Diffusion Barriers for Electrodes in Resistance Spot Welding of Aluminum Alloys—Investigation of Coating Characteristics Using Nanoindentation and SEM Analysis

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

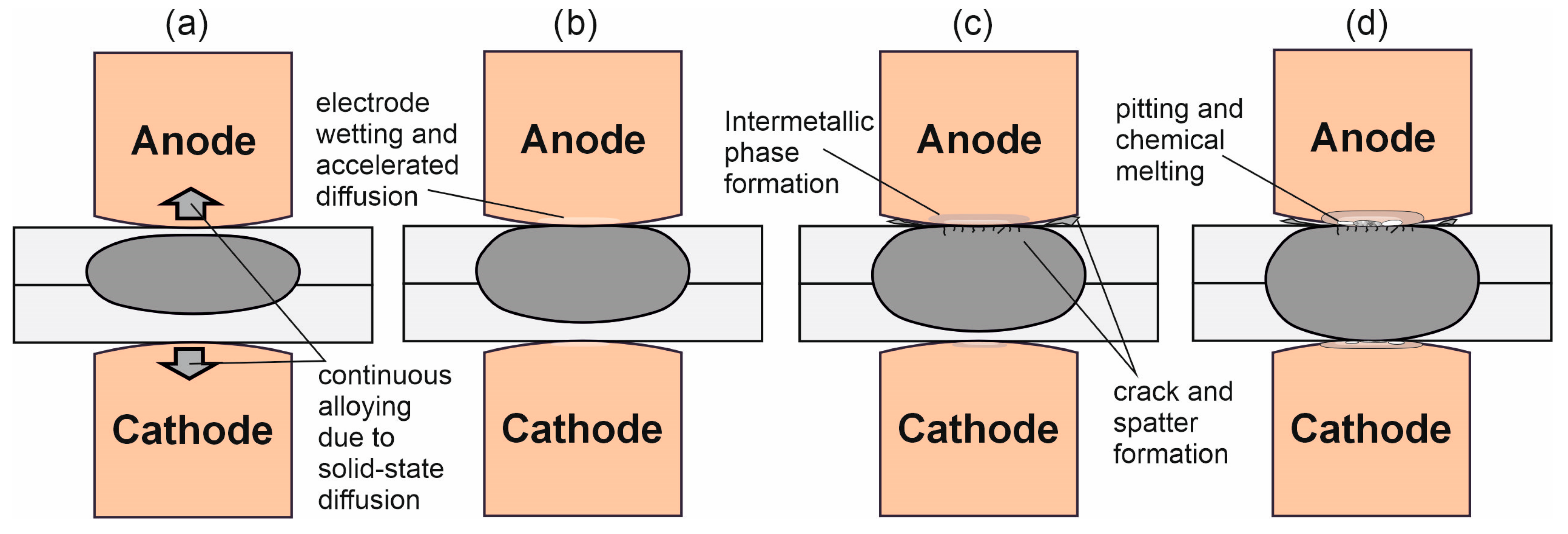

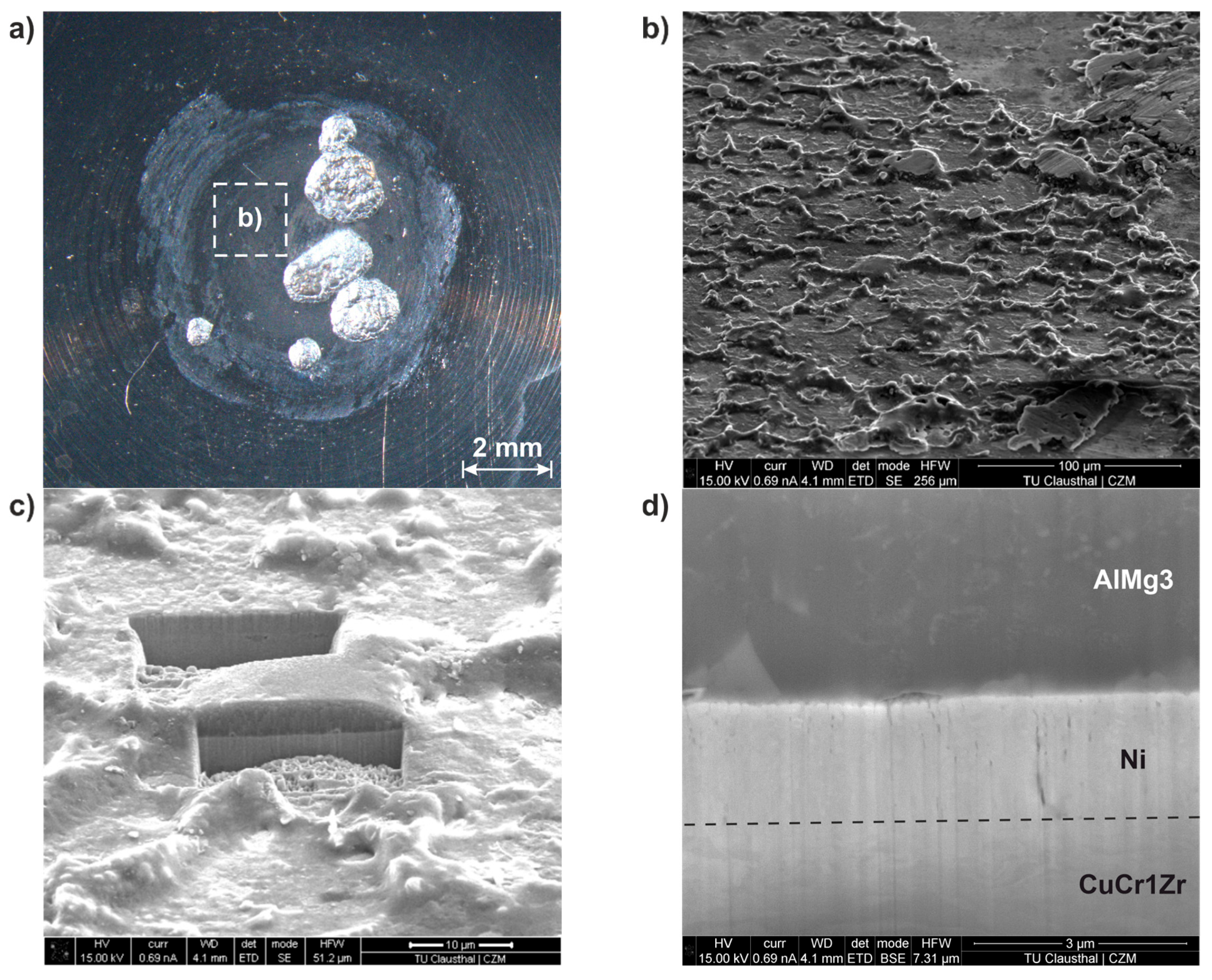

3.1. Resistance Spot Welding—Electrode Degradation

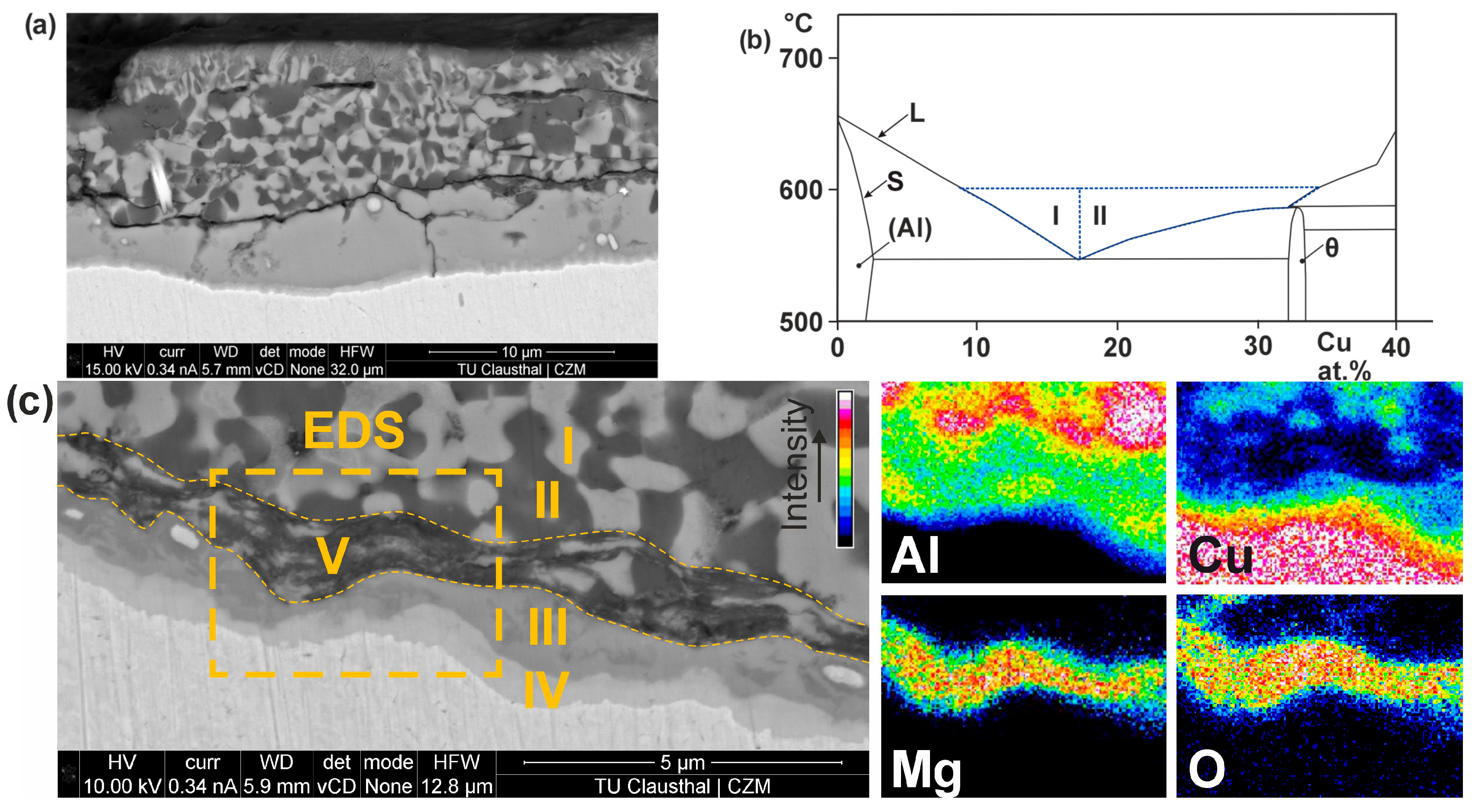

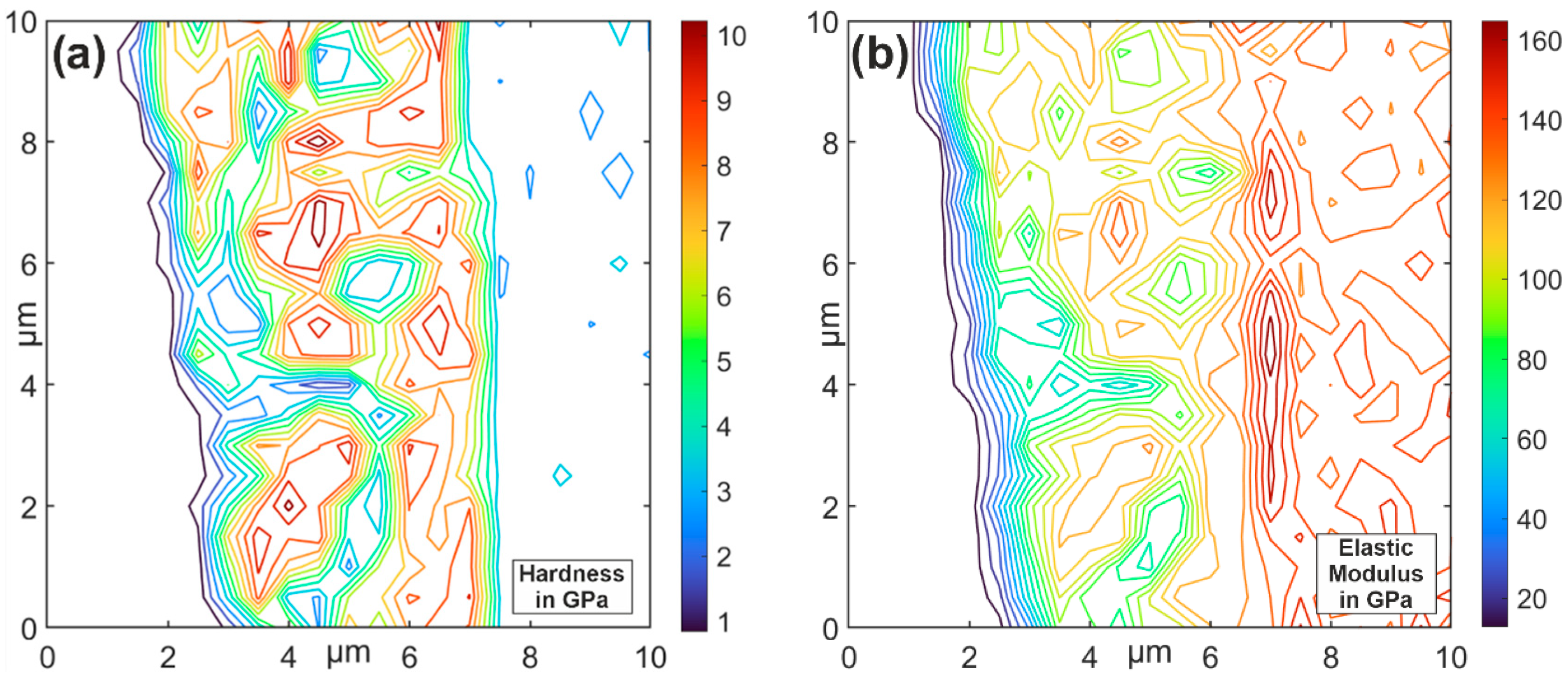

3.2. Analysis of the Electrode Degradation by Nanoindentation

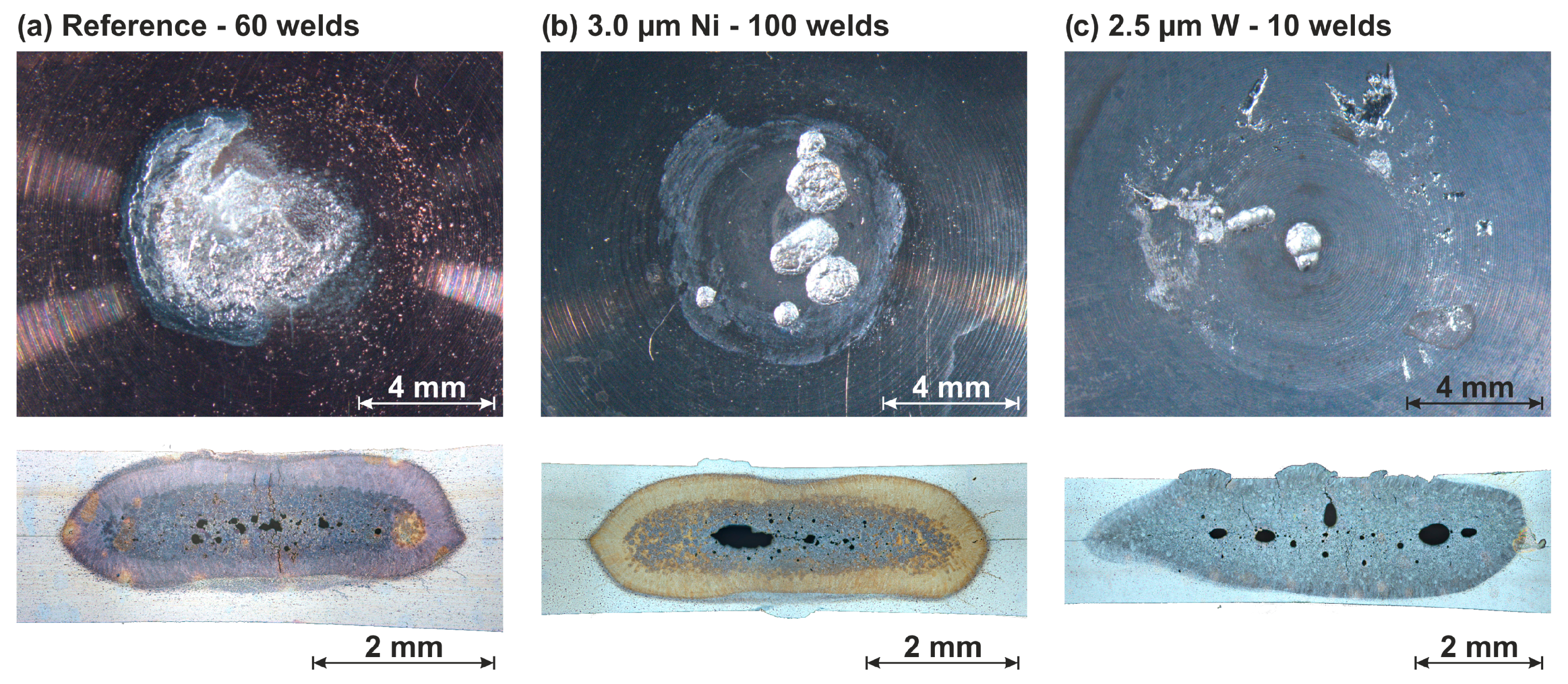

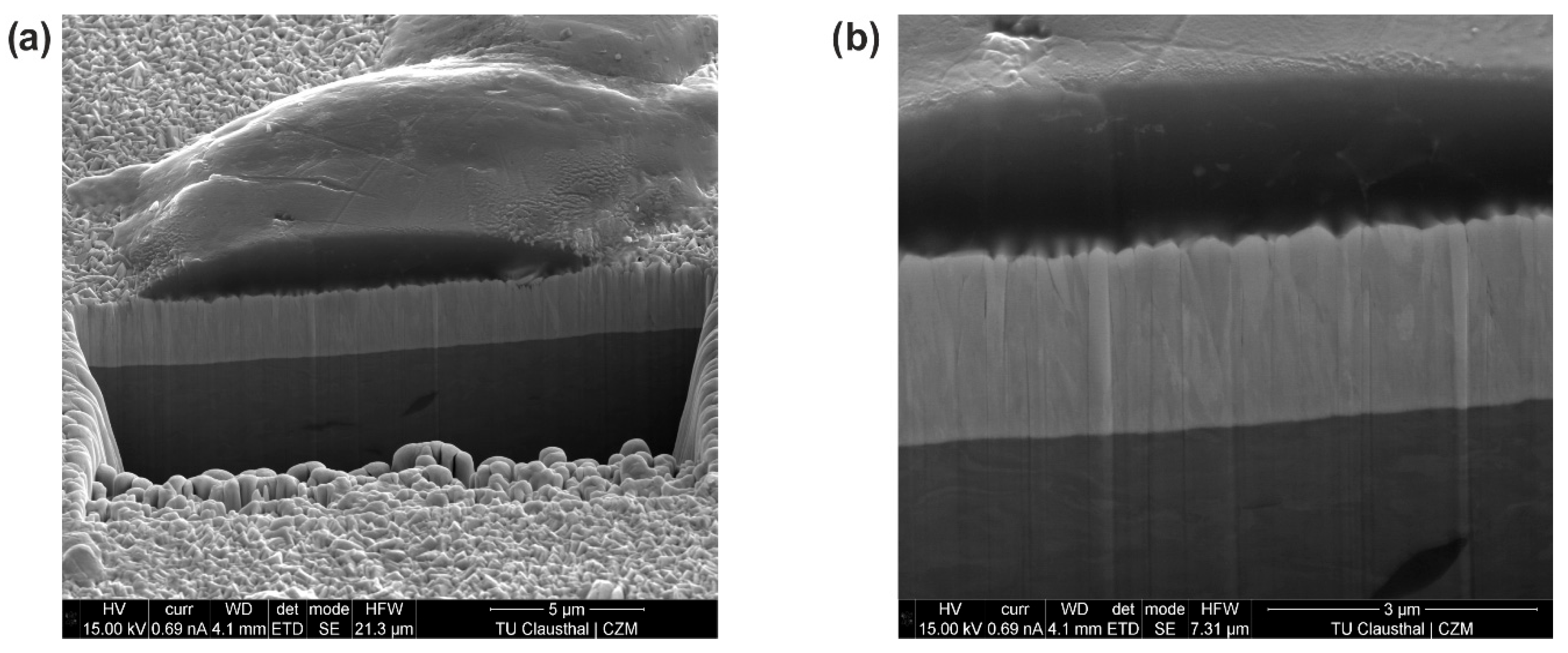

3.3. Thin-Film Diffusion Barriers in Resistance Spot Welding

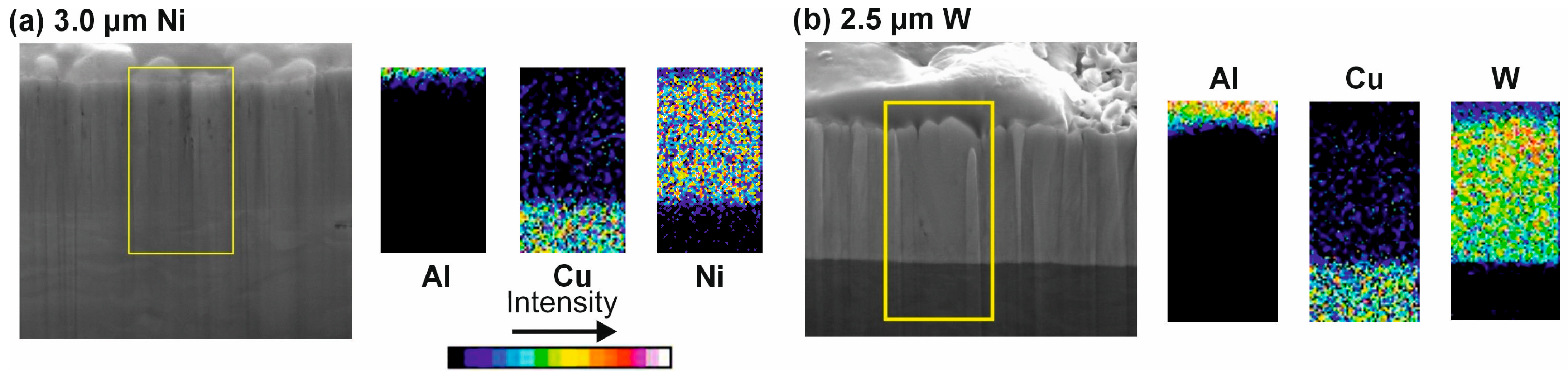

3.4. Influence of Aluminum Adhesion on the Diffusion Barriers

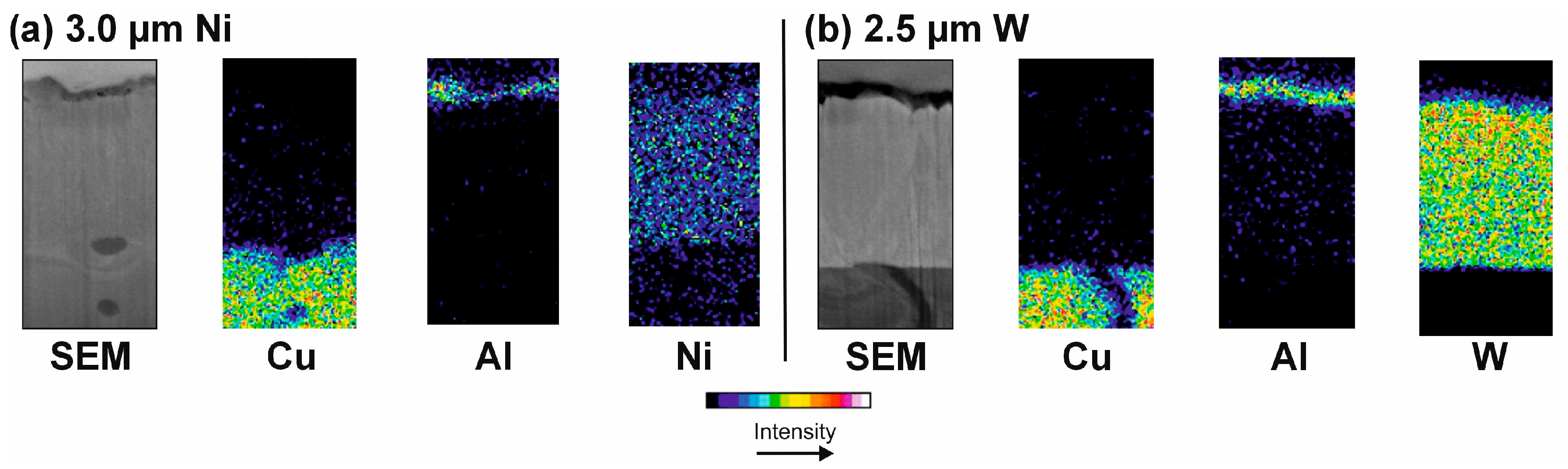

3.5. Diffusion Experiments

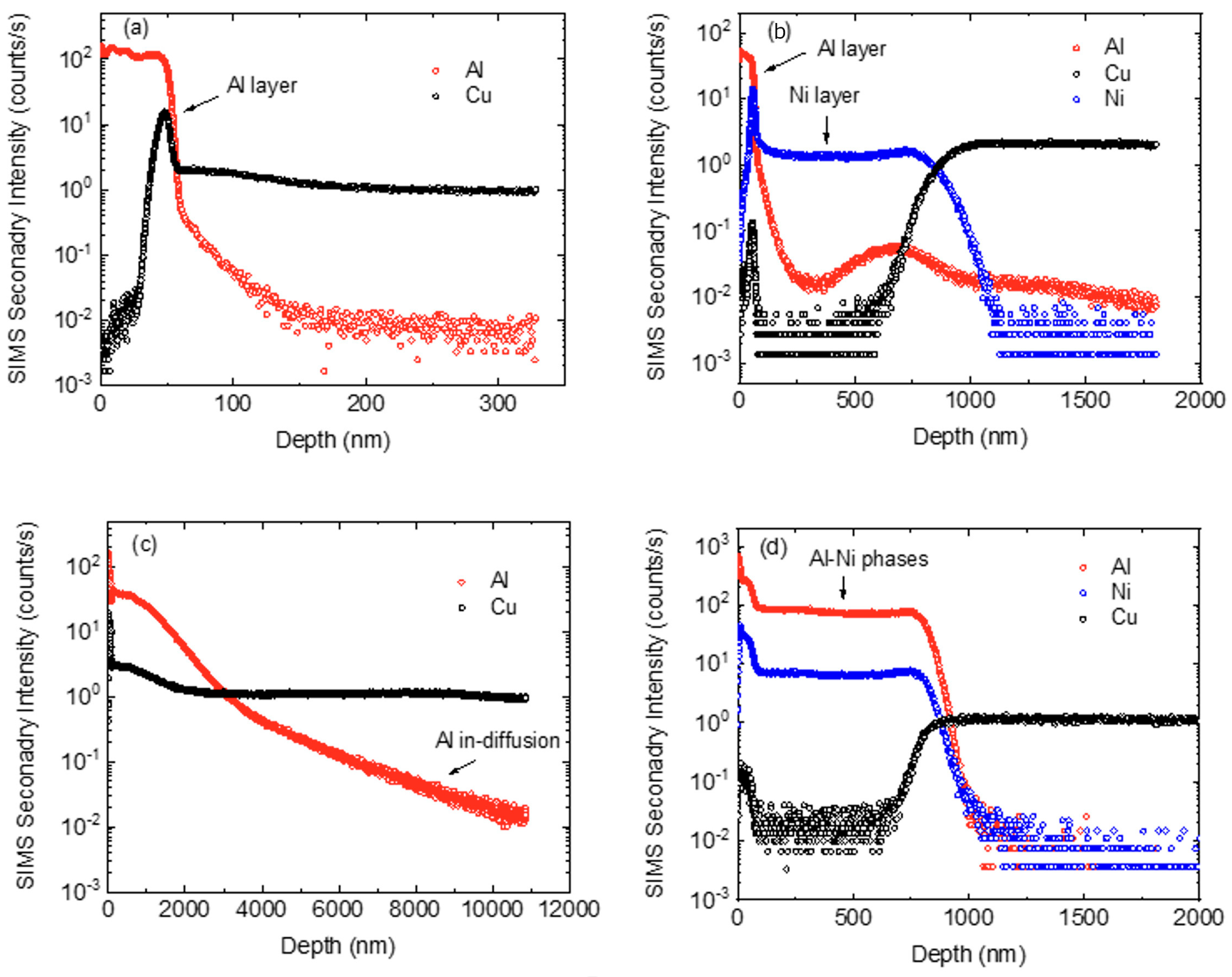

4. Conclusions

- In the area of intermetallic phase formation, the δ and Θ phases were detected.

- The hardness of the intermetallic phase boundary is 7.3–8.7 GPa, and the modulus of elasticity is up to 158.9 GPa.

- The hardness of the unaffected electrode material CuCr1Zr is 2.9 GPa, and the modulus of elasticity is 135.6 GPa.

- In order to differentiate between the mechanical properties of the two intermetallic phases, reduced measurement distances < 500 nm will be required for nanoindentation in the future.

- The contact resistance between the reference electrode CuCr1Zr and an AlMg3 sheet material is 210 µOhm.

- An additional diffusion barrier reduces the contact resistance noticeably—83 µOhm (Ni) and 55 µOhm (W).

- The coefficient of friction of the reference electrode CuCr1Zr is 0.24.

- Additional diffusion barriers reduce the friction coefficient to 0.15 (W) and 0.16 (Ni).

- The hardness and elasticity moduli of the barriers are 18.5 GPa and 394.1 GPa (W); 6.7 GPa and 180.3 GPa (Ni).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DC | direct current |

| EDX | energy dispersive X-ray spectroscopy |

| L | liquid state |

| PVD | physical vapor deposition |

| S | solid state |

| SEM | scanning electron microscope |

| SIMS | secondary ion mass spectrometry |

| SPM | scanning probe microscopy |

| t | sheet thickness |

References

- Hirsch, J. Aluminium in Innovative Light-Weight Car Design. Mater. Trans. 2011, 52, 818–824. [Google Scholar] [CrossRef]

- Fukumoto, S.; Lum, I.; Biro, E.; Boomer, D.R.; Zhou, Y. Effects of Electrode Degradation on Electrode Life in Resistance Spot Welding of Aluminum Alloy 5182. Weld. J. 2003, 82, 307S–312S. [Google Scholar]

- Chang, B.H.; Du, D.; Chen, Q.; Zhou, Y. Studies on Effects of Pitting Morphology in Resistance Spot Welding of Aluminium Alloy. Sci. Technol. Weld. Join. 2007, 12, 67–72. [Google Scholar] [CrossRef]

- Lum, I.; Fukomoto, S.; Biro, E.; Boomer, D.R.; Zhou, Y. Electrode Pitting in Resistance Spot Welding of Aluminum Alloy 5182. Metall. Mater. Trans. A 2004, 35, 2217–2226. [Google Scholar] [CrossRef]

- Manladan, S.M.; Yusof, F.; Ramesh, S.; Fadzil, M.; Luo, Z.; Ao, S. A review on resistance spot welding of aluminum alloys. Int. J. Adv. Manuf. Technol. 2017, 90, 605–634. [Google Scholar] [CrossRef]

- Patrick, E.P.; Auhl, J.R.; Sun, T.S. Understanding the Process Mechanisms Is Key to Reliable Resistance Spot Welding Aluminum Auto Body Components. SAE Trans. 1984, 93, 435–448. [Google Scholar]

- Kunze, S. Beitrag zur Erhöhung der Prozesssicherheit beim Punktschweißen und Punktschweißkleben von Aluminiumkarosseriewerkstoffen; Berichte aus dem Laboratorium für Werkstoff- und Fügetechnik; Shaker: Aachen, Germany, 2014; Volume 100, ISBN 978-3-8440-2456-2. [Google Scholar]

- Schulz, E.; Mahjoubi, A.; Wagner, M.; Schubert, H.; Balasubramanian, B.; Brewer, L.N. Electrode Wear in Short-Pulse Resistance Spot Welding of Aluminum AA 6016-T4. Weld. World 2021, 65, 127–141. [Google Scholar] [CrossRef]

- Han, L.; Thornton, M.; Boomer, D.; Shergold, M. Effect of Aluminium Sheet Surface Conditions on Feasibility and Quality of Resistance Spot Welding. J. Mater. Process. Technol. 2010, 210, 1076–1082. [Google Scholar] [CrossRef]

- Liu, Q.; Li, Y.; Mao, X.; Zhao, P. Study on life of resistance spot welding copper electrode of 5182-H111 aluminum alloy for automobile. MW Met. Form. 2025, 7, 52–62. [Google Scholar]

- Gáspár, M.; Dobosy, Á.; Tisza, M.; Török, I.; Dong, Y.; Zheng, K. Improving the Properties of AA7075 Resistance Spot-Welded Joints by Chemical Oxide Removal and Post Weld Heat Treating. Weld. World 2020, 64, 2119–2128. [Google Scholar] [CrossRef]

- Rashid, M.; Fukumoto, S.; Medley, J.; Villafuerte, J.; Zhou, Y. Influence of Lubricants on Electrode Life in Resistance Spot Welding of Aluminum Alloys. Weld. J. 2007, 86, 62–70. [Google Scholar]

- Bamberg, P.; Seewald, R.; Schiebahn, A.; Reisgen, U.; Precoma, N.; Epperlein, M. Improvement of the Resistance Spot Welding of Al-Mg-Si Alloys by Using Cladding Technology: An Optical and Mechanical Characterization Study. J. Adv. Join. Process. 2022, 5, 100090. [Google Scholar] [CrossRef]

- Heilmann, S.; Baumgarten, M.; Koal, J.; Zschetzsche, J.; Füssel, U. Electrode Wear Investigation of Aluminium Spot Welding by Motion Overlay. Int. J. Adv. Manuf. Technol. 2022, 123, 749–760. [Google Scholar] [CrossRef]

- Heilmann, S.; Tulke, M.; Mathiszik, C.; Baumgarten, M.; Koal, J.; Brosius, A.; Füssel, U.; Schmale, H.C. Extending the Life of Aluminum Spot Welding Electrodes through Oxide Layer Disruption. Weld. World 2025. [Google Scholar] [CrossRef]

- Heilmann, S.; Zwahr, C.; Knape, A.; Zschetzsche, J.; Lasagni, A.F.; Füssel, U. Improvement of the Electrical Conductivity between Electrode and Sheet in Spot Welding Process by Direct Laser Interference Patterning. Adv. Eng. Mater. 2018, 20, 1700755. [Google Scholar] [CrossRef]

- Li, M.; Wang, Y.; Yang, S.; Tao, W.; Zhang, G. Improving Mechanical Properties and Electrode Life for Joining Aluminum Alloys with Innovatively Designated Newton Ring Electrode. J. Manuf. Process. 2021, 64, 948–959. [Google Scholar] [CrossRef]

- Brechelt, S.; Wiche, H.; Junge, J.; Gustus, R.; Schmidt, H.; Wesling, V. Increase of Electrode Life in Resistance Spot Welding of Aluminum Alloys by the Combination of Surface Patterning and Thin-Film Diffusion Barriers. Weld. World 2023, 67, 2703–2714. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, Y.; Bai, J.; Yang, S.; Zhu, Z.; Li, Q. Mechanism of Pitting-Adhesion Coupling in Aluminum Alloy Resistance Spot Welding Electrodes and Optimization of Asymmetric Electrode Configuration. J. Mater. Process. Technol. 2025, 342, 118942. [Google Scholar] [CrossRef]

- Park, H.; Kumar, D.; Park, K.; Nam, K.S.; Kim, Y.; Kim, Y.-M.; Lee, T. Electrode Life Evaluation for Varied Electrode Material Composition and Geometry in Resistance Spot Welding of Aluminum Alloys. Weld. World 2024, 68, 2701–2712. [Google Scholar] [CrossRef]

- Gradinger, R.; Sotirov, N.; Rettenbacher, G.; Pangerl, C.; Dörner, P.; Minichshofer, S.; Becirovic, A.; Melzer, C.; Uffelmann, D. High Strength Aluminium Sheet Metal Joining by Resistance Spot Welding. Mater. Sci. Forum 2013, 765, 761–765. [Google Scholar] [CrossRef]

- Chan, K.R.; Scotchmer, N.S. Quality and Electrode Life Improvements to Automotive Resistance Welding of Aluminum Sheet. In Proceedings of the Sheet Metal Welding Conference XIII., Livonia, MI, USA, 14–16 May 2008. [Google Scholar]

- Luo, P.; Dong, S.J.; Mei, Z.Q.; Xie, Z.X. Strengthening Mechanism of TiB2-TiC Complex Phases Coated Electrode. Adv. Mater. Res. 2012, 433–440, 251–255. [Google Scholar] [CrossRef]

- Luo, P.; Dong, S.; Yangli, A.; Sun, S.; Zheng, Z. Electrospark Deposition of ZrB2-TiB2 Composite Coating on Cu-Cr-Zr Alloy Electrodes. Int. J. Surf. Sci. Eng. 2016, 10, 41–54. [Google Scholar] [CrossRef]

- Luo, P.; Dong, S.; Yangli, A.; Sun, S.; Zheng, Z.; Wang, H. Electrospark Deposition of Al2O3–TiB2/Ni Composite-Phase Surface Coatings on Cu–Cr–Zr Alloy Electrodes. J. Asian Ceram. Soc. 2015, 3, 103–107. [Google Scholar] [CrossRef]

- Glagola, M.; Roest, C. Nickel Plated Electrodes for Spot Welding Aluminum. SAE Trans. 1976, 85, 780–794. [Google Scholar] [CrossRef]

- Hedenqvist, P.; Jacobson, S.; Hogmark, S. Tribological PVD Coatings—Characterisation of Mechanical Properties. Surf. Coat. Technol. 1997, 97, 212–217. [Google Scholar] [CrossRef]

- Tayebi, N.; Polycarpou, A.A.; Conry, T.F. Effects of Substrate on Determination of Hardness of Thin Films by Nanoscratch and Nanoindentation Techniques. J. Mater. Res. 2004, 19, 1791–1802. [Google Scholar] [CrossRef]

- Wang, X.; Xu, P.; Han, R.; Ren, J.; Li, L.; Han, N.; Xing, F.; Zhu, J. A Review on the Mechanical Properties for Thin Film and Block Structure Characterised by Using Nanoscratch Test. Nanotechnol. Rev. 2019, 8, 628–644. [Google Scholar] [CrossRef]

- Saha, R.; Nix, W.D. Effects of the Substrate on the Determination of Thin Film Mechanical Properties by Nanoindentation. Acta Mater. 2002, 50, 23–38. [Google Scholar] [CrossRef]

- Mao, A.; Zhang, J.; Yao, S.; Wang, A.; Wang, W.; Li, Y.; Qiao, C.; Xie, J.; Jia, Y. The Diffusion Behaviors at the Cu-Al Solid-Liquid Interface: A Molecular Dynamics Study. Results Phys. 2020, 16, 102998. [Google Scholar] [CrossRef]

- Yang, C.-W. Tensile Mechanical Properties and Failure Behaviors of Friction Stir Processing (FSP) Modified Mg-Al-Zn and Dual-Phase Mg-Li-Al-Zn Alloys. In Materials Science—Advanced Topics; IntechOpen: London, UK, 2013; ISBN 978-953-51-1140-5. [Google Scholar] [CrossRef]

- Zobac, O.; Kroupa, A.; Zemanova, A.; Richter, K.W. Experimental Description of the Al-Cu Binary Phase Diagram. Metall. Mater. Trans. A 2019, 50, 3805–3815. [Google Scholar] [CrossRef]

- Bauer, C.L.; Lessmann, G.G. Metal-Joining Methods. Annu. Rev. Mater. Sci. 1976, 6, 361–387. [Google Scholar] [CrossRef]

- Divinski, S.V.; Herzig, C. Ni Tracer Self-Diffusion, Interdiffusion and Diffusion Mechanisms in NiAl. Defect Diffus. Forum 2002, 203, 177–192. [Google Scholar] [CrossRef]

- Frank, S.T.; Södervall, U.; Herzig, C. Self-Diffusion of Ni in Single and Polycrystals of Ni3Al. A Study of SIMS and Radiotracer Analysis. Phys. Status Solidi B 1995, 191, 45–55. [Google Scholar] [CrossRef]

- Romig, A.D., Jr. Interdiffusion in β phase Cu–Al alloys. J. Appl. Phys. 1983, 54, 3172–3175. [Google Scholar] [CrossRef]

- Neumann, G. Self-Diffusion and Impurity Diffusion in Pure Metals: Handbook of Experimental Data, 1st ed.; Pergamon Materials Series; Pergamon: Amsterdam, The Netherlands, 2009. [Google Scholar]

| Electrode Force | Squeeze Time | Current | Weld Time | Hold Time |

|---|---|---|---|---|

| 6 kN | 300 ms | 19.5 kA | 60 ms | 300 ms |

| Experiments | Melted Sheet Surface | Cracking of Sheet Surface | Weld Spatter | Electrode Sticking (End of Electrode Life) |

|---|---|---|---|---|

| Run 1 | 2 | 14 | 26 | 63 |

| Run 2 | 2 | 8 | 30 | 58 |

| Run 3 | 2 | 10 | 29 | 60 |

| (worst case) | 2 | 8 | 26 | 58 |

| CuCr1Zr | +Ni 3.0 µm | +W 2.5 µm | |

|---|---|---|---|

| Hardness in GPa | 3.7 | 6.7 | 18.5 |

| Modulus of Elasticity in GPa | 140.4 | 180.3 | 394.1 |

| Friction Coefficient in µN/µN | 0.24 | 0.16 | 0.15 |

| Electrical Resistance in µOhm | 210 | 55 | 83 |

| Thermal Conductivity in W/(m∙K) | |||

| RT (25 °C) | 300.3 | 227.9 | 183.8 |

| 200 °C | 353.5 | 275.7 | 194.3 |

| 400 °C | 368.4 | 285.1 | 204.0 |

| 600 °C | 378.9 | 302.6 | 218.3 |

| Diffusion Barrier | Electrode Force | Squeeze Time | Current | Weld Time | Hold Time |

|---|---|---|---|---|---|

| Ni 3.0 µm | 6 kN | 300 ms | 21.1 kA | 60 ms | 300 ms |

| W 2.5 µm | 6 kN | 300 ms | 21.1 kA | 60 ms | 300 ms |

| Experiments | Melted Sheet Surface | Cracking of Sheet Surface | Weld Spatter | Electrode Sticking (End of Electrode Life) |

|---|---|---|---|---|

| Ni 3.0 µm | 37 | 95 | - | 108 |

| W 2.5 µm | 1 | 1 | 1 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brechelt, S.; Wiche, H.; Junge, J.; Gustus, R.; Schmidt, H.; Wesling, V. Diffusion Barriers for Electrodes in Resistance Spot Welding of Aluminum Alloys—Investigation of Coating Characteristics Using Nanoindentation and SEM Analysis. Surfaces 2025, 8, 81. https://doi.org/10.3390/surfaces8040081

Brechelt S, Wiche H, Junge J, Gustus R, Schmidt H, Wesling V. Diffusion Barriers for Electrodes in Resistance Spot Welding of Aluminum Alloys—Investigation of Coating Characteristics Using Nanoindentation and SEM Analysis. Surfaces. 2025; 8(4):81. https://doi.org/10.3390/surfaces8040081

Chicago/Turabian StyleBrechelt, Sascha, Henning Wiche, Jochen Junge, René Gustus, Harald Schmidt, and Volker Wesling. 2025. "Diffusion Barriers for Electrodes in Resistance Spot Welding of Aluminum Alloys—Investigation of Coating Characteristics Using Nanoindentation and SEM Analysis" Surfaces 8, no. 4: 81. https://doi.org/10.3390/surfaces8040081

APA StyleBrechelt, S., Wiche, H., Junge, J., Gustus, R., Schmidt, H., & Wesling, V. (2025). Diffusion Barriers for Electrodes in Resistance Spot Welding of Aluminum Alloys—Investigation of Coating Characteristics Using Nanoindentation and SEM Analysis. Surfaces, 8(4), 81. https://doi.org/10.3390/surfaces8040081