Virtually Reconstructing Bernhard Heine’s Osteotome

Abstract

1. Introduction

1.1. Overview

1.2. Background

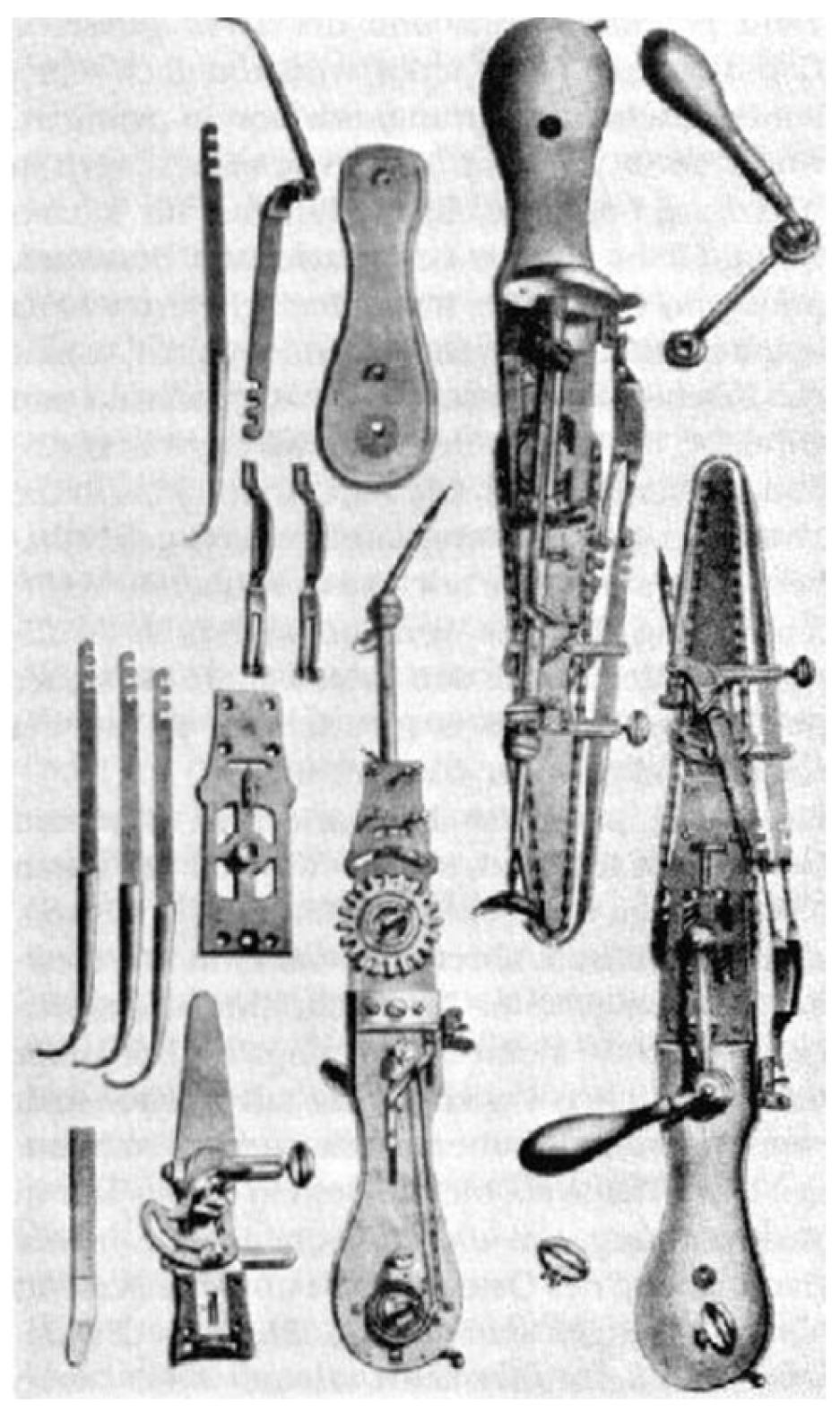

1.2.1. Tool Summary

1.2.2. Surgical Requirements

1.2.3. Manual Tools

1.2.4. Contemporary Orthopedic Tools

1.2.5. Contemporary Chainsaws

2. Materials and Methods

2.1. Research Methodology

2.2. Digital Replication

2.3. Chainsaw Comparison

3. Results

3.1. Model Overview

3.2. Chainsaw Component Comparison

3.2.1. Summary

3.2.2. Grip

3.2.3. Bar

3.2.4. Chain Drive

3.2.5. Chain

4. Discussion

4.1. Model Overview

4.2. Comparison to Hand Tools

4.3. Comparison to Contemporary Tools

4.4. Study Limitations

4.5. Future Work

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hawk, A.J. ArtiFacts: Bernhard Heine’s osteotome. Clin. Orthop. Relat. Res. 2016, 474, 1108–1109. [Google Scholar] [CrossRef] [PubMed]

- Vriend-Vermeer, W. The osteotome of Bernhard Heine. Ned. Tijdschr. Voor Geneeskd. 1963, 107, 1930–1932. [Google Scholar]

- Seufert, W.D. The chain osteotome by Heine. J. Hist. Med. Allied Sci. 1980, 35, 454. [Google Scholar] [CrossRef] [PubMed]

- Hernigou, P. Fathers of orthopaedics in Germany (eighteenth and early nineteenth centuries): Lorenz Heister in Helmsted; Johann Friedrich Dieffenbach in Berlin; Heine and family in Würzburg. Int. Orthop. 2016, 40, 425–431. [Google Scholar] [CrossRef] [PubMed]

- LaRocco, J.; Paeng, D.G. A functional analysis of two 3D-scanned antique pistols from New Zealand. Virtual Archaeol. Rev. 2020, 11, 85–94. [Google Scholar] [CrossRef]

- Kanun, E.; Kanun, G.M.; Yakar, M. 3D modeling of car parts by photogrammetric methods: Example of brake discs. Mersin Photogramm. J. 2022, 4, 7–13. [Google Scholar] [CrossRef]

- Rogers, W.A.; McGlynn, S.A. Human factors and ergonomics: History, scope, and potential. In Human Factors and Ergonomics for the Gulf Cooperation Council; CRC Press: Boca Raton, FL, USA, 2018; pp. 1–20. [Google Scholar]

- Reilly, R.F. Medical and surgical care during the American Civil War, 1861–1865. Bayl. Univ. Med. Cent. Proc. 2016, 29, 138–142. [Google Scholar] [CrossRef] [PubMed]

- Rudert, M. SICOT international orthopaedics specialized knee surgery. Orthopädie Unfallchirurgie–Mitteilungen Nachrichten 2016, 5, 570–571. [Google Scholar] [CrossRef]

- Zellem, R.T. Wounded by bayonet, ball, and bacteria: Medicine and neurosurgery in the American Civil War. Neurosurgery 1985, 17, 850–860. [Google Scholar] [CrossRef] [PubMed]

- Bartnicka, J. Knowledge-based ergonomic assessment of working conditions in surgical ward—A case study. Saf. Sci. 2015, 71, 178–188. [Google Scholar] [CrossRef]

- Thivierge, M.M. Dealing with the dead and wounded: Field medicine and the American Civil War. Gen. Brock Univ. Undergrad. J. Hist. 2017, 2, 2017. [Google Scholar] [CrossRef]

- Ellis, H.; Abdalla, S. A History of Surgery; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Heckler, H. Bernhard Heine. Available online: http://www.hanshekler.de/ch/history/Heine/bheine.htm (accessed on 2 April 2023).

- Wójcik, K. Vibrations produced by petrol chainsaws with variable-length guide bars during cross-cutting. Ann. Wars. Univ. Life Sci.-SGGW Agric. (Agric. For. Eng.) 2017, 70, 37–47. [Google Scholar] [CrossRef]

- Wu, J. Theoretical Investigation of Kickback in Diamond Chainsaw and Circular Cut-off Saw. Master’s Thesis, Massachusetts Institute of Technology, Boston, MA, USA, 2018. [Google Scholar]

- Feyzi, M.; Jafari, A.; Ahmadi, H. Investigation and analysis the vibration of handles of chainsaw without cutting. J. Agric. Mach. 2016, 6, 20–101. [Google Scholar]

- Homelite, XL-12 Chainsaw Owners Operators and Maintenance Manual; Textron, Inc.: Charlotte, NC, USA, 1988.

- Brooke, G.; Cheung, L. Body Sizes in Nineteenth-Century New Zealand: An Empirical Investigation Using the NZ Contingents in the Second Boer War; Auckland University of Technology, Department of Economics: Auckland, New Zealand, 2019. [Google Scholar]

- ISO 10303-21:2016; Industrial Automation Systems and Integration—Product Data Representation and Exchange. International Standards Organization: Geneva, Switzerland, 1994.

- Jakuscheit, A.; Rudert, M. Two hundred years of orthopaedics in Würzburg—One hundred years of the König-Ludwig-Haus. Int. Orthop. 2016, 40, 1781–1785. [Google Scholar] [CrossRef] [PubMed]

- Green, S.A. Orthopaedic surgeons: Inheritors of tradition. Clin. Orthop. Relat. Res. 1999, 363, 258–263. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

LaRocco, J.; Zachariah, E. Virtually Reconstructing Bernhard Heine’s Osteotome. Heritage 2024, 7, 3756-3765. https://doi.org/10.3390/heritage7070178

LaRocco J, Zachariah E. Virtually Reconstructing Bernhard Heine’s Osteotome. Heritage. 2024; 7(7):3756-3765. https://doi.org/10.3390/heritage7070178

Chicago/Turabian StyleLaRocco, John, and Eric Zachariah. 2024. "Virtually Reconstructing Bernhard Heine’s Osteotome" Heritage 7, no. 7: 3756-3765. https://doi.org/10.3390/heritage7070178

APA StyleLaRocco, J., & Zachariah, E. (2024). Virtually Reconstructing Bernhard Heine’s Osteotome. Heritage, 7(7), 3756-3765. https://doi.org/10.3390/heritage7070178