Design Thinking for the Development of an Affordable Pea Sheller: Addressing Co-Design in Rural Areas

Abstract

1. Introduction

2. Methodology and Tools

3. Implementation

3.1. Empathize

Context Exploration

- Noise mitigation system: It is important to consider the electrical operation of the product; therefore, it must be ensured that the appliance does not generate excessive noise that could affect the person handling the product.

- Pods waste collector: The product should include a compartment designed to collect husk waste, avoid disorder in the workspace, and optimize the available space.

- Lightweight: To ensure the product is portable, the materials used in its production should be considered without compromising the quality and resistance.

- Easy to clean: The mechanism must be designed so that water does not affect its operation, thus maintaining the cleanliness of the compartments once the product has been used.

- Automatic operation: The product must have a mechanism to speed up the shelling process.

3.2. Define

3.2.1. Mechanism Benchmarking

3.2.2. Needs Analysis and Definition of Preliminary Technical Specifications

3.3. Ideate

3.3.1. Brainstorm for Ideation

3.3.2. Concept Scoring

3.4. Prototype

3.5. Test

4. Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dahl, W.J.; Foster, L.M.; Tyler, R.T. Review of the Health Benefits of Peas (Pisum sativum L.). Br. J. Nutr. 2012, 108, S3–S10. [Google Scholar] [CrossRef] [PubMed]

- Cousin, R. Peas (Pisum sativum L.). Field Crops Res. 1997, 53, 111–130. [Google Scholar] [CrossRef]

- Biggs, S.; Justice, S. Rural and Agricultural Mechanization: A History of the Spread of Small Engines in Selected Asian Countries; International Food Policy Research Institute: Washington, DC, USA, 2015. [Google Scholar]

- Vaculik, J.; Brezik, D.; Tesak, P. Pea Pod Sheller. TESCOMA S.R.O.: Zlín, Czech Republic Patent No. CZ24353U1, 1 October 2012. Available online: https://patents.google.com/patent/CZ24353U1/en?oq=CZ24353U1 (accessed on 19 July 2024).

- Moser, T.D. Green Cicer Bean Harvesting Apparatus and Method. U.S. Patent 6,960,131, 1 November 2005. [Google Scholar]

- Wilder, J.E. Green Pea Sheller. U.S. Patent US1831772A, 10 November 1931. Available online: https://worldwide.espacenet.com/patent/search/family/023829631/publication/US1831772A?q=pn%3DUS1831772A (accessed on 19 July 2024).

- Selvan, M.M.; Mani, I. Development of Power-Operated Continuous-Feed Green-Pea Sheller. Indian J. Agric. Sci. 2020, 90, 396–400. [Google Scholar] [CrossRef]

- FAO Investment Centre. What Factors Shape Small-Scale Farmers’ and Firms’ Adoption of New Technologies? Food and Agriculture Organization of the United Nations, 9 October 2023. Available online: https://www.fao.org/investment-centre/latest/news/detail/what-factors-shape-small-scale-farmers--and-firms--adoption-of-new-technologies/en (accessed on 4 October 2025).

- Doss, C.R. Designing Agricultural Technology for African Women Farmers: Lessons from 25 Years of Experience. World Dev. 2001, 29, 2075–2092. [Google Scholar] [CrossRef]

- Doss, C.R. Women and Agricultural Productivity: Reframing the Issues. Dev. Policy Rev. 2018, 36, 35–50. [Google Scholar] [CrossRef]

- Farhall, K.; Rickards, L. The “Gender Agenda” in Agriculture for Development and Its (Lack of) Alignment with Feminist Scholarship. Front. Sustain. Food Syst. 2021, 5, 573424. [Google Scholar] [CrossRef]

- Haapala, H. The Potential of User-Centered Design (UCD) to Make Radical Agricultural Innovations. In Proceedings of the International Conference of Agricultural Engineering CIGR-AgEng 2012, Valencia, Spain, 8–12 July 2012. [Google Scholar]

- Simon, S. The Role of Design Thinking to Promote a Sustainability Transition within Participatory Urban Governance: Insights from Urban Agriculture Initiatives in Lisbon. Urban Gov. 2023, 3, 189–199. [Google Scholar] [CrossRef]

- Sigauke, E. Connecting Urban Agriculture with Design Thinking: A Case Study from Zimbabwe. J. Environ. Educ. 2020, 52, 53–68. [Google Scholar] [CrossRef]

- Moretti, D.M.; Baum, C.M.; Wustmans, M.; Bröring, S. Application of Journey Maps to the Development of Emergent Sustainability-Oriented Technologies: Lessons for User Involvement in Agriculture. Bus. Strategy Dev. 2022, 5, 209–221. [Google Scholar] [CrossRef]

- Yi, Y.; Irvine, K.; Jamieson, I.; Ratchadawan, N.-K. Design Thinking to Integrate Community Development and Product Innovation: Case Study of a Pandan Farming Collective. Master’s Thesis, Thammasat University, Pathum Thani, Thailand, 2022. [Google Scholar]

- Stratakis, C.; Stivaktakis, N.M.; Bouloukakis, M.; Leonidis, A.; Doxastaki, M.; Kapnas, G.; Evdaimon, T.; Korozi, M.; Kalligiannakis, E.; Stephanidis, C. Integrating Ambient Intelligence Technologies for Empowering Agriculture. Eng. Proc. 2022, 9, 41. [Google Scholar] [CrossRef]

- Urbieta, M.; Firmenich, S.; Zaraté, P.; Fernandez, A. Web-Augmentation, Design Thinking, and Collaboration Engineering to Foster Innovation in DSS for Agriculture: A Case Study. In Agriculture Value Chain-Challenges and Trends in Academia and Industry: RUC-APS Volume 1; Hernández, J.E., Kacprzyk, J., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 1–18. ISBN 978-3-030-51047-3. [Google Scholar]

- Castiblanco Jimenez, I.A.; Mauro, S.; Napoli, D.; Marcolin, F.; Vezzetti, E.; Rojas Torres, M.C.; Specchia, S.; Moos, S. Design Thinking as a Framework for the Design of a Sustainable Waste Sterilization System: The Case of Piedmont Region, Italy. Electronics 2021, 10, 2665. [Google Scholar] [CrossRef]

- Andrews, D. The Circular Economy, Design Thinking and Education for Sustainability. Local Econ. 2015, 30, 305–315. [Google Scholar] [CrossRef]

- Conlon, E. The New Engineer: Between Employability and Social Responsibility. Eur. J. Eng. Educ. 2008, 33, 151–159. [Google Scholar] [CrossRef]

- Bielefeldt, A.R.; Canney, N.E. Changes in the Social Responsibility Attitudes of Engineering Students Over Time. Sci. Eng. Ethics 2016, 22, 1535–1551. [Google Scholar] [CrossRef] [PubMed]

- Ochoa-Guevara, N.E.; Díaz, C.O.; Sguerra, M.D.; Martínez, M.H.; Agudelo, O.A.; Suárez, J.A.R.; Rodriguez, A.P.M.; Acuña, G.A.Á.; Garcia, A.C.L. Towards the Design and Implementation of a Smart City in Bogotá, Colombia. Rev. Fac. Ing. Univ. Antioq. 2019, 93, 41–56. [Google Scholar] [CrossRef]

- Mendoza-Garrido, R.; Cabarcas-Álvarez, A.; Puello-Beltran, J.J.; Fabregat-Gesa, R.; Baldiris-Navarro, S.M. Heritage Education Experience Supported in Augmented Reality. Rev. Fac. Ing. Univ. Antioq. 2021, 99, 52–62. [Google Scholar] [CrossRef]

- Tamwoy, N.; Rosas, S.; Davis, S.; Farthing, A.; Houghton, C.; Johnston, H.; Maloney, C.; Samulkiewicz, N.; Seaton, J.; Tuxworth, G.; et al. Co-Design with Aboriginal and Torres Strait Islander Communities: A Journey. Aust. J. Rural Health 2022, 30, 816–822. [Google Scholar] [CrossRef]

- Parsons, M.; Fisher, K.; Nalau, J. Alternative Approaches to Co-Design: Insights from Indigenous/Academic Research Collaborations. Curr. Opin. Environ. Sustain. 2016, 20, 99–105. [Google Scholar] [CrossRef]

- Castiblanco Jimenez, I.A.; Cepeda García, L.C.; Marcolin, F.; Violante, M.G.; Vezzetti, E. Validation of a TAM Extension in Agriculture: Exploring the Determinants of Acceptance of an e-Learning Platform. Appl. Sci. 2021, 11, 4672. [Google Scholar] [CrossRef]

- Lowder, S.K.; Skoet, J.; Raney, T. The Number, Size, and Distribution of Farms, Smallholder Farms, and Family Farms Worldwide. World Dev. 2016, 87, 16–29. [Google Scholar] [CrossRef]

- Behera, U.K.; France, J. Chapter Four-Integrated Farming Systems and the Livelihood Security of Small and Marginal Farmers in India and Other Developing Countries. In Advances in Agronomy; Sparks, D.L., Ed.; Advances in Agronomy; Academic Press: Cambridge, MA, USA, 2016; Volume 138, pp. 235–282. [Google Scholar]

- Behera, H.C.; Kodirekkala, K.R.; Sinha, A.A. Small and Marginal Farmers’ Participation in Potato Contract Farming in West Bengal, India. J. Asian Afr. Stud. 2022, 57, 604–624. [Google Scholar] [CrossRef]

- Departamento Administrativo Nacional de Estadística (DANE). Boletín Mensual: Insumos y Factores Asociados a la Producción Agropecuaria. El Cultivo de la Arveja en Colombia, No. 33; DANE: Bogotá, Colombia, 2015. Available online: https://www.dane.gov.co/files/investigaciones/agropecuario/sipsa/Bol_Insumos31_mar_2015.pdf (accessed on 5 March 2024).

- Zuluaga-Mogollón, M.; Romero Barrera, Y.; Cadena-Pastrana, A. Tipología de Productores de Arveja (Pisum sativum L.) En Los Municipios Córdoba y Puerres, Nariño (Colombia). Cienc. Agric. 2023, 20, 15543. [Google Scholar] [CrossRef]

- Castiblanco, F.M.; Castiblanco, I.A.; Cruz, J.P. Qualitative Analysis of Lean Tools in the Construction Sector in Colombia. In Proceedings of the 27th Annual Conference of the International Group for Lean Construction (IGLC), Dublin, Ireland, 1–7 July 2019; pp. 1023–1036. [Google Scholar] [CrossRef]

- Dobni, C.B.; Klassen, M. The Decade of Innovation: From Benchmarking to Execution. J. Bus. Strategy 2020, 42, 23–31. [Google Scholar] [CrossRef]

- Bonnardel, N.; Didier, J. Brainstorming Variants to Favor Creative Design. Appl. Ergon. 2020, 83, 102987. [Google Scholar] [CrossRef]

- Ulrich, K.; Eppinger, S. Product Design and Development; McGraw-Hill Education: Boston, MA, USA, 2004; ISBN 978-0-07-247146-5. [Google Scholar]

- Datta, J.; Błażek, K.; Włoch, M.; Bukowski, R. A New Approach to Chemical Recycling of Polyamide 6.6 and Synthesis of Polyurethanes with Recovered Intermediates. J. Polym. Environ. 2018, 26, 4415–4429. [Google Scholar] [CrossRef]

- Pierotti, R.S.; Friedson-Ridenour, S.; Olayiwola, O. Women Farm What They Can Manage: How Time Constraints Affect the Quantity and Quality of Labor for Married Women’s Agricultural Production in Southwestern Nigeria. World Dev. 2022, 152, 105800. [Google Scholar] [CrossRef]

| Objective | Tools | |

|---|---|---|

| Empathize | Define the context and users and discover their perceptions and needs. |

|

| Define | Summarize the problem based on the gathered insights and express the users’ requirements as technical specifications. |

|

| Ideate | Generate shared ideas to solve the problem. |

|

| Prototype | Concretize the idea. |

|

| Test | Evaluate the prototype and provide feedback. |

|

| System | |||

|---|---|---|---|

| Specifications | [A] CZ24353U1 [4] | [B] US6960131B2 [5] | [C] US1831772A [6] |

|

Target market

(household/industrial) | Household | Industrial | Household |

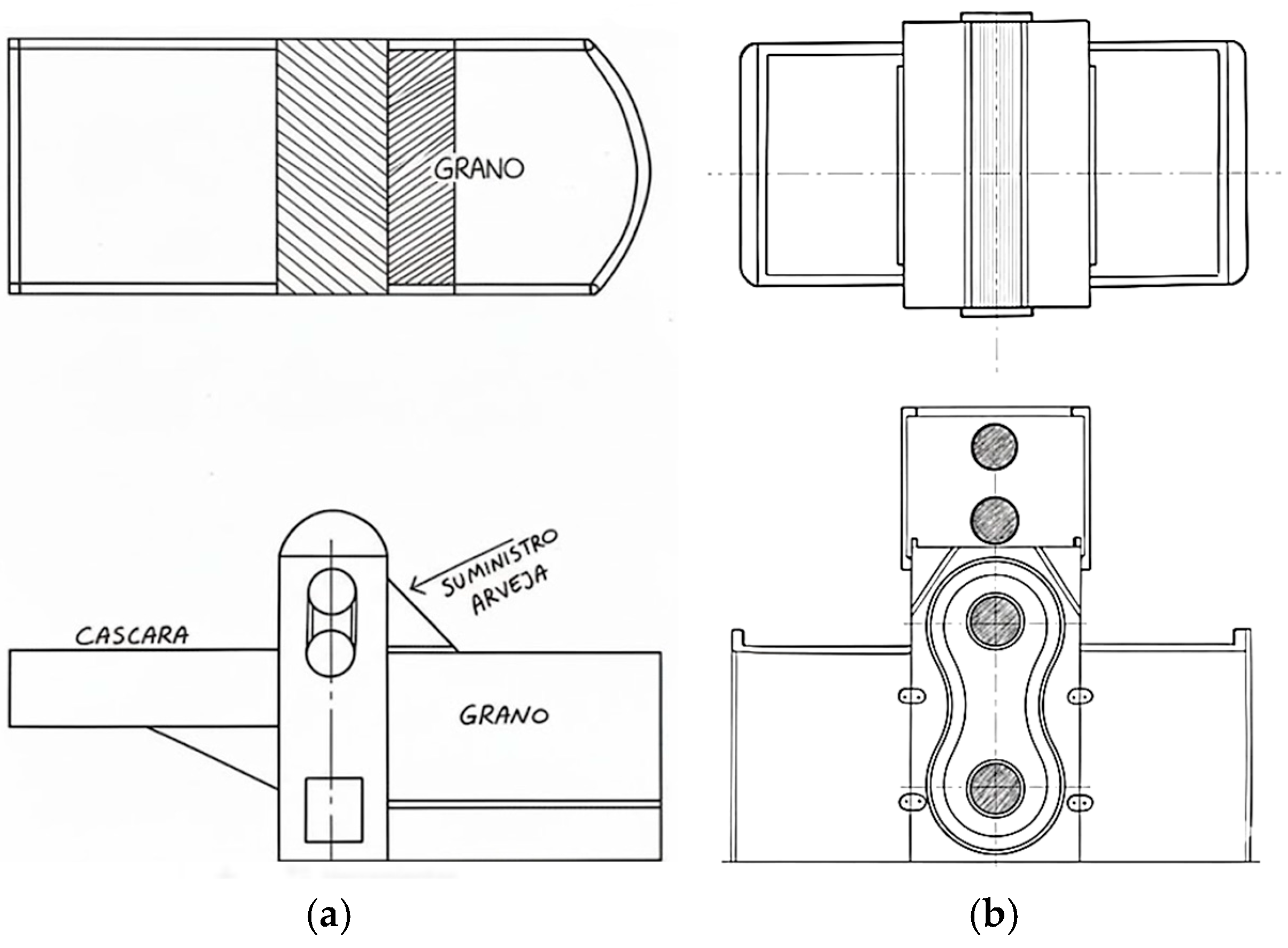

| Shelling mechanism | Pressure rollers | Cylindrical rotating drum/satellite beaters | Moving blades |

| Feeding and process orientation | Horizontal | Horizontal | Circular motion |

| Final product storage | Container | Container | N/A |

| Shell deposition | N/A | N/A | N/A |

| Feeding system | Manual | Vibrating belt | Manual |

| Activation type | Handle | Handle | Pedals |

| Requirement | Description | Specification |

|---|---|---|

| Size | The product should not occupy significant space within the area available to the user. | The sheller should be of average size for home use and small farmers. |

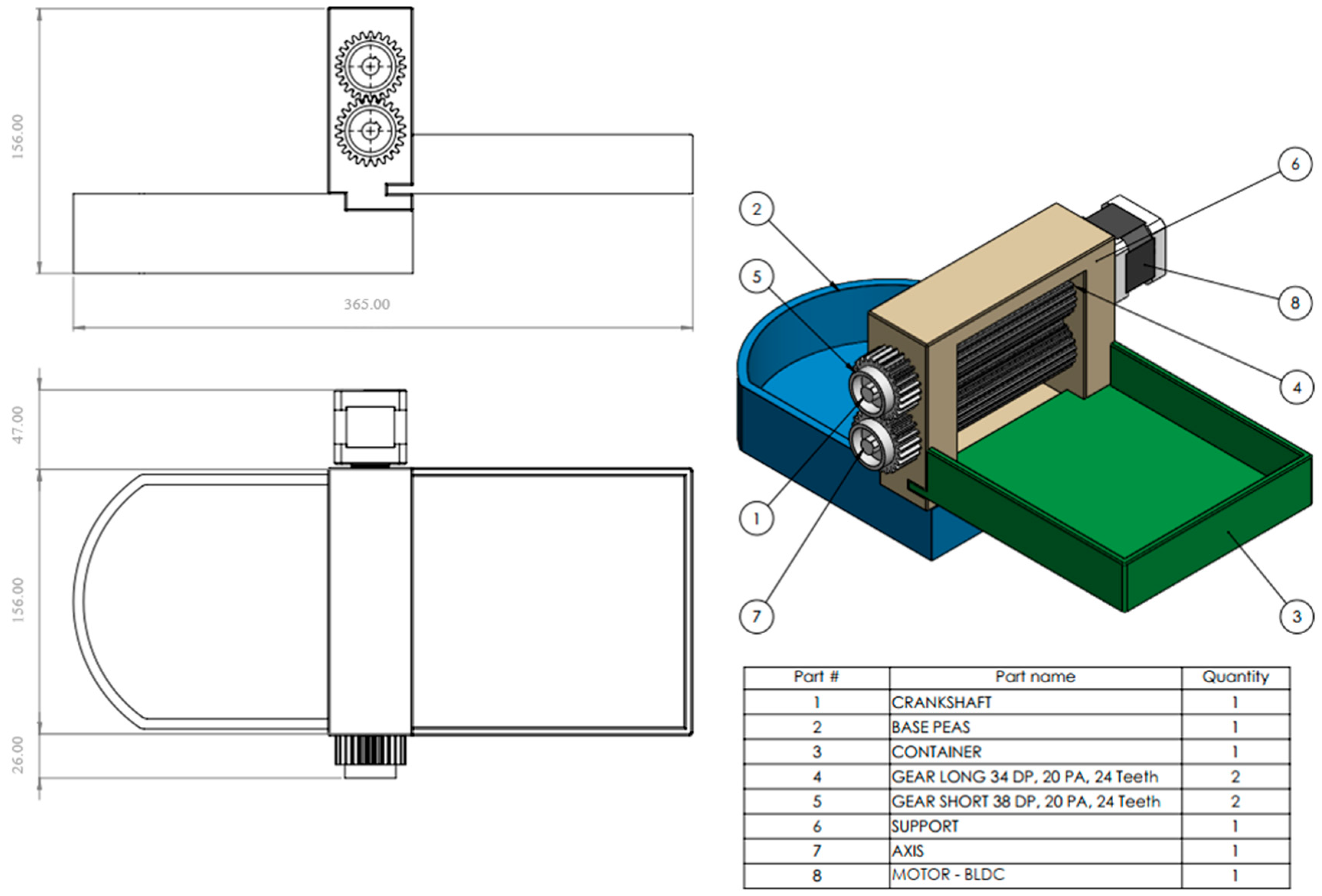

| Mechanism and Activation | The mechanism must ensure that the shelling process does not compromise the integrity or quality of the final product. It must be automatic. | The roller mechanism will operate at 40 rpm, enabling the proper extraction of the pod without causing any damage due to pressure. Furthermore, this mechanism will be powered by an electric motor to facilitate the task. |

| Final product storage | The storage compartment for storing grains outside the pod must meet strict hygienic standards, employing a food-grade material that is both safe for human consumption and easy to handle. | The disintegrator material will be Nylon 6.6, which is suitable for food handling and will not compromise the quality of the final product. |

| Shell disposal | To ensure proper waste management, the sheller should be equipped with a distinct compartment designated for the storage of residual materials. | The sheller will have two compartments arranged in opposite directions to collect the empty husk and the grains. |

| Power Supply | Motion Type | Mechanism | Peas Storage | Shells Storage | Material | |

|---|---|---|---|---|---|---|

| Preliminary concept C1: Electrical sheller | Power outlet | Electric engine | Horizontal roller motion | Compartment | Compartment | High-density polyethylene (HDPE) |

| Preliminary concept C2: Battery operated | Battery | Battery-powered engine | Vertical roller motion | Compartment | Vertical Tray | Aluminum |

| C1: Electrical Sheller | C2: Battery Operated | ||||

|---|---|---|---|---|---|

| Selection Criteria | Weight | Rating | Weighted Score | Rating | Weighted Score |

| Size and weight | 20% | 4 | 0.8 | 2 | 0.4 |

| Mechanism | 10% | 4 | 0.4 | 3 | 0.3 |

| Peas storage | 20% | 5 | 1 | 5 | 1 |

| Shell storage | 10% | 4 | 0.4 | 2 | 0.2 |

| Material | 10% | 3 | 0.3 | 4 | 0.4 |

| Budget | 30% | 4 | 1.2 | 2 | 0.6 |

| Total Score | 4.1 | 2.9 | |||

| Rank | 1 | 2 | |||

| Continue? | Develop | No | |||

| Roller Speed (RPM) | Extraction Efficiency (%) | Grain Damage (%) | Grain Integrity (%) | Processing Time (s/pod) |

|---|---|---|---|---|

| 20 | 72 | 3 | 97 | 5–6 |

| 30 | 85 | 4 | 96 | 4–5 |

| 40 * | 94 | 5 | 95 | 3–4 |

| 50 | 96 | 12 | 88 | 2–3 |

| 60 | 97 | 22 | 78 | 2–3 |

| Performance Indicator | Mean Value | Standard Deviation | Range |

|---|---|---|---|

| Shell removal rate (%) | 93.5 | ±3.5 | 86–98 |

| Grain damage rate (%) | 5.6 | ±1.8 | 3–9 |

| Intact grain rate (%) | 94.4 | ±1.8 | 90–97 |

| Processing time for 2 kg pods (min) | 53 | ±8 | 45–65 |

| Grain yield (kg grains/kg pods) | 0.71 | ±0.07 | 0.62–0.82 |

| Processing capacity (kg pods/hour) | 0.86 | ±0.16 | 0.65–1.12 |

| Physical effort (scale 1–5) | 1.6 | ±0.6 | 1–3 |

| Time reduction vs. manual (%) | 75 | ±7 | 63–82 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castiblanco Jimenez, I.A.; Cruz Gonzalez, J.P. Design Thinking for the Development of an Affordable Pea Sheller: Addressing Co-Design in Rural Areas. AgriEngineering 2025, 7, 360. https://doi.org/10.3390/agriengineering7110360

Castiblanco Jimenez IA, Cruz Gonzalez JP. Design Thinking for the Development of an Affordable Pea Sheller: Addressing Co-Design in Rural Areas. AgriEngineering. 2025; 7(11):360. https://doi.org/10.3390/agriengineering7110360

Chicago/Turabian StyleCastiblanco Jimenez, Ivonne Angelica, and Joan Paola Cruz Gonzalez. 2025. "Design Thinking for the Development of an Affordable Pea Sheller: Addressing Co-Design in Rural Areas" AgriEngineering 7, no. 11: 360. https://doi.org/10.3390/agriengineering7110360

APA StyleCastiblanco Jimenez, I. A., & Cruz Gonzalez, J. P. (2025). Design Thinking for the Development of an Affordable Pea Sheller: Addressing Co-Design in Rural Areas. AgriEngineering, 7(11), 360. https://doi.org/10.3390/agriengineering7110360