Abstract

Aggregates are generally thought of as inert filler within a concrete mix, and a typical concrete mix is comprised of as much as 70–80% of them. They play an essential role in the properties of both fresh and hardened concrete. Nowadays, scientists are aiming to use waste materials, thereby replacing natural aggregates for economic and environmental considerations. This study investigates the effect of the utilization of steel slag by-product aggregates (air- and water-cooled slag) as concrete aggregates on the behavior characteristics of concrete. Various concrete mixtures, with different levels of replacement of slag aggregate (50, 75, and 100%), were conducted in order to find the optimum percentages to improve the microstructure and different properties of concrete (fresh and hardened). The results showed that increasing the fine aggregate replacement percentage led to a decrease in compressive strength values, in contrast with coarse aggregate replaced with slag aggregate. The steel slag aggregates showed potential to be used as replacement for natural aggregate with comparable compressive strength and acceptable workability.

1. Introduction

Concrete is considered to be one of the most used construction material all over the world. It is estimated that the production of concrete will reach about 18 billion tons/year by 2050 [1,2,3]. Concrete manufacturing consumes a massive amount of raw material, such as natural aggregate and lime stone, which are among the basic and main components involved in concrete production and the cement industry, and these materials may soon be subjected to vanishing. Many researchers found that aggregates represent about 70–80% of concrete volume, and they have a vital role in various concrete characteristics such as consistency, strength and durability [4,5,6]. The increasing demand on concrete raises the alarm on the future availability of the natural aggregate resources for the coming generations, as natural aggregates were extracted by 28.6 gigatons in 2010 only and became the most extracted materials worldwide [7]. Many countries put a restriction and additional taxes on using virgin aggregate resources [8,9], so it becomes a crucial issue to find a suitable substitutional as a replacement of natural aggregate in concrete without affecting the concrete characteristics [10,11,12,13,14].

Various entities encourage the use of waste materials for their social, environmental and economic impact [15,16]. Using waste material decreases concrete cost by using unexploited waste sources, in addition saving both the cost of the natural source extraction and eliminating the cost of waste disposal [17,18]. Many researchers studied various waste and by-product materials that are available in the local market to find a proper substitute for natural aggregate while eliminating the transportation pollution and expenses [19,20]. For example, recycled concrete aggregate [21,22,23,24,25,26,27], recycled tires [28,29,30,31,32], post-consumer glass [33,34,35,36], recycled plastic [37,38,39], and steel by-product aggregate have been suggested a replacement for fine or coarse aggregate [40,41,42,43,44,45,46,47]. Steel slag aggregate, a by-product of the steel manufacturing process, is another possibility. Reports indicate that over 400 million tons of steel slag by-products were produced worldwide according to the World Steel Association [48]. Steel slag is usually available in two forms: the fine granulated form like water -cooled slag (WCS), and the coarse form like air-cooled slag (ACS) after being crushed and screened [49,50,51,52,53,54,55,56,57]. Several studies investigated the possibility of using WCS and ACS to replace natural aggregate (sand and crushed dolomite). The studies showed that using the steel slag aggregate in concrete mainly enhance the physical and mechanical properties of concrete [58,59,60,61,62,63,64,65,66,67].

Air-cooled slag (ACS), or blast furnace slag (BFS), is produced when raw steel materials (iron pellets or iron ore, coke and a flux) are melted together in a blast furnace. After the fusion process is finished, the lime in the flux combines chemically with the silicates and aluminates of the ore, and coke ash produces a non-metallic product named blast furnace slag. Then, blast furnace slag is cooled slowly by ambient air. In contrast, water-cooled slag (WCS), or ground granulated blast furnace slag (GGBFS), is sand-type slag produced by applying high-pressure water jets on a molten blast-furnace slag [67,68,69].

Numerous researchers study the effect of replacing the natural coarse aggregates with ACS aggregates. There was not a specific replacement ratio, as the optimum percentage varied among studies. K. Thangaselvi [68] and Vasanthi1 [67] found that steel slag aggregate could replace up to 60% by-weight of the natural aggregate. Hiraskar et al. [51] stated that the replacement ratio is 50% from the total weight of aggregates. In contrast, Devi et al. [69] reported that the optimum replacing ratio is 30% of the weight of the aggregate, while for fine aggregate replacement, Y. Guo et al. [64] stated that the optimum replacement ratio of sand by WCS was 20% of the total weight of fine aggregate. However, other researchers reported that the optimum replacement ratio of sand was 30% and 40%, depending on the type and the finesses of the slag used [55,69]. Generally, the results indicated that increasing the replacement percentage to a certain limit positively affected the compressive strength and increased the workability of the mixes to certain limit.

Few researchers studied the effect of using both WCS and ACS combined in concrete instead of natural sand and dolomite as a fine and coarse aggregate replacement, and the results showed the possibility of partial or full replacement of natural aggregates by steel slag aggregates with comparable features to traditional concrete [40,41,42,66].

Many researchers discussed the impact of using slag as a partial or total replacement for natural aggregate, and the results were not in agreement. In contrast, in this study, the effect of using slag as a fine and coarse aggregate was investigated individually. In addition, a combination of two types of aggregates was also studied. Sixteen concrete mixes were casted to study the effect of replacement on the consistency through a slump test, and on the mechanical properties by testing the compressive and tensile strength of concrete. The cement content and water-to-cement ratio were the same for all the mixes, while those for the replacing aggregate ratios were different percentages: 50, 75, and 100% from the total weight of the aggregates.

2. Materials and Methods

2.1. Material

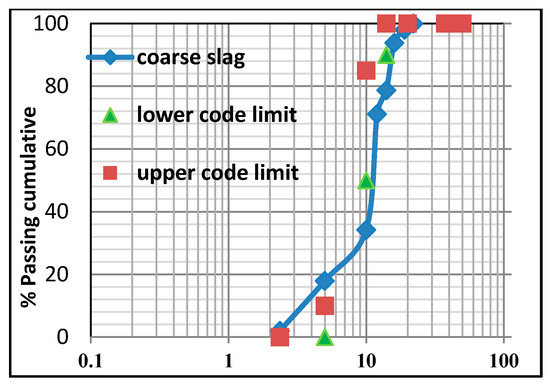

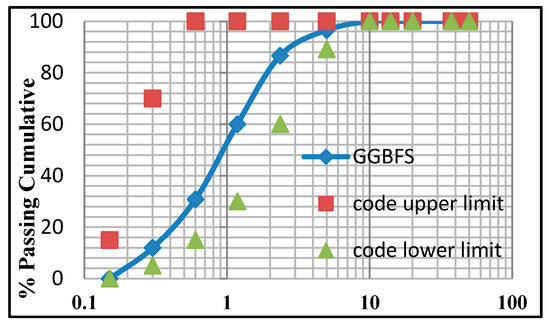

Ordinary Portland cement (CEM I) was used in this study, achieving ASTM C150 [70] requirements. The chemical components of Portland cement are listed in Table 1. Local, natural, siliceous and clean sand with a particles size smaller than 5 mm, complying with ASTM C33 [71], was used as a fine aggregate. Clean crushed dolomite with a maximum size of 12 mm was used as a coarse aggregate. Table 2 shows the properties of the natural aggregate used in the control mix. Air-cooled slag (ACS), Figure 1, and water-cooled slag (WCS), Figure 2, were obtained from Iron and Steel Company, Helwan, Egypt. Figure 3 and Figure 4 show the sieve analysis for ACS and WCS, respectively, according to the Egyptian code ES 1109/2002. The superplasticizer used was naphthalene sulfonate with a synthetic polymer, which allowed for the mixing water condensate to be de-foamed; admixture (Adicrete PVF) was used with a fixed percentage of 1.6% in relation to the cement weight.

Table 1.

Chemical composition of cement and slag.

Table 2.

Physical properties of natural and steel slag aggregates.

Figure 1.

Air-cooled slag aggregate (ACS).

Figure 2.

Water-cooled slag aggregate (WCS).

Figure 3.

Air-cooled slag (ACS) sieve analysis.

Figure 4.

Water-cooled slag (WCS) sieve analysis.

2.2. Mix Design, Preparation of Samples, and Curing

The absolute volume method was used to calculate the mix design. The cement content and the water-to-cement ratio remained constant for all mixes with 390 kg/m3 and 0.45, respectively. In this study, 6 cubes of 10 × 10 × 10 cm were casted for each mix to measure the compressive strength, while 4 cylinders with a height of 30 cm and a diameter of 20 cm were casted to measure the tensile strength of the concrete mixes. The mixtures were prepared with different replacement percentages of slag aggregate of 50%, 75% and 100% by weight of coarse and fine aggregate in the mix. The mixtures’ constituents are represented in Table 3.

Table 3.

Mixtures constituents (kg/m3).

All mixtures were prepared by mixing the coarse aggregates, fine aggregates and cement in dry conditions for 2 min in a concrete drum mixer. Then, the superplasticizer with water was added to the mix and mixing continued for another 2 min. The specimens were demolded after one day and cured in water at room temperature until the day of the test.

2.3. Testing

The slump test was used to measure the consistency of the mixes according to ASTM C143 [72]. While the compressive strength test was measure after 7 and 28 days of casting in accordance with ASTM C39 [73], the tensile strength test was tested only after 28 days in accordance with ASTM C496 [74].

3. Results and Discussion

3.1. Consistency

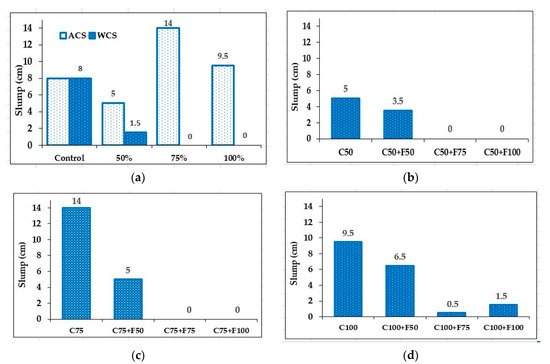

The slump test was carried out to measure the effect of using ACS and WCS on the consistency of concrete. Generally, using ACS as a coarse aggregate in concrete improves the workability. However, using WCS as a fine aggregate had a negative effect on the workability, as shown in Figure 5a, while replacing the coarse aggregate with ACS with a constant ratio, and increasing the percentages of WCS with ratios from 50% to 100% showed the same behavior of reducing the workability of concrete, as shown in Figure 5b–d. Generally, the reduction in the workability due to the addition of WCS to concrete was due to increasing the surface area of the aggregate, resulting in higher water absorption and water demand than that of using natural aggregate as a fine aggregate, and typically the mix became stiffer. These results agree with the results reported by Nataraja et al. [57].

Figure 5.

Consistency results of concrete mixes; (a) using WCS and ACS only, (b) using ACS at 50% with different WCS percentages (50, 75, and 100%), (c) using ACS at 75% with different WCS percentages (50, 75, and 100%), and (d) using ACS at 100% with different WCS percentage (50, 75, and 100%).

As shown in Figure 5a, increasing the content of WCS results in a reduced consistency of the concrete mixes; this can be attributed to the highly specific surface area of WCS, which increases the high water demand of the aggregate. In contrast, the value of consistency was improved at 75% ACS. This can be attributed to that the high angularity, porosity of ACS and the rougher surface texture than that of the natural aggregate, which improves the workability of concrete at a certain value. Following this, the value reduced at 100% replacement due to the high volume of slag aggregate, which increased the high water demand of the concrete mixes [75].

3.2. Compressive Strength

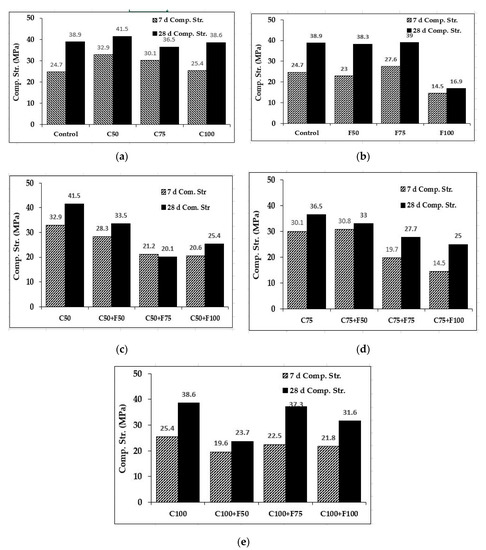

Figure 6 shows the effect of using WCS and ACS aggregate individually and combined with different replacing ratios on the compressive strength of concrete. The results show that using ACS as a partial or total replacement to natural coarse aggregate has the same behavior on concrete as using natural aggregate, as shown in Figure 6a. This can be attributed to the angularity and the high surface roughness that improve the cohesion between ACS and the mortar, resulting in a better bond between them in regard to the higher porosity of ACS. This lowers the free water content in the mix, subsequently resulting in improved strength of the concrete. However, using WCS as a partial or total replacement for fine natural aggregate results in lowering the strength of the concrete due to the highly specific surface area of WCS that absorbs more free water, thus decreasing the water content needed for the hydration of cement and resulting in lowering of the strength, as can be observed clearly in Figure 5b. On the other hand, when replacing 50% of WCS with the natural fine aggregate, the compressive strength did not change; this can be explained by the fact that at lower ratios, the WCS acts as a filler between the micro voids of the cement matrix and thus improves the strength. The same trend was obtained by adding WCS with different percentages to the ACS aggregate, as the compressive strength was reduced due to the lowering of the free water for hydration of cement. This was clearly observed in the consistency test, which has a negative effect on the compaction of the concrete on the molds, as shown in Figure 6c–e. These results agree with the results obtained by different authors [45,50,58,76]. Table 4 shows the standard deviation and the coefficient of variation of the results.

Figure 6.

Seven- and twenty-eight-day compressive strength of mixes; (a) using ACS only, (b) using WCS only, (c) using ACS at 50% with different WCS percentages (50, 75, 100%), (d) using ACS at 75% with different WCS percentages (50, 75, 100%), and (e) using ACS at 100% with different WCS percentages (50, 75, 100%).

Table 4.

Standard deviation and coefficient of variation for concrete mixes.

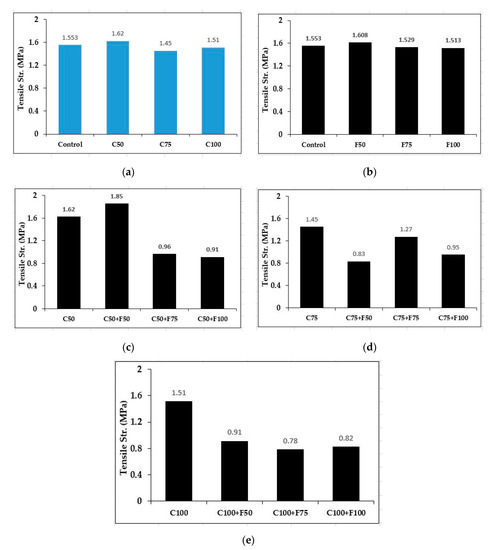

3.3. Tensile Strength

The tensile strength results follow the same trend previously found in the compressive strength results, as shown in Figure 7. The optimum replacement ratio obtained was at 50% of WCS and 50% of ACS of the natural aggregate use, where WCS acts as a micro filler and reduces the voids, thus improving the strength, while ACS, with its angularity and rough surface, improves the bond between the aggregate and the cement matrix, resulting in improved mechanical properties of the mix compared to the control mix.

Figure 7.

Tensile strength of mixes; (a) using ACS only, (b) using WCS only, (c) using ACS at 50% with different WCS percentages (50, 75, 100%), (d) using ACS at 75% with different WCS percentages (50, 75, 100%), and (e) using ACS at 100% with different WCS percentages (50, 75, 100%).

4. Conclusions

In this the current research, the effect of replacement of both natural sand and dolomite by water-cooled slag and air-cooled slag (50, 75, and 100% wt.) was studied on the fresh and the hardened properties of concrete, and the following conclusions were made:

- Increasing the replacement of fine aggregate by water-cooled slag (0–100%) significantly decreases the workability of concrete. Increasing the replacement of coarse aggregate by air-cooled slag (0–100%) increases the workability of concrete.

- Replacement of fine aggregate with water-cooled slag up to 50% has no influence on the compressive strength, as the same compressive strength for both mixes is obtained. Meanwhile, increasing the replacement up to 100% leads to a significant decrease in compressive strength by 56% than that of the control mix.

- Replacement of coarse aggregate with slag aggregate up to 50% increases the compressive strength by 6%, while increasing the replacement over 50% slightly decreases the compressive strength. This means that the replacement of coarse aggregate alone has trivial influence on compressive strength.

- The replacement of natural aggregate has an insignificant effect on the tensile strength of mixes.

Author Contributions

Methodology, M.S.E.-F. and M.K.; Investigation, R.B.; Writing-Original Draft Preparation and writing (original draft), A.M.E.-T.; Writing-Review & Editing, S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Djamil, B. Concrete as a Suitable Construction Material. Key Eng. Mater. 2017, 744, 196–200. [Google Scholar]

- Ravindrarajah, R.S. Concrete for sustainable construction. In Proceedings of the 3rd Asian conference on ecstasy in concrete (ACECON 2010), Chennai, India, 5–9 December 2010; pp. 135–153. [Google Scholar]

- Pacheco-Torgal, F.; Labrincha, J.A. The future of construction materials research and the seventh UN Millennium development goal: A few insights. Constr. Build. Mater. 2013, 40, 729–737. [Google Scholar] [CrossRef]

- Kang, M.; Weibin, L. Effect of the aggregate size on strength properties of recycled aggregate concrete. Adv. Mater. Sci. Eng. 2018. [Google Scholar] [CrossRef]

- Arslan, B.; Kamas, T. Investigation of aggregate size effects on the compressive behavior of concrete by electromechanical and mechanical impedance spectroscopy. Procedia Struct. Integr. 2017, 5, 171–178. [Google Scholar] [CrossRef]

- Musa, M.F.; Saim, A.A.B. The effect of aggregate size on the strength of concrete. Colloquium 2017, 10, 9–11. [Google Scholar]

- Torres, A.; Brandt, J.; Lear, K.; Liu, J. A looming tragedy of the sand commons. Science 2017, 6355, 970–971. [Google Scholar] [CrossRef]

- Soderholm, P. Taxing virgin natural resources: Lessons from aggregates taxation in Europe. Resour. Conserv. Recycl. 2011, 55, 911–922. [Google Scholar] [CrossRef]

- Kylili, A.; Fokaides, P.A. Policy trends for the sustainability assessment of construction materials: A review. Sustain. Cities Soc. 2017, 35, 280–288. [Google Scholar] [CrossRef]

- Prusty, J.K.; Patro, S.K.; Basarkar, S.S. Concrete using agro-waste as fine aggregate for sustainable built environment-A review. Int. J. Sustain. Built Environ. 2016, 5, 312–333. [Google Scholar] [CrossRef]

- Wahab, A.M.; Latif, I.A.; Kohail, M.; Almasry, A. The use of wallastonite to enhance the mechanical properties of mortar mixes. Constr. Build. Mater. 2017, 152, 304–309. [Google Scholar] [CrossRef]

- Yehia, S.; Helal, K.; Abusharkh, A.; Zaher, A.; Istaitiyeh, H. Strength and durability evaluation of recycled aggregate concrete. Int. J. Concr. Struct. Mater. 2015, 9, 219–239. [Google Scholar] [CrossRef]

- Sikora, P.; Rucinska, T.; Stephan, D.; Chung, S.Y.; Elrahman, M.A. Evaluating the effects of nano-silica on the material properties of lightweight and ultra-light weight concrete using image-based approaches. Constr. Build. Mater. 2020, 264, 120241. [Google Scholar] [CrossRef]

- Elrahman, M.A.; ElMadawy, M.E.; Chung, S.Y.; Shikora, P.; Stephan, D. Preparation and characterization of ultra-light weight foamed concrete incorporating lightweight aggregates. Appl. Sci. 2016, 9, 1447. [Google Scholar] [CrossRef]

- VanGeem, M.G.; Marceau, M.L. Using concrete to increase LEED ratings of building. Archit. Eng. Conf. (AEI) 2003. [Google Scholar] [CrossRef]

- VanGeem, G.M.; Marceau, M.L. Using Concrete to Maximize LEED™ Points. Concr. Int. 2002, 24, 69–73. [Google Scholar]

- Batayneh, M.; Marie, I.; Asi, I. Use of selected waste materials in concrete mixes. Waste Manag. 2007, 27, 1870–1876. [Google Scholar] [CrossRef] [PubMed]

- Veirian, K.P.; Whiting, N.M.; Olek, J.; Jain, J.; Snyder, M.B. Using Recycled Concrete as Aggregate in Concrete Pavements to Reduce Materials Cost; Joint Transportation Research Program; Indiana Department of Transportation and Purdue University: West Lafayette, IN, USA, 2013. [Google Scholar]

- Shan, X.; Zhou, J.; Chang, V.W.C.; Yang, E.H. Life cycle assessment of adoption of local recycled aggregates and green concrete in Singapore perspective. J. Clean. Prod. 2017, 164, 918–926. [Google Scholar] [CrossRef]

- Marinković, S.B.; Ignjatović, I.; Radonjanin, V. Life-cycle Assessment (LCA) of Concrete with Recycled Aggregates (RAs). In Handbook of Recycled Concrete and Demolition Waste; Woodhead Publishing: Cambridge, UK, 2013; pp. 569–604. [Google Scholar]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Hansen, T.C. Recycling of Demolished Concrete and Masonry; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Nováková, I.; Mikulica, K. Properties of concrete with partial replacement of natural aggregate by recycled concrete aggregates from precast production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- Marinković, S.; Carević, V. Comparative Studies of the Life Cycle Analysis between Conventional and Recycled Aggregate Concrete, in New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; pp. 257–291. [Google Scholar]

- Sarhat, S. An Experimental Investigation on the Viability of Using Fine Concrete Recycled Aggregate in Concrete Production. In Proceedings of the International Conference on Sustainable Construction Materials and Technologies, Coventry, UK, 11–13 June 2007. [Google Scholar]

- Berndt, M. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Aly, A.M.; El-Feky, M.S.; Kohail, M.; Nasr, E.S.A. A Performance of geopolymer concrete containing recycled rubber. Constr. Build. Mater. 2019, 207, 136–144. [Google Scholar] [CrossRef]

- Abdelmonem, A.; El-Feky, M.S.; Nasr, S.E.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660. [Google Scholar] [CrossRef]

- Sofi, A. Effect of waste tire rubber on mechanical and durability properties of concrete—A review. AIN Shams Eng. J. 2017, 9, 2691–2700. [Google Scholar] [CrossRef]

- Rashid, K.; Yazdanbakhsh, A.; Rehman, M.U. Sustainable selection of the concrete incorporating recycled tire aggregate to be used as medium to low strength material. J. Clean. Prod. 2019, 224, 396–410. [Google Scholar] [CrossRef]

- Gerges, N.N.; Issa, C.A.; Fawaz, S.A. Rubber concrete: Mechanical and dynamical properties. Case Stud. Constr. Mater. 2018, 9, e00184. [Google Scholar] [CrossRef]

- Park, S.B.; Lee, B.C.; Kim, J.H. Studies on mechanical properties of concrete containing waste glass aggregate. Cem. Concr. Res. 2004, 34, 2181–2189. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S. Properties of self-compacting concrete prepared with recycled glass aggregate. Cem. Concr. Compos. 2009, 31, 107–113. [Google Scholar] [CrossRef]

- Jin, W.; Meyer, C.; Baxter, S. Glascrete-Concrete with Glass Aggregate. Aci Mater. J. 2000, 97, 208–213. [Google Scholar]

- Olofinnade, O.M.; Ndambuki, J.; Ede, A.; Olukanni, D.O. Effect of substitution of crushed waste glass as partial replacement for natural fine and coarse aggregate in concrete. Mater. Sci. Forum 2016, 866, 58–62. [Google Scholar] [CrossRef]

- Balkum, E.T. Aggregate Using Recycled Plastics. Google Patents No. 6,488,766, 3 December 2002. [Google Scholar]

- Siddique, R.; Khatib, J.; Kaur, I. Use of recycled plastic in concrete: A review. Waste Manag. 2008, 28, 1835–1852. [Google Scholar] [CrossRef] [PubMed]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef] [PubMed]

- Chunlin, L.; Kunpeng, Z.; Depeng, C. Possibility of concrete prepared with steel slag as fine and coarse aggregates: A preliminary study. Procedia Eng. 2011, 24, 412–416. [Google Scholar] [CrossRef]

- Nadeem, M.; Pofale, A.D. Utilization of industrial waste slag as aggregate in concrete applications by adopting Taguchi’s approach for optimization. Open J. Civ. Eng. 2012, 2, 10. [Google Scholar] [CrossRef]

- Ríos, J.D.; de Medina, A.V.S.; de la Conche, A.M.; Cifuentes, H.; Leiva, C. Analysis of the Utilization of Air-Cooled Blast Furnace Slag as Industrial Waste Aggregates in Self-Compacting Concrete. Sustainability 2019, 11, 1072. [Google Scholar] [CrossRef]

- Krishnasami, R.; Malathy, R. Significance of blast furnace slag as coarse aggregate in self-compacting concrete. Appl. Mech. Mater. 2013, 357, 829–833. [Google Scholar] [CrossRef]

- Chinnaraj, D.K. Study on concrete using steel slag as coarse aggregate replacement and eco sand as fine aggregate replacement. IJREAT Int. J. Res. Eng. Adv. Technol. 2013, 1, 65–69. [Google Scholar]

- Abu-Eishah, S.I.; El-Dieb, A.S.; Bedir, M.S. Performance of concrete mixtures made with electric arc furnace (EAF) steel slag aggregate produced in the Arabian Gulf region. Constr. Build. Mater. 2012, 34, 249–256. [Google Scholar] [CrossRef]

- Netinger, I.; Bjegović, D.; Vrhovac, G. Utilisation of steel slag as an aggregate in concrete. Mater. Struct. 2011, 44, 1565–1575. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Sharif, A.; Shameem, M.; Mohammed, I.; Barry, M.S. Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr. Build. Mater. 2003, 17, 105–112. [Google Scholar] [CrossRef]

- World Steel Association. Steel Facts. A Collection of Amazing Facts about Steel. World Steel 2018. Available online: https://www.worldsteel.org/en/dam/jcr:1b916a6d-06fd-4e84-b35d-c1d911d18df4/Fact_By-products_2018.pdf (accessed on 24 August 2020).

- Singh, V. High Performance Concrete Using Blast Furnace Slag as Coarse Aggregate. Recent Adv. Energy Environ. Mater. 2014, 90, 94. [Google Scholar]

- Pang, B.; Zhou, Z.; Xu, H. Utilization of carbonated and granulated steel slag aggregate in concrete. Constr. Build. Mater. 2015, 84, 454–467. [Google Scholar] [CrossRef]

- Hiraskar, K.; Patil, C. Use of blast furnace slag aggregate in concrete. Int. J. Sci. Eng. Res. 2013, 4, 95–98. [Google Scholar]

- Netinger, I.; Rukavina, M.J.; Bjegovic, D.; Mladenovic, A. Concrete containing steel slag aggregate: Performance after high temperature exposure. Concr. Repair Rehabil. Retrofit. III 2012, 3, 1347–1352. [Google Scholar]

- Yüksel, I. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Faleschini, F.; Fernandez-Ruiz, M.A.; Zanini, M.A.; Brunelli, K.; Pellefrino, C.; Hernandez-Montes, E. High performance concrete with electric arc furnace slag as aggregate: Mechanical and durability properties. Constr. Build. Mater. 2015, 101, 113–121. [Google Scholar] [CrossRef]

- Kothai, P.; Malathy, R. Utilization of steel slag in concrete as a partial replacement material for fine aggregates. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 11585–11592. [Google Scholar]

- el Nouhy, H.A. Effect of High Temperature on Properties of Bricks Using Granulated Blast-furnace Slag as Aggregate Replacement. Key Eng. Mater. 2014, 600, 227–239. [Google Scholar] [CrossRef]

- Nataraja, M.; Kumar, P.; Manu, A.S.; Sanjay, M.C. Use of granulated blast furnace slag as fine aggregate in cement mortar. Int. J. Struct. Civ. Eng. Res. 2013, 2, 60–68. [Google Scholar]

- Yuji, W. The effect of bond characteristics between steel slag fine aggregate and cement paste on mechanical properties of concrete and mortar. MRS Online Proc. Libr. Arch. 1987, 113, 301–306. [Google Scholar] [CrossRef]

- Saikia, N.; Cornelis, G.; Cizer, O.; Vandecasteele, C.; van Gemert, D.A.; van Balen, K.; van Gerven, T. Use of Pb blast furnace slag as a partial substitute for fine aggregate in cement mortar. J. Mater. Cycles Waste Manag. 2012, 14, 102–112. [Google Scholar] [CrossRef]

- Khan, R.; Shinde, S. Effect of Unprocessed Steel slag on Shear Strength of Concrete when used as Fine Aggregate. Int. J. It Eng. Appl. Sci. Res. (IJIEASR) 2013, 2, 51–53. [Google Scholar]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace stag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Václavík, V.; Dvorsky, T.; Simicek, V.; Ondova, M.; Valicek, J.; Kusnerova, M.; Gola, L. Steel slag as a substitute for natural aggregate in the production of concrete. Solid State Phenom. 2016, 244, 77–87. [Google Scholar] [CrossRef]

- Han, Y.; Jung, H.; Seong, S. A Fundamental Study on the Steel Slag Aggregate for Concrete. Geosystem Eng. 2002, 5, 38–45. [Google Scholar]

- Guo, Y.; Xie, J.; Zheng, W.; Li, J. Effects of steel slag as fine aggregate on static and impact behaviours of concrete. Constr. Build. Mater. 2018, 192, 194–201. [Google Scholar] [CrossRef]

- Guo, Y.; Xie, J.; Zhao, J.; Zuo, K. Utilization of unprocessed steel slag as fine aggregate in normal-and high-strength concrete. Constr. Build. Mater. 2019, 204, 41–49. [Google Scholar] [CrossRef]

- Tarawneh, S.A.; Gharaibeh, E.S.; Saraireh, F.M. Effect of using steel slag aggregate on mechanical properties of concrete. Am. J. Appl. Sci. 2014, 11, 700. [Google Scholar] [CrossRef]

- Vasanthi, P. Flexural behavior of reinforced concrete slabs using steel slag as coarse aggregate replacement. IJRET Int. J. Res. Eng. Technol. 2014, 3, 141–146. [Google Scholar]

- Thangaselvi, K. Strength and Durability of Concrete Using Steel Slag as a Partial Replacement of Coarse Aggregate in Concrete. Int. J. Adv. Res. Trends Eng. Technol. 2015, 2, 1–6. [Google Scholar]

- Devi, V.S.; Gnanavel, B. Properties of concrete manufactured using steel slag. Procedia Eng. 2014, 97, 95–104. [Google Scholar] [CrossRef]

- ASTM. C150/C150M-19a, Standard Specification for Portland Cement ASTM International; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. C33, Standard Specification for Concrete Aggregate; American Society for Testing and Materials: West Conshohocken, PA, USA, 2004. [Google Scholar]

- ASTM. C143/C143M, Standard Test Method for Slump of Hydraulic-Cement Concrete; American Society for Testing and Materials: West Conshohocken, PA, USA, 2005. [Google Scholar]

- ASTM. C39/C39M-20, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM. C496/C496M-17, Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens; American Society for Testing and Materials: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Tyson, S.; Tayabji, S.D. Use of Air-Cooled Blast Furnace Slag as Coarse Aggregate in Concrete Pavements; Final Report, No. FHWA-HIF-12–008; USA Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2012. [Google Scholar]

- Qasrawi, H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment. Constr. Build. Mater. 2014, 54, 298–304. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).