HBIM-Based Multicriteria Method for Assessing Internal Insulation in Heritage Buildings

Abstract

1. Introduction

2. Background

2.1. The HERIT4AGES Project

2.2. Case Study: The Faculty of Engineering in Bologna

3. Methodology

3.1. Workflow Overview

3.2. Data Acquisition

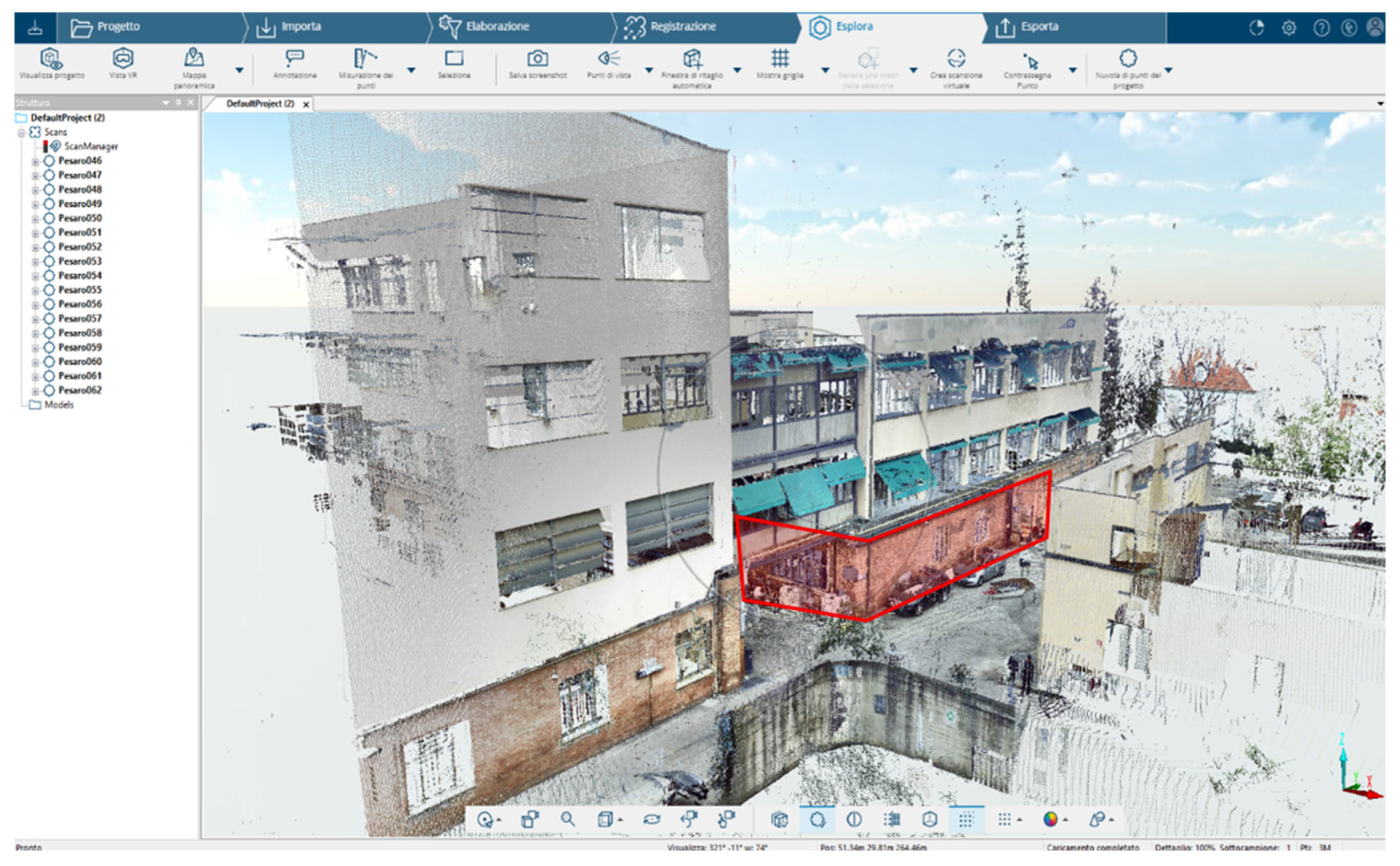

3.2.1. Geometric Data

3.2.2. Construction Data

- X-ray diffraction (XRD): Small material samples were extracted from the walls to investigate the chemical composition of the materials (Figure 4), identify the primary mineralogical phases, and comprehend the nature of the inner walls. All this information will be used to identify renovation solutions compatible with existing materials and develop accordingly the HERIT4AGES’ renovation solutions.

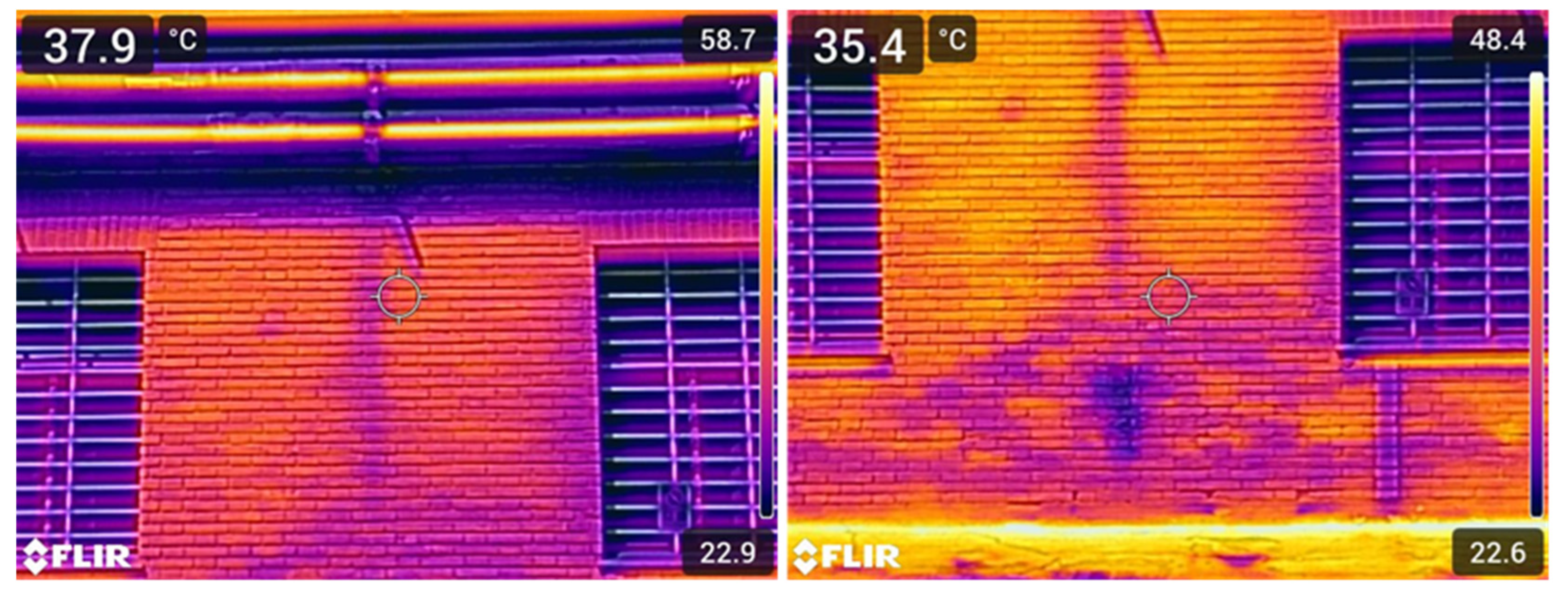

- Thermal imaging: Thermal images were used to analyze potential construction anomalies on the façade and to identify signs of superficial degradation (Figure 5). For instance, rising damp phenomena were experienced in the exteriors along all the perimetral walls of the classroom.

3.2.3. Occupancy Data

3.2.4. HVAC Data

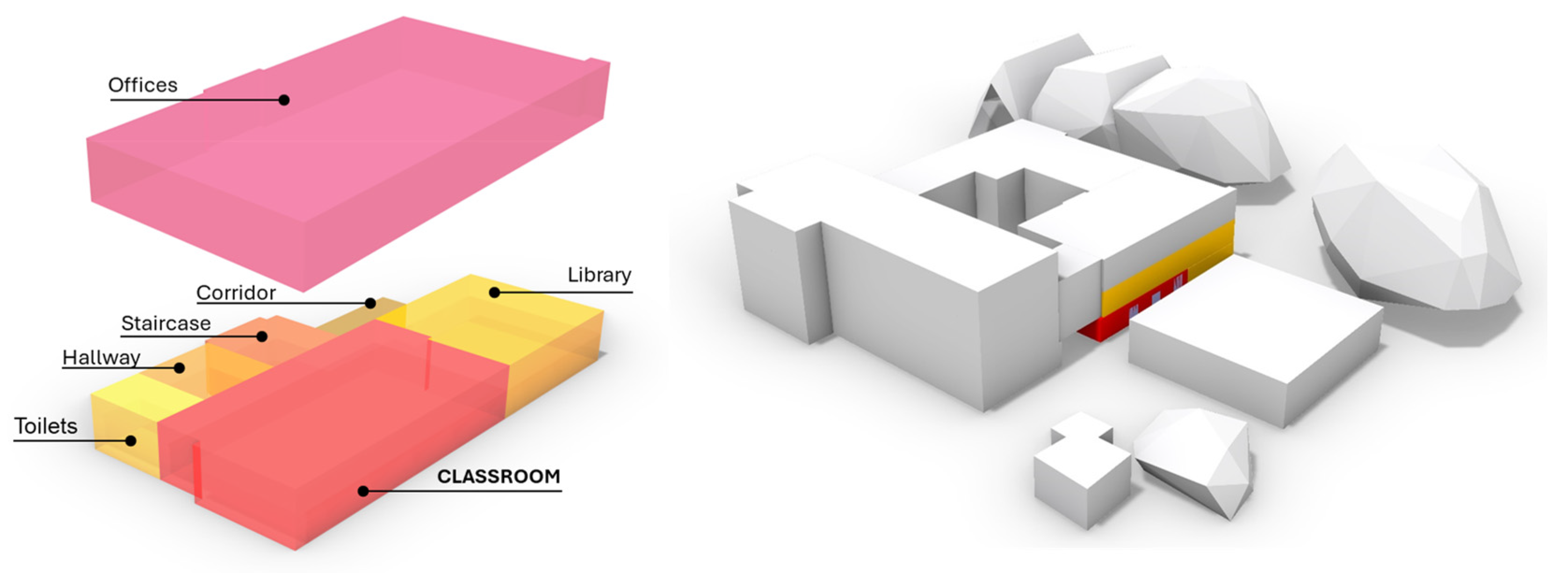

3.3. Building Information Modeling

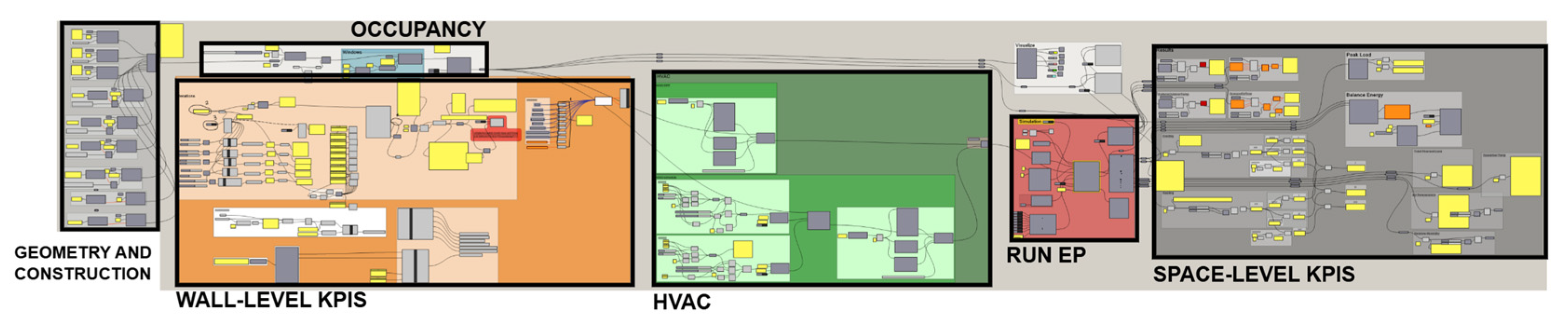

3.4. Building Energy Modeling

3.5. Multicriteria Analysis

- Thermal transmittance (UTOT): Measured in W/(m2K), it represents the amount of heat that passes through 1 square meter of surface per unit Kelvin of temperature difference. A lower value indicates reduced heat transfer, preferable for energy efficiency. This parameter is critical in retrofit processes and is subject to regulatory limits (e.g., Emilia Romagna standards set a maximum of 0.26 W/m2K for renovated walls [26]).

- Periodic transmittance (YIE): Measured in W/(m2K), it is defined as the ratio between the overall amplitude of the thermal flux density through the component’s surface adjacent to a given zone and the overall amplitude of the temperature variation in the adjacent zone, when the temperature in the first zone is maintained constant (EN ISO 13786:2017 [27]).

- Damping factor (DF): Dimensionless parameter defined as the ratio of the amplitude of the temperature oscillation on the internal surface to that on the external surface. A lower damping factor indicates a more significant attenuation of external thermal fluctuations, enhancing thermal comfort and reducing heating/cooling loads (EN ISO 13786:2017 [27]).

- Phase shift (PS): Measured in hours, the phase shift is the time delay between the peak external temperature and the corresponding peak internal surface temperature. A larger phase shift indicates that the thermal wave is delayed as it passes through the envelope, contributing to improved thermal inertia and indoor comfort (EN ISO 13786:2017).

- Weight (W): Weight in kg/m2 of the installed insulation panel, calculated by multiplying the thickness of the panel and its density.

- Surface density (SD): Expressed in kg/m2, surface mass refers to the mass per unit area of the building component (including existing and new materials). Higher surface mass implies greater thermal inertia, which helps to moderate temperature variations by storing and releasing heat more effectively.

- Periodic internal/external areal heat capacity (AHCI/AHCE): Measured in kJ/m2K, it corresponds to the thermal capacity per unit area of the element on the internal/external side.

- Maximum monthly condensation (MMC): It evaluates the potential for condensation formation and quantifies the total amount of condensation present in a month, expressed in g/m2.

- Total yearly condensation (TYC): It evaluates the potential for condensation formation and quantifies the amount of total condensation present in the year, expressing it in g/m2. For the purposes of this study, the drying effects were not taken into account.

- Internal/external surface temperatures (STI/STE): They represent the temperatures on the interior and exterior sides of each surface, respectively.

- Total energy demand for heating (EDH): The annual energy demand required for heating the space in kWh.

- Total energy demand for cooling (EDC): The annual energy demand required for cooling the space in kWh.

- Total energy demand (EDTOT): The sum of the heating and cooling energy demands in kWh.

- Energy Load Reduction (ELR): The percentage of energy load reduction calculated by comparing the total energy demand of the renovation state with that of the current state.

- Reduced space (RS): The percentage of floor reduction due to the installation of internal insulation panels.

4. Results

4.1. Baseline Model

4.2. Design Model

- The thermal transmittance must comply with the limit U ≤ 0.26 W/m2·K.

- The attenuation factor (thermal decrement factor) should preferably be below 0.10.

- A thermal phase shift of at least 10–12 h is recommended to ensure effective summer performance.

- The surface mass should be no less than 230 kg/m2 to provide adequate thermal inertia.

- The internal areal heat capacity is considered optimal when above 40 kJ/m2·K. Historic buildings often meet or exceed this threshold due to their construction characteristics.

- Although no strict threshold is defined for external areal heat capacity, higher values are preferable, as they enhance the building’s thermal inertia, mitigating summer overheating and thereby reducing cooling demand.

- Regarding hygrothermal performance, the risk of surface condensation must be checked to prevent potential mold growth. Additionally, monthly moisture accumulation must not exceed 500 g/m2, and any residual moisture should fully evaporate by the end of the annual cycle.

4.3. Design Iterations

5. Discussion

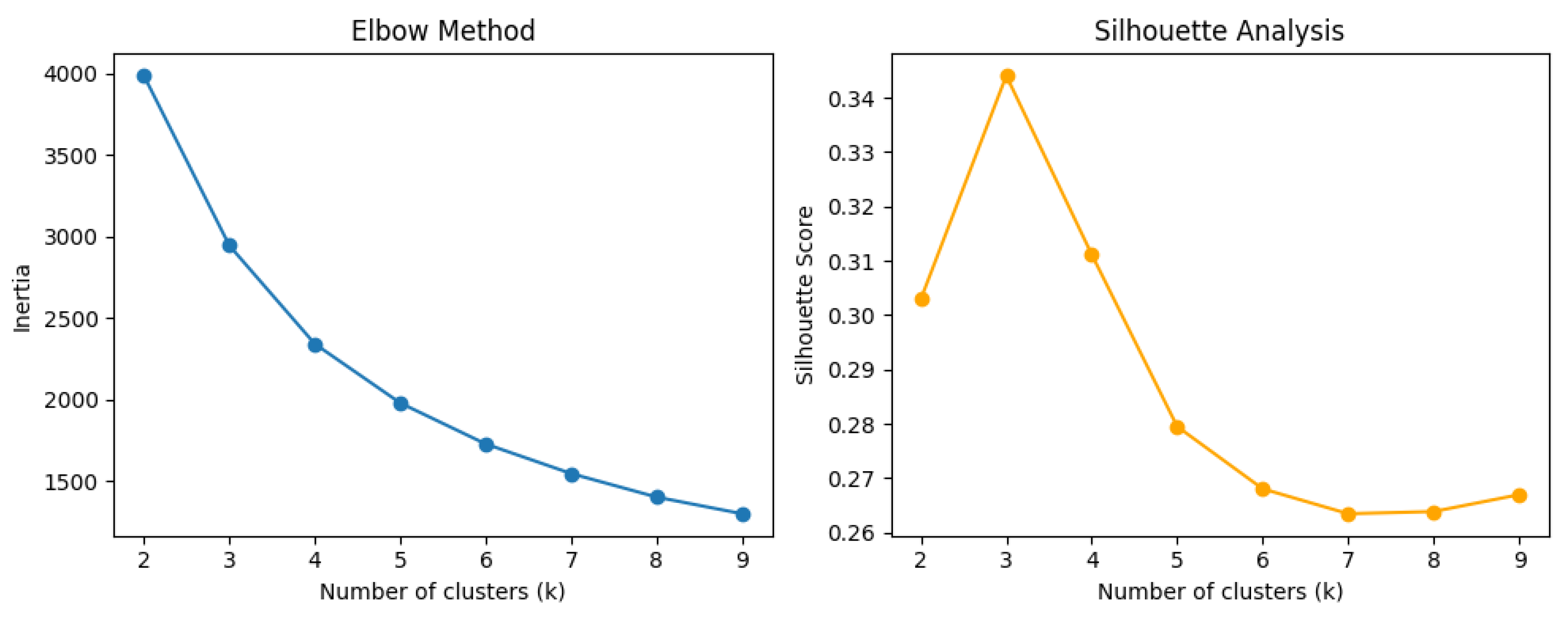

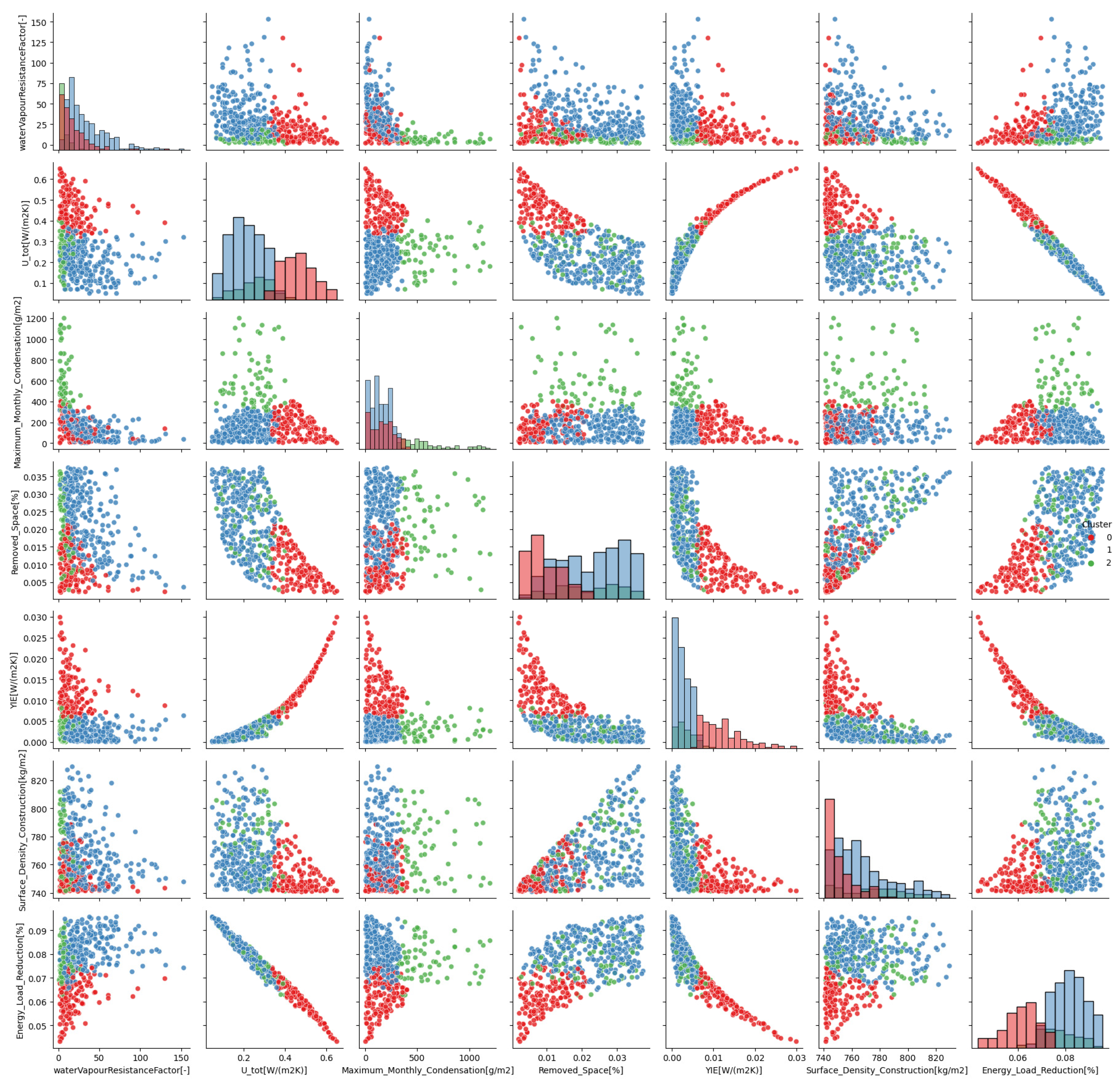

5.1. Interpretation of Multicriteria Analysis

- Cluster C1 represents solutions characterized by high thickness, low thermal conductivity, and medium-to-low vapor resistance. This cluster shows the lowest U-values, typically below the regional regulatory threshold of 0.26 W/m2K, coupled with low YIE values, resulting in the highest energy load reduction (up to 9%). Furthermore, solutions in this cluster present a low condensation risk, consistently remaining below the critical threshold of 500 g/m2 monthly condensation (as defined by UNI standards). However, these solutions also necessitate considerable space removal (up to 3.2%) and have a medium panel weight (ranging approximately from 15 to 40 kg/m2).

- Cluster C2 consists of solutions characterized by high thickness, medium-to-low thermal conductivity, and low vapor resistance. This cluster has a relatively low U-value (averaging around the regulatory limit of 0.26 W/m2K) and exhibits low YIE and acceptable energy load reduction. However, it demonstrates a very high risk of condensation, typically exceeding the threshold of 500 g/m2. The space reduction is similar to that of Cluster C1, and the panel weight is also medium. Due to the significant condensation risk, this cluster should generally be avoided unless additional vapor barriers or retarders are implemented, potentially compromising overall envelope breathability.

- Cluster C3 groups solutions with reduced thickness, medium thermal conductivity, and low vapor resistance. These solutions consistently exhibit U-values above 0.26 W/m2K, medium YIE, thus resulting in lower energy load reduction but maintaining low condensation risk (always below 500 g/m2). Additionally, these solutions offer minimal space reduction and lighter weight.

- Cluster N1 represents solutions characterized by high thickness, medium thermal conductivity, and high vapor resistance. This cluster typically demonstrates moderate-to-low U-values (often below 0.26 W/m2K), low YIE, significant space removal, good energy load reduction, and relatively high panel weight.

- Cluster N2 consists of solutions characterized by low thickness, high thermal conductivity, and high vapor resistance. This cluster consistently shows high U-values (well above the regulatory threshold of 0.26 W/m2K), high YIE, minimal space reduction, and negligible energy consumption reduction. Solutions in this cluster are lightweight but significantly underperforming.

5.2. Contribution of the Paper

5.3. Limitations and Future Work

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AHCE | Periodic external areal heat capacity |

| AHCI | Periodic internal areal heat capacity |

| BEM | Building energy modeling/model |

| BIM | Building information modeling/model |

| DF | Damping factor |

| EDH | Total energy demand for heating |

| EDC | Total energy demand for cooling |

| EDTOT | Total energy demand |

| ELR | Energy load reduction |

| EP | EnergyPlus |

| GH | Grasshopper |

| HVAC | Heating, ventilation, air conditioning |

| HB | Honeybee (Ladybug Tools) |

| HBIM | Heritage building information modeling/model |

| IDF | Input Data Format |

| IFC | Industry Foundation Class |

| IoT | Internet of Things |

| KPI | Key performance indicator |

| LCC | Life Cycle Cost |

| LCA | Life Cycle Assessment |

| MMC | Maximum monthly condensation |

| PS | Phase shift |

| RS | Reduced space |

| SD | Surface density |

| STE | External surface temperature |

| STI | Internal surface temperature |

| TLS | Terrestrial laser scanner |

| TYC | Total yearly condensation |

| UTOT | Thermal transmittance |

| VP | Visual programming |

| YIE | Periodic thermal transmittance |

Appendix A

| Property Name | Description | Quantity |

|---|---|---|

| Artificial Lighting | Indication whether this space requires artificial lighting. | Boolean [-] |

| Equipment Power Density | The maximum electrical power input to using electric appliances in a zone, including PCs, plotters, elevators and other equipment. | Power Density [W/m2] |

| Illuminance | Required average illuminance value for this space. | Illuminance [lux] |

| IsCooled | Indicates whether this space requires air conditioning provided. | Boolean [-] |

| IsHeated | Indicates whether this space requires heating provided. | Boolean [-] |

| Is Mechanically Ventilated | Indicates whether the space is required to have mechanical ventilation. | Boolean [-] |

| Is Naturally Ventilated | Indicates whether the space is required to have natural ventilation. | Boolean [-] |

| Is Occupied | Indicates whether the space is permanently occupied or not according to energy modeling purposes. | Boolean [-] |

| Lighting Power Density | The maximum electrical power input to lighting in a zone, including ballasts, if present. | Power Density [W/m2] |

| Mechanical Ventilation Rate | Indication of the requirement of a particular mechanical air ventilation rate, given in air changes per hour. | Air Changes [h−1] |

| Mechanical Ventilation Rate Per Person | Mechanical ventilation rate per person standard value for mechanical ventilation of spaces given by UNI EN 10339. | Air Changes [L/s pp] |

| Mechanical Ventilation Rate Per Volume | Mechanical ventilation rate standard value for mechanical ventilation of special spaces given by UNI EN 10339. | Air Changes [L/s pp] |

| Natural VentilationRate | Indication of the requirement of a particular natural air ventilation rate, given in air changes per hour. | Air Changes [L/s pp] |

| Occupancy Density | Design occupancy loading for this type of usage assigned to this space according to UNI EN 10339. | Occupancy Density [pp/m2] |

| Occupancy Density Peak | Number of people estimated to be in an area of the facility in occupancy peak hours. | Occupancy Density [pp/m2] |

| Occupancy Number | Number of people required for the activity assigned to this space. | People Count [pp] |

| Space Humidity Max | Max humidity of the space or zone that is required from user/designer view point | Relative Humidity [%] |

| Space Humidity Min | Min humidity of the space or zone that is required from user/designer view point | Relative Humidity [%] |

| Space Temperature Summer Max | Maximal temperature of the space or zone for the hot (summer) period, that is required from user/designer view point. | Temperature [°C] |

| Space Temperature Summer Min | Minimal temperature of the space or zone for the hot (summer) period, that is required from user/designer view point. | Temperature [°C] |

| Space Temperature Winter Max | Maximal temperature of the space or zone for the cold (winter) period, that is required from user/designer view point. | Temperature [°C] |

| Space Temperature Winter Min | Minimal temperature of the space or zone for the cold (winter) period, that is required from user/designer view point. | Temperature [°C] |

| Space Wind Load Rating | Wind load resistance rating for the window and doors located in the space (according to EN15254). | Label [-] |

| Property Name | Description | Quantity |

|---|---|---|

| Construction Type | Name of the set of materials associated with walls, roofs, floors, windows, and doors modeled in BIM (i.e., wall type, floor type, or roof type) | Label [-] |

| Is External | Indicates whether the element is designed for use in the exterior or not. | Boolean [-] |

| Surface Type | Type of surface according to EnergyPlus: can be “Exterior”, “Adiabatic”, “Underground”, “Interzone” | Label [-] |

| Thermal Transmittance * | Thermal transmittance coefficient (U-Value) of the interface element. | Thermal Transmittance [W/m2K] |

| Thickness ** | Thickness of the interface element. | Length [m] |

| Property Name | Description | Quantity |

|---|---|---|

| Frame Material | Material of the frame of the opening | Label [-] |

| Frame Thermal Transmittance * | Thermal transmittance of the frame of the opening | Thermal Transmittance [W/m2K] |

| Frame Thickness | Thickness of the frame of the opening | Length [m] |

| Glass1 Thickness | Thickness of the first (inner) glass layer. | Length [m] |

| Glass2 Thickness | Thickness of the second (intermediate or outer) glass layer, if present. | Length [m] |

| Glass3 Thickness | Thickness of the third (outer) glass layer, if present. | Length [m] |

| Glass Layers | Number of glass layers within the frame. | Count [-] |

| Glass Thermal Transmittance * | Thermal transmittance coefficient (U-Value) of the gas. | Thermal Transmittance [W/m2K] |

| Glazing Area Fraction | Fraction of the glazing area relative to the total area of the filling element. | Ratio [%] |

| Height | Total outer height of the window lining | Length [m] |

| Is External | Indication whether the element is designed for use in the exterior or not. | Boolean [-] |

| Solar Heat Gain Transmittance * | The ratio of incident solar radiation that contributes to the heat gain of the interior, it is the solar radiation that directly passes plus the part of the absorbed radiation that is distributed to the interior. | Ratio [%] |

| Solar Reflectance | The ratio of incident solar radiation that is reflected by a glazing system. | Ratio [%] |

| Solar Transmittance | The ratio of incident solar radiation that directly passes through a system. | Ratio [%] |

| Thermal Transmittance * | Overall thermal transmittance coefficient (U-Value) of the opening element. | Thermal Transmittance [W/m2K] |

| Visible Light Reflectance | Fraction of the visible light that is reflected by the glazing at normal incidence. It is a value without a unit. | Ratio [%] |

| Visible Light Transmittance | Fraction of the visible light that passes the object at normal incidence. It is a value without a unit. | Ratio [%] |

| Width | Total outer width of the window lining. | Length [m] |

| Wind Load Rating | Wind load resistance rating for this object. It is provided according to the national building code. | Label [-] |

References

- European Green Deal. Available online: https://commission.europa.eu/strategy-and-policy/priorities-2019-2024/european-green-deal_en (accessed on 5 June 2025).

- Renovation Wave. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/renovation-wave_en (accessed on 5 June 2025).

- European Commission, New European Bauhaus. 2021. Available online: https://new-european-bauhaus.europa.eu/index_en (accessed on 5 June 2025).

- European Commission, Built4People. 2023. Available online: https://build-up.ec.europa.eu/en/resources-and-tools/links/built4people-b4p (accessed on 5 June 2025).

- Ide, L.; Gutland, M.; Bucking, S.; Santana Quintero, M. Balancing Trade-offs between Deep Energy Retrofits and Heritage Conservation: A Methodology and Case Study. Int. J. Archit. Herit. 2022, 16, 97–116. [Google Scholar] [CrossRef]

- Pagoni, P.; Møller, E.B.; Peuhkuri, R.H.; Jensen, N.F. Evaluation of the performance of different internal insulation systems in real-life conditions—A case study. Build. Environ. 2025, 267, 112319. [Google Scholar] [CrossRef]

- Andreotti, M.; Calzolari, M.; Davoli, P.; Dias Pereira, L. Hygrothermal performance of an internally insulated masonry wall: Experimentations without a vapour barrier in a historic Italian Palazzo. Energy Build. 2022, 260, 111896. [Google Scholar] [CrossRef]

- Zhou, X.; Derome, D.; Carmeliet, J. Analysis of moisture risk in internally insulated masonry walls. Build. Environ. 2022, 212, 108734. [Google Scholar] [CrossRef]

- Angrisano, M.; Fabbrocino, F.; Iodice, P.; Girard, L.F. The Evaluation of Historic Building Energy Retrofit Projects through the Life Cycle Assessment. Appl. Sci. 2021, 11, 7145. [Google Scholar] [CrossRef]

- Lisitano, I.M.; Laggiard, D.; Fantucci, S.; Serra, V.; Fenoglio, E. Evaluating the Impact of Indoor Insulation on Historic Buildings: A Multilevel Approach Involving Heat and Moisture Simulations. Appl. Sci. 2021, 11, 7944. [Google Scholar] [CrossRef]

- Hutkai, K.; Katunský, D.; Zozulák, M. Internal insulation systems and their assessment for historic buildings by hygrothermal simulation. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1252, 012069. [Google Scholar] [CrossRef]

- Herit4Ages-User-Centric and Data-Driven Retrofitting Solutions for a Resilient, Energy-Efficient, Low Emission and Inclusive Cultural Heritage. Available online: https://www.herit4ages.eu/ (accessed on 5 June 2025).

- Predari, G.; Prati, D.; Massafra, A. Modern Construction in Bologna. The Faculty of Engineering by Giuseppe Vaccaro, 1932–1935. In Digital Modernism Heritage Lexicon; Springer Nature Switzerland AG: Cham, Switzerland, 2021; pp. 233–258. [Google Scholar]

- Decreto Legislativo 22 Gennaio 2004, n. 42. Codice dei Beni Culturali e del Paesaggio, ai Sensi Dell’articolo 10 Della Legge 6 Luglio 2002, n. 137; 2004. Available online: https://www.torrossa.com/en/resources/an/2461925 (accessed on 5 June 2025).

- Gulli, R.; Predari, G. Il Moderno a Bologna: La Facoltà di Ingegneria di Giuseppe Vaccaro (1932–1935). ANANKE 2018, 83, 101–108. [Google Scholar]

- Predari, G.; Gulli, R. Types and models of Italian Modern Heritage. The work of Giuseppe Vaccaro in Emilia Romagna Region (1930–1950). Tema Technol. Eng. Mater. Archit. 2017, 3, 37–48. [Google Scholar]

- Massafra, A.; Gulli, R. Enabling Bidirectional Interoperability Between BIM and BPS Through Lightweight Topological Models. In Proceedings of the eCAADe 2023: Digital Design Reconsidered, Graz, Austria, 18–23 September 2023; pp. 187–196. [Google Scholar] [CrossRef]

- Massafra, A.; Costantino, C.; Predari, G.; Gulli, R. Building Information Modeling and Building Performance Simulation-Based Decision Support Systems for Improved Built Heritage Operation. Sustainability 2023, 15, 11240. [Google Scholar] [CrossRef]

- buildingSMART International, Industry Foundation Classes (IFC). Available online: https://technical.buildingsmart.org/standards/ifc (accessed on 18 August 2023).

- EnergyPlus. Available online: https://energyplus.net/ (accessed on 8 May 2023).

- Robert McNell & Associates, Rhino-Rhinoceros 3D. Available online: https://www.rhino3d.com/it/ (accessed on 30 April 2024).

- Rhino.Inside.Revit. Available online: https://www.rhino3d.com/inside/revit/beta/ (accessed on 5 June 2025).

- LadyBug Tools. Available online: https://www.ladybug.tools/ (accessed on 18 January 2023).

- LadybugTools, EPW Map. Available online: https://www.ladybug.tools/epwmap/ (accessed on 8 January 2024).

- Zwierzycki Mateusz, Anemone. 2015. Available online: https://www.Food4rhino.com/en/app/anemone (accessed on 10 April 2025).

- Regione Emilia Romagna. Approvazione Delle Modifiche all’ “Atto di Coordinamento Tecnico Regionale per la Definizione dei Requisiti minimi di Prestazione Energetica degli Edifici” di cui alla Propria Deliberazione N. 967/2015 e S.M.I.; Regione Emilia Romagna: Bologna, Italy, 2022; Volume DGR 1261/2022. [Google Scholar]

- ISO 13786:2017; Thermal Performance of Building Components—Dynamic Thermal Characteristics—Calculation Methods. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/standard/65711.html (accessed on 5 June 2025).

- UNI EN ISO 13788:2012; Hygrothermal Performance of Building Components and Building Elements—Internal Surface Temperature to Avoid Critical Surface Humidity and Interstitial Condensation—Calculation Methods. ISO: Geneva, Switzerland, 2012. Available online: https://www.iso.org/standard/51615.html (accessed on 5 June 2025).

- EnergyPlus Input Output Reference, Version 8.0. Big Ladder Software. Available online: https://bigladdersoftware.com/epx/docs/8-0/input-output-reference/index.html (accessed on 5 June 2025).

- MacQueen, J.B. Some Methods for Classification and Analysis of Multivariate Observations. In Proceedings of the Fifth Berkeley Symposium on Mathematical Statistics and Probability, Davis Davis, CA, USA, 18–21 July, 27 December 1965–7 January 1966; Le Cam, L.M., Neyman, J., Eds.; University of California Press: Berkeley, CA, USA, 1967; Volume 1, pp. 281–297. Available online: https://projecteuclid.org/euclid.bsmsp/1200512992 (accessed on 27 February 2025).

- Thorndike, R.L. Who Belongs in the Family? Psychometrika 1953, 18, 267–276. [Google Scholar] [CrossRef]

- Rousseeuw, P.J. Silhouettes: A graphical aid to the interpretation and validation of cluster analysis. J. Comput. Appl. Math. 1987, 20, 53–65. [Google Scholar] [CrossRef]

- Daniel, S.; Ghiaus, C. Multicriteria Decision Analysis for Energy Retrofit of Residential Buildings: Methodology and Feedback from Real Application. Energies 2023, 16, 902. [Google Scholar] [CrossRef]

- Choi, S.; Lim, H.; Lim, J.; Yoon, S. Retrofit building energy performance evaluation using an energy signature-based symbolic hierarchical clustering method. Build. Environ. 2024, 251, 111206. [Google Scholar] [CrossRef]

- Villalba, P.; Sánchez-Garrido, A.J.; Yepes, V. A review of multicriteria decision-making methods for building assessment, selection, and retrofit. J. Civ. Eng. Manag. 2024, 30, 465–480. [Google Scholar] [CrossRef]

- de Wilde, P. The gap between predicted and measured energy performance of buildings: A framework for investigation. Autom. Constr. 2014, 41, 40–49. [Google Scholar] [CrossRef]

| Output | Calculation Methods and Tools | Reference |

|---|---|---|

| UTOT | “Honeybee_Decompose EP Construction” GH component, supported by custom GHPython node for better computational speed. | EN ISO 13786:2017 [27] |

| YIE | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | EN ISO 13786:2017 [27] |

| DF | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | EN ISO 13786:2017 [27] |

| PS | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | EN ISO 13786:2017 [27] |

| W | Multiplication of panel’s thickness and density, computed through basic GH components. | - |

| SD | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | EN ISO 13786:2017 [27] |

| AHCI/AHCE | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | EN ISO 13786:2017 [27] |

| MMC | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | UNI EN ISO 13788:2012 [28] |

| TYC | Custom GHPython node compliant, developed following the calculation procedures of reference standards. | UNI EN ISO 13788:2012 [28] |

| STI/STE | Calculated through the “Honeybee_Run EP Simulation” GH component, assumed equal to the EP variable “Surface Inside Face Temperature”. | EnergyPlus Input Output Reference [29] |

| EDH | Calculated through the “Honeybee_Run EP Simulation” GH component, assumed equal to the EP variable “Zone Ideal Loads Zone Total Heating Energy”. | EnergyPlus Input Output Reference [29] |

| EDC | Calculated through the “Honeybee_Run EP Simulation” GH component, assumed equal to the EP variable “Zone Ideal Loads Zone Total Cooling Energy”. | EnergyPlus Input Output Reference [29] |

| EDTOT | Sum of EDH and EDC, computed in GH through the “Addition” component. | EnergyPlus Input Output Reference [29] |

| ELR | Difference between current EDTOT and design EDTOT, computed through basic GH components. | - |

| RS | Ratio between the footprint area of the panel and the net floor area of the space, computed through basic GH components. | - |

| Material | Thermal Conductivity [W/mK] | Density [kg/m3] | Specific Heat [J/kgK] | Vapor Resistance [-] | Thickness [m] | UTOT [W/m2K] | YIE [W/m2K] | DF [-] | PS [hh] | SD [kg/m2] |

|---|---|---|---|---|---|---|---|---|---|---|

| Reed panels | 0.055 | 200 | 1500 | 2.0 | 0.030 | 0.52 | 0.0158 | 0.030 | 17.32 | 746.36 |

| 0.050 | 0.44 | 0.0106 | 0.024 | 17.98 | 750.36 | |||||

| Hemp-based thermal plaster | 0.085 | 400 | 1500 | 5.0 | 0.020 | 0.63 | 0.0259 | 0.041 | 16.99 | 748.36 |

| 0.100 | 0.39 | 0.0064 | 0.016 | 21.06 | 780.36 | |||||

| Hemp panels (lower density) | 0.036 | 40 | 1300 | 2.0 | 0.030 | 0.46 | 0.0118 | 0.026 | 17.13 | 741.56 |

| 0.200 | 0.14 | 0.0019 | 0.014 | 20.06 | 748.36 | |||||

| Hemp panels (higher density) | 0.034 | 80 | 1700 | 3.9 | 0.020 | 0.45 | 0.0112 | 0.025 | 17.07 | 742.76 |

| 0.160 | 0.16 | 0.0018 | 0.012 | 21.89 | 753.16 | |||||

| Clay panels | 0.353 | 1450 | 1100 | 7.5 | 0.016 | 0.71 | 0.0412 | 0.058 | 16.67 | 763.56 |

| 0.022 | 0.52 | 0.0158 | 0.030 | 17.32 | 746.36 |

| Material | Thermal Conductivity [W/mK] | Density [kg/m3] | Specific Heat [J/kgK] | Vapor Resistance [-] | Thickness [m] | MMC [g/m2] | EDTOT [kWh] | ELR [%] | RS [%] |

|---|---|---|---|---|---|---|---|---|---|

| Reed panels | 0.055 | 200 | 1500 | 2.0 | 0.030 | 410 | 21,257 | 2.4 | 0.6 |

| 0.050 | 404 | 21,113 | 3.1 | 0.9 | |||||

| Hemp-based thermal plaster | 0.085 | 400 | 1500 | 5.0 | 0.020 | 178 | 21,477 | 1.4 | 0.4 |

| 0.100 | 214 | 21,084 | 3.2 | 1.8 | |||||

| Hemp panels (lower density) | 0.036 | 40 | 1300 | 2.0 | 0.030 | 385 | 21,111 | 3.1 | 0.5 |

| 0.200 | 1466 | 20,589 | 5.5 | 3.7 | |||||

| Hemp panels (higher density) | 0.034 | 80 | 1700 | 3.9 | 0.020 | 390 | 21,100 | 3.1 | 0.4 |

| 0.160 | 949 | 20,637 | 5.2 | 2.9 | |||||

| Clay panels | 0.353 | 1450 | 1100 | 7.5 | 0.016 | 0 | 21,733 | 0.2 | 0.3 |

| 0.022 | 0 | 21,718 | 0.3 | 0.4 |

| Thermal Conductivity [W/mK] | Density [kg/m3] | Specific Heat [J/kgK] | Vapor Resistance [-] | Thickness [m] | UTOT [W/m2K] | YIE [W/m2K] | DF [-] | PS [hh] | SD [kg/m2] | AHCI [kJ/m2K] | MMC [g/m2] | TYC [g/m2] | EDTOT [kWh] | ELR [%] | RS [%] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.094 | 126 | 1547 | 39 | 0.086 | 0.44 | 0.0104 | 0.024 | 18.09 | 751 | 14.14 | 0 | 0 | 20,404 | 6.3 | 1.6 |

| 0.024 | 290 | 1841 | 49 | 0.165 | 0.12 | 0.0002 | 0.002 | 8.61 | 788 | 12.15 | 16 | 16 | 19,869 | 8.8 | 3.1 |

| 0.035 | 332 | 1638 | 156 | 0.197 | 0.14 | 0.0002 | 0.002 | 8.64 | 805 | 14.53 | 0 | 0 | 19,922 | 8.5 | 3.7 |

| 0.012 | 169 | 1745 | 10 | 0.169 | 0.06 | 0.0001 | 0.001 | 9.84 | 768 | 6.66 | 905 | 302 | 19,731 | 9.4 | 3.2 |

| 0.043 | 272 | 874 | 234 | 0.096 | 0.28 | 0.0044 | 0.016 | 19.90 | 766 | 9.95 | 0 | 0 | 20,123 | 7.6 | 1.8 |

| 0.070 | 91 | 1137 | 230 | 0.037 | 0.53 | 0.0164 | 0.031 | 17.08 | 743 | 18.37 | 0 | 0 | 20,537 | 5.7 | 0.7 |

| 0.039 | 464 | 1800 | 4 | 0.092 | 0.27 | 0.0021 | 0.008 | 0.66 | 783 | 18.45 | 765 | 469 | 20,166 | 7.4 | 1.7 |

| 0.055 | 25 | 1077 | 98 | 0.193 | 0.21 | 0.0033 | 0.016 | 18.21 | 745 | 4.23 | 0 | 0 | 19,944 | 8.4 | 3.6 |

| 0.032 | 148 | 1479 | 20 | 0.189 | 0.14 | 0.0008 | 0.006 | 1.99 | 768 | 9.22 | 179 | 104 | 19,878 | 8.7 | 3.5 |

| 0.034 | 25 | 1369 | 19 | 0.143 | 0.18 | 0.0028 | 0.015 | 18.32 | 743 | 3.66 | 189 | 124 | 19,901 | 8.6 | 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Massafra, A.; Mattioli, L.; Kozlova, I.; Mazzoli, C.; Predari, G.; Gulli, R. HBIM-Based Multicriteria Method for Assessing Internal Insulation in Heritage Buildings. Heritage 2025, 8, 259. https://doi.org/10.3390/heritage8070259

Massafra A, Mattioli L, Kozlova I, Mazzoli C, Predari G, Gulli R. HBIM-Based Multicriteria Method for Assessing Internal Insulation in Heritage Buildings. Heritage. 2025; 8(7):259. https://doi.org/10.3390/heritage8070259

Chicago/Turabian StyleMassafra, Angelo, Luca Mattioli, Iuliia Kozlova, Cecilia Mazzoli, Giorgia Predari, and Riccardo Gulli. 2025. "HBIM-Based Multicriteria Method for Assessing Internal Insulation in Heritage Buildings" Heritage 8, no. 7: 259. https://doi.org/10.3390/heritage8070259

APA StyleMassafra, A., Mattioli, L., Kozlova, I., Mazzoli, C., Predari, G., & Gulli, R. (2025). HBIM-Based Multicriteria Method for Assessing Internal Insulation in Heritage Buildings. Heritage, 8(7), 259. https://doi.org/10.3390/heritage8070259