Hydrogen Peroxide as a Green Oxidant for the Selective Catalytic Oxidation of Benzylic and Heterocyclic Alcohols in Different Media: An Overview

Abstract

1. Introduction

2. Selective Catalytic Oxidation of Benzylic and Heterocyclic Alcohols

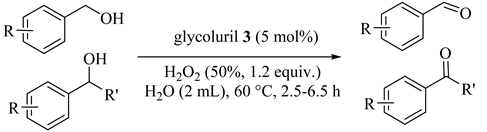

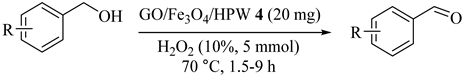

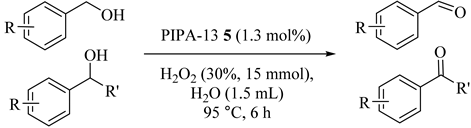

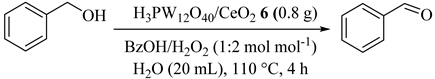

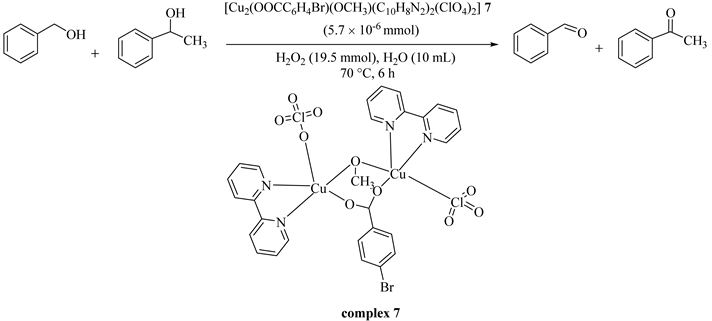

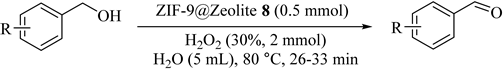

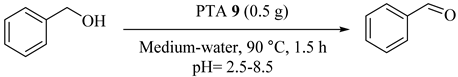

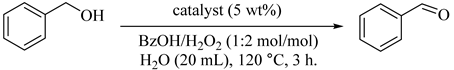

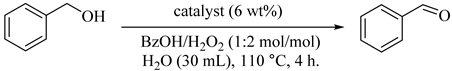

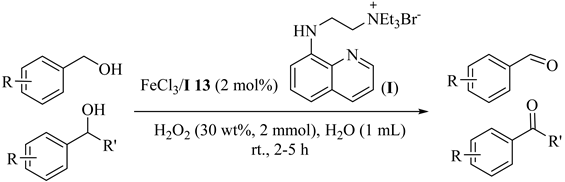

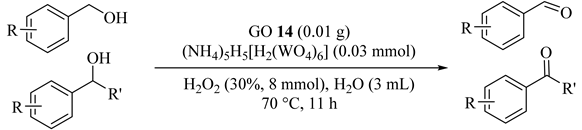

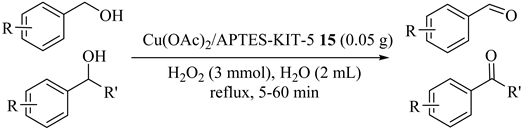

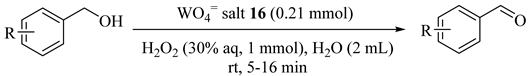

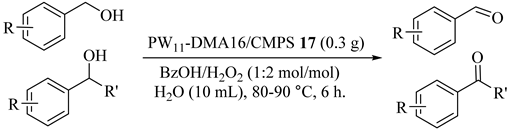

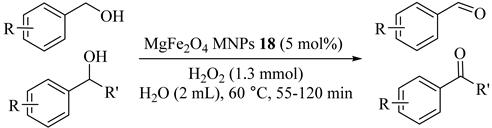

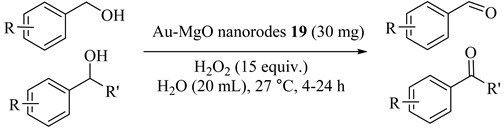

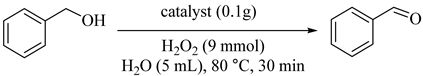

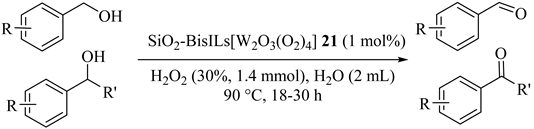

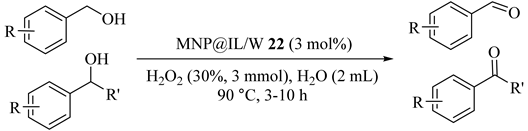

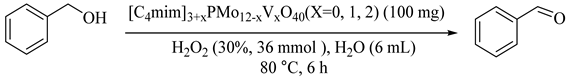

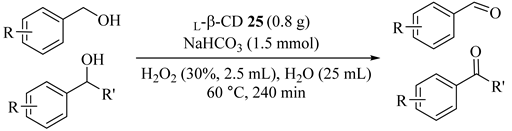

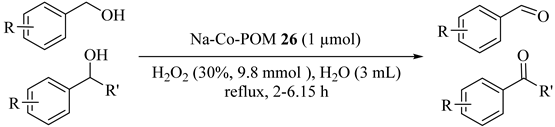

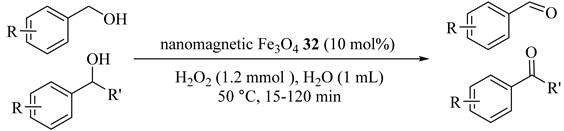

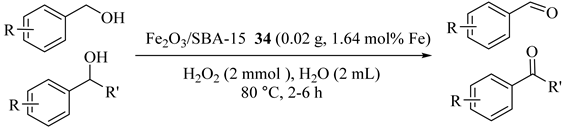

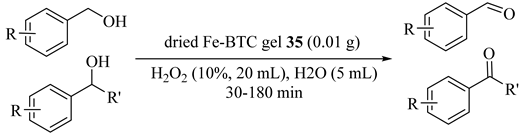

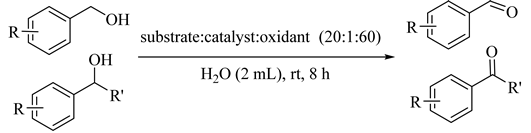

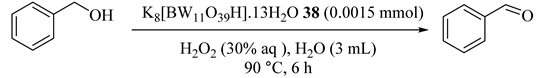

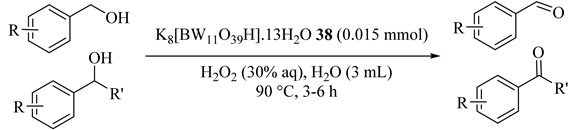

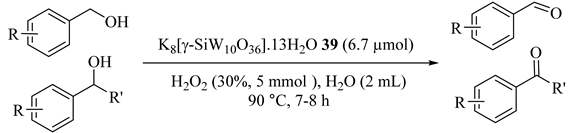

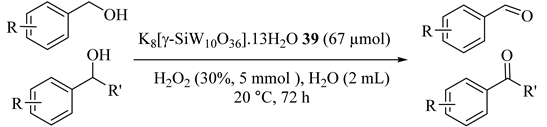

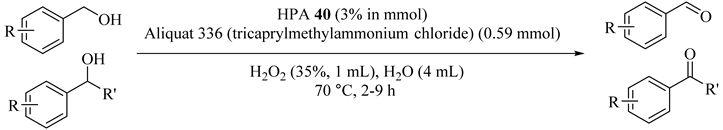

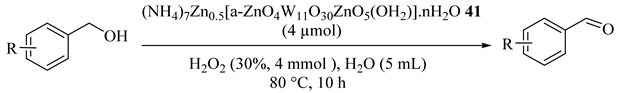

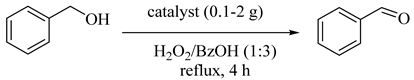

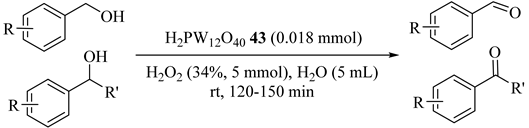

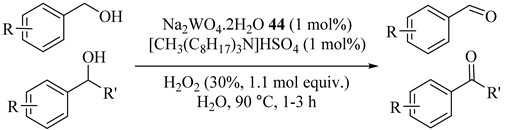

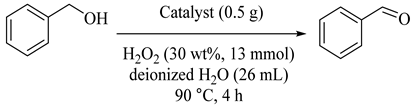

2.1. Oxidation of Benzylic and Heterocyclic Alcohols in Aqueous Media

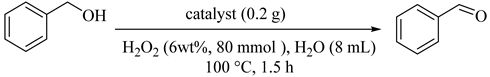

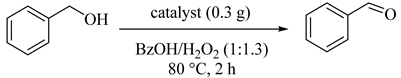

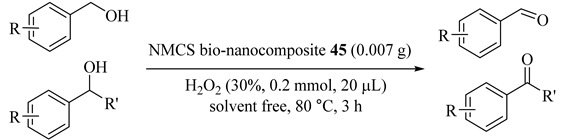

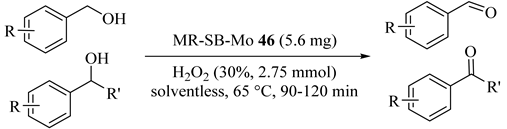

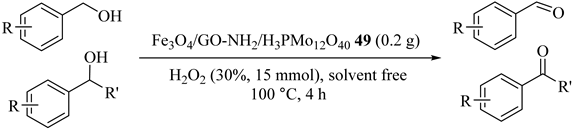

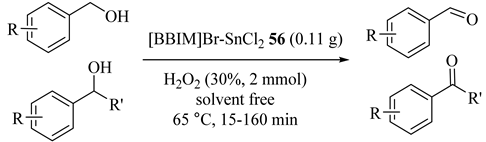

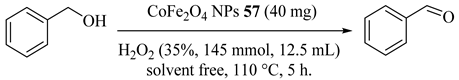

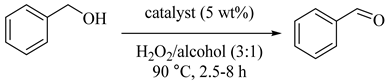

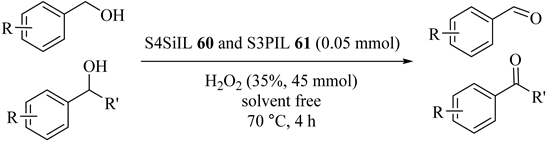

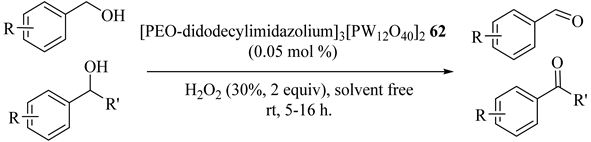

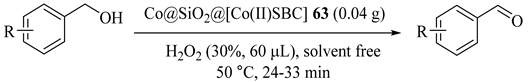

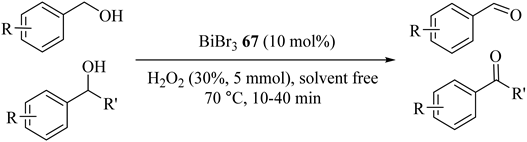

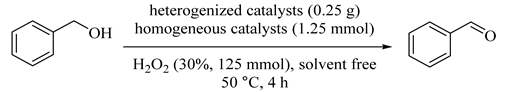

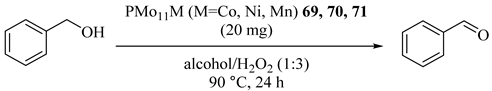

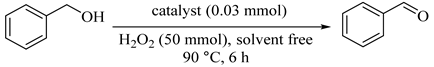

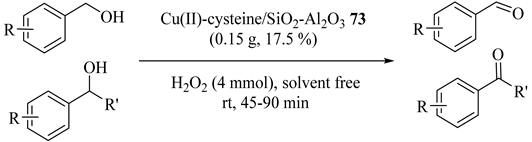

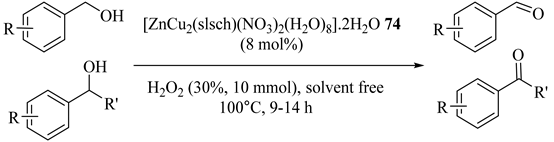

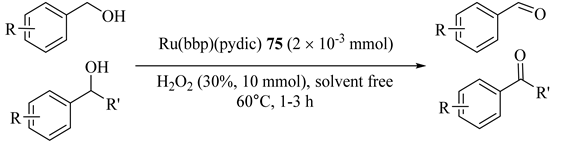

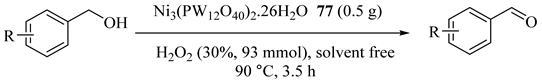

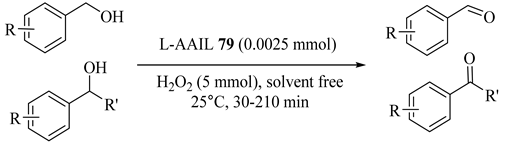

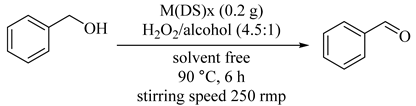

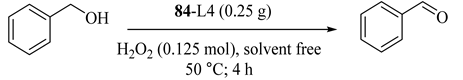

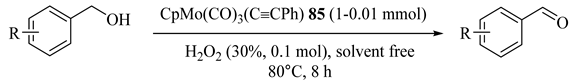

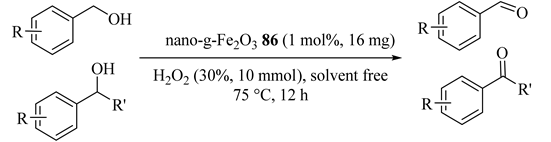

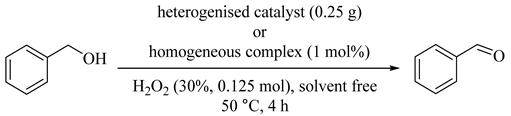

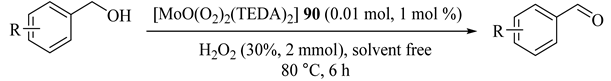

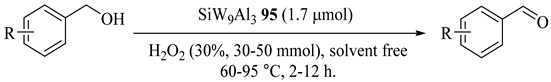

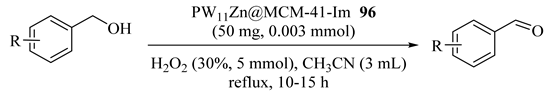

2.2. Oxidation of Benzylic and Heterocyclic Alcohols in a Solvent-Free System

2.3. Oxidation of Benzylic and Heterocyclic Alcohols in the Presence of Various Solvents

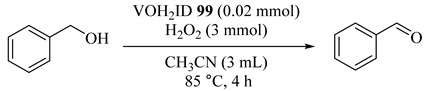

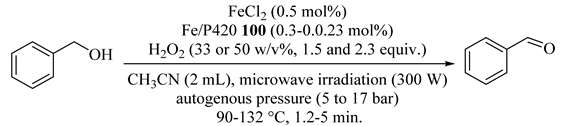

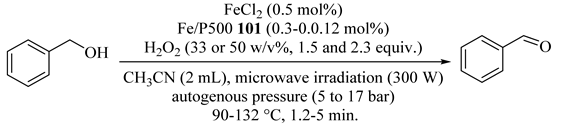

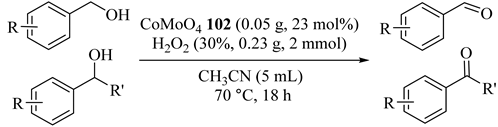

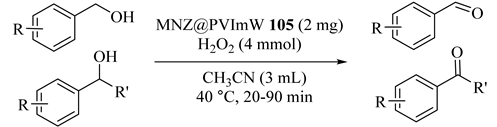

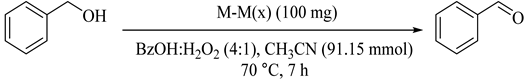

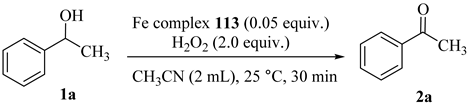

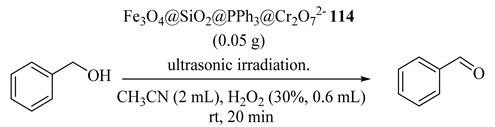

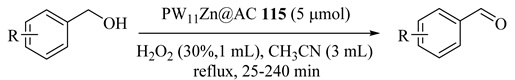

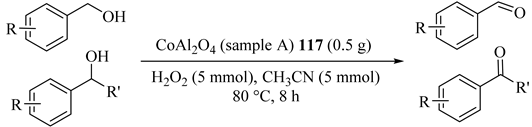

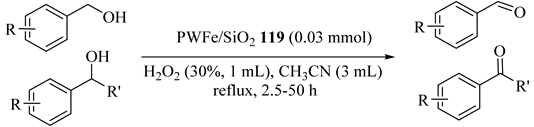

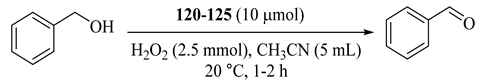

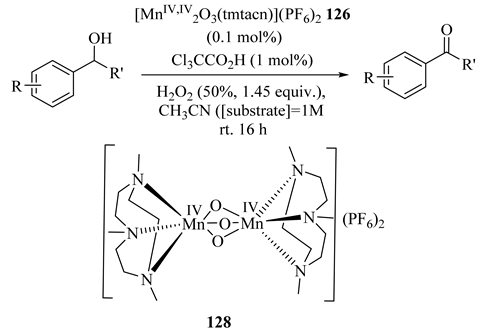

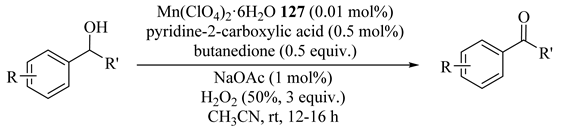

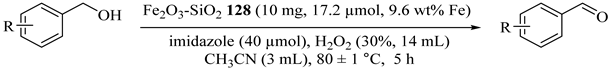

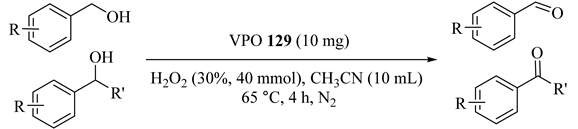

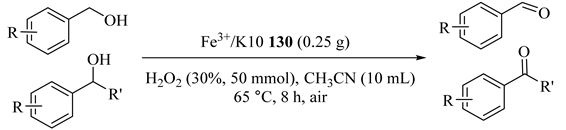

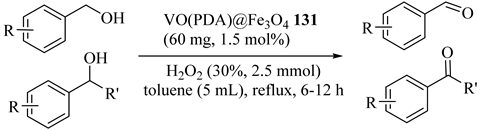

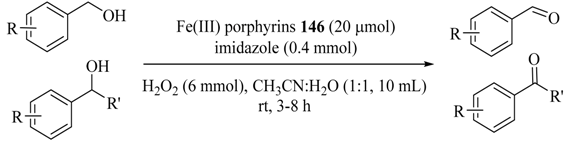

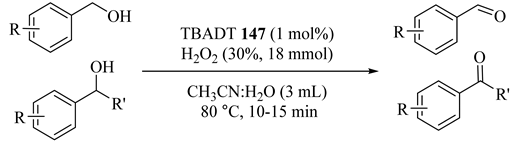

2.3.1. Acetonitrile Solvent

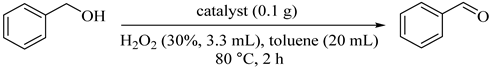

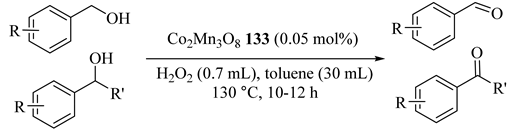

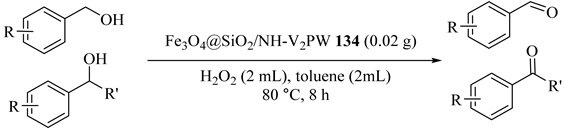

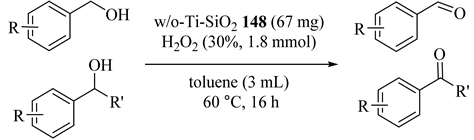

2.3.2. Toluene Solvent

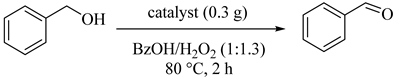

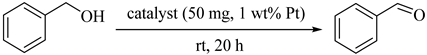

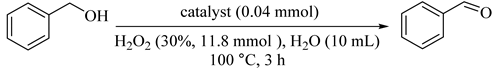

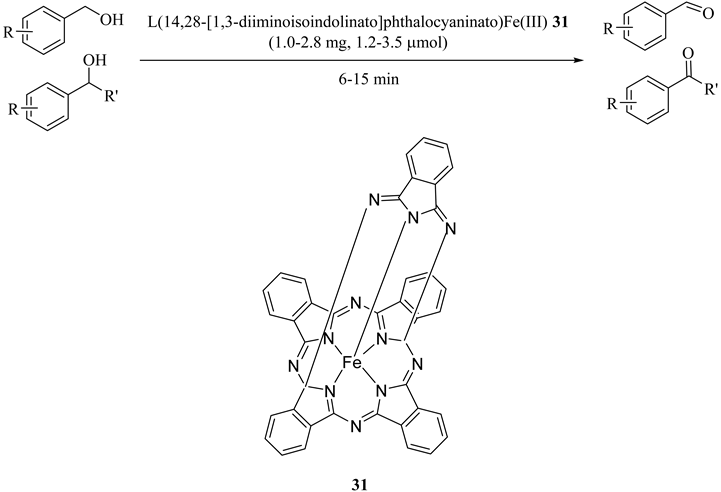

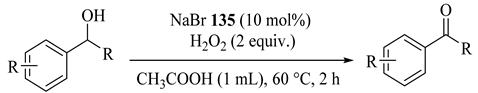

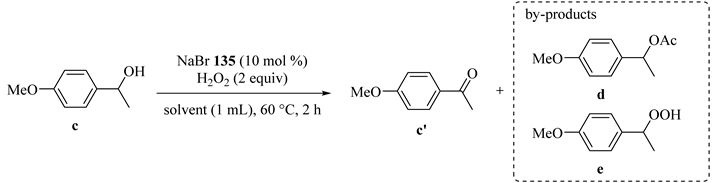

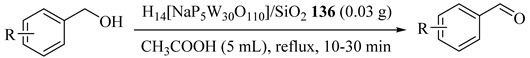

2.3.3. Acetic Acid Solvent

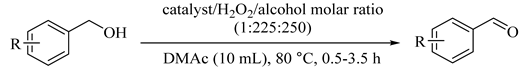

2.3.4. Dimethylacetamide Solvent

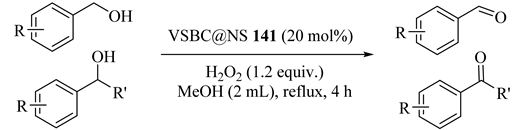

2.3.5. Methanol Solvent

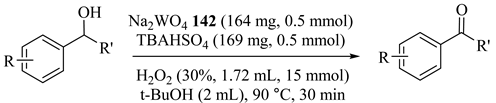

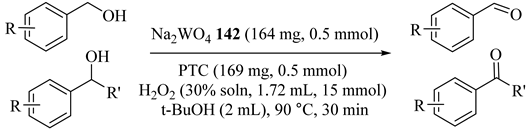

2.3.6. tert-Buthanol Solvent

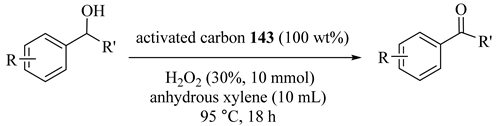

2.3.7. Xylene Solvent

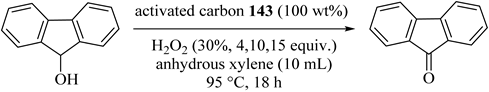

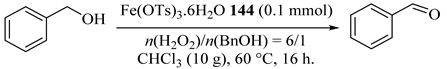

2.3.8. Chloroform Solvent

2.4. Oxidation of Benzylic and Heterocyclic Alcohols in Dual-Phase System

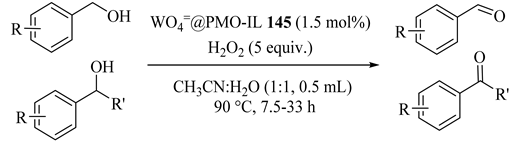

2.4.1. Acetonitrile-Water

2.4.2. Water-Toluene

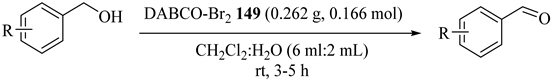

2.4.3. Dichloromethane-Water

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| PCC | pyridinium chlorochromate |

| BzOH | benzyl alcohol |

| BzH | benzaldehyde |

| RSM | response surface methodology |

| PTA | phosphotungstic acid |

| APTES | 3-aminopropyltriethoxysilane |

| TLC | thin layer chromatography |

| MNPs | magnetic nanoparticles |

| EPI | epichlorohydrin |

| MEG | ethylene glycol |

| EPR | electron paramagnetic resonance spectroscopy |

| TEA | trimethylamine |

| TBHP | tert-butyl hydroperoxide |

| Fe-BTC | iron(III)-benzenetricarboxylate |

| BET | Brunauer–Emmett–Teller |

| TEDA | 1,4-diazabicyclo[2.2.2]octane |

| OKR | oxidative kinetic resolution |

| POM | Polyoxometalate |

| AC | activated carbon |

| ABTSC | 1-(4-dimethylaminobenzylidene) thiosemicarbazide |

| TCTS | 1-(2-pyridincarboxyl-idene) thiosemicarbazide |

| TEOS | tetraethyl orthosilicate |

| TBA | tetra-n-butylammonium |

| PVP | polyvinylpolypyrrolidone |

| VPO | vanadium phosphorus oxide |

| DMAc | dimethylacetamide |

| UHP | urea-hydrogen peroxide |

| PEGDME250 | polyethylene glycol dimethyl ether 250 |

| TBAHSO4 | tetrabutyl ammonium hydrogen sulfate |

| PTC | phase transfer catalyst |

| TBADT | tetrabutylammonium decatungstate |

| DABCO | 1,4-diazabicyclo[2.2.2] octane |

References

- Chen, G.; Zhou, Y.; Long, Z.; Wang, X.; Li, J.; Wang, J. Mesoporous polyoxometalate-based ionic hybrid as a triphasic catalyst for oxidation of benzyl alcohol with H2O2 on water. ACS Appl. Mater. Interfaces 2014, 6, 4438–4446. [Google Scholar] [CrossRef] [PubMed]

- Anastas, P.T.; Warner, J.C. Principles of green chemistry. In Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Sheldon, R.A.; Arends, I.; Dijksman, A. New developments in catalytic alcohol oxidations for fine chemicals synthesis. Catal. Today 2000, 57, 157–166. [Google Scholar] [CrossRef]

- Lee, D.G.; Spitzer, U.A. Aqueous dichromate oxidation of primary alcohols. J. Org. Chem. 1970, 35, 3589–3590. [Google Scholar] [CrossRef]

- Trost, B.M. The atom economy--a search for synthetic efficiency. Science 1991, 254, 1471–1477. [Google Scholar] [CrossRef]

- Carey, J.S.; Laffan, D.; Thomson, C.; Williams, M.T. Analysis of the reactions used for the preparation of drug candidate molecules. Org. Biomol. Chem. 2006, 4, 2337–2347. [Google Scholar] [CrossRef]

- Parmeggiani, C.; Cardona, F. Transition metal based catalysts in the aerobic oxidation of alcohols. Green Chem. 2012, 14, 547–564. [Google Scholar] [CrossRef]

- Goti, A.; Cardona, F. Hydrogen peroxide in green oxidation reactions: Recent catalytic processes. In Green Chemical Reactions; Springer: Berlin/Heidelberg, Germany, 2008; pp. 191–212. [Google Scholar]

- Jones, C. Applications of Hydrogen Peroxide and Derivatives; Royal Society of Chemistry: Cambridge, UK, 1999; Volume 5, pp. 65–69. [Google Scholar]

- Strukul, G. Catalytic Oxidations with Hydrogen Peroxide as Oxidant; Kluwer Academic: Dordrecht, The Netherlands, 1992. [Google Scholar]

- Sato, K.; Hyodo, M.; Aoki, M.; Zheng, X.-Q.; Noyori, R. Oxidation of sulfides to sulfoxides and sulfones with 30% hydrogen peroxide under organic solvent-and halogen-free conditions. Tetrahedron 2001, 57, 2469–2476. [Google Scholar] [CrossRef]

- Dumitriu, E.; Guimon, C.; Cordoneanu, A.; Casenave, S.; Hulea, T.; Chelaru, C.; Martinez, H.; Hulea, V. Heterogeneous sulfoxidation of thioethers by hydrogen peroxide over layered double hydroxides as catalysts. Catal. Today 2001, 66, 529–534. [Google Scholar] [CrossRef]

- Noyori, R.; Aoki, M.; Sato, K. Green oxidation with aqueous hydrogen peroxide. Chem. Commun. 2003, 16, 1977–1986. [Google Scholar] [CrossRef]

- Dixneuf, P.; Cadierno, V. Metal-Catalyzed Reactions in Water; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Guajardo, N.; Carlesi, C.; Schrebler, R.; Morales, J. Applications of liquid/liquid biphasic oxidations by hydrogen peroxide with ionic liquids or deep eutectic solvents. ChemPlusChem 2017, 82, 165–176. [Google Scholar] [CrossRef]

- Ahmad, J.U.; Räisänen, M.T.; Leskelä, M.; Repo, T. Copper catalyzed oxidation of benzylic alcohols in water with H2O2. Appl. Catal A. Gen. 2012, 411, 180–187. [Google Scholar] [CrossRef]

- Ahmad, J.U.; Figiel, P.J.; Räisänen, M.T.; Leskelä, M.; Repo, T. Aerobic oxidation of benzylic alcohols with bis (3, 5-di-tert-butylsalicylaldimine) copper (II) complexes. Appl. Catal A. Gen. 2009, 371, 17–21. [Google Scholar] [CrossRef]

- Figiel, P.J.; Leskelä, M.; Repo, T. TEMPO-Copper (II) Diimine-Catalysed Oxidation of Benzylic Alcohols in Aqueous Media. Adv. Synth. Catal 2007, 349, 1173–1179. [Google Scholar] [CrossRef]

- Heravi, M.M.; Ajami, D.; Ghassemzadeh, M. Wet alumina supported chromium (VI) oxide: A mild, efficient and inexpensive reagent for oxidative deprotection of trimethylsilyl and tetrahydropyranyl ethers in a solventless system. Synthesis 1999, 1999, 393–394. [Google Scholar] [CrossRef]

- Heravi, M.M.; Behbahani, F.K.; Oskooie, H.A.; Shoar, R.H. Catalytic aromatization of Hantzsch 1,4-dihydropyridines by ferric perchlorate in acetic acid. Tetrahedron Lett. 2005, 46, 2775–2777. [Google Scholar] [CrossRef]

- Heravi, M.M.; Abdolhosseini, N.; Oskooie, H.A. Regioselective and high-yielding bromination of aromatic compounds using hexamethylenetetramine–bromine. Tetrahedron Lett. 2005, 46, 8959–8963. [Google Scholar] [CrossRef]

- Heravi, M.M.; Behbahani, F.K.; Oskooie, H.A.; Shoar, R.H. Mild and efficient tetrahydropyranylation of alcohols and dehydropyranylation of THP ethers catalyzed by ferric perchlorate. Tetrahedron Lett. 2005, 46, 2543–2545. [Google Scholar] [CrossRef]

- Bamoharram, F.F.; Heravi, M.M.; Roshani, M.; Tavakoli, N. N-oxidation of pyridine carboxylic acids using hydrogen peroxide catalyzed by a green heteropolyacid catalyst: Preyssler’s anion,[NaP5W30O110] 14−. J. Mol. Catal A Chem. 2006, 252, 219–225. [Google Scholar] [CrossRef]

- Bamoharram, F.F.; Heravi, M.M.; Roshani, M.; Akbarpour, M. Catalytic performance of Preyssler heteropolyacid as a green and recyclable catalyst in oxidation of primary aromatic amines. J. Mol. Catal A Chem. 2006, 255, 193–198. [Google Scholar] [CrossRef]

- Heravi, M. ‘Zeofen’, a user-friendly oxidizing reagent. Chem. Commun. 1999, 9, 833–834. [Google Scholar] [CrossRef]

- Heravi, M.M.; Zadsirjan, V.; Bakhtiari, K.; Oskooie, H.A.; Bamoharram, F.F. Green and reusable heteropolyacid catalyzed oxidation of benzylic, allylic and aliphatic alcohols to carbonyl compounds. Catal. Commun. 2007, 8, 315–318. [Google Scholar] [CrossRef]

- Heravi, M.M.; Derikvand, F.; Ghassemzadeh, M.; Neumüller, B. Synthesis, characterization and structure of a tetrameric DABCO–bromine complex: A novel oxidizing agent for oxidation of alcohols to carbonyl compounds. Tetrahedron Lett. 2005, 46, 6243–6245. [Google Scholar] [CrossRef]

- M Heravi, M.; Fazeli, A.; Faghihi, Z. Recent Advances in Application of Pyridinium Chlorochromate (PCC) in Organic Synthesis. Curr. Org. Synth. 2016, 13, 220–254. [Google Scholar] [CrossRef]

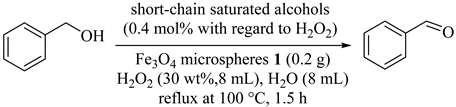

- Xiao, S.; Zhang, C.; Chen, R.; Chen, F. Selective oxidation of benzyl alcohol to benzaldehyde with H2O2 in water on epichlorohydrin-modified Fe 3 O 4 microspheres. New J. Chem. 2015, 39, 4924–4932. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, J.; Huang, X.; Chen, F. One-step nonaqueous synthesis of modified magnetic Fe3O4 microspheres by using epichlorohydrin as functional solvent. Chem. Lett. 2018, 48, 22–25. [Google Scholar] [CrossRef]

- Zhang, J.; Xiao, S.; Chen, R.; Chen, F. Promotional effect of short-chain saturated alcohols on Fe3O4-catalyzed decomposition of H2O2 and its application in selective oxidation of benzyl alcohol. J. Chem. Technol. Biot. 2019, 94, 1613–1621. [Google Scholar] [CrossRef]

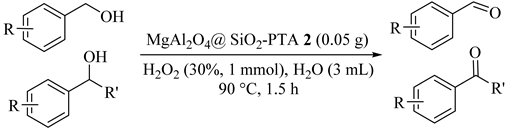

- Hajavazzade, R.; Kargarrazi, M.; Mahjoub, A.R. Phosphotungstic Acid Supported on MgAl2O4 Nanoparticles as an Efficient and Reusable Nanocatalyst for Benzylic Alcohols Oxidation with Hydrogen Peroxide. J. Inorg. Organomet. P 2019, 29, 1–10. [Google Scholar] [CrossRef]

- Farsani, M.R.; Yadollahi, B. Synthesis, characterization and catalytic performance of a Fe polyoxometalate/silica composite in the oxidation of alcohols with hydrogen peroxide. J. Mol. Catal A Chem. 2014, 392, 8–15. [Google Scholar] [CrossRef]

- Patel, P.; Nandi, S.; Menapara, T.; Biradar, A.V.; Nagarale, R.K.; Khan, N.H.; Kureshy, R.I. Glycoluril: A heterogeneous organocatalyst for oxidation of alcohols and benzylic sp3 carbons. App. Catal. A. Gen. 2018, 565, 127–134. [Google Scholar] [CrossRef]

- Darvishi, K.; Amani, K.; Rezaei, M. Preparation, characterization and heterogeneous catalytic applications of GO/Fe3O4/HPW nanocomposite in chemoselective and green oxidation of alcohols with aqueous H2O2. Appl. Organomet. Chem. 2018, 32, e4323. [Google Scholar] [CrossRef]

- Hao, P.; Zhang, M.; Zhang, W.; Tang, Z.; Luo, N.; Tan, R.; Yin, D. Polyoxometalate-based Gemini ionic catalysts for selective oxidation of benzyl alcohol with hydrogen peroxide in water. Catal. Sci. Technol. 2018, 8, 4463–4473. [Google Scholar] [CrossRef]

- Xiaoxiang, H.; Yingying, K.; Chunhua, X.; Xiujuan, T.; Qing, C.; Kuiwu, W.; Chin-Te, H.; Li-Li, L.; Shang-Bin, L. Heteropoly Tungstate Supported on Metal Oxide Catalysts for Liquid Phase Oxidation of Benzyl Alcohol with Hydrogen Peroxide. J. Braz. Chem. Soc. 2018, 29, 88–98. [Google Scholar] [CrossRef]

- Ünver, H. Crystal structure of an alkoxide bridged dinuclear copper (II) complex: Mild and selective oxidation of primary and secondary alcohols in water. Transit. Met. Chem. 2018, 43, 641–646. [Google Scholar] [CrossRef]

- Hashemian, S.; Sedrpoushan, A.; Eshbala, F.H. Co-Zeolite Imidazolate Frameworks (ZIF-9@ Zeolite) as Heterogen Catalyst for Alcohols Oxidation. Catal. Lett. 2017, 147, 196–203. [Google Scholar] [CrossRef]

- Bhattacharjee, R.R.; Mal, S.S. A Liquid Derivative of Phosphotungstic Acid as Catalyst for Benzyl Alcohol Oxidation in Water: Facile Separation and Stability of Benzaldehyde at Room Temperature. ChemistrySelect 2017, 2, 4368–4375. [Google Scholar] [CrossRef]

- Kai, O.; Xiaoxiang, H.; Chunhua, X.; Xiujuan, T.; Qing, C. Water-soluble heteropolyacid-based ionic liquids as effective catalysts for oxidation of benzyl alcohol in water with hydrogen peroxide. Green Process. Synth. 2017, 6, 385–395. [Google Scholar] [CrossRef]

- Han, X.; Kuang, Y.; Xiong, C.; Tang, X.; Chen, Q.; Hung, C.-T.; Liu, L.-L.; Liu, S.-B. Heterogeneous amino acid-based tungstophosphoric acids as efficient and recyclable catalysts for selective oxidation of benzyl alcohol. Korean J. Chem. Eng. 2017, 34, 1914–1923. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Li, X.; Zhao, J.; Bai, S.; Liu, J.; Yang, Q. A yolk–shell nanoreactor with a basic core and an acidic shell for cascade reactions. Angew. Chem. Int. Ed. 2012, 51, 9164–9168. [Google Scholar] [CrossRef]

- Yan, Q.; Fang, Y.C.; Jia, Y.X.; Duan, X.H. Chemoselective hydrogen peroxide oxidation of primary alcohols to aldehydes by a water-soluble and reusable iron (III) catalyst in pure water at room temperature. New J. Chem. 2017, 41, 2372–2377. [Google Scholar] [CrossRef]

- Fu, H.; Hu, C.; Huang, Z.; Zhou, J.; Peng, X. Ammonium Tungstate as an Effective Catalyst for Selective Oxidation of Alcohols to Aldehydes or Ketones with Hydrogen Peroxide under Water–A Synergy of Graphene Oxide. Synlett 2018, 29, 447–451. [Google Scholar]

- Mirsafaei, R.; Heravi, M.M.; Hosseinnejad, T.; Ahmadi, S. Copper (II) nanoparticles: An efficient and reusable catalyst in green oxidation of benzyl alcohols to benzaldehydes in water. Appl. Organomet. Chem 2016, 30, 823–830. [Google Scholar] [CrossRef]

- Hosseini Eshbala, F.; Mohanazadeh, F.; Sedrpoushan, A. Tungstate ions (WO4=) supported on imidazolium framework as novel and recyclable catalyst for rapid and selective oxidation of benzyl alcohols in the presence of hydrogen peroxide. Appl. Organomet. Chem 2017, 31, e3597. [Google Scholar] [CrossRef]

- Wang, H.; Fang, L.; Yang, Y.; Hu, R.; Wang, Y. Immobilization Na7PW11O39 on quanternary ammonium functionalized chloromethylated polystyrene by electrostatic interactions: An efficient recyclable catalyst for alcohol oxidation. App. Catal A Gen 2016, 520, 35–43. [Google Scholar] [CrossRef]

- Sloboda-Rozner, D.; Witte, P.; Alsters, P.L.; Neumann, R. Aqueous Biphasic Oxidation: A Water-Soluble Polyoxometalate Catalyst for Selective Oxidation of Various Functional Groups with Hydrogen Peroxide. Adv. Synth. Catal. 2004, 346, 339–345. [Google Scholar] [CrossRef]

- Sadri, F.; Ramazani, A.; Ahankar, H.; Taghavi Fardood, S.; Azimzadeh Asiabi, P.; Khoobi, M.; Woo Joo, S.; Dayyani, N. Aqueous-phase oxidation of alcohols with green oxidants (Oxone and hydrogen peroxide) in the presence of MgFe2O4 magnetic nanoparticles as an efficient and reusable catalyst. J. Nanostruct. 2016, 6, 264–272. [Google Scholar]

- Emayavaramban, P.; Babu, S.G.; Karvembu, R.; Kadirvelu, K.; Dharmaraj, N. Gold Nanoparticles Supported on Magnesium Oxide Nanorods for Oxidation of Alcohols. J. Nanosci. Nanotechno. 2016, 16, 2517–2526. [Google Scholar] [CrossRef]

- Cruz, P.; Pérez, Y.; del Hierro, I.; Fajardo, M. Copper, copper oxide nanoparticles and copper complexes supported on mesoporous SBA-15 as catalysts in the selective oxidation of benzyl alcohol in aqueous phase. Microporous Mesoporous Mater. 2016, 220, 136–147. [Google Scholar] [CrossRef]

- Kalbasi, R.J.; Nourbakhsh, A.A.; Zia, M. Aerobic Oxidation of Alcohols Catalyzed by Copper Nanoparticle-Polyacrylamide/SBA-15 as Novel Polymer-Inorganic Hybrid. J. Inorg. Organomet. P 2012, 22, 536–542. [Google Scholar] [CrossRef]

- Valodkar, V.; Tembe, G.; Ravindranathan, M.; Ram, R.; Rama, H. Catalytic oxidation by polymer-supported copper (II)–l-valine complexes. J. Mol. Catal. A Chem. 2004, 208, 21–32. [Google Scholar] [CrossRef]

- Fan, J.; Pu, F.; Sun, M.; Liu, Z.-W.; Han, X.-Y.; Wei, J.-F.; Shi, X.-Y. Immobilized bis-layered ionic liquids/peroxotungstates as an efficient catalyst for selective oxidation of alcohols in neat water. New J. Chem. 2016, 40, 10498–10503. [Google Scholar] [CrossRef]

- Zohreh, N.; Tavakolizadeh, M.; Hosseini, S.H.; Jahani, M.; Pourjavadi, A.; Bennett, C. Highly dispersible bis-imidazolium/WO 4 2− modified magnetic nanoparticles: A heterogeneous phase transfer catalyst for green and selective oxidations. New J. Chem. 2016, 40, 10325–10332. [Google Scholar] [CrossRef]

- Tong, J.; Su, L.; Li, W.; Wang, W.; Ma, H.; Wang, Q. Hybrids of [C4mim] 3+ xPMo12− xVxO40: A new catalyst for oxidation of benzyl alcohol to benzaldehyde in water with greatly improved performances. Polyhedron 2016, 115, 282–287. [Google Scholar] [CrossRef]

- Yao, X.; Bai, C.; Chen, J.; Li, Y. Efficient and selective green oxidation of alcohols by MOF-derived magnetic nanoparticles as a recoverable catalyst. RSC Adv. 2016, 6, 26921–26928. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, X.; Yao, X.; Fang, Y.; Chen, H.; Ji, H. β-cyclodextrin grafted on lignin as inverse phase transfer catalyst for the oxidation of benzyl alcohol in H2O. Tetrahedron 2016, 72, 1773–1781. [Google Scholar] [CrossRef]

- Farsani, M.R.; Assady, E.; Jalilian, F.; Yadollahi, B.; Rudbari, H.A. Green oxidation of alcohols with hydrogen peroxide catalyzed by a tetra-cobalt polyoxometalate in water. J. Iran. Chem. Soc. 2015, 12, 1207–1212. [Google Scholar] [CrossRef]

- Long, N.Q.; Quan, N.A. Highly selective oxidation of benzyl alcohol to benzaldehyde catalyzed by nano Au/γ-Al2O3 under environment-friendly conditions. React. Kinet. Mech. Catal. 2015, 114, 147–155. [Google Scholar] [CrossRef]

- Hong, Y.; Yan, X.; Liao, X.; Li, R.; Xu, S.; Xiao, L.; Fan, J. Platinum nanoparticles supported on Ca (Mg)-zeolites for efficient room-temperature alcohol oxidation under aqueous conditions. Chem. Commun. 2014, 50, 9679–9682. [Google Scholar] [CrossRef]

- Su, H.; Yang, C. Selective oxidation of benzyl alcohol catalyzed by (TEAH) nH3-nPW12O40 and its reaction mechanism. Chin. J. Catal. 2014, 35, 1224–1234. [Google Scholar] [CrossRef]

- Peterson, B.M.; Herried, M.E.; Neve, R.L.; McGaff, R.W. Oxidation of primary and secondary benzylic alcohols with hydrogen peroxide and tert-butyl hydroperoxide catalyzed by a “helmet” phthalocyaninato iron complex in the absence of added organic solvent. Dalton Trans. 2014, 43, 17899–17903. [Google Scholar] [CrossRef]

- Sadri, F.; Ramazani, A.; Massoudi, A.; Khoobi, M.; Tarasi, R.; Shafiee, A.; Azizkhani, V.; Dolatyari, L.; Joo, S.W. Green oxidation of alcohols by using hydrogen peroxide in water in the presence of magnetic Fe3O4 nanoparticles as recoverable catalyst. Green Chem. Lett. Rev. 2014, 7, 257–264. [Google Scholar] [CrossRef]

- Mu, B.; Liu, P.; Dong, Y.; Lu, C.; Wu, X. Superparamagnetic pH-sensitive multilayer hybrid hollow microspheres for targeted controlled release. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 3135–3144. [Google Scholar] [CrossRef]

- Wang, P.; Dong, Z.; Lei, Y.; Du, Y.; Li, H.; Yang, H.; Nie, Y.; Ma, J. Highly selective oxidation of alcohols catalyzed by Cu (II)-Schiff base-SBA-15 with hydrogen peroxide in water. J. Porous Mater. 2013, 20, 277–284. [Google Scholar] [CrossRef]

- Atashin, H.; Malakooti, R. Magnetic iron oxide nanoparticles embedded in SBA-15 silica wall as a green and recoverable catalyst for the oxidation of alcohols and sulfides. J. Saudi Chem. Soc. 2017, 21, S17–S24. [Google Scholar] [CrossRef]

- Davis, S.E.; Ide, M.S.; Davis, R.J. Selective oxidation of alcohols and aldehydes over supported metal nanoparticles. Green Chem. 2013, 15, 17–45. [Google Scholar] [CrossRef]

- Wei, Q.; James, S.L. A metal–organic gel used as a template for a porous organic polymer. Chem. Commun. 2005, 3, 1555–1556. [Google Scholar] [CrossRef]

- Hosseini-Monfared, H.; Näther, C.; Winkler, H.; Janiak, C. Highly selective and “green” alcohol oxidations in water using aqueous 10% H2O2 and iron-benzenetricarboxylate metal–organic gel. Inorg. Chim. Acta 2012, 391, 75–82. [Google Scholar] [CrossRef]

- Kharat, A.N.; Bakhoda, A.; Jahromi, B.T. Green and chemoselective oxidation of alcohols with hydrogen peroxide: A comparative study on Co (II) and Co (III) activity toward oxidation of alcohols. Polyhedron 2011, 30, 2768–2775. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Ma, B.; Ding, Y.; Qiu, W. Oxidation of alcohols with hydrogen peroxide in water catalyzed by recyclable keggin-type tungstoborate catalyst. Catal. Commun. 2010, 11, 527–531. [Google Scholar] [CrossRef]

- Ma, B.; Zhang, Y.; Ding, Y.; Zhao, W. A water-soluble dilacunary silicotungstate as an effective catalyst for oxidation alcohols in water with hydrogen peroxide. Catal. Commun. 2010, 11, 853–857. [Google Scholar] [CrossRef]

- Tundo, P.; Romanelli, G.P.; Vázquez, P.G.; Aricò, F. Multiphase oxidation of alcohols and sulfides with hydrogen peroxide catalyzed by heteropolyacids. Catal. Commun. 2010, 11, 1181–1184. [Google Scholar] [CrossRef]

- Maity, P.; Bhaduri, S.; Lahiri, G.K. A water soluble heteropolyoxotungstate as a selective, efficient and environment friendly oxidation catalyst. J. Chem. Sci. 2009, 121, 377–385. [Google Scholar] [CrossRef][Green Version]

- Sato, K.; Aoki, M.; Takagi, J.; Noyori, R. Organic solvent-and halide-free oxidation of alcohols with aqueous hydrogen peroxide. J. Amer. Chem. Soc. 1997, 119, 12386–12387. [Google Scholar] [CrossRef]

- Sato, K.; Takagi, J.; Aoki, M.; Noyori, R. Hydrogen peroxide oxidation of benzylic alcohols to benzaldehydes and benzoic acids under halide-free conditions. Tetrahedron Lett. 1998, 39, 7549–7552. [Google Scholar] [CrossRef]

- Jia, A.; Lou, L.-L.; Zhang, C.; Zhang, Y.; Liu, S. Selective oxidation of benzyl alcohol to benzaldehyde with hydrogen peroxide over alkali-treated ZSM-5 zeolite catalysts. J. Mol. Catal A. Chem 2009, 306, 123–129. [Google Scholar] [CrossRef]

- Tayebee, R.; Alizadeh, M.H. Water as an efficient solvent for oxygenation transformations with 34% hydrogen peroxide catalyzed by some heteropolyoxometalates. Monatsh. Chem. 2007, 138, 763–769. [Google Scholar] [CrossRef]

- Hulce, M.; Marks, D.W. Organic-solvent-free phase-transfer oxidation of alcohols using hydrogen peroxide. J. Chem. Educ. 2001, 78, 66. [Google Scholar] [CrossRef]

- Lampman, G.M.; Sharpe, S.D. A phase transfer catalyzed permanganate oxidation: Preparation of vanillin from isoeugenol acetate. J. Chem. Educ. 1983, 60, 503. [Google Scholar] [CrossRef]

- Naeimi, A.; Honarmand, M.; Sedri, A. Ultrasonic assisted fabrication of first MoO3/copper complex bio-nanocomposite based on Sesbania sesban plant for green oxidation of alcohols. Ultrason. Sonochem. 2019, 50, 331–338. [Google Scholar] [CrossRef]

- Boruah, J.J.; Das, S.P. Solventless, selective and catalytic oxidation of primary, secondary and benzylic alcohols by a Merrifield resin supported molybdenum (vi) complex with H2O2 as an oxidant. RSC Adv. 2018, 8, 34491–34504. [Google Scholar] [CrossRef]

- Dimitratos, N.; Lopez-Sanchez, J.A.; Morgan, D.; Carley, A.F.; Tiruvalam, R.; Kiely, C.J.; Bethell, D.; Hutchings, G.J. Solvent-free oxidation of benzyl alcohol using Au–Pd catalysts prepared by sol immobilisation. PCCP 2009, 11, 5142–5153. [Google Scholar] [CrossRef]

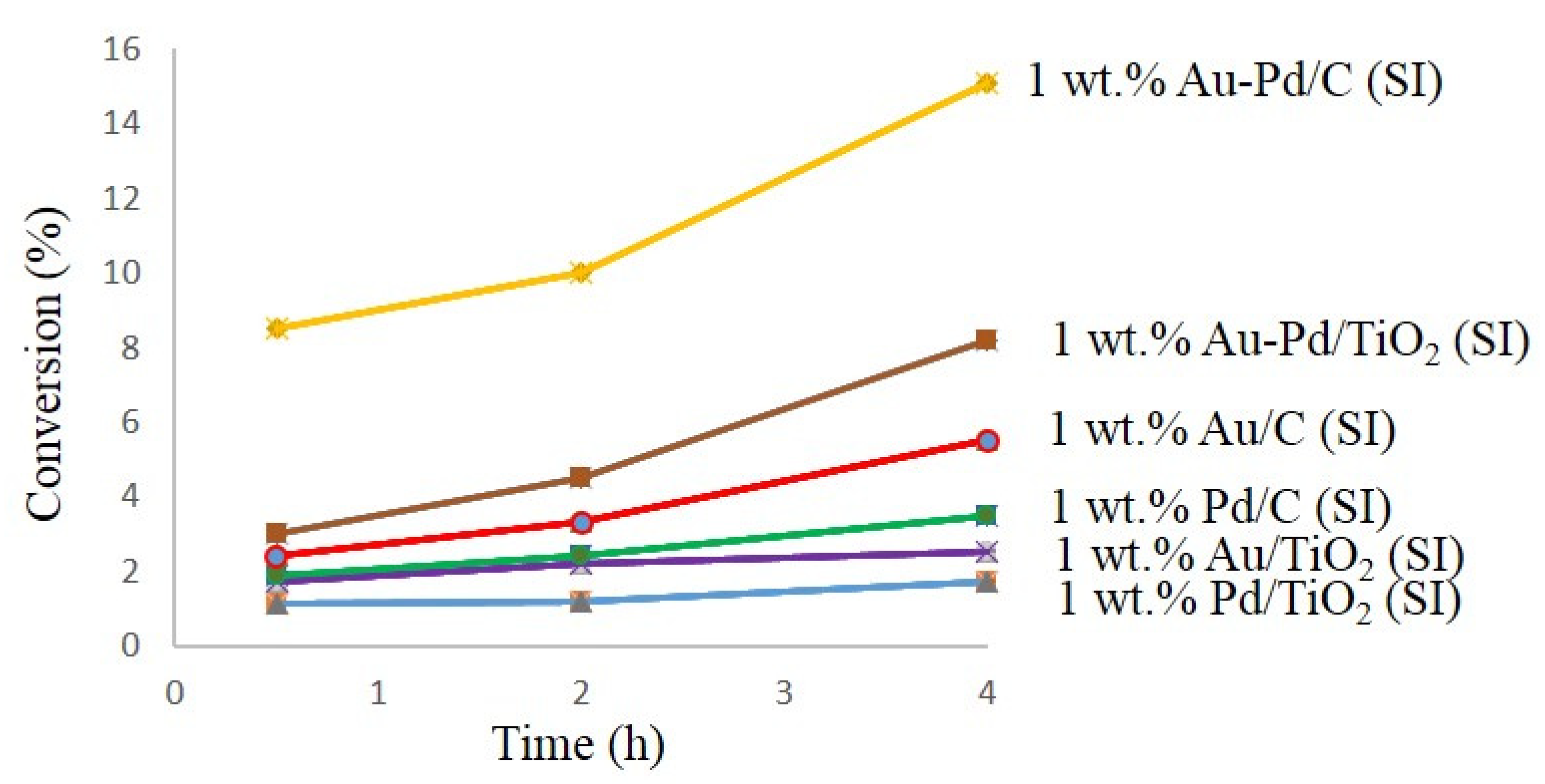

- Tareq, S.S.; Saiman, M.I.; Hin, T.-Y.Y.; Abdullah, A.H.; Rashid, U. The impact of hydrogen peroxide as an oxidant for solvent-free liquid phase oxidation of benzyl alcohol using Au-Pd supported carbon and titanium catalysts. Bull. Chem. React. Eng. 2018, 13, 373–385. [Google Scholar] [CrossRef]

- Farhadi, S.; Hakimi, M.; Maleki, M. 12-Molybdophosphoric acid anchored on aminopropylsilanized magnetic graphene oxide nanosheets (Fe3O4/GrOSi(CH2)3–NH2/H3 PMo12O40): A novel magnetically recoverable solid catalyst for H2O2-mediated oxidation of benzylic alcohols under solvent-free conditions. RSC Adv. 2018, 8, 6768–6780. [Google Scholar]

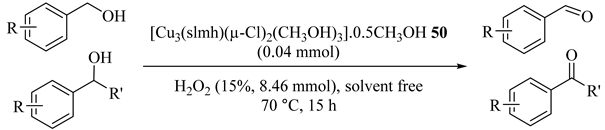

- D Kurbah, S.; Kumar, A.; Shangpung, S.; Asthana, M.; Syiemlieh, I.; A Lal, R. Oxidation of Alcohols by Hydrogen Peroxide Catalyzed by Trinuclear Copper (II) Complex [Cu3(slmh)(μ-Cl)2(CH3OH)3]. 0.5 CH3OH derived from Disalicylaldehyde Malonoyldihydrazone. Curr. Organocatalysis 2017, 4, 62–68. [Google Scholar] [CrossRef]

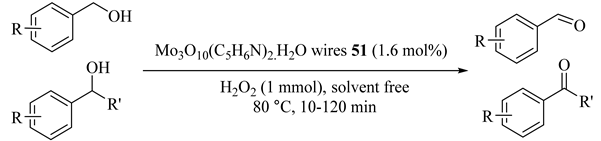

- Malakooti, R.; Feghhi, A. MoO x–pyridine organic–inorganic hybrid wires as a reusable and highly selective catalyst for the oxidation of alcohols: A comparison study between reaction-controlled phase-transfer catalysis and heterogeneous catalysis. New J. Chem. 2017, 41, 3405–3413. [Google Scholar] [CrossRef]

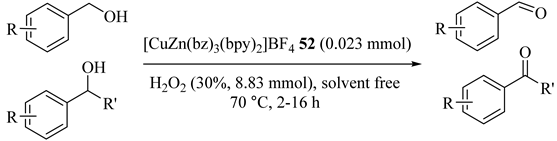

- D Kurbah, S.; Kumar, A.; Asthana, M.; Shangpung, S.; Koch, A.; A Lal, R. Water Soluble Heterobimetallic Complex [CuZn (bz)3(bpy)2] BF4 a Catalyzed Selective Oxidation of Alcohols to Aldehydes Mediated by Hydrogen Peroxide in Aqueous Medium in the Absence of a Base and Co-Catalyst. Curr. Organocatalysis 2016, 3, 45–51. [Google Scholar] [CrossRef]

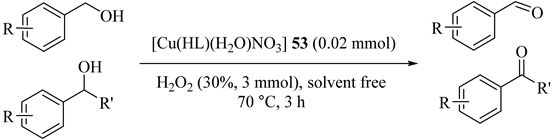

- Saeednia, S.; Ardakani, M.H.; Pakdin-Parizi, Z.; Iranmanesh, P.; Sinaei, S. Solvent-free chemoselective oxidation of alcohols by hydrogen peroxide using a new synthesized copper complex as reusable heterogeneous nanocatalyst. J. Iran. Chem. Soc. 2016, 13, 1963–1975. [Google Scholar] [CrossRef]

- Saxena, S.K.; Viswanadham, N.; Ala’a, H. Enhanced selective oxidation of benzyl alcohol to benzaldehyde on mesopore created mordenite catalyst. J. Porous Mater. 2016, 23, 1671–1678. [Google Scholar] [CrossRef]

- Wang, B.; Hu, Y.; Fang, D.; Wu, L.; Xing, R. Efficient and Reusable Sn (II)-containing Imidazolium-based Ionic Liquid as a Catalyst for the Oxidation of Benzyl Alcohol. J. Chin. Chem. Soc. 2016, 63, 991–999. [Google Scholar] [CrossRef]

- Nasrollahzadeh, M.; Bagherzadeh, M.; Karimi, H. Preparation, characterization and catalytic activity of CoFe2O4 nanoparticles as a magnetically recoverable catalyst for selective oxidation of benzyl alcohol to benzaldehyde and reduction of organic dyes. J. Colloid Interface Sci. 2016, 465, 271–278. [Google Scholar] [CrossRef]

- Trakarnpruk, W. Mn-and Co-substituted polyoxotungstates on MCM-41 and layered double hydroxide as catalysts in the oxidation of benzyl alcohol and cyclohexane. Mendeleev. Commun. 2016, 3, 256–258. [Google Scholar] [CrossRef]

- Varadwaj, G.B.B.; Rana, S.; Parida, K. Cs salt of Co substituted lacunary phosphotungstate supported K10 montmorillonite showing binary catalytic activity. Biochem. Eng. J. 2013, 215, 849–858. [Google Scholar] [CrossRef]

- Zhou, W.; Liu, J.; Pan, J.; Sun, F.a.; He, M.; Chen, Q. Effect of Mg2+ on the catalytic activities of CoMgAl hydrotalcites in the selective oxidation of benzyl alcohol to benzaldehyde. Catal. Commun. 2015, 69, 1–4. [Google Scholar] [CrossRef]

- Hasannia, S.; Yadollahi, B. Zn–Al LDH nanostructures pillared by Fe substituted Keggin type polyoxometalate: Synthesis, characterization and catalytic effect in green oxidation of alcohols. Polyhedron 2015, 99, 260–265. [Google Scholar] [CrossRef]

- Li, X.; Cao, R.; Lin, Q. Selective oxidation of alcohols with H2O2 catalyzed by long chain multi-SO3H functionalized heteropolyanion-based ionic liquids under solvent-free conditions. Catal. Commun. 2015, 69, 5–10. [Google Scholar] [CrossRef]

- Wang, Z.-G.; Yang, Y.; Cao, X.-H.; Lu, M. Highly selective oxidation of alcohols with hydrogen peroxide and polyethylene oxide-supported long-chain imidazolium polyoxometalate hybrid catalyst. J. Iran. Chem. Soc. 2015, 12, 1765–1770. [Google Scholar] [CrossRef]

- Judy-Azar, A.-R.; Mohebbi, S. A novel magnetic hybrid nanomaterial as a highly efficient and selective catalyst for alcohol oxidation based on new Schiff base complexes of transition metal ions. J. Mol. Catal A Chem. 2015, 397, 158–165. [Google Scholar] [CrossRef]

- Han, M.-K.; Kim, S.; Kim, S.T.; Lee, J.C. Bismuth Tribromide Catalyzed Oxidation of Alcohols with Aqueous Hydrogen Peroxide. Synlett 2015, 26, 2434–2436. [Google Scholar]

- Wu, G.; Wang, X.; Liu, X.; Ding, K.; Zhang, F.; Zhang, X. Environmental benign oxidation of benzyl alcohol catalyzed by sulphonato-salphen–chromium (III) complexes immobilized on MCM-41. Catal. Lett. 2014, 144, 364–371. [Google Scholar] [CrossRef]

- Pathan, S.; Patel, A. Solvent free clean selective oxidation of alcohols catalyzed by mono transition metal (Co, Mn, Ni)-substituted Keggin-phosphomolybdates using hydrogen peroxide. App. Catal A. Gen. 2013, 459, 59–64. [Google Scholar] [CrossRef]

- Jing, L.; Shi, J.; Zhang, F.; Zhong, Y.; Zhu, W. Polyoxometalate-based amphiphilic catalysts for selective oxidation of benzyl alcohol with hydrogen peroxide under organic solvent-free conditions. Ind. Eng. Chem. Res. 2013, 52, 10095–10104. [Google Scholar] [CrossRef]

- Zamani, F.; Izadi, E. Synthesis and Characterization of Copper (II)–Cysteine/SiO2–Al2O3 as an Efficient and Reusable Heterogeneous Catalyst for the Oxidation of Aromatic Alcohols. J. Inorg. Organomet. P 2013, 23, 1501–1510. [Google Scholar] [CrossRef]

- Borthakur, R.; Asthana, M.; Kumar, A.; Koch, A.; Lal, R. Solvent free selective oxidation of alcohols catalyzed by a trinuclear complex with a dicopper (II)–monozinc (II) centre using hydrogen peroxide as an oxidant. RSC Adv. 2013, 3, 22957–22962. [Google Scholar] [CrossRef]

- Zhou, X.-T.; Ji, H.-B.; Liu, S.-G. Solvent-free selective oxidation of primary and secondary alcohols catalyzed by ruthenium-bis (benzimidazole) pyridinedicarboxylate complex using hydrogen peroxide as an oxidant. Tetrahedron Lett. 2013, 54, 3882–3885. [Google Scholar] [CrossRef][Green Version]

- Tian, W.; Hou, Y.; Wang, X.; Lu, B.; Zhao, J.; Cai, Q. A Simple Polyoxometallate for Selective Oxidation of Benzyl Alcohol to Benzaldehyde with Hydrogen Peroxide. Chin. J. Chem. 2012, 30, 433–437. [Google Scholar] [CrossRef]

- Karthikeyan, P.; Arunrao, A.S.; Narayan, M.P.; Kumar, S.S.; Kumar, S.S.; Bhagat, P.R. Selective oxidation of alcohol to carbonyl compound catalyzed by l-aspartic acid coupled imidazolium based ionic liquid. J. Mol. Liq. 2012, 173, 180–183. [Google Scholar] [CrossRef]

- Yu, Y.; Lu, B.; Wang, X.; Zhao, J.; Wang, X.; Cai, Q. Highly selective oxidation of benzyl alcohol to benzaldehyde with hydrogen peroxide by biphasic catalysis. Biochem. Eng. J. 2010, 162, 738–742. [Google Scholar] [CrossRef]

- Cui, S.; Lu, B.; Xiao, X.; Han, Y.; Cai, Q. Synthesis of diphenylmethane from benzene and paraformaldehyde catalyzed by acidic ionic liquids. Catal. Lett. 2007, 119, 277–282. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Wei, W.; Sun, Y. Solvent-free oxidation of alcohols by hydrogen peroxide over chromium Schiff base complexes immobilized on MCM-41. Transit. Met. Chem. 2010, 35, 213–220. [Google Scholar] [CrossRef]

- Biradar, A.V.; Dongare, M.K.; Umbarkar, S.B. Selective oxidation of aromatic primary alcohols to aldehydes using molybdenum acetylide oxo-peroxo complex as catalyst. Tetrahedron Lett. 2009, 50, 2885–2888. [Google Scholar] [CrossRef]

- Shi, F.; Tse, M.K.; Pohl, M.-M.; Radnik, J.; Brückner, A.; Zhang, S.; Beller, M. Nano-iron oxide-catalyzed selective oxidations of alcohols and olefins with hydrogen peroxide. J. Mol. Catal A. Chem 2008, 292, 28–35. [Google Scholar] [CrossRef]

- Wang, X.; Wu, G.; Li, J.; Zhao, N.; Wei, W.; Sun, Y. Surface-modified improvement in catalytic performance of Cr (salen) complexes immobilized on MCM-41 in solvent-free selective oxidation of benzyl alcohol. Catal. Lett. 2007, 119, 87–94. [Google Scholar] [CrossRef]

- Wang, G.; Feng, L.; Luck, R.L.; Evans, D.G.; Wang, Z.; Duan, X. Sol–gel synthesis, characterization and catalytic property of silicas modified with oxomolybdenum complexes. J. Mol. Catal A Chem. 2005, 241, 8–14. [Google Scholar] [CrossRef]

- Ming-Lin, G.; Hui-Zhen, L. Selective oxidation of benzyl alcohol to benzaldehyde with hydrogen peroxide over tetra-alkylpyridinium octamolybdate catalysts. Green Chem. 2007, 9, 421–423. [Google Scholar] [CrossRef]

- Wang, J.; Yan, L.; Qian, G.; Li, S.; Yang, K.; Liu, H.; Wang, X. Na4H3[SiW9Al3(H2O)3O37]·12H2O/H2O: A new system for selective oxidation of alcohols with H2O2 as oxidant. Tetrahedron 2007, 63, 1826–1832. [Google Scholar] [CrossRef]

- Hajian, R.; Jafari, F. Zinc polyoxometalate immobilized on ionic liquid-modified MCM-41: An efficient reusable catalyst for the selective oxidation of alcohols with hydrogen peroxide. J. Iran. Chem. Soc. 2019, 16, 563–570. [Google Scholar] [CrossRef]

- Sedighipoor, M.; Kianfar, A.H.; Mahmood, W.A.K.; Azarian, M.H. Epoxidation of alkenes by an oxidovanadium (IV) tetradentate Schiff base complex as an efficient catalyst with tert-butyl hydroperoxide. Inorg. Chim. Acta 2017, 457, 116–121. [Google Scholar] [CrossRef]

- Adam, M.S.S. Catalytic activity of nickel (II), copper (II) and oxovanadium (II)-dihydroindolone complexes towards homogeneous oxidation reactions. Appl. Organomet. Chem. 2018, 32, e4234. [Google Scholar] [CrossRef]

- Mangin, F.; Prinsen, P.; Yepez, A.; Gilani, M.R.H.S.; Xu, G.; Len, C.; Luque, R. Microwave assisted benzyl alcohol oxidation using iron particles on furfuryl alcohol derived supports. Catal. Commun. 2018, 104, 67–70. [Google Scholar] [CrossRef]

- Chuanfeng, H.; Jianhao, Z.; Zhida, H.; Huihui, F.; Xinhua, P. Metal Molybdate Catalysts for the Selective Oxidation of Olefins and Alcohols Using Hydrogen Peroxide as Oxidant. Chin. J. Org. Chem. 2018, 38, 486–491. [Google Scholar]

- Maleki, M.; Baghbanian, S.M.; Tajbakhsh, M. Heteropolyacid immobilized on polymer/magnetic zeolite nanocomposite as a new and recyclable catalyst for the selective oxidation of alcohols. J. Iran.Chem. Soc. 2018, 15, 359–368. [Google Scholar] [CrossRef]

- Kurbah, S.D.; Asthana, M.; Syiemlieh, I.; Lal, R.A. Peroxidative catalytic oxidation of alcohols catalyzed by heterobinuclear vanadium (V) complexes using H2O2 as terminal oxidizing agents. Appl. Organomet. Chem. 2018, 32, e4299. [Google Scholar] [CrossRef]

- Cánepa, A.L.; Elías, V.R.; Vaschetti, V.M.; Sabre, E.V.; Eimer, G.A.; Casuscelli, S.G. Selective oxidation of benzyl alcohol through eco-friendly processes using mesoporous V-MCM-41, Fe-MCM-41 and Co-MCM-41 materials. App. Catal A. Gen. 2017, 545, 72–78. [Google Scholar] [CrossRef]

- Miao, C.; Li, X.-X.; Lee, Y.-M.; Xia, C.; Wang, Y.; Nam, W.; Sun, W. Manganese complex-catalyzed oxidation and oxidative kinetic resolution of secondary alcohols by hydrogen peroxide. Chem. Sci. 2017, 8, 7476–7482. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, S.; Kon, Y.; Ogawa, A.; Uesaka, Y.; Tamura, M.; Sato, K. Mixed Picolinate and Quinaldinate Iron (III) Complexes for the Catalytic Oxidation of Alcohols with Hydrogen Peroxide. ChemCatChem 2016, 8, 2930–2938. [Google Scholar] [CrossRef]

- Maleki, A.; Rahimi, R.; Maleki, S. Efficient oxidation and epoxidation using a chromium (VI)-based magnetic nanocomposite. Environ. Chem. Lett. 2016, 14, 195–199. [Google Scholar] [CrossRef]

- Assady, E.; Yadollahi, B.; Riahi Farsani, M.; Moghadam, M. Zinc polyoxometalate on activated carbon: An efficient catalyst for selective oxidation of alcohols with hydrogen peroxide. Appl. Organomet. Chem 2015, 29, 561–565. [Google Scholar] [CrossRef]

- Tayebani, M.; Shafaat, B.; Iravani, M. Hydrogen peroxide oxidation of primary alcohols by thiosemicarbazide Schiff base metal complexes. Iran. J. Catal. 2015, 5, 213–221. [Google Scholar]

- Ragupathi, C.; Vijaya, J.J.; Narayanan, S.; Jesudoss, S.; Kennedy, L.J. Highly selective oxidation of benzyl alcohol to benzaldehyde with hydrogen peroxide by cobalt aluminate catalysis: A comparison of conventional and microwave methods. Ceram. Int. 2015, 41, 2069–2080. [Google Scholar] [CrossRef]

- Prakash, S.; Charan, C.; Singh, A.K.; Shahi, V.K. Mixed metal nanoparticles loaded catalytic polymer membrane for solvent free selective oxidation of benzyl alcohol to benzaldehyde in a reactor. App. Catal B: Environ. 2013, 132, 62–69. [Google Scholar] [CrossRef]

- Szávuly, M.; Szilvási, S.D.; Csonka, R.; Klesitz, D.; Speier, G.; Giorgi, M.; Kaizer, J. Catalytic oxidation of alcohols and sulfides with hydrogen peroxide using isoindoline and phthalazine-based diiron complexes. J. Mol.Catal A. Chem 2014, 393, 317–324. [Google Scholar] [CrossRef]

- Saisaha, P.; Buettner, L.; van der Meer, M.; Hage, R.; Feringa, B.L.; Browne, W.R.; de Boer, J.W. Selective catalytic oxidation of alcohols, aldehydes, alkanes and alkenes employing manganese catalysts and hydrogen peroxide. Adv. Synth. Catal 2013, 355, 2591–2603. [Google Scholar] [CrossRef]

- de Boer, J.W.; Brinksma, J.; Browne, W.R.; Meetsma, A.; Alsters, P.L.; Hage, R.; Feringa, B.L. Cis-dihydroxylation and epoxidation of alkenes by [Mn2O(RCO2)2(tmtacn)2]: Tailoring the selectivity of a highly H2O2-efficient catalyst. J. Am. Chem. Soc. 2005, 127, 7990–7991. [Google Scholar] [CrossRef] [PubMed]

- de Boer, J.W.; Browne, W.R.; Brinksma, J.; Alsters, P.L.; Hage, R.; Feringa, B.L. Mechanism of cis-dihydroxylation and epoxidation of alkenes by highly H2O2 efficient dinuclear manganese catalysts. Inorg. Chem. 2007, 46, 6353–6372. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.J.; Unjaroen, D.; Mecozzi, F.; Harvey, E.C.; Saisaha, P.; Pijper, D.; de Boer, J.W.; Alsters, P.; Feringa, B.L.; Browne, W.R. Manganese-Catalyzed Selective Oxidation of Aliphatic C–H groups and Secondary Alcohols to Ketones with Hydrogen Peroxide. ChemSusChem 2013, 6, 1774–1778. [Google Scholar] [CrossRef]

- Masoudian, S.; Monfared, H.H.; Aghaei, A. Silica aerogel–iron oxide nanocomposites: Recoverable catalysts for the oxidation of alcohols with hydrogen peroxide. Transit. Met. Chem 2011, 36, 521–530. [Google Scholar] [CrossRef]

- Weng, Z.; Liao, G.; Wang, J.; Jian, X. Selective oxidation of benzyl alcohol with hydrogen peroxide over reaction-controlled phase-transfer catalyst. Catal. Commun. 2007, 8, 1493–1496. [Google Scholar] [CrossRef]

- Pillai, U.R.; Sahle-Demessie, E. Selective oxidation of alcohols over vanadium phosphorus oxide catalyst using hydrogen peroxide. App. Catal A. Gen. 2004, 276, 139–144. [Google Scholar] [CrossRef]

- Pillai, U.R.; Sahle-Demessie, E. Oxidation of alcohols over Fe3+/montmorillonite-K10 using hydrogen peroxide. App. Catal A. Gen. 2003, 245, 103–109. [Google Scholar] [CrossRef]

- Veisi, H.; Safarimehr, P.; Hemmati, S. Oxo-vanadium immobilized on polydopamine coated-magnetic nanoparticles (Fe3O4): A heterogeneous nanocatalyst for selective oxidation of sulfides and benzylic alcohols with H2O2. J. Taiwan. Inst. Chem. E 2018, 88, 8–17. [Google Scholar] [CrossRef]

- Kimi, M.; Jaidie, M.M.H.; Pang, S.C. Bimetallic Cu-Ni nanoparticles supported on activated carbon for catalytic oxidation of benzyl alcohol. J. Phys. Chem. Solids 2018, 112, 50–53. [Google Scholar] [CrossRef]

- Sarmah, K.; Pal, J.; Maji, T.K.; Pratihar, S. Magnetically Recoverable Heterobimetallic Co2Mn3O8: Selective and Sustainable Oxidation and Reduction Reactions. Acs Sustain. Chem. Eng. 2017, 5, 11504–11515. [Google Scholar] [CrossRef]

- Dong, X.; Zhang, X.; Wu, P.; Zhang, Y.; Liu, B.; Hu, H.; Xue, G. Divanadium-Substituted Phosphotungstate Supported on Magnetic Mesoporous Silica Nanoparticles as Effective and Recyclable Catalysts for the Selective Oxidation of Alcohols. ChemCatChem 2016, 8, 3680–3687. [Google Scholar] [CrossRef]

- Pääkkönen, S.; Pursiainen, J.; Lajunen, M. Room-temperature oxidation of secondary alcohols by bromate–bromide coupling in acidic water. Synth. Commun. 2012, 42, 534–540. [Google Scholar] [CrossRef]

- Kuroboshi, M.; Goto, K.; Tanaka, H. Electrooxidation of alcohols in N-oxyl-immobilized silica gel/water disperse system: Approach to totally closed system. Synthesis 2009, 2009, 903–908. [Google Scholar] [CrossRef]

- Moriyama, K.; Takemura, M.; Togo, H. Selective oxidation of alcohols with alkali metal bromides as bromide catalysts: Experimental study of the reaction mechanism. J. Org. Chem. 2014, 79, 6094–6104. [Google Scholar] [CrossRef]

- Komagawa, H.; Maejima, Y.; Nagano, T. Sodium bromide-catalyzed oxidation of secondary benzylic alcohols using aqueous hydrogen peroxide as terminal oxidant. Synlett 2016, 27, 789–793. [Google Scholar] [CrossRef]

- Weng, Z.; Wang, J.; Zhang, S.; Jian, X. Selective oxidation of benzyl alcohol by heteropolytungstate as reaction-controlled phase-transfer catalyst with hydrogen peroxide. Bull. Chem. Soc. Jpn 2008, 81, 525–529. [Google Scholar] [CrossRef]

- Dabiri, M.; Koohshari, M.; Shafipour, F.; Kasmaei, M.; Salari, P.; MaGee, D. Supported vanadium Schiff bases complex on nano silica: A heterogeneous catalyst for the selective oxidation of sulfides and alcohols. J. Iran. Chem. Soc. 2016, 13, 1265–1272. [Google Scholar] [CrossRef]

- Chhikara, B.S.; Chandra, R.; Tandon, V. A versatile method for the hydrogen peroxide oxidation of alcohols using ptc condition in tert-butanol. Synlett 2005, 2005, 0872–0874. [Google Scholar] [CrossRef]

- Nishida, S.; Hayashi, M. Oxidation of secondary benzylic alcohols to ketones and benzylic oxygenation of alkylarenes with hydrogen peroxide in the presence of activated carbon. Synlett 2012, 23, 1683–1685. [Google Scholar] [CrossRef]

- Zhao, Y.; Yu, C.; Wu, S.; Zhang, W.; Xue, W.; Zeng, Z. Synthesis of Benzaldehyde and Benzoic Acid by Selective Oxidation of Benzyl Alcohol with Iron (III) Tosylate and Hydrogen Peroxide: A Solvent-Controlled Reaction. Catal. Lett. 2018, 148, 3082–3092. [Google Scholar] [CrossRef]

- Karimi, B.; Rostami, F.B.; Khorasani, M.; Elhamifar, D.; Vali, H. Selective oxidation of alcohols with hydrogen peroxide catalyzed by tungstate ions (WO4=) supported on periodic mesoporous organosilica with imidazolium frameworks (PMO-IL). Tetrahedron 2014, 70, 6114–6119. [Google Scholar] [CrossRef]

- Masoudian, S.; Yahyaei, H. Oxidation of Alcohols with Hydrogen Peroxide Catalyzed by Supported Fe (III) Porphyrins; NISCAIR-CSIR: New Delhi, India, 2011. [Google Scholar]

- Galica, M.; Kasprzyk, W.; Bednarz, S.; Bogdał, D. Microwave-assisted oxidation of alcohols by hydrogen peroxide catalysed by tetrabutylammonium decatungstate. Chem. Pap. 2013, 67, 1240–1244. [Google Scholar] [CrossRef]

- Hayashi, H.; Kikawa, K.; Murai, Y.; Shigemoto, N.; Sugiyama, S.; Kawashioro, K. Competitive oxidation of 1-and 2-propanol catalyzed by titanium silicalite-1 and the application for selective oxidation of 1-methoxy-2-propanol to 1-methoxy-2-propanone. Catal. Lett. 1996, 36, 99–102. [Google Scholar] [CrossRef]

- Choi, K.-M.; Ikeda, S.; Ishino, S.; Ikeue, K.; Matsumura, M.; Ohtani, B. Oxidation of hydrophobic alcohols using aqueous hydrogen peroxide over amphiphilic silica particles loaded with titanium (IV) oxide as a liquid–liquid phase-boundary catalyst. Appl. Catal A. Gen. 2005, 278, 269–274. [Google Scholar] [CrossRef]

| ||||

| Entry | Additive | Conv. (%) | Yield (%) | Sel. (%) |

| 1 | No additive | 5.7 | 5.6 | 98.8 |

| 2 | Glycerol | 48.9 | 42.6 | 87.2 |

| 3 | Tert-butanol | 45.3 | 38.9 | 86 |

| 4 | Iso-propanol | 41.8 | 34.9 | 83.5 |

| 5 | Methanol | 22.8 | 19.5 | 85.5 |

| 6 | Ethanol | 13.5 | 11.5 | 85.4 |

| 7 | MEG | 17.4 | 14.5 | 83.2 |

| |||

| Entry | Substrate | Product | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 96 |

| 2 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 91 |

| 3 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 85 |

| 4 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 81 |

| 5 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 93 |

| 6 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 94 |

| 7 | C6H5CH(OH)CH3 | C6H5COCH3 | 98 |

| 8 | 4-MeC6H4CH(OH)CH3 | 4-MeC6H4COCH3 | 97 |

| 9 | 4-ClC6H4CH(OH)CH3 | 4-ClC6H4COCH3 | 95 |

| 10 | 3-BrC6H4CH(OH)CH3 | 3-BrC6H4COCH3 | 92 |

| 11 c | C6H5CH2OH | - | - |

| |||||

| Entry | Substrate | Product | t (h) | Conv. (%) | Sel. (%) |

| 1 | C6H5CH2OH | C6H5CHO | 3 | 99 | 98 |

| 2 | 4-OHC6H4CH2OH | 4-OHC6H4CHO | 5 | 93 | 97 |

| 3 | 4-FC6H4CH2OH | 4-FC6H4CHO | 4 | 95 | 98 |

| 4 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 4.5 | 92 | 98 |

| 5 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 4.5 | 93 | 96 |

| 6 | 3-Pyridinemethanol | 3-Pyridinecarboxaldehyde | 2.5 | 100 | 59 |

| 7 | 2-Pyridinemethanol | Picolinaldehyde | 2.5 | 99 | 52 |

| 8 | C6H5CH(OH)CH3 | C6H5COCH3 | 3.5 | 99 | 98 |

| 9 | 4-MeC6H4CH(OH)CH3 | 4-MeC6H4COCH3 | 4 | 94 | 97 |

| 10 | 4-NO2C6H4CH(OH)CH3 | 4-NO2C6H4COCH3 | 6.5 | 72 | 98 |

| 11 | (C6H5)2CHOH | (C6H5)2CO | 3 | 99 | 99 |

| 12 | C6H5CH(OH)(CH)2C6H5 | C6H5CO(CH)2C6H5 | 3 | 99 | 91 |

| |||||

| Entry | Substrate | Product | t/h | Yield (%) b | Sel. (%) c |

| 1 | C6H5CH2OH | C6H5CHO | 3 | 99 | 100 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 1.5 | 100 | 100 |

| 3 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 2 | 99 | 100 |

| 4 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 4 | 94 | 100 |

| 5 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 9 | 70 | 100 |

| 6 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 7 | 90 | 100 |

| 7 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 6 | 85 | 100 |

| 8 | 4-CH2OHC6H5CH2OH | 4-CHOC6H5CHO | 7 | 70 | 100 |

| |||||

| Entry | Substrate | Product | Catalyst | Conv. (%) b | Sel. (%) c |

| 1 | C6H5CH2OH | C6H5CHO | HPW | 48 | 67 |

| 2 | [BMIm]Cl | Trace | - | ||

| 3 | IL-PW | 59 | 80 | ||

| 4 | PIPA-0 | 71 | 82 | ||

| 5 | PIPA-4 | 88 | 79 | ||

| 6 | PIPA-8 | 91 | 84 | ||

| 7 | PIPA-13 | 96 | 86 | ||

| 8 | C6H5CH(OH)CH3 | C6H5COCH3 | HPW | 48 | >99 |

| 9 | IL-PW | 70 | >99 | ||

| 10 | PIPA-13 | 95 | >99 | ||

| 11 | (C6H5)2CHOH | (C6H5)2CO | HPW IL-PW | 37 | >99 |

| 12 | 56 | >99 | |||

| 13 | PIPA-13 | 74 | >99 | ||

| ||||

| Entry | Catalyst | BzOH Conv. (%) | BzH Sel. (%) | BzH yield (%) |

| 1 | CeO2 | Nil | Nil | Nil |

| 2 | 15HPW/CeO2 | 77.9 | 97.6 | 76 |

| 3 | 20HPW/CeO2 | 94 | 98.2 | 92.3 |

| 4 | 25HPW/CeO2 | 93.2 | 94.7 | 88.4 |

| 5 | 20HPW/TiO2 | 84 | 96.6 | 81.2 |

| 6 | 20HPW/ZrO2 | 90.8 | 91.7 | 83.3 |

| 7 | 20HPW/CeTiO b | 89.3 | 93.2 | 83.2 |

| |||||

| Entry | Substrate | Product | Yield (%)b | TON | TOF (h−1) |

| 1 | C6H5CH2OH | C6H5CHO | 100 | 100 | 16 |

| 2 | C6H5CH(OH)CH3 | C6H5COCH3 | 100 | 100 | 17 |

| |||

| Entry | Substrate | Product(s) | Conv. (%) b |

| 1 | C6H5CH2OH + C6H5CH(OH)CH3 | C6H5CHO + C6H5COCH3 | 16.4 + 62.4 |

| ||||||

| Entry | Substrate | Product | t/min | Yield (%) | B.P/M.P (°C) | |

| Found | Lit b | |||||

| 1 | C6H5CH2OH | C6H5CHO | 28 | 98 | 177 | 178 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 27 | 99 | 246 | 248 |

| 3 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 28 | 93 | 47 | 48 |

| 4 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 29 | 84 | 104–106 | 106 |

| 5 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 26 | 98 | 206 | 204–205 |

| 6 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 30 | 85 | 58 | 55–58 |

| 7 | 4-FC6H4CH2OH | 4-FC6H4CHO | 31 | 76 | 179–180 | 180 |

| 8 | 4-PhC6H4CH2OH | 4-PhC6H4CHO | 28 | 86 | 58–59 | 57–59 |

| 9 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 33 | 88 | 213–214 | 213–314 |

| 10 | 4-CO2MeC6H4CH2OH | 4-CO2MeC6H4CHO | 30 | 83 | 60–62 | 59–63 |

| 11 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 31 | 93 | 58–60 | 58.5 |

| 12 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 29 | 95 | 42–44 | 43 |

| 13 | 3-MeC6H4CH2OH | 3-MeC6H4CHO | 33 | 98 | 199 | 198–200 |

| 14 | 3-OMeC6H4CH2OH | 3-OMeC6H4CHO | 27 | 99 | 142–144 | 143 |

| 15 | 3,4,5-OMeC6H2CH2OH | 3,4,5-OMeC6H2CHO | 26 | 99 | 72–74 | 73 |

| ||||

| Entry | Catalyst | pH | Conv. (%) | Sel. (%) |

| 1 | No catalyst | - | 2.9 | 5 |

| 2 | PTA (0.5 g) | 2.5 | 9 | 100 |

| 3 | Potassium salt of PTA (0.5 g) | 7.5 | 5 | 100 |

| 4 | PTA-Jffamine® (0.5 g) | 7.5 | 100 | 74 |

| 5 | PTA-Jffamine® (0.5 g) | 3.5 | 25 | 73 |

| 6 | PTA-Jffamine® (0.5 g) | 4.5 | 100 | 63 |

| 7 | PTA-Jffamine® (0.5 g) | 6.5 | 100 | 59 |

| 8 | PTA-Jffamine® (0.5 g) | 8.5 | 100 | 73 |

| ||||

| Entry | Catalyst | Conv. (%) b | Yield (%) | Sel. (%) b |

| 1 | H3PW12O40 | 62.3 | 60.4 | 93.5 |

| 2 | DMBPS | 5.4 | 5.3 | 99.7 |

| 3 | [TEAPSH]H2PW12O40 c | 68.1 | 65.1 | 95.6 |

| 4 | [DMPPSH]H2PW12O40 d | 89.5 | 85.3 | 95.3 |

| 5 | [DMBPSH]H2PW12O40 | 94.4 | 91.6 | 96.4 |

| 6 | [DMBPSH]2HPW12O40 | 92.5 | 88.4 | 95.6 |

| 7 | [DMBPSH]3PW12O40 | 90.6 | 86.7 | 95.7 |

| ||||

| Entry | Catalyst | Conv. (%) b | Yield (%) b | Sel. (%) b |

| 1 | Phe | Nil | Nil | Nil |

| 2 | H3PW12O40 | 96.7 | 87 | 90 |

| 3 | [PheH]H2PW12O40 | 97.9 | 95.4 | 97.4 |

| 4 | [PheH]2HPW12O40 | 97.5 | 89.7 | 92 |

| 5 | [PheH]3PW12O40 | 96.3 | 88.4 | 91.8 |

| 6 | [AlaH]H2PW12O40 | 97.8 | 92.7 | 94.7 |

| 7 | [GlyH]H2PW12O40 | 97.7 | 90.8 | 92.9 |

| ||||

| Entry | Substrate | Product | t/h | Yield (%) b |

| 1 | 2-OMeC6H4CH2OH | 2-OMeC6H4CHO | 2 | 87 |

| 2 | 4-PhC6H4CH2OH | 4-PhC6H4CHO | 2 | 91 |

| 3 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 3 | 89 |

| 4 | 3,4-OCH2OC6H3CH2OH | 3,4-OCH2OC6H3CHO | 3 | 94 |

| 5 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 3 | 82 |

| 6 | 2-FC6H4CH2OH | 2-FC6H4CHO | 3 | 73 |

| 7 | 4-N(CH3)2C6H4CH2OH | 4-N(CH3)2C6H4CHO | 3 | 85 |

| 8 | 4-COOCH3C6H4CH2OH | 4-COOCH3C6H5CHO | 3 | 86 |

| 9 | 1-Naphthylmethanol | 1-Naphthaldehyde | 3 | 83 |

| 10 | Indole-3-carbinol | Indole-3-carboxaldehyde | 3 | 80 |

| 11 | 4-Pyridinemethanol | Isonicotinaldehyde | 2 | 79 |

| 12 | (5-Bromothiophen-2-yl)methanol | 5-Bromothiophene-2-carbaldehyde | 3 | 77 |

| 13 | [5-(4-Bromophenyl)-2-furyl]methanol | 5-(4-Bromophenyl)furan-2-carbaldehyde | 3 | 88 |

| 14 | C6H5CH(OH)Et | C6H5COEt | 5 | Trace c 91 recovery |

| 15 | 4-OMeC6H4CH2OH (a) + C6H5CH(OH)Et (b) | 4-OMeC6H4CHO | 2 | 85 d |

| |||

| Entry | Substrate | Product | Yield (%) b |

| 1 | C6H5CH(OH)CH3 | C6H5COCH3 | 96 |

| 2 | 3-MeC6H4CH(OH)CH3 | 3-MeC6H4COCH3 | 94 |

| 3 | 3-ClC6H4CH(OH)CH3 | 3-ClC6H4COCH3 | 93 |

| 4 | (C6H5)2CHOH | (C6H5)2CO | 98 |

| 5 | C6H5CH(OH)CH2C6H5 | C6H5COCH2C6H5 | 96 |

| 6 | C6H5CH2OH | C6H5CHO | 91 |

| ||||

| Entry | Substrate | Product | t/min c | Yield (%) d,e |

| 1 | C6H5CH2OH | C6H5CHO | 21 | 90 |

| 2 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 23 | 75 |

| 3 b | 3-OHC6H4CH2OH | 3-OHC6H4CHO | 50 | 85 |

| 4 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 5 | 97 |

| 5 | 4-OHC6H4CH2OH | 4-OHC6H4CHO | 5 | 98 |

| 6 | 2-NH2C6H5CH2OH | 2-NH2C6H5CHO | 7 | 97 |

| 7 | 3-OMeC6H5CH2OH | 3-OMeC6H5CHO | 22 | 83 |

| 8 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 23 | 48 |

| 9 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 35 | 61 |

| 10 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 22 | 56 |

| 11 | Hydroquinone | Benzoquinone | 5 | 96 |

| 12 | (C6H5)2CHOH | (C6H5)2CO | 60 | 70 |

| ||||||

| Entry | Substrate | Product | t/min | Yield (%) | B.P/M.P (°C) | |

| Found | Lit. | |||||

| 1 | C6H5CH2OH | C6H5CHO | 5 | 99 | 177–178 | 178 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 7 | 93 | 246–248 | 248 |

| 3 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 7 | 95 | 47–48 | 48 |

| 4 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 10 | 94 | 104–105 | 106 |

| 5 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 11 | 95 | 204–206 | 205 |

| 6 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 13 | 93 | 56–58 | 55–58 |

| 7 | 4-PhC6H4CH2OH | 4-PhC6H4CHO | 8 | 97 | 57–59 | 56–58 |

| 8 | 4-CO2MeC6H4CH2OH | 4-CO2MeC6H4CHO | 3 | 87 | 59–61 | 61–62 |

| 9 | 4-FC6H4CH2OH | 4-FC6H4CHO | 13 | 86 | 178–180 | 180 |

| 10 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 16 | 90 | 213–215 | 211–213 |

| 11 | 4-(tert-Butyl)-C6H4CH2OH | 4-(tert-Butyl)-C6H4CHO | 11 | 94 | 128–130 | 130 |

| 12 | 4-N(CH3)2C6H4CH2OH | 4-N(CH3)2C6H4CHO | 5 | 96 | 73–75 | 74 |

| 13 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 14 | 87 | 58-60 | 57–59 |

| 14 | 3-OPhC6H4CH2OH | 3-OPhC6H4CHO | 14 | 92 | 168–169 | 169 |

| 15 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 12 | 92 | 43–45 | 43 |

| 16 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 14 | 95 | 210–215 | 212–213 |

| 17 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 15 | 85 | 196–198 | 197 |

| 18 | 3,4-ClC6H3CH2OH | 3,4-ClC6H3CHO | 10 | 96 | 40–42 | 43 |

| 19 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 15 | 86 | 71–73 | 69–70 |

| 20 | 3,4-OMeC6H3CH2OH | 3,4-OMeC6H3CHO | 10 | 88 | 42–44 | 42–43 |

| |||||

| Entry | Substrate | Product | T (°C) | XANOL (%) | SANOL (%) |

| 1 | (C6H5)2CHOH | (C6H5)2CO | 80 | 100 | 97.5 |

| 2 | C6H5CH(OH)CH3 | C6H5COCH3 | 90 | 92 | 98.7 |

| 3 | C6H5CH2OH | C6H5CHO | 80 | 91.7 | 84 |

| ||||

| Entry | Substrate | Product | t/min | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 55 | 88 |

| 2 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 60 | 86 |

| 3 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 65 | 87 |

| 4 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 60 | 85 |

| 5 | 2,5-ClC6H3CH2OH | 2,5-ClC6H3CHO | 80 | 85 |

| 6 | 2-BrC6H4CH2OH | 2-BrC6H4CHO | 65 | 87 |

| 7 | 3-BrC6H4CH2OH | 3-BrC6H4CHO | 65 | 86 |

| 8 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 60 | 84 |

| 9 | 4-FC6H4CH2OH | 4-FC6H4CHO | 70 | 88 |

| 10 | 3-FC6H4CH2OH | 3-FC6H4CHO | 70 | 88 |

| 11 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 120 | 81 |

| 12 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 120 | 85 |

| 13 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 120 | 86 |

| 14 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 50 | 92 |

| 15 | (C6H5)2CHOH | (C6H5)2CO | 70 | 87 |

| 16 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 100 | 72 |

| |||||

| Entry | Substrate | Product | t/h | Yield (%) b | Sel. (%) d |

| 1 | C6H5CH(OH)CH3 | C6H5COCH3 | 5 | 68 | 100 |

| 2 | 4-ClC6H4CH(OH)CH3 | 4-ClC6H4COCH3 | 24 | 21 | 100 |

| 3 | 4-BrC6H4CH(OH)CH3 | 4-BrC6H4COCH3 | 24 | 4 | 100 |

| 4 | 1-(naphthalene-2-yl)ethanol | 2-Acetonaphthanone | 5 | 98 | 100 |

| 5 | (C6H5)2CHOH | (C6H5)2CO | 5 | 41 c | 100 |

| 6 | 1-Indanol | 1-Indanone | 6 | 90 | 100 |

| 7 | C6H5CH2OH | C6H5CHO | 4 | 50 | 99 |

| 8 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 24 | 15c | 100 |

| 9 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 3 | 99 | 99 |

| 10 | 4-CH2ClC6H4CH2OH | 4-CH2ClC6H4CHO | 4 | 50 | 67 |

| ||||

| Entry | Catalyst | Conv. (%) | Sel. (%) b | TOF (h−1) c |

| 1 | SBA-15 | 0.9 | 100 | - |

| 2 | Cu(II)-PADO-HMDS-SBA-15 | 16 | 78 | 23 |

| 3 | Cu(II)-IMIL-SBA-15-G1 | 32 | 69 | 39 |

| 4 | Cu(II)-IMIL-SBA-15-G2 | 65 | 51 | 32 |

| 5 | Cu(II)-IMIL-SBA-15-G2-R d | 14 | 71 | 7 |

| 6 | CuO/SBA-15-C1 | 19 | 83 | 63 |

| 7 | 3.7%CuO/SBA-15-C2 | 11 | 82 | 11 |

| 8 | 5%CuO/SBA-15-C2 | 20 | 73 | 15 |

| 9 | Cu/IMIL-SBA-15-G1 | 73 | 54 | 66 |

| 10 | Cu/IMIL-SBA-15-G2 | 66 | 33 | 27 |

| 11 | Cu/IMIL-SB-15-G2-R d | 16 | 66 | 7 |

| 12 | 2%Cu/PEG/SBA-15 | 27 | 68 | 52 |

| 13 | 2%Cu/PEG/SBA-15-R d | 25 | 67 | 48 |

| |||||

| Entry | Substrate | Product | t/h | Yield (%) b | Sel. (%) c |

| 1 | C6H5CH2OH | C6H5CHO | 18 | 96 | 98 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 18 | 94 | 95 |

| 3 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 18 | 88 | 96 |

| 4 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 22 | 81 | 87 |

| 5 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 22 | 80 | 85 |

| 6 | 2-BrC6H4CH2OH | 2-BrC6H4CHO | 22 | 73 | 88 |

| 7 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 30 | 75 | 82 |

| 8 | 3,4-OMeC6H3CH2OH | 3,4-OMe C6H3CHO | 26 | 67 | 97 |

| 9 | (C6H5)2CHOH | (C6H5)2CO | 24 | 58 | 100 |

| 10 | C6H5CH(OH)CH3 | C6H5COCH3 | 18 | 88 | 99 |

| 11 | C6H5CH2OH | C6H5CHO | 18 | 89 | 99 |

| |||||

| Entry | Substrate | Product | t/h | Conv. (%) b | Yield (%) c |

| 1 | C6H5CH2OH | C6H5CHO | 3 | 99 | 95 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 4 | 89 | 85 |

| 3 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 5 | 96 | 95 |

| 4 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 3 | 99 | 94 |

| 5 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 3 | 99 | 97 |

| 6 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 8 | 85 | 85 d |

| 7 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 10 | 68 | 65 d |

| 8 | C6H5CH(OH)Et | C6H5COEt | 4 | 99 | 99 d |

| |||||

| Entry | Catalyst | Reaction System b | Conv. (%) | Sel. (%) c | H2O2-Efficiency (%) |

| 1 | None | L-L | 3 | 99 | 10 |

| 2 | [C4mim] Br | L-L | 3 | 99 | 10 |

| 3 | H3PMo12O40 | L-L | 22 | 99 | 48 |

| 4 | H4PMo11VO40 | L-L | 20 | 99 | 45 |

| 5 | H5PMo10V2O40 | L-L | 12 | 99 | 33 |

| 6 | [C4mim]3PMo12O40 | L-L | 47 | 88 | 66 |

| 7 | [C4mim]4PMo11VO40 | L-L-S | 34 | 99 | 59 |

| 8 | [C4mim]5PMo10V2O40 | L-L | 16 | 99 | 40 |

| ||||

| Entry | Substrate | Product | Conv. (%) b | Sel. (%) b |

| 1 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 86 | 99 |

| 2 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 93 | 99 |

| 3 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 91 | 99 |

| 4 | 2-NH2C6H4CH2OH | 2-NH2C6H4CHO | >99 | 99 |

| 5 | 4-COOMeC6H4CH2OH | 4-COOMeC6H4CHO | 88 | 99 |

| 6 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 84 | 99 |

| 7 | 4-FC6H4CH2OH | 4-FC6H4CHO | 96 | 99 |

| 8 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 94 | 99 |

| 9 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 83 | 99 |

| 10 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | >99 | 99 |

| 11 | C6H5CH(OH)CH3 | C6H5COCH3 | 81 | 99 |

| 12 | 4-MeC6H4CH(OH)CH3 | 4-MeC6H4COCH3 | 82 | 99 |

| 13 | 4-ClC6H4CH(OH)CH3 | 4-ClC6H4COCH3 | 89 | 99 |

| 14 | 4-BrC6H4CH(OH)CH3 | 4-BrC6H4COCH3 | 91 | 99 |

| 15 | (C6H5)2CHOH | (C6H5)2CO | 81 | 99 |

| 16 | 4,4-(CH2OH)2C6H4 | 4,4-(CHO)2C6H4 | 91 | 90 |

| 17 c | 2-Pyridinemethanol | Picolinaldehyde | 98 | 96 |

| 18 c | Furfuryl alcohol | Furfural | 90 | 99 |

| |||

| Entry | Substrate | Product | Yield (%) b |

| 1 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 99 |

| 2 | 3-OMeC6H4CH2OH | 3-OMeC6H4CHO | 98 |

| 3 | 2-OMeC6H4CH2OH | 2-OMeC6H4CHO | 97 |

| 4 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 99 |

| 5 | 3-MeC6H4CH2OH | 3-MeC6H4CHO | 97 |

| 6 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 96 |

| 7 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 83 |

| 8 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 81 |

| 9 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 79 |

| 10 | (C6H5)2CHOH | (C6H5)2CO | Trace |

| ||||

| Entry | Substrate | Product | t/h | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 3 | 97 |

| 2 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 4 | 95 |

| 3 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 4.15 | 95 |

| 4 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 4.30 | 95 |

| 5 | 4-FC6H4CH2OH | 4-FC6H4CHO | 6 | 98 |

| 6 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 6.15 | 97 |

| 7 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 6.45 | 98 |

| 8 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 6.15 | 92 |

| 9 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 2 | 97 |

| 10 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 2.10 | 97 |

| 11 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 2 | 99 |

| 12 | 2-OMeC6H4CH2OH | 2-OMeC6H4CHO | 2.05 | 99 |

| 13 | 3-OMeC6H4CH2OH | 3-OMeC6H4CHO | 2.30 | 99 |

| 14 | C6H5CH(OH)Et | C6H5COEt | 3 | 96 |

| ||||

| Entry | Catalyst | BzOH Conv. (%) | BzH yield (%) | Sel. (%) b |

| 1 | None | 0 | 0 | 0 |

| 2 | ECH (1 g) | 2 | 2 | 100 |

| 3 | Fe3O4-blank | 8.3 | 7.9 | 94.8 |

| 4 | Fe3O4-ECH-P-1g | 25.5 | 25.2 | 98.9 |

| 5 | Fe3O4-ECH-P-3g | 39.2 | 33.2 | 84.8 |

| 6 | Fe3O4-ECH-P-4g | 34.7 | 32.6 | 93.9 |

| 7 | Fe3O4-ECH-P-5g | 37.7 | 32.5 | 86.3 |

| 8 | Fe3O4-ECH-D | 36.6 | 34.2 | 93.5 |

| 9 c | Fe3O4-ECH-D | 23.1 | 22.4 | 96.9 |

| 10 d | Fe3O4-ECH-D | 1.7 | 1.7 | 100 |

| 11 e | Fe3O4-ECH-D | 23.4 | 21.7 | 92.9 |

| ||||

| Entry | Catalyst | Conv. (%) | Yield (%) | Sel. (%) |

| 1 | No catalyst | 1.8 | - | - |

| 2 | S823 | 3.4 | 0.8 | 25 |

| 3 | 1%Au/S823 | 24.7 | 12.4 | 50.2 |

| 4 | 2%Au/S823 | 29.6 | 18.4 | 61.9 |

| 5 | 4%Au/S823 | 33.3 | 21.3 | 63.9 |

| |||||||

| Entry | Type of Al2O3 Support | Conv. (%) | Yield (%) | Sel. (%) | |||

| 1%Au | 2%Au | 1%Au | 2%Au | 1%Au | 2%Au | ||

| 1 | M | 37.1 | 33..8 | 11.5 | 16.7 | 31 | 49.4 |

| 2 | S823 | 24.7 | 29.6 | 12.4 | 18.4 | 50.2 | 61.9 |

| 3 | S723 | 20.4 | 18.1 | 10.9 | 15.6 | 53.7 | 86.3 |

| |||||

| Entry | Catalyst | Substrate b | Solvent | Conv. (%) | Sel. (%) |

| 1 | Pt/Ca-ZSM-5 | BA | H2O | 98.8 | 99 |

| 2 | Pt/Mg-ZSM-5 | BA | H2O | 95.5 | 98 |

| 3 | Pt/Ca-ZSM-5 c | BA | H2O | 89 | 96 |

| 4 | Pt/HZSM-5 | BA | H2O | 65 | 87 |

| 5 | Pt/SiO2 | BA | H2O | 64 | 87 |

| 6 | Pt/CaO | BA | H2O | 0 | - |

| 7 | Pt/MgO | BA | H2O | 0 | - |

| 8 | Au/Ca-ZSM-5 | BA | H2O | 0 | - |

| 9 | Pd/Ca-ZSM-5 | BA | H2O | 0 | - |

| 10 | Pt/Mg-ZSM-5 | CHA | H2O | 20.7 | 85.5 |

| 11 | Pt/Ca-ZSM-5 | CHA | H2O | 21.8 | 82 |

| 12 | Pt/SiO2 | CHA | H2O | 5.1 | 90 |

| 13 | Pt/Ca-ZSM-5 | BA | CH3CN | <1 | - |

| 14 | Pt/Ca-ZSM-5 | BA | EtOH | <1 | - |

| 15 | Pt/Ca-ZSM-5 | BA | CCl4 | <1 | - |

| |||||

| Entry | Catalyst | Conv. of BA (%) c | Sel. for BzH (%) c | Yield of Benzoic Acid | Recovery Rate of Catalyst (%) |

| 1 | Blank | 17.9 | 100 | 0 | - |

| 2 | H3PW12O40 | 100 | 92.4 | 7.6 | 0 |

| 3 | [TEAH]3PW12O40 | 95 | 100 | 0 | 77 |

| 4 | [TEAH]3P W12O40+H2SO4 b | 84.4 | 100 | 0 | 62 |

| 5 | [TEAH]2HPW12O40 | 97.5 | 100 | 0 | 58 |

| 6 | [TEAH]H2PW12O40 | 99.6 | 100 | 0 | 53 |

| 7 | [TEAH]H2PW12O40 + H2SO4 b | 86.7 | 100 | 0 | 42 |

| 8 | [TEAH]H2PW12O40 (cycle 3) | 99.8 | 100 | 0 | - |

| 9 | [TEAH]H2PW12O40 (cycle 5) | 99.5 | 100 | 0 | - |

| ||||||

| Entry | Substrate | Product | t/min | Yield (%) e | TON f | TOF (h−1) g |

| 1 | C6H5CH2OH | C6H5CHO | 15 15 b | 1.6 0.03 | 84 - | 340 - |

| 2 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 15 c 15 b | 40 0.41 | 940 - | 3800 - |

| 3 | C6H5CH(OH)CH3 | C6H5COCH3 | 6 6 b | 4.9 0.085 | 230 - | 2300 - |

| 4 | (C6H5)2CHOH | (C6H5)2CO | 10 d 10 b | 3.7 0.77 | 210 - | 1200 - |

| ||||

| Entry | Substrate | Product | t/min | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 20 | 91 |

| 2 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 30 | 89 |

| 3 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 35 | 87 |

| 4 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 40 | 90 |

| 5 | 2,5-ClC6H3CH2OH | 2,5-ClC6H3CHO | 45 | 87 |

| 6 | 2-BrC6H4CH2OH | 2-BrC6H4CHO | 30 | 85 |

| 7 | 3-BrC6H4CH2OH | 3-BrC6H4CHO | 35 | 88 |

| 8 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 35 | 85 |

| 9 | 4-FC6H4CH2OH | 4-FC6H4CHO | 40 | 88 |

| 10 | 3-FC6H4CH2OH | 3-FC6H4CHO | 40 | 85 |

| 11 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 120 | 85 |

| 12 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 120 | 81 |

| 13 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 120 | 82 |

| 14 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 15 | 90 |

| 15 | (C6H5)2CHOH | (C6H5)2CO | 30 | 88 |

| 16 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 120 | 85 |

| |||||

| Entry | Substrate | Product | t/h | Conv. (%) | Sel. (%) |

| 1 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 3 | 43.9 | >99 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 3 | 30.5 | >99 |

| 3 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 2 | 72.7 | >99 |

| 4 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 2 | 48.6 | >99 |

| ||||

| Entry | Substrate | Product | t/h | Conv. (%) |

| 1 | C6H5CH2OH | C6H5CHO | 3.5 | 95 |

| 2 | C6H5CH(OH)CH3 | C6H5COCH3 | 4 | 80 |

| 3 | Furfuryl alcohol | Furfural | 2 | 100 |

| 4 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 2.5 | 100 |

| 5 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 2 | 100 |

| 6 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 3 | 100 |

| 7 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 4.5 | 90 |

| 8 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 4.5 | 80 |

| 9 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 2 | 95 |

| 10 | C6H5CH(OH)Et | C6H5COEt | 4 | 40 |

| 11 | (C6H5)2CHOH | (C6H5)2CO | 6 | 45 |

| 12 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 6 | 85 |

| ||||||

| Entry | Substrate | Product | t/min | Conv. (%) | Sel. (%) | TON b |

| 1 | C6H5CH2OH | C6H5CHO | 180 | 98 | >99 | 504 |

| 2 | C6H5CH(OH)CH3 | C6H5COCH3 | 30 180 | 56 100 | >99 >99 | 288 514 |

| ||||||

| Entry | Substrate | Product | Co(II) catalyst | Co(III) catalyst | ||

| Conv. (%) | Carbonyl Compound: Carboxylic Acid/Hydroperoxide | Conv. (%) | Carbonyl Compound: Carboxylic Acid/Hydroperoxide | |||

| 1 | C6H5CH2OH | C6H5CHO | 94 | 13:1 | 34 | 6:1 |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 95 | 15:1 | 37 | 12:1 |

| 3 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 73 | 9:1 | 24 | 8:1 |

| 4 | 1-Indanol | 1-Indanone | 91 | 31:1 | 30 | 22:1 |

| 5 | Furfuryl alcohol | Furfural | 89 c | 5:1 | 42 | 4:1 |

| 6 | 2-Thiophenemethanol | 2-Thiophenecarboxaldehyde | 87 c | 8:1 | 49 | 5:1 |

| 7 | (C6H5)2CHOH | (C6H5)2CO | 93 d | 19:1 | 36 | 17:1 |

| 8 | 4,4-(OMe)2(C6H4)2CHOH | 4,4-(OMe)2(C6H4)2CO | 96 d | 22:1 | 39 | 19:1 |

| 9 | 2-FC6H4CH(OH)C6H5 | 2-FC6H4COC6H5 | 94 e | 19:1 | 37 | 18:1 |

| |||

| Entry | H2O2/BzOH (mol/mol) | Sel. of BzH (mol%) | BzH Yield (mol%) |

| 1 b | 1/2 | 98 | 98 |

| 2 | 1/1 | 90 | 86 |

| 3 | 2/1 | 83 | 81 |

| 4 | 3/1 | 80 | 79 |

| 5 | 4/1 | 78 | 77 |

| 6 | 5/1 | 61 | 61 |

| ||||||

| Entry | Substrate | Product | t/h | Conv. (mol%) | Sel. (mol%) | H2O2 Efficiency (%) |

| 1 | C6H5CH(OH)CH3 | C6H5COCH3 | 3 | 99 | 99 | 67 |

| 2 | C6H5CH2OH | C6H5CHO C6H5COOH | 6 6 | 98 98 | 83 16 | 67 |

| |||||

| Entry | Substrate | Product | t/h | Conv. (mol%) | Yield (mol%) |

| 1 | C6H5CH2OH | C6H5CO2H | 8 | 100 | 100 |

| 2 b | C6H5CH2OH | C6H5CHO | 7 | 84 | 84 |

| 3 | C6H5CH(OH)CH3 | C6H5COCH3 | 7 | 100 | 100 |

| 4 | (C6H5)2CHOH | (C6H5)2CO | 7 | 100 | 100 |

| ||||

| Entry | Substrate | Product | Conv. (mol%) | Yield (mol%) |

| 1 | C6H5CH2OH | C6H5CHO | 64 | 64 |

| 2 | C6H5CH(OH)CH3 | C6H5COCH3 | 78 | 78 |

| ||||||

| Entry | Substrate | Product | Catalyst | t/h | C6H5COCH3 (%) | Other Products (%) |

| 1 2 3 | C6H5CH(OH)CH3 C6H5CH(OH)CH3 C6H5CH(OH)CH3 | C6H5COCH3 C6H5COCH3 C6H5COCH3 | H3PMo12O40 Py3PMo12O40 H6PMo11AlO40 | 9 5 7 | 95 (5) b 100 (6) b 99 | None None None |

| 4 5 | (C6H5)2CHOH (C6H5)2CHOH | (C6H5)2CO (C6H5)2CO | H3PMo12O40 Py3PMo12O40 | 5 4 | 99 (8) b 99 | None None |

| 6 7 8 | C6H5CH2OH C6H5CH2OH C6H5CH2OH | C6H5CHO C6H5CHO C6H5CHO | H3PMo12O40 Py3PMo12O40 H6PMo11AlO40 | 5 3 4 | 84 (12) b 89 (5) b 85 | (Benzoic acid) (4) (Benzoic acid) (2) (Benzoic acid) (2) |

| 9 10 | 4-ClC6H4CH2OH 4-ClC6H4CH2OH | 4-ClC6H4CHO 4-ClC6H4CHO | H3PMo12O40 H6PMo11AlO40 | 53 | 93 (10) b 95 | (4-Chlorobenzoic acid) (1) (4-Chlorobenzoic acid) (2) |

| 11 12 | 4-MeC6H4CH2OH 4-MeC6H4CH2OH | 4-MeC6H4CHO 4-MeC6H4CHO | H3PMo12O40 Py3PMo12O40 | 43 | 96 (7) b 96 | (4-Methylbenzoic acid) (3) (4-Methylbenzoic acid) (3) |

| 13 14 | 4-OMeC6H4CH2OH 4-OMeC6H4CH2OH | 4-OMeC6H4CHO 4-OMeC6H4CHO | H3PMo12O40 Py3PMo12O40 | 3 2 | 90 91 | (4-Methoxybenzoic acid) (6) (4-Methoxybenzoic acid) (5) |

| |||

| Entry | Substrate | Product | Conv. (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 80 |

| 2 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 82 |

| ||||||

| Entry | Catalyst | Amount of Catalyst (g) | Conv. (%) | Sel. (%) | ||

| BzH | BzA | Benzyl Benzoate (%) | ||||

| 1 | None | - | 2 | 73 | 27 | 0 |

| 2 | 25ZSM(AT-0) | 1 | 44 | 80 | 19 | 1 |

| 3 | 25HZSM(AT-0.5) b | 1 | 52 | 85 | 14 | 1 |

| 4 | 25ZSM(AT-0.5) | 0.1 | 37 | 61 | 31 | 8 |

| 5 | 25ZSM(AT-0.5) | 0.2 | 45 | 68 | 27 | 5 |

| 6 | 25ZSM(AT-0.5) | 0.5 | 52 | 80 | 18 | 2 |

| 7 | 25ZSM(AT-0.5) | 1 | 53 | 86 | 13 | 1 |

| 8 | 25ZSM(AT-0.5) | 1.5 | 49 | 87 | 13 | 0 |

| 9 | 25ZSM(AT-0.5) | 2 | 47 | 88 | 11 | 1 |

| 10 | 25ZSM(AT-1.0) | 1 | 50 | 85 | 14 | 1 |

| 11 | 25ZSM(AT-1.5) | 1 | 48 | 86 | 13 | 1 |

| 12 | 25ZSM(AT-3.0) | 1 | 37 | 89 | 10 | 1 |

| 13 | 38ZSM(AT-0.5) | 1 | 41 | 86 | 14 | 0 |

| 14 | 50ZSM(AT-0.5) | 1 | 33 | 84 | 15 | 1 |

| |||||

| Entry | Substrate | Product | t/min | Conv. (%) | Sel. (%) |

| 1 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 120 | 73 | 100 |

| 2 | C6H5CH2OH | C6H5CHO | 150 | 78 | 100 |

| 3 | C6H5CH(OH)CH3 | C6H5COCH3 | 150 | 85 | 100 |

| 4 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 150 | 90 | 100 |

| |||||

| Entry | Substrate | Product | Work-Up | Yield (%) | Purity (%) b |

| 1 | C6H5CH(OH)CH3 | C6H5COCH3 | Extractive | 88 91 94 | >98 96 c 94 |

| 2 | C6H5CH(OH)Et | C6H5COEt | Extractive | 85 94 | >98 >98 |

| 3 | (C6H5)2CHOH | (C6H5)2CO | Extractive | 93 98 | >98 >98 |

| 4 | 4-MeC6H4CH(OH)C6H5 | 4-MeC6H4COC6H5 | Vacuum filtration | 99 65 d | >98 >98 |

| 5 | C6H5CH2OH | C6H5CHO | Extractive | 91 81 88 e | 98 94 97 |

| |||

| Entry | Substrate | Product | Yield (%) |

| 1 | 4-(tert-Butyl)C6H4CH(OH)CH3 | 4-(tert-Butyl)C6H4COCH3 | 100 |

| 2 | C6H5CH(OH)Et | C6H5COEt | 90 |

| 3 | (C6H5)2CHOH | (C6H5)2CO | 60 |

| 4 | C6H5CH(OH)CH3 | C6H5COCH3 | 100 |

| 5 | 2-SHC6H4CH2OH | 2-SHC6H4CHO | 100 |

| 6 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 100 |

| 7 | Furfuryl alcohol | Furfural | 100 |

| 8 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 90 |

| 9 | C6H5CH2OH | C6H5CHO | 100 |

| 10 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 90 |

| 11 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 85 |

| 12 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 80 |

| |||||

| Entry | Substrate | Product | t (min) | Yield (%) b | TOF (h−1) c |

| 1 | C6H5CH2OH | C6H5CHO | 90 90 90 | 99 98 d 97 e | 660 653 646 |

| 2 f | 4-FC6H4CH2OH | 4-FC6H4CHO | 100 | 97 | 582 |

| 3 f | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 100 | 96 | 576 |

| 4 f | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 100 | 97 | 582 |

| 5 f | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 105 | 97 | 554 |

| 6 f | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 100 | 99 | 594 |

| 7 | 4-OHC6H4CH2OH | 4-OHC6H4CHO | 100 | 98 | 588 |

| 8 | (C6H5)2CHOH | (C6H5)2CO | 120 | 98 | 490 |

| 9 | C6H5CH2OH | C6H5CHO | 105 | 97 | 554 |

| |||

| Entry | Substrate | Product | Yield (%)b |

| 1 | C6H5CH2OH | C6H5CHO | 90 |

| 2 | 4-iPrC6H4CH2OH | 4-iPrC6H4CHO | 96 |

| 3 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 94 |

| 4 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 86 |

| 5 | 2-NO2C6H4CH2OH | 2-NO2C6H4CHO | 60 |

| 6 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 82 |

| 7 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 92 |

| 8 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 94 |

| 9 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 82 |

| 10 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 90 |

| 11 | (C6H5)2CHOH | (C6H5)2CO | 90 |

| 12 | C6H5CH(OH)CH3 | C6H5COCH3 | 90 |

| 13 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 90 |

| |||

| Entry | Substrate | Product | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 78 |

| 2 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 80 |

| 3 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 88 |

| 4 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 94 |

| 5 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 81 |

| 6 | 2-pyridinemethanol | picolinaldehyde | 93 |

| 7 | 3,4,5-OMeC6H2CH2OH | 3,4,5-OMeC6H2CHO | 88 |

| 8 | Furfuryl alcohol | Furfural | 92 |

| 9 | 2-Thiophenemethanol | 2-Thiophenecarboxaldehyde | 90 |

| 10 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 97 |

| 11 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 85 |

| 12 | C6H5CH(OH)CH3 | C6H5COCH3 | 1 |

| 13 | 4-OMeC6H4CH2OH:C6H5CH(OH)CH3 | 4-OMeC6H4CHO:C6H5COCH3 | 77:1 |

| ||||

| Entry | Substrate | Product | t/min | Conv. (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 45 | >95 |

| 2 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 90 | 95 |

| 3 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 60 | >95 |

| 4 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 120 | 90 |

| 5 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 10 | 50 |

| 6 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 70 | 95 |

| 7 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 30 | 90 |

| 8 | C6H5CH(OH)Et | C6H5COEt | 75 | 95 |

| 9 | C6H5CH(OH)CH3 | C6H5COCH3 | 90 | 95 |

| 10 | (C6H5)2CHOH | (C6H5)2CO | 60 | 95 |

| 11 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 50 | 95 |

| 12 | Furfuryl alcohol | Furfural | 40 | 80 |

| ||||

| Entry | Substrate | Product | t/h | Yield (%) b Isolated Product (GC) c |

| 1 | C6H5CH2OH | C6H5CHO | 7 | 84 (86)c |

| 2 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 3 | 98 (100)c |

| 3 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 9 | 97 |

| 4 | 3-MeC6H4CH2OH | 3-MeC6H4CHO | 10 | 93 |

| 5 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 4 | 98 |

| 6 | 3-ClC6H4CH2OH | 3-ClC6H4CHO | 9 | 97 |

| 7 | 3-NO2C6H4CH2OH | 3-NO2C6H4CHO | 3 | 85 (97) c |

| 8 | Furfuryl alcohol | Furfural | 3 | 97 (100) c |

| 9 | 2-Pyridinemethanol | Picolinaldehyde | 3 | 96 |

| 10 | 2-Thiophenemethanol | 2-Thiophenecarboxaldehyde | 3 | 98 |

| 11 | C6H5CH(OH)COC6H5 | (C6H5)2(CO)2 | 2 | 98 (100) c |

| 12 | 3,4,5-OMeC6H2CH2OH | 3,4,5-OMeC6H2CHO | 6 | 98 |

| 13 | C6H5CH(OH)CH3 | C6H5COCH3 | 16 | 1 c |

| |||

| Entry | Substrate | Product b | Yield (%) c |

| 1 | C6H5CH2OH | C6H5CHO | 94 |

| 2 | 2-OHC6H4CH2OH | 2-OHC6H4CHO | 62 |

| 3 | 4-OHC6H4CH2OH | 4-OHC6H4CHO | 69 |

| 4 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 65 |

| 5 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 84 d |

| 6 | 2,4-ClC6H3CH2OH | 2,4-ClC6H3CHO | 90 |

| 7 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 81 e |

| 8 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 82 |

| 9 | Furfuryl alcohol | Furfural | 68 |

| 10 | 4-OMeC6H5CH(OH)CH3 | 4-OMeC6H5COCH3 | 86 |

| 11 | C6H5CH(OH)CH3 | C6H5COCH3 | 87 |

| 12 | 1-Tetralol | 1-Tetralone | 70 |

| ||||

| Entry | Catalyst | Conv. of BzOH (wt%) | Product Yield (wt%) BzH | Product Yield (wt%) Benzoic Acid |

| 1 | MOR | 42.95 | 41.15 | 1.80 |

| 2 | MOR-HN | 99.94 | 99.84 | 0.1 |

| 3 | MOR-HC | 54.49 | 54.35 | 0.14 |

| 4 | MOR-OX | 60.37 | 60.25 | 0.12 |

| |||||

| Entry | Substrate | Product | t/min | Conv. (%) b | Sel. (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 15 | 100 | 95.1 |

| 2 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 60 | 71 | 99 |

| 3 | 4-CH2OHC6H4CH2OH | 4-CH2OHC6H4CHO | 15 c | 99 | 90 |

| 4 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 160 | 87 | 91 |

| 5 | 4-iPrC6H4CH2OH | 4-iPrC6H4CHO | 15 | 99 | 50 |

| 6 | 4-OHC6H4CH2OH | 4-OHC6H4CHO | 15 | 99 | 98 |

| 7 | (C6H5)2CHOH | (C6H5)2CO | 15 | 99 | >99 |

| ||||

| Entry | Substrate | Product | Conv. (%) | Sel. (%) |

| 1 | C6H5CH2OH | C6H5CHO | >99 | 100 |

| ||||

| Entry | Catalyst | t/h | Conv. (%) | Sel. for BzH (%) |

| 1 | - | 5 | 2 | 70 |

| 2 | MnPOM/MCM | 5 8 | 67 76 | 75 69 |

| 3 | CoPOM/MCM | 5 8 | 70 78 | 71 67 |

| 4 | TBA-MnPOM b | 5 | 49 | 75 |

| 5 | TBA-CoPOM b | 5 | 52 | 70 |

| 6 | TBA-MnPOM c | 2.5 | 35 | Not determined |

| 7 | TBA-CoPOM c | 2.5 | 13 | Not determined |

| 8 | LDH | 5 | 3 | 91 |

| 9 | MnPOM/LDH | 5 | 45 | 97 |

| 10 | CoPOM/LDH | 5 | 37 | 96 |

| 11 | LDH-adi | 5 | 4 | 90 |

| 12 | MnPOM/LDH-adi | 5 | 66 | 100 |

| 13 | CoPOM/LDH-adi | 5 | 69 | 99 |

| ||||

| Entry | Substrate | Product | Conv. (%) | Yield (%) |

| 1 | C6H5CH2OH | C6H5CHO C6H5CO2H | 100 b 99 c | 94 b 83 c |

| 2 | 4-MeC6H4CH2OH | 4-MeC6H4CHO 4-MeC6H4CO2H | 100 b 99 c | 100 b 87 b |

| 3 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO 4-OMeC6H4CO2H | 100 b 99 c | 100 c 94 c |

| 4 | 4-ClC6H4CH2OH | 4-ClC6H4CHO 4-ClC6H4CO2H | 99 b 97 c | 91 c 77 c |

| 5 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO 4-NO2C6H4CO2H | 96 b 95 c | 81 c 64 c |

| 6 d | C6H5CH(OH)CH3 | C6H5COCH3 | 98 b/95c | 94 b/80 c |

| 7 d | (C6H5)2CHOH | (C6H5)2CO | 95 b/89c | 83 b/76 c |

| |||||

| Entry | Substrate | Product | t/h | Conv. (%) | Yield (%) |

| 1 | C6H5CH2OH | C6H5CHO | 6 | 100 | 98 |

| 2 | 2-OMeC6H4CH2OH | 2-OMeC6H4CHO | 6 | 99 | 96 |

| 3 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 5 | >99 | 98 |

| 4 | 3-OMeC6H4CH2OH | 3-OMeC6H4CHO | 8 | 98 | 94 |

| 5 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 5 | >99 | 99 |

| 6 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 8 | 96 | 95 |

| 7 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 8 | 95 | 93 |

| 8 | (C6H5)2CHOH | (C6H5)2CO | 16 | 81 | 80 |

| 9 | C6H5CH(OH)CH3 | C6H5COCH3 | 14 | 83 | 81 |

| 10 | 2-Pyridinemethanol | Picolinaldehyde | 16 | 86 | 84 |

| 11 | Furfuryl alcohol | Furfural | 12 | 90 | 82 |

| |||||

| Entry | Substrate | Product | t/min | Yield (%) b | Sel. (%) |

| 1 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 27–28 | 91 | 100 |

| 2 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 24–26 | 93 | 100 |

| 3 | 4-FC6H4CH2OH | 4-FC6H4CHO | 32–33 | 94 | 100 |

| 4 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 22–25 | 90 | 100 |

| 5 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 25–27 | 91 | 100 |

| 6 | C6H5CH2OH | C6H5CHO | 24–26 | 92 | 100 |

| ||||

| Entry | Substrate | Product | t/min | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 30 | 90 |

| 2 | 2-MeC6H4CH2OH | 2-MeC6H4CHO | 30 | 93 |

| 3 | 4-MeC6H4CH2OH | 4-MeC6H4CHO | 30 | 92 |

| 4 | 2-ClC6H4CH2OH | 2-ClC6H4CHO | 30 | 85 |

| 5 | 4-ClC6H4CH2OH | 4-ClC6H4CHO | 30 | 89 |

| 6 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 30 | 85 |

| 7 | 4-OMeC6H4CH2OH | 4-OMeC6H4CHO | 30 | 72 |

| 8 | 4-NO2C6H4CH2OH | 4-NO2C6H4CHO | 30 | 80 |

| 9 | 1-Naphthalenmethanol | 1-Naphthaldehyde | 10 | 75 |

| 10 | C6H5CH(OH)CH3 | C6H5COCH3 | 10 | 80 |

| 11 | C6H5CH(OH)C2H5 | C6H5COC2H5 | 10 | 85 |

| 12 | 4-MeC6H5CH(OH)CH3 | 4-MeC6H5COCH3 | 20 | 90 |

| 13 | 4-ClC6H5CH(OH)CH3 | 4-ClC6H5COCH3 | 10 | 95 |

| 14 | 4-BrC6H5CH(OH)CH3 | 4-BrC6H5COCH3 | 10 | 95 |

| 15 | 4-FC6H5CH(OH)CH3 | 4-FC6H5COCH3 | 10 | 96 |

| 16 | 1-(Naphthalen-2-yl)ethanol | 2-Acetonaphthone | 10 | 80 |

| 17 | 1-Tetralol | 1-Tetralone | 10 | 85 |

| 18 | (C6H5)2CHOH | (C6H5)2CO | 40 | 85 |

| 19 | C6H5CH(OH)CO2Et | C6H5COCO2Et | 10 | 88 |

| ||||||

| Entry | Catalyst | Conv. of BzOH (%) | Sel. (%) | H2O2 Efficiency (mol %) | ||

| BzH | Benzoic Acid | Benzyl Benzoate | ||||

| 1 | Blank | 3 | 100 | 0 | 0 | 5.1 |

| 2 | Cr(salen) | 12.2 | 65.4 | 23.5 | 11.1 | 15.3 |

| 3 | Cr(salten) | 15 | 70.2 | 19.8 | 10 | 17.8 |

| 4 | Cr(salphen) | 20.5 | 75.6 | 18.2 | 6.2 | 23.6 |

| 5 | Cr(SO3-salen) | 25 | 76.5 | 17.5 | 6 | 28 |

| 6 | Cr(SO3-salten) | 31.4 | 82 | 15.3 | 2.7 | 35.5 |

| 7 | Cr(SO3-salphen) | 34.7 | 80.5 | 15.4 | 4.1 | 37.9 |

| 8 | Cr(salen)-MCM-41 | 42.5 | 98.2 | 1.3 | 0.4 | 45.6 |

| 9 | Cr(salten)-MCM-41 | 43.2 | 100 | 0 | 0 | 48.1 |

| 10 | Cr(salphen)-MCM-41 | 45.2 | 100 | 0 | 0 | 52 |

| 11 | Cr(SO3-salen)-MCM-41 | 53.1 | 100 | 0 | 0 | 62.5 |

| 12 | Cr(SO3-salten)-MCM-41 | 57 | 100 | 0 | 0 | 68.3 |

| 13 | Cr(SO3-salphen)-MCM-41 | 60.3 | 100 | 0 | 0 | 72.5 |

| ||||

| Entry | Substrate | Product | Conv. (%) | Sel. (%) |

| 1 | C6H5CH2OH | C6H5CHO | 56.5 b 37.9 c 56.2 d | 90.9 84.9 81.3 |

| |||

| Entry | Catalyst | Conv. (%) b | Sel. (%) c |

| 1 | H3PMo12O40 | 19.1 ± 1.9 d | 88.6 ± 1.6 d |

| 2 | H4PMo11VO40 | 28.2 ± 1.8 | 90 ± 1.4 |

| 3 | (ODA)4PMo11VO40 | 60.6 ± 1.5 | 99 ± 0.8 |

| 4 | ODACl | 0 | 0 |

| 5 | (ODA)3PMo12VO40 | 36.5 ± 1.7 | 94.5 ± 1.1 |

| 6 | (ODA)4PMo11VO40-P | 58.9 ± 1.6 | 99 ± 0.8 |

| 7 | (ODACl + H4PMo11VO40) e | 57.1 ± 1.7 | 98.8 ± 0.9 |

| 8 | (DODA)4PMo11VO40 | 53.3 ± 1.8 | 99 ± 0.9 |

| 9 | (DDA)4PMo11VO40 | 51.6 ± 1.8 | 98 ± 1 |

| 10 | (HDA)PMo11VO40 | 56.3 ± 1.8 | 99 ± 0.9 |

| 11 | (TBA)4PMo11VO40 | 28.9 ± 1.2 | 91.1 ± 1.4 |

| ||||

| Entry | Substrate | Product | t/min | Yield (%) b |

| 1 | C6H5CH2OH | C6H5CHO | 60 | 95 |

| 2 | 4-BrC6H4CH2OH | 4-BrC6H4CHO | 45 | 80 |