Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete

Abstract

:1. Introduction

2. Characteristics of Fresh UHPFRC

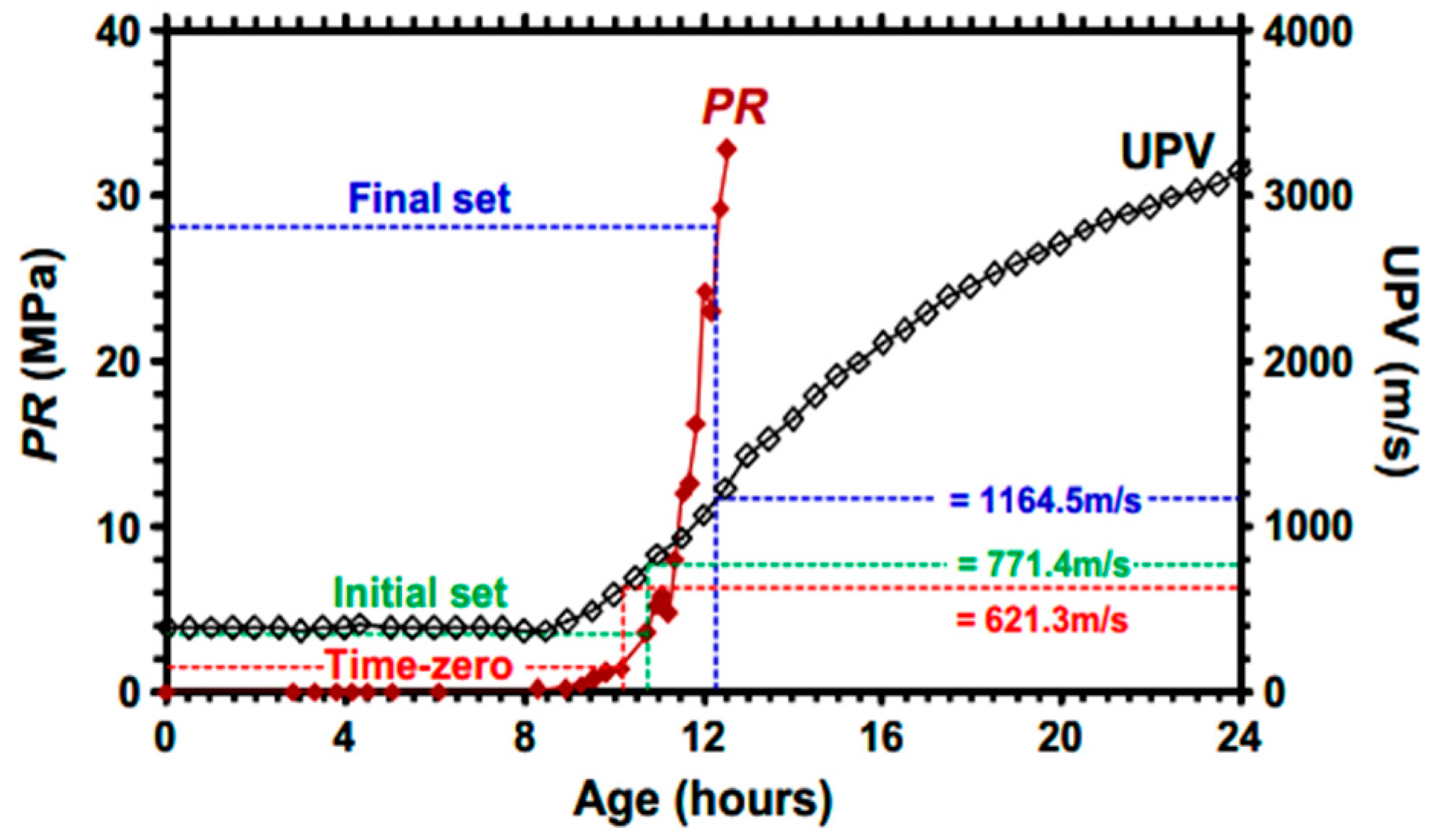

2.1. Effect of Steel Fiber Percentages and Aspect Ratio on Setting Times

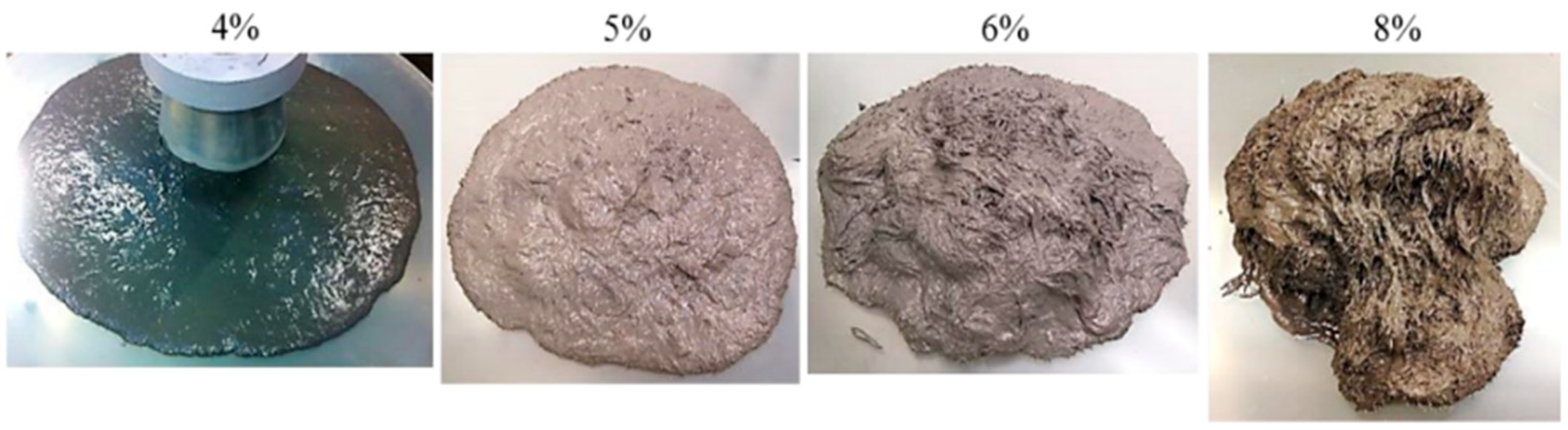

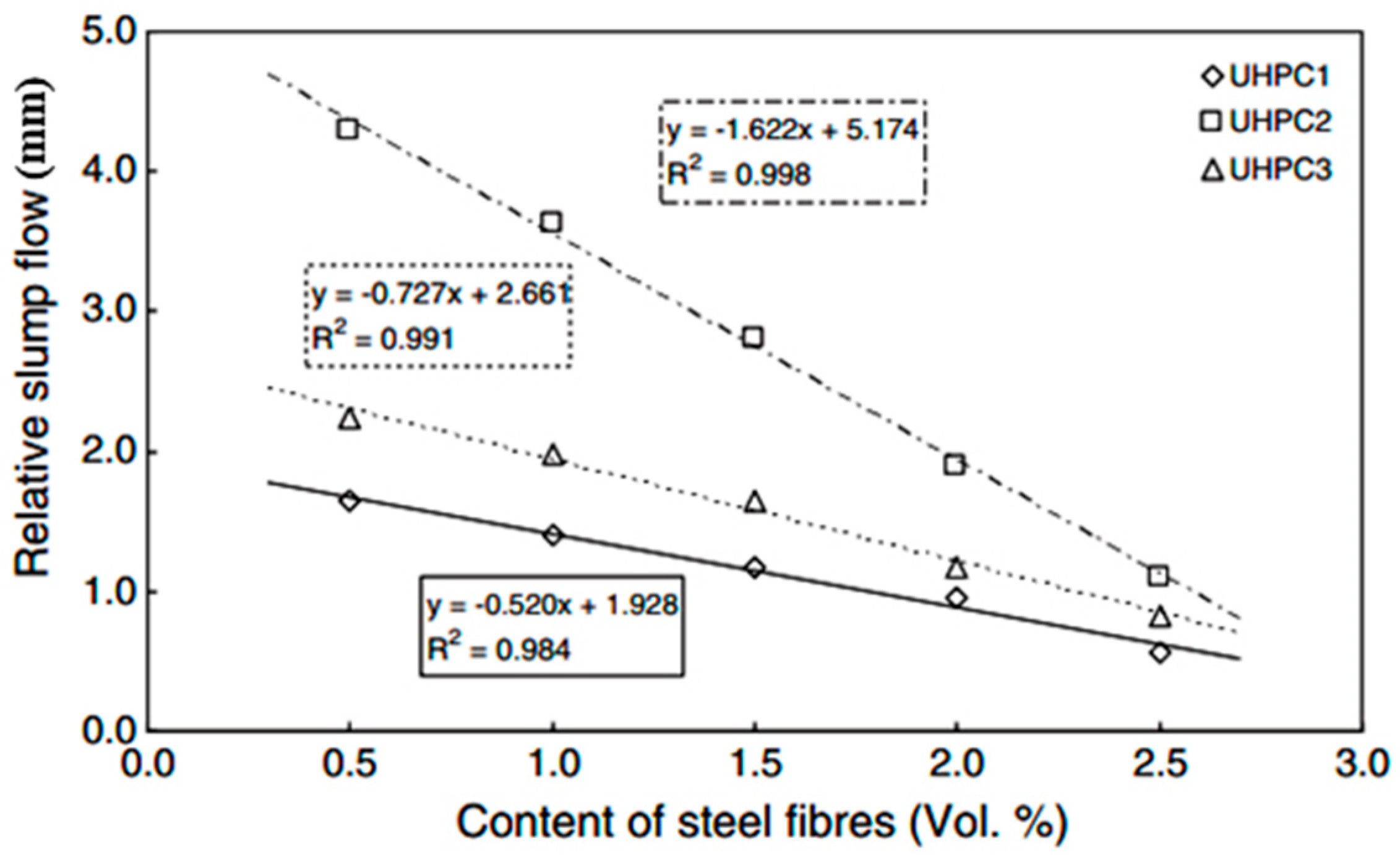

2.2. Effects of Steel Fiber Percentages and Aspect Ratios on Slump or Workability

3. Mechanical Characteristics of UHPFRC

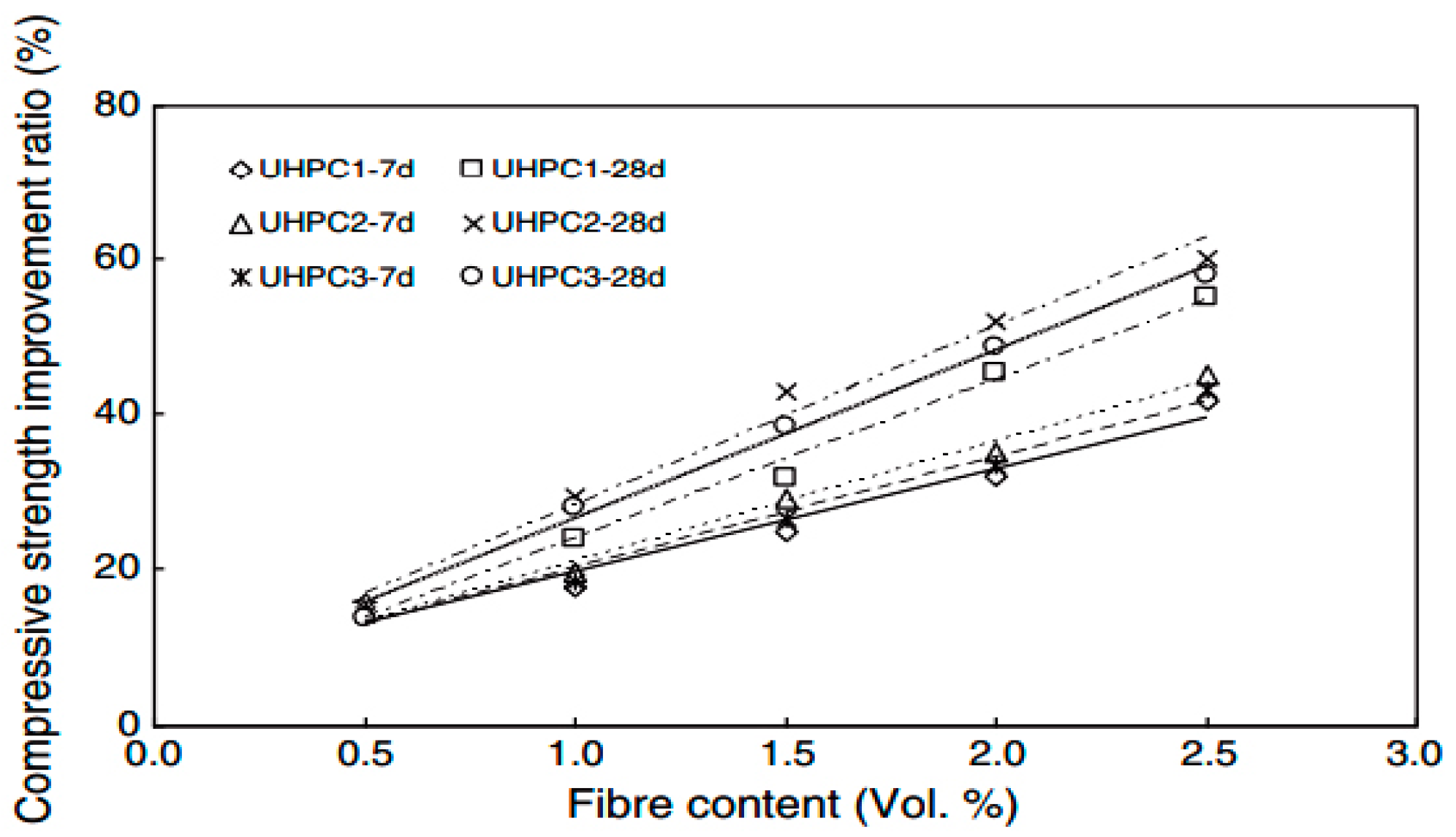

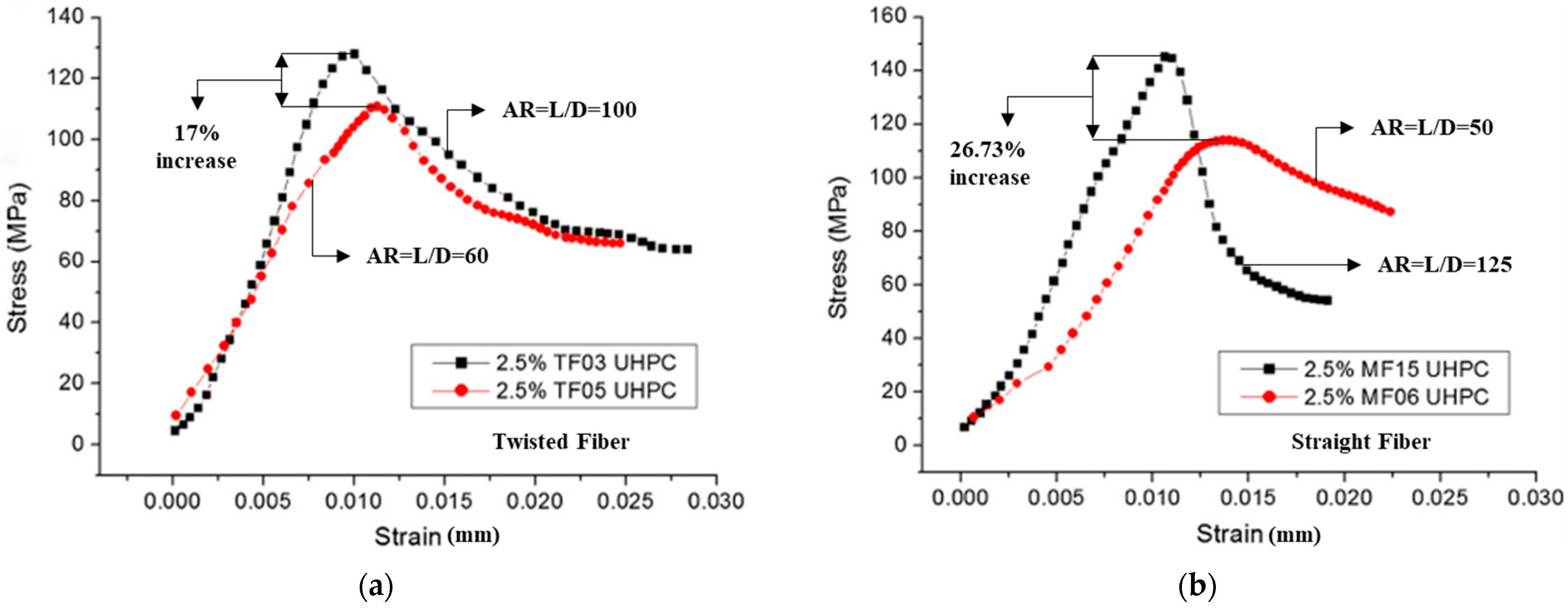

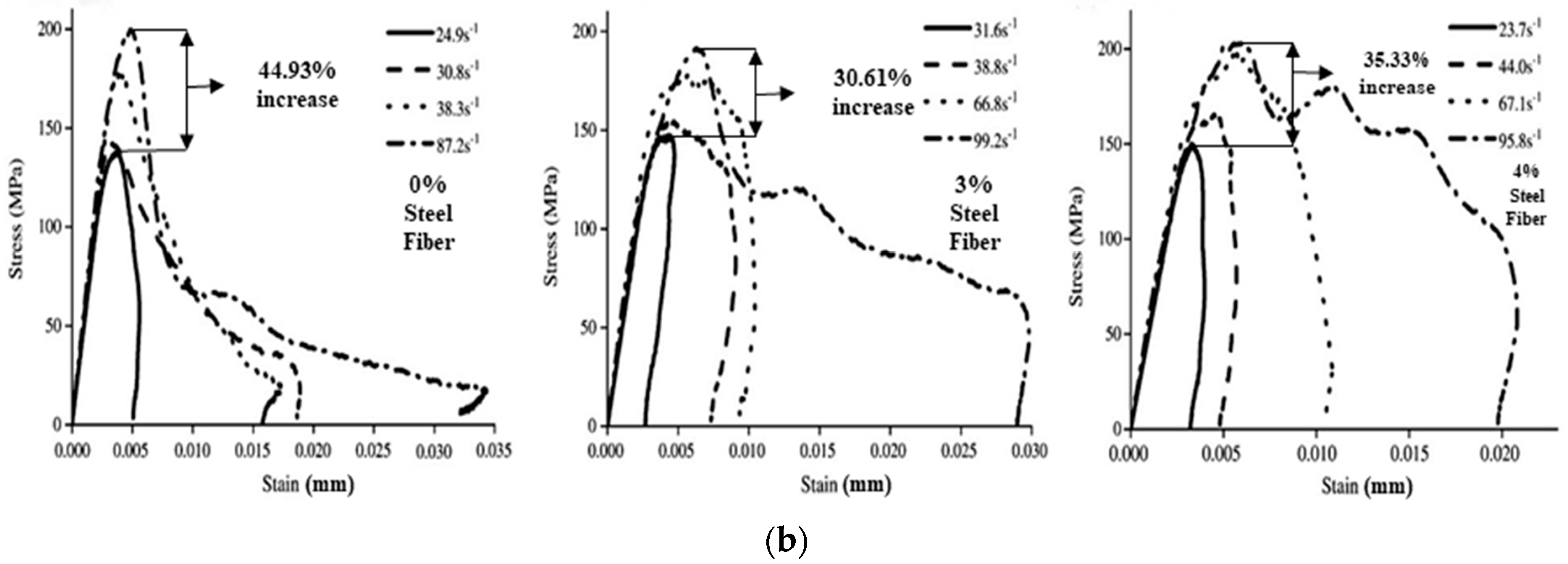

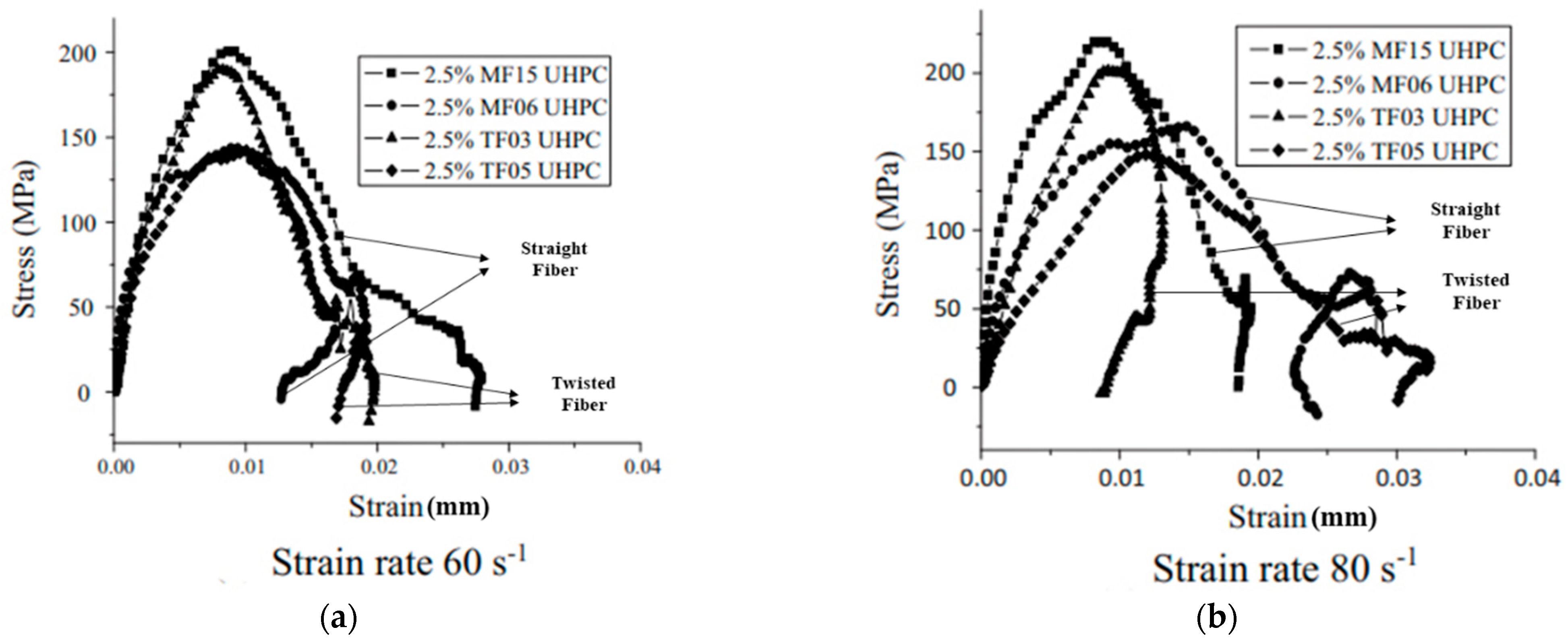

3.1. Effects of Steel Fiber Percentages and Aspect Ratios on Compressive Behavior

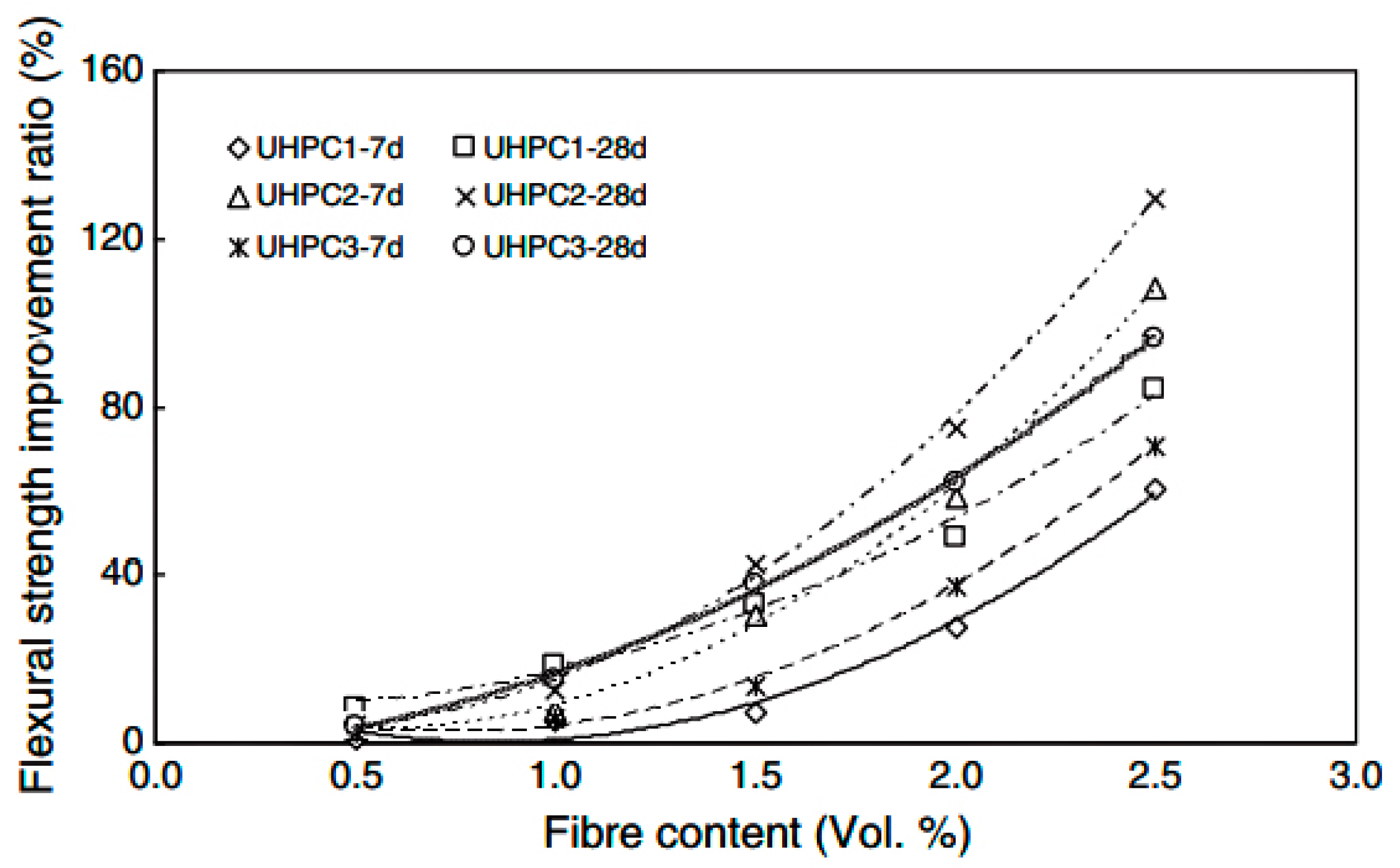

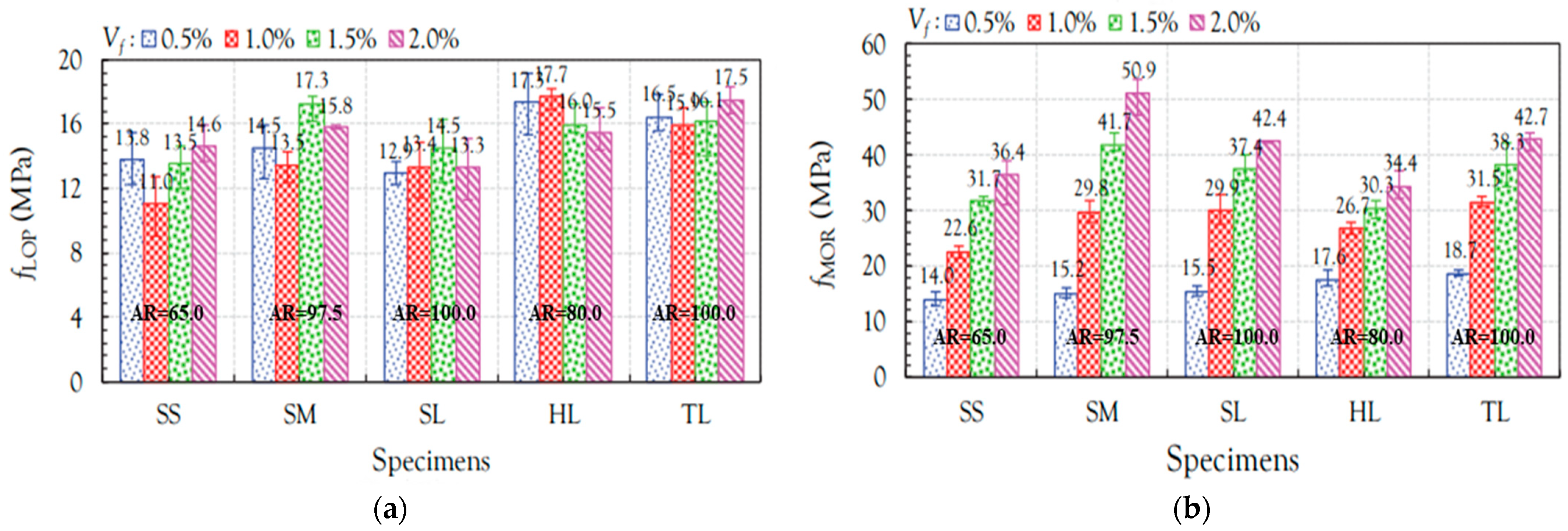

3.2. Effects of Steel Fiber Percentages and Aspect Ratios on Flexural Strength

3.3. Effects of Steel Fiber Percentages and Aspect Ratios on Split Tensile Strength

4. Conclusions and Future Research Needs

- Steel fiber amount and aspect ratio significantly influence the workability of UHPFRC. Higher steel fiber percentages and aspect ratios cause interlocking among fibers and ultimately lead to reduced slump flow;

- The compressive strength of UHPFRC is gradually increased with increased steel fiber dosage for the capability of delaying crack formation and propagation. Nevertheless, improper fiber distribution in a concrete mixture may lead to the decreased compressive strength of UHPFRC;

- Steel fibers with a high aspect ratio resist crack opening and improve compressive strength. In contrast, steel fibers with a low aspect ratio can only control microcrack opening and propagation;

- The effects of aspect ratios were examined for flexural and split tensile strength. Higher-aspect ratio steel fibers could improve flexural and split tensile strength with a constant fiber percentage, owing to the large bonding surface between fibers and the concrete matrix;

- A faster strain rate significantly improved the mechanical properties of UHPFRC.

- Extensive research should be carried out to understand the effect of fiber percentage or aspect ratio on the setting time of UHPFRC;

- Owing to the low water-to-cement ratio, the outer surface of UHPFRC has a much faster evaporation rate than that of the inner surface. Therefore, an accurate measurement method for setting time needs to be developed;

- Steel fibers significantly influenced the mechanical properties of UHPFRC. Hence, to reduce manufacturing costs, the effects of other factors such as avoiding high-pressure compaction and heat treatments should be further investigated;

- Because the distribution of steel fibers can affect compressive strength, a proper mixing procedure needs to be developed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Li, Z. Advanced Concrete Technology, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Ragavendra, S.; Reddy, I.P.; Dongre, A.R. Fibre reinforced concrete—A case study. In Proceedings of the Architectural Engineering Aspect for Sustainable Building Envelopes, Khairatabad, Hyderabad, India, 10–11 November 2017; pp. 1–15. [Google Scholar]

- Biswas, R.K.; Iwanami, M.; Chijiwa, N.; Uno, K. Effect of non-uniform rebar corrosion on structural performance of RC structures: A numerical and experimental investigation. Constr. Build. Mater. 2020, 230, 116908. [Google Scholar] [CrossRef]

- Biswas, R.K.; Iwanami, M.; Chijiwa, N.; Uno, K. Finite element analysis of rc beams subjected to non-uniform corrosion of steel bars. In Proceedings of the Fifth International Conference on Sustainable Construction Materials and Technologies, London, UK, 14–17 July 2019. [Google Scholar]

- Biswas, R.K.; Iwanami, M.; Chijiwa, N.; Nakayama, K. Numerical evaluation on the effect of steel bar corrosion on the cyclic behaviour of RC bridge piers. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Paul, S.C.; Pirskawetz, S.; Van Zijl, G.P.A.G.; Schmidt, W. Acoustic emission for characterising the crack propagation in strain-hardening cement-based composites (SHCC). Cem. Concr. Res. 2015, 69, 19–24. [Google Scholar] [CrossRef]

- Paul, S.C.; Babafemi, A.J. A review of the mechanical and durability properties of strain hardening cement-based composite (SHCC). J. Sustain. Cem. Mater. 2018, 7, 57–78. [Google Scholar] [CrossRef]

- Chao, S.-H.; Liao, W.-C.; Wongtanakitcharoen, T.; Naaman, A.E. Large scale tensile tests of high performance fiber reinforced cement composites. In Proceedings of the Fifth International RILEM Workshop on High Performance Fiber Reinforced Cement Composites (HPFRCC5), Mainz, Germany, 10–13 July 2007; pp. 77–86. [Google Scholar]

- Bonopera, M.; Chang, K.-C.; Chen, C.-C.; Sung, Y.-C.; Tullini, N. Prestress force effect on fundamental frequency and deflection shape of PCI beams. Struct. Eng. Mech. An Int. J. 2018, 67, 255–265. [Google Scholar]

- Singh, B.P.; Yazdani, N.; Ramirez, G. Effect of a time dependent concrete modulus of elasticity on prestress losses in bridge girders. Int. J. Concr. Struct. Mater. 2013, 7, 183–191. [Google Scholar] [CrossRef] [Green Version]

- Bin Ahmed, F.; Biswas, R.K.; Abid Ahsan, K.; Islam, S.; Rahman, M.R. Estimation of strength properties of geopolymer concrete. Mater. Today Proc. 2021, 44, 871–877. [Google Scholar] [CrossRef]

- Yudenfreund, M.; Odler, I.; Brunauer, S. Hardened portland cement pastes of low porosity I. Materials and experimental methods. Cem. Concr. Res. 1972, 2, 313–330. [Google Scholar] [CrossRef]

- Roy, D.M.; Gouda, G.R.; Bobrowsky, A. Very high strength cement pastes prepared by hot pressing and other high pressure techniques. Cem. Concr. Res. 1972, 2, 349–366. [Google Scholar] [CrossRef]

- Alford, N.M.; Birchall, J.D. The properties and potential applications of macro-defect-free cement. MRS Online Proc. Libr. OPL 1984, 42, 265–276. [Google Scholar] [CrossRef]

- Bache, H.H. Introduction to Compact Reinforced Composite; Nordic Concrete Federation: Denmark, 1987. [Google Scholar]

- de Larrard, F.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-high performance Concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way. ACI Mater. J. 2011, 108, 46–54. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S.; Parra-Montesinos, G.J. Ultra-high performance concrete and fiber reinforced concrete: Achieving strength and ductility without heat curing. Mater. Struct. Constr. 2012, 45, 309–324. [Google Scholar] [CrossRef]

- Wille, K.; Naaman, A.E.; El-Tawil, S. Optimizing Ultra-High-Performance Fiber-Reinforced Concrete Mixtures with twisted fibers exhibit record performance under tensile loading. Concr. Int. 2011, 33, 35–41. [Google Scholar]

- Russel, H.G.; Graybeal, B.A. Ultra-High Performance Concrete: A State-of-the-Art Report for the Bridge Community; Federal Highway Administration, Office of Infrastructure Research and Development: Washington, DC, USA, 2013; pp. 2101–2296.

- Aghdasi, P.; Heid, A.E.; Chao, S.H. Developing ultra-high-performance fiber-reinforced concrete for large-scale structural applications. ACI Mater. J. 2016, 113, 559–569. [Google Scholar] [CrossRef]

- Tong, T.; Wang, J.; Lei, H.; Liu, Z. UHPC jacket retrofitting of reinforced concrete bridge piers with low flexural reinforcement ratios: Experimental investigation and three-dimensional finite element modeling. Struct. Infrastruct. Eng. 2020. [Google Scholar] [CrossRef]

- Hanifehzadeh, M.; Aryan, H.; Gencturk, B.; Akyniyazov, D. Structural response of steel jacket-uhpc retrofitted reinforced concrete columns under blast loading. Materials 2021, 14, 1521. [Google Scholar] [CrossRef]

- Lee, J.Y.; Aoude, H.; Yoon, Y.S.; Mitchell, D. Impact and blast behavior of seismically-detailed RC and UHPFRC-Strengthened columns. Int. J. Impact Eng. 2020, 143, 103628. [Google Scholar] [CrossRef]

- Charron, J.P.; Denarié, E.; Brühwiler, E. Permeability of ultra high performance fiber reinforced concretes (UHPFRC) under high stresses. Mater. Struct. Constr. 2007, 40, 269–277. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2012, 26, 79–89. [Google Scholar] [CrossRef]

- Azmee, N.M.; Shafiq, N. Ultra-high performance concrete: From fundamental to applications. Case Stud. Constr. Mater. 2018, 9, e00197. [Google Scholar] [CrossRef]

- Gosavi, J.S.; Awari, U.R. A Review on High-Performance Concrete. Int. Res. J. Eng. Technol. 2018, 5, 1965–1968. [Google Scholar]

- He, Z.-h.; Du, S.-g.; Chen, D. Microstructure of ultra high performance concrete containing lithium slag. J. Hazard. Mater. 2018, 353, 35–43. [Google Scholar] [CrossRef]

- Kim, J.K.; Han, S.H.; Song, Y.C. Effect of temperature and aging on the mechanical properties of concrete: Part, I. Experimental results. Cem. Concr. Res. 2002, 32, 1087–1094. [Google Scholar] [CrossRef]

- Soliman, N.A.; Tagnit-Hamou, A. Development of ultra-high-performance concrete using glass powder—Towards ecofriendly concrete. Constr. Build. Mater. 2016, 125, 600–612. [Google Scholar] [CrossRef]

- Pyo, S.; Kim, H.K. Fresh and hardened properties of ultra-high performance concrete incorporating coal bottom ash and slag powder. Constr. Build. Mater. 2017, 131, 459–466. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Effect of fiber length and placement method on flexural behavior, tension-softening curve, and fiber distribution characteristics of UHPFRC. Constr. Build. Mater. 2014, 64, 67–81. [Google Scholar] [CrossRef]

- Wille, K.; Kim, D.J.; Naaman, A.E. Strain-hardening UHP-FRC with low fiber contents. Mater. Struct. Constr. 2011, 44, 583–598. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kang, S.T.; Yoon, Y.S. Enhancing the flexural performance of ultra-high-performance concrete using long steel fibers. Compos. Struct. 2016, 147, 220–230. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Zi, G.; Kang, S.T.; Yoon, Y.S. Biaxial flexural behavior of ultra-high-performance fiber-reinforced concrete with different fiber lengths and placement methods. Cem. Concr. Compos. 2015, 63, 51–66. [Google Scholar] [CrossRef]

- Ryu, G.S.; Kang, S.T.; Park, J.J.; Koh, K.T.; Kim, S.W. Mechanical behavior of UHPC(ultra high performance concrete) according to hybrid use of steel fibers. Adv. Mater. Res. 2011, 287–290, 453–457. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Time of Setting of Concrete Mixtures by Penetration Resistance; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Yoo, D.Y.; Park, J.J.; Kim, S.W.; Yoon, Y.S. Early age setting, shrinkage and tensile characteristics of ultra high performance fiber reinforced concrete. Constr. Build. Mater. 2013, 41, 427–438. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, W.; She, W.; Ma, L.; Zhu, W. Ultrasound monitoring of setting and hardening process of ultra-high performance cementitious materials. NDT E Int. 2012, 47, 177–184. [Google Scholar] [CrossRef]

- Svec, O.; Pade, C. Ultra high performance fibre reinforced concrete as a waterproofing solution for concrete bridge deck renovations. In Proceedings of the XXII Nordic Concrete Research Symposia, Reykjavik, Iceland, 13–15 August 2014; pp. 273–276. [Google Scholar]

- Yoo, D.Y.; Lee, J.H.; Yoon, Y.S. Effect of fiber content on mechanical and fracture properties of ultra high performance fiber reinforced cementitious composites. Compos. Struct. 2013, 106, 742–753. [Google Scholar] [CrossRef]

- Martinie, L.; Rossi, P.; Roussel, N. Rheology of fiber reinforced cementitious materials: Classification and prediction. Cem. Concr. Res. 2010, 40, 226–234. [Google Scholar] [CrossRef]

- Abbas, S.; Soliman, A.M.; Nehdi, M.L. Exploring mechanical and durability properties of ultra-high performance concrete incorporating various steel fiber lengths and dosages. Constr. Build. Mater. 2015, 75, 429–441. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of Ultra-High Performance Fibre Reinforced Concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Le Hoang, A.; Fehling, E. Influence of steel fiber content and aspect ratio on the uniaxial tensile and compressive behavior of ultra high performance concrete. Constr. Build. Mater. 2017, 153, 790–806. [Google Scholar] [CrossRef]

- Arel, H.Ş. Effects of curing type, silica fume fineness, and fiber length on the mechanical properties and impact resistance of UHPFRC. Results Phys. 2016, 6, 664–674. [Google Scholar] [CrossRef] [Green Version]

- Rossi, P. Development of new cement composite materials for construction. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2005, 219, 67–74. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wang, D. Static and dynamic compressive properties of ultra-high performance concrete (UHPC) with hybrid steel fiber reinforcements. Cem. Concr. Compos. 2017, 79, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Static properties and impact resistance of a green Ultra-High Performance Hybrid Fibre Reinforced Concrete (UHPHFRC): Experiments and modeling. Constr. Build. Mater. 2014, 68, 158–171. [Google Scholar] [CrossRef] [Green Version]

- Schmidt, M.; Fehling, E.; Teichmann, T.; Bunje, K.; Bornemann, R. Ultra-high performance concrete: Perspective for the precast concrete industry | Request PDF. Concr. Precast. Plant Tech 2003, 69, 16–29. [Google Scholar]

- Abbas, S.; Nehdi, M.L.; Saleem, M.A. Ultra-high performance concrete: Mechanical performance, durability, sustainability and implementation challenges. Int. J. Concr. Struct. Mater. 2016, 10, 271–295. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.Y.; Shin, H.O.; Yang, J.M.; Yoon, Y.S. Material and bond properties of ultra high performance fiber reinforced concrete with micro steel fibers. Compos. Part B Eng. 2014, 58, 122–133. [Google Scholar] [CrossRef]

- Rong, Z.; Sun, W.; Zhang, Y. Dynamic compression behavior of ultra-high performance cement based composites. Int. J. Impact Eng. 2010, 37, 515–520. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Muhyaddin, G.F.; Asaad, D.S. Strain hardening ultra-high performance fiber reinforced cementitious composites: Effect of fiber type and concentration. Compos. Part B Eng. 2016, 103, 74–83. [Google Scholar] [CrossRef]

- Jin, L.; Zhang, R.; Tian, Y.; Dou, G.; Du, X. Experimental investigation on static and dynamic mechanical properties of steel fiber reinforced ultra-high-strength concretes. Constr. Build. Mater. 2018, 178, 102–111. [Google Scholar] [CrossRef]

- Ibrahim, M.A.; Farhat, M.; Issa, M.A.; Hasse, J.A. Effect of material constituents on mechanical & fracture mechanics properties of ultra-high-performance concrete. ACI Struct. J. 2017, 114, 453–465. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X. Relationship between flowability, entrapped air content and strength of UHPC mixtures containing different dosage of steel fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef] [Green Version]

- Kazemi, S.; Lubell, A.S. Influence of Specimen Size and Fiber Content on Mechanical Properties of Ultra-High-Performance Fiber-Reinforced Concrete. ACI Mater. J. 2012, 109. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50 mm] Cube Specimens); ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- ASTM International. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar]

- Liao, W.C.; Perceka, W.; Liu, E.J. Compressive stress-strain relationship of high strength steel fiber reinforced concrete. J. Adv. Concr. Technol. 2015, 13, 379–392. [Google Scholar] [CrossRef] [Green Version]

- Su, Y.; Li, J.; Wu, C.; Wu, P.; Li, Z.X. Effects of steel fibres on dynamic strength of UHPC. Constr. Build. Mater. 2016, 114, 708–718. [Google Scholar] [CrossRef]

- Lai, J.; Sun, W. Dynamic behaviour and visco-elastic damage model of ultra-high performance cementitious composite. Cem. Concr. Res. 2009, 39, 1044–1051. [Google Scholar] [CrossRef]

- Park, J.J.; Yoo, D.Y.; Park, G.J.; Kim, S.W. Feasibility of reducing the fiber content in ultra-high-performance fiber-reinforced concrete under flexure. Materials 2017, 10, 118. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.Y.; Kim, S.; Park, G.J.; Park, J.J.; Kim, S.W. Effects of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high-performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- ASTM International. Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete (Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 2019. [Google Scholar]

- ASTM International. Standard Test Method for Flexural Toughness and First-Crack Strength of Fiber-Reinforced Concrete ( Using Beam with Third-Point Loading); ASTM International: West Conshohocken, PA, USA, 1997. [Google Scholar]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N.; Zi, G.; Yoon, Y.-S. Comparative biaxial flexural behavior of ultra-high-performance fiber-reinforced concrete panels using two different test and placement methods. J. Test. Eval. 2017, 45, 624–641. [Google Scholar] [CrossRef]

- Method of Testing Cement-Determination of Strength. GB National Standard; GB/T 17671-1999; AQSIQ: China, 1999.

- Yunsheng, Z.; Wei, S.; Sifeng, L.; Chujie, J.; Jianzhong, L. Preparation of C200 green reactive powder concrete and its static-dynamic behaviors. Cem. Concr. Compos. 2008, 30, 831–838. [Google Scholar] [CrossRef]

- Kang, S.T.; Lee, Y.; Park, Y.D.; Kim, J.K. Tensile fracture properties of an Ultra High Performance Fiber Reinforced Concrete (UHPFRC) with steel fiber. Compos. Struct. 2010, 92, 61–71. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Yoon, Y.S.; Banthia, N. Flexural response of steel-fiber-reinforced concrete beams: Effects of strength, fiber content, and strain-rate. Cem. Concr. Compos. 2015, 64, 84–92. [Google Scholar] [CrossRef]

- Farnam, Y.; Shekarchi, M.; Mirdamadi, A. Experimental investigation of impact behaviour of high strength fiber reinforced concrete panels. In Proceedings of the 2nd International Symposium on Ultra-High Performance Concrete, Kassel, Germany, 5–7 March 2008; pp. 751–758. [Google Scholar]

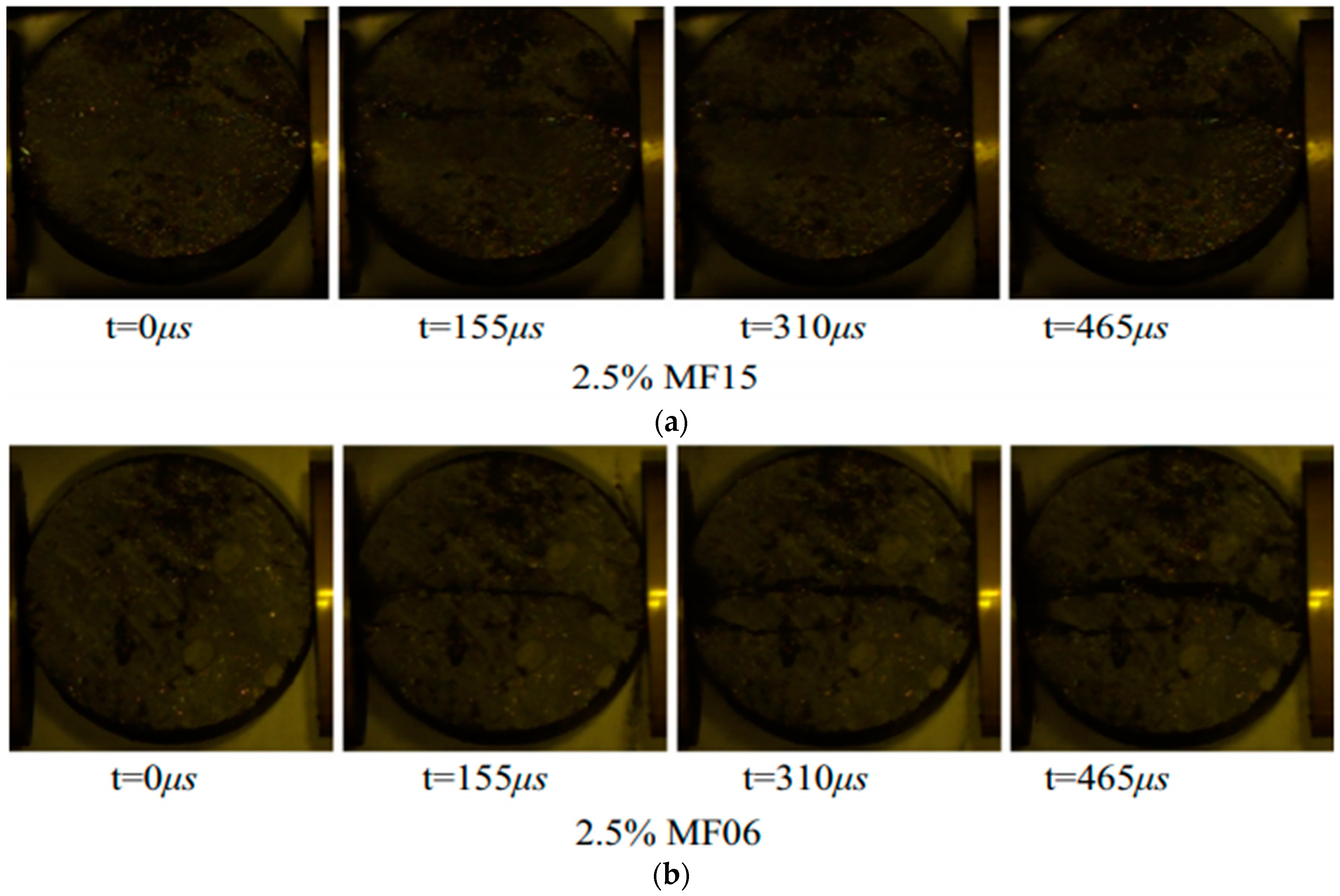

- Ngo, T.T.; Park, J.K.; Kim, D.J. Loading rate effect on crack velocity in ultra-high-performance fiber-reinforced concrete. Constr. Build. Mater. 2019, 197, 548–558. [Google Scholar] [CrossRef]

- Prem, P.R.; Bharatkumar, B.H.; Iyer, N.R. Mechanical Properties of Ultra High Performance Concrete. Int. J. Civ. Environ. Eng. 2012, 6, 676–685. [Google Scholar]

- El-Din, H.S.; Mohamed, H.; Khater, M.A.E.-H.; Ahmed, S. Effect of Steel Fibers on Behavior of Ultra High Performance Concrete. In International Interactive Symposium on Ultra-High Performance Concrete; Iowa State University Digital Press: Iowa, IA, USA, 2016; pp. 1–10. [Google Scholar]

- Sudarshan, N.M.; Rao, T.C. Experimental investigations on tensile strength behavior and microstructure of ultra-high-performance fiber-reinforced concrete. SN Appl. Sci. 2019, 1, 1–11. [Google Scholar] [CrossRef] [Green Version]

| Sample Name | Temperature (°C) | Binder Composition (%) | Binder and Sand Ratio | Sand and Aggregate Ratio | Fiber Percentage | Setting Times (Min) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | Fa | Sf | Sl | Initial | Final | |||||

| SFRC6 | 90 | 50 | 10 | 10 | 30 | 1:1 | 1:1 | 1 | 670 | 1010 |

| SFRC7 | 90 | 50 | 10 | 10 | 30 | 1:1 | 1:1 | 2 | 1030 | 1430 |

| SFRC8 | 90 | 50 | 10 | 10 | 30 | 1:1 | 1:1 | 3 | 1165 | 1915 |

| Sample Series Name | Aspect Ratio | Fiber Percentage | Loading Speed (m/s) | Average Peak Load (KN) |

|---|---|---|---|---|

| SS | 13/0.2 | 0 | 6.94 | 2.75 |

| SS | 13/0.2 | 0.5 | 6.94 | 9.90 |

| SS | 13/0.2 | 1.5 | 6.94 | 11.49 |

| SS | 13/0.2 | 0 | 13.83 | 5.58 |

| SS | 13/0.2 | 0.5 | 13.83 | 14.36 |

| SS | 13/0.2 | 1.5 | 13.83 | 18.88 |

| LS | 19/0.2 | 1.5 | 6.94 | 14.16 |

| LS | 19/0.2 | 1.5 | 13.83 | 22.37 |

| Sample No | Aspect Ratio | Fiber Percentage | Split Tensile Strength (MPa) | Increased Strength Percentage (Compared to No Fiber Percentage) | Difference Between Two Aspect Ratios Strength Percentage |

|---|---|---|---|---|---|

| 1 | 0 | 0 | 11.5 | - | - |

| 2 | 30 | 1 | 12.73 | 10.70 | 23.22 |

| 3 | 50 | 1 | 15.4 | 33.91 | |

| 4 | 30 | 2 | 15.59 | 35.57 | 16.17 |

| 5 | 50 | 2 | 17.45 | 51.74 | |

| 6 | 30 | 3 | 17.82 | 54.96 | 11.13 |

| 7 | 50 | 3 | 19.10 | 66.09 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biswas, R.K.; Bin Ahmed, F.; Haque, M.E.; Provasha, A.A.; Hasan, Z.; Hayat, F.; Sen, D. Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete. Appl. Mech. 2021, 2, 501-515. https://doi.org/10.3390/applmech2030028

Biswas RK, Bin Ahmed F, Haque ME, Provasha AA, Hasan Z, Hayat F, Sen D. Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete. Applied Mechanics. 2021; 2(3):501-515. https://doi.org/10.3390/applmech2030028

Chicago/Turabian StyleBiswas, Rajib Kumar, Farabi Bin Ahmed, Md. Ehsanul Haque, Afra Anam Provasha, Zahid Hasan, Faria Hayat, and Debasish Sen. 2021. "Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete" Applied Mechanics 2, no. 3: 501-515. https://doi.org/10.3390/applmech2030028

APA StyleBiswas, R. K., Bin Ahmed, F., Haque, M. E., Provasha, A. A., Hasan, Z., Hayat, F., & Sen, D. (2021). Effects of Steel Fiber Percentage and Aspect Ratios on Fresh and Harden Properties of Ultra-High Performance Fiber Reinforced Concrete. Applied Mechanics, 2(3), 501-515. https://doi.org/10.3390/applmech2030028