Raw Material and Technological Analysis of Longshan Culture Pottery from the Hui River Basin, Yongcheng, Henan

Abstract

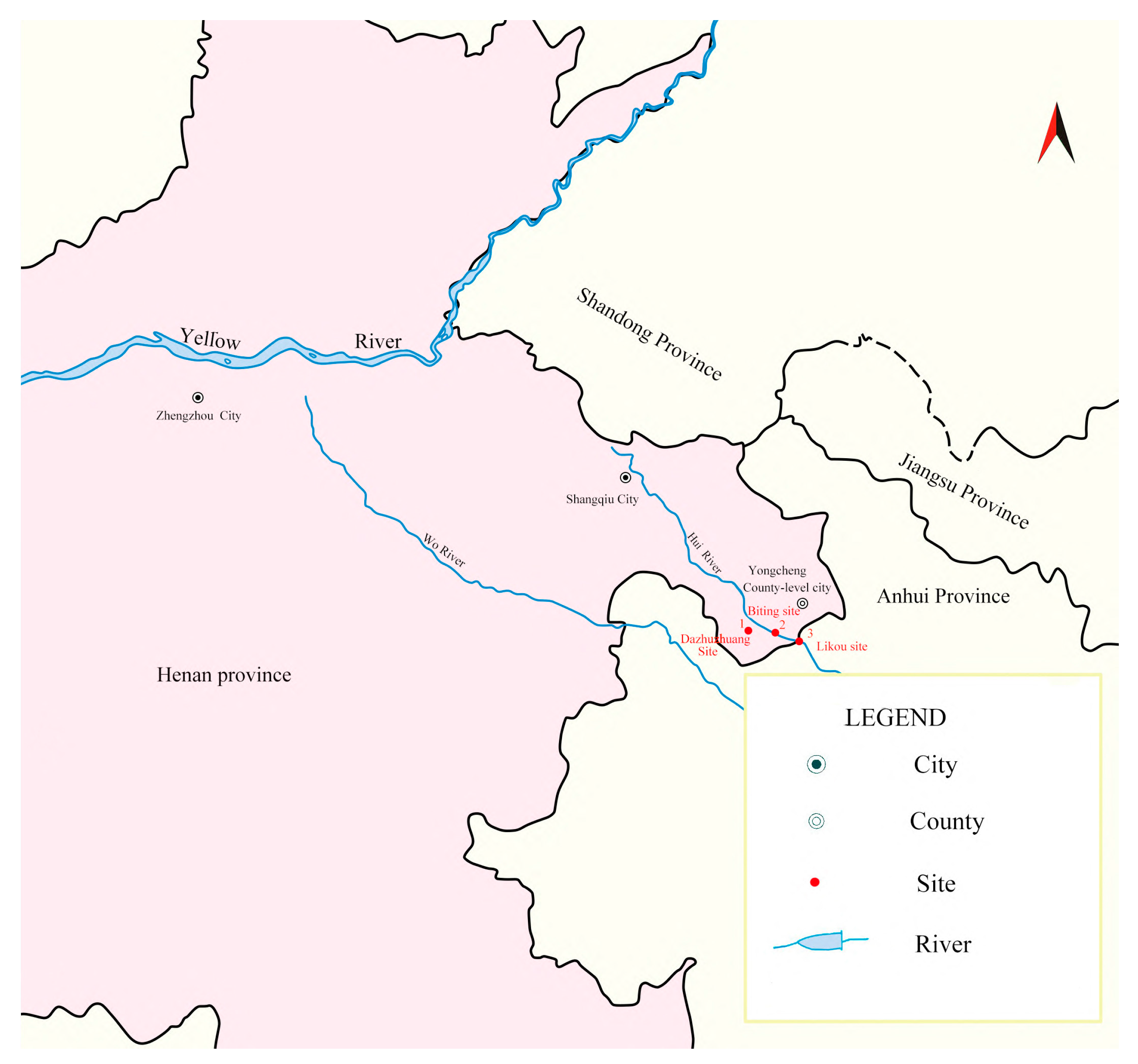

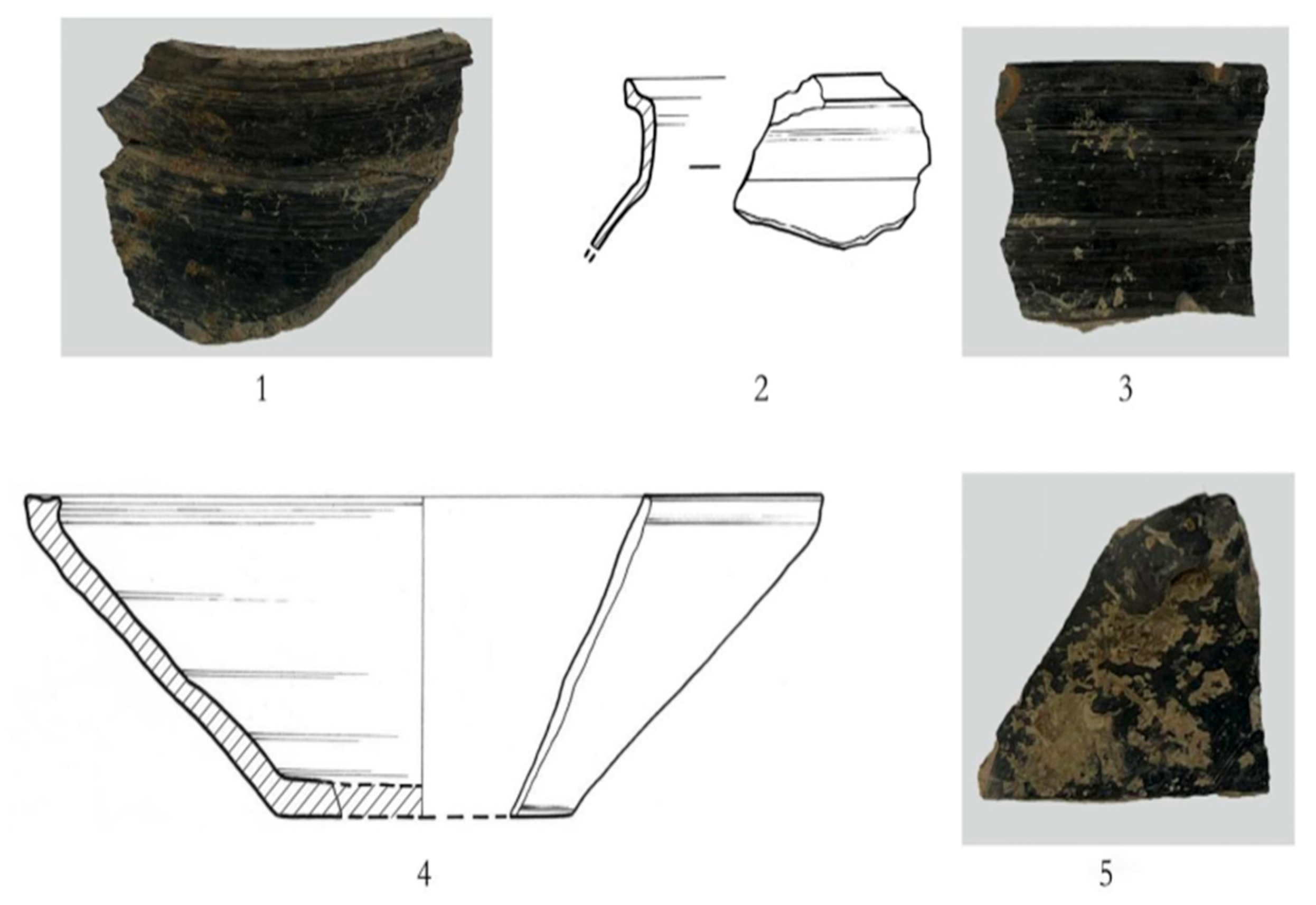

1. Introduction

2. Experimental Part

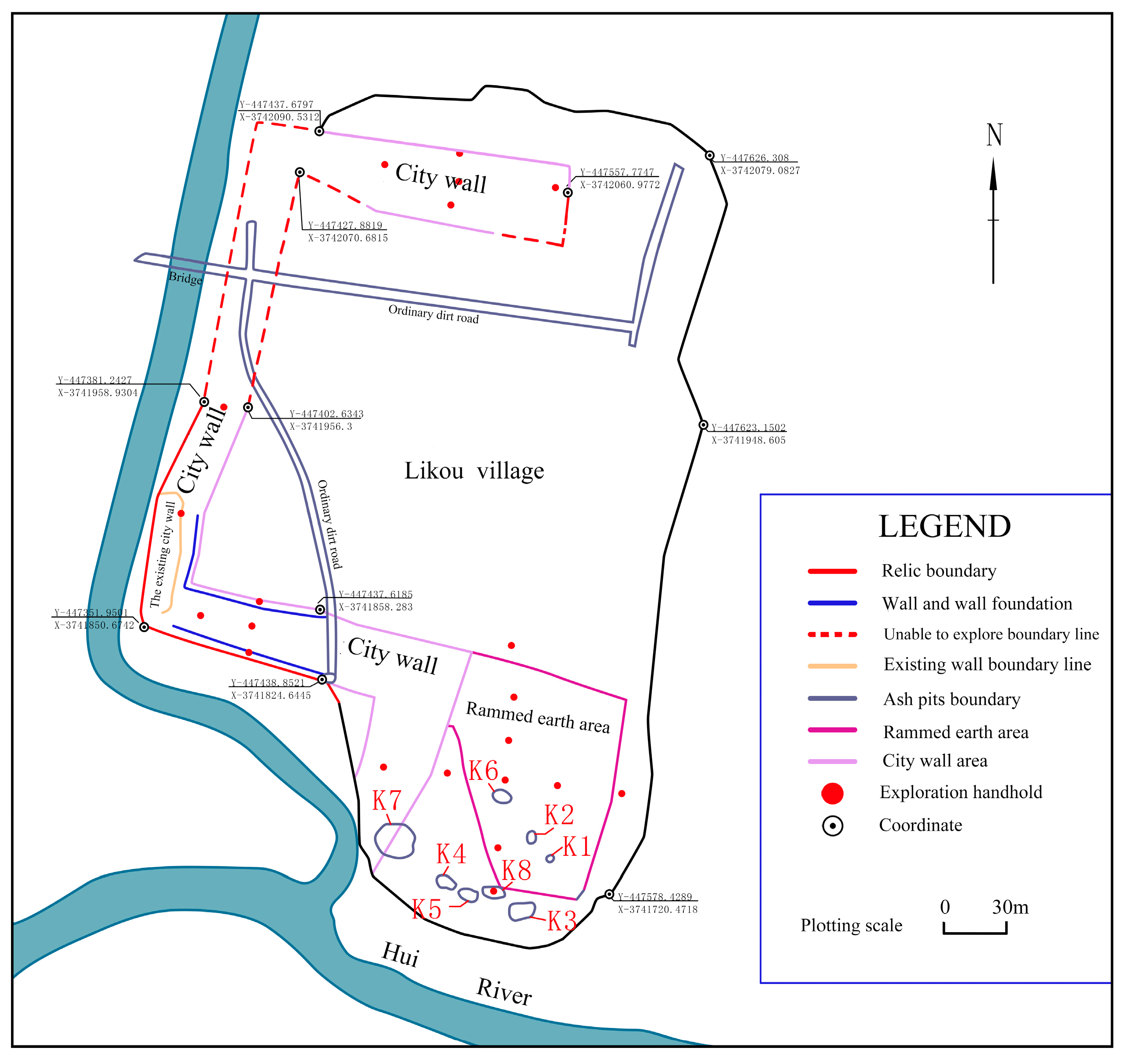

2.1. Sites

2.2. Sample Preparation

2.2.1. Energy-Dispersive X-Ray Fluorescence Analysis

2.2.2. Thermogravimetric Analysis

2.2.3. Scanning Electron Microscopy Test

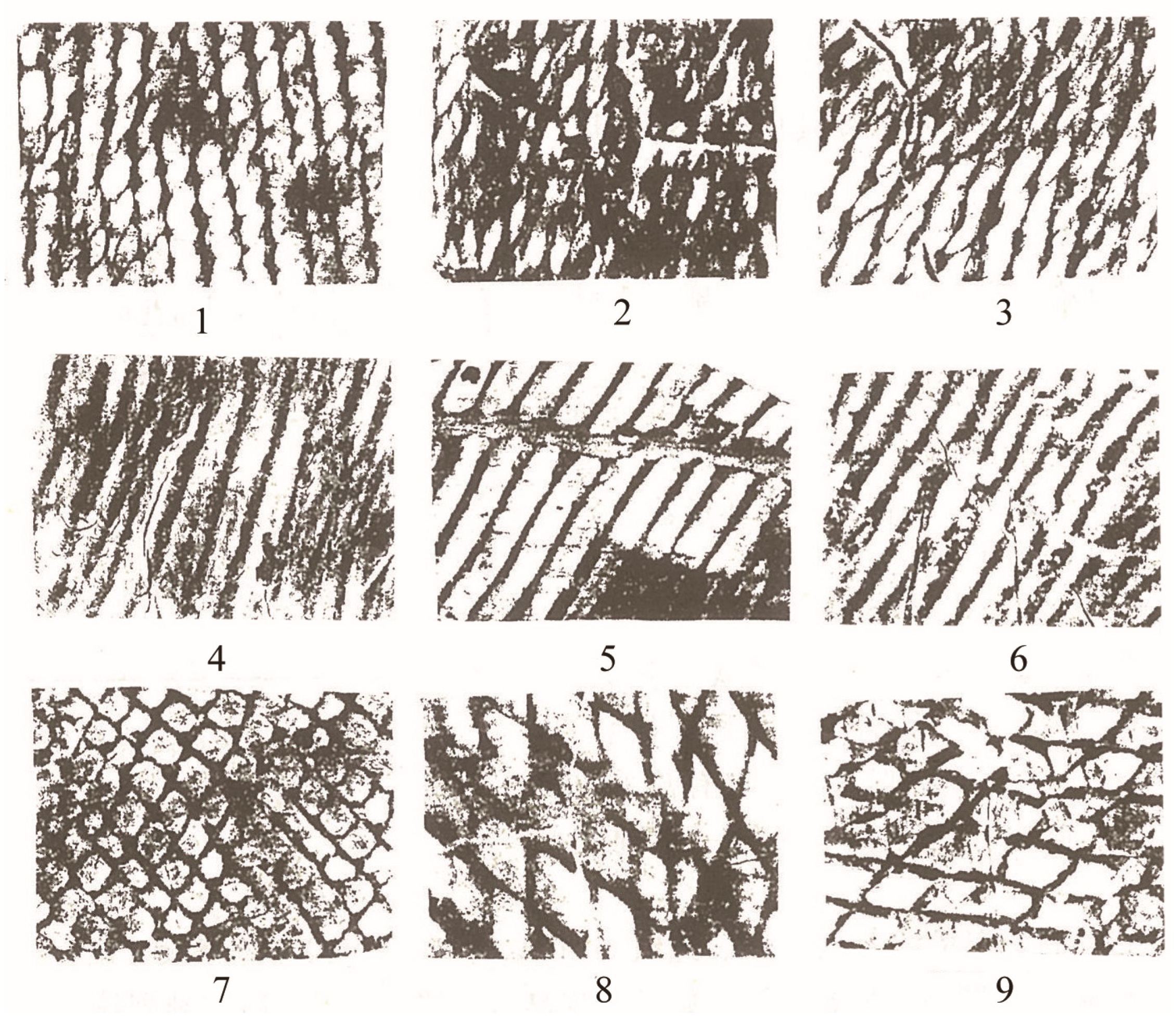

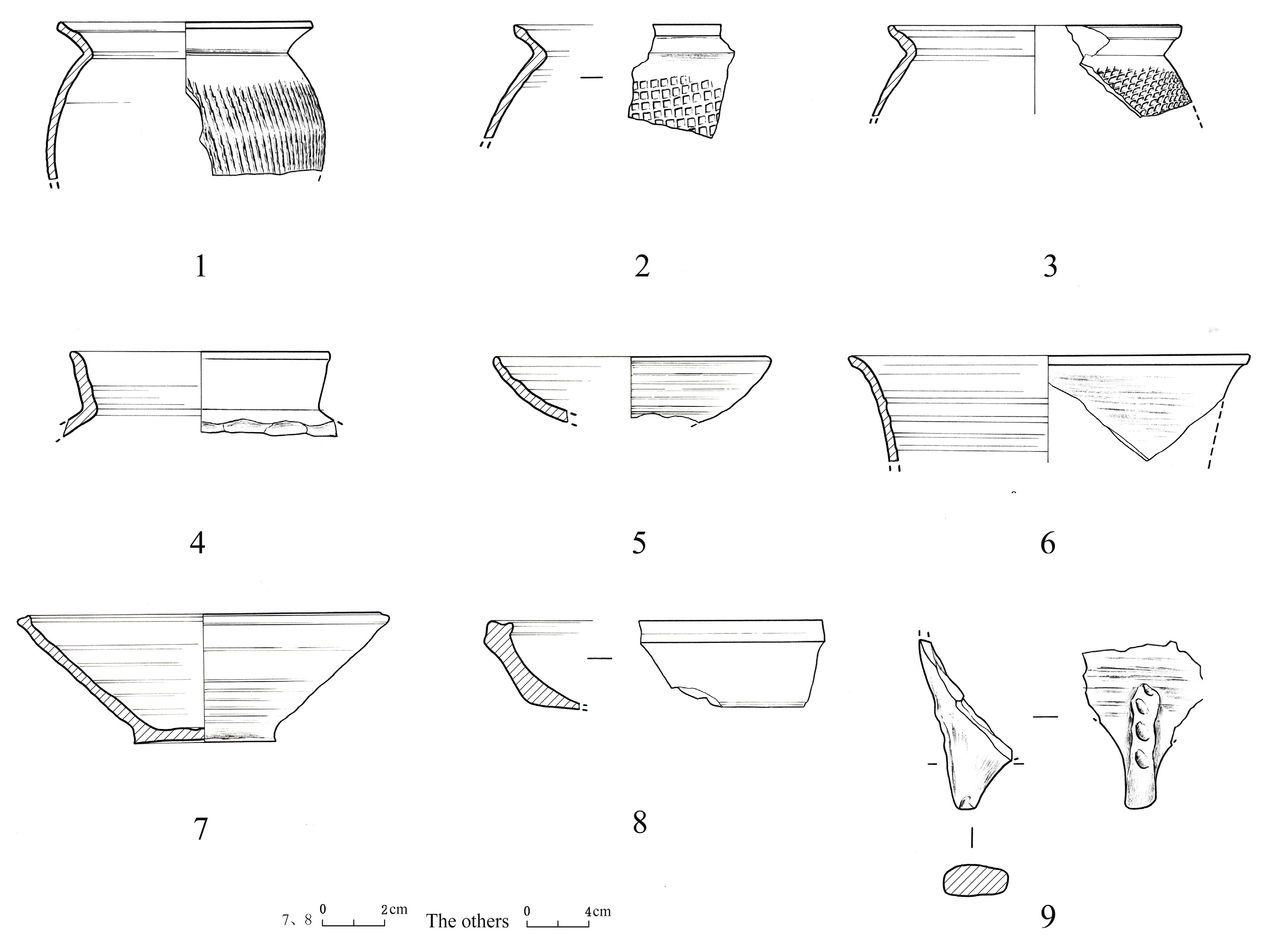

3. Results and Discussion

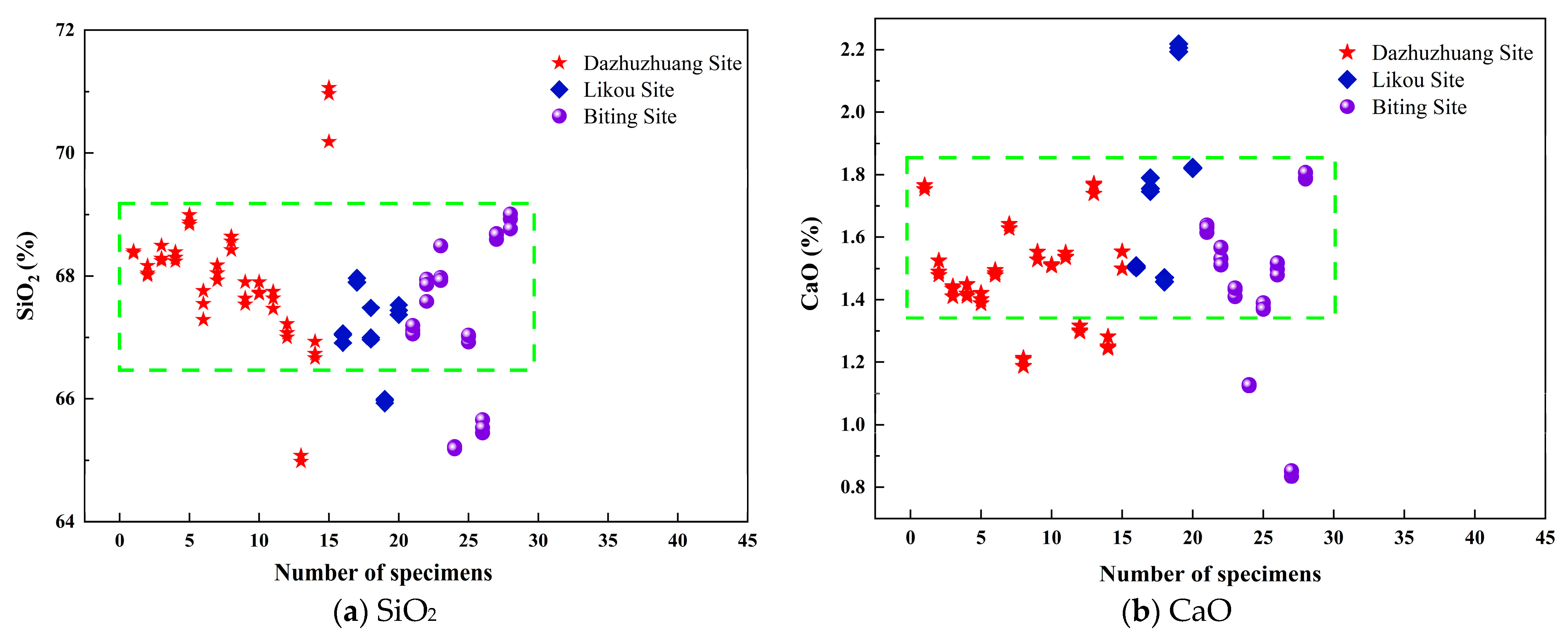

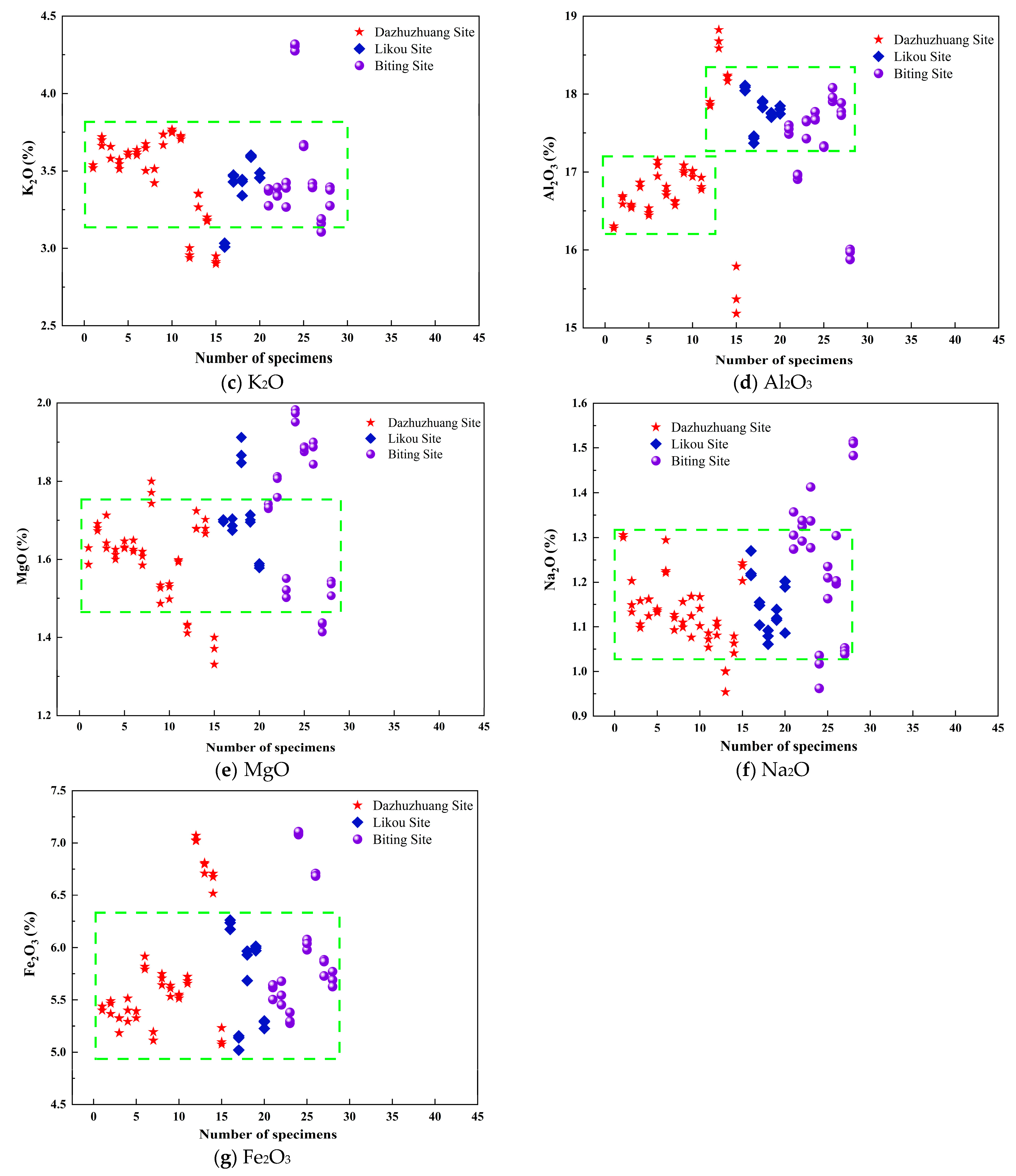

3.1. Chemical Composition Analysis

3.2. XRF Data Distribution Analysis

3.3. Thermal Analysis

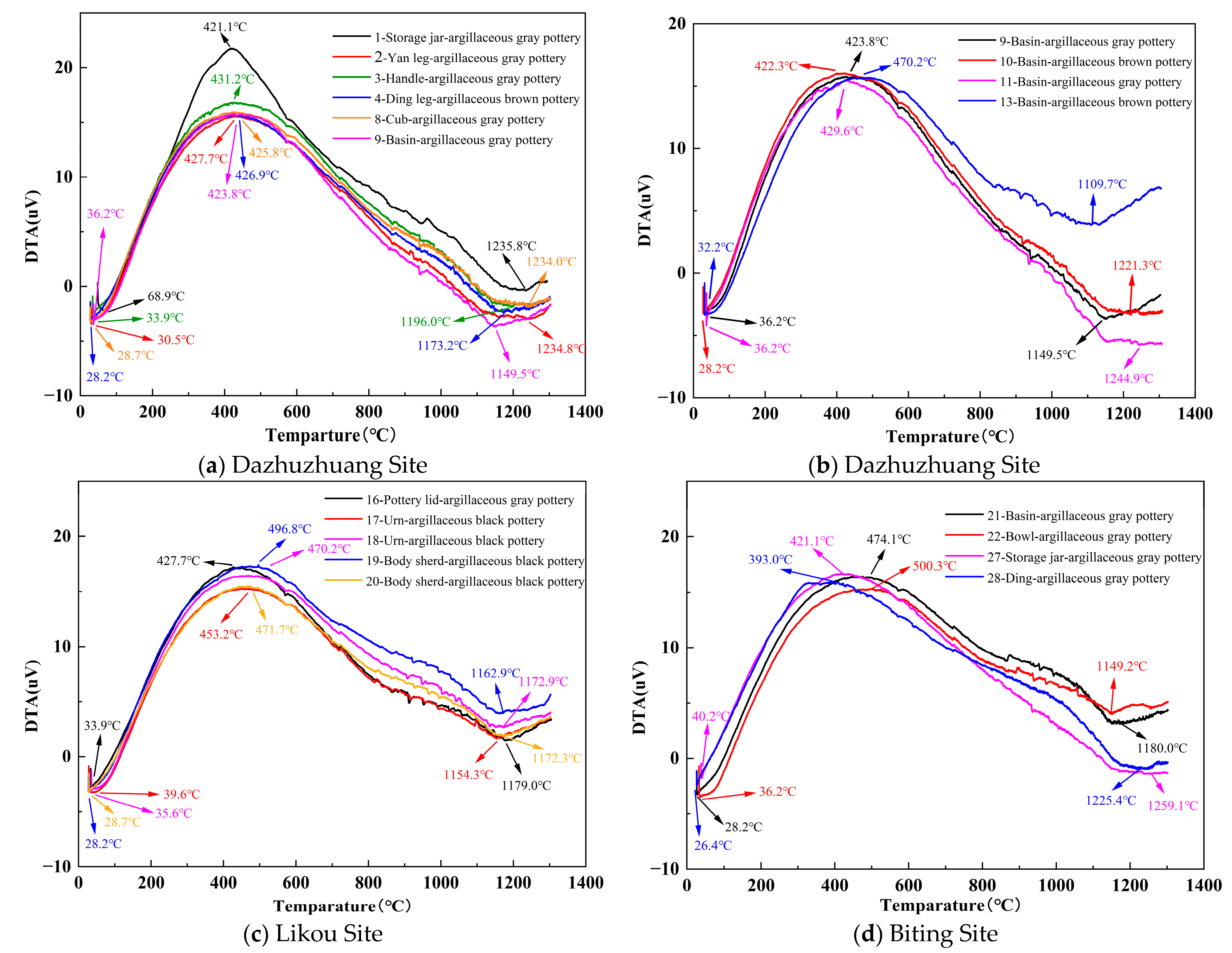

3.4. Microstructural Characteristics

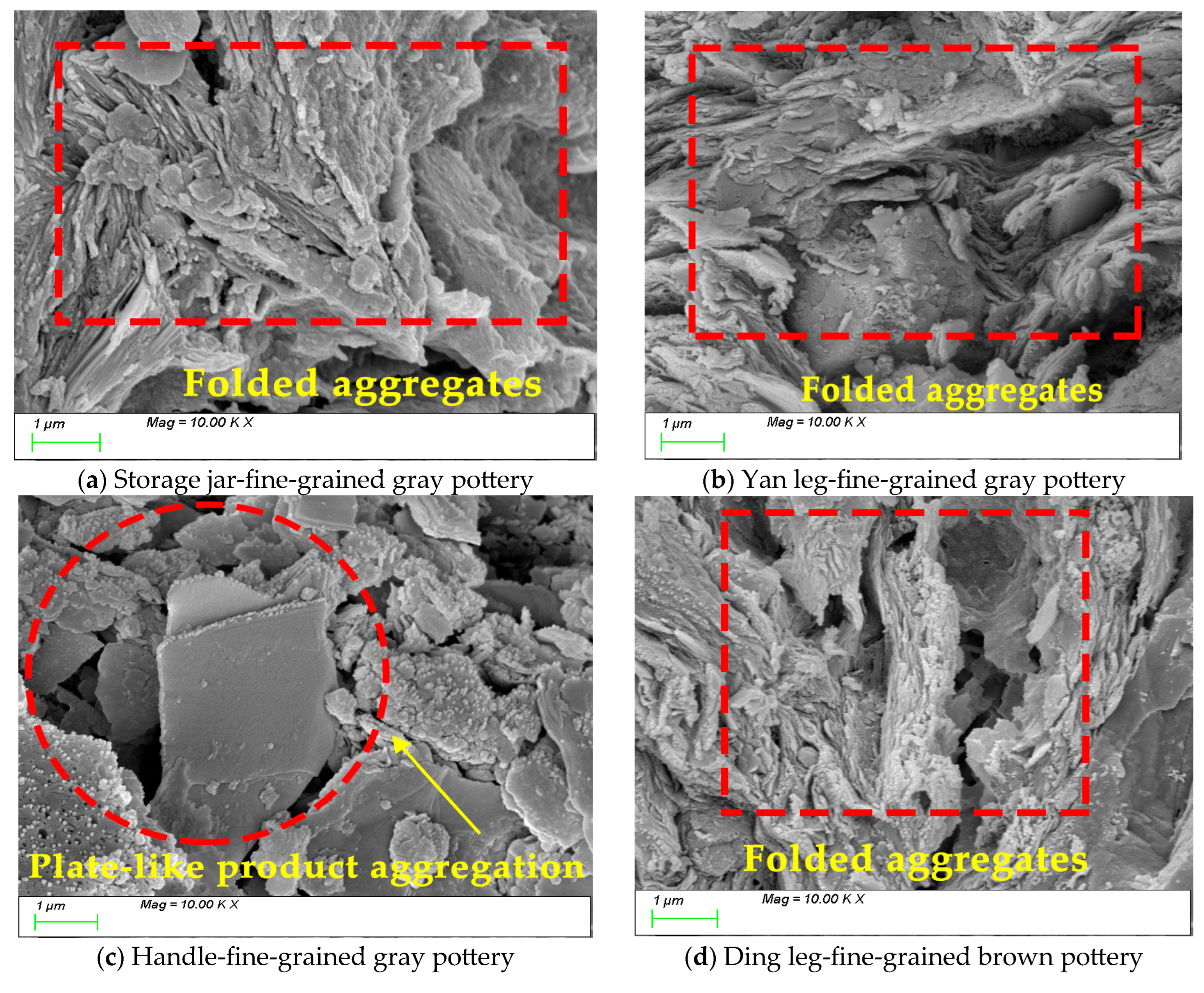

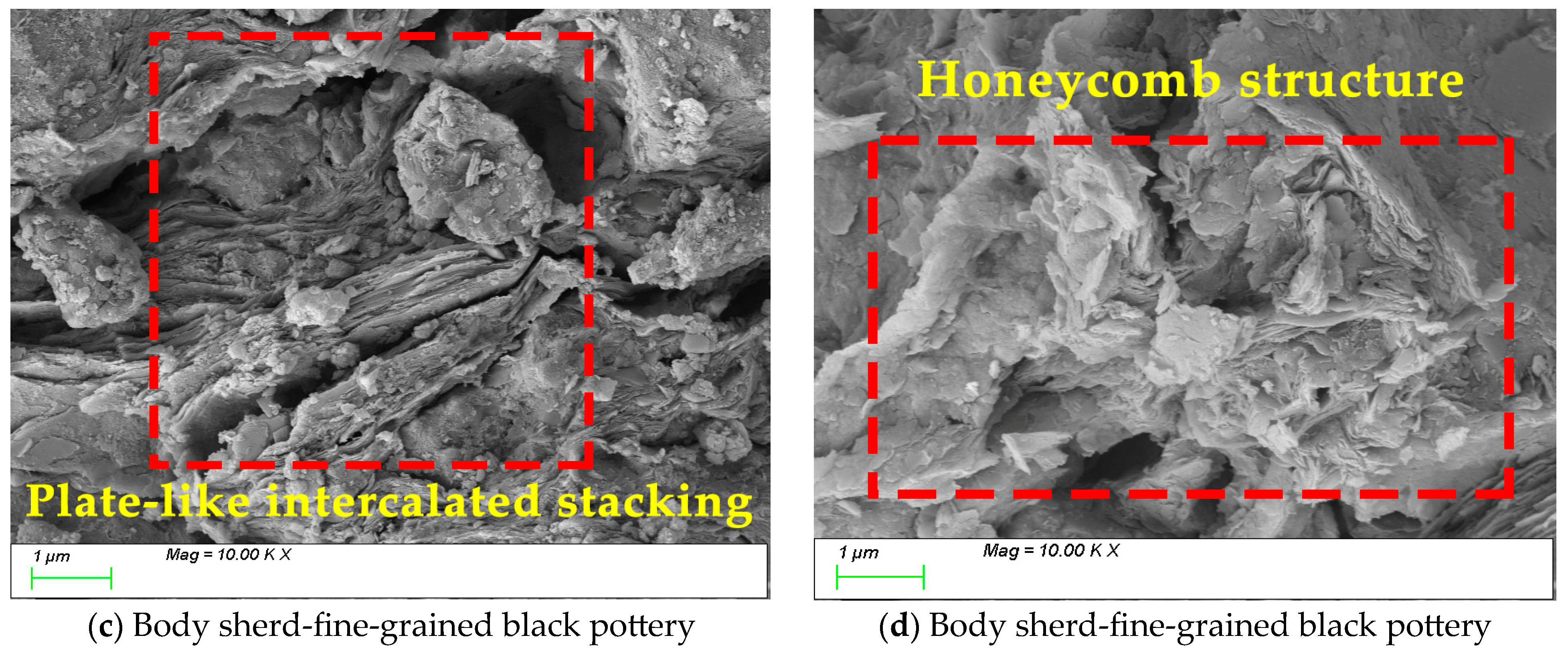

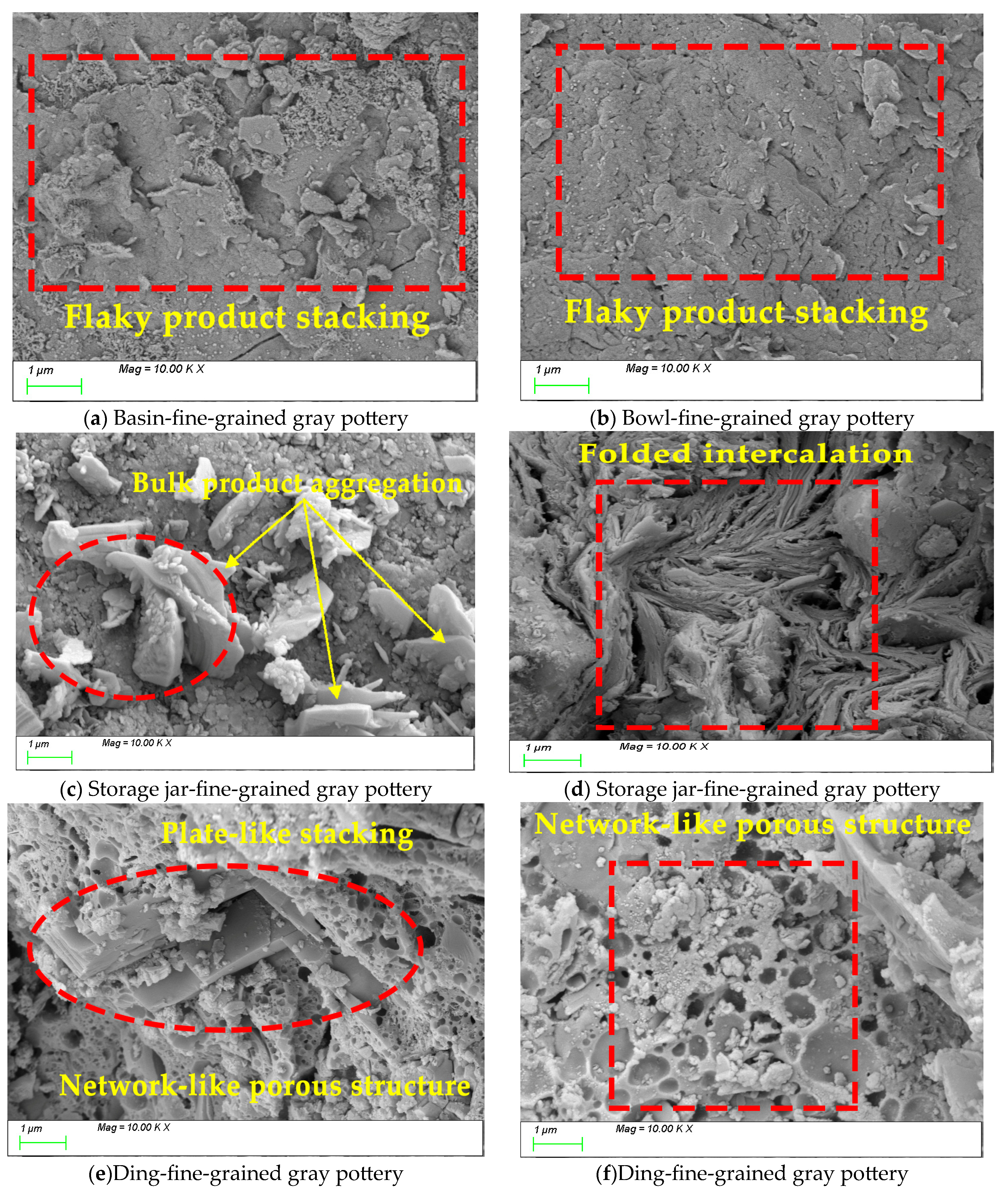

3.4.1. Dazhuzhuang Site

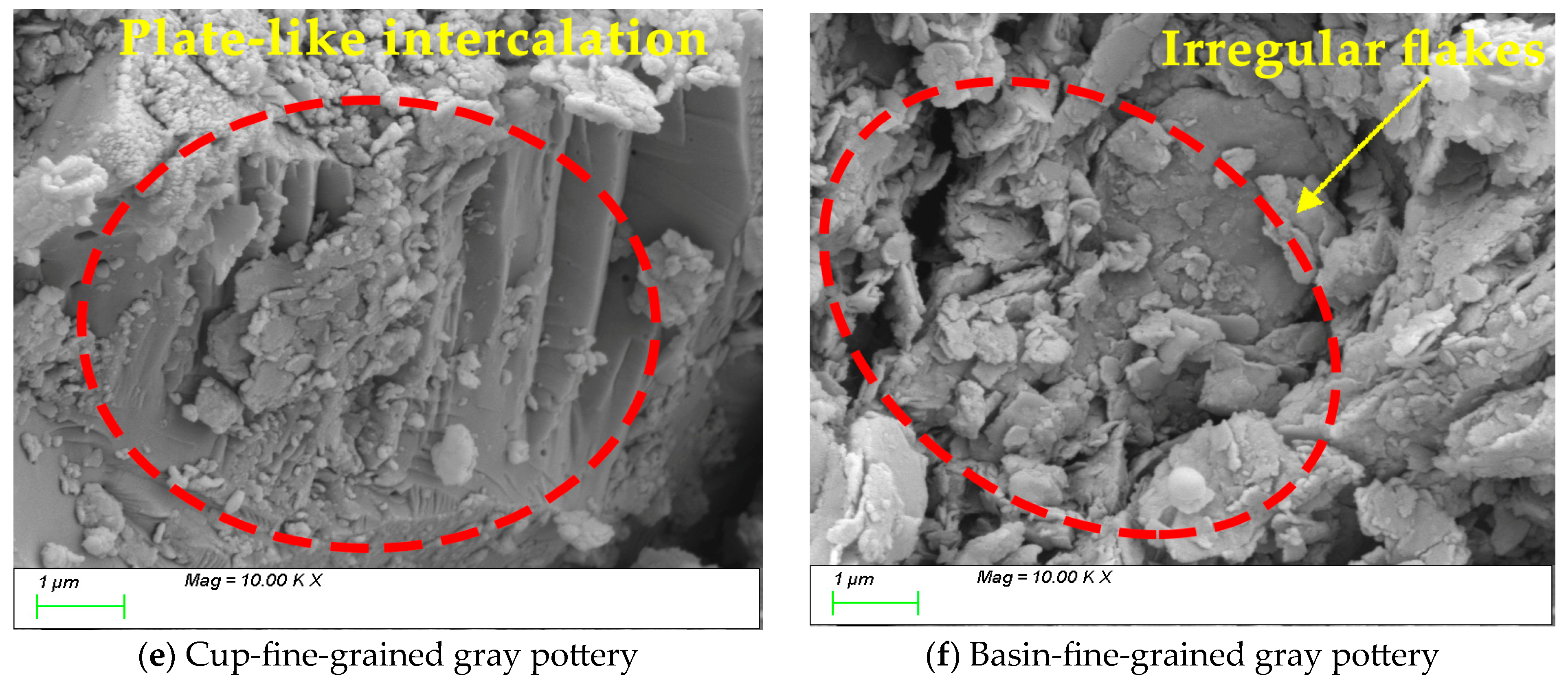

3.4.2. Likou Site

3.4.3. Biting Site

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sun, G.Q. The Dawenkou and Qujialing cultures in Henan Province. Cult. Relics Cent. China 2000, 2, 22–28. [Google Scholar]

- Zhang, G.; Zhao, J. The Niumugang Site in Minquan County and Archaeology in Eastern Henan Province; Science Press: Beijing, China, 2013; pp. 1–285. [Google Scholar]

- Henan Provincial Institute of Cultural Relics and Archaeology. Excavation of the Wuzhuang site in Luyi County, Henan Province. Archaeology 2002, 3, 5–17. [Google Scholar]

- Li, J. Investigation of Yongcheng in Shangqiu, Eastern Henan and Small-Scale Excavations at Zaolütai, Hegu Dui and Caoqiao. J. Chin. Archaeol. 1947, 2, 83–120+7–8. [Google Scholar]

- Department of Archaeology, School of History, Zhengzhou University. Brief Report on Archaeological Survey in the Shangqiu Area, Eastern Henan. Huaxia Archaeol. 2005, 2, 12–37. [Google Scholar] [CrossRef]

- Su, B.; Yin, W. On the Regional Systems and Types of Archaeological Cultures. Cult. Relics 1981, 5, 10–17. [Google Scholar]

- Yan, W. The Longshan Era and Longshan Culture. Cult. Relics 1981, 6, 41–48. [Google Scholar]

- Yang, Z.; Wang, S. A Tentative Discussion on Longshan Culture. Archaeology 1963, 7, 377–380. [Google Scholar]

- Liang, S. Longshan Culture—The Prehistoric Stage of Chinese Civilization. In Originally Published in English in the Proceedings of the Sixth Pacific Science Congress, San Francisco, CA, USA, 1939; Volume 4; Chinese Translation in Acta Archaeological Sinica; University of California Press: Los Angeles, CA, USA, 1954; Volume 7, pp. 5–14. [Google Scholar]

- An, Z. A Preliminary Discussion on the Neolithic Cultures in the Yellow River Basin. Archaeology 1959, 10, 559–565. [Google Scholar]

- Gao, T.; Meng, F. A Preliminary Study on the “Wangwan Type” of Longshan Culture in Henan. Cult. Relics Cent. China 1983, 2, 15–21. [Google Scholar]

- Luan, F. A Preliminary Study of the Wangyoufang Type of Longshan Culture. Archaeology 1992, 10, 924–935+958. [Google Scholar]

- Luan, F. A Comprehensive Study on Haidai Longshan Culture. Dongyue Trib. 1995, 3, 77–82. [Google Scholar]

- Chen, H. Settlement Distribution and Environmental Change in the Ancient Cultural Area of Shandong-Henan-Anhui. Archaeology 2007, 2, 48–60+2. [Google Scholar]

- Da, H. Settlement Distribution and Environmental Relationship in the Middle Yangtze River During the Neolithic Period. Ph.D. Dissertation, Central China Normal University, Wuhan, China, 2009. [Google Scholar]

- Zheng, Q. A Preliminary Study on the Longshan Culture in Eastern Henan and Its Origins. Cult. Relics Cent. China 1995, 3, 46–52. [Google Scholar]

- Hu, H.; Deng, Z.; Qin, L.; Zhang, H.; Zhang, C.; Cao, Y. Agricultural economic foundation of early social complexity in the east part of Henan: New evidence from the Pingliangtai site of Huaiyang City. Quat. Sci. 2022, 42, 1697–1708. [Google Scholar]

- Zhao, J. Study on the Diffusion and Distribution of Haidai Longshan Culture: Centered on Cultural Factor Analysis. Ph.D. Dissertation, Shandong University, Jinan, China, 2021. [Google Scholar] [CrossRef]

- Zhao, J. Another Discussion on Formation of Wangyoufang Type in Eastern Henan. Huaxia Archaeol. 2024, 1, 77–86. [Google Scholar] [CrossRef]

- Cohen, D.J. The Advent and Spread of Early Pottery in East Asia: New Dates and New Considerations for the World’s Earliest Ceramic Vessels. J. Austronesian Stud. 2013, 4, 55–92. [Google Scholar] [CrossRef]

- Jordan, P.; Zvelebil, M. Ceramics Before Farming: The Dispersal of Pottery Among Prehistoric Eurasian Hunter-Gatherers; University College London Institute of Archaeology Publications: London, UK, 2010. [Google Scholar] [CrossRef]

- Du, J. Pottery Jue—A Study of Ancient Chinese Wine Vessels Part One. Archaeology 1990, 6, 519–530+564. [Google Scholar]

- Yan, Z.; Lacquered, G. Round Pottery Discs, and Handle-shaped Objects. J. Natl. Mus. China 2020, 1, 6–22. [Google Scholar]

- Zhao, H. Periodization and Regional Types of Longshan Culture. In Collected Studies on Archaeological Cultures (III); Cultural Relics Press: Beijing, China, 1993. [Google Scholar]

- Luan, F. Periodization and Typology of Haidai Longshan Culture. In Archaeological Research on the Haidai Region; Shandong University Press: Jinan, China, 1997. [Google Scholar]

- Zhang, J. Typological Study of Early Houli Pottery. Cult. Relics Cent. China 1998, 4, 36–44. [Google Scholar]

- Beijing Municipal Institute of Cultural Relics. Zhenjiangying and Tazhao: Typology and Pedigree of Pre-Qin Archaeological Cultures in the Juma River Basin; Encyclopedia of China Publishing House: Beijing, China, 1999. [Google Scholar]

- Li, W. A Study of the Pottery-Making Technology in Ancient China; Science Press: Beijing, China, 1996. [Google Scholar]

- Dai, X. Pottery Production, Settlement Patterns, and Social Change: The Yuanqu Basin from the Neolithic to the Early Bronze Age; Cultural Relics Press: Beijing, China, 2010. [Google Scholar]

- Li, J.; Gao, G. Preliminary Study on the Origin, Development, and Social Nature of Typical Longshan Culture. Cult. Relics 1979, 11, 56–62. [Google Scholar]

- Hu, X. The Origin and Firing Technology Research of Guanzhuang Ceramic. Master’s Dissertation, School of History, Zhengzhou University, Zhengzhou, China, 2014. [Google Scholar]

- Zhu, T.; Wang, C.; Xu, D.; Wu, J. Preliminarily exploration to the carbonization technique of the black pottery in Shuangdun site. Sci. Conserv. Archaeol. 2005, 2, 1–8. [Google Scholar] [CrossRef]

- Guo, M.; Wen, D.; Luan, F.; Zhu, T.; Drucker, I.; Wan, J.; Lu, Q.; Sun, B.; Liang, Z. Preliminary Study on the Origin of Longshan Culture White Pottery: Examples from Samples of Liangchengzhen and Other Sites. Archaeology 2024, 2, 89–106. [Google Scholar]

- Cui, J.; Wu, X.; Yang, Y. Compositional Analysis and Preliminary Provenance Study of Pottery from Neolithic Sites in Maoxian County, Sichuan. Cult. Relics 2011, 2, 79–85. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, Q.; Wang, F. Ceramic Petrography and Its Application in Archaeology. Jianghan Archaeol. 2021, 2, 109–115, 136. [Google Scholar]

- Liu, S. Ceramic Mineral Raw Materials and Petrographic Analysis; Wuhan University of Technology Press: Wuhan, China, 2015. [Google Scholar]

- Wang, X.; Nan, P.; Guo, Y. Chemical analysis of pottery and clay raw materials from the Longshan period at the Pingtou sit-e in Hequ county, Shanxi province. Sci. Conserv. Archaeol. 2015, 27, 61–69. [Google Scholar] [CrossRef]

- Liu, X.; Hu, Y.; Wang, S.; Yang, Y.; Ren, M.; Fu, Y. Residue Analysis of Pottery and Related Issues at Dayan and Dingsishan Sites, Guangxi. Archaeology 2023, 7, 104–120. [Google Scholar]

- Shoda, S.; Lucquin, A.; Sou, C.I.; Nishida, Y.; Sun, G.; Kitano, H.; Son, J.H.; Nakamura, S.; Craig, O.E. Molecular and Isotopic Evidence for the Processing of Starchy Plants in Early Neolithic Pottery from China. Sci. Rep. 2018, 8, 17044. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Gao, Y.; Yang, J.; Wang, Y.; Wang, Y.; Sun, Q.; Chen, S.; Wang, Q.; Ran, J.; He, W.; et al. Patterns in Pottery Use Reveal Different Adaptive Strategies Between Lower and Higher Altitude Regions on the Tibetan Plateau: Chemical Evidence from Pottery Residues. J. Archaeol. Sci. 2022, 138, 105544. [Google Scholar] [CrossRef]

- College of Culture and Museum, Zhengzhou University, Kaifeng City Cultural Relics Team. Excavation Report of Qixian County in Eastern Henan; Science Press: Beijing, China, 2000; p. 42. [Google Scholar]

- Wu, H.; Han, J.; Zhang, X.; Cui, J.; Chen, G. Scientific research on white potteries from the Nan-zuo site in Qingyang, Gansu province. Archaeometry 2025, 67, 902–916. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, F.; Luan, F.; Wen, D.; Druck, I.; Sun, B. Petrographic and Chemical Composition Analysis of White Pottery from the Dinggong Site and Surrounding Sites of the Long-shan Culture. Archaeology 2019, 106–120. [Google Scholar]

- Zhao, W.; Xie, J.; Li, G.; Gao, Z.; Li, R.; Zang, B.; Feng, S.; Huang, Z.; Jia, X.; Han, S. Study on the Origin Relationship Between Ancient Ru Porcelain and Ancient Jun Porcelain by Fingerprint Element Analysis. Nucl. Tech. 2002, 25, 461–466. [Google Scholar]

- Ai, L.; Han, Z.; Wu, X.; Bi, N.; Wang, H. Geochemical characteristics and provenance indication of clay-sized sediments in the Yangtze River and Yellow River. Mar. Geol. Quat. Geol. 2020, 40, 109–118. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, F.; Zhang, X.; Wu, H.; Jiang, C.; Luan, F.; Wen, D. Provenance analysis of pottery from Jinzhai site in Xiaoxian, Anhui. Archaeology 2024, 102–113. [Google Scholar]

- Lu, X.; Fang, Y.; Li, W. Scientific study on white pottery of Longshan Culture from Wadian site. Huaxia Archaeol. 2015, 118–124. [Google Scholar]

- Zhang, X.; Zhao, X.; Li, B.; Wang, C. Division of soil texture types on Hebei Plain based on regional soil elemental geochemistry. Quat. Res. 2017, 37, 25–35. [Google Scholar]

- Li, W.; Qian, H.; Xu, P.; Hou, K.; Zhang, Q.; Chen, Y.; Chen, J.; Qu, W.; Ren, W. Tracing sediment provenance in the Yellow River, China: Insights from weathering, recycling, and rock compositions. Catena 2023, 220 Pt B, 106727. [Google Scholar] [CrossRef]

- Xia, L.; Li, Y.; Zhang, G.; Li, J.; Jaang, L. Compositional Analysis of Longshan Period Pottery and Ceramic Raw Materials in the Yongcheng Region, Henan Province. Materials 2025, 18, 2681. [Google Scholar] [CrossRef]

- Stoltman, J.B. A Quantitative Approach to the Petrographic Analysis of Ceramic Thin Sections. Am. Antiq. 1989, 54, 147–160. [Google Scholar] [CrossRef]

- Stoltman, J.B. Ceramic Petrography as a Technique for Documenting Culture Interaction: An Example from the Upper Mississippi Valley. Am. Antiq. 1991, 56, 108–109. [Google Scholar] [CrossRef]

- Zhou, R.; Zhang, F.; Zheng, Y. A Scientific Study of Pottery Technology in the Neolithic and Shang-Zhou Periods in the Yellow River Valley, China. Acta Archaeol. Sin. 1964, 1, 1–27+132–139. [Google Scholar]

| Performance Index | Specimen Size | Specimen Size |

|---|---|---|

| Energy-dispersive X-ray fluorescence (XRF) | 40 mm × 40 mm × 40 mm | 36 |

| Thermogravimetric analysis (TGA) | 40 mm × 40 mm × 40 mm | 36 |

| Scanning electron microscopy (SEM) | 40 mm × 40 mm × 40 mm | 36 |

| Site | Statistical Measures | SiO2 | Al2O3 | Fe2O3 | K2O | MgO | CaO | Na2O | TiO2 |

|---|---|---|---|---|---|---|---|---|---|

| Dazhuzhuang Site | Sample Size | 45 | 45 | 45 | 45 | 45 | 45 | 45 | 45 |

| Average | 67.93 | 16.96 | 5.74 | 3.49 | 1.60 | 1.49 | 1.14 | 0.75 | |

| Maximum | 71.07 | 18.83 | 7.07 | 3.77 | 1.80 | 1.81 | 1.31 | 0.80 | |

| Minimum | 64.98 | 15.18 | 5.08 | 2.90 | 1.33 | 1.19 | 0.95 | 0.71 | |

| Standard Deviation | 1.19 | 0.78 | 0.58 | 0.26 | 0.11 | 0.16 | 0.08 | 0.02 | |

| Likou Site | Sample Size | 15 | 15 | 15 | 15 | 15 | 15 | 15 | 15 |

| Average | 67.10 | 17.78 | 5.69 | 3.39 | 1.71 | 1.75 | 1.15 | 0.81 | |

| Maximum | 67.97 | 18.11 | 6.26 | 3.60 | 1.91 | 2.22 | 1.27 | 0.83 | |

| Minimum | 65.93 | 17.37 | 5.02 | 3.01 | 1.58 | 1.46 | 1.06 | 0.78 | |

| Standard Deviation | 0.68 | 0.23 | 0.45 | 0.20 | 0.10 | 0.28 | 0.06 | 0.01 | |

| Biting Site | Sample Size | 24 | 24 | 24 | 24 | 24 | 24 | 24 | 24 |

| Average | 67.29 | 17.36 | 5.98 | 3.49 | 1.72 | 1.41 | 1.25 | 0.81 | |

| Maximum | 69.01 | 18.08 | 7.11 | 4.32 | 1.98 | 1.81 | 1.52 | 0.93 | |

| Minimum | 65.19 | 15.88 | 5.28 | 3.11 | 1.41 | 0.84 | 0.96 | 0.70 | |

| Standard Deviation | 1.30 | 0.62 | 0.59 | 0.34 | 0.19 | 0.28 | 0.16 | 0.06 | |

| ANOVA | F-value | 4.11 | 9.08 | 1.76 | 0.79 | 7.90 | 11.12 | 9.09 | 36.70 |

| Significance | 0.02 | 0.00 | 0.18 | 0.46 | 0.00 | 0.00 | 0.00 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xia, L.; Zhang, G.; Li, J.; Geng, Y.; Zhao, Y.; Li, Y. Raw Material and Technological Analysis of Longshan Culture Pottery from the Hui River Basin, Yongcheng, Henan. Heritage 2025, 8, 342. https://doi.org/10.3390/heritage8090342

Xia L, Zhang G, Li J, Geng Y, Zhao Y, Li Y. Raw Material and Technological Analysis of Longshan Culture Pottery from the Hui River Basin, Yongcheng, Henan. Heritage. 2025; 8(9):342. https://doi.org/10.3390/heritage8090342

Chicago/Turabian StyleXia, Linyu, Ge Zhang, Jialing Li, Yufan Geng, Yongtao Zhao, and Yinhong Li. 2025. "Raw Material and Technological Analysis of Longshan Culture Pottery from the Hui River Basin, Yongcheng, Henan" Heritage 8, no. 9: 342. https://doi.org/10.3390/heritage8090342

APA StyleXia, L., Zhang, G., Li, J., Geng, Y., Zhao, Y., & Li, Y. (2025). Raw Material and Technological Analysis of Longshan Culture Pottery from the Hui River Basin, Yongcheng, Henan. Heritage, 8(9), 342. https://doi.org/10.3390/heritage8090342