrossRef]

- Ganjian, E.; Khorami, M.; Maghsoudi, A.A. Scrap-tyre-rubber replacement for aggregate and filler in concrete. Constr. Build. Mater. 2009, 23, 1828–1836. [Google Scholar] [CrossRef]

- ASTM International. Standard Specification for Portland Cement ASTM International; C150/C150M-19a; ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; C39/C39M-20; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. Standard Test Method for Infiltration Rate of in Place Pervious Concrete; C1701/C 1701M-09; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Khalil, W.; Al Obeidy, N. Some properties of sustainable concrete containing two environmental wastes. In Proceedings of the MATEC Web of Conferences, Sharm el-Shiekh, Egypt, 23–25 October 2017; EDP Sciences: Paris, France, 2018; Volume 162, p. 02029. [Google Scholar]

- Najim, K.B.; Hall, M.R. Crumb rubber aggregate coatings/pre-treatments and their effects on interfacial bonding, air entrapment and fracture toughness in self-compacting rubberised concrete (SCRC). Mater. Struct. 2013, 46, 2029–2043. [Google Scholar] [CrossRef]

- Suleiman, M.T.; Kevern, J.; Schaefer, V.R.; Wang, K. Effect of compaction energy on pervious concrete properties. In Submitted to Concrete Technology Forum-Focus on Pervious Concrete; National Ready Mix Concrete Association: Nashville, TN, USA, 2006; pp. 23–25. [Google Scholar]

- Pezzi, L.; De Luca, P.A.; Vuono, D.; Chiappetta, F.; Nastro, A. Concrete products with waste’s plastic material (bottle, glass, plate). In Materials Science Forum; Trans Tech Publications Ltd.: Zürich, Switzerland, 2006; Volume 514, p. 1753. [Google Scholar]

- Hameed, A.M.; Ahmed, B.A.F. Employment the plastic waste to produce the light weight concrete. Energy Procedia 2019, 157, 30–38. [Google Scholar] [CrossRef]

- Bamforth, P.B. The water permeability of concrete and its relationship with strength. Mag. Concr. Res. 1991, 43, 233–241. [Google Scholar] [CrossRef]

- Li, L.G.; Feng, J.J.; Zhu, J.; Chu, S.; Kwan, A.K.H. Pervious concrete: Effects of porosity on permeability and strength. Mag. Concr. Res. 2019, 1–35. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).