Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing

Abstract

:1. Introduction

1.1. Additive Manufacturing and Stereolithography

1.2. The Curing Process

Literature Review on Curing Effects for SLA Resins

2. Materials and Methods

2.1. 3D Printer

2.2. SLA Resins

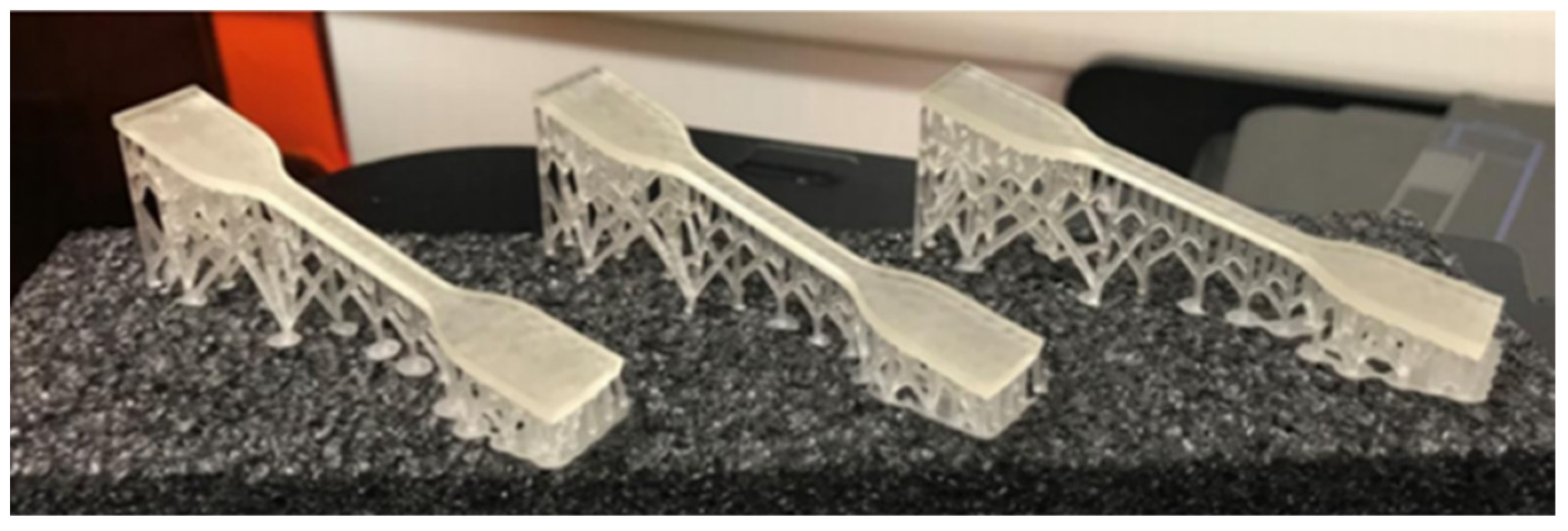

2.3. Test Specimens (Pre- and Post-Curing)

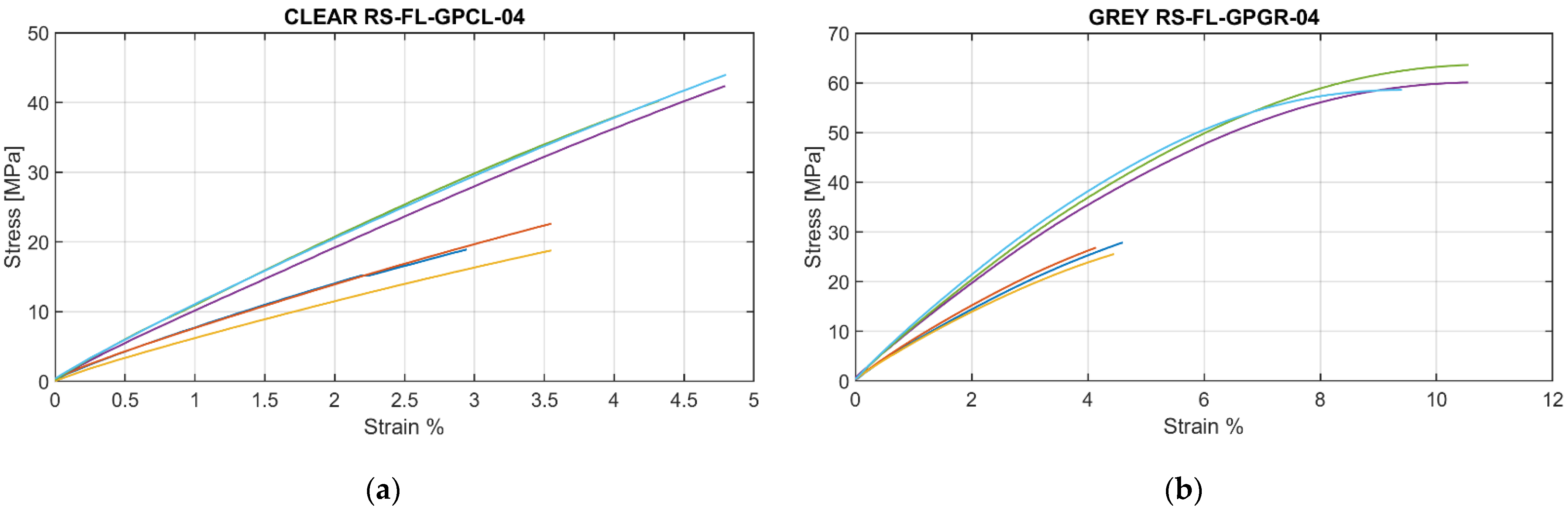

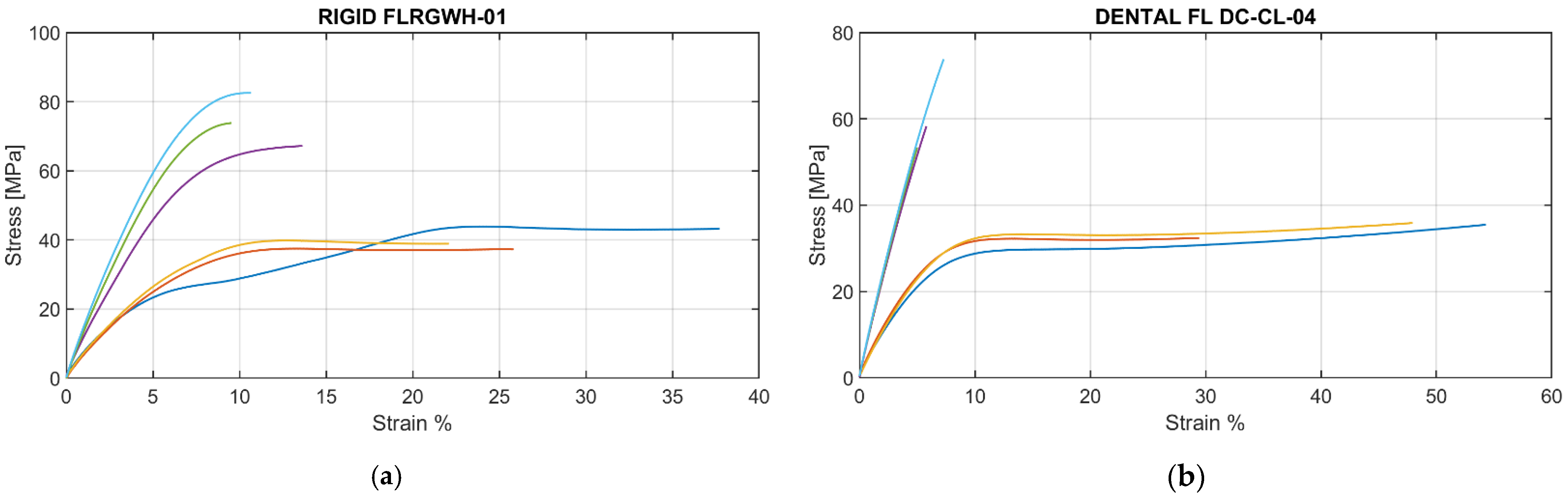

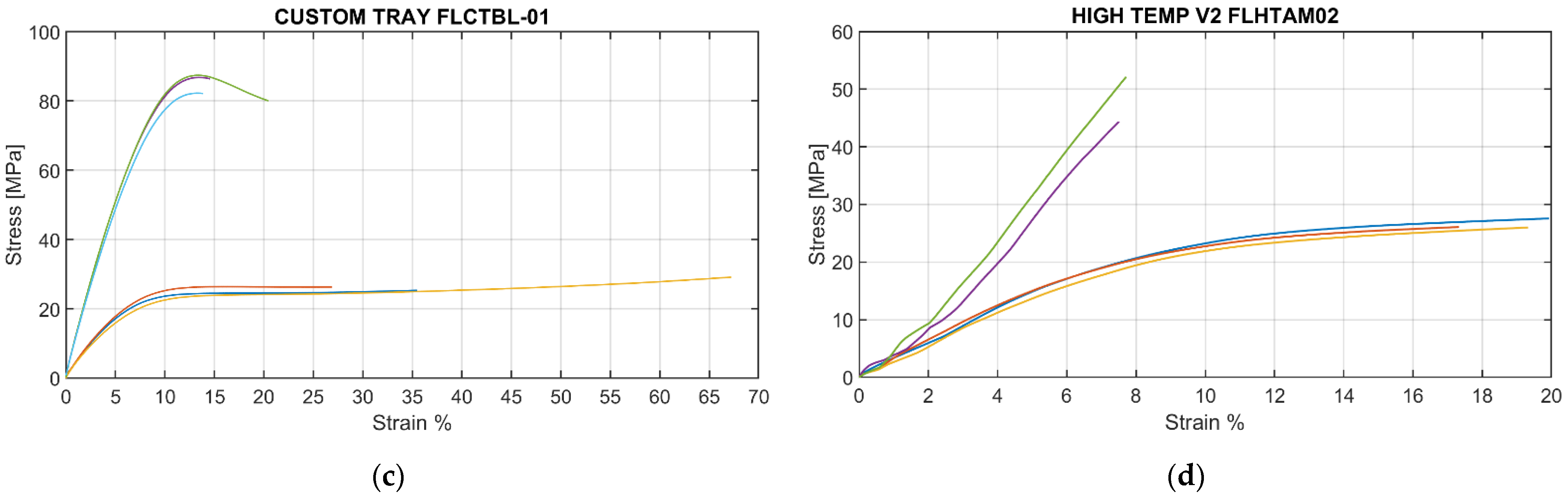

2.4. Uniaxial Tensile Tests

3. Results

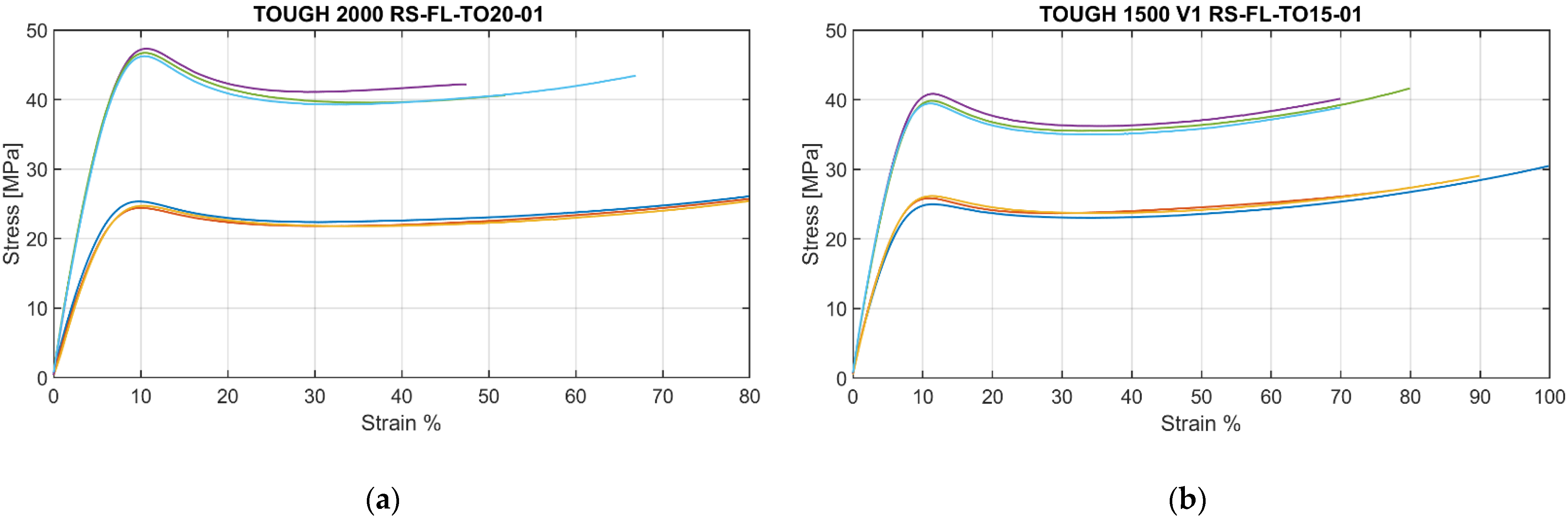

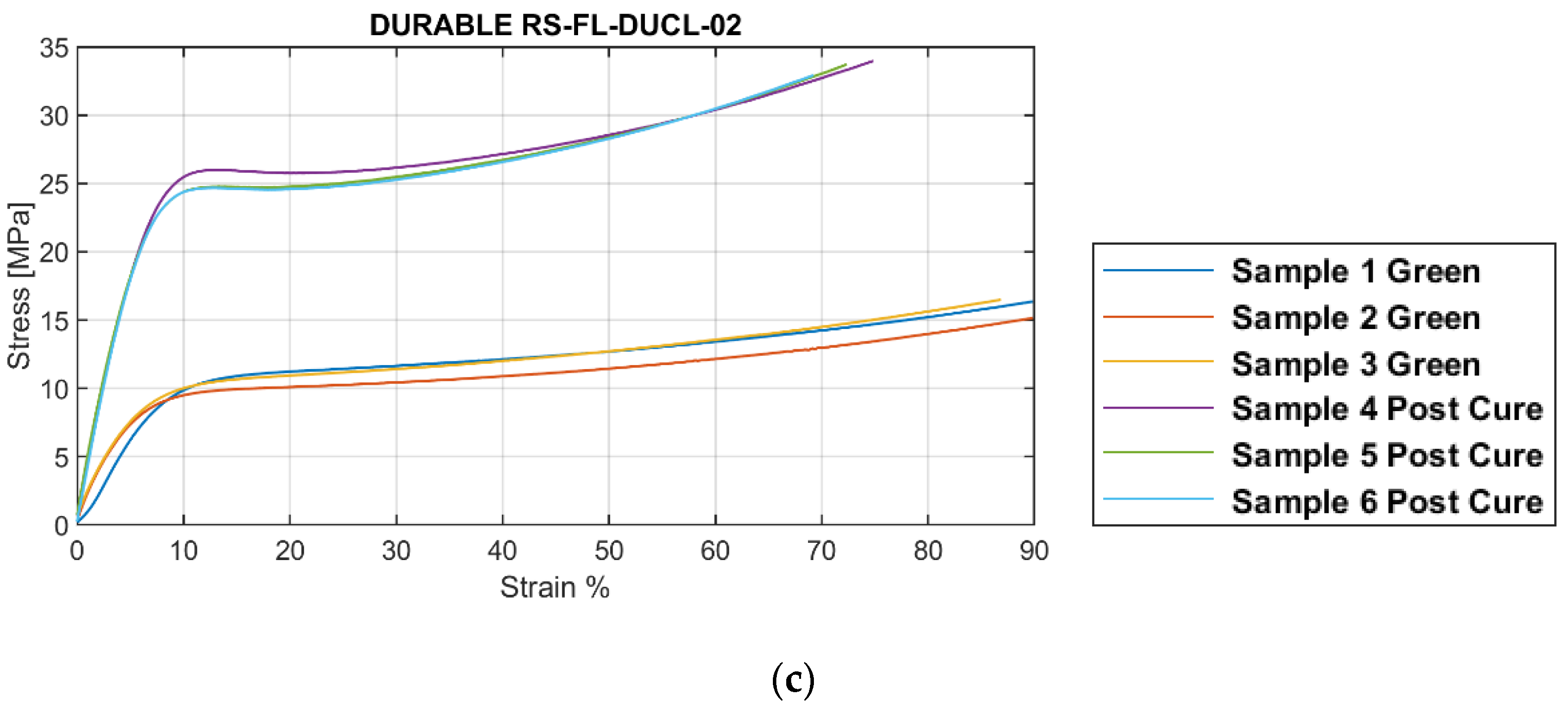

3.1. Load at Break and Young’s Modulus

3.2. Ductility, Resilience, and Toughness

4. Discussion

- The curing process increases the values of Young’s modulus and tensile strength for all resins.

- The process reduces the plasticity of all resins, in some cases causing brittle behaviour.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ziguris, Z. How Mechanical Properties of Stereolithography 3D Prints Are Affected by UV Curing. 2021. Available online: Formlabs.com (accessed on 27 September 2021).

- Miedzinska, D.; Gieleta, R.; Popławski, A. Experimental Study on Influence of Curing Time on Strength Behavior of SLA-Printed Samples Loaded with Different Strain Rates. J. Mater. 2020, 13, 5825. [Google Scholar] [CrossRef] [PubMed]

- Martín-Montal, J.; Pernas-Sánchez, J.; Varas, D. Experimental Characterization Framework for SLA Additive Manufacturing Materials. Polym. J. 2021, 13, 1147. [Google Scholar] [CrossRef] [PubMed]

- Formlabs. Available online: https://formlabs.com/eu/3d-printers/form-2/ (accessed on 16 May 2021).

- 3D Printing for Model Making Entertainment. (s.d.). Formlabs. Available online: https://formlabs.com/industries/model-making-entertainment/ (accessed on 16 May 2021).

- Pasricha, A.; Greeninger, R. Exploration of 3D printing to create zero-waste sustainable fashion notions and jewelry. Fash. Text. 2018, 5, 30. [Google Scholar] [CrossRef]

- Tommasi, A.; Maillol, N.; Bertinetti, A.; Penchev, P.; Bajolet, J.; Gili, F.; Pullini, D.; Mataix, D.B. Influence of Surface Preparation and Heat Treatment on Mechanical Behavior of Hybrid Aluminum Parts Manufactured by a Combination of Laser Powder Bed Fusion and Conventional Manufacturing Processes. J. Met. 2021, 11, 522. [Google Scholar] [CrossRef]

- Basi di Dimensionamento Geometrico e Tolleranza (GD&T)—MKRLAB. MKRLAB—Ideas Factory. Available online: https://www.mkrlab.eu/2019/05/16/basi-di-dimensionamento-geometrico-e-tolleranza-gdt/ (accessed on 16 May 2021).

- Zhakeyev, A.; Wang, P.; Zhang, L.; Shu, W.; Wang, H.; Xuan, J. Additive Manufacturing: Unlocking the Evolution of Energy Materials. Adv. Sci. 2017, 4, 1700187. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taneva, I.; Uzunov, T. Influence of post-polymerization processing on the mechanical characteristics of 3D-printed occlusal splints. J. Phys. Conf. Ser. 2020, 1492, 012018. [Google Scholar] [CrossRef]

- Ahmad, K.W.H.; Mohamad, Z.; Othman, N.; Che Man, S.H.; Jusoh, M. The Mechanical Properties of Photopolymer Prepared Via 3D Stereolithography Printing: The Effect of UV Curing Time and Anisotropy. Chem. Eng. Trans. 2020, 78, 565–570. [Google Scholar]

- Marin, E.; Boschetto, F.; Zanocco, M.; Doan, H.N.; Sunthar, T.P.M.; Kinashi, K.; Iba, D.; Zhu, W.; Pezzotti, G. UV-curing and thermal ageing of methacrylated stereo-lithographic resin. Polym. Degrad. Stab. 2021, 185, 109503. [Google Scholar] [CrossRef]

- Hao, J.; Nangunoori, R.; Wu, Y.Y.; Rajaraman, M.; Cook, D.; Yu, A.; Cheng, B.; Shimada, K. Material characterization and selection for 3D-printed spine models. 3D Print. Med. 2018, 4, 8. [Google Scholar] [CrossRef] [PubMed]

- Watters, M.P.; Bernhardt, M.L. Curing parameters to improve the mechanical properties of stereolithographic printed specimens. Rapid Prototyp. J. 2018, 24, 46–51. [Google Scholar] [CrossRef]

- Surace, R.; Basile, V.; Bellantone, V.; Modica, F.; Fassi, I. Micro Injection Molding of Thin Cavities Using Stereolithography for Mold Fabrication. Polymers 2021, 13, 1848. [Google Scholar] [CrossRef] [PubMed]

- Kawana, M.; Takahashi, J.; Guo, J.; Tomita, Y. Measurement of polymerization-shrinkage evolution during curing in photopolymer with a white-light Fabry-Pérot interferometer. Opt. Express 2015, 23, 15356–15364. [Google Scholar] [CrossRef] [PubMed]

- Karalekas, D.; Aggelopoulos, A. Study of shrinkage strains in a stereolithography cured acrylic photopolymer resin. J. Mater. Process. Technol. 2003, 136, 146–150. [Google Scholar] [CrossRef]

- Cheah, C.M.; Fuh, J.Y.H.; Nee, A.Y.C.; Lu, L.; Choo, Y.S.; Miyazawa, T. Characteristics of photopolymeric material used in rapid prototypes Part II. Mechanical properties at post-cured state. J. Mater. Process. Technol. 1997, 67, 46–49. [Google Scholar] [CrossRef]

- Crivello, J.V.; Dietliker, K. Photoinitiators for Free Radical, Cationic & Anionic Photopolymerization, 2nd ed.; Bradley, G., Ed.; formulation for coatings, inks and paints; John Wiley & Sons, Inc.: Chichester, UK; New York, NY, USA, 1998; Volume III. [Google Scholar]

- The Ultimate Guide to Stereolithography (SLA) 3D Printing. Available online: www.formlabs.com (accessed on 27 September 2021).

- BS EN ISO 527-1:2019. Available online: http://store.uni.com/catalogo/en-iso-527-1-2019 (accessed on 27 September 2021).

- Material Data Sheet; Tough Resin (FLTOTL05); Formlabs, Inc.: Somerville, MA, USA, 2018.

- Material Data Sheet; Standard Clear Resin (FLGPCL04); Formlabs, Inc.: Somerville, MA, USA, 2016.

- Material Data Sheet; Grey Pro Resin (FLGPCL04); Formlabs, Inc.: Somerville, MA, USA, 2018.

- Material Data Sheet; BioMed Amber Resin (FLBMAM01); Formlabs, Inc.: Somerville, MA, USA, 2019.

- Material Data Sheet; Dental LT Clear Resin (FLDLCL01); Formlabs, Inc.: Somerville, MA, USA, 2017.

- Material Data Sheet; Tough 1500 Resin (FLTO1501); Formlabs, Inc.: Somerville, MA, USA, 2019.

- Material Data Sheet; Tough 2000 Resin (FLTO2001); Formlabs, Inc.: Somerville, MA, USA, 2020.

- Material Data Sheet; Custom Tray Resin (FLCTBL01); Formlabs, Inc.: Somerville, MA, USA, 2020.

- Material Data Sheet; High Temp Resin (FLHTAM02); Formlabs, Inc.: Somerville, MA, USA, 2016.

- Material Data Sheet; Durable Resin (FLDUCL02); Formlabs, Inc.: Somerville, MA, USA, 2018.

- Material Data Sheet; BioMed Clear Resin (FLBMCL01); Formlabs, Inc.: Somerville, MA, USA, 2020.

- Material Data Sheet; Rigid Resin (FLRGWH01); Formlabs, Inc.: Somerville, MA, USA, 2018.

- Brostow, W.; Hagg Lobland, H.; Narkis, M. Sliding wear, viscoelasticity, and brittleness of polymers. J. Mater. Res. 2006, 21, 2422–2428. [Google Scholar] [CrossRef] [Green Version]

- Brostow, W.; Hagg Lobland, H. Materials: Introduction and Applications; Cambridge University: Cambridge, UK, 2017; p. 974. [Google Scholar]

- Jindal, P.; Juneja, M.; Siena, F.L.; Bajaj, D.; Breedon, P. Mechanical and geometric properties of thermoformed and 3D printed clear dental aligners. Am. J. Orthod. Dentofac. Orthop. 2019, 156, 694–701. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Resin | Time (min) | Temperature (°C) |

|---|---|---|

| Tough | 60 | 60 |

| Standard Clear | 15 | 60 |

| Grey Pro | 15 | 80 |

| BioMed Amber | 30 | 60 |

| Dental LT Clear | 60 | 60 |

| Tough 1500 | 60 | 70 |

| Tough 2000 | 60 | 70 |

| Custom Tray | 30 | 60 |

| High Temp | 120 | 80 |

| Durable | 60 | 60 |

| Rigid | 15 | 80 |

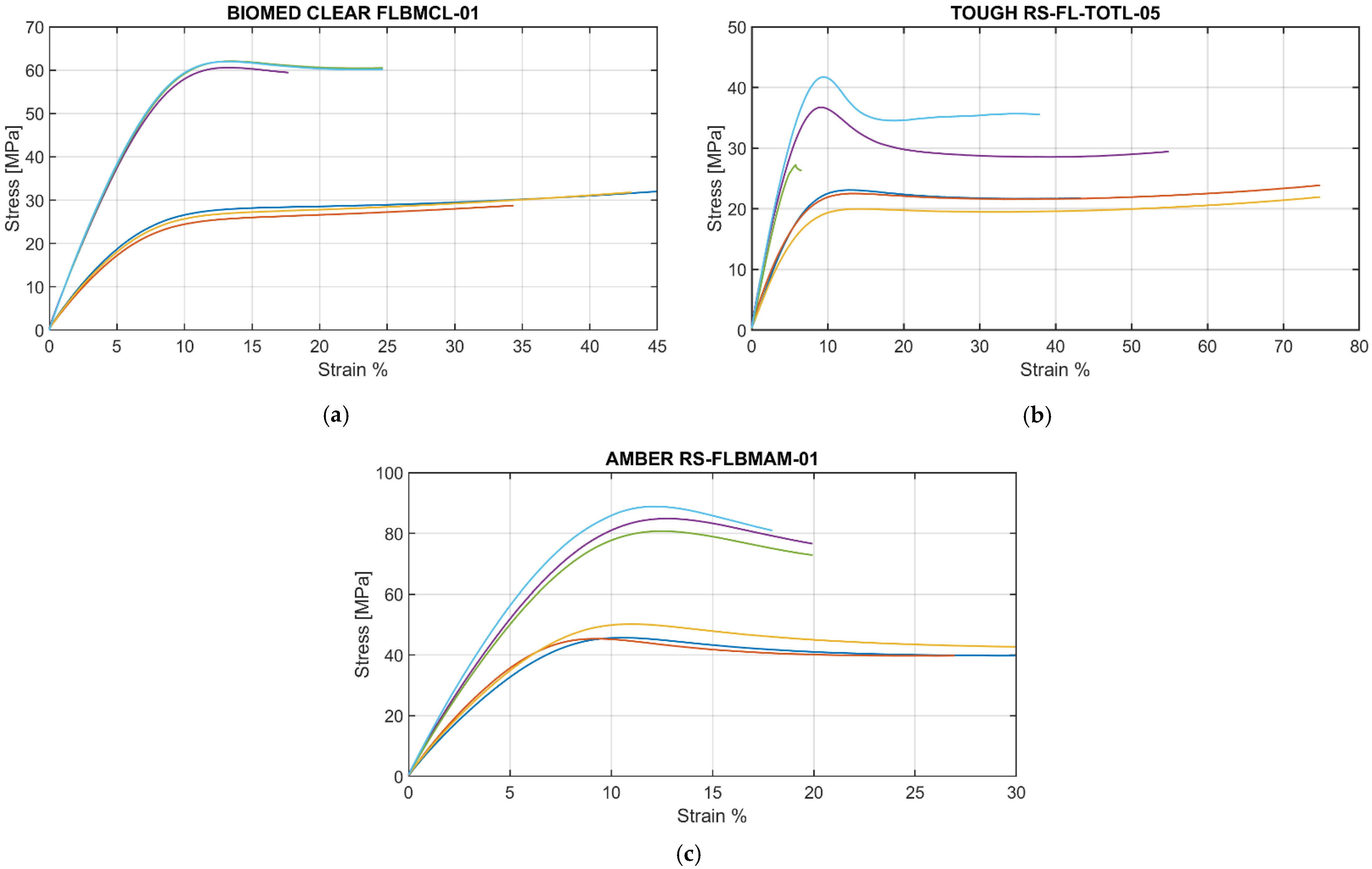

| Load at Break (MPa) | Young’s Modulus (GPa) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Green | Post-Cure | Green | Post-Cure | |||||||||

| Data Sheet | Exp. Results | Data Sheet | Exp. Results | Data Sheet | Exp. Results | Data Sheet | Exp. Results | |||||

| Resin | σ | σ | σ | σ | ||||||||

| Tough | 34.7 [22] | 23.5 | 1.83 | 55.7 [22] | 30.4 | 22.17 | 1.7 [22] | 0.3 | 0.03 | 2.7 [22] | 0.6 | 0.08 |

| Standard Clear | 38.0 [23] | 20.1 | 2.17 | 65.0 [23] | 42.2 | 1.91 | 1.6 [23] | 0.7 | 0.09 | 2.8 [23] | 1.0 | 0.03 |

| Grey Pro | 35.0 [24] | 32.2 | 5.68 | 61.0 [24] | 60.4 | 1.90 | 1.4 [24] | 0.8 | 0.02 | 2.6 [24] | 1.0 | 0.03 |

| BioMed Amber | N.A. [25] | 41.2 | 1.04 | 73.0 [25] | 76.8 | 4.09 | N.A. [25] | 0.8 | 0.02 | 2.9 [25] | 1.2 | 0.02 |

| Dental LT Clear | N.A. [26] | 34.6 | 1.89 | 50.0 [26] | 61.8 | 10.69 | N.A. [26] | 0.6 | 0.04 | 1.3 [26] | - (*) | - (*) |

| Tough 1500 | 26.0 [27] | 30.4 | 2.63 | 33.0 [27] | 41.2 | 0.96 | 0.9 [27] | 0.4 | 0.02 | 1.5 [27] | 0.6 | 0.01 |

| Tough 2000 | 29.0 [28] | 26.5 | 0.41 | 46.0 [28] | 42.0 | 1.43 | 1.2 [28] | 0.4 | 0.04 | 2.2 [28] | 0.8 | 0.02 |

| Custom Tray | N.A. [29] | 26.9 | 1.98 | 70.0 [29] | 84.7 | 2.43 | N.A. [29] | 0.4 | 0.01 | 2.5 [29] | 1.1 | 0.01 |

| High Temp | 20.9 [30] | 26.2 | 0.30 | 58.3 [30] | 48.2 | 7.90 | 0.8 [30] | 0.3 | 0.01 | 2.8 [30] | 0.8 | 0.00 |

| Durable | 18.6 [31] | 17.0 | 0.79 | 31.8 [31] | 34.5 | 1.34 | 0.5 [31] | 0.2 | 0.03 | 1.3 [31] | 0.4 | 0.01 |

| BioMed Clear | N.A. [32] | 30.9 | 1.87 | 52.0 [32] | 60.1 | 0.55 | N.A. [32] | 0.4 | 0.02 | 2.1 [32] | 0.9 | 0.02 |

| Rigid | 40.0 [33] | 39.8 | 3.07 | 75.0 [33] | 74.5 | 7.69 | 2.2 [33] | 0.7 | 0.02 | 4.1 [33] | 1.3 | 0.18 |

| Ductility (%) | Toughness (MPa) | Resilience (MPa) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Green | Post-Cure | Green | Post-Cure | Green | Post-Cure | |||||||

| Resin | σ | σ | σ | σ | σ | σ | ||||||

| Tough | 64.35 | 18.19 | 33.15 | 24.49 | 1299.04 | 370.31 | 990.41 | 774.89 | 50.38 | 5.35 | 100.08 | 43.97 |

| Standard Clear | 3.52 | 0.06 | 4.64 | 0.28 | 36.69 | 6.45 | 104.68 | 10.10 | 30.35 | 11.52 | 101.72 | 15.06 |

| Grey Pro | 4.30 | 0.26 | 10.10 | 0.60 | 66.19 | 4.94 | 403.83 | 36.58 | 32.33 | 13.67 | 68.00 | 30.58 |

| BioMed Amber | 28.95 | 1.73 | 19.27 | 1.14 | 1123.57 | 109.10 | 1246.93 | 47.18 | 91.42 | 7.87 | 113.24 | 7.47 |

| Dental LT Clear | 43.92 | 12.94 | 6.03 | 1.17 | 1303.65 | 409.41 | 205.04 | 79.02 | 39.62 | 11.93 | 116.82 | 46.81 |

| Tough 1500 | 89.87 | 9.95 | 73.23 | 5.77 | 2171.27 | 254.22 | 2603.43 | 228.82 | 74.87 | 17.81 | 130.92 | 9.43 |

| Tough 2000 | 79.90 | 0.00 | 55.11 | 9.59 | 1788.43 | 30.38 | 2182.97 | 395.78 | 88.93 | 7.45 | 134.59 | 19.33 |

| Custom Tray | 43.11 | 21.27 | 16.28 | 3.62 | 996.49 | 534.99 | 998.78 | 318.25 | 18.11 | 8.52 | 65.92 | 17.55 |

| High Temp | 18.87 | 1.35 | 7.61 | 0.15 | 355.74 | 37.98 | 166.34 | 23.94 | 59.34 | 4.74 | 88.69 | 37.51 |

| Durable | 88.85 | 1.73 | 72.14 | 2.81 | 1052.63 | 43.54 | 1885.03 | 111.95 | 21.46 | 9.51 | 66.96 | 23.42 |

| BioMed Clear | 41.18 | 5.76 | 22.43 | 4.06 | 1042.01 | 204.33 | 1102.70 | 254.53 | 57.52 | 10.27 | 95.94 | 7.61 |

| Rigid | 28.55 | 8.16 | 11.28 | 2.12 | 950.90 | 323.74 | 565.48 | 103.19 | 27.40 | 9.90 | 98.20 | 20.90 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riccio, C.; Civera, M.; Grimaldo Ruiz, O.; Pedullà, P.; Rodriguez Reinoso, M.; Tommasi, G.; Vollaro, M.; Burgio, V.; Surace, C. Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. Appl. Mech. 2021, 2, 942-955. https://doi.org/10.3390/applmech2040055

Riccio C, Civera M, Grimaldo Ruiz O, Pedullà P, Rodriguez Reinoso M, Tommasi G, Vollaro M, Burgio V, Surace C. Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. Applied Mechanics. 2021; 2(4):942-955. https://doi.org/10.3390/applmech2040055

Chicago/Turabian StyleRiccio, Carmela, Marco Civera, Oliver Grimaldo Ruiz, Perla Pedullà, Mariana Rodriguez Reinoso, Giulia Tommasi, Martina Vollaro, Vito Burgio, and Cecilia Surace. 2021. "Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing" Applied Mechanics 2, no. 4: 942-955. https://doi.org/10.3390/applmech2040055

APA StyleRiccio, C., Civera, M., Grimaldo Ruiz, O., Pedullà, P., Rodriguez Reinoso, M., Tommasi, G., Vollaro, M., Burgio, V., & Surace, C. (2021). Effects of Curing on Photosensitive Resins in SLA Additive Manufacturing. Applied Mechanics, 2(4), 942-955. https://doi.org/10.3390/applmech2040055