Mats Made from Recycled Tyre Rubber and Polyurethane for Improving Growth Performance in Buffalo Farms

Abstract

1. Introduction

2. Materials and Methods

2.1. Defining Benchmarks and Features for Prototype Construction

2.1.1. Prototypes Layout Features

- The shape of the mat, which can be either square or rectangular;

- The type of surface, which can be flat or raised, providing more or less friction for the hooves, and more or less stability in terms of the risk of slipping;

- The type of base, i.e., the design of the lower surface of the mat, which determines the way in which it is anchored to the underlying surface (smooth, studded, grooved);

- The shape of the edges, which can be smooth and regular, or interlocking (jigsaw);

- The colour of the mat, which can be similar to the natural colour of tyres or coloured with additives to simulate a more natural environment (e.g., dark green).

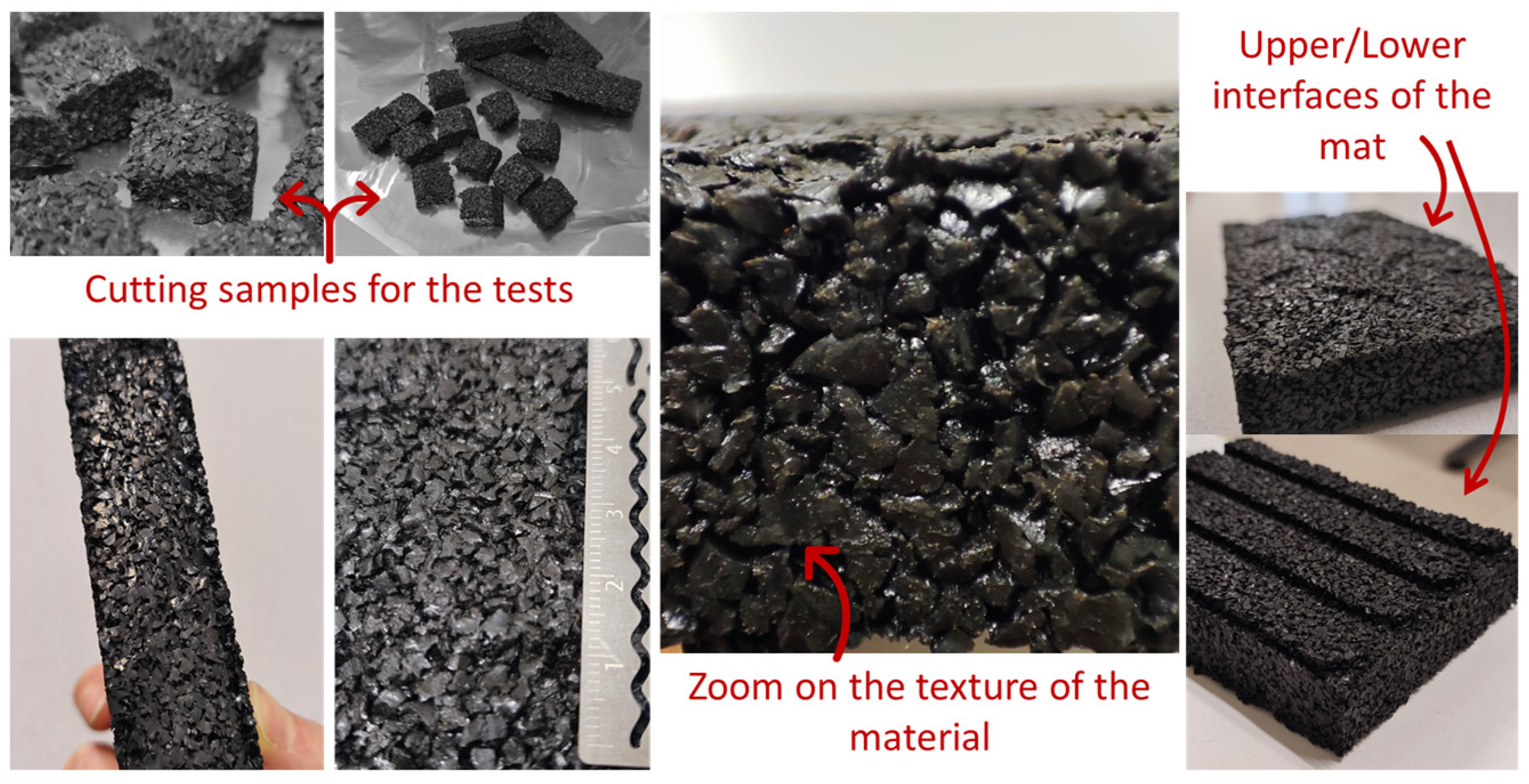

2.1.2. Prototypes Texture Features

- The final polymeric density of the mat, which depends on the properties of the materials used for its preparation and its dimension;

- The thickness of the mat, which together with the density represents another crucial structural parameter that can result in greater or less comfort for the animals;

- Type and quantity of binder, i.e., the resinous adhesive substance added to the rubber powder to make the material compact and compressible.

- Use of rubber fragments from ELTs with a grain size in the range of 0.8 to 3 mm.In this study, we selected for all of the prototypes the finest rubber fraction, i.e., rubber powder with a particle size ≤ 3 mm. The raw material was supplied directly by the company TCycle industries srl, in which, after thorough washing of the ELTs, dedicated industrial equipment performs a dismantling protocol characterised by the following steps: coarse shredding, 2 stages of granulation at increasingly finer cuts, purification of the granules from textile fibres and metal parts, and finally sieving into the various fractions with different grain size. The ELTs granules used in this study for the production of the mats were characterised by a density of 0.487 kg/dm3, which is in line with similar studies on this category of ELT waste [82]. Rubber granule density is typically determined by the manufacturer using simple gravimetric measurement. The protocol involves measuring the mass of granules filling vessels of known volume and calculating the ratio between the weighed mass and the filled volume. The outcome of this operation is significant because, as explained below, it comes into play when the moulding machinery must be programmed to extract the correct amount of product to produce the final mat, given a defined final bulk density.

- Before feeding the granules into the mould, they must be thoroughly mixed with the chemical substances required to aggregate/enrich the final product, such as binders, colouring agents, reaction catalysts, etc. For this type of product, the use of an isocyanate-based adhesive was suggested, in varying percentages in the range 5–8% by weight of the total mat mass. Generally, the higher the percentage of binder, the greater the hardness of the mat.Here, the choice of binder category fell precisely on polyurethane resins with a low isocyanate content. For all of the prototypes we used the chemical binder V-PUR 126 (Vervit® srl, Trento, Italy). This is a one-component polyurethane that reacts with humidity and has very good elasticity. It is normally used to agglomerate SBR (styrene-butadiene rubber) or EPDM (ethylene-propylene-diene monomer) rubber granules in hot presses or at room temperature. This category of adhesives is particularly suitable for this purpose because it also performs better in terms of surface chemical interactions with ELT rubber granules [83], as well as being commercially available and economically competitive. Specific chemical composition properties of V-PUR 126 are given in Table 1.

- Overall density of the mat (bulk) should stay in the range of 0.8 to 0.9 kg/dm3. It plays a very important role because it affects the hardness and deformability of the mat.

- In this study, knowing the specific density of the rubber granules, the density of the binder, and the shape and size each mat should have had (thus the volume occupied), it was sufficient to enter the value of the desired final bulk density for each prototype on the moulding machinery so that it would automatically pick up the amount of raw materials to be combined for the production of the mat. Thickness of the mat in the range 20–30 mm, corresponding to an approximate total volume in the range 0.020–0.030 m3 (length and width of the mat being fixed at 1 m × 1 m—see Section 2.1.1).

- Addition of a small fraction of water (2% by weight) in the rubber/polyurethane mixture to speed up the catalysing reaction.

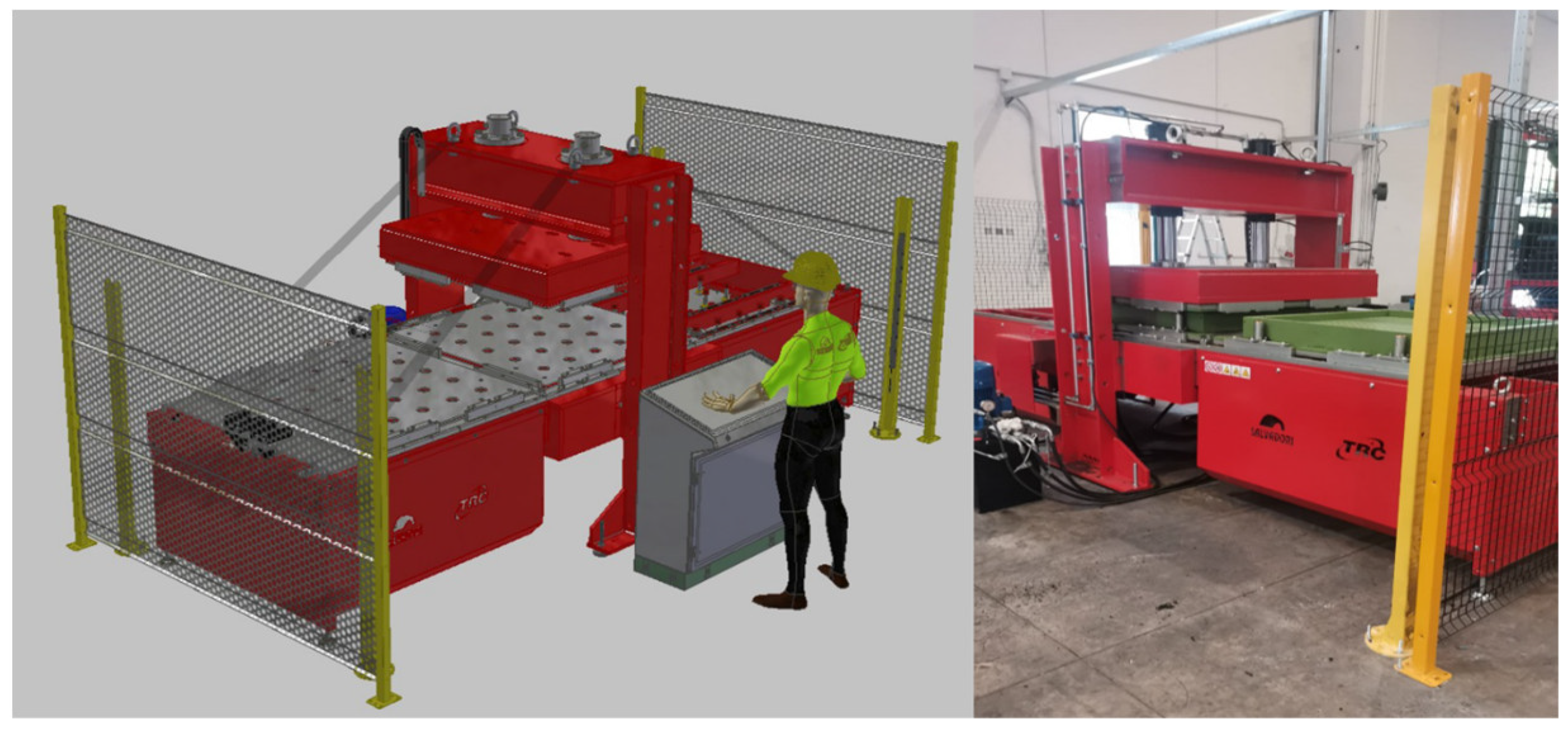

2.2. Moulding Machinery

2.3. Experimental Setup #1: Hardness and Chemical Resistance Tests

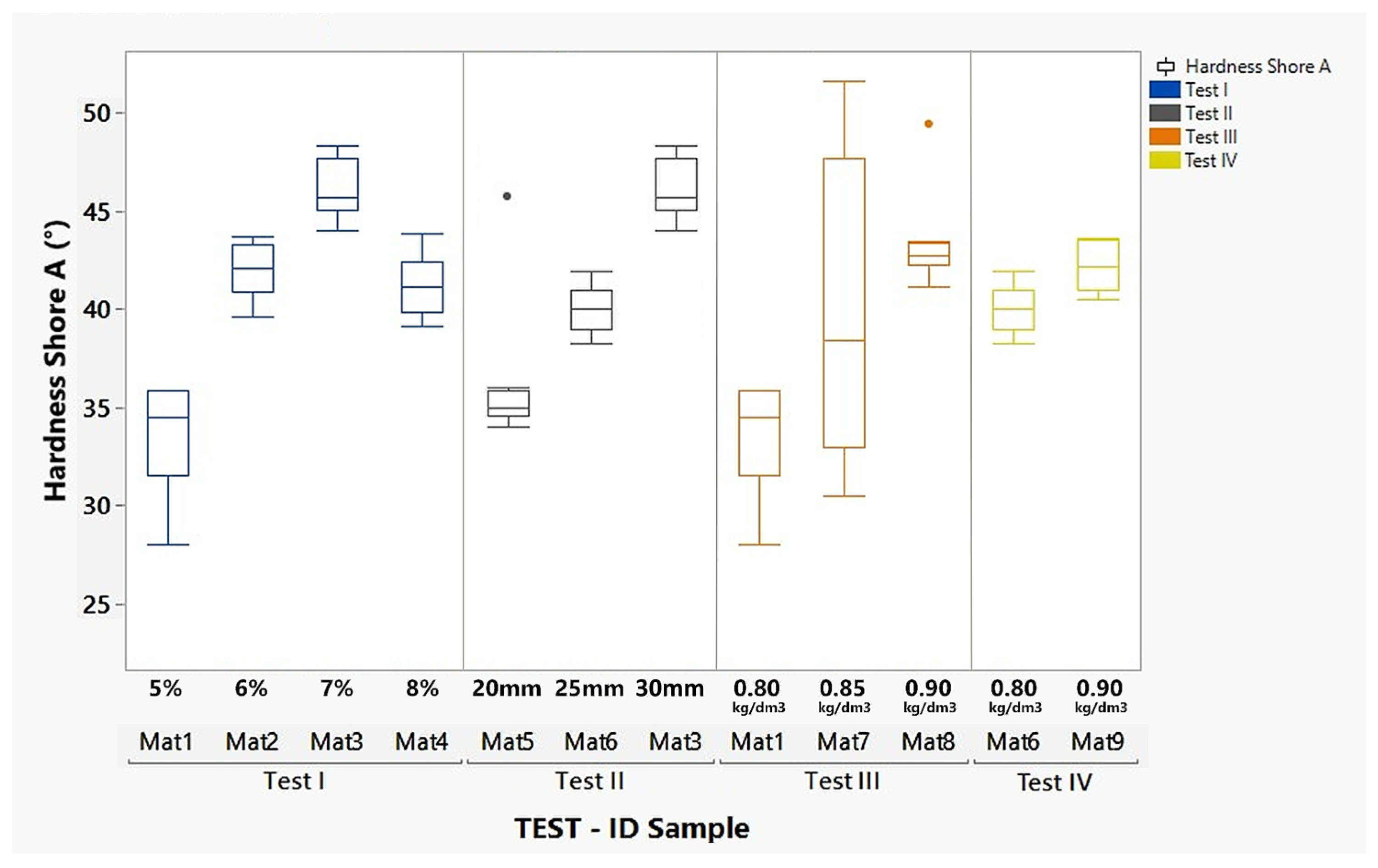

2.3.1. Hardness Shore A Tests

- Binder percentage equal to 5%–6%–7%–8%;

- Final mat density equal to 0.80 kg/dm3–0.85 kg/dm3–0.90 kg/dm3;

- Thickness equal to 20 mm–25 mm–30 mm.

2.3.2. Statistical Analysis

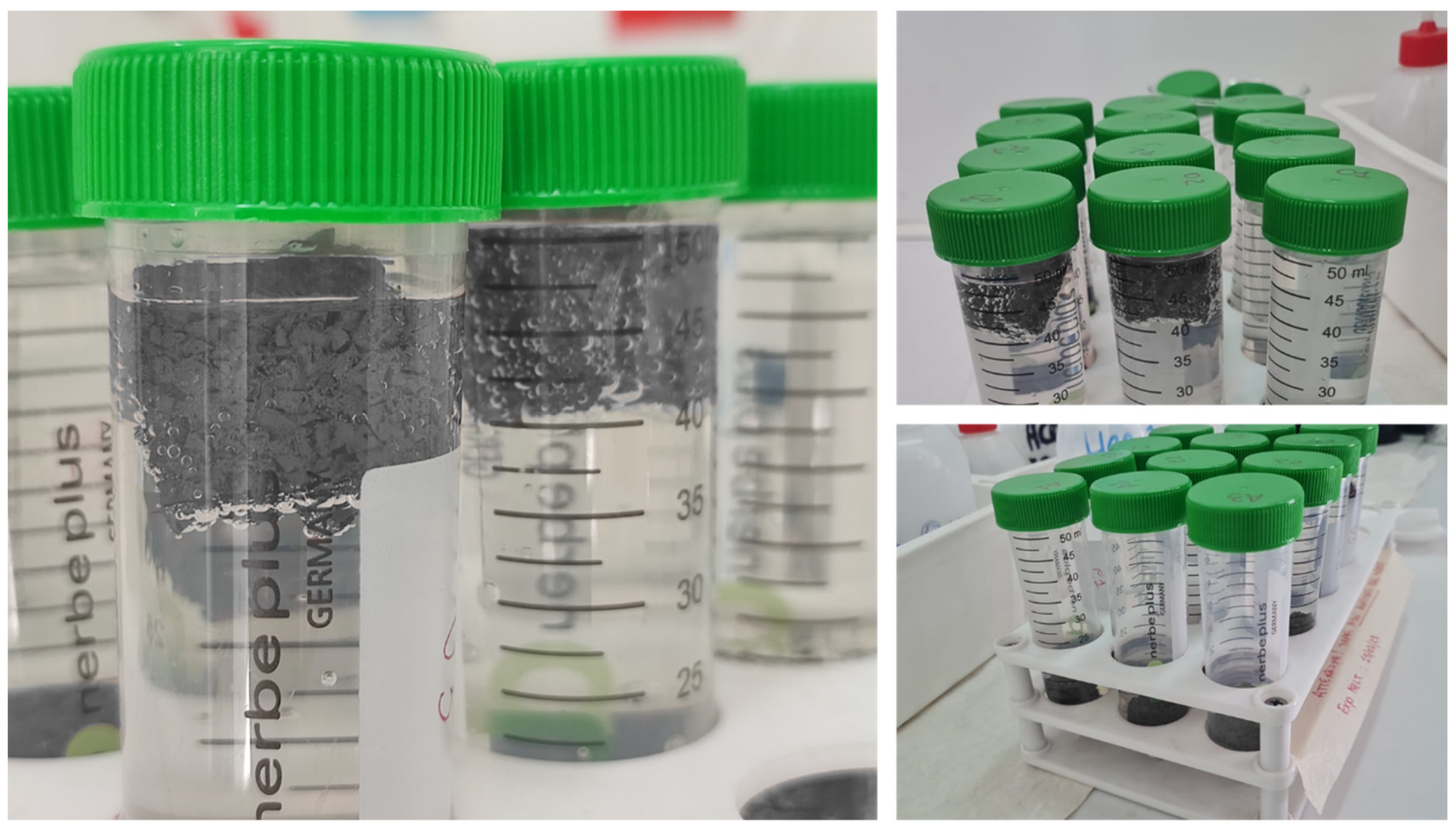

2.3.3. Chemical Resistance

- Ammonia NH3 [32% concentration];

- Hydrochloric acid HCl [concentration 3%];

- Formic acid HCOOH [concentration 2%];

- Hydrogen peroxide H2O2 [concentration 30%].

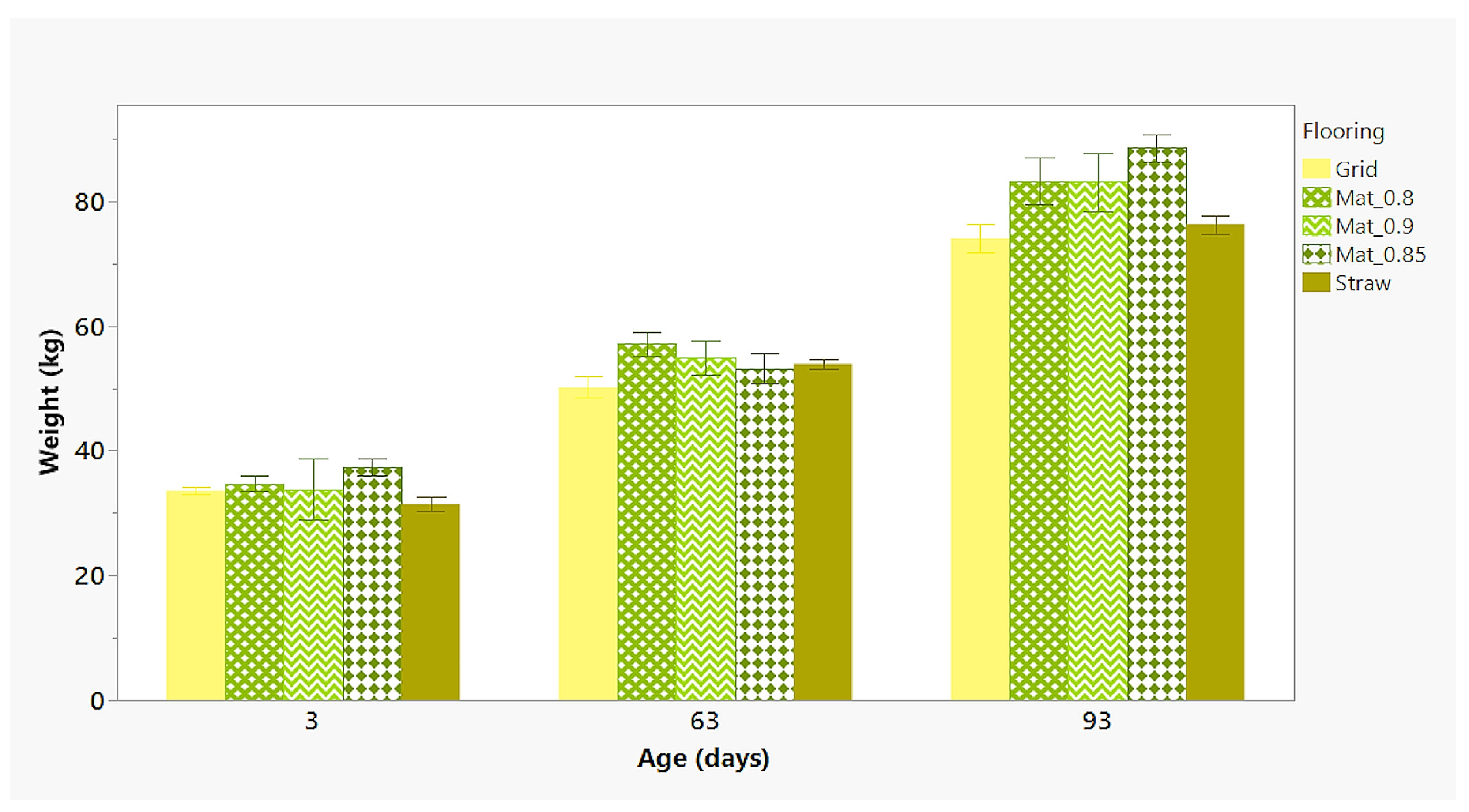

2.4. Experimental Setup #2: Assessment of the Growth Performance

2.4.1. Floorings

- Code Mat_0.8: density 0.80 kg/dm3;

- Code Mat_0.85: density 0.85 kg/dm3;

- Code Mat_0.9: density 0.90 kg/dm3.

2.4.2. Body Weight Monitoring

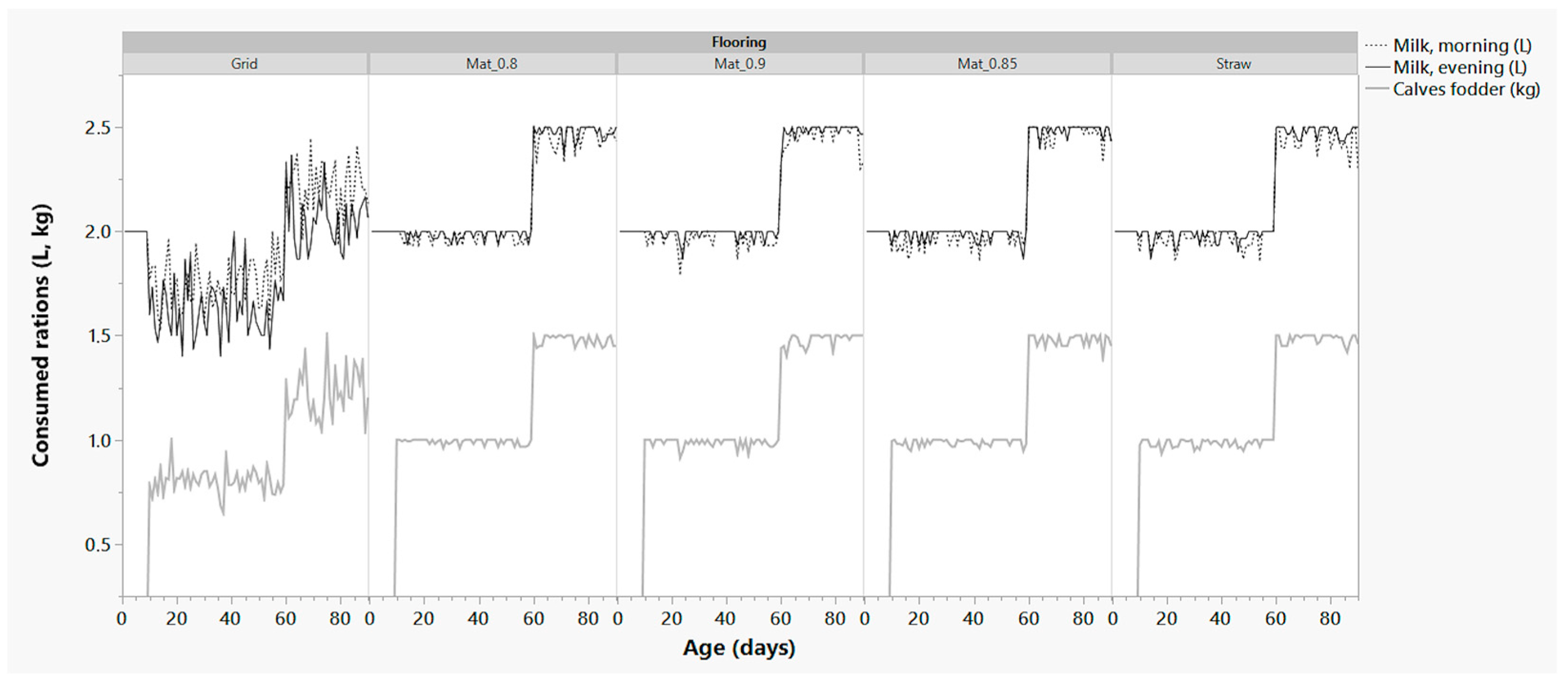

2.4.3. Appetite Level Monitoring

- Milk (liquid ration), prepared from high-quality powdered milk specific for the feeding of calves (product name: Zoo Latte Benefit, manufactured by COMAZOO soc. coop. a r.l., Brescia, Italy), fed through graduated buckets (0.1 L sensitivity) equipped with rubber teats and intended specifically for use with calves during the first months of life. For detailed information on the milk and its preparation, please refer to the Supplementary Materials (“Report Comazoo”, pages 24–25).

- Fodder (solid ration) for the weaning phases of young calves (product name: Svezza Plus I Periodo-M10, manufactured by Mangimificio Iabichella S.p.A., Ragusa, Italy), delivered by means of non-fixed feeders, in order to be able to easily weigh the incoming ration and any residues at the end of the meal. A professional scale with 10 g sensitivity (Model ICP-WP, ISHIDA Co. Ltd., Kyoto, Japan) was used to measure the feed. For detailed information on the feed and nutritional values, please refer to the Supplementary Materials (“Report Iabichella”).

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eftestøl, E.J.; Yliheljo, E. Paving the way for a European Emissions Trading System for shipping: EU and IMO on different paths. In Disruptive Technologies, Climate Change and Shipping; Informa Law; Routledge: London, UK, 2022; pp. 176–193. [Google Scholar]

- Cifuentes-Faura, J. European Union policies and their role in combating climate change over the years. Air Qual. Atmos. Health 2022, 15, 1333–1340. [Google Scholar] [CrossRef]

- Dechezleprêtre, A.; Fabre, A.; Kruse, T.; Planterose, B.; Chico, A.S.; Stantcheva, S. Fighting Climate Change: International Attitudes toward Climate Policies; National Bureau of Economic Research: Cambridge, MA, USA, 2022. [Google Scholar]

- Bermeo-Ayerbe, M.A.; Ocampo-Martinez, C.; Diaz-Rozo, J. Data-driven energy prediction modeling for both energy efficiency and maintenance in smart manufacturing systems. Energy 2022, 238, 121691. [Google Scholar] [CrossRef]

- Vetromile, C.; Spagnuolo, A.; Petraglia, A.; Masiello, A.; di Cicco, M.R.; Lubritto, C. Pre- and post-operam comparison of the energy consumption of a radio base station under energy efficiency actions. Energy Build. 2021, 236, 110772. [Google Scholar] [CrossRef]

- Spagnuolo, A.; De Santo, G.; Vetromile, C.; Masiello, A.; Di Costanzo, P.; Esposito, S.; Buono, U.; di Cicco, M.R.; Lubritto, C. Characterizing passenger-ship emissions: Towards improved sustainability for MedMar fleet (gulf of Naples). Energy Effic. 2022, 15, 55. [Google Scholar] [CrossRef]

- di Cicco, M.R.; Spagnuolo, A.; Masiello, A.; Vetromile, C.; Nappa, M.; Lubritto, C. Energetic and environmental analysis of a wastewater treatment plant through static and dynamic monitoring activities. Int. J. Environ. Sci. Technol. 2020, 17, 4299–4312. [Google Scholar] [CrossRef]

- Bautista, E.; Romanus, M.; Davis, T.; Whitney, C.; Kubaska, T. Collecting, Monitoring, and Analyzing Facility and Systems Data at the National Energy Research Scientific Computing Center. In Proceedings of the 48th International Conference on Parallel Processing: Workshops, Kyoto, Japan, 5–8 August 2019; p. 10. [Google Scholar]

- Miranda, J.; Ponce, P.; Molina, A.; Wright, P. Sensing, smart and sustainable technologies for Agri-Food 4.0. Comput. Ind. 2019, 108, 21–36. [Google Scholar] [CrossRef]

- Nižetić, S.; Djilali, N.; Papadopoulos, A.; Rodrigues, J.J.P.C. Smart technologies for promotion of energy efficiency, utilization of sustainable resources and waste management. J. Clean. Prod. 2019, 231, 565–591. [Google Scholar] [CrossRef]

- Spagnuolo, A.; Vetromile, C.; Masiello, A.; De Santo, G.; Suriano, M.; Mercuri, G.; Pellegrino, M.; Piccolo, G.; Lubritto, C.; Di Cicco, M.R. Industrial Drying of Fruit and Vegetable Products: Customized Smart Monitoring and Analytical Characterization of Process Variables in the OTTORTO Project. Processes 2023, 11, 1635. [Google Scholar] [CrossRef]

- Goswami, R.K.; Mehariya, S.; Verma, P.; Lavecchia, R.; Zuorro, A. Microalgae-based biorefineries for sustainable resource recovery from wastewater. J. Water Process Eng. 2020, 40, 101747. [Google Scholar] [CrossRef]

- Hena, S.; Znad, H.; Heong, K.; Judd, S. Dairy farm wastewater treatment and lipid accumulation by Arthrospira platensis. Water Res. 2018, 128, 267–277. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Mohan, S.V. Fungal biorefinery for sustainable resource recovery from waste. Bioresour. Technol. 2022, 345, 126443. [Google Scholar] [CrossRef]

- Bhatia, S.K.; Ahuja, V.; Chandel, N.; Mehariya, S.; Kumar, P.; Vanayak, V.; Saratale, G.D.; Raj, T.; Kim, S.-H.; Yang, Y.-H. An overview on microalgal-bacterial granular consortia for resource recovery and wastewater treatment. Bioresour. Technol. 2022, 351, 127028. [Google Scholar]

- Sirohi, R.; Joun, J.; Lee, J.Y.; Yu, B.S.; Sim, S.J. Waste mitigation and resource recovery from food industry wastewater employing microalgae-bacterial consortium. Bioresour. Technol. 2022, 352, 127129. [Google Scholar] [CrossRef]

- Pollmann, K.; Kutschke, S.; Matys, S.; Raff, J.; Hlawacek, G.; Lederer, F.L. Bio-recycling of metals: Recycling of technical products using biological applications. Biotechnol. Adv. 2018, 36, 1048–1062. [Google Scholar] [CrossRef] [PubMed]

- Iovinella, M.; Palmieri, M.; Papa, S.; Auciello, C.; Ventura, R.; Lombardo, F.; Race, M.; Lubritto, C.; di Cicco, M.R.; Davis, S.J.; et al. Biosorption of rare earth elements from luminophores by G. sulphuraria (Cyanidiophytina, Rhodophyta). Environ. Res. 2023, 239, 117281. [Google Scholar] [CrossRef]

- Palmieri, M.; Iovinella, M.; Davis, S.J.; di Cicco, M.R.; Lubritto, C.; Race, M.; Papa, S.; Fabbricino, M.; Ciniglia, C. Galdieria sulphuraria ACUF427 Freeze-Dried Biomass as Novel Biosorbent for Rare Earth Elements. Microorganisms 2022, 10, 2138. [Google Scholar] [CrossRef]

- Udugama, I.A.; Petersen, L.A.H.; Falco, F.C.; Junicke, H.; Mitic, A.; Alsina, X.F.; Mansouri, S.S.; Gernaey, K.V. Resource recovery from waste streams in a water-energy-food nexus perspective: Toward more sustainable food processing. Food Bioprod. Process. 2020, 119, 133–147. [Google Scholar] [CrossRef]

- Pires, A.; Martinho, G. Waste hierarchy index for circular economy in waste management. Waste Manag. 2019, 95, 298–305. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Ansanelli, G.; Fiorentino, G.; Tammaro, M.; Zucaro, A. A Life Cycle Assessment of a recovery process from End-of-Life Photovoltaic Panels. Appl. Energy 2021, 290, 116727. [Google Scholar] [CrossRef]

- Smol, M.; Adam, C.; Preisner, M. Circular economy model framework in the European water and wastewater sector. J. Mater. Cycles Waste Manag. 2020, 22, 682–697. [Google Scholar] [CrossRef]

- Valentini, F.; Pegoretti, A. End-of-life options of tyres. A review. Adv. Ind. Eng. Polym. Res. 2022, 5, 203–213. [Google Scholar] [CrossRef]

- Perišić, P.; Bogdanović, V.; Mekić, C.; Ružić-Muslić, D.; Stanojević, D.; Popovac, M.; Stepić, S. The importance of buffalo in milk production and buffalo population in Serbia. Biotechnol. Anim. Husb. 2015, 31, 255–263. [Google Scholar] [CrossRef]

- Garau, V.; Manis, C.; Scano, P.; Caboni, P. Compositional Characteristics of Mediterranean Buffalo Milk and Whey. Dairy 2021, 2, 469–488. [Google Scholar] [CrossRef]

- Trabalzi, F. Regional Networks in Southern Italy: Innovation and Adaptation in the Buffalo Mozzarella Industry; University of California: Los Angeles, CA, USA, 2002. [Google Scholar]

- Cseke, L. Biosecurity and more-than-human political economy: Veterinary interventions as productive economic forces in the ‘mozzarella landscape’in Italy. Trans. Inst. Br. Geogr. 2023, 48, 276–289. [Google Scholar] [CrossRef]

- Altieri, S.; Saiano, K.; Biondi, M.; Ricci, P.; Lubritto, C. Traceability of ‘Mozzarella di Bufala Campana’production chain by means of carbon, nitrogen and oxygen stable isotope ratios. J. Sci. Food Agric. 2020, 100, 995–1003. [Google Scholar] [CrossRef] [PubMed]

- Cappelli, G.; Di Vuolo, G.; Gerini, O.; Noschese, R.; Bufano, F.; Capacchione, R.; Rosini, S.; Limone, A.; De Carlo, E. Italian Tracing System for Water Buffalo Milk and Processed Milk Products. Animals 2021, 11, 1737. [Google Scholar] [CrossRef]

- Borghese, A.; Chiariotti, A.; Barile, V.L. Buffalo in the World: Situation and Perspectives. In Biotechnological Applications in Buffalo Research; Chauhan, M.S., Selokar, N., Eds.; Springer: Singapore, 2022; pp. 3–31. [Google Scholar]

- Hegde, N.G. Buffalo husbandry for sustainable development of small farmers in india and other developing countries. Asian J. Res. Anim. Vet. Sci. 2019, 3, 1–20. [Google Scholar]

- Jogal, K.; Trivedi, S.; Lakhlani, C. Adoption of improved animal husbandry practices by dairy farmers. Indian J. Anim. Sci. 2021, 91, 1115–1117. [Google Scholar] [CrossRef]

- Panchbhai, D.; Gubbawar, S. Housing and breeding practices followed by buffalo owners in Katol Tahsil of Nagpur district. Pharma Innov. J. 2021, 10, 451–453. [Google Scholar]

- El Sabry, M.I.; Almasri, O. Space allowance: A tool for improving behavior, milk and meat production, and reproduction performance of buffalo in different housing systems—A review. Trop. Anim. Health Prod. 2022, 54, 266. [Google Scholar] [CrossRef]

- De Rosa, G.; Grasso, F.; Braghieri, A.; Bilancione, A.; Di Francia, A.; Napolitano, F. Behavior and milk production of buffalo cows as affected by housing system. J. Dairy Sci. 2009, 92, 907–912. [Google Scholar] [CrossRef]

- Tripaldi, C.; De Rosa, G.; Grasso, F.; Terzano, G.; Napolitano, F. Housing system and welfare of buffalo (Bubalus bubalis) cows. Anim. Sci. 2004, 78, 477–483. [Google Scholar] [CrossRef]

- Benedičič, J.; Erjavec, K.; Klopčič, M. Environmental sustainability: Farmers’ views of housing systems for cattle. Ital. J. Anim. Sci. 2022, 21, 18–30. [Google Scholar] [CrossRef]

- Elmore, M.; Elischer, M.; Claeys, M.; Pajor, E. The effects of different flooring types on the behavior, health, and welfare of finishing beef steers. J. Anim. Sci. 2015, 93, 1258–1266. [Google Scholar] [CrossRef]

- Tuyttens, F.A.M. The importance of straw for pig and cattle welfare: A review. Appl. Anim. Behav. Sci. 2005, 92, 261–282. [Google Scholar] [CrossRef]

- Park, R.M.; Foster, M.; Daigle, C.L. A Scoping Review: The Impact of Housing Systems and Environmental Features on Beef Cattle Welfare. Animals 2020, 10, 565. [Google Scholar] [CrossRef] [PubMed]

- Bergsten, C.; Telezhenko, E.; Ventorp, M. Influence of soft or hard floors before and after first calving on dairy heifer locomotion, claw and leg health. Animals 2015, 5, 662–686. [Google Scholar] [CrossRef] [PubMed]

- Weerasinghe, W.; Rajapaksha, E.; Gunawardena, W.; Ammunekumbura, I.; Samarakone, T. Effect of rubber and concrete flooring on resting behavior, hock injuries, and milk production of primiparous Friesian crossbred dairy cows housed in a free-stall barn in Mid-Country, Sri Lanka. Trop. Anim. Health Prod. 2021, 53, 447. [Google Scholar] [CrossRef]

- Herzog, A.; Hörtenhuber, S.; Winckler, C.; Kral, I.; Zollitsch, W. Welfare intervention and environmental impacts of milk production–cradle-to-farm-gate effects of implementing rubber mats in Austrian dairy farms. J. Clean. Prod. 2020, 277, 123953. [Google Scholar] [CrossRef]

- Sadharakiya, K.; Sorathiya, L.; Raval, A.; Sabapara, G.; Patel, P. Effects of rubber mat flooring on hygiene, locomotion, hock and knee injury in crossbred cows. Int. J. Livest. Res. 2019, 9, 1. [Google Scholar] [CrossRef]

- Eicher, S.; Lay, D., Jr.; Arthington, J.; Schutz, M. Effects of rubber flooring during the first 2 lactations on production, locomotion, hoof health, immune functions, and stress. J. Dairy Sci. 2013, 96, 3639–3651. [Google Scholar] [CrossRef] [PubMed]

- Sabia, E.; Napolitano, F.; Claps, S.; De Rosa, G.; Braghieri, A.; Pacelli, C. Dairy buffalo life cycle assessment as affected by heifer rearing system. J. Clean. Prod. 2018, 192, 647–655. [Google Scholar] [CrossRef]

- Kumar, A.; Kamboj, M.; Chandra, S.; Bharti, P. Effect of modified housing system on physiological parameters of Murrah buffaloes during autumn and winter season. Indian J. Anim. Res. 2018, 52, 829–833. [Google Scholar] [CrossRef]

- Bulei, C.; Todor, M.; Heput, T.; Kiss, I. Directions for material recovery of used tires and their use in the production of new products intended for the industry of civil construction and pavements. IOP Conf. Ser. Mater. Sci. Eng. 2018, 294, 012064. [Google Scholar] [CrossRef]

- Re Depaolini, A.; Bianchi, G.; Fornai, D.; Cardelli, A.; Badalassi, M.; Cardelli, C.; Davoli, E. Physical and chemical characterization of representative samples of recycled rubber from end-of-life tires. Chemosphere 2017, 184, 1320–1326. [Google Scholar] [CrossRef] [PubMed]

- Valentín, J.L.; Pérez-Aparicio, R.; Fernandez-Torres, A.; Posadas, P.; Herrero, R.; Salamanca, F.M.; Navarro, R.; Saiz-Rodríguez, L. Advanced characterization of recycled rubber from end-of-life tires. Rubber Chem. Technol. 2020, 93, 683–703. [Google Scholar] [CrossRef]

- Hoyer, S.; Kroll, L. Material Recycling of End-of-Life Tires: The Influence of Recyclates on the Processing of Rubber Compounds. In Manufacturing Driving Circular Economy; Springer: Cham, Switzerland, 2023; pp. 273–281. [Google Scholar]

- Tran, T.Q.; Skariah Thomas, B.; Zhang, W.; Ji, B.; Li, S.; Brand, A.S. A comprehensive review on treatment methods for end-of-life tire rubber used for rubberized cementitious materials. Constr. Build. Mater. 2022, 359, 129365. [Google Scholar] [CrossRef]

- Milad, A.; Ahmeda, A.G.F.; Taib, A.M.; Rahmad, S.; Solla, M.; Yusoff, N.I.M. A review of the feasibility of using crumb rubber derived from end-of-life tire as asphalt binder modifier. J. Rubber Res. 2020, 23, 203–216. [Google Scholar] [CrossRef]

- Grammelis, P.; Margaritis, N.; Dallas, P.; Rakopoulos, D.; Mavrias, G. A review on management of end of life tires (ELTs) and alternative uses of textile Fibers. Energies 2021, 14, 571. [Google Scholar] [CrossRef]

- Cardona-Uribe, N.; Betancur, M.; Martínez, J.D. Towards the chemical upgrading of the recovered carbon black derived from pyrolysis of end-of-life tires. Sustain. Mater. Technol. 2021, 28, e00287. [Google Scholar] [CrossRef]

- Abbas-Abadi, M.S.; Kusenberg, M.; Shirazi, H.M.; Goshayeshi, B.; Van Geem, K.M. Towards full recyclability of end-of-life tires: Challenges and opportunities. J. Clean. Prod. 2022, 374, 134036. [Google Scholar] [CrossRef]

- Lapkovskis, V.; Mironovs, V.; Kasperovich, A.; Myadelets, V.; Goljandin, D. Crumb Rubber as a Secondary Raw Material from Waste Rubber: A Short Review of End-Of-Life Mechanical Processing Methods. Recycling 2020, 5, 32. [Google Scholar] [CrossRef]

- Bianco, I.; Panepinto, D.; Zanetti, M. End-of-life tyres: Comparative life cycle assessment of treatment scenarios. Appl. Sci. 2021, 11, 3599. [Google Scholar] [CrossRef]

- Guglielmotti, A.; Lucignano, C.; Quadrini, F. Production of rubber pads by tyre recycling. Int. J. Mater. Eng. Innov. 2009, 1, 91–106. [Google Scholar] [CrossRef]

- Fjeldaas, T.; Sogstad, Å.; Østerås, O. Locomotion and claw disorders in Norwegian dairy cows housed in freestalls with slatted concrete, solid concrete, or solid rubber flooring in the alleys. J. Dairy Sci. 2011, 94, 1243–1255. [Google Scholar] [CrossRef]

- Shearer, J.; Van Amstel, S. Lameness detection, examination, and record-keeping. In Manual of Foot Care in Cattle, 2nd ed.; WD Hoards & Sons Compan: Fort Atkinson, WI, USA, 2013; pp. 98–99. [Google Scholar]

- Bicalho, R.C.; Machado, V.; Caixeta, L. Lameness in dairy cattle: A debilitating disease or a disease of debilitated cattle? A cross-sectional study of lameness prevalence and thickness of the digital cushion. J. Dairy Sci. 2009, 92, 3175–3184. [Google Scholar] [CrossRef]

- Sanders, A.; Shearer, J.; De Vries, A. Seasonal incidence of lameness and risk factors associated with thin soles, white line disease, ulcers, and sole punctures in dairy cattle. J. Dairy Sci. 2009, 92, 3165–3174. [Google Scholar] [CrossRef]

- Tamas-Benyei, P.; Bitay, E.; Kishi, H.; Matsuda, S.; Czigany, T. Toughening of epoxy resin: The effect of water jet milling on worn tire rubber particles. Polymers 2019, 11, 529. [Google Scholar] [CrossRef]

- Zambelis, G.; Enginsoy, H.-M.; Bayraktar, E.; Larbi, A.; Katundi, D. Mechanical Properties of Recycled Rubber Modified Epoxy Resin Based Composites for Aircraft Auxiliary Structures. In Mechanics of Composite, Hybrid and Multifunctional Materials, Fracture, Fatigue, Failure and Damage Evolution, Volume 3: Proceedings of the 2021 Annual Conference on Experimental and Applied Mechanics, Virtual, 14–17 June 2021; Springer: Cham, Switzerland, 2022; pp. 55–63. [Google Scholar]

- Moreno, D.D.P.; Ribeiro, S.; Saron, C. Compatibilization of recycled rubber aggregate in mortar. Mater. Struct. 2020, 53, 23. [Google Scholar] [CrossRef]

- Ghaleh, M.B.; Asadi, P.; Eftekhar, M.R. Enhancing mechanical performance of waste tire concrete with surface double pre-coating by resin and micro-silica. J. Build. Eng. 2022, 50, 104084. [Google Scholar] [CrossRef]

- Maderuelo-Sanz, R.; Barrigón Morillas, J.M.; Martín-Castizo, M.; Gómez Escobar, V.; Rey Gozalo, G. Acoustical performance of porous absorber made from recycled rubber and polyurethane resin. Lat. Am. J. Solids Struct. 2013, 10, 585–600. [Google Scholar] [CrossRef]

- Revelo, C.F.; Correa, M.; Aguilar, C.; Colorado, H.A. Composite materials made of waste tires and polyurethane resin: A case study of flexible tiles successfully applied in industry. Case Stud. Constr. Mater. 2021, 15, e00681. [Google Scholar] [CrossRef]

- Sułkowski, W.W.; Danch, A.; Moczyński, M.; Radoń, A.; Sułkowska, A.; Borek, J. Thermogravimetric study of rubber waste-polyurethane composites. J. Therm. Anal. Calorim. 2004, 78, 905–921. [Google Scholar] [CrossRef]

- Mishra, K.; Das, S.; Vaidyanathan, R. The Use of Recycled Carpet in Low-Cost Composite Tooling Materials. Recycling 2019, 4, 12. [Google Scholar] [CrossRef]

- Basfar, A.A. Hardness measurements of silicone rubber and polyurethane rubber cured by ionizing radiation. Radiat. Phys. Chem. 1997, 50, 607–610. [Google Scholar] [CrossRef]

- Hejna, A.; Kosmela, P.; Olszewski, A.; Zedler, Ł.; Formela, K.; Skórczewska, K.; Piasecki, A.; Marć, M.; Barczewski, R.; Barczewski, M. Management of ground tire rubber waste by incorporation into polyurethane-based composite foams. Environ. Sci. Pollut. Res. 2023. [Google Scholar] [CrossRef] [PubMed]

- Kiss, L.; Simon, D.Á.; Petrény, R.; Kocsis, D.; Bárány, T.; Mészáros, L. Ground tire rubber filled low-density polyethylene: The effect of particle size. Adv. Ind. Eng. Polym. Res. 2022, 5, 12–17. [Google Scholar] [CrossRef]

- Qi, H.; Joyce, K.; Boyce, M. Durometer hardness and the stress-strain behavior of elastomeric materials. Rubber Chem. Technol. 2003, 76, 419–435. [Google Scholar] [CrossRef]

- Gao, J.; Chen, J.; Meng, X.; Wang, H.; Xu, N. Research on the selection of polyurethane adhesive and direct tensile properties of polyurethane rubber particle mixture. Case Stud. Constr. Mater. 2023, 18, e01728. [Google Scholar] [CrossRef]

- Gao, J.; Wang, H.; Chen, J.; Meng, X.; You, Z. Laboratory evaluation on comprehensive performance of polyurethane rubber particle mixture. Constr. Build. Mater. 2019, 224, 29–39. [Google Scholar] [CrossRef]

- Maton, A.; Daelemans, J. Modern housing of cattle and their welfare. In Agricultural Engineering Volume 2: Agricultural Buildings; CRC Press: Boca Raton, FL, USA, 2022; pp. 921–925. [Google Scholar]

- Earley, B.; McNamara, J.D.; Jerrams, S.J.; O’Riordan, E.G. Effect of concrete slats, three mat types and out-wintering pads on performance and welfare of finishing beef steers. Acta Vet. Scand. 2017, 59, 34. [Google Scholar] [CrossRef] [PubMed]

- Ecopneus. Guida per la Produzione di Bitumi con Polverino di Gomma da Pneumatico Fuori Uso—Translation of the Original Text of the Signus Guide by Ecopneus; TMB Stampa: Rome, Italy, 2015. [Google Scholar]

- Acierno, D.; Ciccarelli, I.; Romano, V.; Russo, P. Mechanical and thermal analysis of composites based on rubbers from used tires. Macromol. Symp. 2007, 247, 244–251. [Google Scholar] [CrossRef]

- Zamani, N.; Culbertson, H. Effects of Physical Hardness on the Perception of Rendered Stiffness in an Encountered-Type Haptic Display. IEEE Trans. Haptics 2022, 16, 46–56. [Google Scholar] [CrossRef]

- Bhaduri, A.; Bhaduri, A. Hardness. In Mechanical Properties and Working of Metals and Alloys; Springer: Cham, Switzerland, 2018; pp. 119–171. [Google Scholar]

- Zhao, H.; Allanson, D.; Ren, X. Use of shore hardness tests for in-process properties estimation/monitoring of silicone rubbers. J. Mater. Sci. Chem. Eng. 2015, 3, 142–147. [Google Scholar] [CrossRef] [PubMed]

- Quirce, S.; Barranco, P. Cleaning agents and asthma. J. Investig. Allergol. Clin. Immunol. 2010, 20, 542–550. [Google Scholar]

- Hasan, F.; Shah, A.A.; Javed, S.; Hameed, A. Enzymes used in detergents: Lipases. Afr. J. Biotechnol. 2010, 9, 4836–4844. [Google Scholar]

- Lu, H.; Dun, C.; Jariwala, H.; Wang, R.; Cui, P.; Zhang, H.; Dai, Q.; Yang, S.; Zhang, H. Improvement of bio-based polyurethane and its optimal application in controlled release fertilizer. J. Control. Release 2022, 350, 748–760. [Google Scholar] [CrossRef]

- Dos Santos, D.; Tavares, L.; Gouveia, J.; Batalha, G. Lignin-based polyurethane and epoxy adhesives: A short review. Arch. Mater. Sci. Eng. 2021, 107, 56–63. [Google Scholar] [CrossRef]

- Suárez-Usbeck, A.; Villagómez-Estrada, S.; Vinueza, P.; Haro, A.; Maldonado, T. The Type of Bedding on the Welfare of Dairy Cattle. J. Surv. Fish. Sci. 2023, 10, 379–384. [Google Scholar]

- Telezhenko, E.; Bergsten, C.; Magnusson, M.; Ventorp, M.; Nilsson, C. Effect of Different Flooring Systems on Weight and Pressure Distribution on Claws of Dairy Cows. J. Dairy Sci. 2008, 91, 1874–1884. [Google Scholar] [CrossRef] [PubMed]

| Feature | Value |

|---|---|

| Basis | Polyurethane |

| Appearance | Liquid |

| Colour | Straw yellow |

| NCO content | 12% |

| Viscosity, 20 °C (Type RVTD spindle n°2 speed 50) | 4000 mPa · s |

| Density, 20 °C | 1.18 g/cm3 |

| Flammable | No |

| TEST | Sample ID | Final Density (kg/dm3) | Binder Fraction (%w) | Thickness (mm) |

|---|---|---|---|---|

| TEST I Density 0.8 kg/dm3 Thickness 30 mm Binder fraction variable | Mat1 | 0.80 | 5 | 30 |

| Mat2 | 0.80 | 6 | 30 | |

| Mat3 | 0.80 | 7 | 30 | |

| Mat4 | 0.80 | 8 | 30 | |

| TEST II Density 0.8 kg/dm3 Thickness variable Binder fraction 7%w | Mat3 | 0.80 | 7 | 30 |

| Mat5 | 0.80 | 7 | 20 | |

| Mat6 | 0.80 | 7 | 25 | |

| TEST III Density variable Thickness 30 mm Binder fraction 5%w | Mat1 | 0.80 | 5 | 30 |

| Mat7 | 0.85 | 5 | 30 | |

| Mat8 | 0.90 | 5 | 30 | |

| TEST IV Density variable Thickness 25 mm Binder fraction 7%w | Mat6 | 0.80 | 7 | 25 |

| Mat9 | 0.90 | 7 | 25 |

| Phases | Ration Size | Number of Rations Per Day |

|---|---|---|

| Phase 1 From day 0 to day 9 since the start of trials | 2 L of milk | 2 (morning and evening) |

| Phase 2 From day 10 to day 59 since the start of trials | 2 L of milk | 2 (morning and evening) |

| 1 kg of fodder | 1 | |

| Phase 3 From day 60 to day 90 since the start of trials | 2.5 L of milk | 2 (morning and evening) |

| 1.5 kg of fodder | 1 |

| Sample ID | Final Density (kg/dm3) | Binder Fraction (%w) | Thickness (mm) | Grid Point | Hardness Shore A (°) | Hardness Shore A Value (°) as: Mean ± SD |

|---|---|---|---|---|---|---|

| Mat1 | 0.8 | 5 | 30 | Pt.1 | 35.84 | 33.5 ± 2.7 |

| Mat1 | 0.8 | 5 | 30 | Pt.2 | 33.74 | |

| Mat1 | 0.8 | 5 | 30 | Pt.3 | 35.85 | |

| Mat1 | 0.8 | 5 | 30 | Pt.4 | 34.57 | |

| Mat1 | 0.8 | 5 | 30 | Pt.5 | 34.49 | |

| Mat1 | 0.8 | 5 | 30 | Pt.6 | 32.08 | |

| Mat1 | 0.8 | 5 | 30 | Pt.7 | 35.88 | |

| Mat1 | 0.8 | 5 | 30 | Pt.8 | 31.03 | |

| Mat1 | 0.8 | 5 | 30 | Pt.9 | 28.01 | |

| Mat2 | 0.8 | 6 | 30 | Pt.1 | 40.89 | 42.0 ± 1.3 |

| Mat2 | 0.8 | 6 | 30 | Pt.2 | 43.48 | |

| Mat2 | 0.8 | 6 | 30 | Pt.3 | 40.83 | |

| Mat2 | 0.8 | 6 | 30 | Pt.4 | 43.67 | |

| Mat2 | 0.8 | 6 | 30 | Pt.5 | 41.95 | |

| Mat2 | 0.8 | 6 | 30 | Pt.6 | 42.45 | |

| Mat2 | 0.8 | 6 | 30 | Pt.7 | 43.06 | |

| Mat2 | 0.8 | 6 | 30 | Pt.8 | 42.07 | |

| Mat2 | 0.8 | 6 | 30 | Pt.9 | 39.60 | |

| Mat3 | 0.8 | 7 | 30 | Pt.1 | 47.49 | 46.3 ± 1.5 |

| Mat3 | 0.8 | 7 | 30 | Pt.2 | 47.87 | |

| Mat3 | 0.8 | 7 | 30 | Pt.3 | 47.48 | |

| Mat3 | 0.8 | 7 | 30 | Pt.4 | 45.12 | |

| Mat3 | 0.8 | 7 | 30 | Pt.5 | 44.93 | |

| Mat3 | 0.8 | 7 | 30 | Pt.6 | 44.05 | |

| Mat3 | 0.8 | 7 | 30 | Pt.7 | 45.72 | |

| Mat3 | 0.8 | 7 | 30 | Pt.8 | 45.61 | |

| Mat3 | 0.8 | 7 | 30 | Pt.9 | 48.33 | |

| Mat4 | 0.8 | 8 | 30 | Pt.1 | 42.57 | 41.2 ± 1.5 |

| Mat4 | 0.8 | 8 | 30 | Pt.2 | 40.33 | |

| Mat4 | 0.8 | 8 | 30 | Pt.3 | 42.28 | |

| Mat4 | 0.8 | 8 | 30 | Pt.4 | 39.17 | |

| Mat4 | 0.8 | 8 | 30 | Pt.5 | 39.43 | |

| Mat4 | 0.8 | 8 | 30 | Pt.6 | 41.38 | |

| Mat4 | 0.8 | 8 | 30 | Pt.7 | 41.12 | |

| Mat4 | 0.8 | 8 | 30 | Pt.8 | 40.68 | |

| Mat4 | 0.8 | 8 | 30 | Pt.9 | 43.84 | |

| Mat5 | 0.8 | 7 | 20 | Pt.1 | 34.04 | 36.2 ± 3.6 |

| Mat5 | 0.8 | 7 | 20 | Pt.2 | 35.01 | |

| Mat5 | 0.8 | 7 | 20 | Pt.3 | 35.98 | |

| Mat5 | 0.8 | 7 | 20 | Pt.4 | 34.54 | |

| Mat5 | 0.8 | 7 | 20 | Pt.5 | 34.57 | |

| Mat5 | 0.8 | 7 | 20 | Pt.6 | 34.87 | |

| Mat5 | 0.8 | 7 | 20 | Pt.7 | 35.67 | |

| Mat5 | 0.8 | 7 | 20 | Pt.8 | 34.99 | |

| Mat5 | 0.8 | 7 | 20 | Pt.9 | 45.75 | |

| Mat6 | 0.8 | 7 | 25 | Pt.1 | 38.31 | 40.0 ± 1.2 |

| Mat6 | 0.8 | 7 | 25 | Pt.2 | 41.12 | |

| Mat6 | 0.8 | 7 | 25 | Pt.3 | 39.75 | |

| Mat6 | 0.8 | 7 | 25 | Pt.4 | 40.89 | |

| Mat6 | 0.8 | 7 | 25 | Pt.5 | 41.91 | |

| Mat6 | 0.8 | 7 | 25 | Pt.6 | 40.15 | |

| Mat6 | 0.8 | 7 | 25 | Pt.7 | 40.00 | |

| Mat6 | 0.8 | 7 | 25 | Pt.8 | 38.29 | |

| Mat6 | 0.8 | 7 | 25 | Pt.9 | 39.58 | |

| Mat7 | 0.85 | 5 | 30 | Pt.1 | 42.27 | 40.1 ± 7.3 |

| Mat7 | 0.85 | 5 | 30 | Pt.2 | 45.01 | |

| Mat7 | 0.85 | 5 | 30 | Pt.3 | 30.45 | |

| Mat7 | 0.85 | 5 | 30 | Pt.4 | 33.41 | |

| Mat7 | 0.85 | 5 | 30 | Pt.5 | 37.50 | |

| Mat7 | 0.85 | 5 | 30 | Pt.6 | 39.36 | |

| Mat7 | 0.85 | 5 | 30 | Pt.7 | 32.78 | |

| Mat7 | 0.85 | 5 | 30 | Pt.8 | 48.56 | |

| Mat7 | 0.85 | 5 | 30 | Pt.9 | 51.62 | |

| Mat8 | 0.9 | 5 | 30 | Pt.1 | 42.74 | 43.3 ± 2.4 |

| Mat8 | 0.9 | 5 | 30 | Pt.2 | 41.10 | |

| Mat8 | 0.9 | 5 | 30 | Pt.3 | 43.20 | |

| Mat8 | 0.9 | 5 | 30 | Pt.4 | 42.74 | |

| Mat8 | 0.9 | 5 | 30 | Pt.5 | 42.68 | |

| Mat8 | 0.9 | 5 | 30 | Pt.6 | 42.72 | |

| Mat8 | 0.9 | 5 | 30 | Pt.7 | 41.82 | |

| Mat8 | 0.9 | 5 | 30 | Pt.8 | 43.48 | |

| Mat8 | 0.9 | 5 | 30 | Pt.9 | 49.44 | |

| Mat9 | 0.9 | 7 | 25 | Pt.1 | 42.20 | 42.3 ± 1.2 |

| Mat9 | 0.9 | 7 | 25 | Pt.2 | 42.83 | |

| Mat9 | 0.9 | 7 | 25 | Pt.3 | 41.16 | |

| Mat9 | 0.9 | 7 | 25 | Pt.4 | 42.04 | |

| Mat9 | 0.9 | 7 | 25 | Pt.5 | 43.57 | |

| Mat9 | 0.9 | 7 | 25 | Pt.6 | 43.59 | |

| Mat9 | 0.9 | 7 | 25 | Pt.7 | 40.50 | |

| Mat9 | 0.9 | 7 | 25 | Pt.8 | 40.83 | |

| Mat9 | 0.9 | 7 | 25 | Pt.9 | 43.53 |

| Hardness | ||

|---|---|---|

| Pearson | Spearman | |

| Final density | 0.24605 | 0.24932 |

| Binder fraction | 0.19372 | 0.13415 |

| Thickness of the mat | 0.26405 | 0.24865 |

| Reagent | Sample ID | pH of the Reagent | Colour of the Sample | |||||

|---|---|---|---|---|---|---|---|---|

| Day 0 | Day 1 | Day 2 | Day 7 | Day 1 | Day 2 | Day 7 | ||

| NH3 | A1 | 10.0 | 9.9 | 9.8 | 10.1 | NC | NC | NC |

| A2 | 10.1 | 10.0 | 10.1 | 9.9 | NC | NC | NC | |

| A3 | 10.1 | 10.2 | 10.0 | 10.2 | NC | NC | NC | |

| HCl | C1 | 0.1 | 0.1 | 0.2 | 0.0 | NC | NC | NC |

| C2 | 0.1 | 0.0 | 0.1 | 0.0 | NC | NC | NC | |

| C3 | 0.2 | 0.1 | 0.0 | 0.0 | NC | NC | NC | |

| HCOOH | F1 | 2.5 | 2.5 | 2.4 | 2.5 | NC | NC | NC |

| F2 | 2.5 | 2.6 | 2.5 | 2.5 | NC | NC | NC | |

| F3 | 2.5 | 2.4 | 2.5 | 2.6 | NC | NC | NC | |

| H2O2 | O1 | 4.0 | 3.9 | 4.0 | 4.0 | NC | NC | NC |

| O2 | 4.1 | 4.0 | 4.1 | 4.0 | NC | NC | NC | |

| O3 | 4.1 | 4.1 | 4.0 | 4.0 | NC | NC | NC | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masiello, A.; di Cicco, M.R.; Spagnuolo, A.; Vetromile, C.; De Santo, G.; Costanzo, G.; Marotta, A.; De Cristofaro, F.; Lubritto, C. Mats Made from Recycled Tyre Rubber and Polyurethane for Improving Growth Performance in Buffalo Farms. AgriEngineering 2024, 6, 597-619. https://doi.org/10.3390/agriengineering6010036

Masiello A, di Cicco MR, Spagnuolo A, Vetromile C, De Santo G, Costanzo G, Marotta A, De Cristofaro F, Lubritto C. Mats Made from Recycled Tyre Rubber and Polyurethane for Improving Growth Performance in Buffalo Farms. AgriEngineering. 2024; 6(1):597-619. https://doi.org/10.3390/agriengineering6010036

Chicago/Turabian StyleMasiello, Antonio, Maria Rosa di Cicco, Antonio Spagnuolo, Carmela Vetromile, Giuseppe De Santo, Guido Costanzo, Antonio Marotta, Florindo De Cristofaro, and Carmine Lubritto. 2024. "Mats Made from Recycled Tyre Rubber and Polyurethane for Improving Growth Performance in Buffalo Farms" AgriEngineering 6, no. 1: 597-619. https://doi.org/10.3390/agriengineering6010036

APA StyleMasiello, A., di Cicco, M. R., Spagnuolo, A., Vetromile, C., De Santo, G., Costanzo, G., Marotta, A., De Cristofaro, F., & Lubritto, C. (2024). Mats Made from Recycled Tyre Rubber and Polyurethane for Improving Growth Performance in Buffalo Farms. AgriEngineering, 6(1), 597-619. https://doi.org/10.3390/agriengineering6010036