Assessing the Effect of Fe3O4 Nanoparticles on the Thermomechanical Performance of Different Forms of Carbon Allotropes/Epoxy Hybrid Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

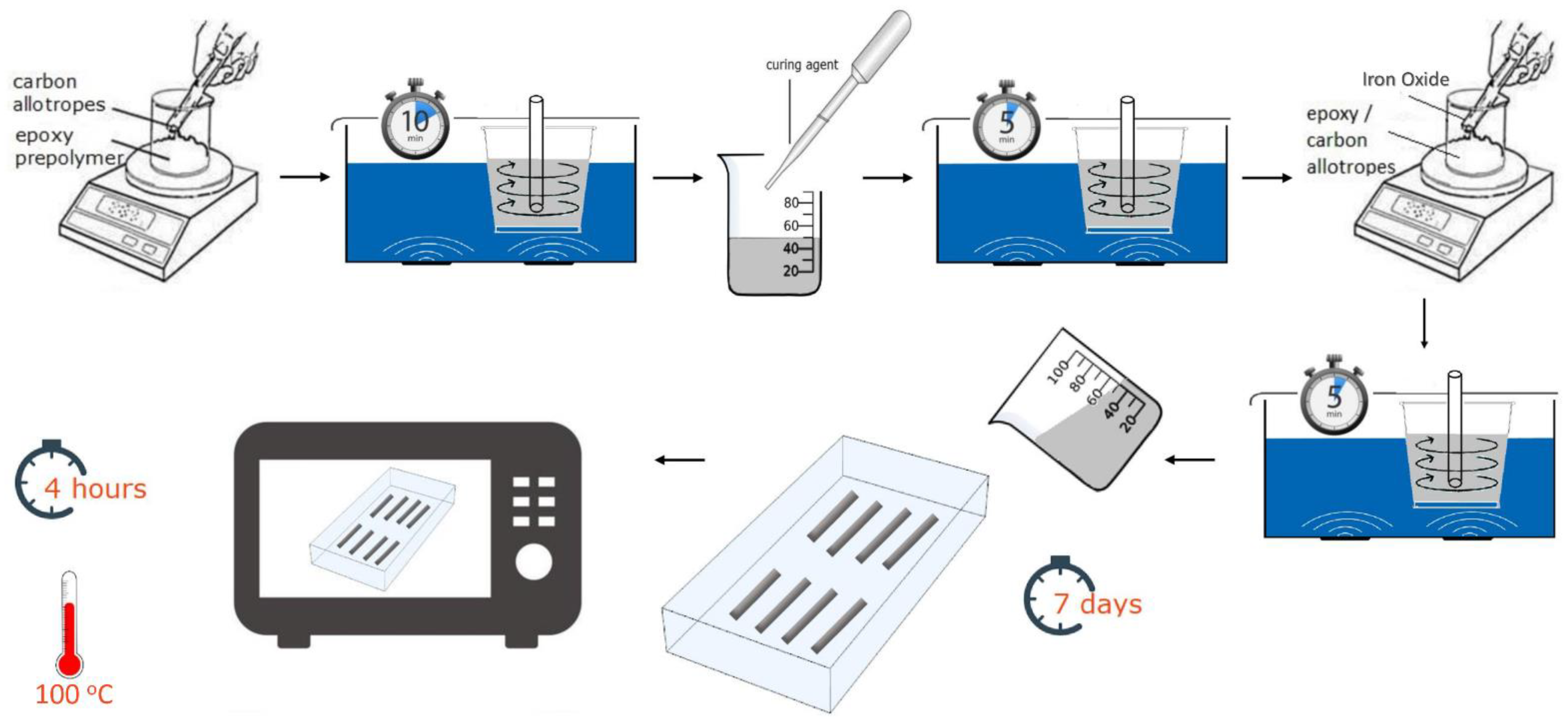

2.2. Fabrication Procedure

2.3. Characterization Techniques

3. Results and Discussion

3.1. Morphology

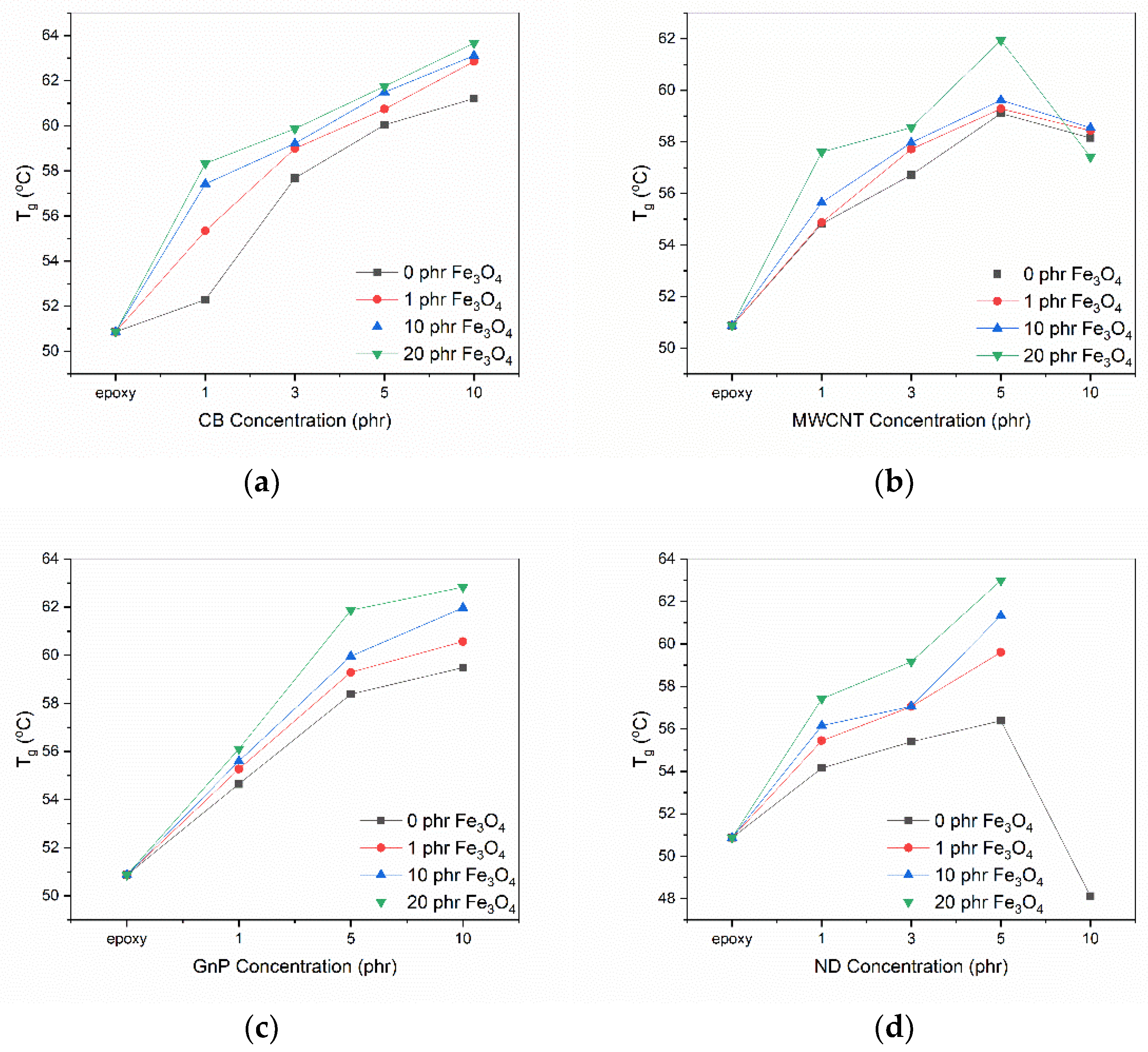

3.2. Differential Scanning Calorimetry

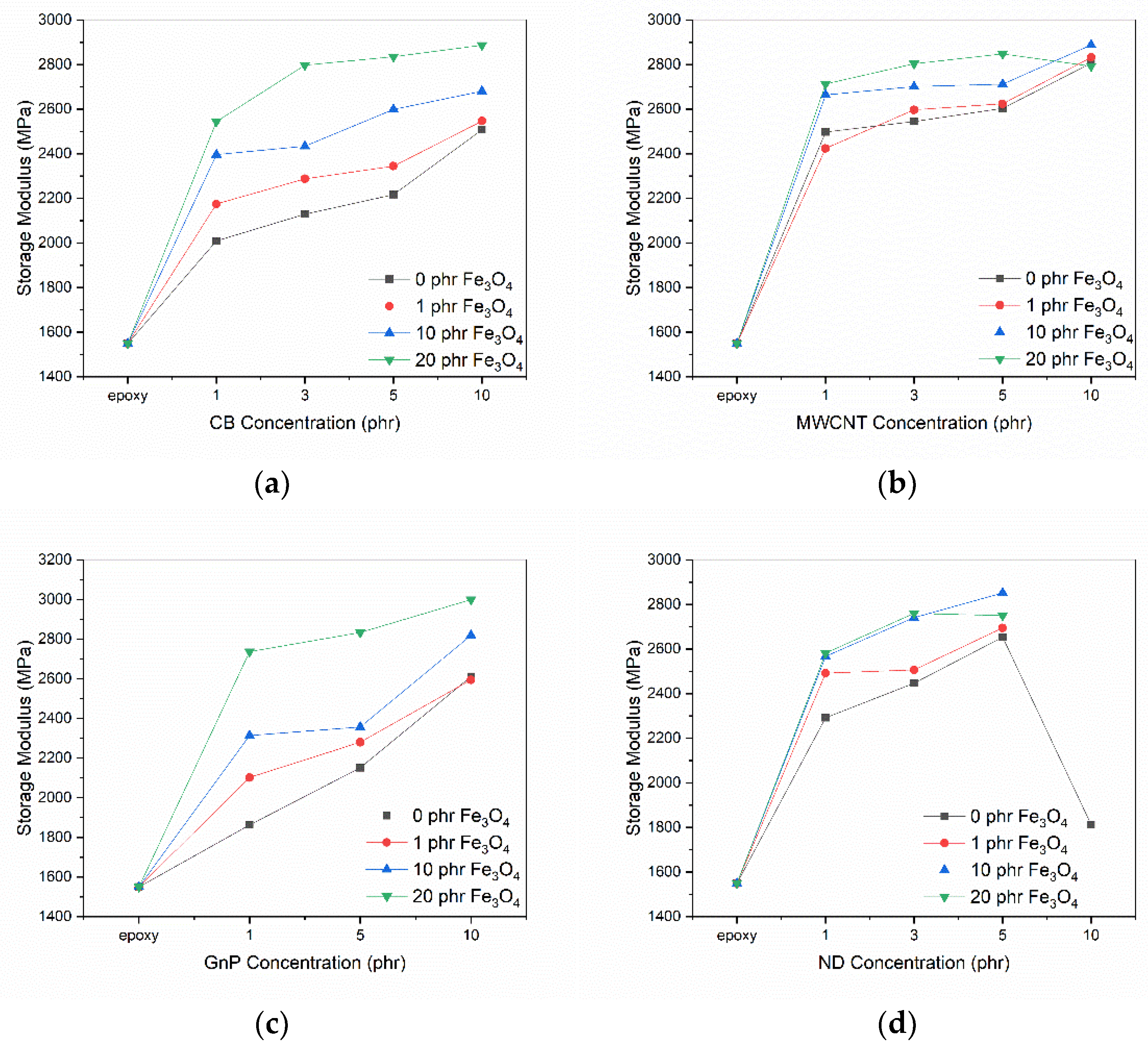

3.3. Dynamic Mechanical Analysis

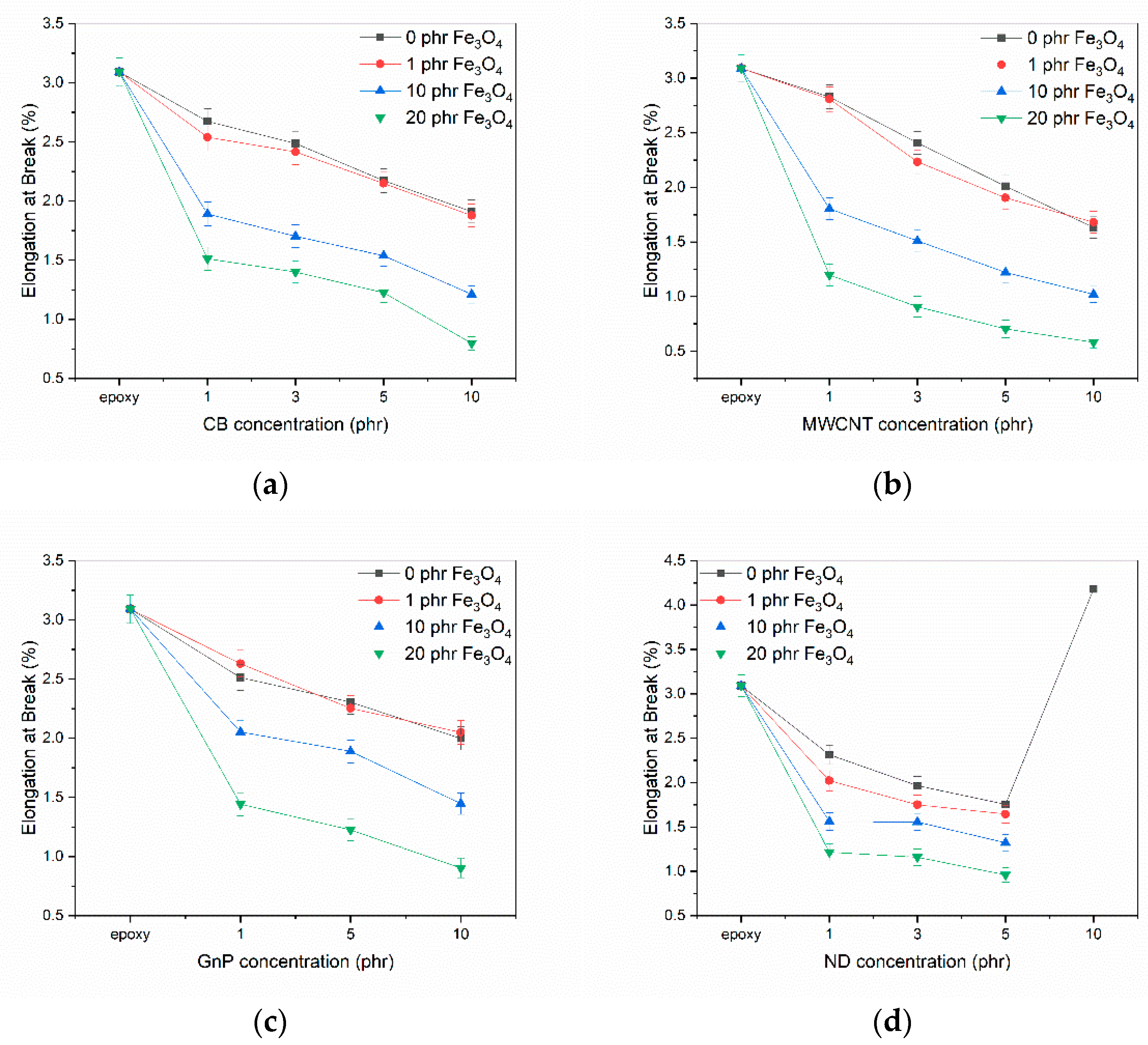

3.4. Static Tensile Tests

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gu, H.; Ma, C.; Gu, J.; Guo, J.; Yan, X.; Huang, J.; Zhang, Q.; Guo, Z. An overview of multifunctional epoxy nanocomposites. J. Mater. Chem. C 2016, 4, 5890–5906. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M. A review on thermomechanical properties of polymers and fibers reinforced polymer composites. J. Ind. Eng. Chem. 2018, 47, 5475–5478. [Google Scholar] [CrossRef]

- Hanemann, T.; Szabó, D.V. Polymer-Nanoparticle Composites: From Synthesis to Modern Applications. Materials 2010, 3, 3468–3517. [Google Scholar] [CrossRef]

- Sanida, A.; Stavropoulos, S.G.; Speliotis, T.; Psarras, G.C. Evaluating the multifunctional performance of polymer matrix nanodielectrics incorporating magnetic nanoparticles: A comparative study. Polymer 2021, 236, 124311. [Google Scholar] [CrossRef]

- Sanida, A.; Stavropoulos, S.G.; Speliotis, T.; Psarras, G.C. Probing the magnetoelectric response and energy efficiency in Fe3O4/epoxy nanocomposites. Polym. Test 2020, 88, 106560. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Thakur, V.K. Carbon-Based Polymer Nanocomposite for High-Performance Energy Storage Applications. Polymers 2020, 12, 505. [Google Scholar] [CrossRef] [Green Version]

- Martins, P.; Kolen’Ko, Y.V.; Rivas, J.; Lanceros-Mendez, S. Tailored Magnetic and Magnetoelectric Responses of Polymer-Based Composites. ACS Appl. Mater. Interfaces 2015, 7, 15017–15022. [Google Scholar] [CrossRef] [Green Version]

- Stavropoulos, S.G.; Sanida, A.; Psarras, G.C. A comparative study on the electrical properties of different forms of carbon allotropes–epoxy nanocomposites. Express Polym. Lett. 2020, 14, 477–490. [Google Scholar] [CrossRef]

- Gioti, S.; Sanida, A.; Mathioudakis, G.N.; Patsidis, A.C.; Speliotis, T.; Psarras, G.C. Multitasking Performance of Fe3O4/BaTiO3/Epoxy Resin Hybrid Nanocomposites. Materials 2022, 15, 1784. [Google Scholar] [CrossRef]

- Stavropoulos, S.G.; Sanida, A.; Psarras, G.C. Carbon Allotropes/Epoxy Nanocomposites as Capacitive Energy Storage/Harvesting Systems. Appl. Sci. 2021, 11, 7059. [Google Scholar] [CrossRef]

- Balguri, P.K.; Samuel, D.G.H.; Thumu, U. A review on mechanical properties of epoxy nanocomposites. Mater. Today Proc. 2021, 44, 346–355. [Google Scholar] [CrossRef]

- Domun, N.; Hadavinia, H.; Zhang, T.; Sainsbury, T.; Liaghat, G.H.; Vahid, S. Improving the fracture toughness and the strength of epoxy using nanomaterials—A review of the current status. Nanoscale 2015, 7, 10294–10329. [Google Scholar] [CrossRef] [Green Version]

- Frigione, M.; Lettieri, M. Recent Advances and Trends of Nanofilled/Nanostructured Epoxies. Materials 2020, 13, 3415. [Google Scholar] [CrossRef]

- Paipetis, A.; Kostopoulos, V. (Eds.) Carbon Nanotube Enhanced Aerospace Composite Materials; Solid Mechanics and Its Applications; Springer: Dordrecht, The Netherlands, 2013; Volume 188, ISBN 978-94-007-4245-1. [Google Scholar]

- Georgakilas, V.; Perman, J.A.; Tucek, J.; Zboril, R. Broad Family of Carbon Nanoallotropes: Classification, Chemistry, and Applications of Fullerenes, Carbon Dots, Nanotubes, Graphene, Nanodiamonds, and Combined Superstructures. Chem. Rev. 2015, 115, 4744–4822. [Google Scholar] [CrossRef]

- Cha, J.; Jun, G.H.; Park, J.K.; Kim, J.C.; Ryu, H.J.; Hong, S.H. Improvement of modulus, strength and fracture toughness of CNT/Epoxy nanocomposites through the functionalization of carbon nanotubes. Compos. Part B Eng. 2017, 129, 169–179. [Google Scholar] [CrossRef]

- Kausar, A. Nanocarbon and macrocarbonaceous filler–reinforced epoxy/polyamide: A review. J. Thermoplast. Compos. Mater. 2020. [Google Scholar] [CrossRef]

- Wang, X.; Tang, F.; Cao, Q.; Qi, X.; Pearson, M.; Li, M.; Pan, H.; Zhang, Z.; Lin, Z. Comparative Study of Three Carbon Additives: Carbon Nanotubes, Graphene, and Fullerene-C60, for Synthesizing Enhanced Polymer Nanocomposites. Nanomaterials 2020, 10, 838. [Google Scholar] [CrossRef]

- Bychanok, D.; Kuzhir, P.; Maksimenko, S.; Bellucci, S.; Brosseau, C. Characterizing epoxy composites filled with carbonaceous nanoparticles from dc to microwave. J. Appl. Phys. 2013, 113, 124103. [Google Scholar] [CrossRef]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides: Structure, Properties, Reactions, Occurences and Uses; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003; ISBN 3527302743. [Google Scholar]

- Goldman, A. Modern Ferrite Technology, 2nd ed.; Springer: Pittsburgh, PA, USA, 2005; ISBN 9780387294131. [Google Scholar]

- Jian, W.; Lau, D. Understanding the effect of functionalization in CNT-epoxy nanocomposite from molecular level. Compos. Sci. Technol. 2020, 191, 108076. [Google Scholar] [CrossRef]

- Domun, N.; Paton, K.R.; Blackman, B.R.K.; Kaboglu, C.; Vahid, S.; Zhang, T.; Dear, J.P.; Kinloch, A.J.; Hadavinia, H. On the extent of fracture toughness transfer from 1D/2D nanomodified epoxy matrices to glass fibre composites. J. Mater. Sci. 2020, 55, 4717–4733. [Google Scholar] [CrossRef] [Green Version]

- Menczel, J.D.; Prime, R.B. Thermal Analysis of Polymers: Fundamentals and Applications; Menczel, J.D., Prime, R.B., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2009; ISBN 9780471769170. [Google Scholar]

- Abraham, R.; Thomas, S.P.; Kuryan, S.; Isac, J.; Varughese, K.T.; Thomas, S. Mechanical properties of ceramic-polymer nanocomposites. Express Polym. Lett. 2009, 3, 177–189. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stavropoulos, S.G.; Sanida, A.; Psarras, G.C. Assessing the Effect of Fe3O4 Nanoparticles on the Thermomechanical Performance of Different Forms of Carbon Allotropes/Epoxy Hybrid Nanocomposites. Appl. Mech. 2022, 3, 560-572. https://doi.org/10.3390/applmech3020033

Stavropoulos SG, Sanida A, Psarras GC. Assessing the Effect of Fe3O4 Nanoparticles on the Thermomechanical Performance of Different Forms of Carbon Allotropes/Epoxy Hybrid Nanocomposites. Applied Mechanics. 2022; 3(2):560-572. https://doi.org/10.3390/applmech3020033

Chicago/Turabian StyleStavropoulos, Sotirios G., Aikaterini Sanida, and Georgios C. Psarras. 2022. "Assessing the Effect of Fe3O4 Nanoparticles on the Thermomechanical Performance of Different Forms of Carbon Allotropes/Epoxy Hybrid Nanocomposites" Applied Mechanics 3, no. 2: 560-572. https://doi.org/10.3390/applmech3020033

APA StyleStavropoulos, S. G., Sanida, A., & Psarras, G. C. (2022). Assessing the Effect of Fe3O4 Nanoparticles on the Thermomechanical Performance of Different Forms of Carbon Allotropes/Epoxy Hybrid Nanocomposites. Applied Mechanics, 3(2), 560-572. https://doi.org/10.3390/applmech3020033