Investigating the Detection Capability of Acoustic Emission Monitoring to Identify Imperfections Produced by the Metal Active Gas (MAG) Welding Process

Abstract

1. Introduction

1.1. Fusion Welding Characteristics Involving Arc Welding

- Material chemistry combinations and microstructures;

- Filler metal chemistry (if used);

- Geometry and thickness;

- Heat source power density;

- Heat flow/thermal cycle;

- Gas–metal reactions.

- Prior substrate temperature;

- Welding power;

- Travel speed.

1.2. Welding Imperfections and Non-Destructive Evaluation (NDE)

- Inadequate fusion;

- Lack of penetration/excessive penetration;

- Porosity;

- Metallic and non-metallic inclusions;

- Cracking;

- Undercutting;

- Lamellar tearing.

- Selection of appropriate filler wire size and welding parameters;

- Consumables with low carbon and higher manganese and silicon;

- Fusion profile that promotes depth-to-width ratio no greater than 2:1;

- Weld pool surface profiles;

- Avoidance of significant gaps;

- Removal of surface contaminants.

- Microstructural sensitivity is due primarily to the HAZ having a hard and brittle microstructure or if the martensitic finish temperature (Mf) is below normal ambient temperature.

- Significant tensile stresses arising from high restraint and steep cooling curves, or a high yield strength filler metal used to join a lower yield strength substrate.

- Hydrogen sources arising from decomposition of hydrocarbons and moisture sources, e.g., flux-based welding processes.

- A temperature near to ambient that retards the rate at which nascent hydrogen diffuses to a position where the above three factors overlap, causing the coalescence of hydrogen molecules (gas) to induce a significant hydrostatic pressure.

1.3. Acoustic Emission (AE) Sensors

- Instead of transmitting energy to the material being examined, it simply records emitted energy over a defined threshold. Weld solidification provides enough energy for generating elastic waves that are above such defined thresholds.

- AE testing is concerned with changes in material discontinuities or density, as it providesthe detection of active features like crack growth or spot indication, respectively, which can be used to determine the quality of the weld.

2. Literature

2.1. Investigating Sensor Technologies Applied to Welding Quality

2.2. Acoustic Emission Sensors Applied to Monitoring Weld Quality In Situ

3. Initiated Cracks during MAG Welding

3.1. Experimentation Phase

Welding Material Considerations

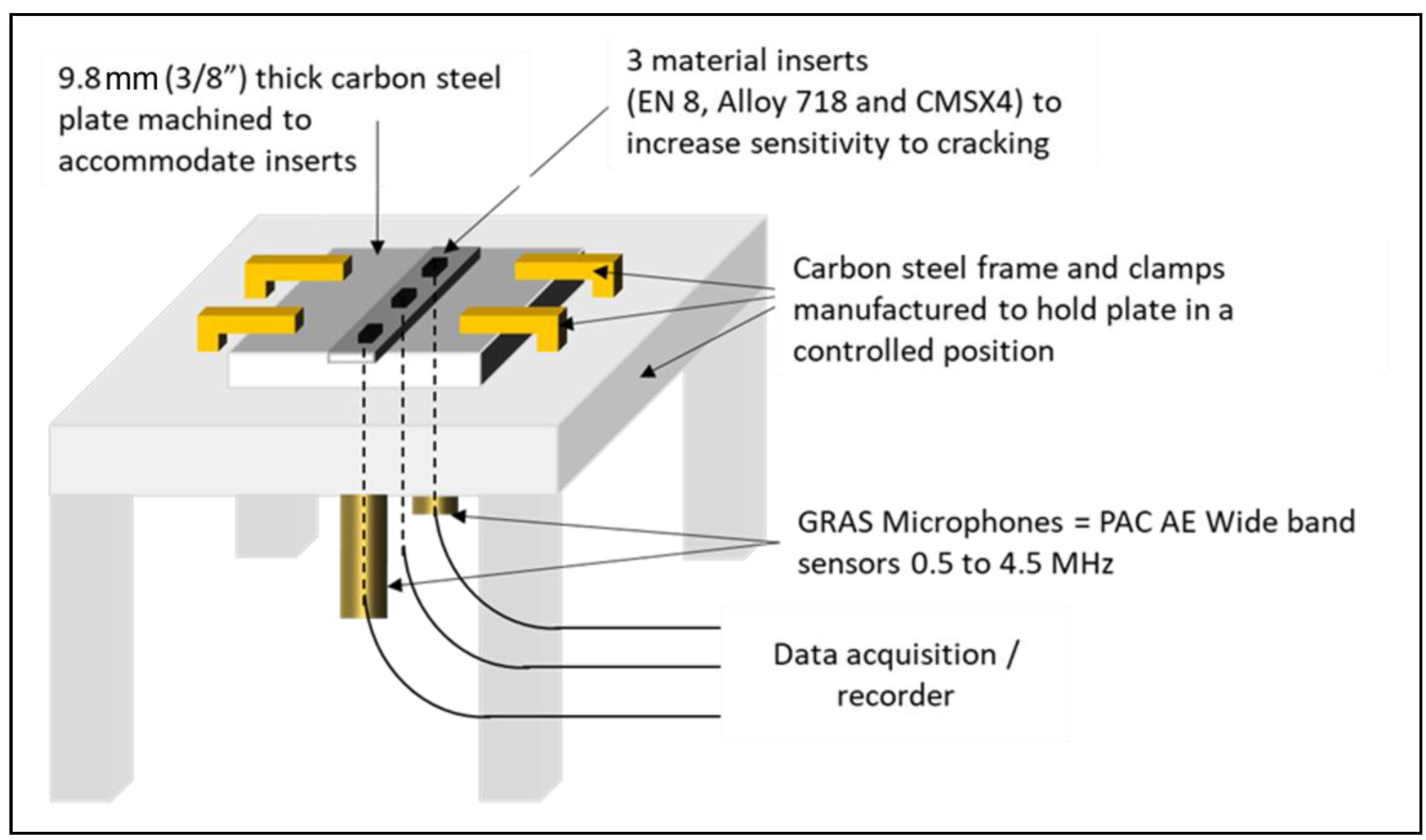

3.2. Sensor Setup

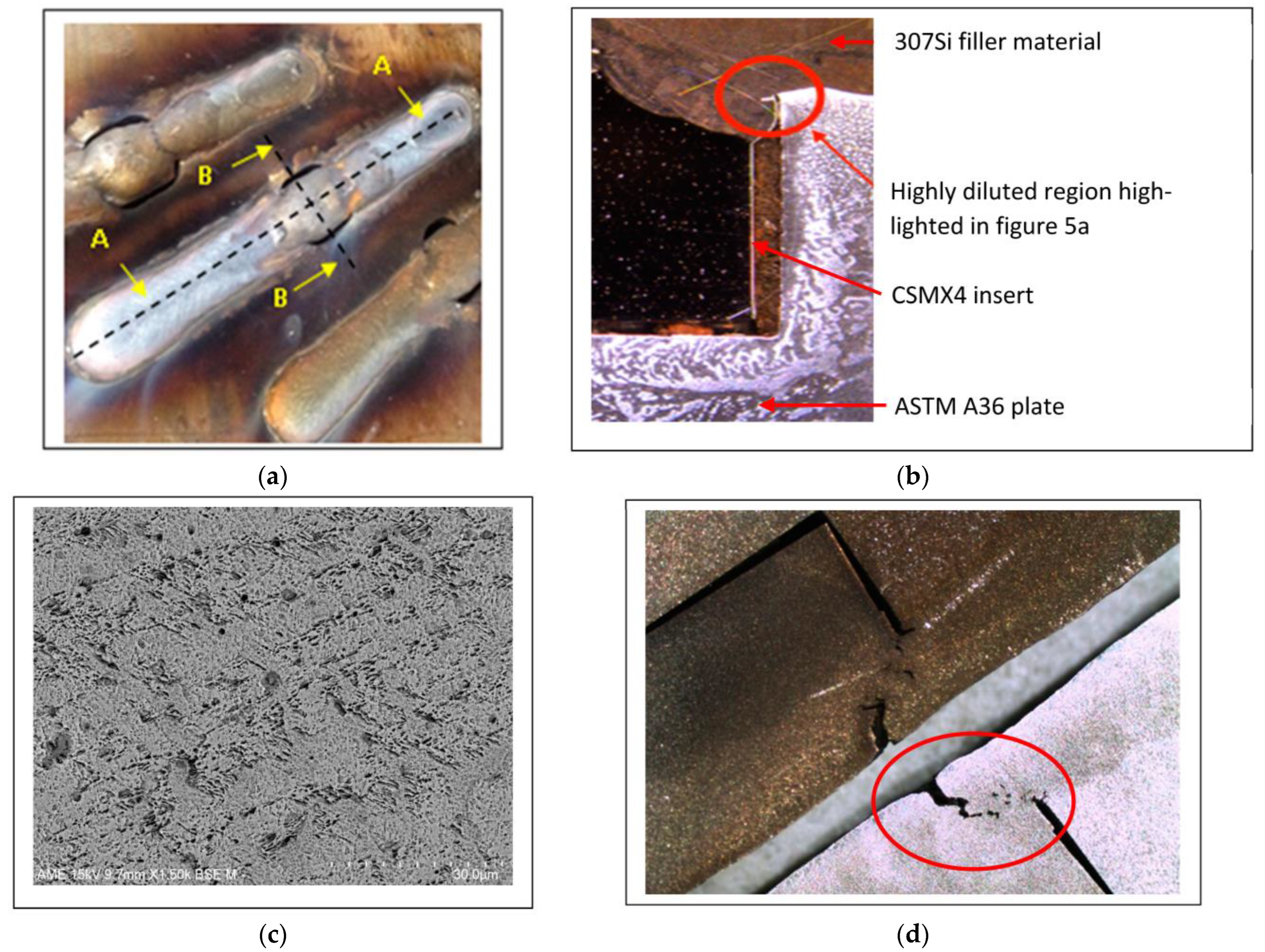

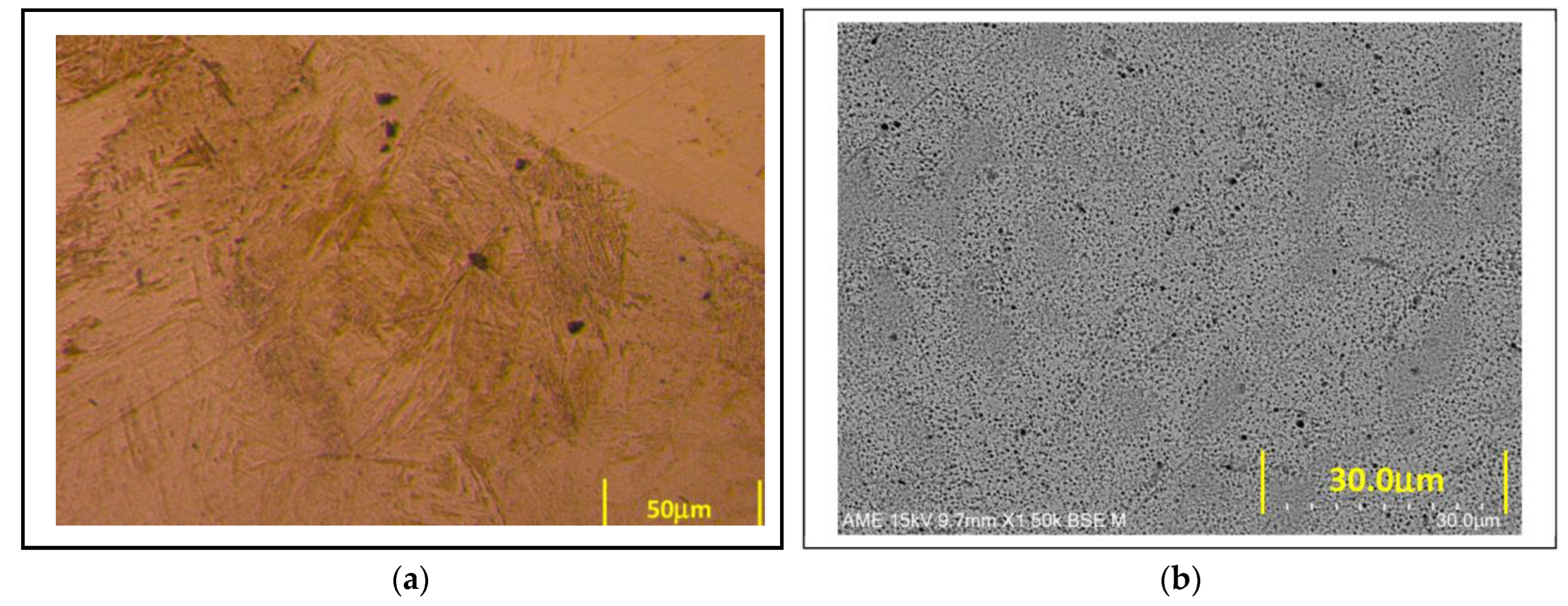

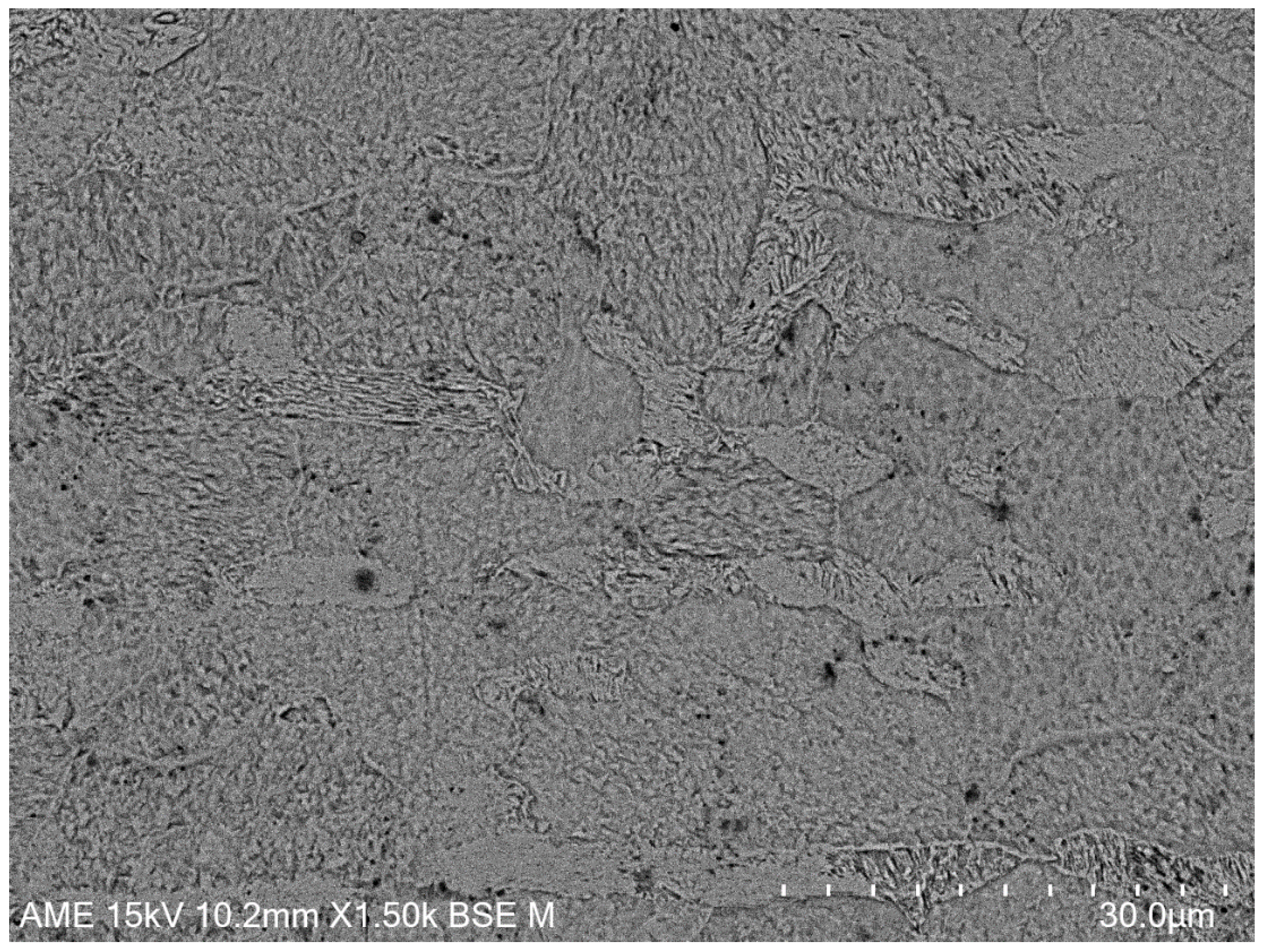

3.3. Material Inspection

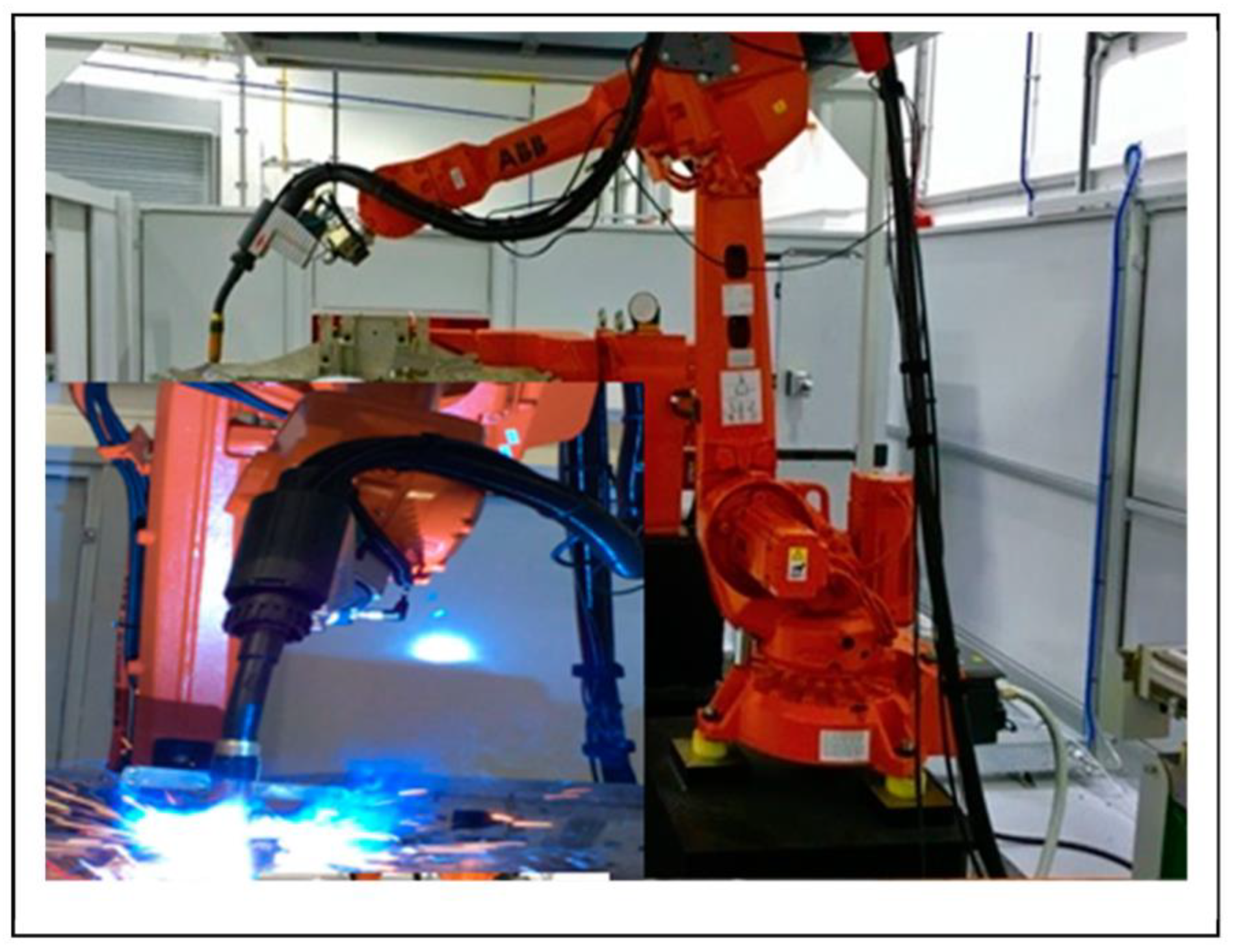

Experimental Setup: Automated MAG Welding with Inserts and Sensing

4. Results and Discussion: Mag Welding

Material Preparation Phase

5. Results and Discussion: AE (Contact and Airborne Sensors)

5.1. GRAS Acoustic Emission Results

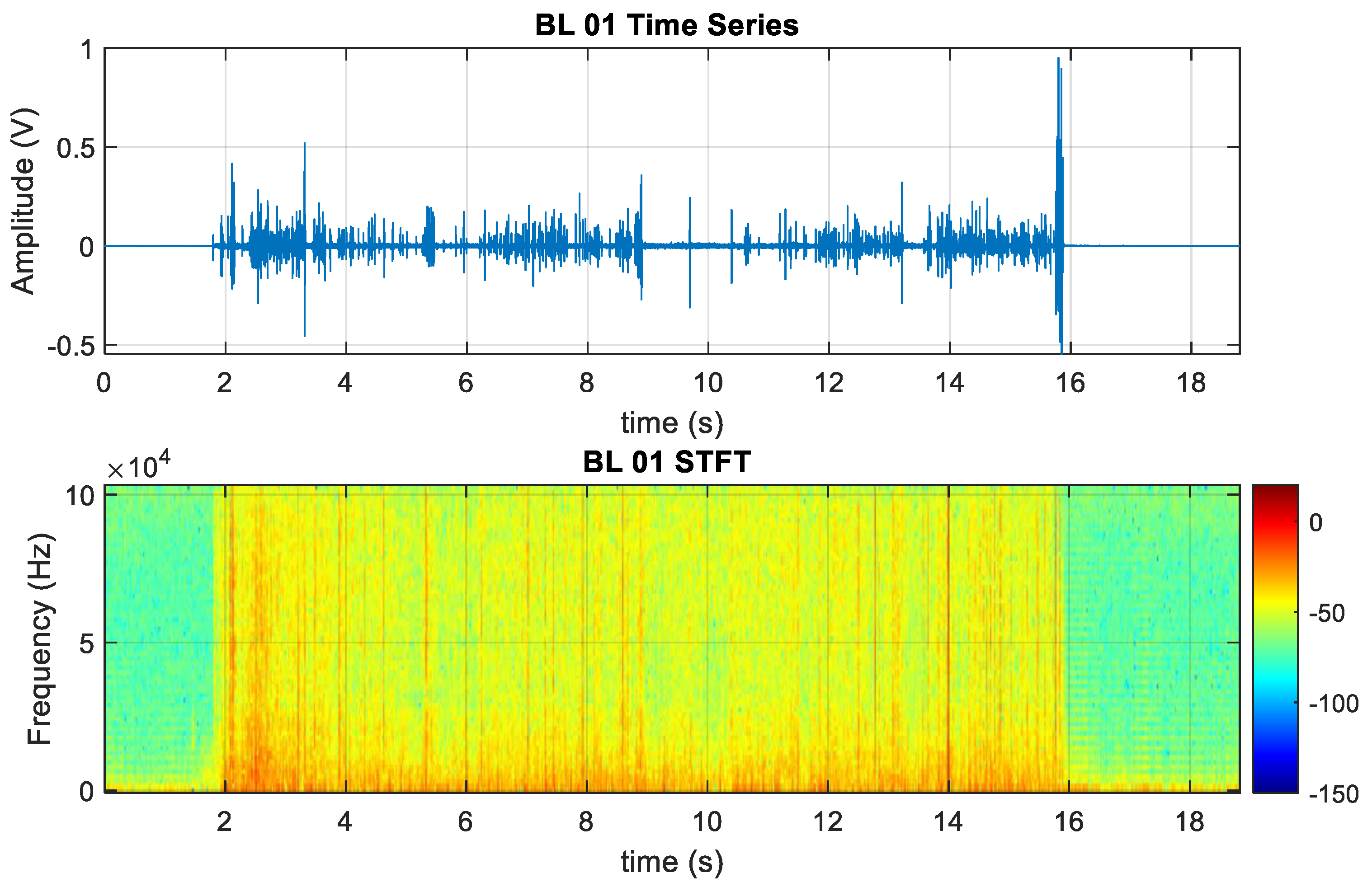

5.1.1. Baseline Welding Assessment

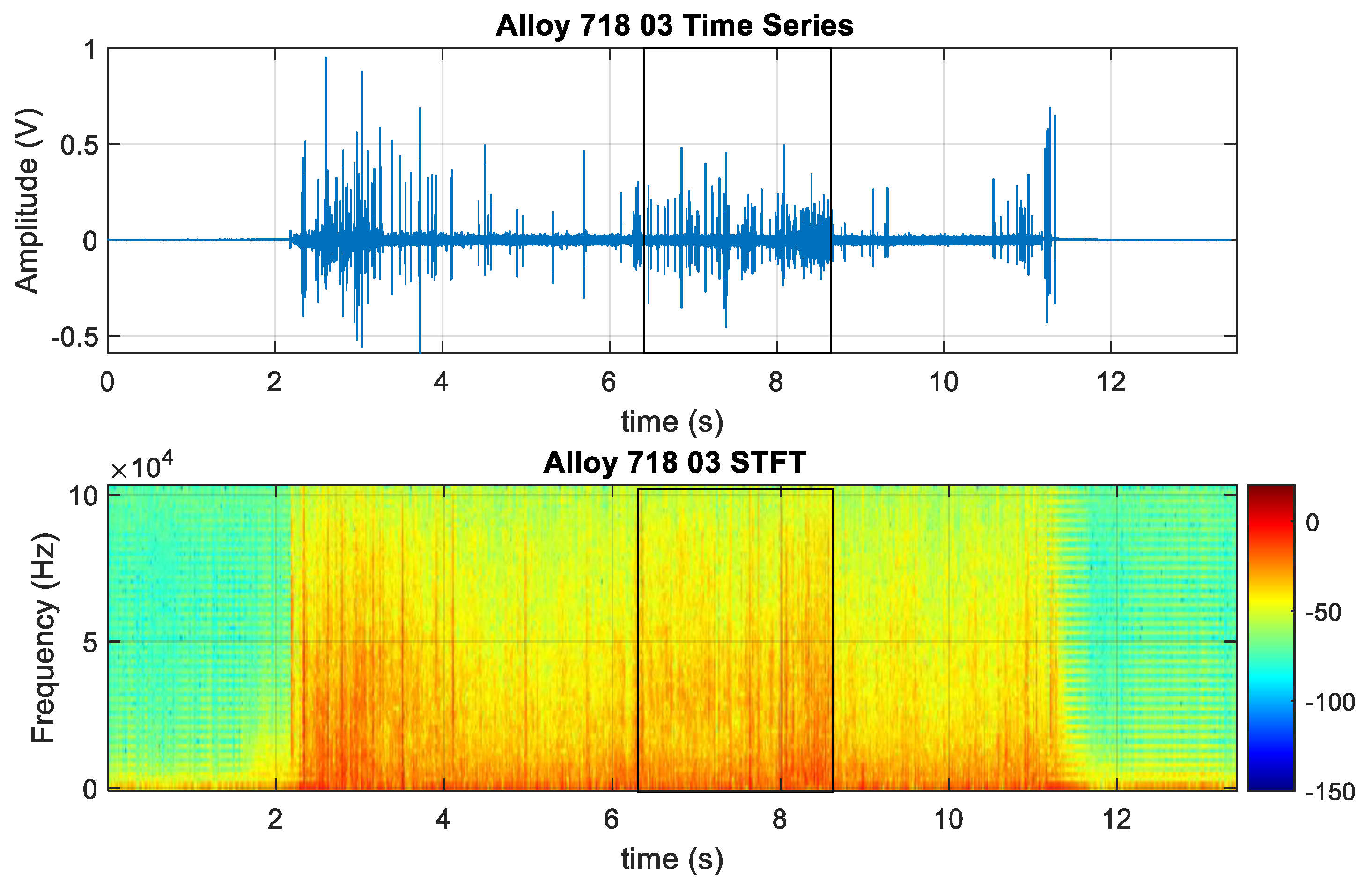

5.1.2. Alloy 718 Insert Welding Assessment

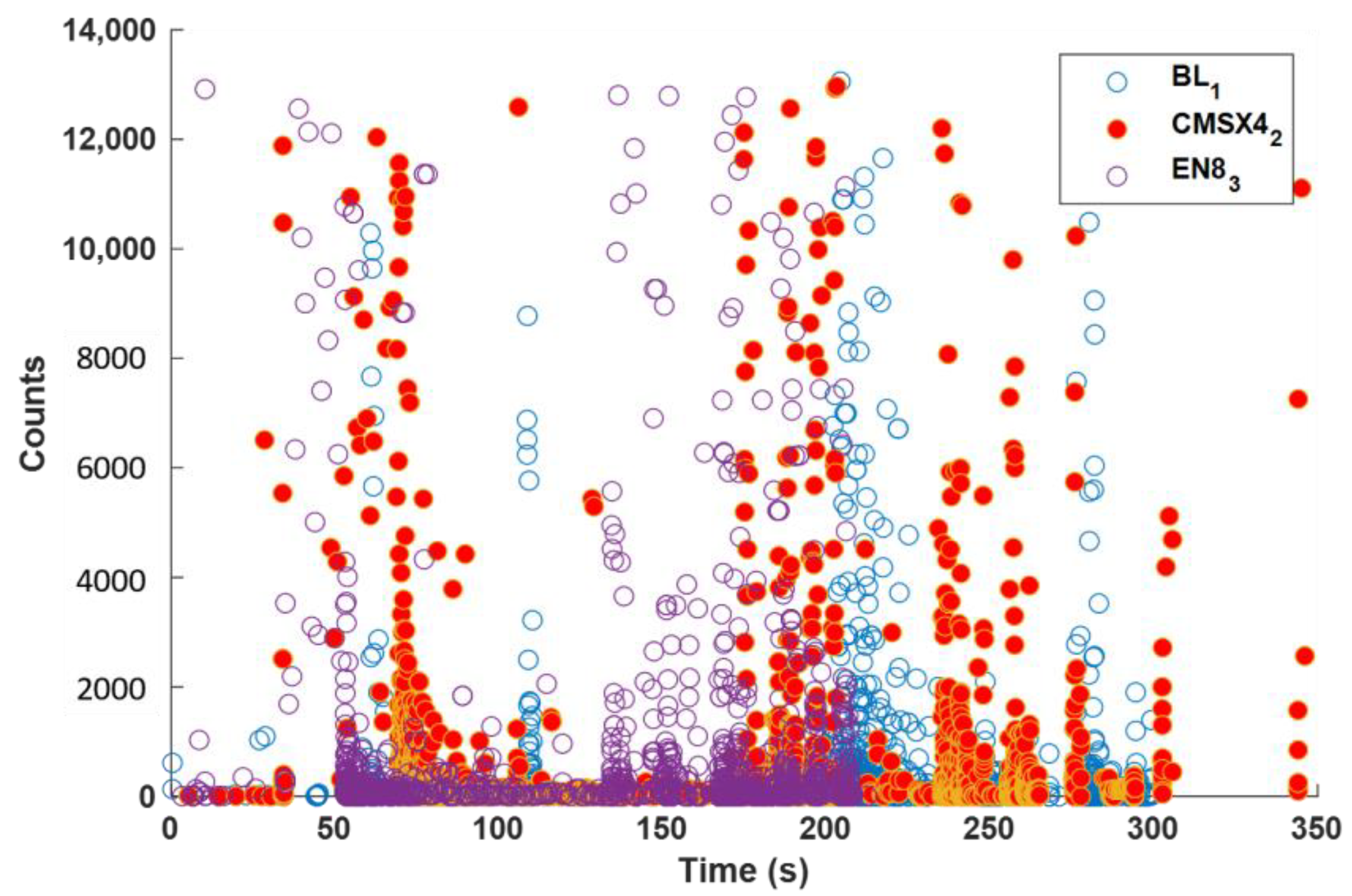

5.1.3. CMSX4 Insert Welding Assessment

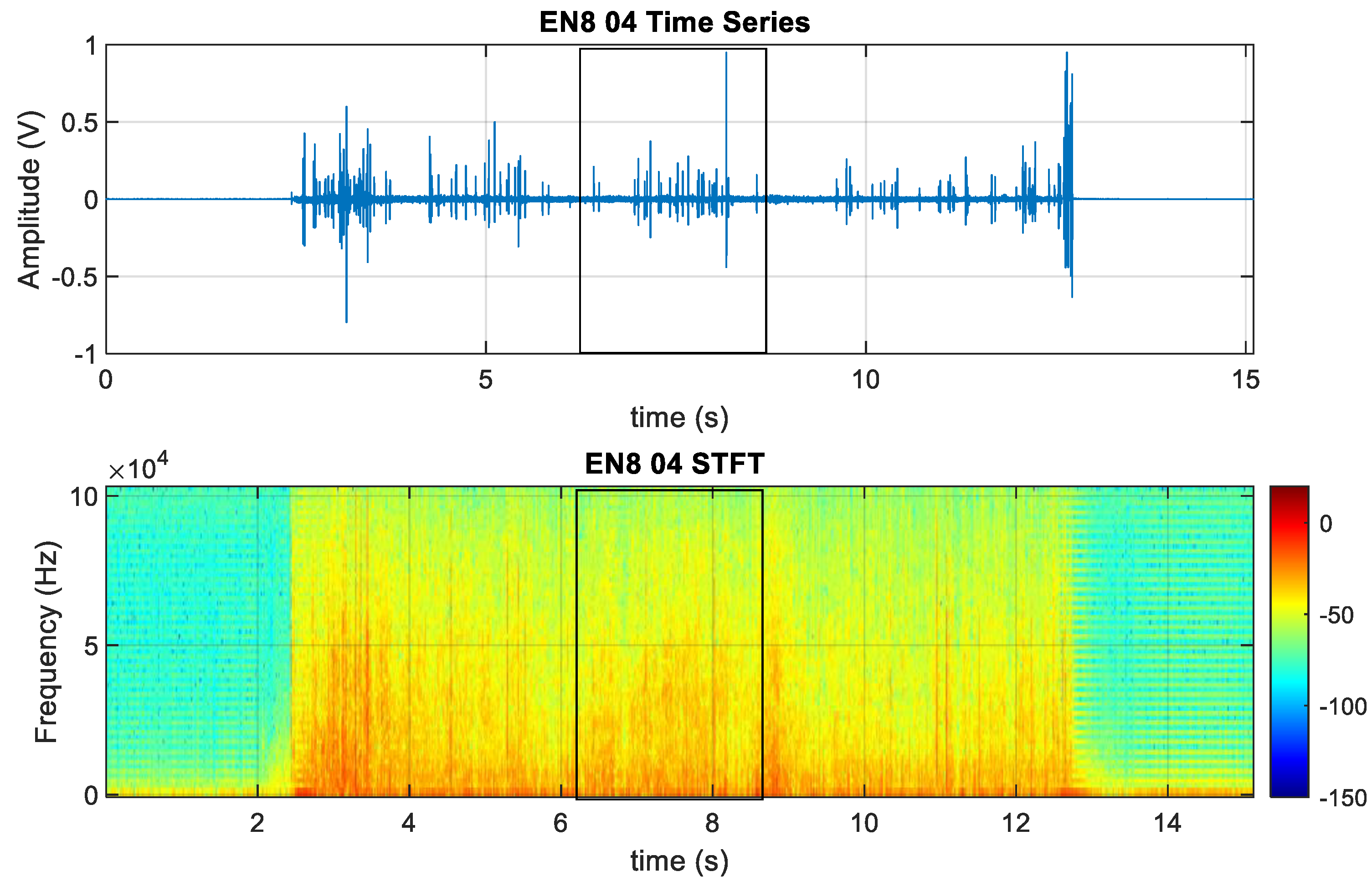

5.1.4. EN8 Insert Welding Assessment

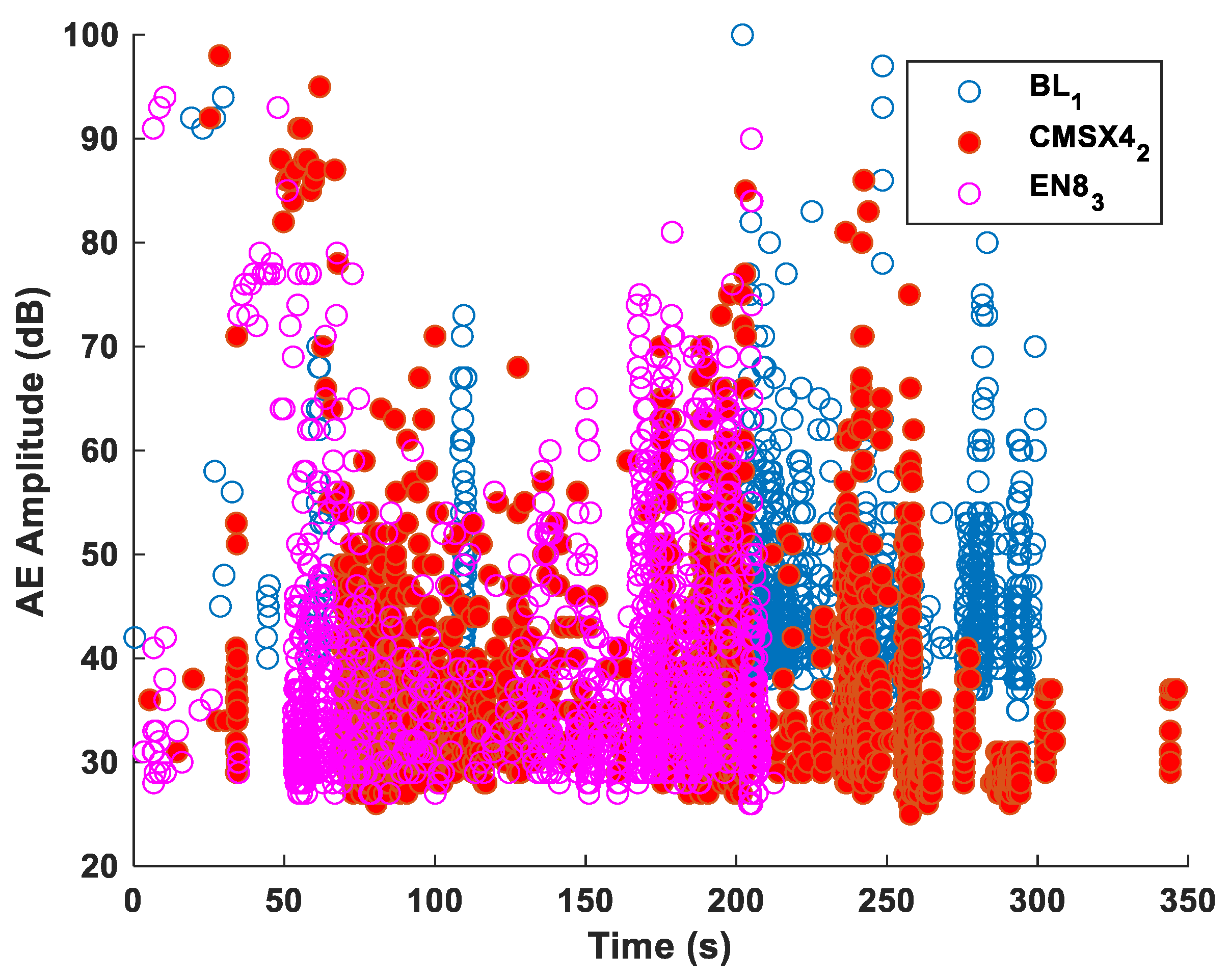

5.2. PAC Contact Acoustic Emissions Sensor Results

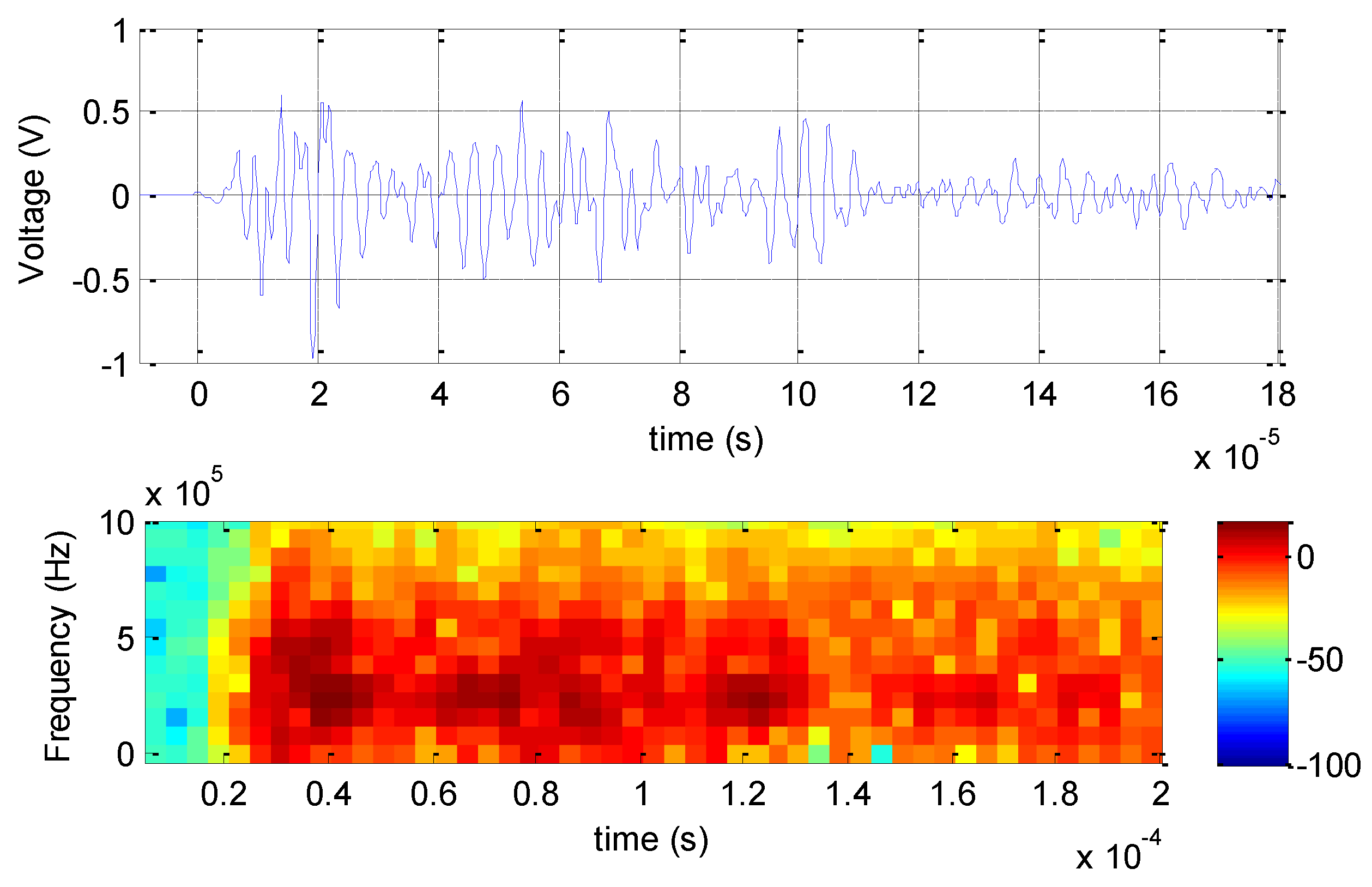

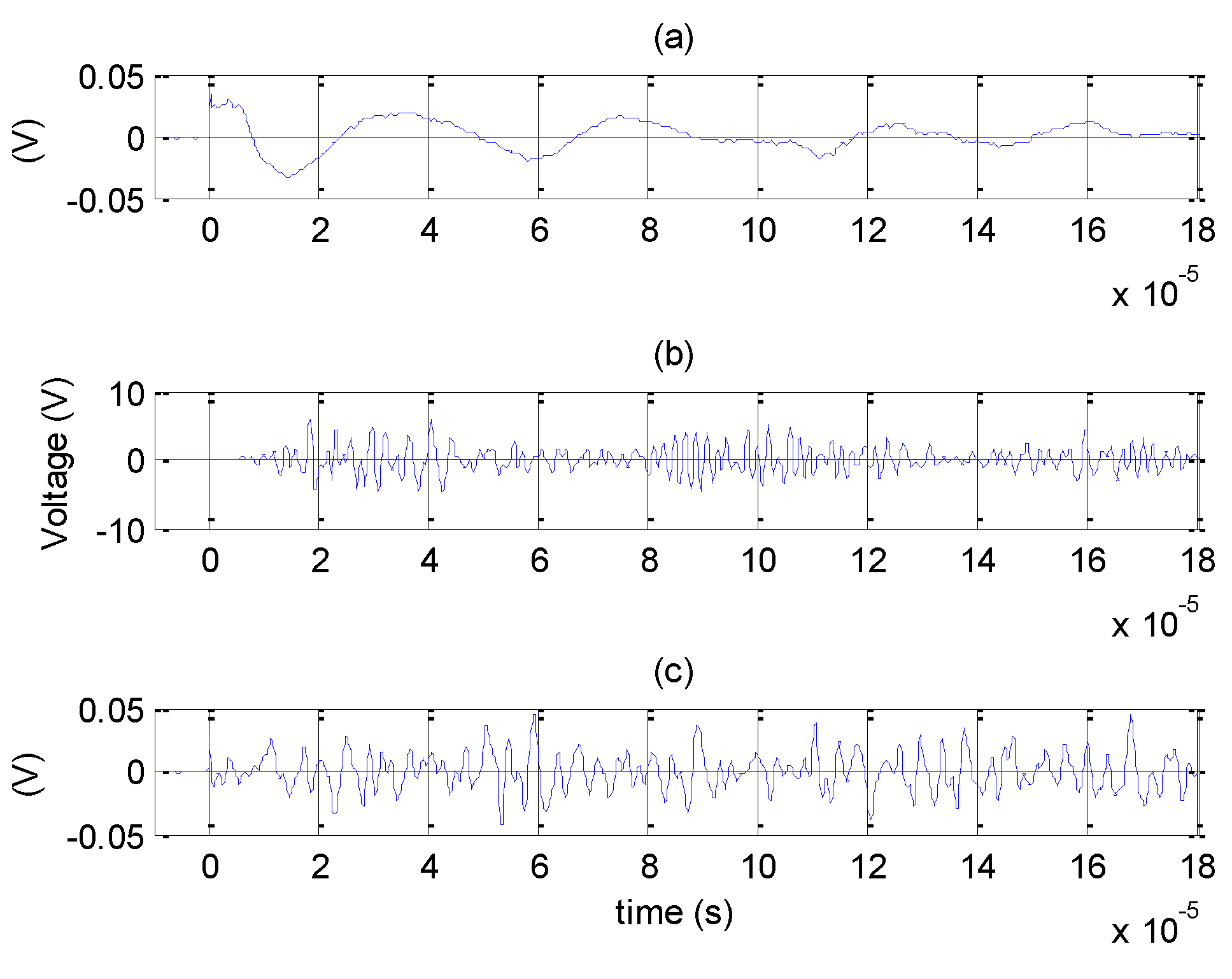

5.2.1. Baseline Welding Condition

5.2.2. CMSX4 Insert Weld

5.2.3. 307Si- CMn-EN8 Insert Weld

6. Discussion

7. Connecting with the State of the Art

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Correction Statement

References

- Shankar, V.; Gill, T.P.S.; Mannan, S.L. Solidification cracking in austenitic stainless steel welds. Sadhana Acad. Proc. Eng. Sci. 2003, 28, 359–382. [Google Scholar] [CrossRef]

- Rush, M.T.; Colegrove, P.A.; Zhang, Z.; Courtot, B. An investigation into cracking in nickel-base superalloy repair welds. Adv. Mater. Res. 2010, 89–91, 467–472. [Google Scholar] [CrossRef]

- ASM Handbook Vol. 6 Welding Brazing and Soldering; ASM International: Materials Park, OH, USA, 1993; p. 2. ISBN 978-0-87170-382-8.

- Dixon, B.; Hakansson, K. Effects of Welding parameters on weld zone toughness and hardness in 690 MPa steel. Weld. J. 1995, 74, 122s–133s. [Google Scholar]

- Pollard, P.; Milner, D.R. Gas-metal reactions in CO2 arc welding. J. Steel Iron Inst. 1971, 209, 291–300. [Google Scholar]

- Littleton, J. Gas-Metal Reactions and Porosity in the Inert Gas Arc Welding of Copper. Ph.D. Thesis, Aston University, Birmingham, UK, 1974; pp. 9–26. [Google Scholar]

- Drouet, M.G.; Nadeau, F. Pressure Waves due to Arcing Faults in a Substation. IEEE Trans. Power Appar. Syst. 1979, 5, 1632–1635. [Google Scholar] [CrossRef]

- Shiraiwa, T.; Kawate, M.; Briffod, F.; Kasuya, T.; Enoki, M. Evaluation of hydrogen-induced cracking in high-strength steel welded joints by acoustic emission technique. J. Mater. Des. 2020, 190, 108573. [Google Scholar] [CrossRef]

- Ser’eznov, A.N.; Stepanova, L.N.; Lebedev, E.Y.; Kabanov, S.I.; Chaplygin, V.N.; Laznenko, K.V.; Ramazanov, I.S. Acoustic-Emission Study of the Possibilities of Localizing Flaws of a Welded Joint during Cooling. Russ. J. Nondestruct. Test. 2009, 45, 310–316. [Google Scholar] [CrossRef]

- Zhang, G.; Song Wu, C.; Liu, X. Single Vision System for Simultaneous Observation of Keyhole and Weld Pool in Plasma Arc Welding. J. Mater. Process. Technol. 2015, 215, 8. [Google Scholar] [CrossRef]

- Rosado, L.S.; Santos, T.G.; Piedade, M.; Ramos, P.M.; Vilaca, P. Advanced Technique for Non-Destructive Testing of Friction Stir Welding of Metals. Measurement 2010, 43, 1021–1030. [Google Scholar] [CrossRef]

- Ferrara, M.; Ancona, A.; Lugara, P.; Sibilano, M. Online quality monitoring of welding processes by means of plasma optical spectroscopy. In High Power Lasers in Manufacturing; SPIE: Bellingham, WA, USA, 2000; p. 750. [Google Scholar]

- Yi, L.; Yan, Z.; Xiaojian, X.; Yang, Z.; Rui, W. Effect of Welding Heat Input to Metal Droplet Transfer Characterized by Structure-Borne Acoustic Emission Signals Detected in MAG. Measurement 2015, 70, 8. [Google Scholar] [CrossRef]

- Kamal, P.; Sandip, B.; Surjya, K.P. Investigation on arc sound and metal transfer modes for on-line monitoring in pulsed gas metal arc welding. J. Mater. Process. Technol. 2010, 210, 1397–1410. [Google Scholar]

- Paoletti, A.; Lambiase, F.; Di Ilio, A. Optimization of Friction Stir Welding of Thermoplastics. In Proceedings of the 9th CIRP Conference on Intelligent Computation in Manufacturing Engineering—CIRP ICME, Gulf of Naples, Italy, 12–14 July 2015; pp. 562–567. [Google Scholar]

- Eriksson, I.; Powell, J.; Kaplan, A.F.H. Signal overlap in the monitoring of laser welding. Meas. Sci. Technol. 2010, 21, 105705. [Google Scholar] [CrossRef]

- Sibillano, T.; Rizzi, D.; Ancona, A.; Saludes-Rodil, S.; Rodriguez Nieto, J.; Chmelíčková, H.; Šebestová, H. Spectroscopic Monitoring of Penetration Depth in CO2 Nd: YAG and Fiber Laser Welding Processes. J. Mater. Process. Technol. 2011, 212, 910–916. [Google Scholar] [CrossRef]

- Zhang, G.; Wu, C.S.; Liu, Z. Experimental observation of both keyhole and its surrounding thermal field in plasma arc welding. Int. J. Heat Mass Transf. 2014, 70, 439–448. [Google Scholar] [CrossRef]

- Suárez, J.; Remartínez, B.; Menéndez, J.; Güemes, A.; Molleda, F. Optical Fibre Sensors for Monitoring of Welding Residual Stresses. J. Mater. Process. Technol. 2003, 143–144, 316–320. [Google Scholar] [CrossRef]

- Grad, L.; Grumb, J.; Polajnar, I.; Slabe, J.M. Feasibility study of acoustic signals for on-line monitoring in short circuit gas metal arc welding. Int. J. Mach. Tools Manuf. 2004, 44, 555–561. [Google Scholar] [CrossRef]

- Cayo, E.H.; Absi Alfaro, S.C. Welding Quality Measurement Based on Acoustic Sensing. ABCM Symp. Ser. Mechatron. 2008, 3, 571–579. [Google Scholar]

- Karlsson, L. Crack Detection in Welding Process Using Acoustic Emission. Master’s Thesis, Mälardalen University, Västerås, Sweden, 2008. [Google Scholar]

- Cayo, H.E.; Alfaro, A. MAG process stability evaluation through acoustic emission by time and frequency domain analysis. J. Achiev. Mater. Manuf. Eng. 2009, 34, 157–164. [Google Scholar]

- Wadley, H.; Scruby, C.B. Elastic wave radiation from cleavage crack extension. Int. J. Fract. 1993, 23, 111–128. [Google Scholar] [CrossRef]

- Sharma, A.; Junaidh, M.I.; Purushothaman, K.K.; Kotwal, C.P.; Paul, J.; Tripathi, S.; Pant, B.; Sankaranarayanan, A.S. Online Monitoring of Electron Beam Welding of TI6AL4V Alloy through Acoustic Emission. In Proceedings of the National Seminar on Non-Destructive Evaluation, Hyderabad, India, 7–9 December 2006. [Google Scholar]

- Rodriguez-Cobo, L.; Mirapeix, J.; Ruiz-Lombera, R.; Cobo, A. Fiber Bragg Grating Sensors for On-Line Welding Diagnostics. J. Mater. Process. Technol. 2015, 214, 839–843. [Google Scholar] [CrossRef]

- Griffin, J.; Chen, X. Real-time Neural Network classifications of characteristics from emitted Acoustic Emission during Horizontal Single Grit Scratch Tests. J. Intell. Manuf. 2014, 2014, 1–17. [Google Scholar] [CrossRef]

- He, K.; Li, X. Time–Frequency Feature Extraction of Acoustic Emission Signals in Aluminum Alloy MIG Welding Process Based on SST and PCA. IEEE Access 2019, 7, 113988–113998. [Google Scholar] [CrossRef]

- Zhang, L.; Basantes-Defaz, A.C.; Ozevin, D.; Indacochea, E. Real-time monitoring of welding process using air-coupled ultrasonics and acoustic emission. Int. J. Adv. Manuf. Technol. 2019, 101, 1623–1634. [Google Scholar] [CrossRef]

- Madhvacharyula, A.S.; Pavan, A.V.S.; Gorthi, S.; Chitral, S.; Venkaiah, N.; Kiran, D.V. In situ detection of welding defects: A review. Weld. World 2022, 66, 611–628. [Google Scholar] [CrossRef]

- Kanungo, T.; Mount, D.M.; Netanyahu, N.S.; Piatko, C.D.; Silverman, R.; Wu, A.Y. An efficient k-means clustering algorithm: Analysis and implementation. IEEE Trans. Pattern Anal. Mach. Intell. 2002, 24, 881–892. [Google Scholar] [CrossRef]

- Kale, A.P.; Wahul, R.M.; Patange, A.D.; Soman, R.; Ostachowicz, W. Development of Deep Belief Network for Tool Faults Recognition. Sensors 2023, 23, 1872. [Google Scholar] [CrossRef]

- Roca, A.S.; Fals, H.; Fernández, J.; Macias, E.; De La Parte, M. Artificial neural networks and acoustic emission applied to stability analysis in gas metal arc welding. Sci. Technol. Weld. Join. 2009, 14, 117–124. [Google Scholar] [CrossRef]

- Pietrzak, P.; Wolkiewicz, M. Demagnetization Fault Diagnosis of Permanent Magnet Synchronous Motors Based on Stator Current Signal Processing and Machine Learning Algorithms. Sensors 2023, 23, 1757. [Google Scholar] [CrossRef]

- BS EN 1011-2; Welding—Recommendations for Welding of Metallic Materials, Part 2: Arc Welding of Ferritic Steels. European Standards: London, UK, 2001.

- MatWeb, Material Property Data. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=afc003f4fb40465fa3df05129f0e88e6&ckck=1 (accessed on 14 June 2023).

- Merchant, S.Y. Investigation on Effect of Heat Input on Cooling Rate and Mechanical Property (Hardness) of Mild Steel Weld Joint by MMAW Process. Int. J. Mod. Eng. Res. 2015, 5, 34–41. [Google Scholar]

- Adams, C.M. Cooling rate and peak temperature in fusion welding. Weld. J. 1958, 37, 210S–215S. [Google Scholar]

- Paulonis, D.F.; Oblak, J.M.; Duvall, D.S. Precipitation in Nickel-Base Alloy 718. Trans. ASM 1969, 62, 611–622. [Google Scholar]

- Dupont, J.N.; Marder, A.R. Thermal Efficiency of Arc Welding Processes. Weld. Res. Suppl. 1995, 74, 406s. [Google Scholar]

| Chemical Composition wt.% | ||||||

|---|---|---|---|---|---|---|

| C | Mn | Si | Cu | P | S | CEv |

| 0.270 | 1.030 | 0.270 | 0.100 | 0.020 | 0.015 | 0.45 |

| Material Insert | Element | wt.% | Element | wt.% |

|---|---|---|---|---|

| Alloy 718 | Ni + Co | 50–55 | Mn | 0.35 max |

| Cr | 17–21 | Si | 0.35 max | |

| Nb + Ta | 4.75–5.5 | P | 0.015 max | |

| Ti | 0.65–1.15 | S | 0.015 max | |

| Al | 0.2–0.8 | B | 0.006 max | |

| Co | 1.00 max | Cu | 0.30 max | |

| C | 0.08 max | Fe | Balance | |

| Material insert | Element | wt.% | Element | wt.% |

| CMSX-4 | Cr | 6.5 | Al | 5.6 |

| Co | 9.6 | Ti | 1.0 | |

| W | 6.4 | Ta | 6.5 | |

| Re | 3.0 | Hf | 0.1 | |

| Mo | 0.6 | Ni | Balance | |

| Material insert | Element | wt.% | Element | wt.% |

| EN8 * | C | 0.36–0.44 | Cr | - |

| Si | 0.1–0.4 | Mo | - | |

| Mn | 0.6–1.0 | Ni | - | |

| S | 0.05 max | Fe | Remainder |

| Current (I) | Wire Feed Speed (m/min) | Arc Voltage (U) | Power (kW) | Efficiency Factor k | Velocity (mm/s) υ | Hnet (kJ/mm) |

|---|---|---|---|---|---|---|

| 186.00 | 9.20 | 22.50 | 4.18 | 0.80 | 8.00 | 0.42 |

| Welding Parameters (2 Decimal Places) | |||||||

|---|---|---|---|---|---|---|---|

| Insert Material | Current (I) | Voltage (U) | Wire Feed Speed (m/min) | Power (kW) | Thermal Efficiency k | Velocity (υ) mm/s | Hnet (kJ/mm) |

| N/A | 186.00 | 22.50 | 9.20 | 4.18 | 0.80 | 8.00 | 0.42 |

| Alloy 718 | 171.00 | 22.30 | 9.20 | 3.81 | 0.80 | 8.00 | 0.38 |

| CMSX-4 | 131.00 | 22.80 | 9.20 | 2.99 | 0.80 | 8.00 | 0.30 |

| EN8 | 118.00 | 21.90 | 9.20 | 2.58 | 0.80 | 8.00 | 0.26 |

| Approximate Composition of the Final Weld (2 Decimal Places) | Dilution % | |||||||

|---|---|---|---|---|---|---|---|---|

| Material | Cr | Mo | Si | Fe | Ni | C | Mn | |

| 307Si | 12.95 | 0.07 | 0.70 | 45.71 | 5.95 | 0.07 | 4.55 | 70 |

| Baseplate | 0.00 | 0.00 | 0.08 | 29.53 | 0.00 | 0.08 | 0.31 | 30 |

| Totals | 12.95 | 0.07 | 0.78 | 75.24 | 5.95 | 0.15 | 4.86 | |

| 307Si | 9.24 | 0.05 | 0.50 | 32.65 | 4.25 | 0.05 | 3.25 | 50 |

| Baseplate | 0.00 | 0.00 | 0.04 | 14.77 | 0.00 | 0.04 | 0.16 | 15 |

| EN8 | 0.00 | 0.00 | 0.09 | 34.49 | 0.00 | 0.14 | 0.28 | 35 |

| Totals | 9.24 | 0.05 | 0.63 | 81.91 | 4.25 | 0.23 | 3.69 | |

| 307Si | 9.24 | 0.05 | 0.50 | 32.65 | 4.25 | 0.05 | 3.25 | 50 |

| Baseplate | 0.00 | 0.00 | 0.04 | 14.76 | 0.00 | 0.04 | 0.16 | 15 |

| Alloy 718 | 6.65 | 0.00 | 0.05 | 7.21 | 18.38 | 0.01 | 0.05 | 35 |

| Totals | 15.89 | 0.05 | 0.59 | 54.62 | 22.63 | 0.10 | 3.46 | |

| 307Si | 9.24 | 0.05 | 0.50 | 32.65 | 4.25 | 0.05 | 3.25 | 50 |

| Baseplate | 0.00 | 0.00 | 0.04 | 14.77 | 0.00 | 0.04 | 0.16 | 15 |

| CMSX-4 | 2.28 | 0.21 | 0.00 | 0.00 | 20.89 | 0.00 | 0.00 | 35 |

| Totals | 11.52 | 0.26 | 0.54 | 47.42 | 25.14 | 0.09 | 3.40 | |

| Average Rise Time Parameter for AE Contact Sensor | ||||

|---|---|---|---|---|

| Insert Material | Max Rise Time (µS) | Min Rise Time (µS) | Standard Deviation | % Difference SD from Max RT |

| N/A | 25,360 | 1 | 1829 | 7.2% |

| Alloy 718 | 31,628 | 1 | 2607 | 8.2% |

| CMSX-4 | 28,422 | 1 | 2716 | 9.5% |

| EN8 | 30,225 | 1 | 2688 | 8.9% |

| Average STFT Energy Utilisation for Airborne Sensor | ||

|---|---|---|

| Insert Material | Frequency Band Utilisation | Percentage Amplitude Energy Utilisation |

| N/A | Partial | 30% |

| Alloy 718 | Full | 50% |

| CMSX-4 | Almost Full: 90 kHz | 40% |

| EN8 | Full | 60% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Griffin, J.M.; Jones, S.; Perumal, B.; Perrin, C. Investigating the Detection Capability of Acoustic Emission Monitoring to Identify Imperfections Produced by the Metal Active Gas (MAG) Welding Process. Acoustics 2023, 5, 714-745. https://doi.org/10.3390/acoustics5030043

Griffin JM, Jones S, Perumal B, Perrin C. Investigating the Detection Capability of Acoustic Emission Monitoring to Identify Imperfections Produced by the Metal Active Gas (MAG) Welding Process. Acoustics. 2023; 5(3):714-745. https://doi.org/10.3390/acoustics5030043

Chicago/Turabian StyleGriffin, James Marcus, Steven Jones, Bama Perumal, and Carl Perrin. 2023. "Investigating the Detection Capability of Acoustic Emission Monitoring to Identify Imperfections Produced by the Metal Active Gas (MAG) Welding Process" Acoustics 5, no. 3: 714-745. https://doi.org/10.3390/acoustics5030043

APA StyleGriffin, J. M., Jones, S., Perumal, B., & Perrin, C. (2023). Investigating the Detection Capability of Acoustic Emission Monitoring to Identify Imperfections Produced by the Metal Active Gas (MAG) Welding Process. Acoustics, 5(3), 714-745. https://doi.org/10.3390/acoustics5030043