Pendulum Mill: The Lifelong Project of Leonardo da Vinci

Abstract

1. Introduction

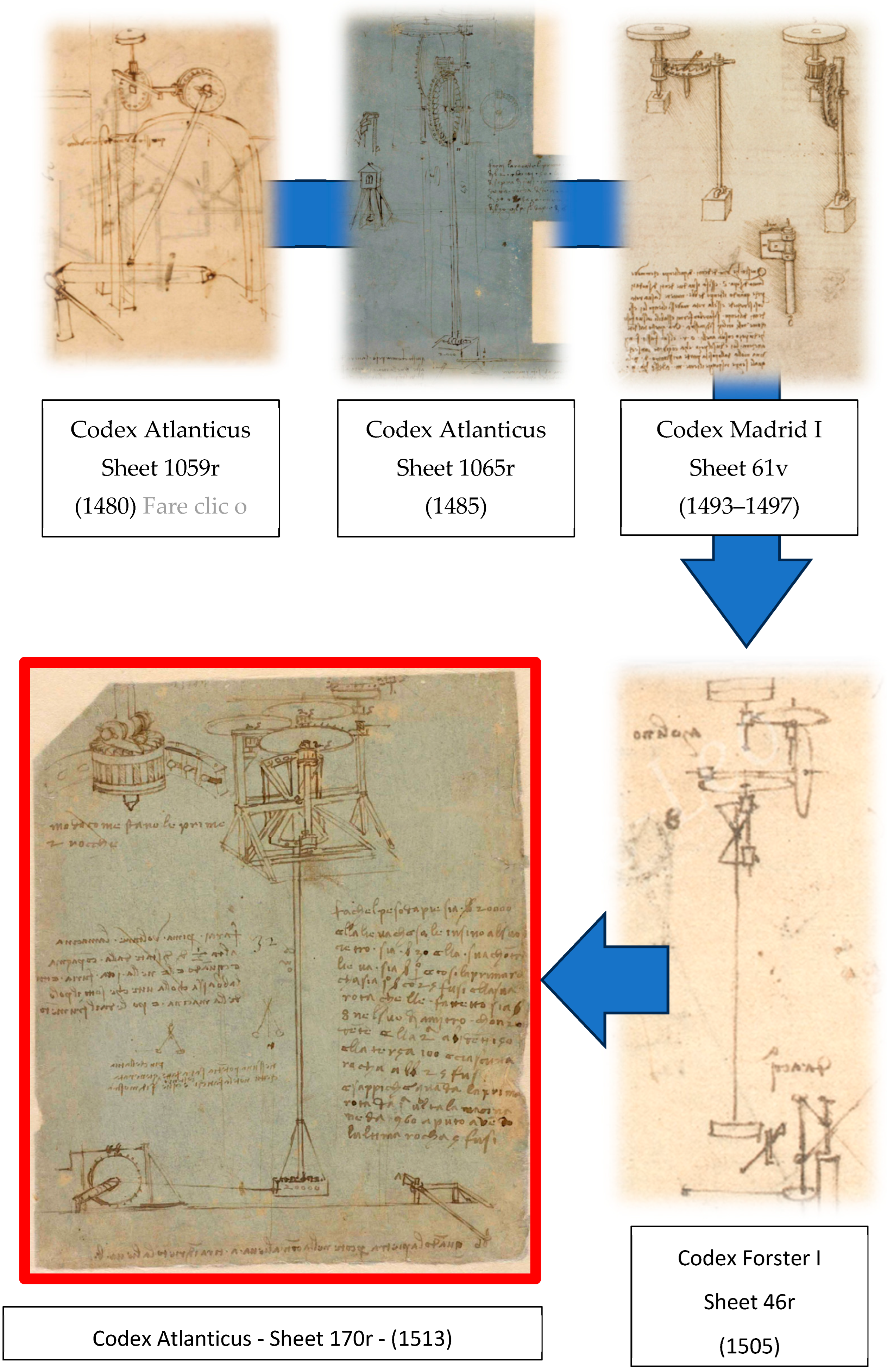

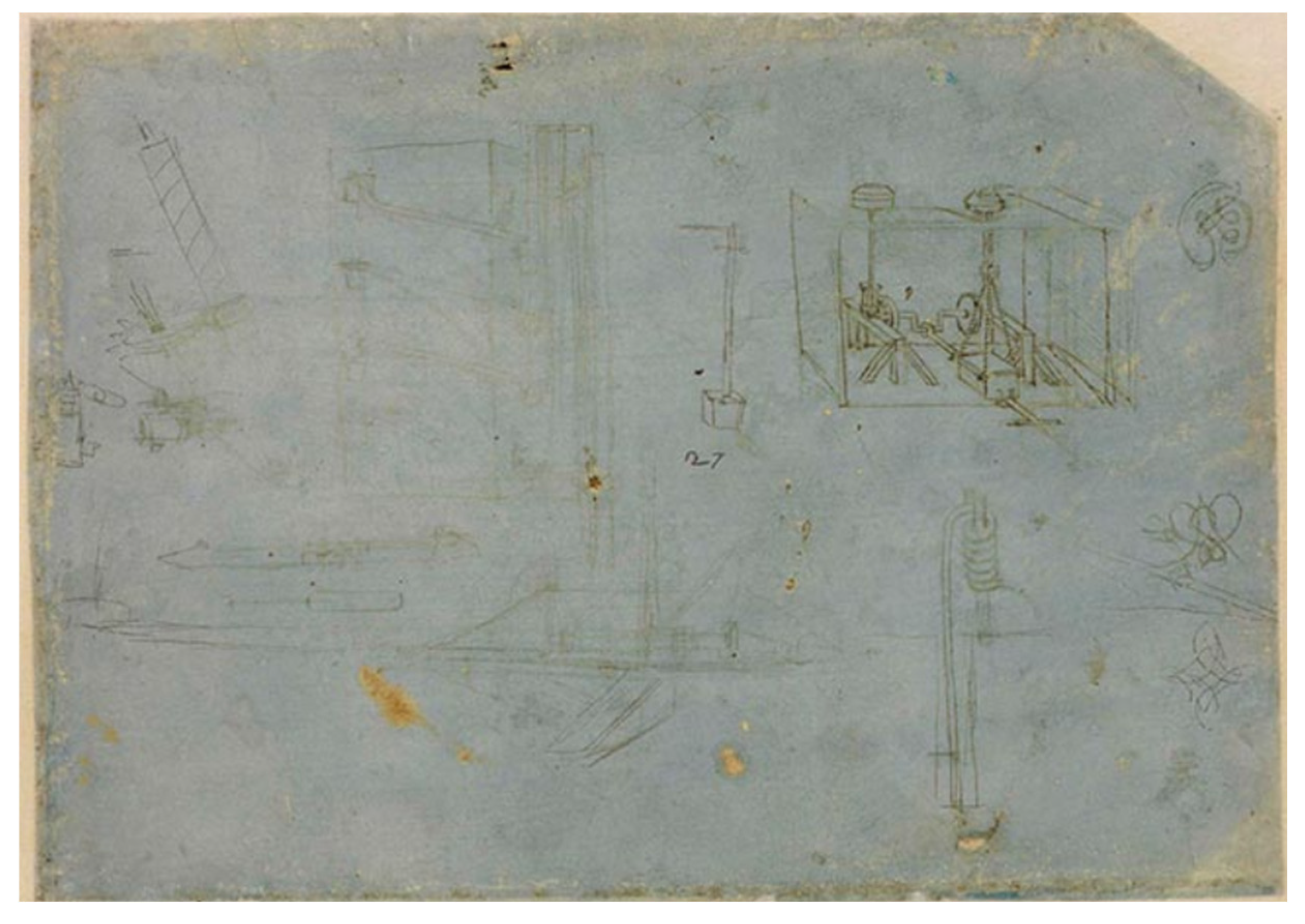

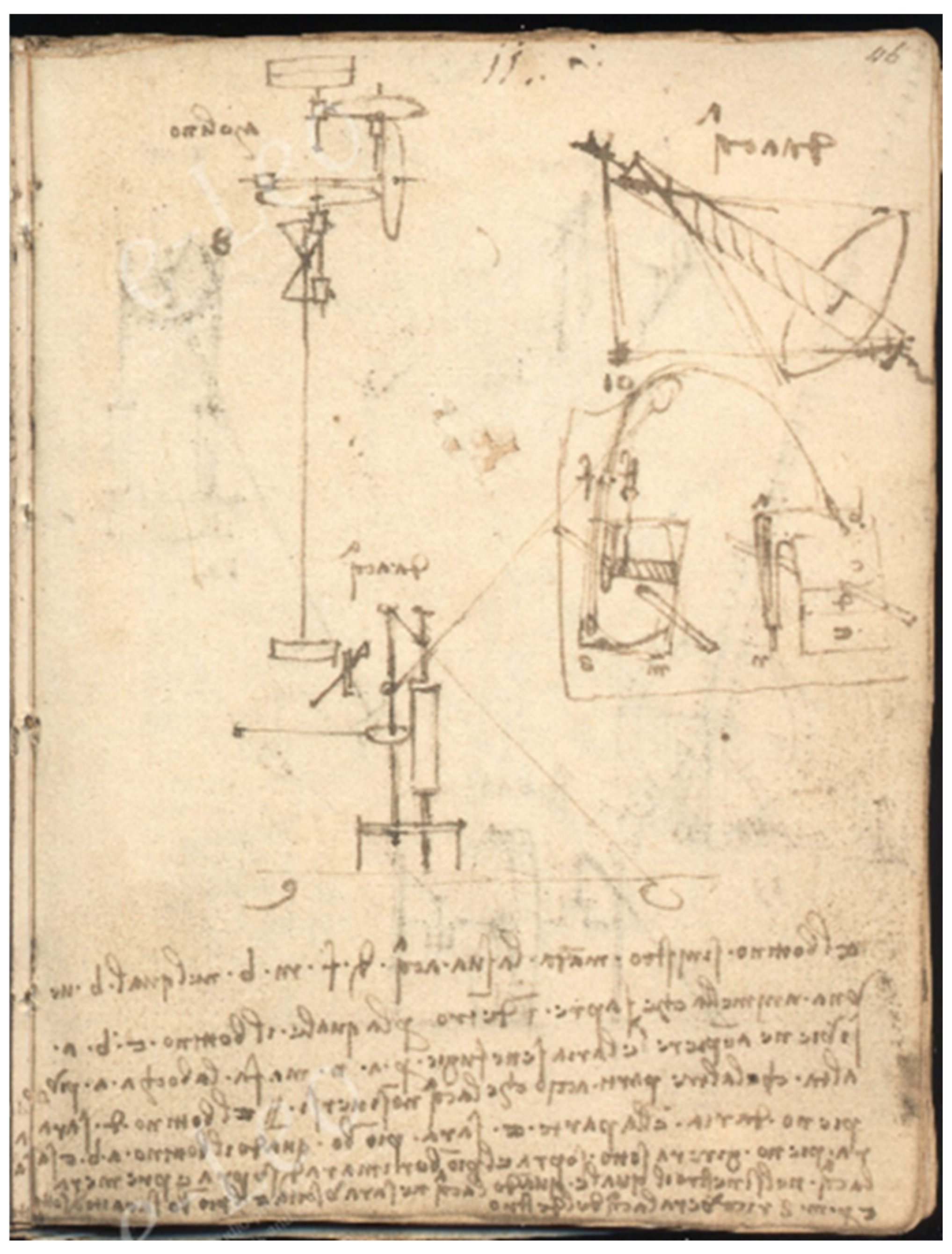

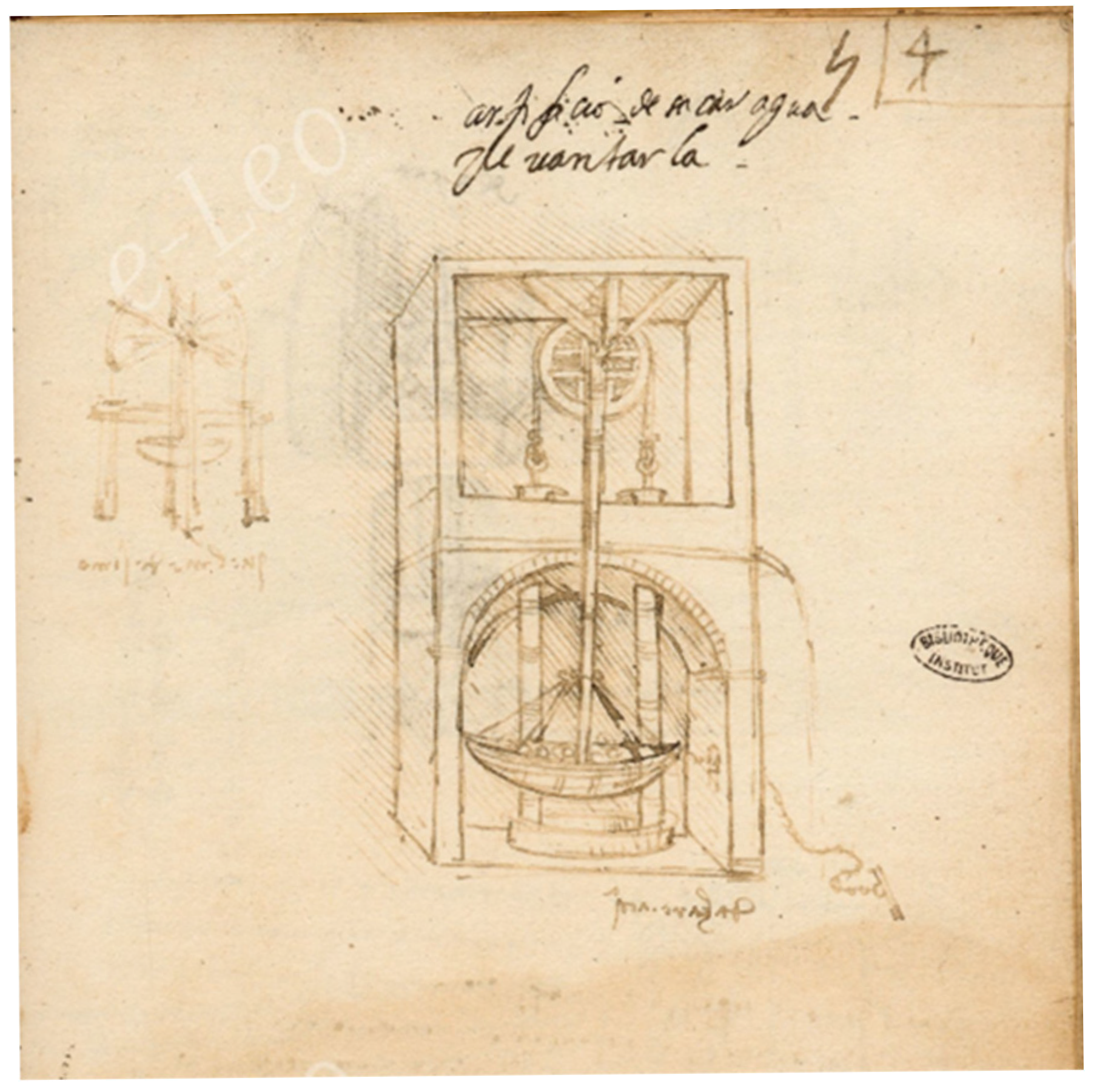

2. Evolution of the Concept

3. Materials and Methods

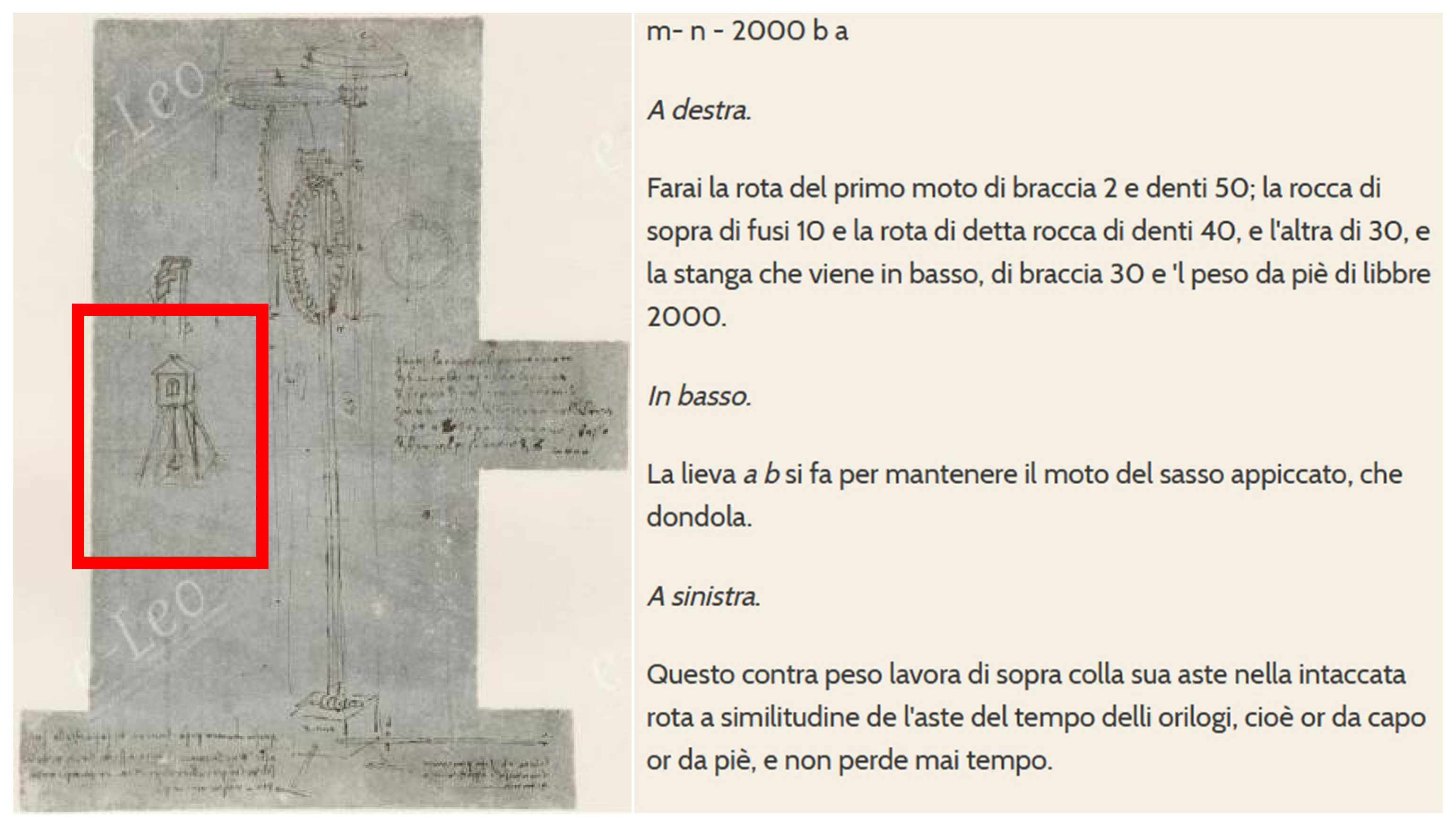

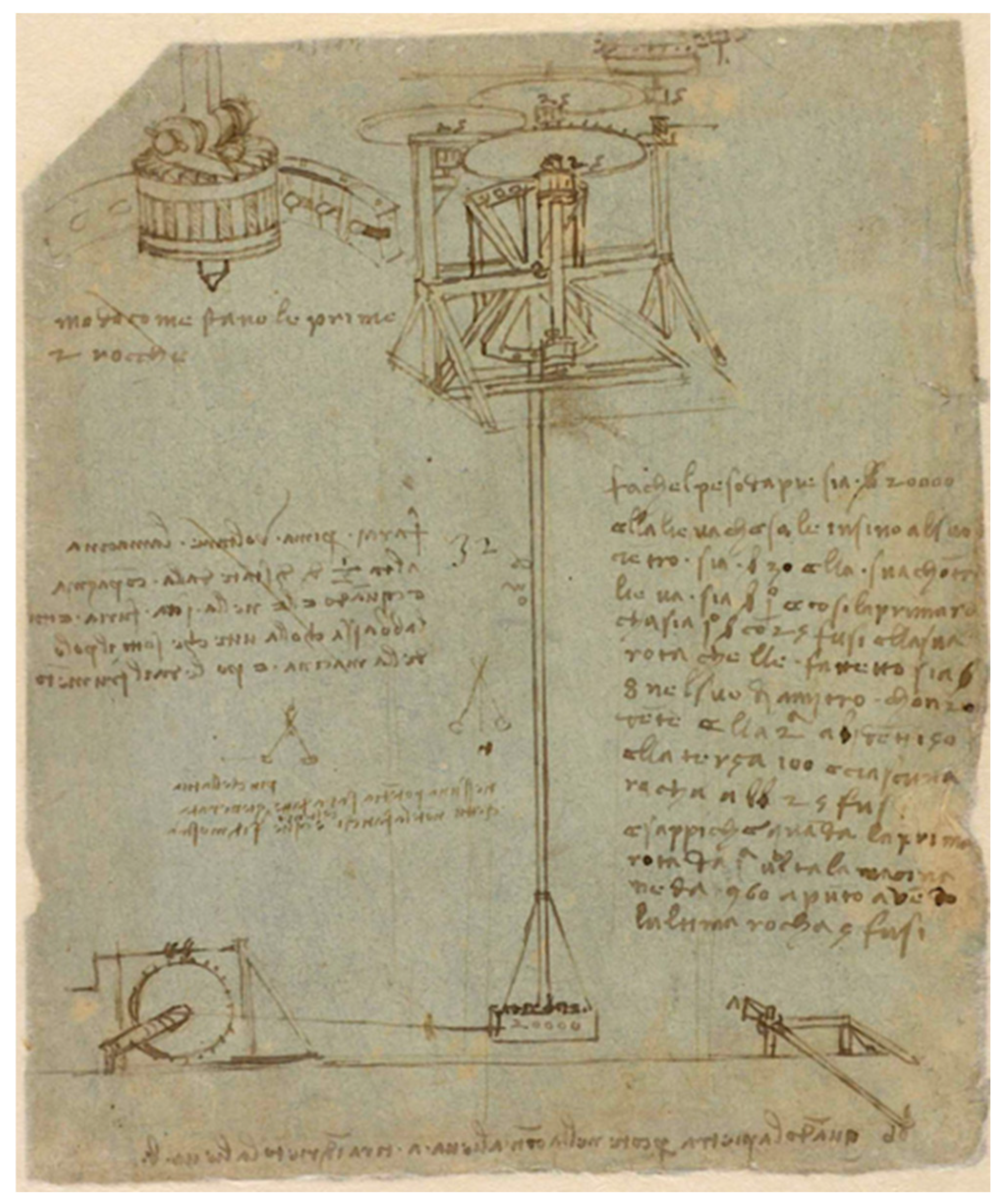

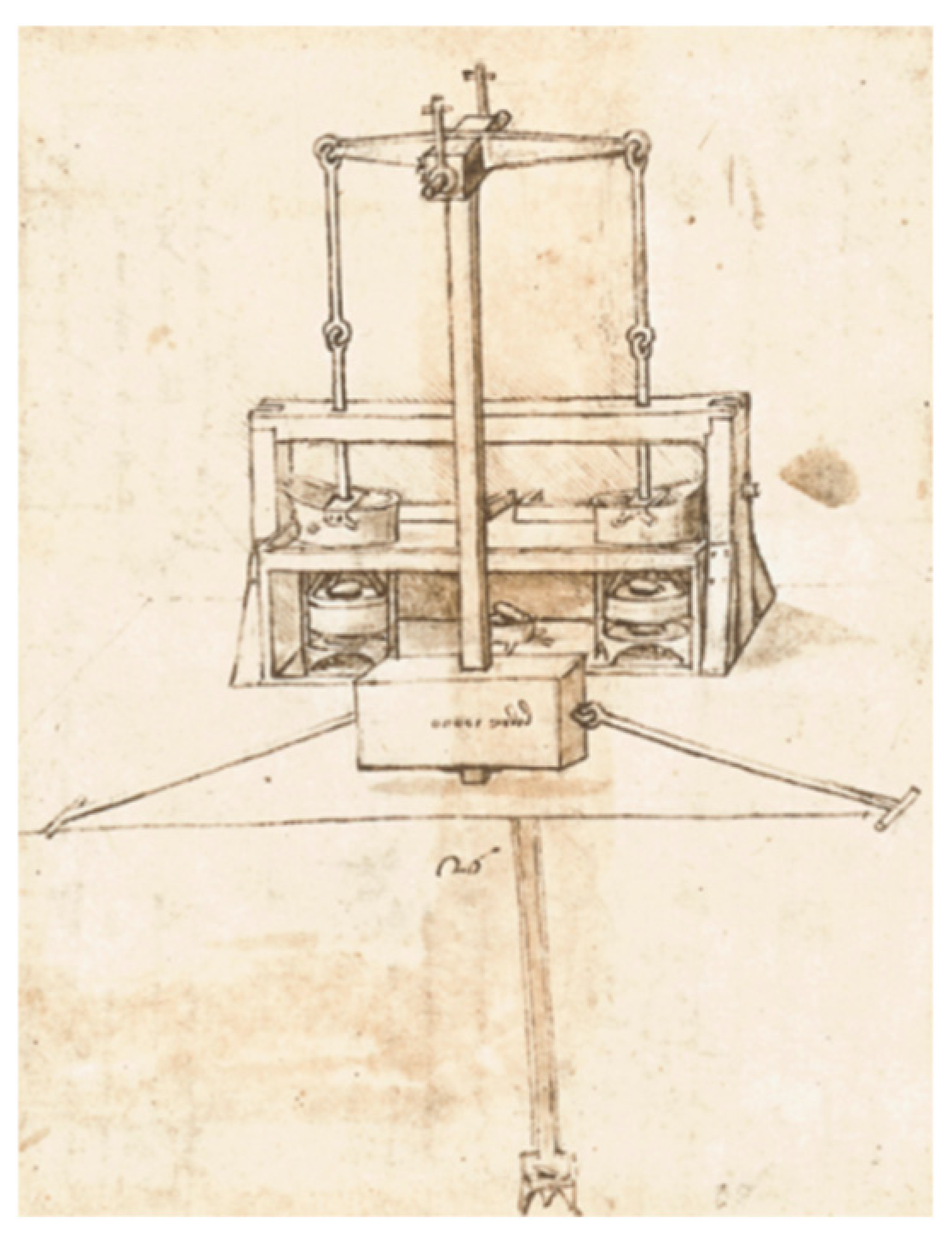

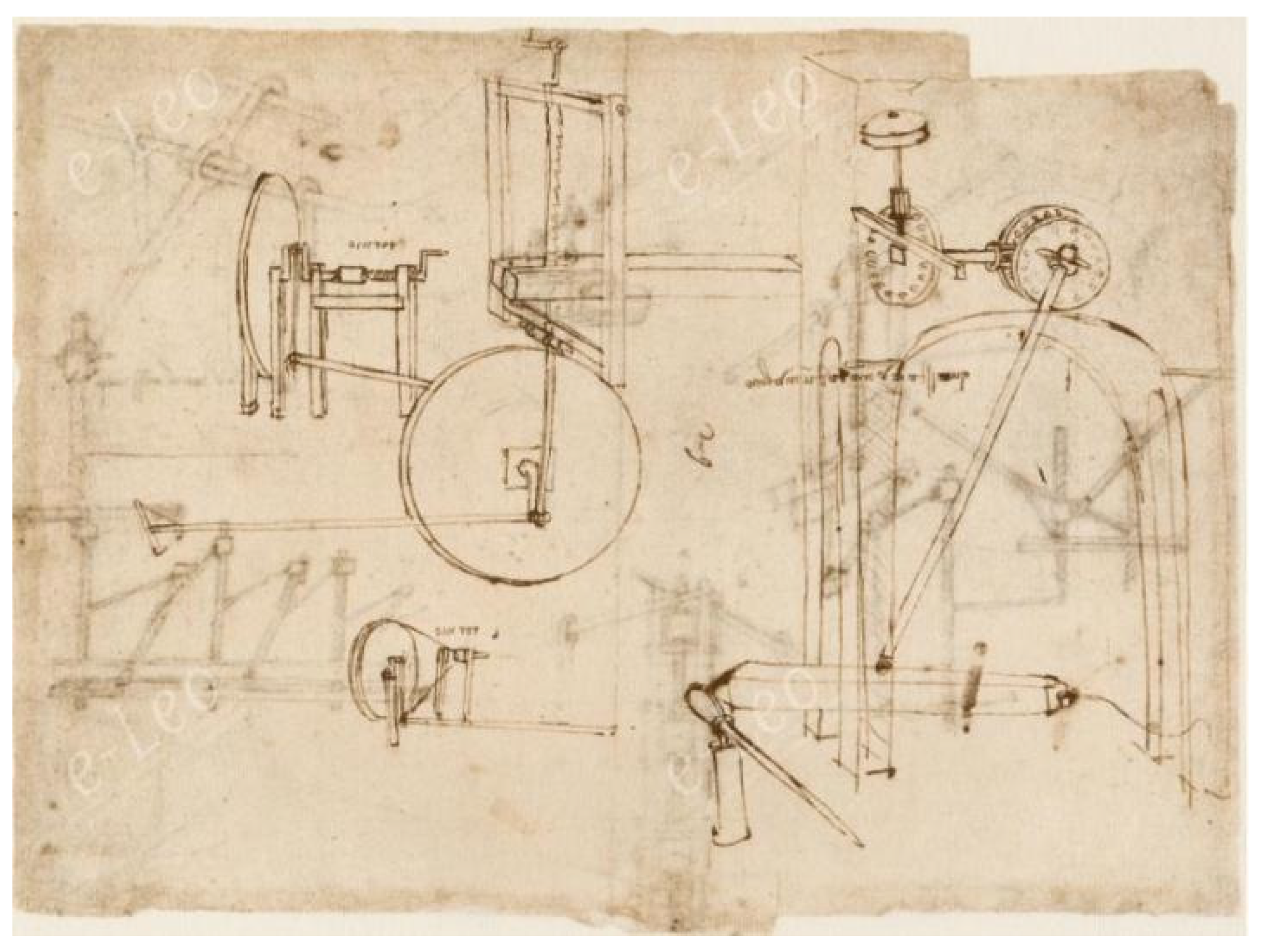

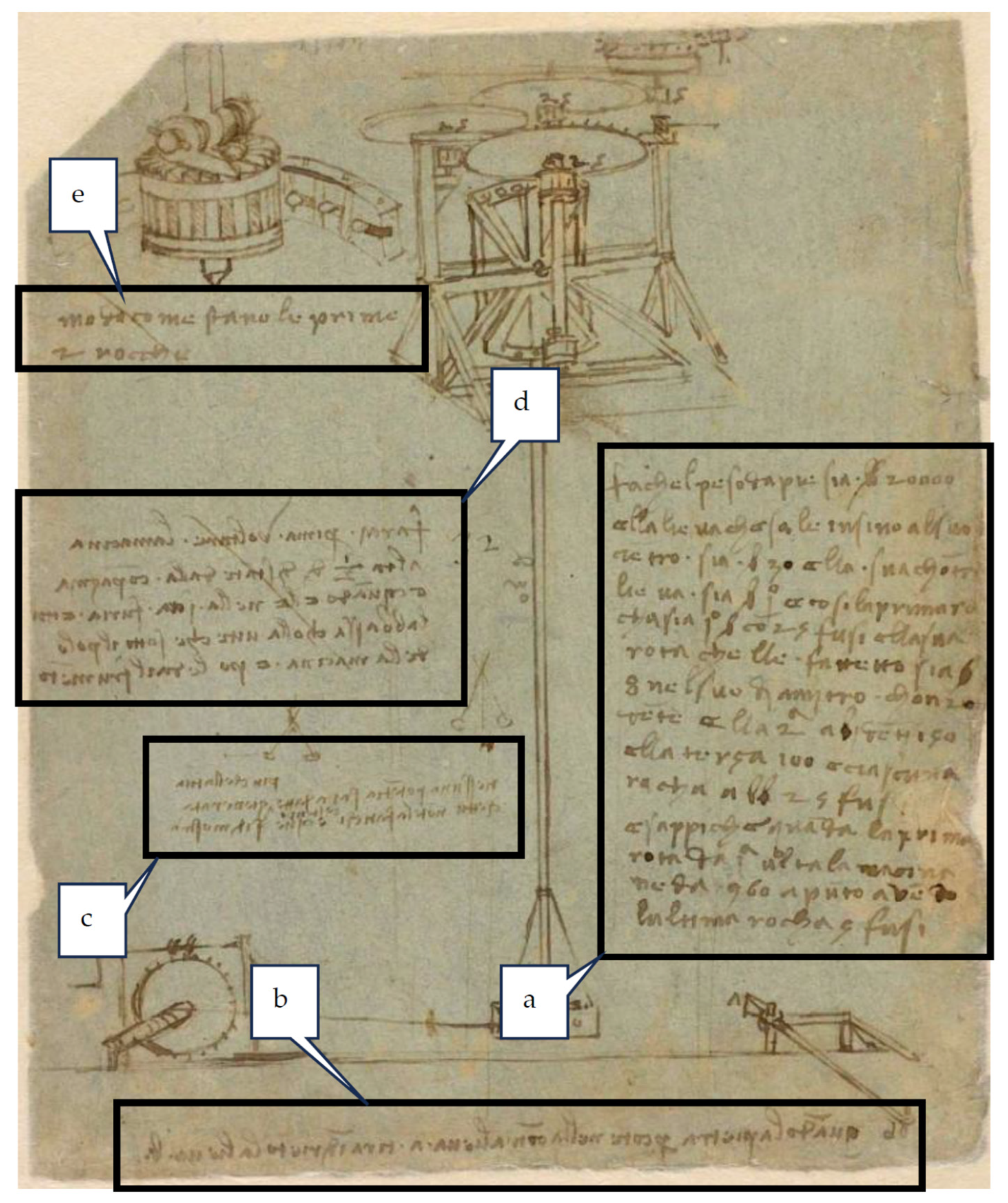

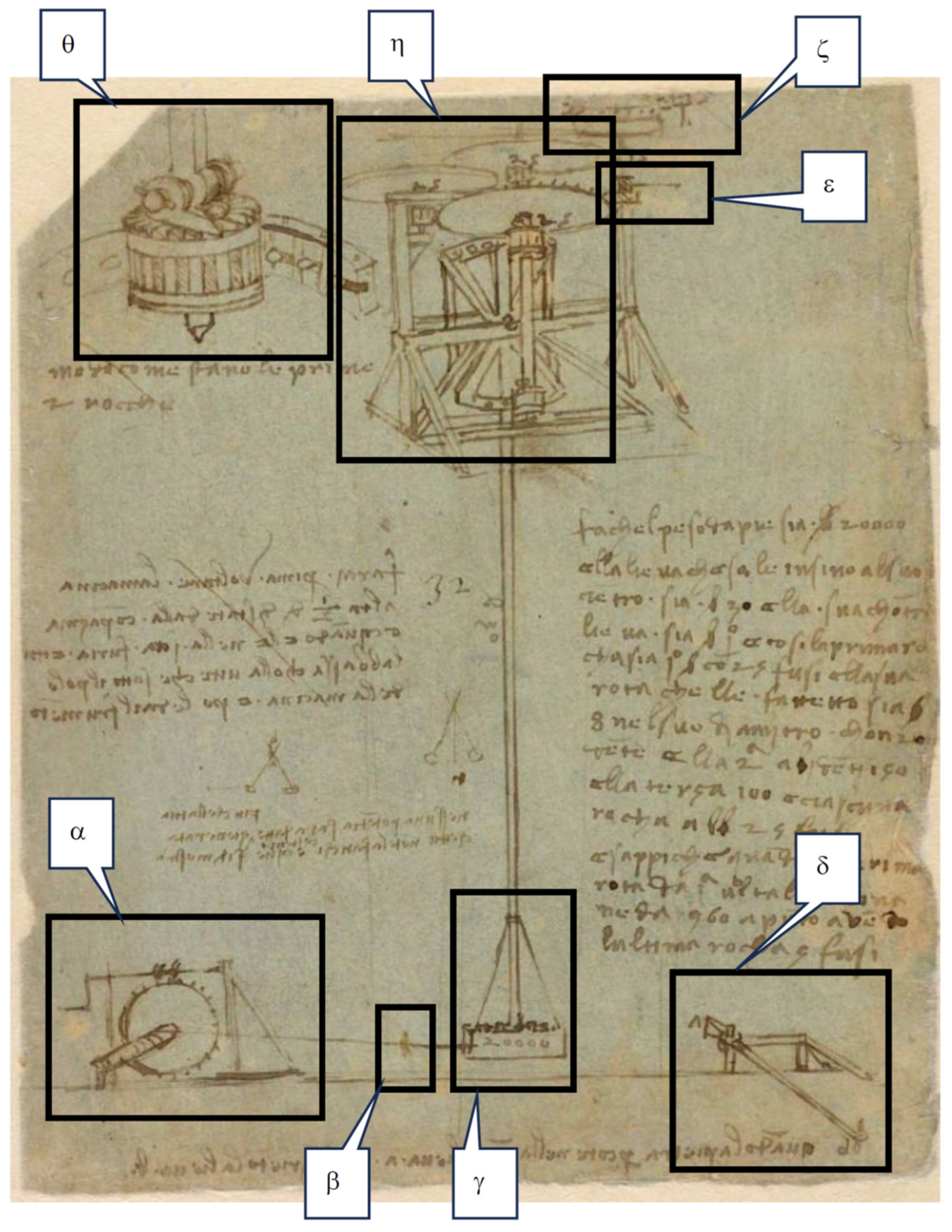

3.1. The Sheet 170r of the Codex Atlanticus

3.2. Approach for the Study and Reconstruction of Leonardo da Vinci’s Pendulum Mill

- 1.

- Systematic analysis of historical sources;

- 2.

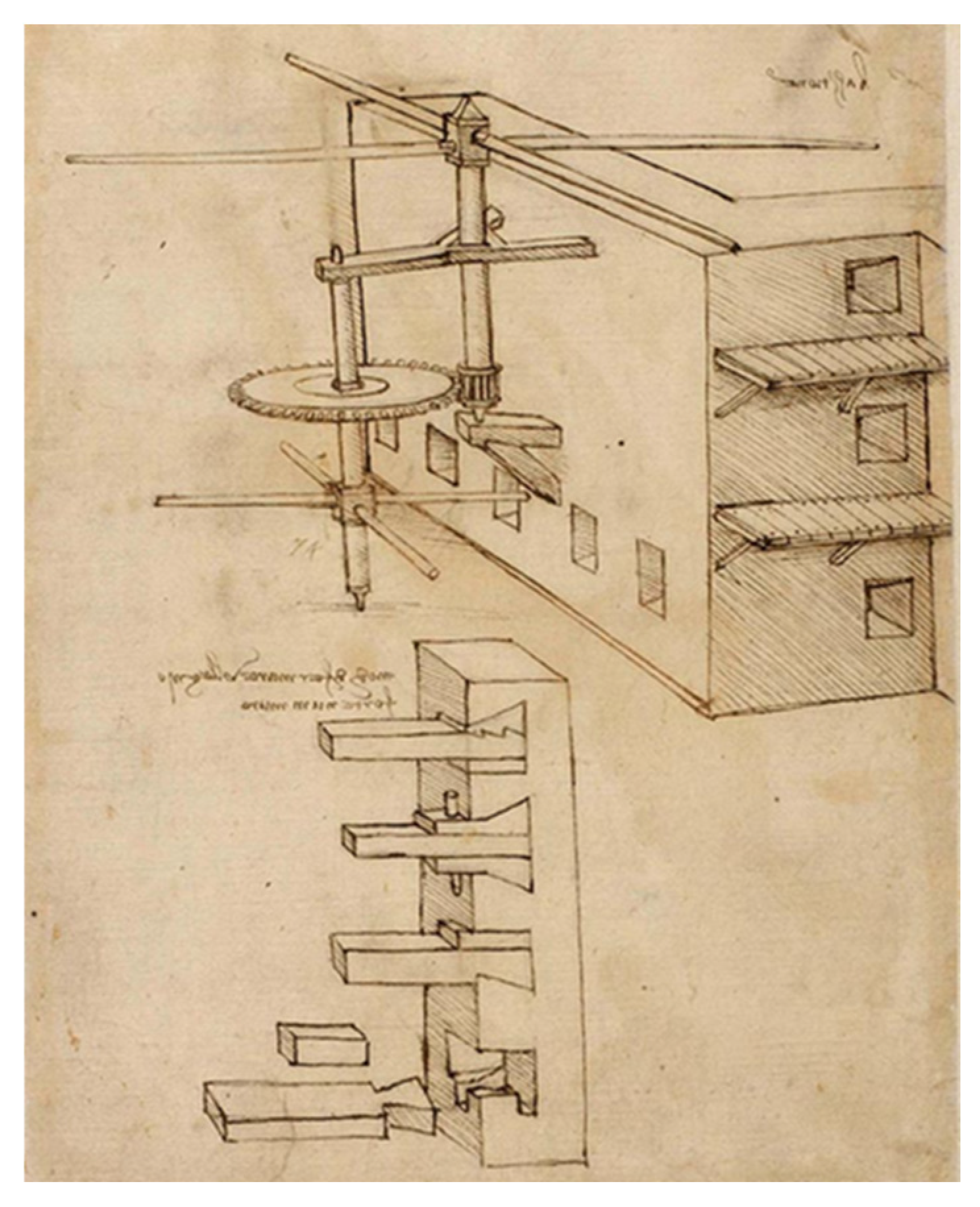

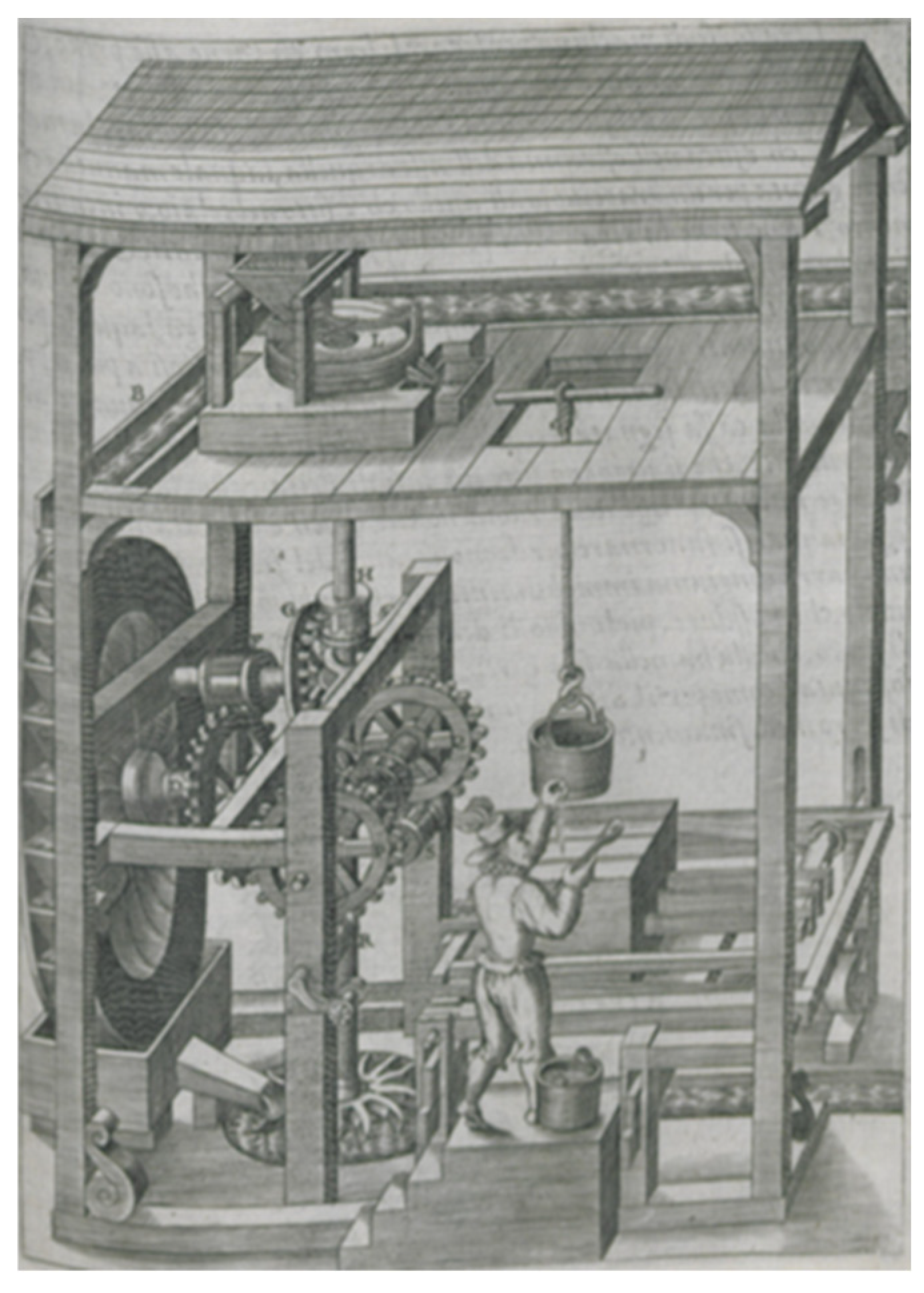

- Interpretative comparison with other known machines from Leonardo and his contemporaries;

- 3.

- Formulation of a coherent digital reconstruction that adheres to both historical and mechanical plausibility.

3.2.1. Historical Source Analysis

3.2.2. Interpretative Reconstruction of the Concept

- Direct Reference to Leonardo’s other works. If a specific mechanism or structural element is not explicitly represented in the sheet under study but can be identified in Leonardo’s other designs with a high degree of certainty, it is incorporated into the reconstruction. This ensures that the inferred components remain consistent with Leonardo’s established design principles and knowledge.

- Comparison with Analogous Machines from Leonardo’s Era. In cases where no clear precedent exists within Leonardo’s own works, reference is made to similar contemporary machines. Given that Renaissance engineering often exhibited a degree of standardization in mechanical solutions, especially in the domains of milling, gearing, and power transmission, this comparative approach provides a historically reliable knowledge basis for reconstructing missing elements.

- Functional and Structural Plausibility Assessment. Where neither of the above strategies yields a definitive answer, the study resorts to a mechanical feasibility analysis informed by established principles of Renaissance engineering. This involves assessing whether a proposed reconstruction would have been manufacturable by using the materials and techniques available in Leonardo’s time, as well as whether it aligns with known principles of mechanical advantage, friction management, and structural integrity.

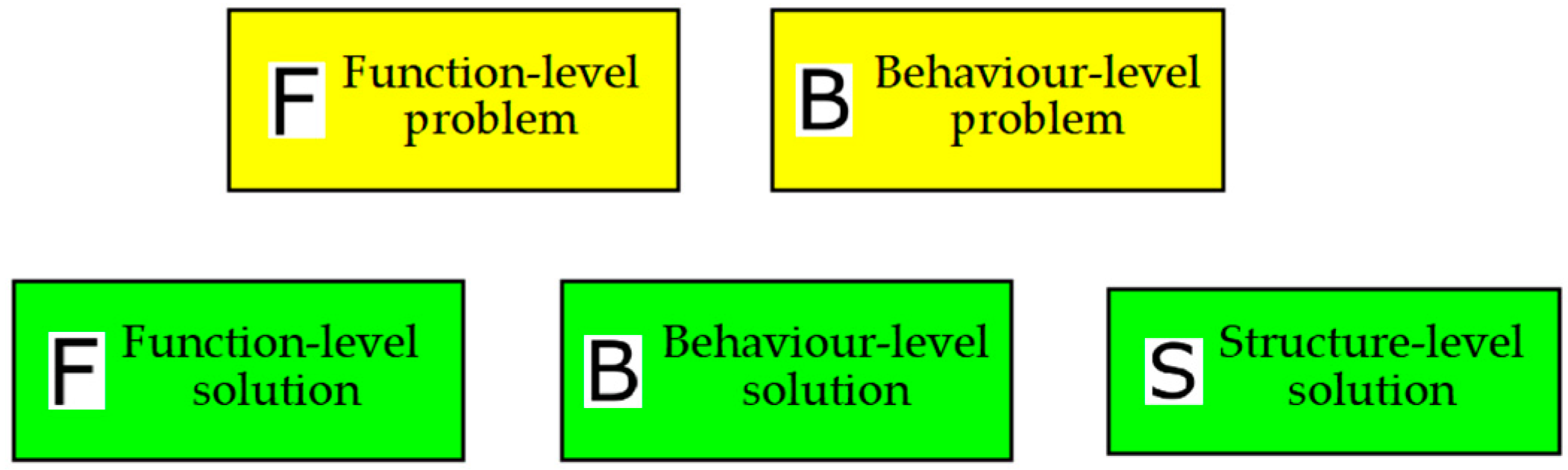

- Function (F): The intended purpose of the machine, as inferred from historical sources and comparative analysis. In this case, the function is the transformation of pendular motion into continuous rotational motion for milling.

- Behavior (B): The operational principles that enable the function to be realized, such as the oscillatory motion of the pendulum, its interaction with the transmission system, and the resulting torque applied to the millstone.

- Structure (S): The physical components that constitute the system, including gears, levers, axles, and the pendulum mechanism itself.

- Annotated sketches derived from Leonardo’s original sheets, with overlays highlighting key mechanical components and hypothesized interactions.

- Comparative analyses referencing similar Renaissance-era machines, aiding in the interpretation of ambiguous design elements.

- Technical literature and historical sources, organized by thematic relevance to facilitate targeted access to background information.

- External resources, including hyperlinks to digitized manuscripts and engineering databases for additional verification.

3.2.3. Digital Reconstruction of the Pendulum Mill

- Proportional calculations based on Leonardo’s original annotations, integrating unit conversions where necessary (e.g., the translation of Renaissance measurement systems into modern SI units).

- Human factor considerations, estimating dimensions according to the average stature and biomechanics of period laborers, ensuring that operational aspects of the machine were realistically scaled.

- Dynamic constraints, particularly in relation to the physics of the pendulum, verifying whether the hypothesized motion transmission system could feasibly generate the required torque and rotational speeds.

4. Results

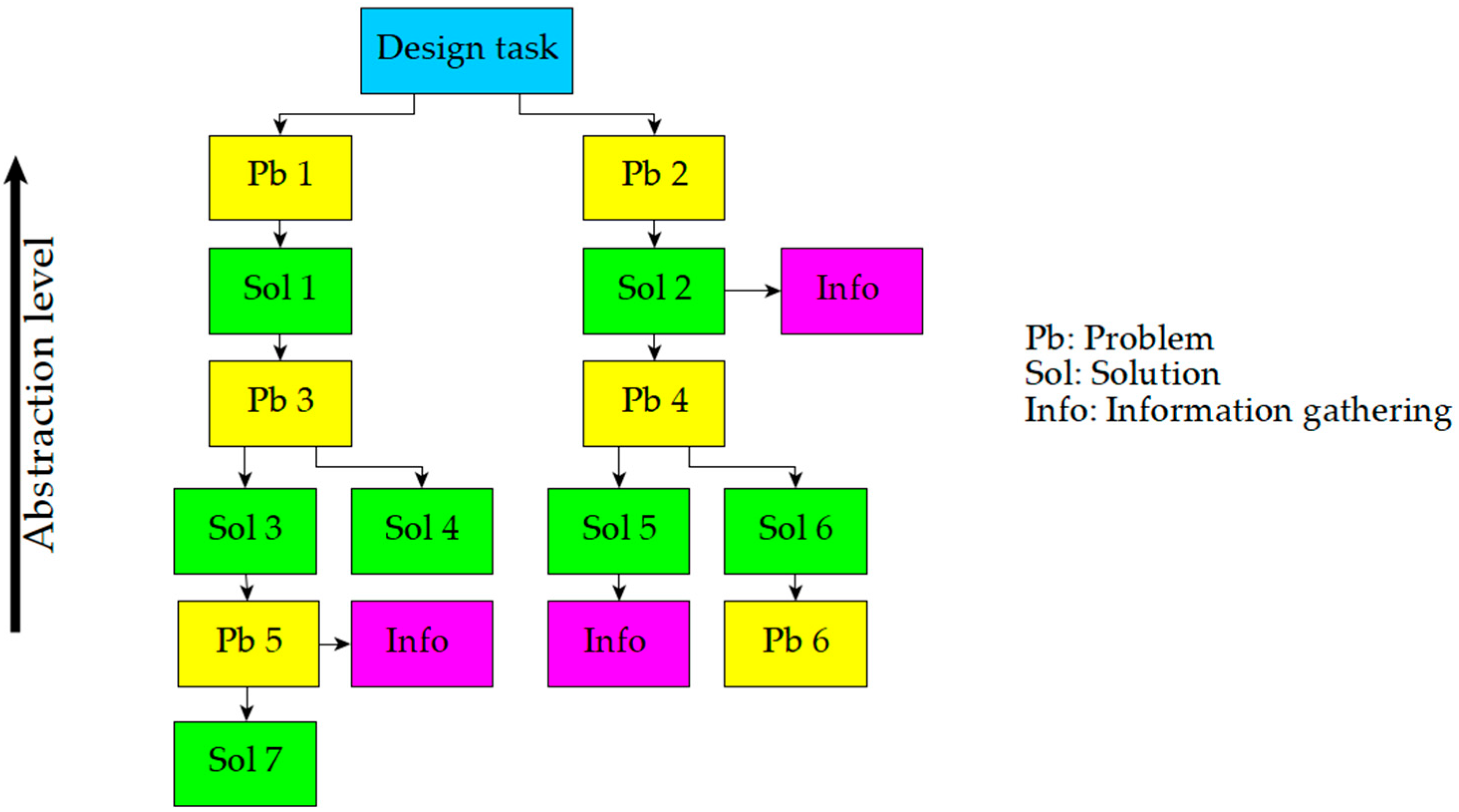

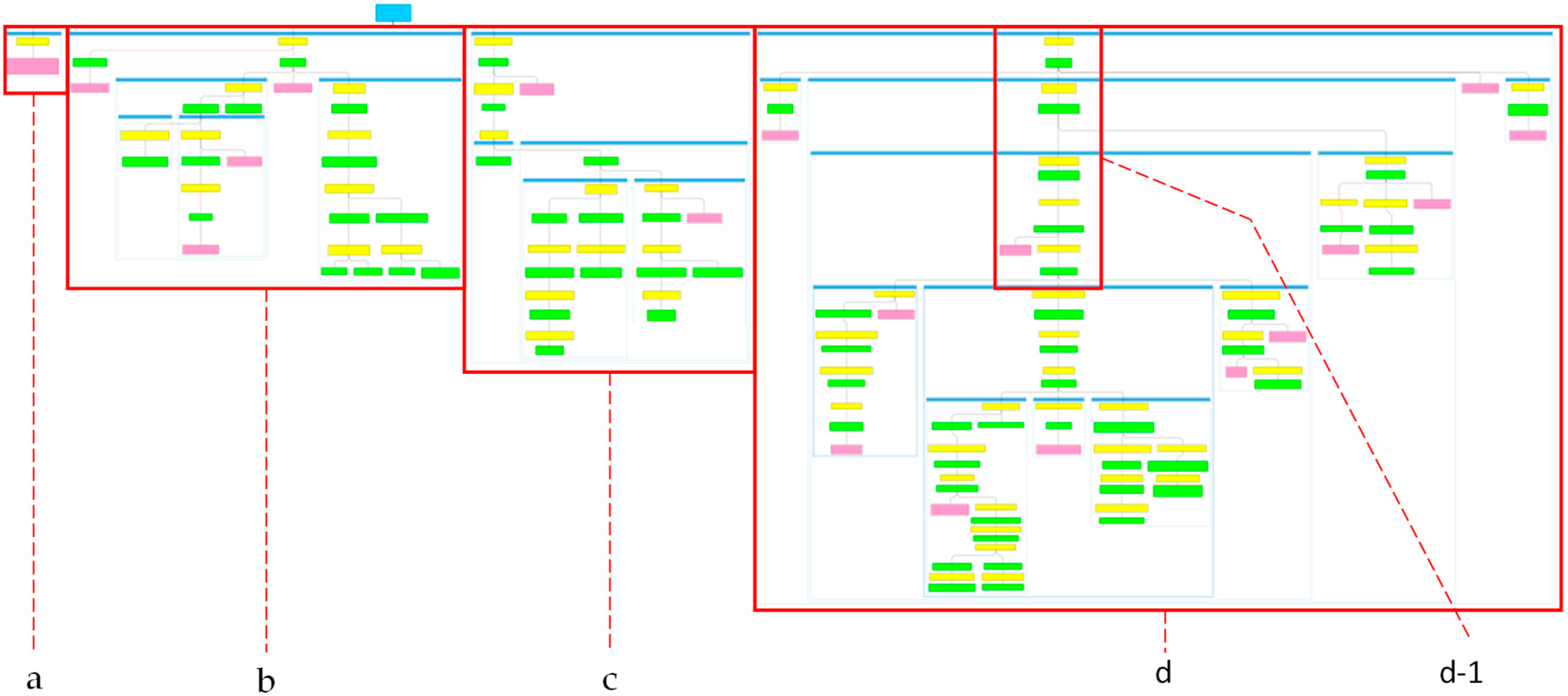

4.1. The PSN

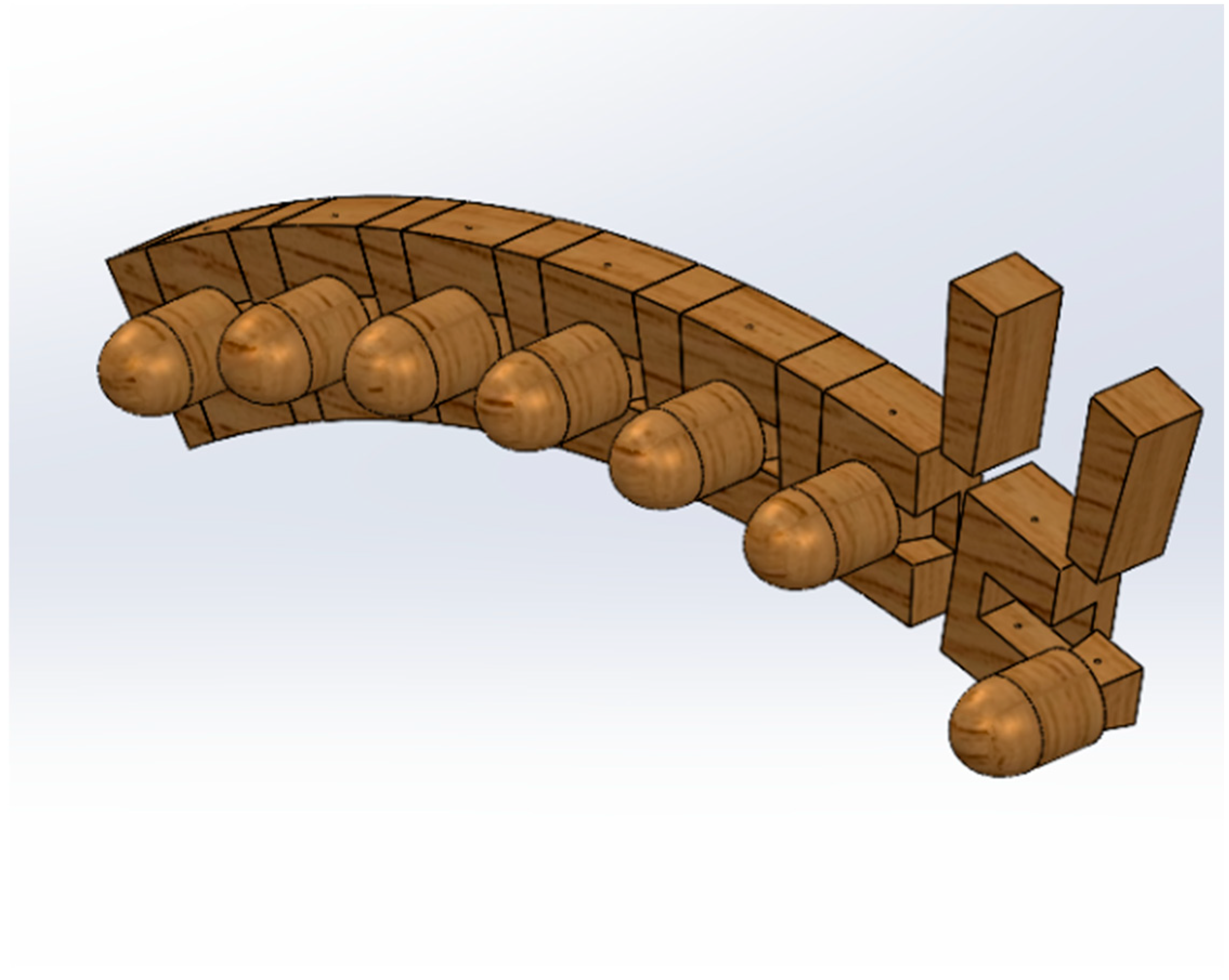

4.2. Key Element: The Gear Train

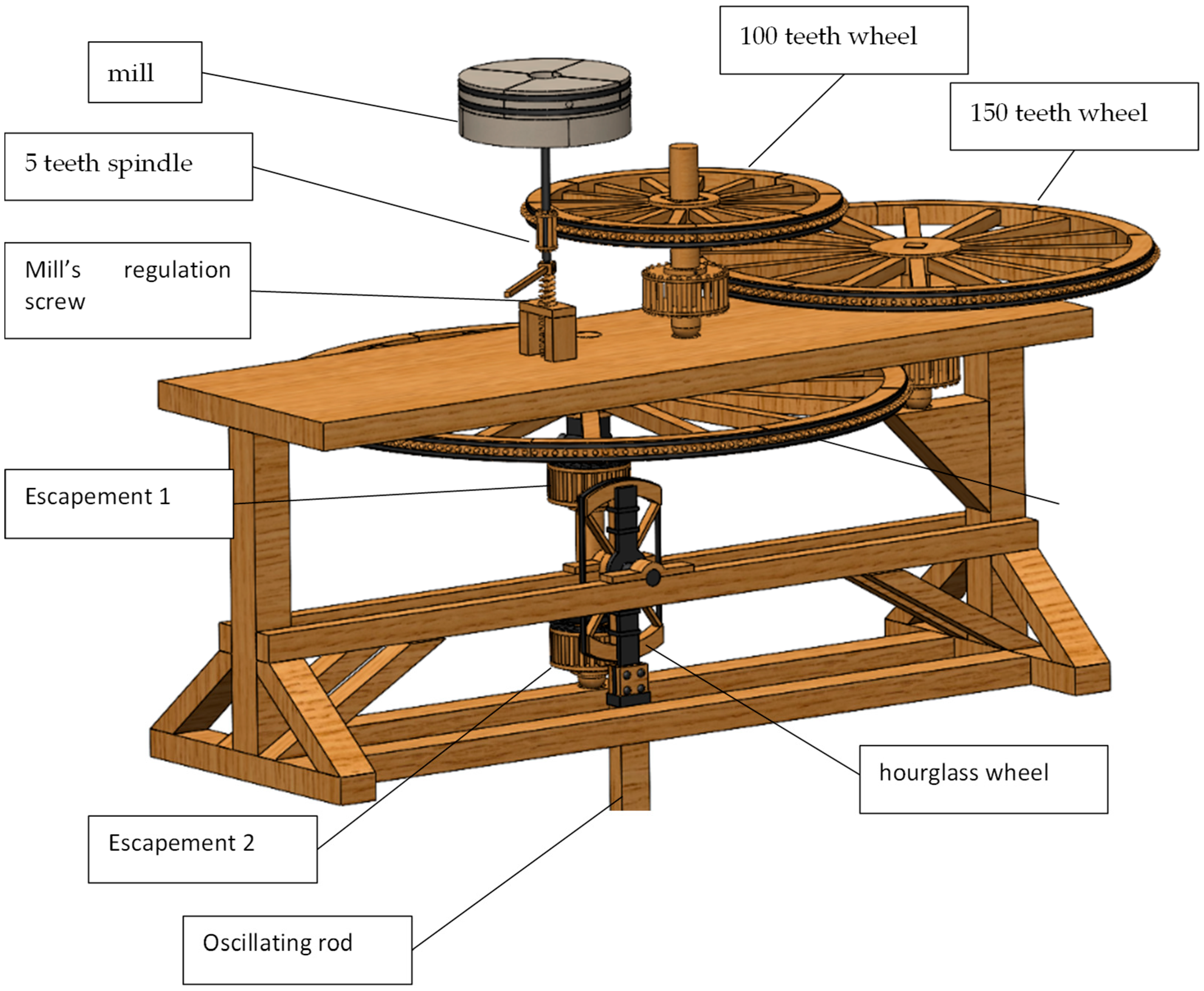

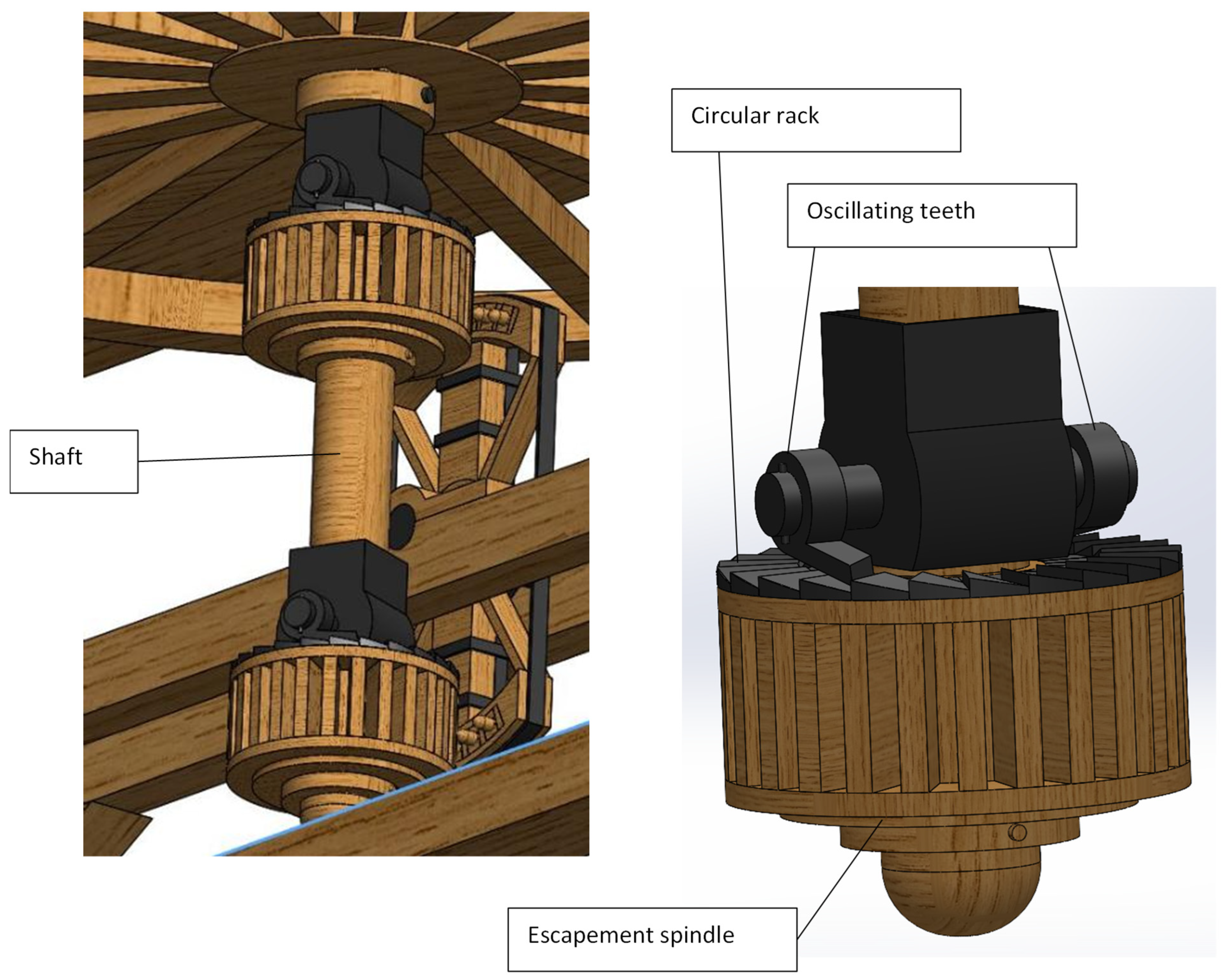

4.3. Digital Model of the Whole Milling Structure

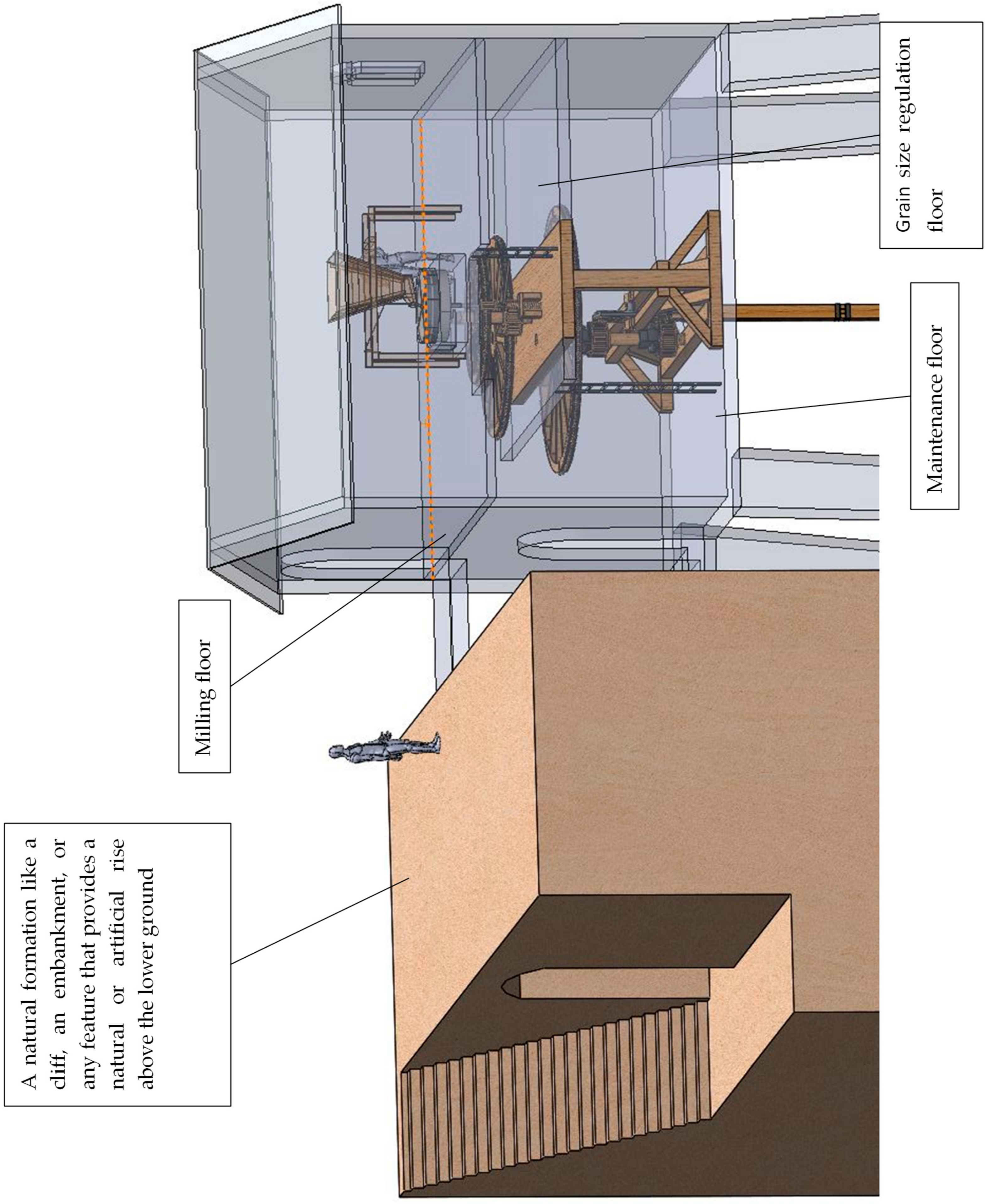

- the “milling floor”, where the raw material is delivered and processed by the mill

- the “grain size regulation floor”, where the regulating screw is placed. The regulating screw is intended to increase or decrease the gap between the two milling stones.

- The “maintenance floor”, where there is full accessibility to the main mechanisms.

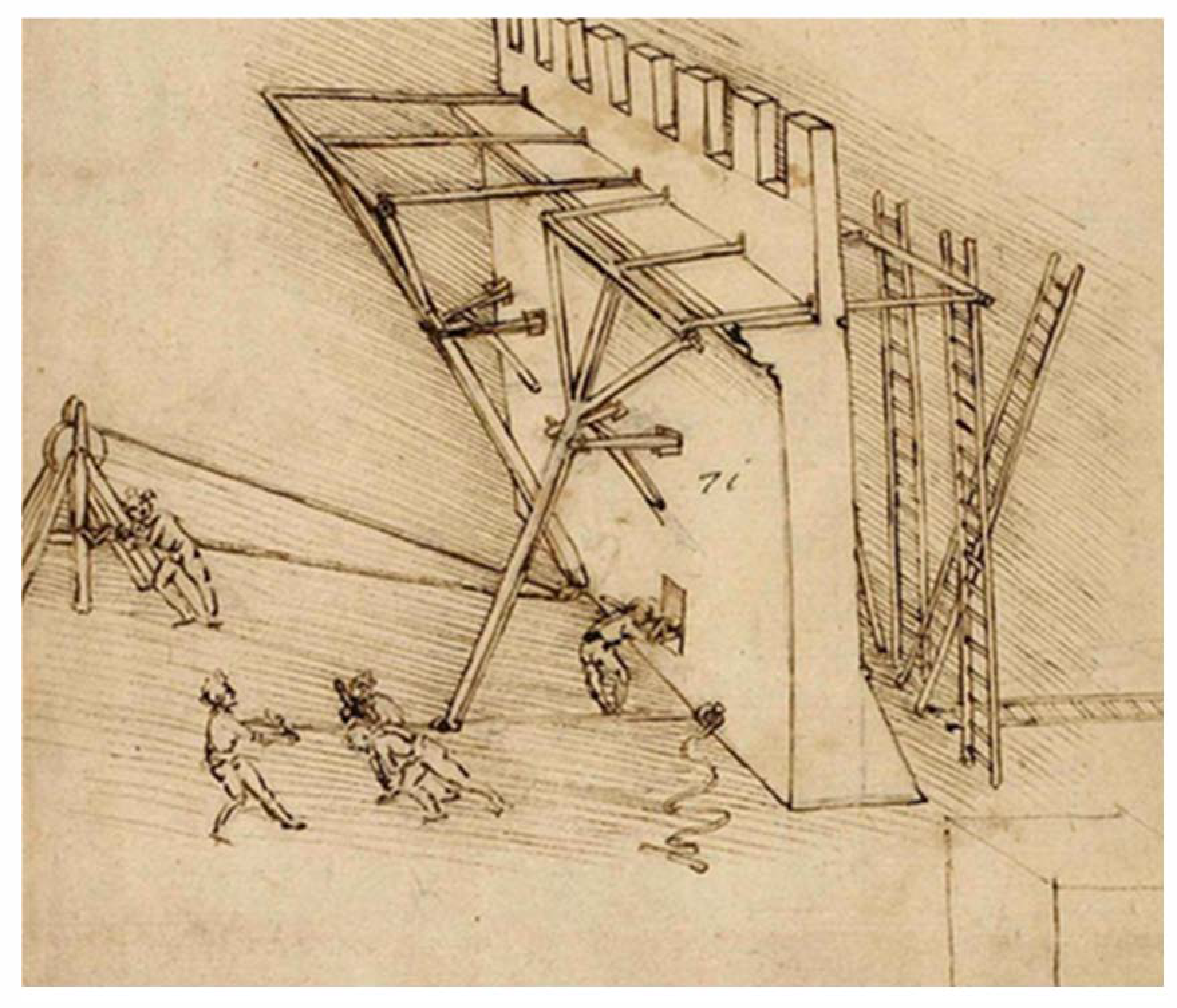

- Op.1 is the winch operator, which pulls the pendulum mass at his starting point.

- Op.2 is the “hammer” operator. Indeed, by taking inspiration from Sheet 141r of the Codex Atlanticus, a disengaging mechanism has been devised, which uses the impact of an hammer to release the mass.

- Op.3 is the “recharger” operator, which periodically uses the lever to give additional acceleration to the mass, in order to ensure a prolongated functioning of the milling plant.

- Op.4 is the “milling operator”, which actually controls the hopper (surely present in a milling plant), the mill and its regulation.

5. Discussions

5.1. Evaluation of Results Against Initial Objectives

5.2. Study Limitations and Future Refinements

- Digital Reconstruction and High-Fidelity Rendering: While the CAD model successfully captures the structural and functional essence of the mill, additional refinements will be necessary to achieve high-fidelity digital visualizations, suitable for museum exhibitions or virtual simulations. This would involve enhancing surface textures, refining mechanical clearances, and integrating accurate material properties to ensure a more realistic representation of Leonardo’s vision.

- Physical Reconstruction and Technical Documentation: Should a scaled or full-scale physical reconstruction be pursued, the model will need to be translated into detailed technical drawings, incorporating considerations for manufacturability and assembly. The level of fidelity required will depend on the intended purpose:

- ○

- If the reconstruction is intended as a museum exhibit, a visually accurate but non-functional model may suffice.

- ○

- If the goal is to create a working prototype, additional engineering analyses, dynamic simulations, and material studies will be required to ensure structural integrity and functional realism.

5.3. Expected Impact on Academia and Society

- Advancing Historical Engineering Research: The methodology developed in this study underscores the importance of interdisciplinary collaboration between historians and engineers, demonstrating how systematic design approaches can enhance historical interpretation. The application of embodiment design principles to Renaissance engineering provides new insights into Leonardo’s mechanical reasoning, offering a structured method for analyzing his conceptual innovations.

- Enhancing Digital Heritage Applications: The results of this study hold potential for interactive digital exhibitions, virtual reality (VR) applications, and augmented reality (AR) experiences, allowing users to engage dynamically with Leonardo’s mechanical inventions. High-fidelity digital models could be integrated into educational platforms, facilitating public engagement with Leonardo’s work while preserving his technological legacy in innovative ways.

6. Conclusions

- The development of high-fidelity digital renderings for educational and museum applications;

- The creation of scaled physical reconstructions, supported by structural and kinematic analyses;

- Comparative research linking Leonardo’s design strategies with those of contemporary engineers, such as Taccola and Francesco di Giorgio Martini.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Document Linked to the PSN Info-Box About the Hosting Structure

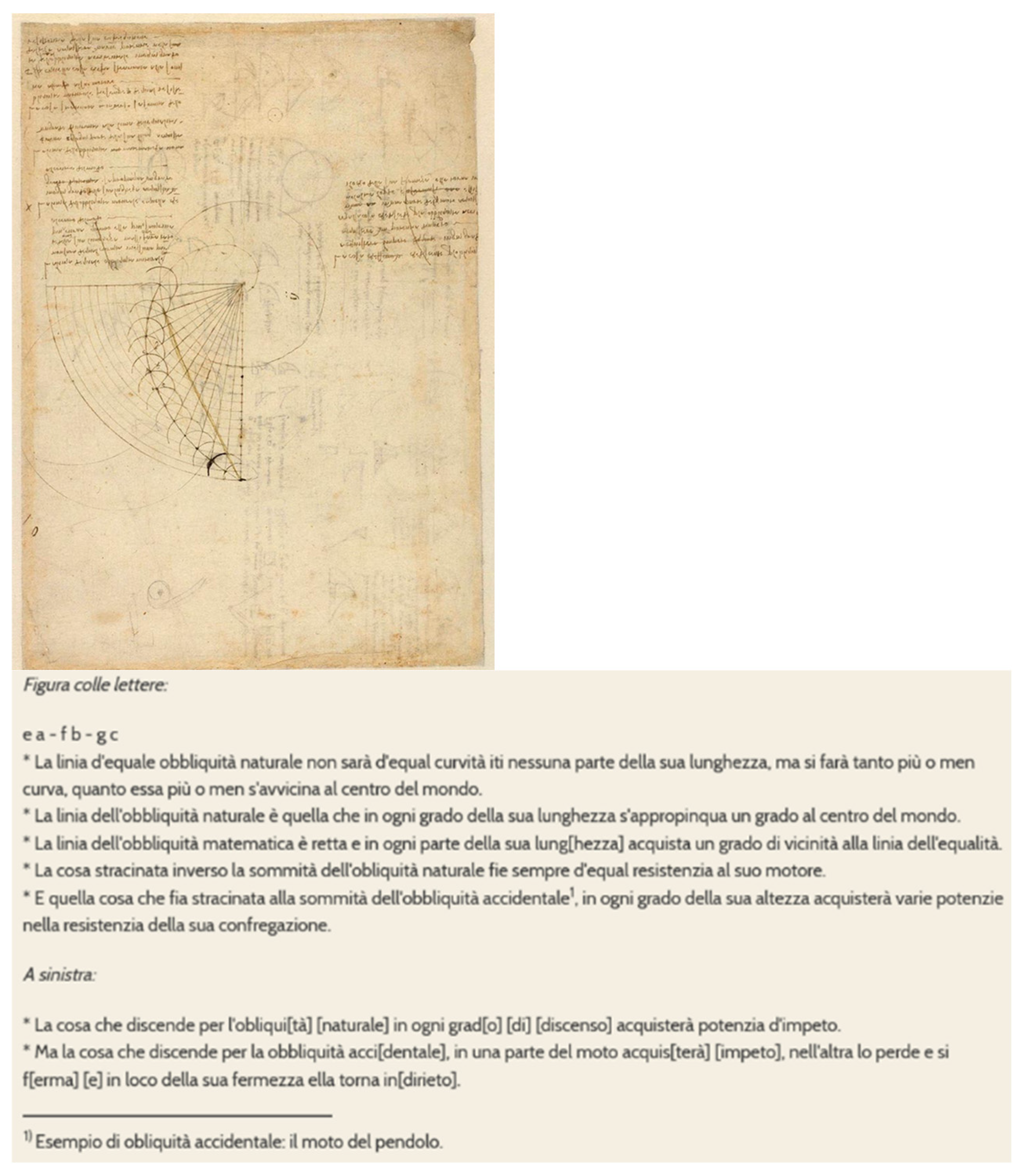

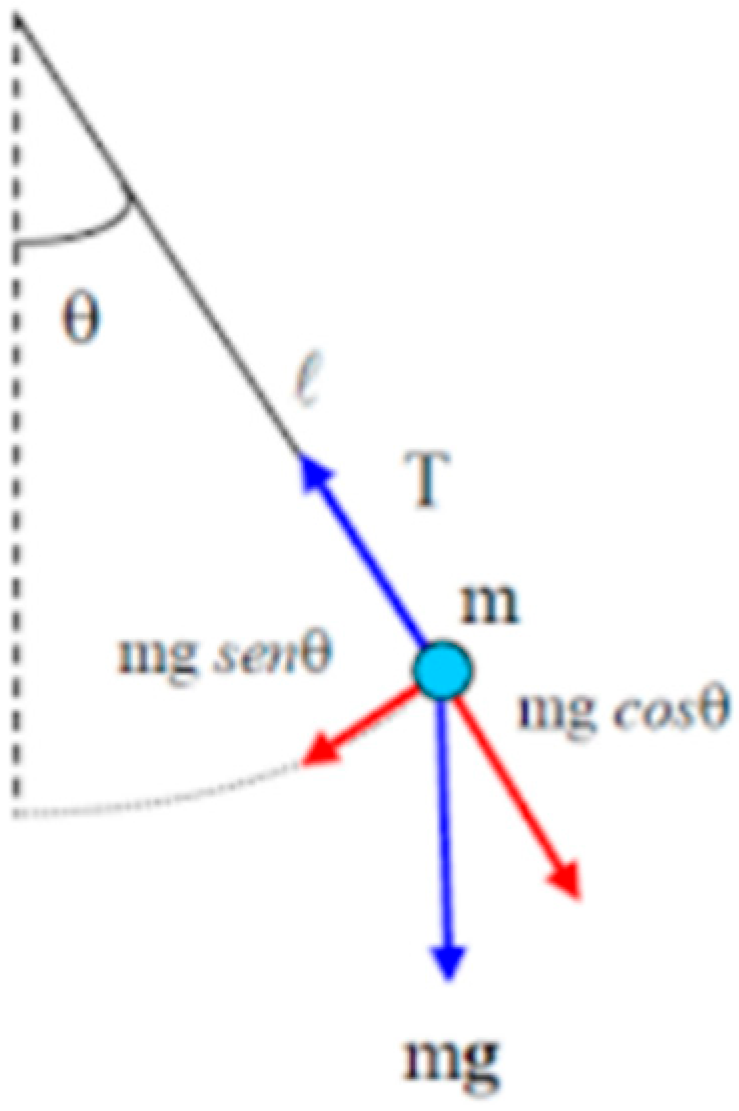

Appendix A.2. Document Linked to the PSN Info-Box About the Principle of the Pendulum

Appendix A.3. Document Linked to the PSN Solution-Box About the Pendulum Mill

- Length: 30 “braccia” (17 m) and the counterweight arm 1

- Weight: 20,000 “Libbre” (6800 kg)

Appendix B

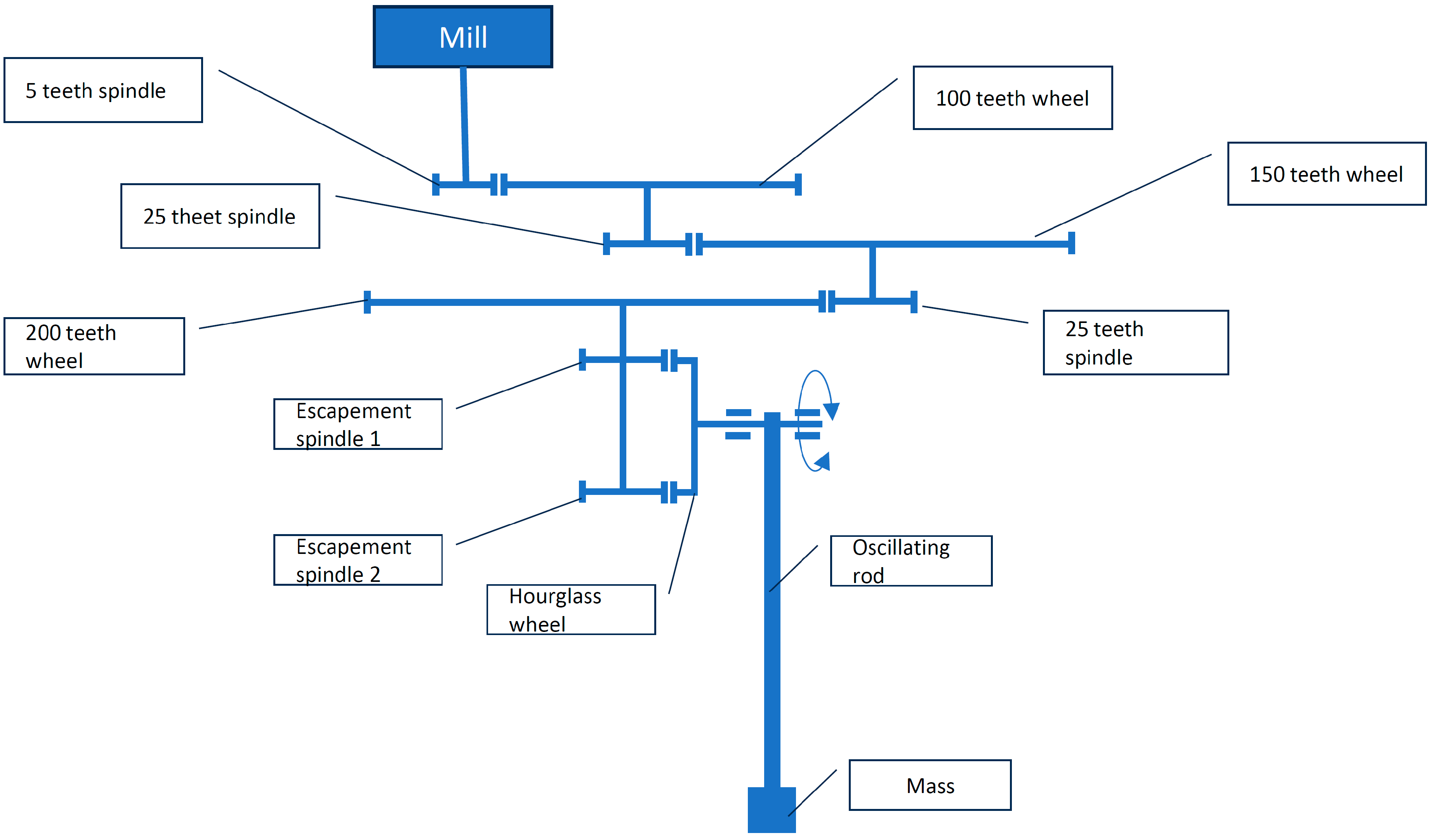

Schematic Representation of the Gear Train of the Mill Shown in Figure 8 (Section 4)

References

- Galluzzi, P. Leonardo Da Vinci: From the “Elementi Macchinali” to the Man-Machine. Hist. Technol. 1987, 4, 235–265. [Google Scholar] [CrossRef]

- Nanni, R. Leonardo and the Artes Mechanicae; Skirà: Milano, Italy, 2013. [Google Scholar]

- Kemp, M. Leonardo Da Vinci: The Marvellous Works of Nature and Man; Oxford University Press: Oxford, UK, 2007. [Google Scholar]

- Pedretti, C. The Literary Works of Leonardo Da Vinci; California University Press: Berkeley, CA, USA, 1977; Volume 1. [Google Scholar]

- Foley, V.; Sedlock, D.; Widule, C.; Ellis, D. Besson, Da Vinci, and the Evolution of the Pendulum: Some Findings and Observations. Hist. Technol. 1988, 6, 1–43. [Google Scholar] [CrossRef]

- Vezzosi, A.; Sabato, A. The New Geneaological Tree of the Da Vinci Family for Leonardo’s DNA. Ancestors and Descendants in Direct Male Line down to the Present XXI Generation. Hum. Evol. 2021, 36, 1–90. [Google Scholar] [CrossRef]

- Galluzzi, P. Gli Ingegneri Del Rinascimento Da Brunelleschi a Leonardo Da Vinci; Giunti: Firenze, Italy, 1996. [Google Scholar]

- Galluzzi, P. Prima Di Leonardo: Cultura Delle Macchine a Siena Nel Rinascimento; Electa: Milano, Italy, 1991. [Google Scholar]

- Fiorineschi, L.; Rotini, F.; Barsanti, R. Systematic Design of Ancient Machines ’ Models: Leonardo Da Vinci’ s Glider. Heritage 2022, 3, 1593–1611. [Google Scholar] [CrossRef]

- Arrighi, V. Leonardo Da Vinci: Alle Origini Del Genio; Barsanti, R., Ed.; Giunti: Florence, Italy, 2019. [Google Scholar]

- Leonardo//Thek@. Available online: https://teche.museogalileo.it/leonardo/home/ (accessed on 20 August 2025).

- Arte Leonardiane. Available online: https://dataleonardo.labdilef.it/ (accessed on 20 August 2025).

- Codice Atlantico Leonardo Da Vinci. Veneranda Biblioteca Ambrosiana. Available online: https://ambrosiana.it/scopri/codice-atlantico-leonardo-da-vinci/ (accessed on 14 November 2025).

- | BNE | National Library of Spain. Available online: https://www.bne.es/es (accessed on 14 November 2025).

- The Family of Art, Design and Performance Museums · V&A. Available online: https://www.vam.ac.uk/?srsltid=AfmBOoqJP6p0bprJ6tUQwW-J9poLgvz5FcvxTgFndxDw2N1U9Plm9oNc (accessed on 14 November 2025).

- Addomine, M. L’orologio Astronomico Di Chiaravalle. La. Voce di Hora 2007, 1–14. [Google Scholar]

- E-Leo. Digital Archive of History of Technology and Science. Available online: https://www.leonardodigitale.com/en/ (accessed on 20 August 2025).

- Cardarelli, F. Encyclopaedia of Scientific Units, Weights and Measures; Springer: London, UK, 2003; ISBN 9781447111221. [Google Scholar]

- Fiorineschi, L.; Rotini, F.; Rissone, P. A New Conceptual Design Approach for Overcoming the Flaws of Functional Decomposition and Morphology. J. Eng. Des. 2016, 27, 438–468. [Google Scholar] [CrossRef]

- Fiorineschi, L. Abstraction Framework to Support Students in Learning Creative Conceptual Design. J. Eng. Des. Technol. 2018, 16, 616–636. [Google Scholar] [CrossRef]

- Dorst, K.; Vermaas, P.E. John Gero’s Function-Behaviour-Structure Model of Designing: A Critical Analysis. Res. Eng. Des. 2005, 16, 17–26. [Google Scholar] [CrossRef]

- Purcell, A.T.; Gero, J.S. Design and Other Types of Fixation. Des. Stud. 1996, 17, 363–383. [Google Scholar] [CrossRef]

- Gero, J.S.; Kanessegiesser, U. The Situated Function–Behaviour–Structure Framework. Pdf. Des. Stud. 2004, 25, 373–391. [Google Scholar] [CrossRef]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design, 3rd ed.; Springer: London, UK, 2007; ISBN 9781846283185. [Google Scholar]

- Fiorineschi, L. Problem-Solution-Network of the Leonardo Da Vinci’s Glider. Mendeley Data 2022, 1. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Rotini, F.; Barsanti, R. Leonardo Da Vinci’s Pendular Mill: Towards a Physical Model for Museum’s Exhibits. Lect. Notes Mech. Eng. 2024, 479–487. [Google Scholar] [CrossRef]

- Bibliothèque de l’Institut de France | Bibliothèque de l’Institut de France. Available online: https://www.bibliotheque-institutdefrance.fr/ (accessed on 14 November 2025).

| Detail | Translation |

|---|---|

| a | “Ensure that the weight at the bottom is 20,000 pounds, and the lever that rises to its center is 30 arms long; its counter-lever is one arm. The first spindle is one arm with 25 teeth, and the wheel above it, serving as a cover, is 8 arms in diameter with 200 teeth; the second wheel has 150 teeth, and the third 100. Each spindle has 25 teeth. Know that when the first wheel makes one turn, the millstone makes exactly 960, with the last spindle having 5 theet.” |

| b | “When the stone strikes the counter-lever at a, it pulls back the lever b.” |

| c | “No power will exceed that which you generate yourself, unless you exert effort over time, and this is demonstrated here.” |

| d | “First, make the millstone turn half a braccio above its counterpart, and when it gains momentum, lower it with the screw beneath the millstone’s axis, then feed it grain.” |

| e | “Arrangement of the first two spindles.” |

| PSN Ramification | Description |

|---|---|

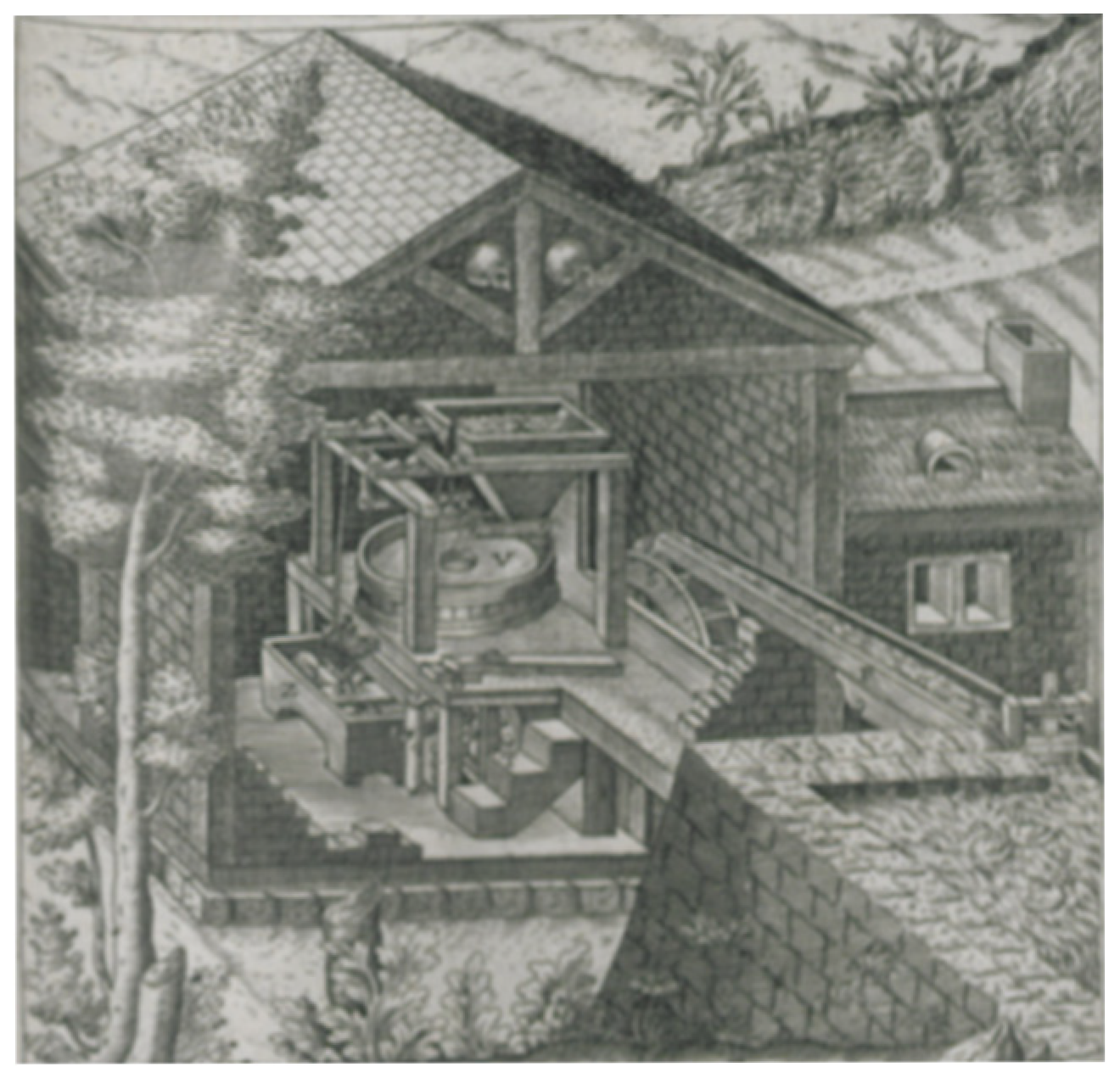

| a | This very simple ramification is related to the functional problem “How to fix the system to the ground?”. Only a pink box (i.e., information-related box) is connected to the problem box, since no final decisions were taken by Leonardo, about how to host the whole mechanism. The document linked to the pink box has been reported in Appendix A.1, and has been used to infer an hypothetical hosting structure for the preliminary CAD model. |

| b | This is the ramification related to the main functional problem “How to import the grain?”. This PSN sub-network led to several solutions and related sub-problems, which allowed the authors to consider a hopper with a vibrating mechanism. Since this system was not shown in the considered sheets of Leonardo, additional documents have been taken into account, both from Leonardo and other Renaissance engineers. |

| c | This ramification develops from the main problem “How to collect the flour?”. Similarly to the precedent one in this table, many references have been considered, since the related sub-system was not represented in the Leonardo’s sheets about the pendulum mill. |

| d | For the contents of this paper, this ramification is the most critical. Indeed, it develops from the problem “How to grind the grain?”, and therefore also concerns the power source (i.e., the pendulum) used to move the stone mill. One of the key groups of PSN boxes related to this branch (d-1) will be described here in the following. |

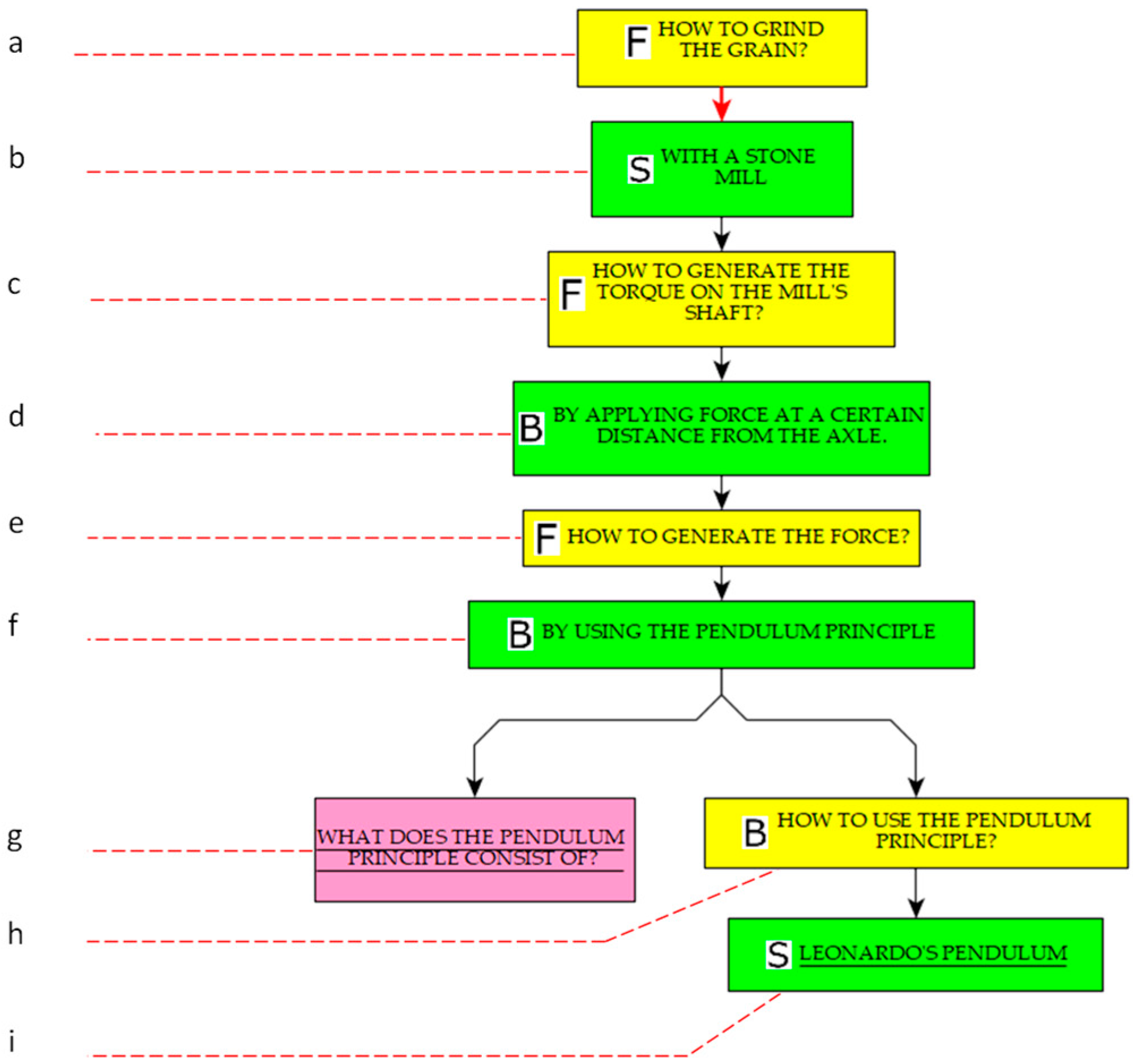

| Node | Description |

|---|---|

| a | This is a functional problem (i.e., “F” level of the FBS construct), and concerns the transformation of the grain into flour. |

| b | Since no alternative are possible, a direct “F-S” passage has been considered (red arrow). In fact, the specific box represents a structural solution (“S” level of the FBS construct), and actually represent the stone mill. |

| c | This is the principal functional problem derived by the adoption of the stone mill, i.e., related to the generation of the torque required to move it. |

| d | This box is a solution at the “Behaviour” level of the FBS construct. It indicates that the application of a force at a certain distance from the axle is used to generate the torque, according to basic physics rule. |

| e | Thanks to the precedent box, it is now possible to consider the specific functional problem related to the generation of the force needed to generate the torque. |

| f | Again, a “B”-level solution is used, in this case to indicate that Leonardo used the principle of the Pendulum in order to generate the force needed to obtain the torque for the movement of the mill. |

| g | This is an “info” box of the PSN, and since the text is underlined, it means that there is an hyperlink to a document concerning some specific information about the principle of the pendulum (see Appendix A.2). |

| h | This is a “B”-level problem, that substantially is a logical sequence of the precedent solution. Indeed, since a “B”-level solution is proposed (in this case, actually used by Leonardo), the next step is to ask how it is intended to be exploited in order to obtain the expected results. |

| i | This “S”-level solution actually answers the precedent question, simply by indicating the solution adopted by Leonardo. Also in this case, the text is underlined because there is an hyperlink to a document concerning the pendulum mill (see Appendix A.3). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiorineschi, L.; Rotini, F.; Barsanti, R. Pendulum Mill: The Lifelong Project of Leonardo da Vinci. Heritage 2025, 8, 497. https://doi.org/10.3390/heritage8120497

Fiorineschi L, Rotini F, Barsanti R. Pendulum Mill: The Lifelong Project of Leonardo da Vinci. Heritage. 2025; 8(12):497. https://doi.org/10.3390/heritage8120497

Chicago/Turabian StyleFiorineschi, Lorenzo, Federico Rotini, and Roberta Barsanti. 2025. "Pendulum Mill: The Lifelong Project of Leonardo da Vinci" Heritage 8, no. 12: 497. https://doi.org/10.3390/heritage8120497

APA StyleFiorineschi, L., Rotini, F., & Barsanti, R. (2025). Pendulum Mill: The Lifelong Project of Leonardo da Vinci. Heritage, 8(12), 497. https://doi.org/10.3390/heritage8120497