A Critical Review of the Sustainable Production and Application of Methanol as a Biochemical and Bioenergy Carrier

Abstract

:1. Introduction

2. Potential of Methanol as a Renewable Energy Carrier

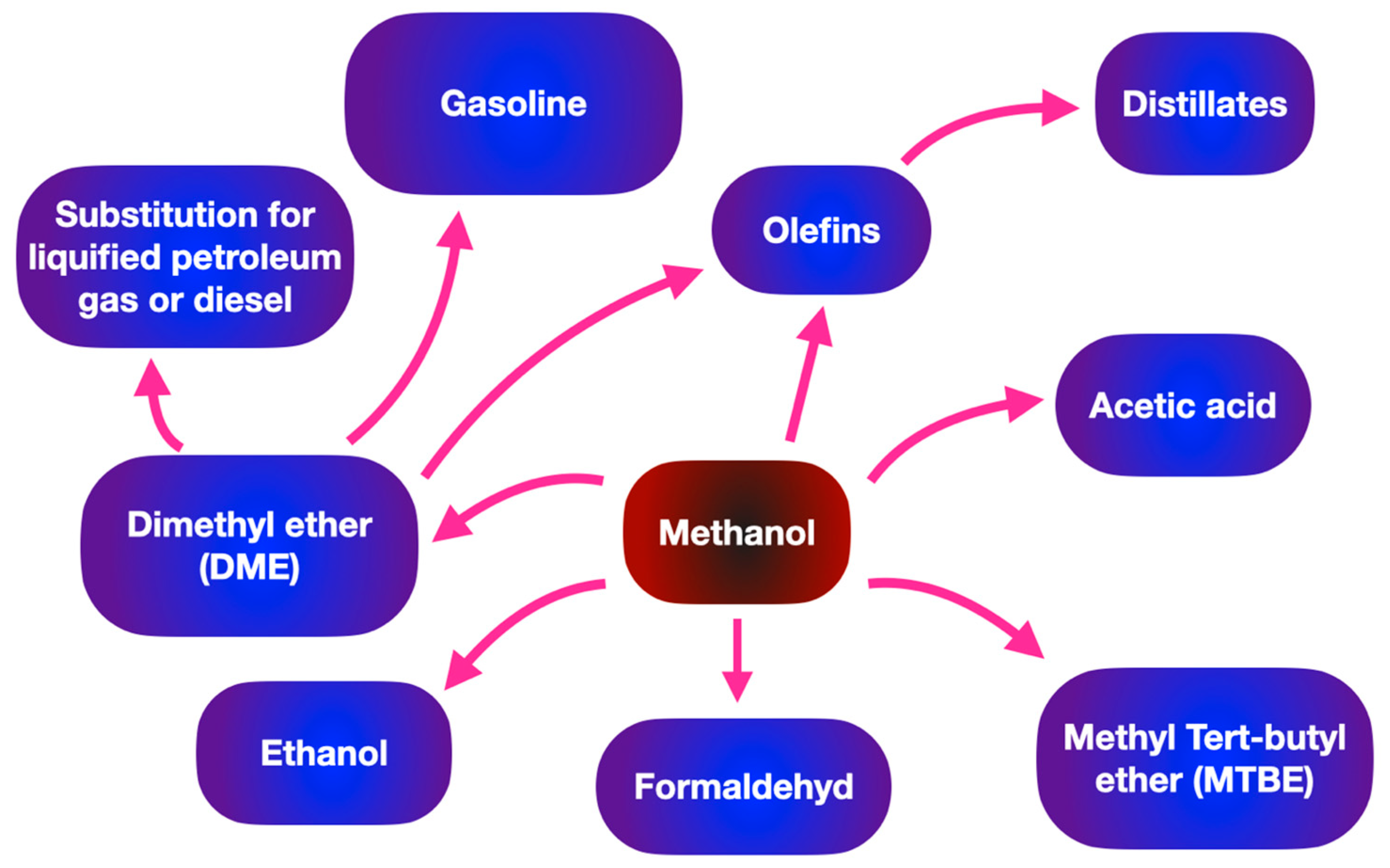

2.1. Industrial Applications of Methanol

| Fuel | Energy Density (MJ/L) | Octane Rating |

|---|---|---|

| Methanol (CH3OH) | 16 | 98.65/108.7 |

| Ethanol (C2H5OH) | 20 | 99.5/108.6 |

| Propanol (C3H7OH) | 24 | 108/118 |

| Butanol (C4H10O) | 30 | 97/103 |

| Dimethyl ether (C2H6O) | 18.9 | - |

| C8H18 (2,2,4-Trimethylpentane) | 33 | 85–96/90–105 |

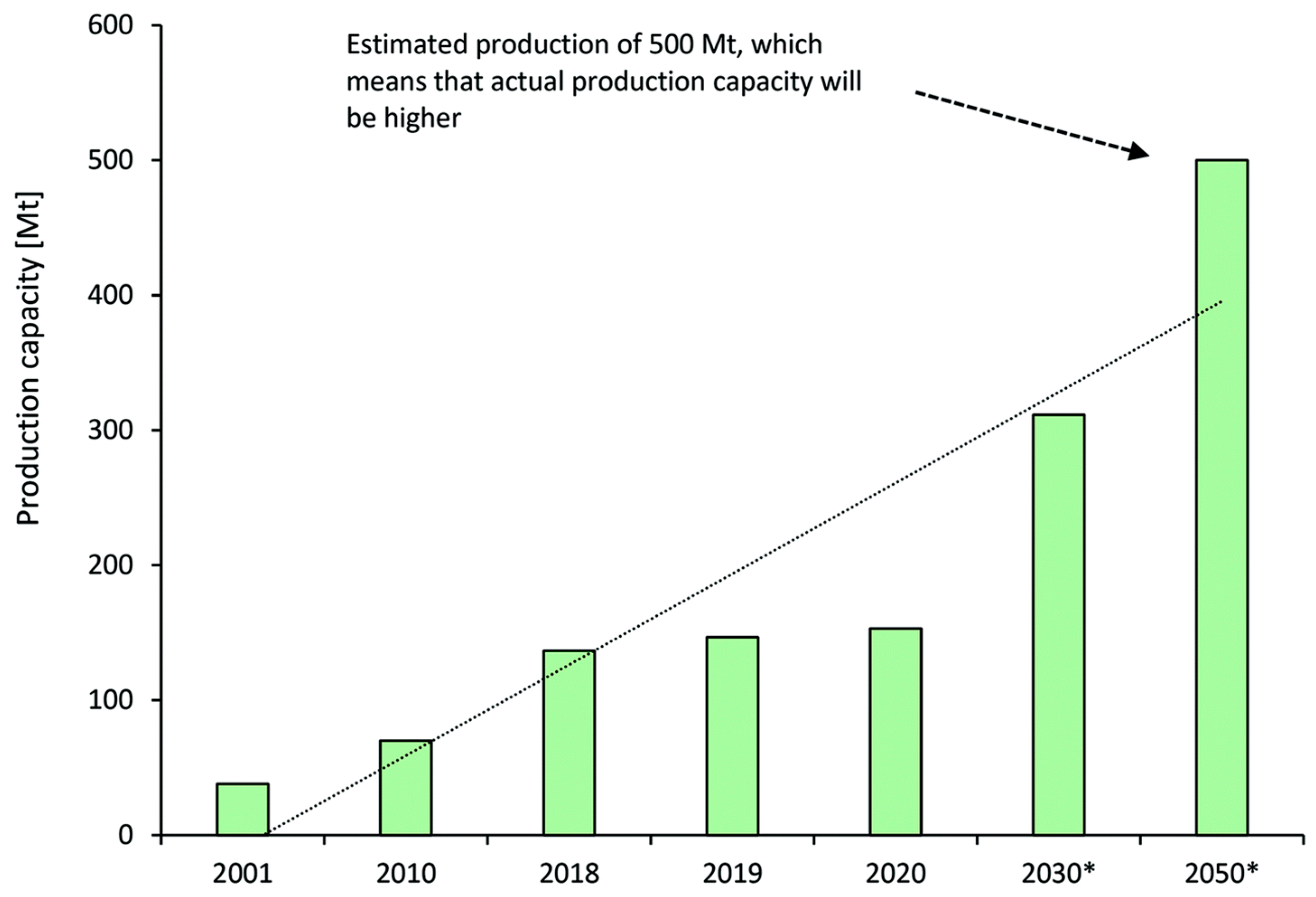

2.2. Techno-Economic Analysis of Methanol Production

2.3. Lifecycle Assessment of Methanol

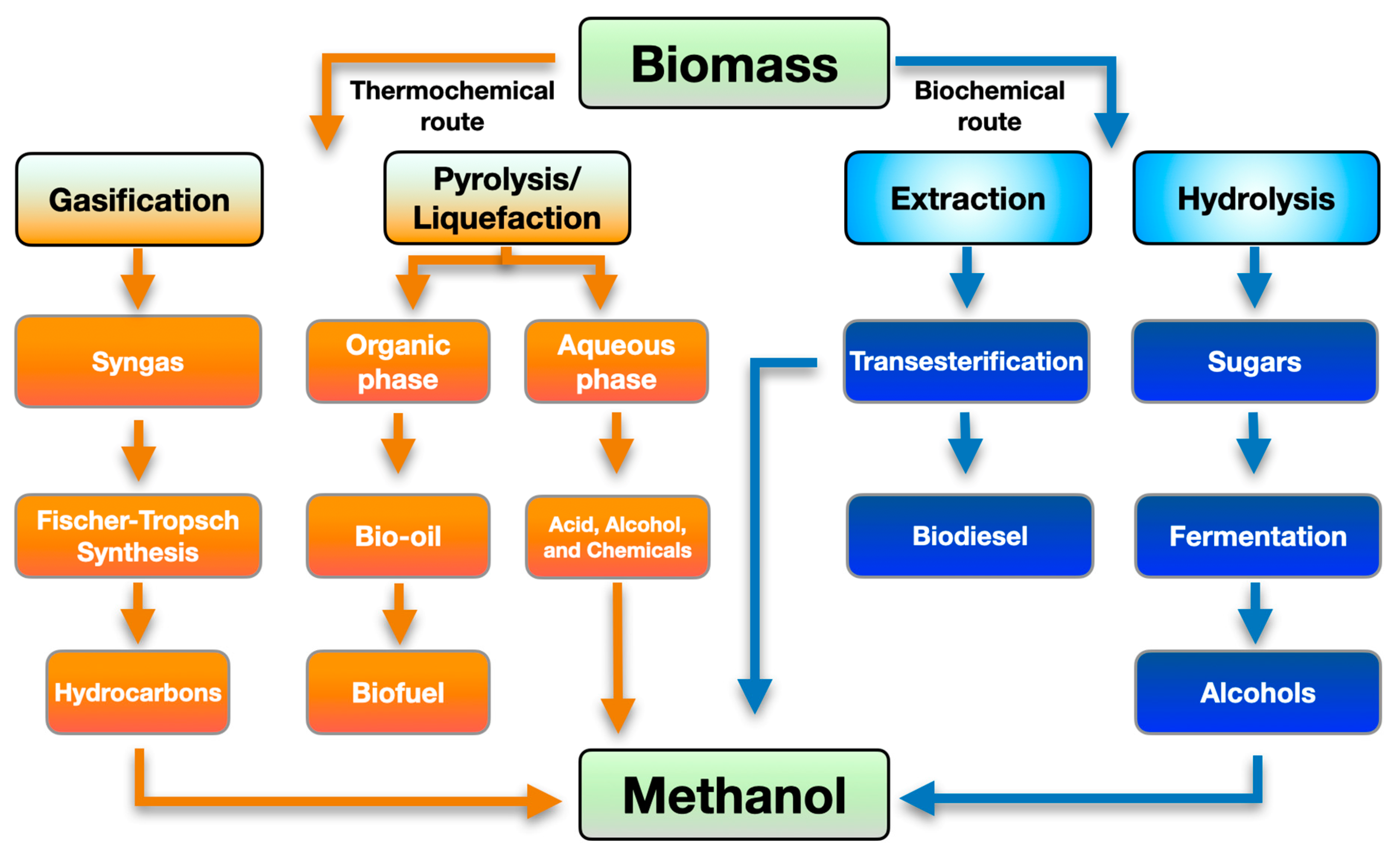

3. Potential of Using Biomass for Methanol Production

3.1. Types of Biomasses

3.2. Biomass Composition

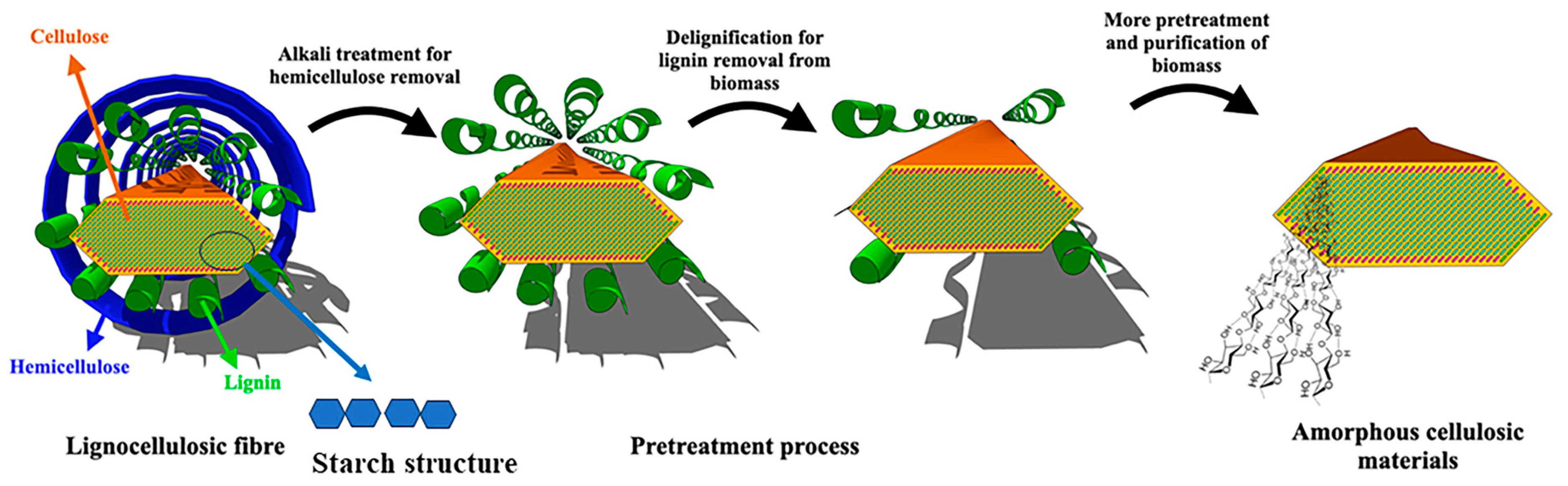

3.3. Pretreatment of Biomass for Higher Conversion Yield

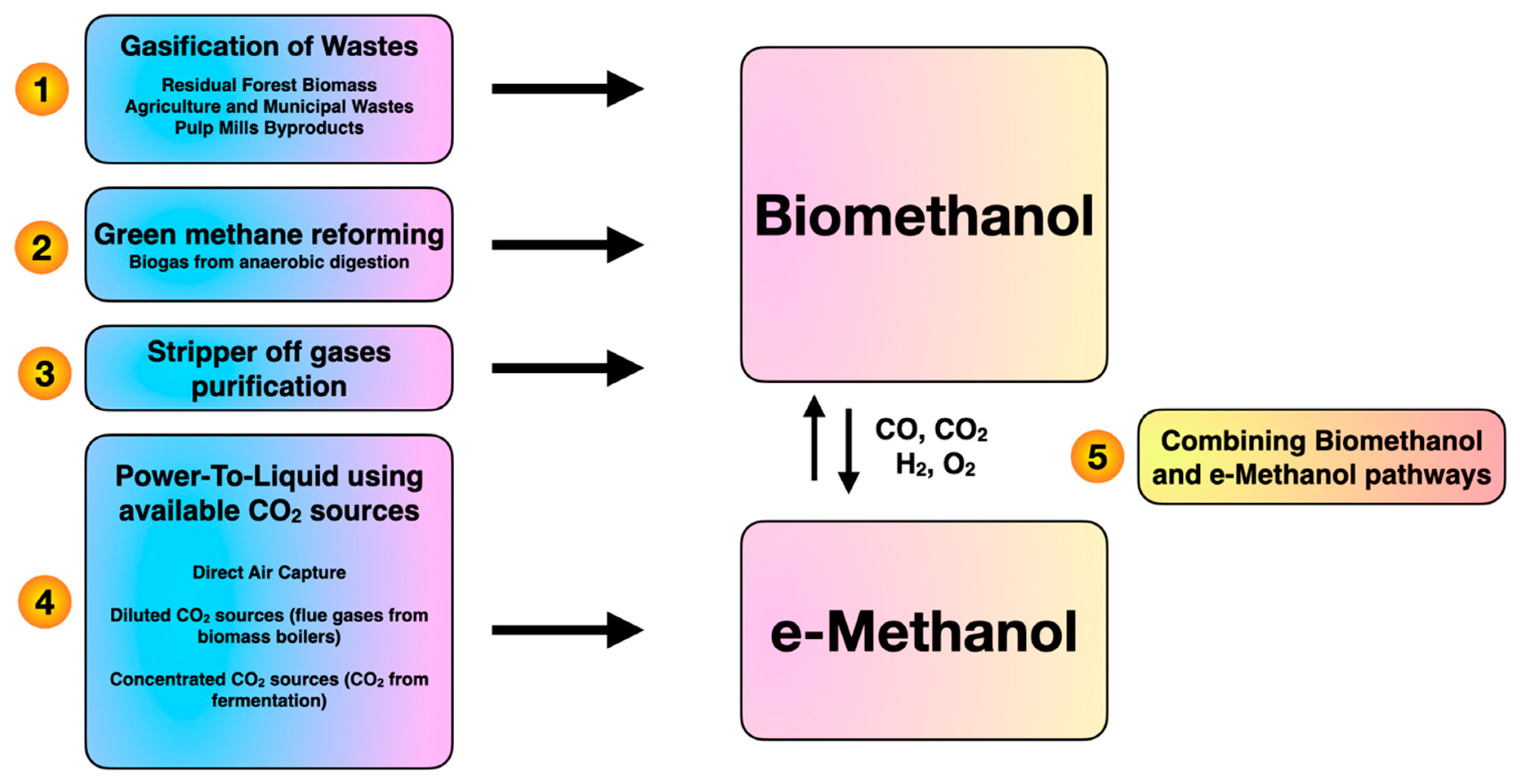

4. Sustainable Production of Methanol

4.1. Pyrolysis

4.2. Gasification

4.3. Methane

4.4. Catalytic Fischer-Tropsch Synthesis

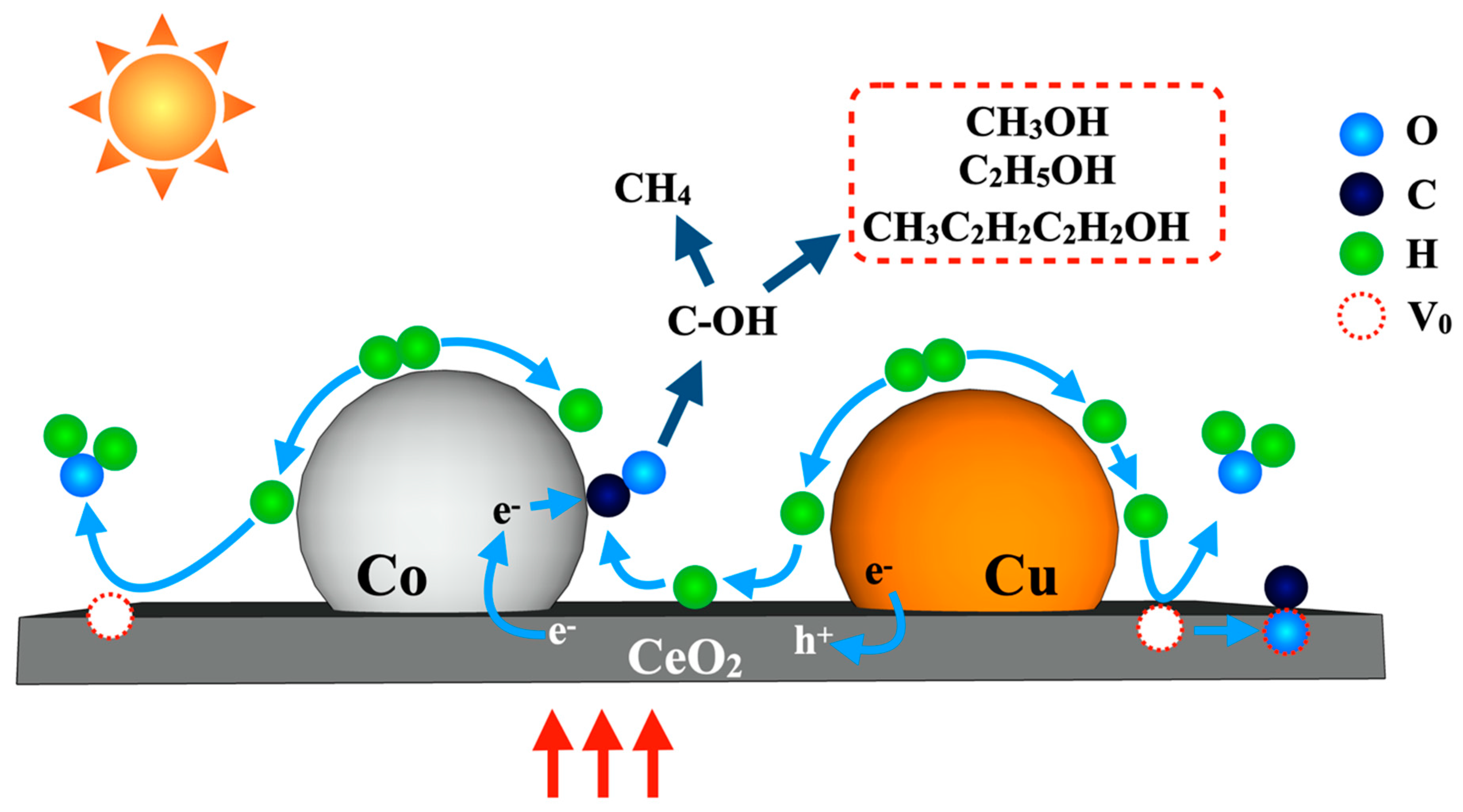

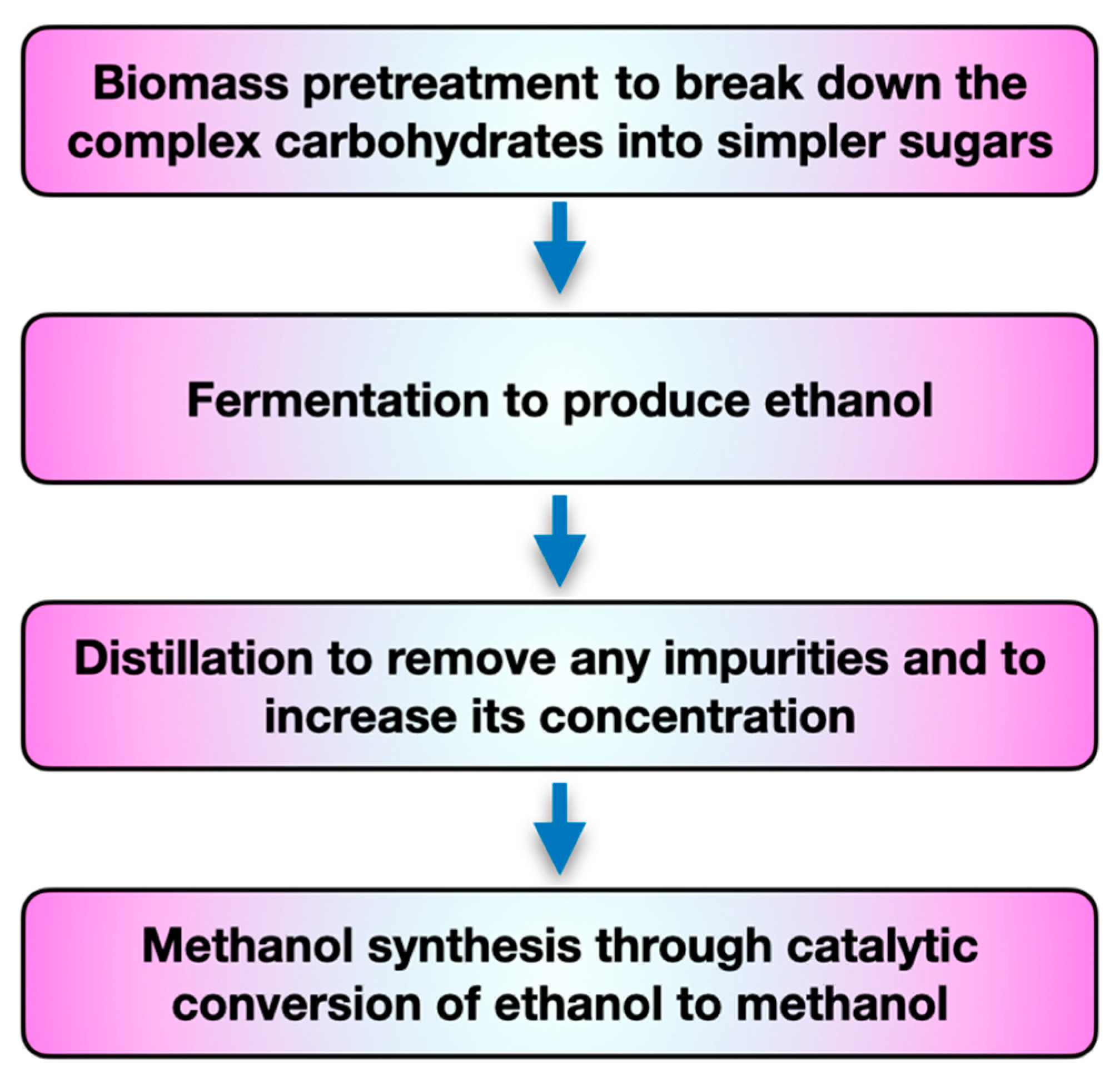

4.5. Methanol Production through Fermentation

4.5.1. Acid and Alkaline Pretreatment

4.5.2. Enzymatic Pretreatment

4.5.3. Fermentation

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fózer, D.; Tóth, A.J.; Varbanov, P.S.; Klemeš, J.J.; Mizsey, P. Sustainability Assessment of Biomethanol Production via Hydrothermal Gasification Supported by Artificial Neural Network. J. Clean. Prod. 2021, 318, 128606. [Google Scholar] [CrossRef]

- Shahbaz, M.; AlNouss, A.; Ghiat, I.; Mckay, G.; Mackey, H.; Elkhalifa, S.; Al-Ansari, T. A Comprehensive Review of Biomass Based Thermochemical Conversion Technologies Integrated with CO2 Capture and Utilisation within BECCS Networks. Resour. Conserv. Recycl. 2021, 173, 105734. [Google Scholar] [CrossRef]

- AlNouss, A.; Shahbaz, M.; Mckay, G.; Al-Ansari, T. Bio-Methanol Production from Palm Wastes Steam Gasification with Application of CaO for CO2 Capture: Techno-Economic-Environmental Analysis. J. Clean. Prod. 2022, 341, 130849. [Google Scholar] [CrossRef]

- Im-orb, K.; Arpornwichanop, A. Comparative Techno-Economic Assessment of Bio-Methanol and Bio-DME Production from Oil Palm Residue. Energy Convers. Manag. 2022, 258, 115511. [Google Scholar] [CrossRef]

- Galusnyak, S.C.; Petrescu, L.; Chisalita, D.A.; Cormos, C.-C.; Ugolini, M. From Secondary Biomass to Bio-Methanol through CONVERGE Technology: An Environmental Analysis. Energies 2023, 16, 2726. [Google Scholar] [CrossRef]

- Pio, D.T.; Vilas-Boas, A.C.M.; Rodrigues, N.F.C.; Mendes, A. Carbon Neutral Methanol from Pulp Mills towards Full Energy Decarbonization: An inside Perspective and Critical Review. Green Chem. 2022, 24, 5403–5428. [Google Scholar] [CrossRef]

- Xiang, D.; Li, P.; Yuan, X.; Cao, H.; Liu, L.; Liu, Y. Energy Consumption and Greenhouse Gas Emissions of Shale Gas Chemical Looping Reforming Process Integrated with Coal Gasification for Methanol Production. Appl. Therm. Eng. 2021, 193, 116990. [Google Scholar] [CrossRef]

- Chen, J.; Yang, S.; Qian, Y. A Novel Path for Carbon-Rich Resource Utilization with Lower Emission and Higher Efficiency: An Integrated Process of Coal Gasification and Coking to Methanol Production. Energy 2019, 177, 304–318. [Google Scholar] [CrossRef]

- Kasmuri, N.H.; Kamarudin, S.K.; Abdullah, S.R.S.; Hasan, H.A.; Som, A.M. Integrated Advanced Nonlinear Neural Network-Simulink Control System for Production of Bio-Methanol from Sugar Cane Bagasse via Pyrolysis. Energy 2019, 168, 261–272. [Google Scholar] [CrossRef]

- Nanda, S.; Berruti, F. A technical review of bioenergy and resource recovery from municipal solid waste. J. Hazard. Mater. 2021, 403, 123970. [Google Scholar] [CrossRef]

- Kasmuri, N.H.; Kamarudin, S.K.; Abdullah, S.R.S.; Hasan, H.A.; Som, A.M. Process System Engineering Aspect of Bio-Alcohol Fuel Production from Biomass via Pyrolysis: An Overview. Renew. Sustain. Energy Rev. 2017, 79, 914–923. [Google Scholar] [CrossRef]

- Kim, T.; Boehman, A.L. Development of Novel Dimethyl Ether–Glycerol Blends with Improved Viscosity and Miscibility for Potential Compression-Ignition Engine Application. Fuel 2023, 346, 128301. [Google Scholar] [CrossRef]

- Sarangi, P.K.; Nanda, S.; Vo, D.V.N. Technological Advancements in the Production and Application of Biomethanol. Biorefinery Altern. In Biorefinery of Alternative Resources: Targeting Green Fuels and Platform Chemicals; Springer: Singapore, 2020; pp. 127–139. [Google Scholar]

- Shamsul, N.S.; Kamarudin, S.K.; Rahman, N.A.; Kofli, N.T. An Overview on the Production of Bio-Methanol as Potential Renewable Energy. Renew. Sustain. Energy Rev. 2014, 33, 578–588. [Google Scholar] [CrossRef]

- Deka, T.J.; Osman, A.I.; Baruah, D.C.; Rooney, D.W. Methanol Fuel Production, Utilization, and Techno-Economy: A Review. Environ. Chem. Lett. 2022, 20, 3525–3554. [Google Scholar] [CrossRef]

- Rivarolo, M.; Bellotti, D.; Magistri, L.; Massardo, A.F. Feasibility Study of Methanol Production from Different Renewable Sources and Thermo-Economic Analysis. Int. J. Hydrogen Energy 2016, 41, 2105–2116. [Google Scholar] [CrossRef]

- Zhang, Z.; Delcroix, B.; Rezazgui, O.; Mangin, P. Simulation and Techno-Economic Assessment of Bio-Methanol Production from Pine Biomass, Biochar and Pyrolysis Oil. Sustain. Energy Technol. Assess. 2021, 44, 101002. [Google Scholar] [CrossRef]

- Choe, C.; Byun, M.; Lee, H.; Lim, H. Techno-Economic and Environmental Assessments for Sustainable Bio-Methanol Production as Landfill Gas Valorization. Waste Manag. 2022, 150, 90–97. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, R.P.B.; Oudenhoven, S.R.G.; Kersten, S.R.A.; van Rossum, G.; van der Ham, A.G.J. Techno-Economic Analysis of Biomethanol Production via Hybrid Steam Reforming of Glycerol with Natural Gas. Energy Fuels 2013, 27, 5962–5974. [Google Scholar] [CrossRef]

- Fajimi, L.I.; Chrisostomou, J.; Oboirien, B.O. A Techno-Economic Analysis (TEA) of a Combined Process of Torrefaction and Gasification of Lignocellulose Biomass (Bagasse) for Methanol and Electricity Production. Biomass Convers. Biorefinery 2022, 1–16. [Google Scholar] [CrossRef]

- Mandegari, M.; Farzad, S.; Görgens, J.F. A New Insight into Sugarcane Biorefineries with Fossil Fuel Co-Combustion: Techno-Economic Analysis and Life Cycle Assessment. Energy Convers. Manag. 2018, 165, 76–91. [Google Scholar] [CrossRef]

- Lim, D.; Lee, B.; Lee, H.; Byun, M.; Lim, H. Projected Cost Analysis of Hybrid Methanol Production from Tri-Reforming of Methane Integrated with Various Water Electrolysis Systems: Technical and Economic Assessment. Renew. Sustain. Energy Rev. 2022, 155, 111876. [Google Scholar] [CrossRef]

- Zang, G.; Sun, P.; Elgowainy, A.; Wang, M. Technoeconomic and Life Cycle Analysis of Synthetic Methanol Production from Hydrogen and Industrial Byproduct CO2. Environ. Sci. Technol. 2021, 55, 5248–5257. [Google Scholar] [CrossRef] [PubMed]

- Alvarado-Morales, M.; Boldrin, A.; Karakashev, D.B.; Holdt, S.L.; Angelidaki, I.; Astrup, T. Life Cycle Assessment of Biofuel Production from Brown Seaweed in Nordic Conditions. Bioresour. Technol. 2013, 129, 92–99. [Google Scholar] [CrossRef] [PubMed]

- Mu, D.; Ruan, R.; Addy, M.; Mack, S.; Chen, P.; Zhou, Y. Life Cycle Assessment and Nutrient Analysis of Various Processing Pathways in Algal Biofuel Production. Bioresour. Technol. 2017, 230, 33–42. [Google Scholar] [CrossRef]

- Aitken, D.; Bulboa, C.; Godoy-Faundez, A.; Turrion-Gomez, J.L.; Antizar-Ladislao, B. Life Cycle Assessment of Macroalgae Cultivation and Processing for Biofuel Production. J. Clean. Prod. 2014, 75, 45–56. [Google Scholar] [CrossRef]

- Sajid, Z.; Khan, F.; Zhang, Y. Process Simulation and Life Cycle Analysis of Biodiesel Production. Renew. Energy 2016, 85, 945–952. [Google Scholar] [CrossRef]

- Sills, D.L.; Paramita, V.; Franke, M.J.; Johnson, M.C.; Akabas, T.M.; Greene, C.H.; Tester, J.W. Quantitative Uncertainty Analysis of Life Cycle Assessment for Algal Biofuel Production. Environ. Sci. Technol. 2013, 47, 687–694. [Google Scholar] [CrossRef]

- Yadav, P.; Athanassiadis, D.; Yacout, D.M.M.; Tysklind, M.; Upadhyayula, V.K.K. Environmental Impact and Environmental Cost Assessment of Methanol Production from Wood Biomass. Environ. Pollut. 2020, 265, 114990. [Google Scholar] [CrossRef]

- Babin, A.; Vaneeckhaute, C.; Iliuta, M.C. Potential and Challenges of Bioenergy with Carbon Capture and Storage as a Carbon-Negative Energy Source: A Review. Biomass Bioenergy 2021, 146, 105968. [Google Scholar] [CrossRef]

- Chan, Y.H.; Cheah, K.W.; How, B.S.; Loy, A.C.M.; Shahbaz, M.; Singh, H.K.G.; Yusuf, N.R.; Shuhaili, A.F.A.; Yusup, S.; Ghani, W.A.W.A.K.; et al. An Overview of Biomass Thermochemical Conversion Technologies in Malaysia. Sci. Total Environ. 2019, 680, 105–123. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, P.K.; Dash, S.; Pattnaik, R. Microbial Pretreatment of Lignocellulosic Biomass for Enhanced Biomethanation and Waste Management. 3 Biotech 2018, 8, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Kumari, D.; Singh, R. Pretreatment of Lignocellulosic Wastes for Biofuel Production: A Critical Review. Renew. Sustain. Energy Rev. 2018, 90, 877–891. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Fennell, P.S.; Shah, N.; Anthony, E.J. Progress in Biofuel Production from Gasification. Prog. Energy Combust. Sci. 2017, 61, 189–248. [Google Scholar] [CrossRef]

- Collard, F.-X.; Blin, J. A Review on Pyrolysis of Biomass Constituents: Mechanisms and Composition of the Products Obtained from the Conversion of Cellulose, Hemicelluloses and Lignin. Renew. Sustain. Energy Rev. 2014, 38, 594–608. [Google Scholar] [CrossRef]

- Rambo, M.K.D.; Schmidt, F.L.; Ferreira, M.M.C. Analysis of the Lignocellulosic Components of Biomass Residues for Biorefinery Opportunities. Talanta 2015, 144, 696–703. [Google Scholar] [CrossRef] [PubMed]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic Biomass Pyrolysis: A Review of Product Properties and Effects of Pyrolysis Parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of Transportation Fuels from Biomass: Chemistry, Catalysts, and Engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef]

- Raveendran, K.; Ganesh, A.; Khilar, K.C. Influence of Mineral Matter on Biomass Pyrolysis Characteristics. Fuel 1995, 74, 1812–1822. [Google Scholar] [CrossRef]

- Ahorsu, R.; Medina, F.; Constantí, M. Significance and Challenges of Biomass as a Suitable Feedstock for Bioenergy and Biochemical Production: A Review. Energies 2018, 11, 3366. [Google Scholar] [CrossRef]

- Abbasi, T.; Abbasi, S.A. Biomass Energy and the Environmental Impacts Associated with Its Production and Utilization. Renew. Sustain. Energy Rev. 2010, 14, 919–937. [Google Scholar] [CrossRef]

- Sharma, S.; Tsai, M.-L.; Sharma, V.; Sun, P.-P.; Nargotra, P.; Bajaj, B.K.; Chen, C.-W.; Dong, C.-D. Environment Friendly Pretreatment Approaches for the Bioconversion of Lignocellulosic Biomass into Biofuels and Value-Added Products. Environments 2022, 10, 6. [Google Scholar] [CrossRef]

- Yang, B.; Dai, Z.; Ding, S.-Y.; Wyman, C.E. Enzymatic Hydrolysis of Cellulosic Biomass. Biofuels 2011, 2, 421–449. [Google Scholar] [CrossRef]

- Mohanty, P.; Singh, P.K.; Adhya, T.K.; Pattnaik, R.; Mishra, S. A Critical Review on Prospects and Challenges in Production of Biomethanol from Lignocellulose Biomass. Biomass Convers. Biorefinery 2021, 12, 1835–1849. [Google Scholar] [CrossRef]

- Kumar, P.; Barrett, D.M.; Delwiche, M.J.; Stroeve, P. Methods for Pretreatment of Lignocellulosic Biomass for Efficient Hydrolysis and Biofuel Production. Ind. Eng. Chem. Res. 2009, 48, 3713–3729. [Google Scholar] [CrossRef]

- Demirbaş, A. Bioethanol from Cellulosic Materials: A Renewable Motor Fuel from Biomass. Energy Sources 2005, 27, 327–337. [Google Scholar] [CrossRef]

- Wen, D.; Jiang, H.; Zhang, K. Supercritical Fluids Technology for Clean Biofuel Production. Prog. Nat. Sci. 2009, 19, 273–284. [Google Scholar] [CrossRef]

- Ab Rasid, N.S.; Shamjuddin, A.; Abdul Rahman, A.Z.; Amin, N.A.S. Recent Advances in Green Pre-Treatment Methods of Lignocellulosic Biomass for Enhanced Biofuel Production. J. Clean. Prod. 2021, 321, 129038. [Google Scholar] [CrossRef]

- Kamarudin, S.K.; Shamsul, N.S.; Ghani, J.A.; Chia, S.K.; Liew, H.S.; Samsudin, A.S. Production of Methanol from Biomass Waste via Pyrolysis. Bioresour. Technol. 2013, 129, 463–468. [Google Scholar] [CrossRef]

- Wang, S.; Dai, G.; Yang, H.; Luo, Z. Lignocellulosic Biomass Pyrolysis Mechanism: A State-of-the-Art Review. Prog. Energy Combust. Sci. 2017, 62, 33–86. [Google Scholar] [CrossRef]

- Amigun, B.; Gorgens, J.; Knoetze, H. Biomethanol Production from Gasification of Non-Woody Plant in South Africa: Optimum Scale and Economic Performance. Energy Policy 2010, 38, 312–322. [Google Scholar] [CrossRef]

- Carvalho, L.; Furusjö, E.; Kirtania, K.; Wetterlund, E.; Lundgren, J.; Anheden, M.; Wolf, J. Techno-Economic Assessment of Catalytic Gasification of Biomass Powders for Methanol Production. Bioresour. Technol. 2017, 237, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Zisopoulos, G.; Detsios, N.; Atsonios, K.; Nikolopoulos, N.; Grammelis, P. Process Analysis and Design Considerations of a Low Carbon Methanol Synthesis Plant from Lignite/Waste Gasification. Fuels 2022, 3, 245–274. [Google Scholar] [CrossRef]

- Yan, L.; Li, Y.; Li, J.; Gao, W. Steam Gasification of Biomass for Biomethanol Production: Model Development and Analysis. Energy Sources, Part A Recover. Energy Sources Part A Recovery Util. Environ. Eff. 2017, 39, 1410–1415. [Google Scholar]

- Brachi, P.; Chirone, R.; Miccio, F.; Miccio, M.; Picarelli, A.; Ruoppolo, G. Fluidized Bed Co-Gasification of Biomass and Polymeric Wastes for a Flexible End-Use of the Syngas: Focus on Bio-Methanol. Fuel 2014, 128, 88–98. [Google Scholar] [CrossRef]

- Kulkarni, P.P.; Khonde, V.K.; Deshpande, M.S.; Sabale, T.R.; Kumbhar, P.S.; Ghosalkar, A.R. Selection of Methanotrophic Platform for Methanol Production Using Methane and Biogas. J. Biosci. Bioeng. 2021, 132, 460–468. [Google Scholar] [CrossRef] [PubMed]

- Sahoo, K.K.; Datta, S.; Goswami, G.; Das, D. Two-Stage Integrated Process for Bio-Methanol Production Coupled with Methane and Carbon Dioxide Sequestration: Kinetic Modelling and Experimental Validation. J. Environ. Manag. 2022, 301, 113927. [Google Scholar] [CrossRef]

- Patel, S.K.S.; Gupta, R.K.; Kumar, V.; Kondaveeti, S.; Kumar, A.; Das, D.; Kalia, V.C.; Lee, J.-K. Biomethanol Production from Methane by Immobilized Co-Cultures of Methanotrophs. Indian J. Microbiol. 2020, 60, 318–324. [Google Scholar] [CrossRef]

- Anitha, M.; Kamarudin, S.K.; Shamsul, N.S.; Kofli, N.T. Determination of Bio-Methanol as Intermediate Product of Anaerobic Co-Digestion in Animal and Agriculture Wastes. Int. J. Hydrogen Energy 2015, 40, 11791–11799. [Google Scholar] [CrossRef]

- Patel, S.K.S.; Kalia, V.C.; Lee, J.-K. Integration of Biogas Derived from Dark Fermentation and Anaerobic Digestion of Biowaste to Enhance Methanol Production by Methanotrophs. Bioresour. Technol. 2023, 369, 128427. [Google Scholar] [CrossRef]

- Sabale, T.; Babu, M.; Panchwagh, S.; Ghosalkar, A. Continuous Culture of Nitrosomonas Eutropha and Biomethanol Production Using Whole Cell Biotransformation. J. Chem. Technol. Biotechnol. 2021, 96, 1411–1418. [Google Scholar] [CrossRef]

- Santos, R.G.D.; Alencar, A.C. Biomass-Derived Syngas Production via Gasification Process and Its Catalytic Conversion into Fuels by Fischer Tropsch Synthesis: A Review. Int. J. Hydrogen Energy 2020, 45, 18114–18132. [Google Scholar] [CrossRef]

- Santos, G.R.S.; Basha, O.M.; Wang, R.; Ashkanani, H.; Morsi, B. Techno-Economic Assessment of Fischer-Tropsch Synthesis and Direct Methane-to-Methanol Processes in Modular GTL Reactors. Catal. Today 2021, 371, 93–112. [Google Scholar] [CrossRef]

- Khademi, M.H.; Alipour-Dehkordi, A.; Tabesh, M. Optimal Design of Methane Tri-Reforming Reactor to Produce Proper Syngas for Fischer-Tropsch and Methanol Synthesis Processes: A Comparative Analysis between Different Side-Feeding Strategies. Int. J. Hydrogen Energy 2021, 46, 14441–14454. [Google Scholar] [CrossRef]

- Yue, X.; Liu, X.; Wang, K.; Yang, Z.; Chen, X.; Dai, W.; Fu, X. Photo-Assisted Thermal Catalytic Fischer–Tropsch Synthesis over Co–Cu/CeO 2. Inorg. Chem. Front. 2022, 9, 1258–1269. [Google Scholar] [CrossRef]

- Marquart, W.; Morgan, D.J.; Hutchings, G.J.; Claeys, M.; Fischer, N. Oxygenate Formation over K/β-Mo 2 C Catalysts in the Fischer–Tropsch Synthesis. Catal. Sci. Technol. 2018, 8, 3806–3817. [Google Scholar] [CrossRef]

- Zaffran, J.; Yang, B. Theoretical Insights into the Formation Mechanism of Methane, Ethylene and Methanol in Fischer-Tropsch Synthesis at Co2C Surfaces. ChemCatChem 2021, 13, 2674–2682. [Google Scholar] [CrossRef]

- Choudhury, H.A.; Chakma, S.; Moholkar, V.S. Chapter 14–Biomass Gasification Integrated Fischer-Tropsch Synthesis: Perspectives, Opportunities and Challenges. In Recent Advances in Thermochemical Conversion of Biomass; Pandey, A., Bhaskar, T., Stocker, M., Sukumaran, R.K., Eds.; Elsevier: Boston, MA, USA, 2015; pp. 383–435. ISBN 978-0-444-63289-0. [Google Scholar]

- Varga, E.; Réczey, K.; Zacchi, G. Optimization of Steam Pretreatment of Corn Stover to Enhance Enzymatic Digestibility. In Proceedings of the Twenty-Fifth Symposium on Biotechnology for Fuels and Chemicals, Breckenridge, CO, USA, 4–7 May 2003; Springer: Berlin/Heidelberg, Germany, 2004; pp. 509–523. [Google Scholar]

- Mosier, N.; Wyman, C.; Dale, B.; Elander, R.; Lee, Y.Y.; Holtzapple, M.; Ladisch, M. Features of Promising Technologies for Pretreatment of Lignocellulosic Biomass. Bioresour. Technol. 2005, 96, 673–686. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Kim, S.-H.; Yoon, J.-J.; Yang, Y.-H. Current Status and Strategies for Second Generation Biofuel Production Using Microbial Systems. Energy Convers. Manag. 2017, 148, 1142–1156. [Google Scholar] [CrossRef]

- Cardona, C.A.; Quintero, J.A.; Paz, I.C. Production of Bioethanol from Sugarcane Bagasse: Status and Perspectives. Bioresour. Technol. 2010, 101, 4754–4766. [Google Scholar] [CrossRef]

- Mosier, N.; Hendrickson, R.; Ho, N.; Sedlak, M.; Ladisch, M.R. Optimization of PH Controlled Liquid Hot Water Pretreatment of Corn Stover. Bioresour. Technol. 2005, 96, 1986–1993. [Google Scholar] [CrossRef]

- Saha, B.C.; Iten, L.B.; Cotta, M.A.; Wu, Y.V. Dilute Acid Pretreatment, Enzymatic Saccharification and Fermentation of Wheat Straw to Ethanol. Process Biochem. 2005, 40, 3693–3700. [Google Scholar] [CrossRef]

- Sarkar, N.; Ghosh, S.K.; Bannerjee, S.; Aikat, K. Bioethanol Production from Agricultural Wastes: An Overview. Renew. Energy 2012, 37, 19–27. [Google Scholar] [CrossRef]

- Pandey, A.; Soccol, C.R.; Nigam, P.; Soccol, V.T. Biotechnological Potential of Agro-Industrial Residues. I: Sugarcane Bagasse. Bioresour. Technol. 2000, 74, 69–80. [Google Scholar] [CrossRef]

- Sun, R.; Lawther, J.M.; Banks, W.B. Influence of Alkaline Pre-Treatments on the Cell Wall Components of Wheat Straw. Ind. Crops Prod. 1995, 4, 127–145. [Google Scholar] [CrossRef]

- Kumar, R.; Wyman, C.E. Effects of Cellulase and Xylanase Enzymes on the Deconstruction of Solids from Pretreatment of Poplar by Leading Technologies. Biotechnol. Prog. 2009, 25, 302–314. [Google Scholar] [CrossRef]

- Ferreira, S.; Duarte, A.P.; Ribeiro, M.H.L.; Queiroz, J.A.; Domingues, F.C. Response Surface Optimization of Enzymatic Hydrolysis of Cistus Ladanifer and Cytisus Striatus for Bioethanol Production. Biochem. Eng. J. 2009, 45, 192–200. [Google Scholar] [CrossRef]

- Das Neves, M.A.; Kimura, T.; Shimizu, N.; Nakajima, M. State of the Art and Future Trends of Bioethanol Production. Dyn. Biochem. Process Biotechnol. Mol. Biol. 2007, 1, 1–14. [Google Scholar]

- Park, Y.; Kang, S.; Lee, J.; Hong, S.; Kim, S. Xylanase Production in Solid State Fermentation by Aspergillus Niger Mutant Using Statistical Experimental Designs. Appl. Microbiol. Biotechnol. 2002, 58, 761–766. [Google Scholar]

- Sun, Y.; Cheng, J. Hydrolysis of Lignocellulosic Materials for Ethanol Production: A Review. Bioresour. Technol. 2002, 83, 1–11. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Enzymatic-Based Hydrolysis Processes for Ethanol from Lignocellulosic Materials: A Review. BioResources 2007, 2, 707–738. [Google Scholar] [CrossRef]

- Banerjee, S.; Mudliar, S.; Sen, R.; Giri, B.; Satpute, D.; Chakrabarti, T.; Pandey, R.A. Commercializing Lignocellulosic Bioethanol: Technology Bottlenecks and Possible Remedies. Biofuels Bioprod. Biorefining Innov. A Sustain. Econ. 2010, 4, 77–93. [Google Scholar] [CrossRef]

- Talebnia, F.; Karakashev, D.; Angelidaki, I. Production of Bioethanol from Wheat Straw: An Overview on Pretreatment, Hydrolysis and Fermentation. Bioresour. Technol. 2010, 101, 4744–4753. [Google Scholar] [CrossRef]

- Öhgren, K.; Bura, R.; Lesnicki, G.; Saddler, J.; Zacchi, G. A Comparison between Simultaneous Saccharification and Fermentation and Separate Hydrolysis and Fermentation Using Steam-Pretreated Corn Stover. Process Biochem. 2007, 42, 834–839. [Google Scholar] [CrossRef]

- Sasaki, C.; Kushiki, Y.; Asada, C.; Nakamura, Y. Acetone–Butanol–Ethanol Production by Separate Hydrolysis and Fermentation (SHF) and Simultaneous Saccharification and Fermentation (SSF) Methods Using Acorns and Wood Chips of Quercus Acutissima as a Carbon Source. Ind. Crop. Prod. 2014, 62, 286–292. [Google Scholar] [CrossRef]

- Unrean, P.; Ketsub, N. Integrated Lignocellulosic Bioprocess for Co-Production of Ethanol and Xylitol from Sugarcane Bagasse. Ind. Crop. Prod. 2018, 123, 238–246. [Google Scholar] [CrossRef]

- Toivari, M.H.; Aristidou, A.; Ruohonen, L.; Penttilä, M. Conversion of Xylose to Ethanol by Recombinant Saccharomyces Cerevisiae: Importance of Xylulokinase (XKS1) and Oxygen Availability. Metab. Eng. 2001, 3, 236–249. [Google Scholar] [CrossRef]

- Taherzadeh, M.J.; Karimi, K. Pretreatment of Lignocellulosic Wastes to Improve Ethanol and Biogas Production: A Review. Int. J. Mol. Sci. 2008, 9, 1621–1651. [Google Scholar] [CrossRef]

- Tuck, C.O.; Pérez, E.; Horváth, I.T.; Sheldon, R.A.; Poliakoff, M. Valorization of Biomass: Deriving More Value from Waste. Science 2012, 337, 695–699. [Google Scholar] [CrossRef]

- Yousef, B.A.A.; Rezk, H.; Abdelkareem, M.A.; Olabi, A.G.; Nassef, A.M. Fuzzy Modeling and Particle Swarm Optimization for Determining the Optimal Operating Parameters to Enhance the Bio-methanol Production from Sugar Cane Bagasse. Int. J. Energy Res. 2020, 44, 8964–8973. [Google Scholar] [CrossRef]

- Im-orb, K.; Phan, A.N.; Arpornwichanop, A. Bio-Methanol Production from Oil Palm Residues: A Thermodynamic Analysis. Energy Convers. Manag. 2020, 226, 113493. [Google Scholar] [CrossRef]

- Shamsul, N.S.; Kamarudin, S.K.; Kofli, N.T.; Rahman, N.A. Optimization of Bio-Methanol Production from Goat Manure in Single Stage Bio-Reactor. Int. J. Hydrogen Energy 2017, 42, 9031–9043. [Google Scholar] [CrossRef]

| Approach | Concluding Remarks | Future Prospects | Reference |

|---|---|---|---|

| Production of bio-methanol as potential renewable energy | Methanol can be produced from additional reactions of decomposed biomass material. Improvement in the electrolysis process and renewable electricity favors methanol synthesis. | In gasification and methanol synthesis the separation of gas and solid needs to be considered to reduce the environmental impacts. | [14] |

| Methanol fuel production | Methanol production and techno-economic viability are influenced by feedstock characteristics, initial investment, and plant location. | Dimethyl ether alongside methanol has a huge potential to be a new generation of fuel source owing to its low calorific value, low density, and low viscosity. | [15] |

| Methanol production from different renewable sources and thermo-economic analysis | The thermo-economic analysis considering different scenarios confirm that the best economic results are obtained with hydroelectric source. | Considering future methanol selling prices of 500 Є/ton, the economic performances can be further improved via the European financial incentives for biofuel production. | [16] |

| Sustainable production and application of methanol | The main advantage of biomass-derived methanol is the eco-friendly aspects of methanol production as a clean fuel. | Biomethanol is a future bioproduct for value-added industries due to its diverse applications. | This study |

| Technique | Plant Size | Feedstock | End Product | Production Cost | Reference |

|---|---|---|---|---|---|

| Biomass torrefaction coupled with gasification | Processing rate of 66.4 tons/h | Bagasse | Electricity and /or methanol production | The annual production cost was estimated at USD 140 M/y | [20] |

| Sugarcane biorefineries with fossil fuel co-combustion | Processing rate of 421,000 t/y | Lignocellulose | Methanol production of 82,700 t/y and electricity production of 3.5 GWH/y | 272.6 USD M/y | [21] |

| Tri-reforming of CH4 integrated with solid oxide fuel cell | Annual cost of USD 277,742 /y | Methane | Methanol production | 5.4 USD M/y | [22] |

| Synthetic methanol production from H2 and CO2 | 243 MT/day H2 and 1978 Mt/day CO2 | CO2 and H2 feedstocks | Methanol production is 1190 Mt/day | The minimum fuel selling price of methanol was between USD 0.61/kg and USD 0.64/kg | [23] |

| Process | Environmental Impact Analysis | Economic Evaluation | Reference |

|---|---|---|---|

| Methanol production from wood biomass | Both production processes had a much lower CO2 emission compared to fossil fuel-based methanol production. | The rectisol-based acid gas removal unit used for removing sulfur and CO2 from syngas corresponds to 20% of the total investment costs. | [29] |

| Biomethanol production from palm wastes steam gasification | The reduction in CO2 using CaO was effective with a slight increase in the total cost of the plant. | The total capital cost is approximately USD 120 M. | [3] |

| Slow Pyrolysis | Fast Pyrolysis | Vacuum Pyrolysis | |

|---|---|---|---|

| Reaction conditions | |||

| Heating rate (°C/s) | 0.2–12 | 12–300 | >1100 |

| Particle size (mm) | 7–52 | <2 | <0.5 |

| Vapor residence time (s) | 460–570 | 0.7–12 | <0.7 |

| Product yield (wt% wet basis) | |||

| Liquid | 40 | 68–83 | 90 |

| Char | 40 | 17–28 | 18 |

| Gas | 37 | 17 | 7 |

| Gasifier Reactor | Packed Bed | Fluidized Bed | Entrained Bed |

|---|---|---|---|

| Product temperature | Low (435–620 °C) | Medium (920–1070 °C) | High (1350–1700 °C) |

| Oxidant demand | Low | Medium | High |

| Ash properties | Dry ash and slagging | Dry ash and agglomerating | Slagging |

| Size of coal feed | 8–52 mm | 7–13 mm | <120 μm |

| Acceptability of fines | Limited | Good | Unlimited |

| Other characteristics | Methan, tar, and volatiles present in syngas | Low carbon conversion | Pure syngas High carbon conversion |

| Feedstock | Methanol Yield | Comments | Reference |

|---|---|---|---|

| Forest residues and lignin | 62–66% | Catalytic gasification provides operational advantages at production costs. | [52] |

| Lignite | 40–60% | Simulations show the proposed low-carbon methanol synthesis plant is an effective alternative for methanol valorization. | [53] |

| Rice straw | 14.01 g/kg biomass for gasification temperature of 900 °C | It was shown that the methanol yield rises owing to a significant growth in gasification temperature. | [54] |

| Biomass and plastics (polyethylene terephthalate) | Methane conversion of 98% | Methanol production costs rely on the purity of the syngas as the feed gas. | [55] |

| Feedstocks | Reaction Conditions | Key Findings | Reference |

|---|---|---|---|

| Glycerol and methane | Gasification at 500 °C under 35 bar Reforming at 900 °C under 20 bar | TEA confirmed that fuel prices and total cost have a significant effect on the average cost of methanol. | [59] |

| Different feedstock and agricultural residues | Anaerobic digestion at psychrophilic temperature (25 °C) | Methanol yield via anaerobic digestion was strongly dependent on the hydraulic retention time. | [60] |

| Biowaste-derived sugars and methane | Integration of biogas to biomethanol for up to 120 h at 30 °C | The integration of dark-fermentative and anaerobic digestion yielded 13.8 mmol/L of methanol via methanotrophs. | [61] |

| Nitrosomonas eutropha cell biomass | Biotransformation reaction at 28 °C under 0.7 bar | The methanol conversion rate was dependent on enzyme activity and its maximum yield was found to be 103 mg/L. | [62] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yahyazadeh, A.; Nanda, S.; Dalai, A.K. A Critical Review of the Sustainable Production and Application of Methanol as a Biochemical and Bioenergy Carrier. Reactions 2024, 5, 1-19. https://doi.org/10.3390/reactions5010001

Yahyazadeh A, Nanda S, Dalai AK. A Critical Review of the Sustainable Production and Application of Methanol as a Biochemical and Bioenergy Carrier. Reactions. 2024; 5(1):1-19. https://doi.org/10.3390/reactions5010001

Chicago/Turabian StyleYahyazadeh, Arash, Sonil Nanda, and Ajay K. Dalai. 2024. "A Critical Review of the Sustainable Production and Application of Methanol as a Biochemical and Bioenergy Carrier" Reactions 5, no. 1: 1-19. https://doi.org/10.3390/reactions5010001

APA StyleYahyazadeh, A., Nanda, S., & Dalai, A. K. (2024). A Critical Review of the Sustainable Production and Application of Methanol as a Biochemical and Bioenergy Carrier. Reactions, 5(1), 1-19. https://doi.org/10.3390/reactions5010001