Cochineal Reds in Iberia and France: A Comparative Study of 18th Century Tin-Mordant Recipes to Dye Wool

Abstract

1. Introduction

1.1. The Royal Manufacture of Covilhã

1.2. Historical Sources on Scarlet Dyeing

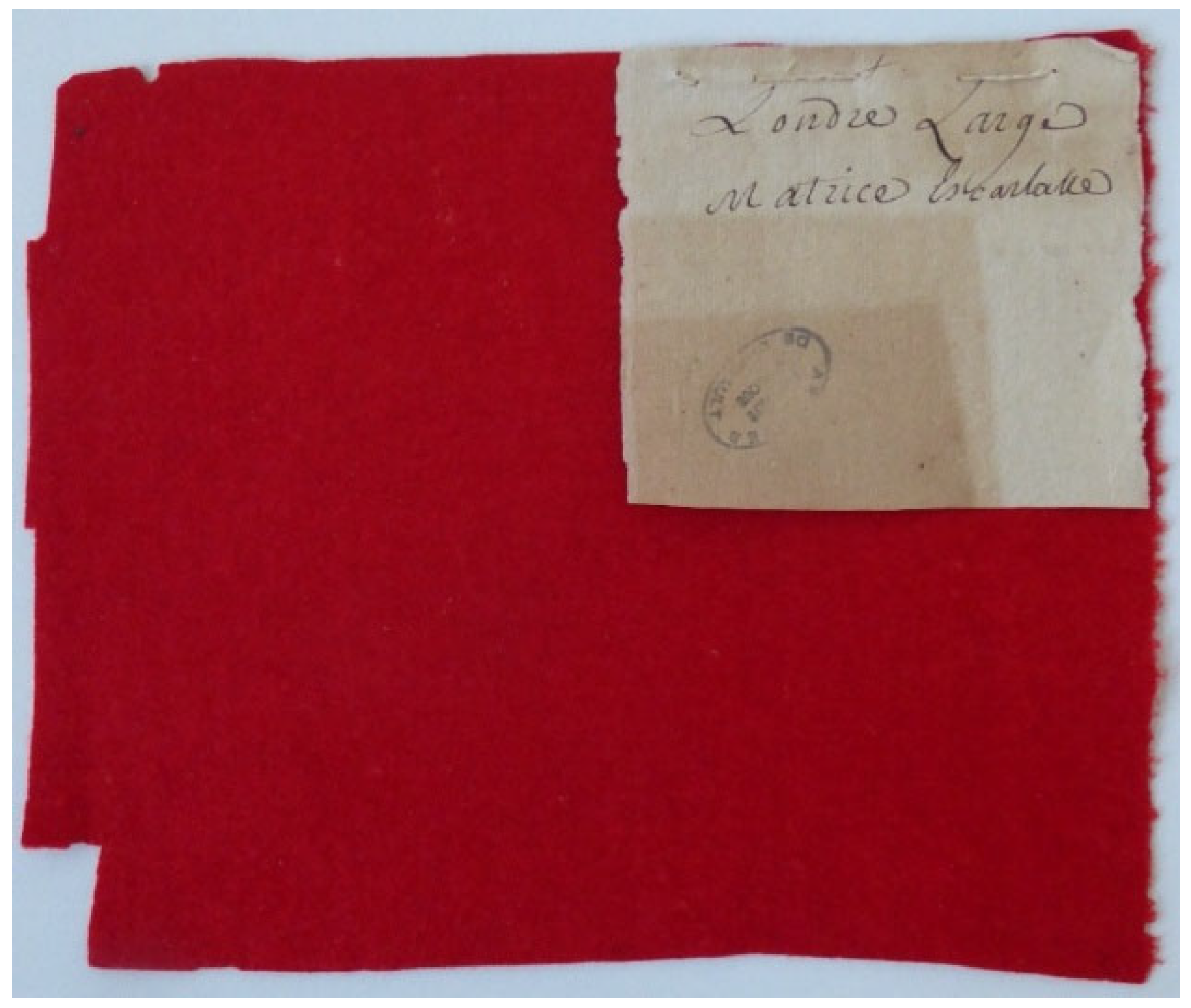

1.2.1. French Sources

1.2.2. Spanish Sources

1.3. Scarlet Reds

2. Materials and Methods

2.1. The Historical Sources

- Title: Memoir—on the processes of dyeing the colours that are consumed in the Levant in the good and fast mode of dyeing, with the quantities and qualities of the drugs from which they are obtained (Mémoire—on trouvera les operations de la teinture du grand et bon teint des couleurs qui se consomment en Levant avec la quantité et qualité des drogues qui les composent). Year: 1744. Author: Antoine Janot; manuscript in Archives départementales de l’Hérault, Montpellier, France, reference C/5569, https://archivespierresvves.herault.fr/ark:/37279/vta4c4f2666d9aa0cef/daogrp/0/111 (accessed on 4 September 2025). Edition: D. Cardon, Des Couleurs pour les Lumières—Vie et Oeuvres d’Antoine Janot (1700–1778). Paris: CNRS Editions, 2019 [11].

- Title: Memoirs on Dyeing (Mémoires de teinture). Year: 1763. Author: Paul Gout; manuscript, private collection. Edition: D. Cardon, Mémoires de teinture—Voyage dans le temps chez un maître des couleurs. Paris: CNRS Editions, 2013; translation into English: D. Cardon, The Dyer’s Handbook—Memoirs of an 18th century Master Colourist. Oxford and Philadelphia: Oxbow Books, 2016; new ed. 2020 [14].

- Title: Instructive and Practical Treatise on the Art of Dyeing: Tried and methodical rules for dyeing silks, wools, threads of all kind, and raw esparto (Tratado instructivo, y práctico sobre el arte de la tintura: Reglas experimentadas y metódicas para tintar sedas, lanas, hilos de todas clases, y esparto en rama). Year: 1778. Author: Luis Fernandez. Place: Madrid; Publisher, Imprenta de Blas Roman.

- Title: The Art of Dyeing Wool, Silks, Threads and Practice of Dyeing, and all that pertains to it. Volume I (Arte de teñir las lanas, sedas, hilo, y algodon, ò Compendio Universal de la teorica, y practica de la tintura, y quanto a ella corresponde. Tomo I). Year: 1779. Author: Miguel Jerónimo Suárez y Nuñes; Place_ Madrid; Publisher: Imprenta de Pedro Marin.Conversions were based on Manuel Carrera Stampa’s article: “The Evolution of Weights and Measures in New Spain” (1949) [48].

2.2. The Materials

2.3. Analytical Techniques

2.3.1. Colourimetry

2.3.2. pH Measurements

2.4. The Recipes

2.5. The Methodology

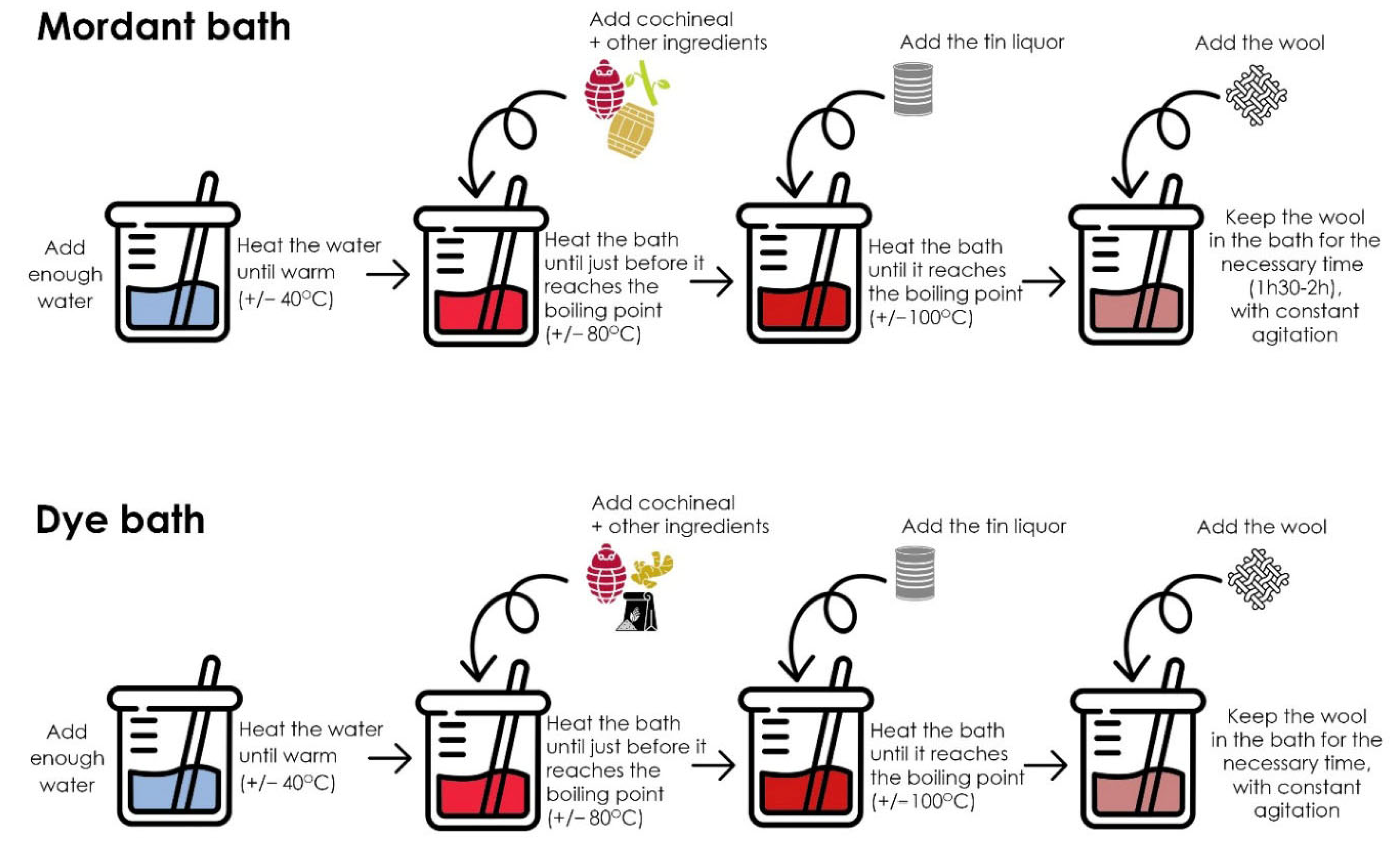

2.5.1. The Mordanting

2.5.2. The Dyeing

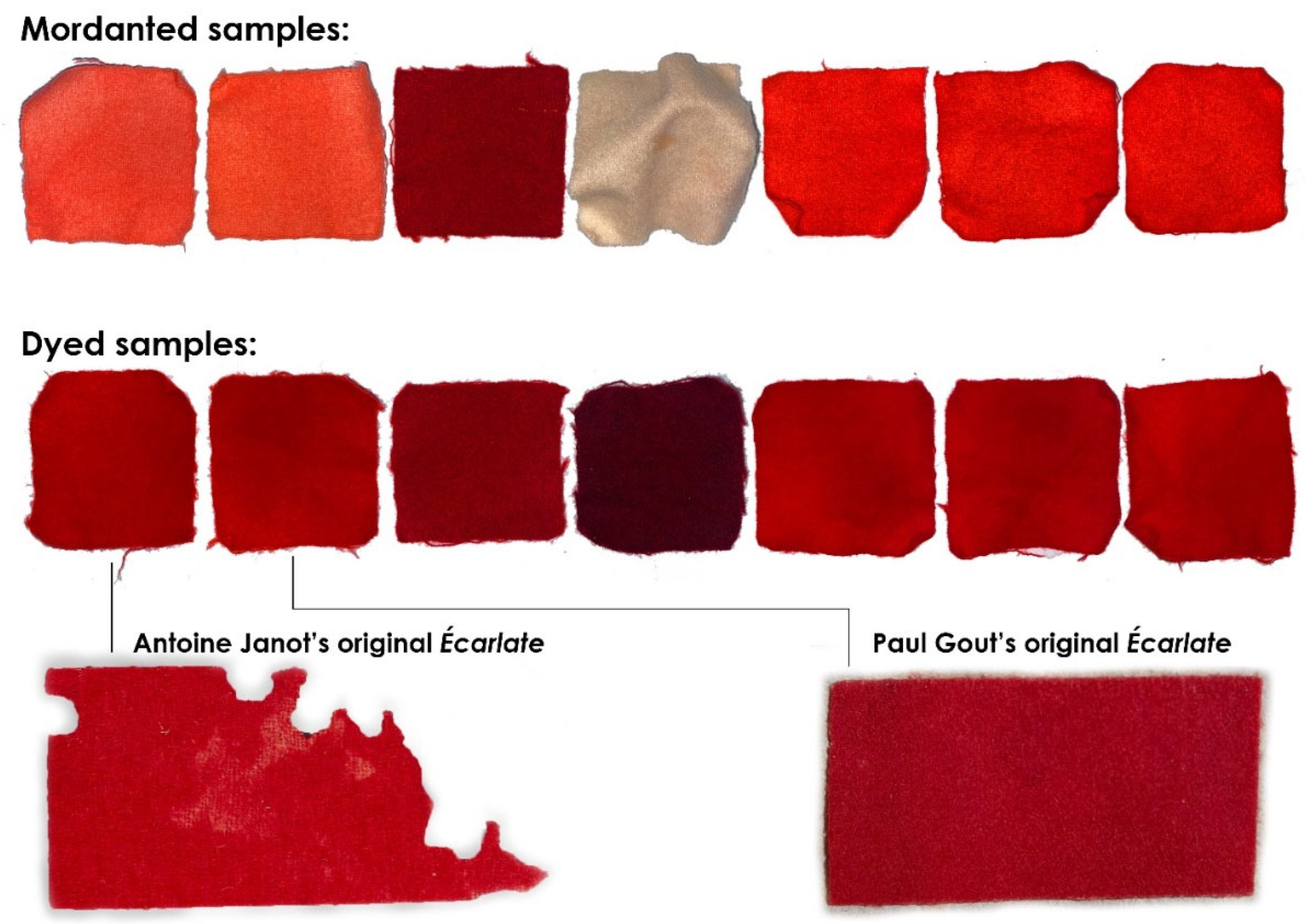

3. Results & Discussion

3.1. Comparative Study of the Recipes

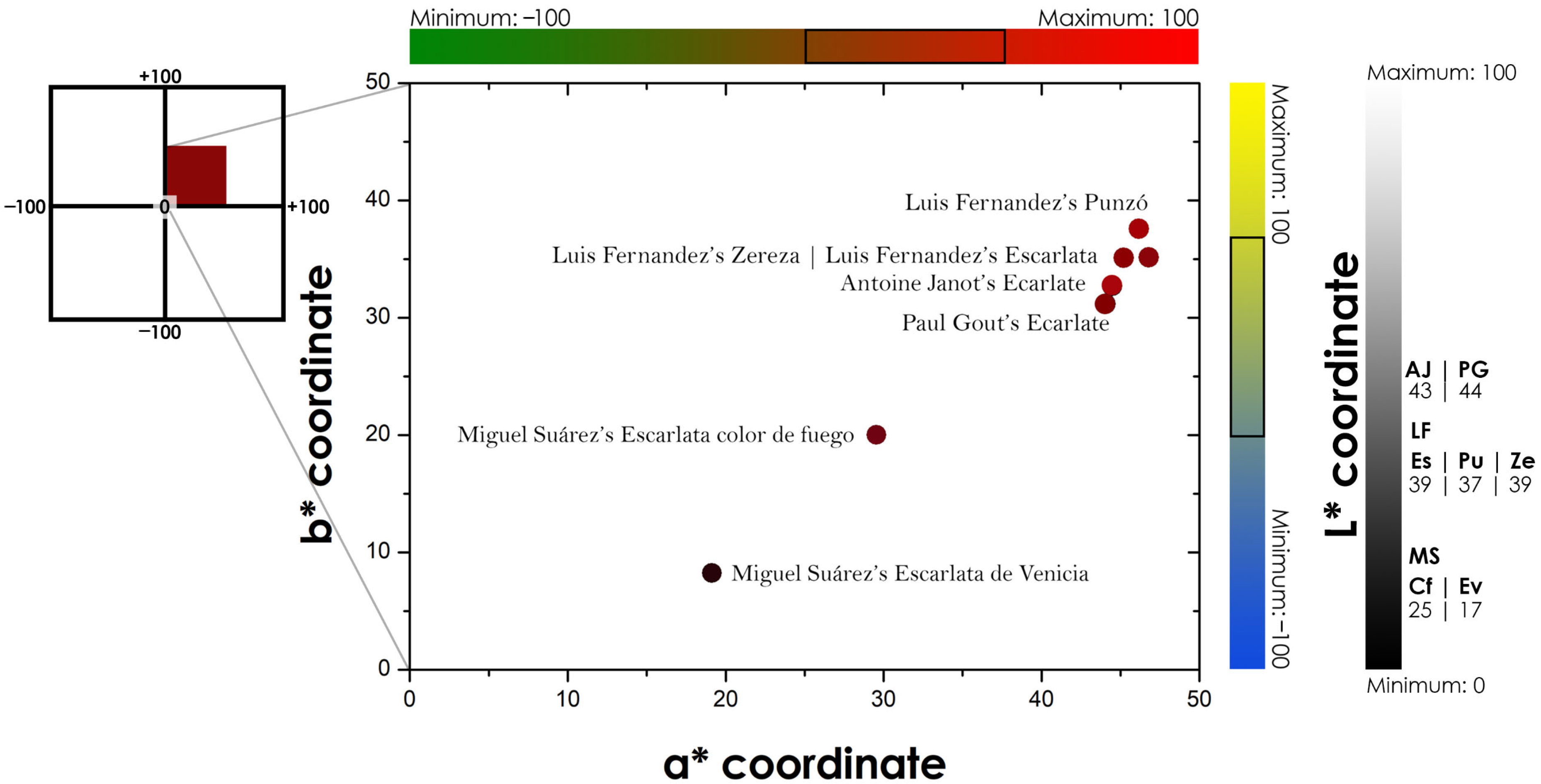

3.2. Analysis of the Reconstructions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

| 1 | Secretary of State for Internal Affairs between 1756 and 1777. In 1770, he received the title of Marquis of Pombal. He is particularly well known for coordinating the reconstruction of downtown Lisbon according to Enlightenment ideas after the earthquake of 1 November 1755. |

| 2 | Translation by the authors, from Father Manuel Cabral de Pina in 1734 [1]. |

| 3 | Arquivo Nacional Torre do Tombo (ANTT), Condes de Linhares, mç. 16, doc. 41. This document was uncovered by Manuel Conceição, a grantee from UBI under the supervision of Rita Salvado, during the archival research carried out as part of the REVIVE project. |

| 4 | All the mordant baths, from the recipes reconstructed, were made separately. |

| 5 | The cochineal used was grounded beforehand, as well as the tartar, to ensure a homogeneous colouring from the start. |

| 6 | Tin chloride was used as a substitute for the tin liquor (a toxic solution); since this is a much-concentrated compound, a reduction of 97% was calculated. |

| 7 | The samples measure 6 × 6 cm, and weigh about 1.20 g. |

| 8 | All the dye baths, from the recipes reconstructed, were made separately. |

References

- Pinheiro, E.C. A Real Fábrica de Panos, um marco histórico na paisagem industrial e cultural da Covilhã. Ubimuseum Rev. Online Museu Lanifícios Univ. Beira Inter. 2017, 4, 136–184. [Google Scholar]

- Ministério da Cultura e Coordenação Científica—Instituto Português do Património Cultural. In Decreto. no 28-82, de Fevereiro de 1982; Diário da República; Imprensa Nacional-Casa da Moeda: Lisboa, Portugal, 1982; pp. 424–430. Available online: https://diariodarepublica.pt/dr/detalhe/decreto/28-1982-600294 (accessed on 27 March 2025).

- Pinheiro, E.C. A Covilhã: Uma paisagem cultural evolutiva. Algumas notas sobre a (re)construção das memórias industriais da cidade. Ubimuseum Rev. Online Museu Lanifícios Univ. Beira Inter. 2012, 1, 53–72. [Google Scholar]

- Dias, L.F.C. História dos Lanifícios (1750–1834); Lisboa, Portugal, 1965; Volume 3. [Google Scholar]

- Pedreira, J. A Indústria in História Económica de Portugal: 1143-2010; Lains, P., Miranda, S.M., Eds.; Esfera dos Livros: Lisboa, Portugal, 2011; pp. 177–208. [Google Scholar]

- Pereira, A.D.S. Produzir na Covilhã: Da feitoria mercantil do século XVI à Real Fábrica de Panos do século XVIII e à presença local de estrangeiros e de representantes do poder central. Ubimuseum Rev. Online Museu Lanifícios Univ. Beira Inter. 2017, 4, 30–41. [Google Scholar]

- Pinheiro, E.C. Da Real Fábrica ao Museu de Lanifícios. In Catálogo do Museu de Lanifícios da Universidade da Beira Interior: Núcleo da Tinturaria da Real Fábrica de Panos; Universidade da Beira Interior, Museu de Lanifícios: Covilhã, Portugal, 1998; pp. 16–38. [Google Scholar]

- Custódio, J. A Tinturaria Pombalina. In Catálogo do Museu de Lanifícios da Universidade da Beira Interior: Núcleo da Tinturaria da Real Fábrica de Panos; Universidade da Beira Interior, Museu de Lanifícios: Covilhã, Portugal, 1998; pp. 93–97. [Google Scholar]

- Costa, M.A.N. Francisco Mailhol, um francês na Indústria Portuguesa do século XVIII. Callipole Rev. Cultu. 1997, 5/6, 103–119. [Google Scholar]

- Tillerot, I. JULLIENNE Jean de (FR). Collectionneurs, Collecteurs et Marchands d’art Asiatique en France 1700–1939. Available online: http://agorha.inha.fr/detail/316 (accessed on 15 June 2025).

- Cardon, D. Des Couleurs Pour Les Lumières—Antoine Janot, Teinturier Occitan, 1700–1778; CNRS Editions: Paris, France, 2019. [Google Scholar]

- Cardon, D.; Brémaud, I. Les 85 Couleurs d’Antoine Janot/Workbook, Antoine Janot’s 85 Colours; Les Mots qui Portent: Gipcy, France, 2025. [Google Scholar]

- Cardon, D.; Brémaud, I. Les 157 Couleurs de Paul Gout/Paul Gout’s 157 Colours; Vieilles Racines et Jeunes Pousses: Mercin, France, 2023. [Google Scholar]

- Cardon, D. The Dyer’s Handbook: Memoirs of an 18th-Century Master Colourist; Oxbow Books: Oxford, UK; Philadelphia, PA, USA, 2020. [Google Scholar]

- Cardon, D.; Brémaud, I. Le Cahier de Couleurs d’Antoine Janot/Workbook, Antoine Janot’s Colours; CNRS Editions: Paris, France, 2020. [Google Scholar]

- Pérez, M.L. Luis Fernández. Historia Hispánica. Available online: https://historia-hispanica.rah.es/biografias/15721-luis-fernandez (accessed on 16 June 2025).

- Piñal, F.A. Miguel Jerónimo Suárez y Núñez. Historia Hispánica. Available online: https://historia-hispanica.rah.es/biografias/43376-miguel-jeronimo-suarez-y-nunez (accessed on 16 June 2025).

- Pastoureau, M. Rouge, Histoire d’une Couleur; SEUIL: Paris, France, 2016. [Google Scholar]

- Donkin, R.A. Spanish Red: An Ethnogeographical Study of Cochineal and the Opuntia Cactus. Trans. Am. Philos. Soc. 1977, 67, 1–84. [Google Scholar] [CrossRef]

- Melo, M.J. History of Natural Dyes in the Ancient Mediterranean World. In Handbook of Natural Colorants; Bechtold, T., Mussak, R., Eds.; John Wiley & Sons: Chichester, UK, 2009; pp. 3–20. [Google Scholar]

- Kirby, J.; van Bommel, M.; Verhecken, A. Natural dyes and their sources: Plants, insect reds and shellfish purple. In Natural Colorants for Dyeing and Lake Pigments—Practical Recipes and Their Historical Sources; Archetype Publications Ltd.: London, UK, 2014; pp. 9–22. [Google Scholar]

- Tamburini, D. Dyes along the Silk Road. In Textiles and Clothing Along the Silk Roads; Zhao, F., Nosch, M.L., Eds.; UNESCO: Paris, France; China National Silk Museum: Hangzhou, China, 2022; pp. 73–94. [Google Scholar] [CrossRef]

- Serrano, A.F.A. The Red Road of the Iberian Expansion: Cochineal and the Global Dye Trade. Ph.D. Thesis, Universidade Nova de Lisboa, Lisboa, Portugal, 2016. [Google Scholar]

- Donkin, R.A. The Insect Dyes of Western and West-Central Asia. Anthropos 1977, 72, 847–880. [Google Scholar]

- Cardon, D. Natural Dyes. Sources, Tradition, Technology and Science; Archetype Publications Ltd.: London, UK, 2007. [Google Scholar]

- Cardon, D. Le Monde des Teintures Naturelles, 2nd ed; Updated and Augmented; BELIN: Paris, France, 2014. [Google Scholar]

- Ferreira, E. Roteiro do Museu de Lanifícios da Universidade da Beira Interior. In Núcleo da Tinturaria da Real Fábrica de Panos; Museu de Lanifícios: Covilhã, Portugal, 1998; pp. 1–136. [Google Scholar]

- Custódio, J. A Tinturaria dos Panos. In Catálogo do Museu de Lanifícios da Universidade da Beira Interior. Núcleo da Tinturaria da Real Fábrica de Panos; Universidade da Beira Interior, Museu de Lanifícios: Covilhã, Portugal, 1998; pp. 54–58. [Google Scholar]

- Campana, M.G.; García, N.M.R.; Tuross, N. America’s red gold: Multiple lineages of cultivated cochineal in Mexico. Ecol. Evol. 2015, 5, 607–617. [Google Scholar] [CrossRef] [PubMed]

- Van Dam, A.R.; May, B. A new species of Dactylopius Costa (Dactylopius gracilipilus sp. nov.) (Hemiptera: Coccoidea: Dactylopiidae) from the Chihuahuan Desert, Texas, U.S.A. Zootaxa 2012, 3573, 33–39. [Google Scholar] [CrossRef]

- Chávez-Moreno, C.; Casas, A.; Claps, L.E. Distribution and Habitat in Mexico of Dactylopius Costa (Hemiptera: Dactylopiidae) and their Cacti Hosts (Cactaceae: Opuntioideae). Soc. Entomol. Bras. 2011, 1, 62–71. [Google Scholar] [CrossRef]

- Kaur, M. Pharmacological actions of Opuntia ficus indica: A Review. J. Appl. Pharm. Sci. 2012, 2, 15–18. [Google Scholar] [CrossRef]

- Zourgui, L.; Golli, E.E.; Bouaziz, C.; Bacha, H.; Hassen, W. Cactus (Opuntia ficus-indica) cladodes prevent oxidative damage induced by the mycotoxin zearalenone in Balb/C mice. Food Chem. Toxicol. 2008, 46, 1817–1824. [Google Scholar] [CrossRef] [PubMed]

- Wolfe, D.; Baker, H. A farther account of the Polish cochineal. Philos. Trans. 1766, 56, 184–186. [Google Scholar]

- Zhang, Z. The Life Tables of Dactylopius Coccus Costa (Homoptera: Dactylopiidae) at Different Temperatures and Humidities. Agric. For. Fish. 2017, 6, 45. [Google Scholar] [CrossRef]

- Favaro, G.; Miliani, C.; Romani, A.; Vagnini, M. Role of protolytic interactions in photo-aging processes of carminic acid and carminic lake in solution and painted layers. J. Chem. Soc. Perkin Trans. 2 2002, 2, 192–197. [Google Scholar] [CrossRef]

- Vitorino, T. A closer look at nineteenth century cochineal lake pigments through historical recipes reconstructions. Ph.D. Thesis, da Universidade Nova de Lisboa, Monte de Caparica, Portugal, 2020. [Google Scholar]

- Stapelfeldt, H.; Jun, H.; Skibsted, L.H. Fluorescence properties of carminic acid in relation to aggregation, complex formation and oxygen activation in aqueous food models. Food Chem. 1993, 48, 1–11. [Google Scholar] [CrossRef]

- Cañamares, M.V.; Garcia-Ramos, J.V.; Domingo, C.; Sanchez-Cortes, S. Surface-enhanced Raman scattering study of the anthraquinone red pigment carminic acid. Vib. Spectrosc. 2006, 40, 161–167. [Google Scholar] [CrossRef]

- Christie, R.M. Colour Chemistry, 2nd ed.; Royal Society of Chemistry: Cambridge, UK, 2015. [Google Scholar]

- Aragon-Martinez, O.H.; Martinez-Morales, F.; González-Chávez, M.M.; Méndez-Gallegos, S.d.J.; González-Chávez, R.; Posadas-Hurtado, J.C.; Isiordia-Espinoza, M.A. Dactylopius opuntiae [Cockerell] Could Be a Source of Antioxidants for the Preservation of Beef Patties. Insects 2023, 14, 811. [Google Scholar] [CrossRef] [PubMed]

- Stathopoulou, K.; Valianou, L.; Skaltsounis, A.-L.; Karapanagiotis, I.; Magiatis, P. Structure elucidation and chromatographic identification of anthraquinone components of cochineal (Dactylopius coccus) detected in historical objects. Anal. Chim. Acta 2013, 804, 264–272. [Google Scholar] [CrossRef]

- Jørgensen, K.; Skibsted, L.H. Light Sensitivity of Cochineal: Quantum Yields for Photodegradation of Carminic Acid and Conjugate Bases in Aqueous Solution. Food Chem. 1991, 40, 25–34. [Google Scholar] [CrossRef]

- Dapson, R. The history, chemistry and modes of action of carmine and related dyes. Biotech. Histochem. 2007, 82, 173–187. [Google Scholar] [CrossRef]

- Liu, D.; Zhong, Y.; Pu, Y.; Li, X.; Chen, S.; Zhang, C. Preparation of pH-Responsive Films from Polyvinyl Alcohol/Agar Containing Cochineal for Monitoring the Freshness of Pork. Foods 2023, 12, 2316. [Google Scholar] [CrossRef] [PubMed]

- Dapson, R. A method for determining identity and relative purity of carmine, carminic acid and aminocarminic acid. Biotech. Histochem. 2005, 80, 201–205. [Google Scholar] [CrossRef] [PubMed]

- Tierie, G. Cornelis Drebbel (1572–1633), 1 Vols. Amsterdam: H. J. Paris. 1932. Available online: https://www.delpher.nl/nl/boeken/view?objectsearch=1623&coll=boeken&identifier=MMKB21:036863000:00010 (accessed on 4 September 2025).

- Stampa, M.C. The Evolution of Weights and Measures in New Spain. Hisp. Am. Hist. Rev. 1949, 29, 2–24. [Google Scholar] [CrossRef]

| Master/Author: | Recipe Name: | Mordant Bath: | Dye Bath: | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  |  |  |  |  |  |  |  |  | ||

| Cochineal | Tin Liquor | Red Tartar | White Tartar | Alum | Acid Water | Ammoniac Salt | Young Fustic | Remaining Dye Bath * | Cochineal | Tin Liquor | Starch | Alum | Turmeric | Bran | ||

| Janot | Écarlate | 0.5 | 18.5 | 8 | 7 | 9.25 | 8 | |||||||||

| Écarlate de feu | 0.5 | 18.5 | 8 | 4 | 6 | 9.25 | 8 | |||||||||

| Jujube | 0.5 | 18.5 | 8 | 16 | 3 | 9.25 | 8 | |||||||||

| Gout | Écarlate | 0.37 | 22 | 8 | 6.6 | 16 | ||||||||||

| Écarlate 2 | 24 | 8 | Écarlate | 7 | 16 | ? ** | ||||||||||

| Couleur de feu | 16 | 8 | 16 | Écarlate | 6 | 16 | ||||||||||

| Couleur de feu 2 | 16 | 8 | 16 | Couleur de feu | 6 | 20 | ||||||||||

| Fleur de grenade | 2 | 8 | 24 | Écarlate 2 | 5 | 16 | ||||||||||

| Jujube | 12 | 8 | 24 | Écarlate 2 | 4 | 8 | ||||||||||

| Jujube 2 | 16 | 4 | 20 | Pourpre | 3 | 8 | ||||||||||

| Fernández | Escarlata | 3 | 66 | 12.5 | 1.6 | 6 | 33 | |||||||||

| Zereza | 4.7 | 66 | 12.5 | 2 | 6 | 33 | ||||||||||

| Punzó | 4.7 | 66 | 12.5 | 6 | 33 | 1.6 | ||||||||||

| Suárez | Escarlata de Venícia | 10 | 20 | 1/5 | 75 | 0.1 | ||||||||||

| Escarlata color de fuego | 18.8 | 12.5 | 12.5 | 4.7 | 12.5 | 3 | ||||||||||

| Master/ Author: | Recipe Name: | Colour: | Mordant Bath: | Dye Bath: | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|  |  |  |  |  |  | pH * |  |  |  |  |  | pH * | |||

| Cochineal | Tin Liquor | Red Tartar | White Tartar | Alum | Acid Water | Ammoniac Salt | Cochineal | Tin Liquor | Starch | Alum | Turmeric | |||||

| Janot | Écarlate |  | 0.5 | 18.5 | 8 | 3.74 | 7 | 9.25 | 8 | 2.47 | ||||||

| Gout | Écarlate |  | 0.37 | 22 | 8 | 3.69 | 6.6 | 16 | 2.35 | |||||||

| Fernández | Escarlata |  | 3 | 66 | 12.5 | 1.6 | 3.66 | 6 | 33 | 2.46 | ||||||

| Zereza |  | 4.7 | 66 | 12.5 | 2 | 3.51 | 6 | 33 | 2.56 | |||||||

| Punzó |  | 4.7 | 66 | 12.5 | 3.47 | 6 | 33 | 1.6 | 3.03 | |||||||

| Suárez | Escarlata de Venícia |  | 10 | 20 | 1/5 | 1.95 | 75 | 0.1 | 3.38 | |||||||

| Escarlata color de fuego |  | 18.8 | 12.5 | 12.5 | 3.55 | 4.7 | 12.5 | 3 | 3.13 | |||||||

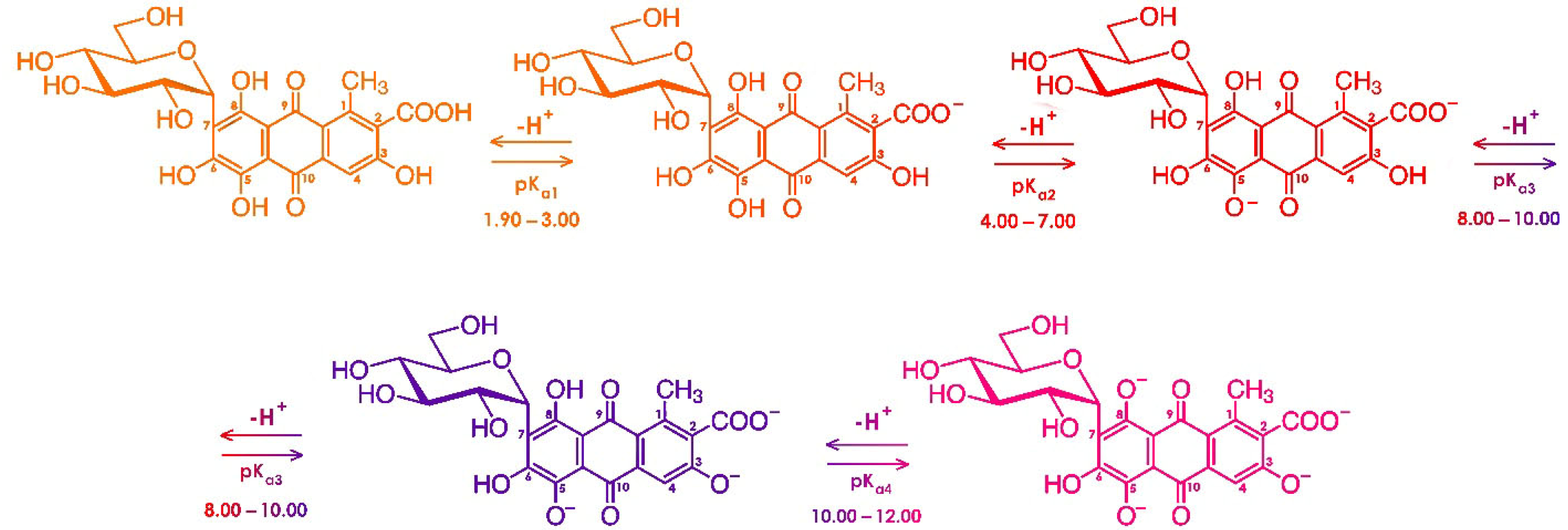

| Species | Charge | pH Range | Deprotonated Groups | Sources |

|---|---|---|---|---|

| CAH5 (Fully Protonated) | 0 | ~1 | None | Vitorino [37], Favaro [36] |

| CA− (Monoanionic) | −1 | ~3 | Carboxyl group (C-2) | Vitorino [37], Cañamares [39] |

| CA2− (Dianionic) | −2 | 4–7 | Carboxyl + one phenol (likely C-8) | Cañamares [39], Vitorino [37] |

| CA3− (Trianionic) | −3 | 9–12 | Carboxyl + two phenols | Cañamares [39], Favaro [36] |

| CA4−/CA5− (Highly Deprotonated) | −4 to −5 | >12 | Most phenolic groups | Vitorino [37], Favaro [36] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Espírito Santo, M.; Díaz Hidalgo, R.; Ferreira, L.G.; Cardon, D.; Sequeira, J.; Otero, V.; Nabais, P. Cochineal Reds in Iberia and France: A Comparative Study of 18th Century Tin-Mordant Recipes to Dye Wool. Heritage 2025, 8, 375. https://doi.org/10.3390/heritage8090375

Espírito Santo M, Díaz Hidalgo R, Ferreira LG, Cardon D, Sequeira J, Otero V, Nabais P. Cochineal Reds in Iberia and France: A Comparative Study of 18th Century Tin-Mordant Recipes to Dye Wool. Heritage. 2025; 8(9):375. https://doi.org/10.3390/heritage8090375

Chicago/Turabian StyleEspírito Santo, Mara, Rafael Díaz Hidalgo, Luís Gonçalves Ferreira, Dominique Cardon, Joana Sequeira, Vanessa Otero, and Paula Nabais. 2025. "Cochineal Reds in Iberia and France: A Comparative Study of 18th Century Tin-Mordant Recipes to Dye Wool" Heritage 8, no. 9: 375. https://doi.org/10.3390/heritage8090375

APA StyleEspírito Santo, M., Díaz Hidalgo, R., Ferreira, L. G., Cardon, D., Sequeira, J., Otero, V., & Nabais, P. (2025). Cochineal Reds in Iberia and France: A Comparative Study of 18th Century Tin-Mordant Recipes to Dye Wool. Heritage, 8(9), 375. https://doi.org/10.3390/heritage8090375