Non-Vascular Ceramic Sherds Coming from Two Italian Etruscan Settlements: Peculiarities and Interpretation of Their Possible Use

Abstract

:1. Introduction

Aim of the Research: Archaeological Open Questions

- -

- Do macroscopic discrepancies in the material mean compositional differences?

- -

- Can compositional characteristics suggest possible different uses?

- -

- Were these slabs subjected to baking during the production process, or were they applied raw and successively exposed to a deliberate fire of the building structure?

- -

- Since some of the fragments show a different aesthetical appearance in terms of color, is this deliberate, for a decorative effect, or the consequence of the natural deterioration of the surface?

- -

- Perhaps most significantly, which were the main advantages of using these slabs as building materials in the Po Delta area?

2. Materials and Methods

2.1. Materials

2.2. Morphological, Chemical and Physical Characterizations

2.3. Production Techniques

3. Results

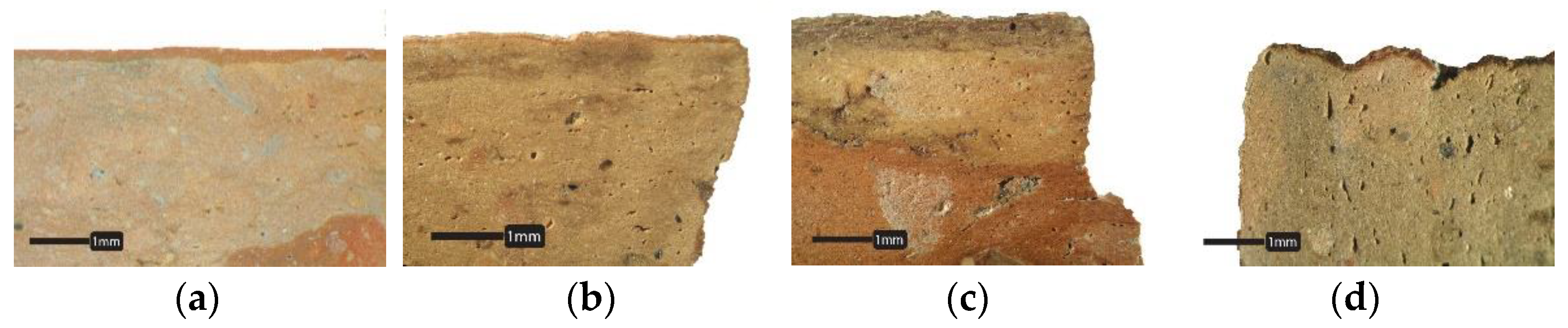

3.1. Morphological, Chemical and Physical Characterizations

- -

- almost all samples from groups C1, 1 and 5 appeared to have a thin reddish outward layer on side A, which was not present in the rest of the fragments. This could be interpreted as either a sort of deliberate colored finishing or as a degradation layer. Furthermore, groups 1 and 5 were considered as a single group (from now on, called 1 + 5);

- -

- samples from groups C2, 2 and 3 seemed to have a similar surface color; therefore, groups 2 and 3 could be combined as a single group (called 2 + 3);

- -

- groups A and 4 displayed heterogeneities in color and some dark spots, suggesting that something different should have happened compared to other fragments, such as a depositional factor or a consequence of different firing temperatures;

- -

- the surface of group 6 fragments appeared to be covered by crystalline efflorescence, as can be seen in the images at higher magnifications (225×) (Table 2). According to the archaeological report, these samples came from the same stratigraphic units (SU 4106 and 4098) (Supplementary Materials S1, Table S2). This suggests a depositional formation of the efflorescence caused by environmental conditions more than a compositional peculiarity.

- -

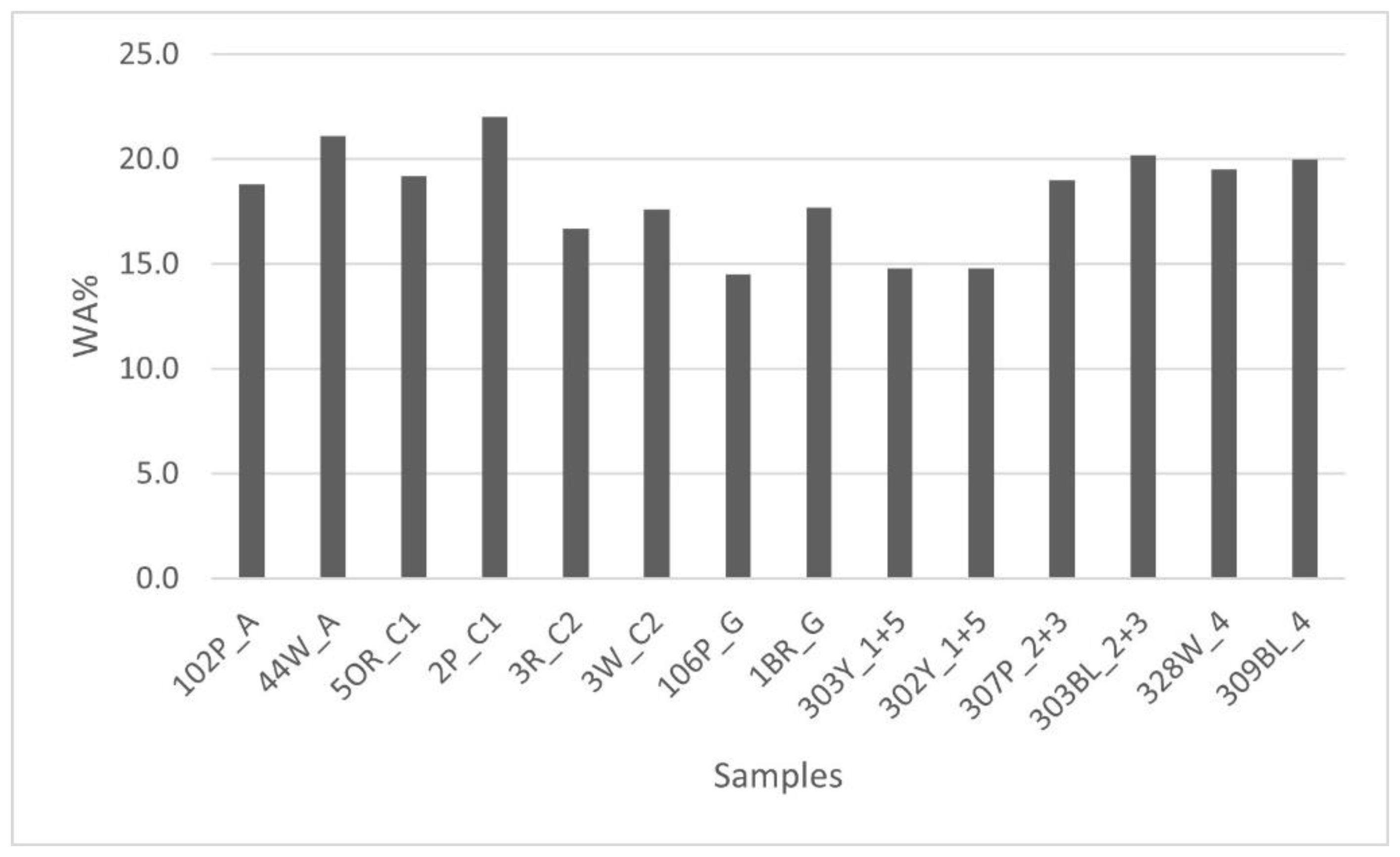

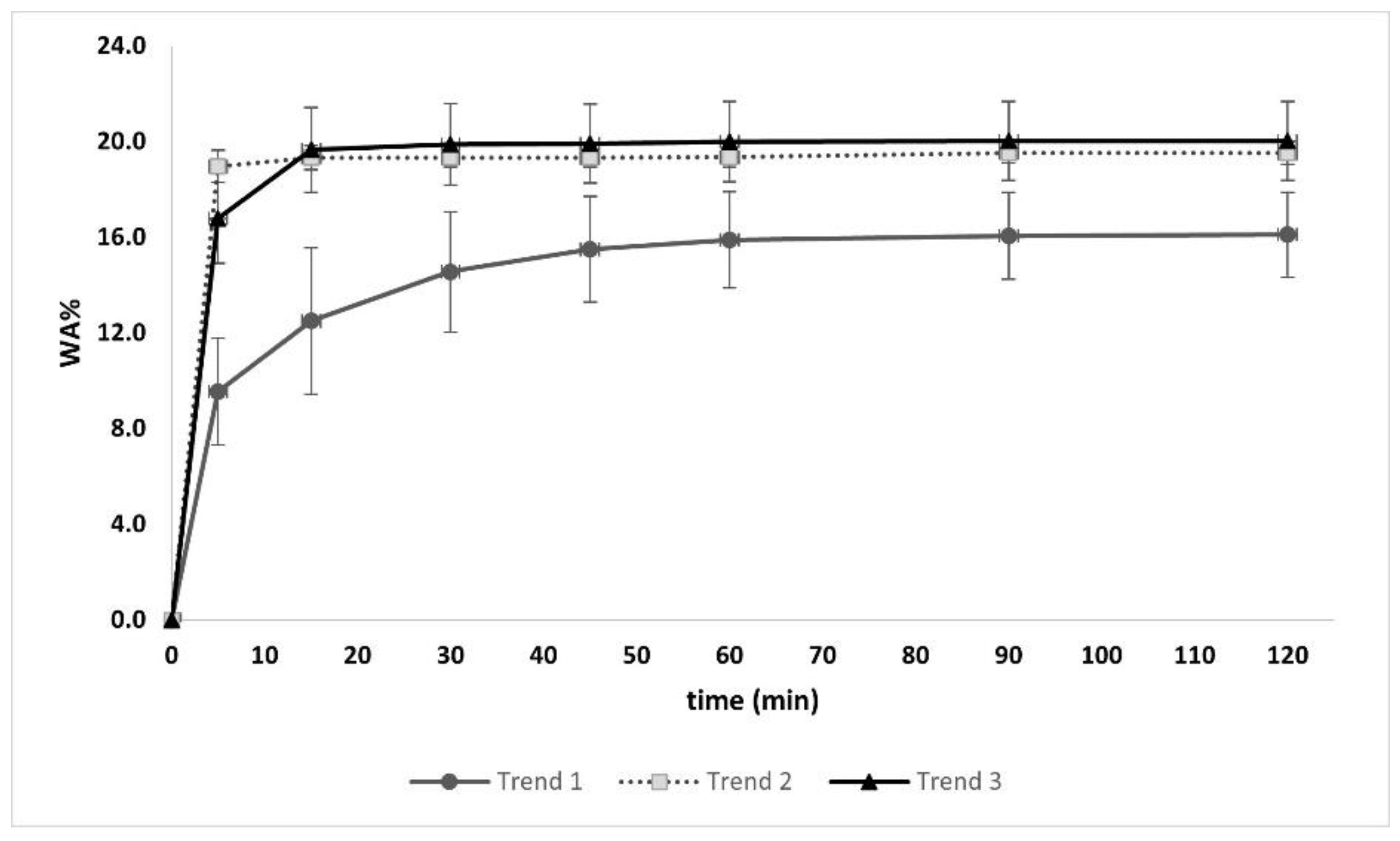

- three samples did not reach 15% of WA, recording the lowest values;

- -

- most of the fragments analyzed displayed similar values, ranging from 16.7% to 22.0%.

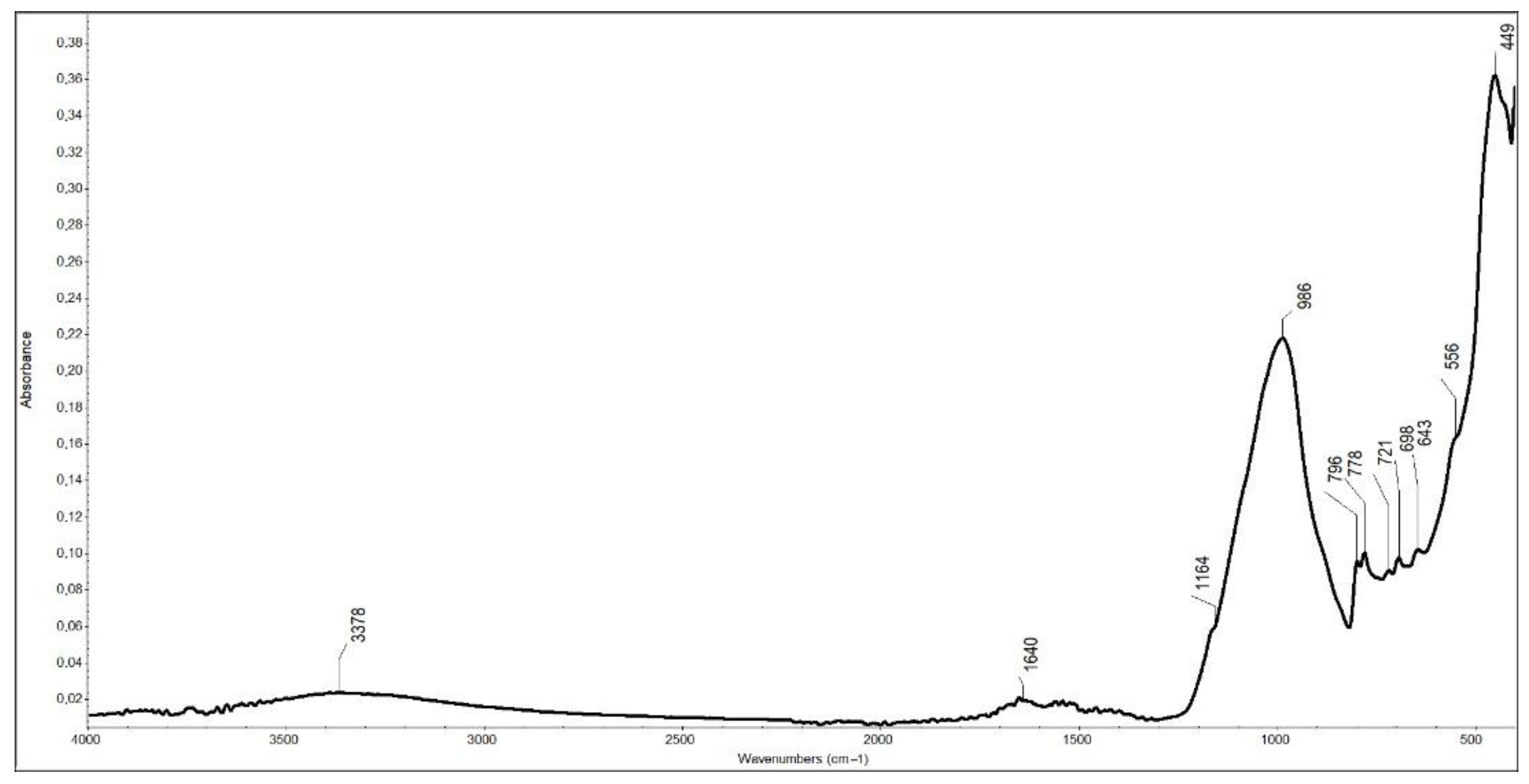

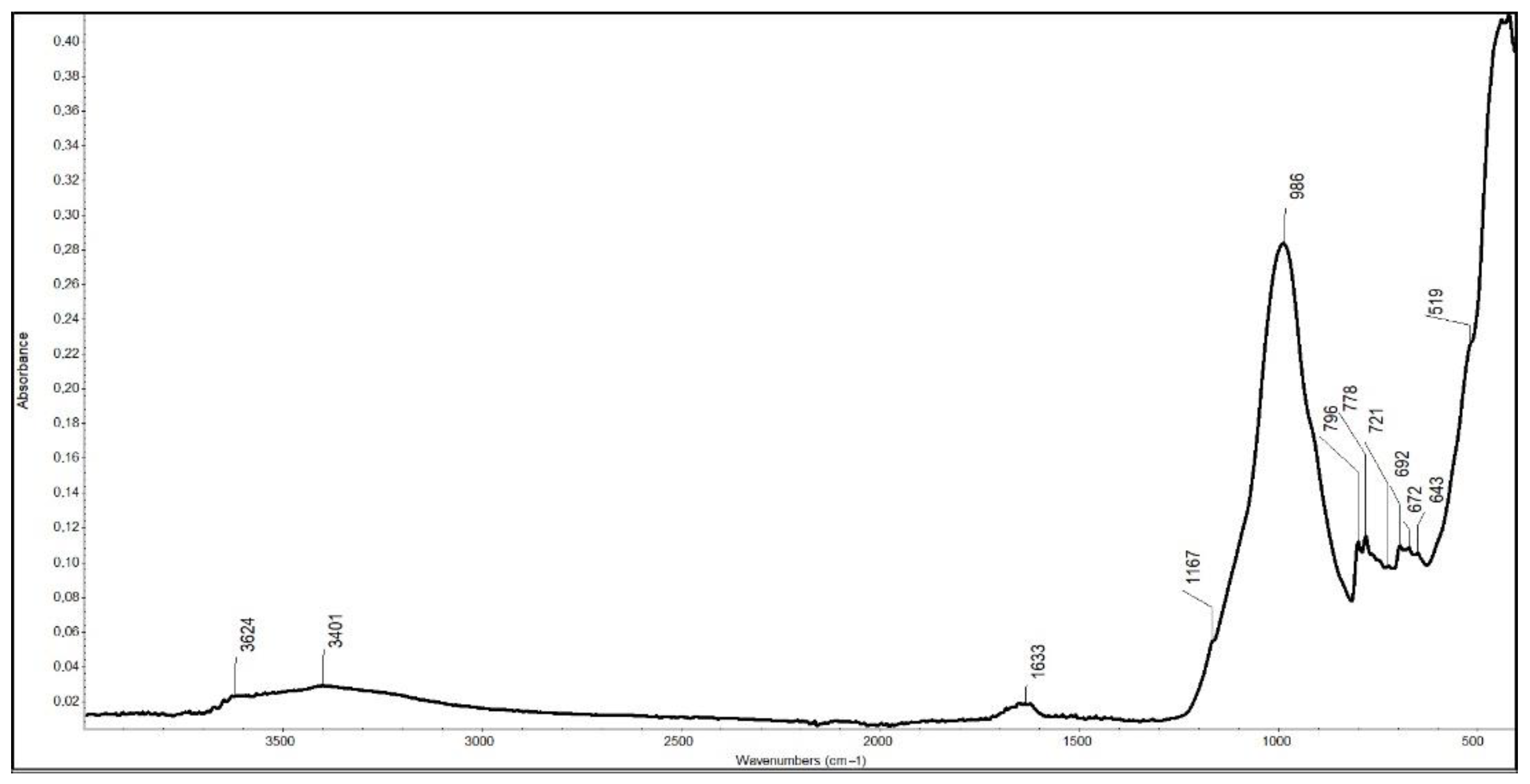

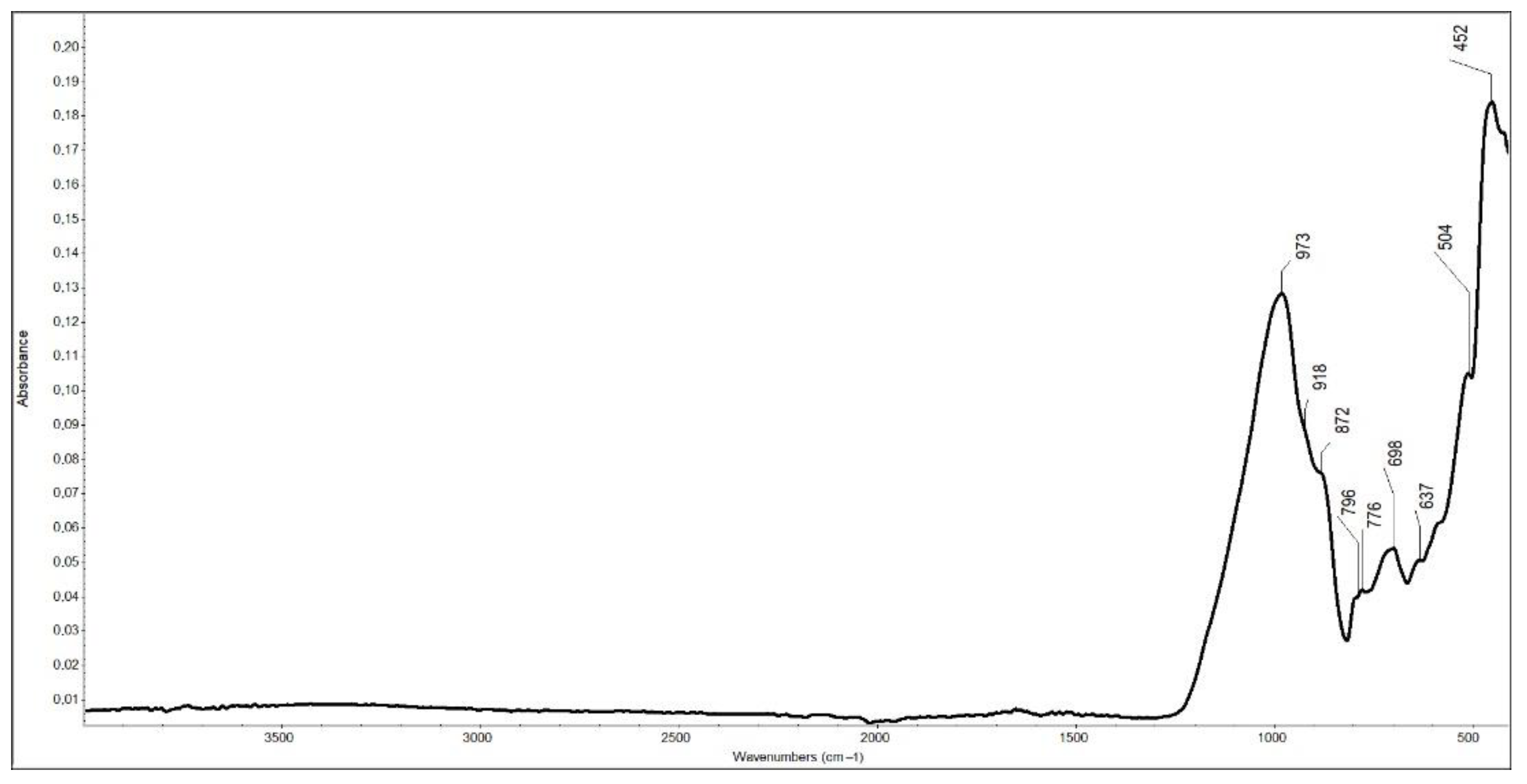

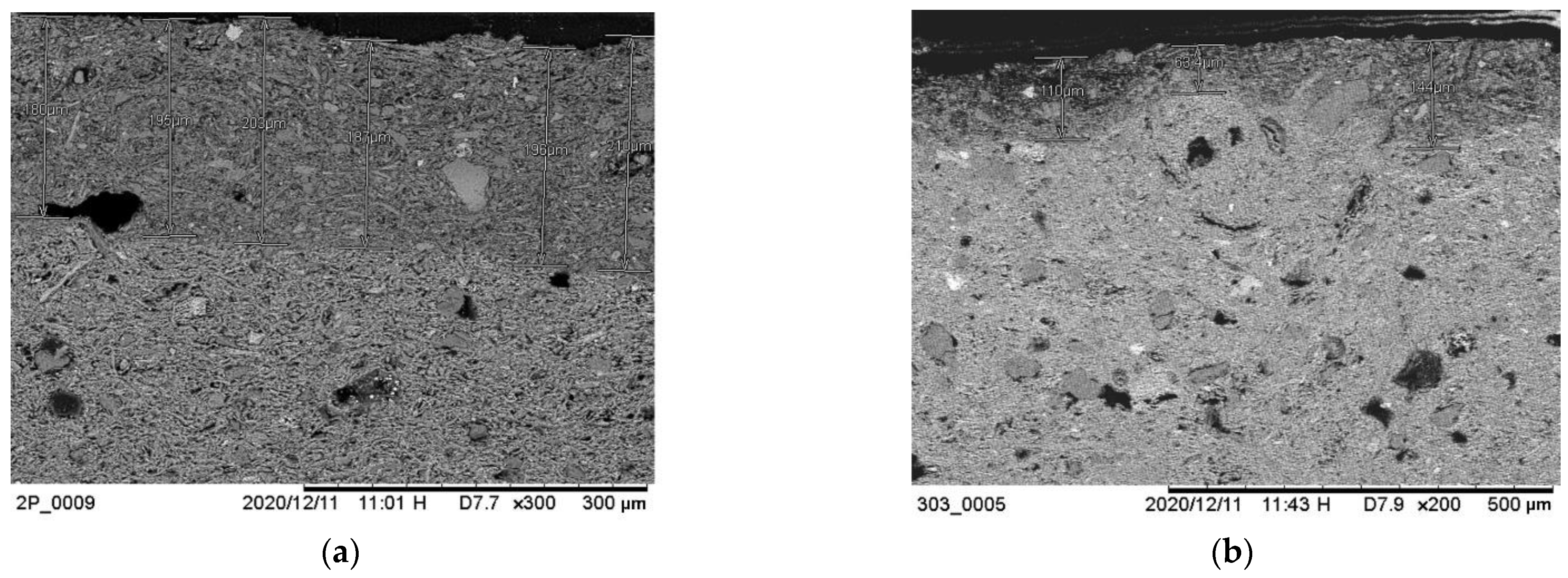

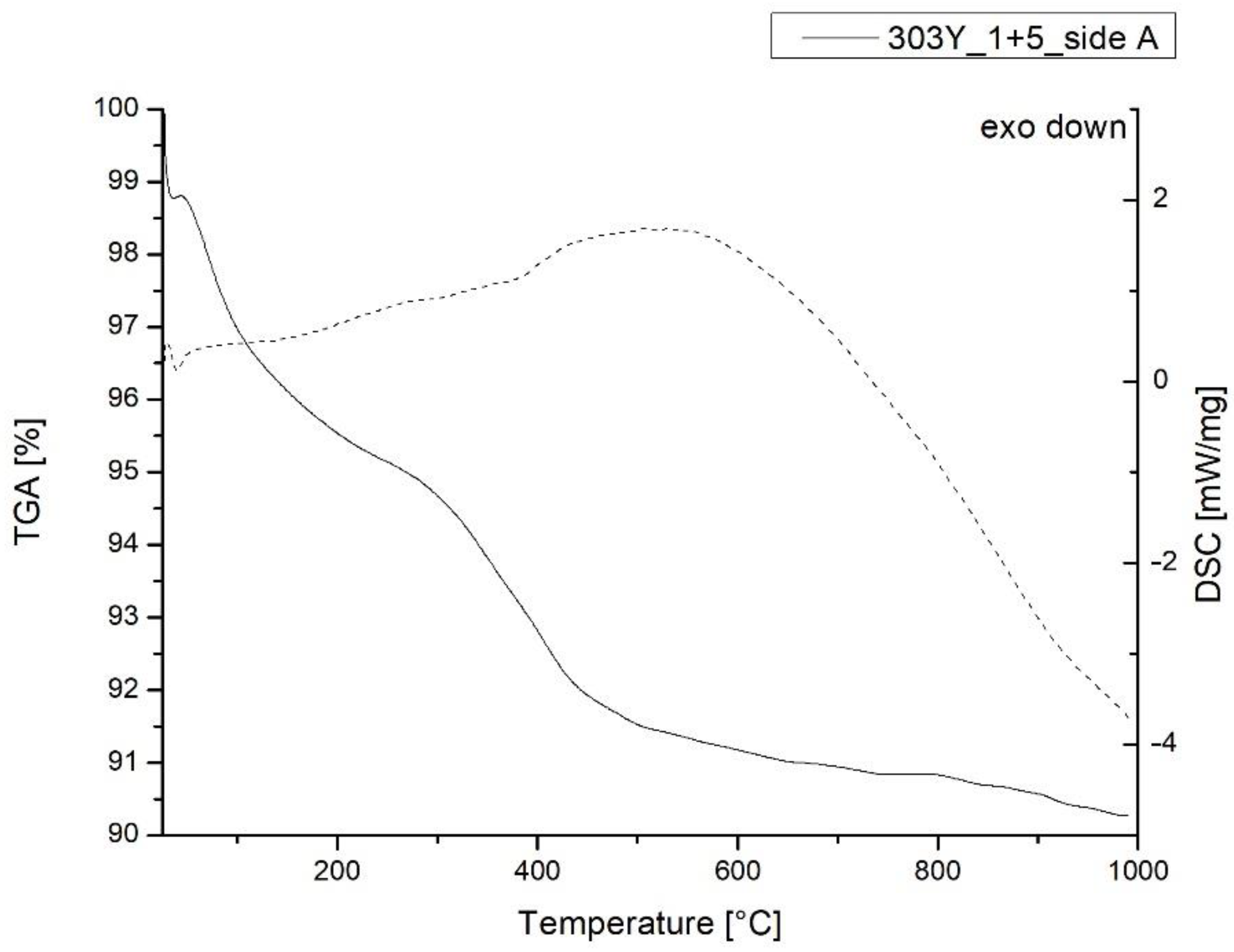

3.2. Production Techniques

4. Discussion

- -

- The first two questions refer to the compositional features: Do macroscopic discrepancies mean compositional differences? Can compositional characteristics suggest possible different uses?

- -

- The subsequent question concerns the firing process: Were they subjected to baking during the production process, or were they applied raw and successively exposed to a deliberate fire of the building structure?

- -

- Another question refers to the superficial chromatic aspect of some slabs: Since some of the fragments show a different aesthetical appearance in terms of color, is this a deliberate effect or the consequence of the natural deterioration of the surface?

- -

- The last question to be addressed is, perhaps, the most significant: What were the main advantages of using these slabs as building materials in the Po Delta area?

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Facchi, A. Adria. La città etrusca che ha dato il nome al Mar Adriatico. In Etruschi. Viaggio Nelle Terre dei Rasna, Catalogo Della Mostra (Bologna, 7 Dicembre 2019–24 Maggio 2020); Electa: Milano, Italy, 2019; pp. 419–422. [Google Scholar]

- Govi, E. L’Etruria padana. In Etruschi. Viaggio Nelle Terre Dei Rasna. Catalogo Della Mostra (Bologna, 7 Dicembre 2019–24 Maggio 2020); Electa: Milano, Italy, 2019; pp. 357–362. [Google Scholar]

- Govi, E.; Sassatelli, G. Marzabotto. La Casa 1 della Regio IV—Insula 2. 1. Lo Scavo; Ante Quem: Bologna, Italy, 2010. [Google Scholar]

- Casini, S.; De Marini, R.C. La città etrusca del Forcello. In L’abitato Etrusco del Forcello di Bagnolo S. Vito (Mantova): Le Fase Arcaiche; De Marini, R.C., Rapi, M., Eds.; Tipografia Latini: Firenze, Italy, 2007; pp. 35–49. [Google Scholar]

- De Min, M. L’abitato arcaico di S. Basilio di Ariano Polesine. In L’antico Polesine: Testimonianze Archeologiche e Paleoambientali; Catalogo Delle Esposizioni di Adria e di Rovigo, Febbraio–Novembre 1986; Museo Archeologico di Adria: Adria, Italy, 1986; pp. 171–184. [Google Scholar]

- Google Maps. 2021. Available online: https://www.google.com/maps/@44.9893084,12.1826729,10z/data=!5m1!1e4 (accessed on 9 April 2021).

- De Min, M. L’abitato arcaico di S. Basilio. In Etruschi a Nord del po; Campanotto Editore: Lombardia, Italy, 1988; pp. 84–91. [Google Scholar]

- Bonomi, S.; Vallicelli, M.C.; Balista, C. The etruscan settlement of Adria (Italy–Rovigo): New data from the excavations in Via Ex Riformati (years 2015–2016). In Crossing the Alps—Early Urbanism between Northern Italy and Central Europe (900–400 BC); Zamboni, L., Fernández-Götz, M., Metzner-Nebelsick, C., Eds.; Sidestone Press: Leiden, The Netherlands, 2020; pp. 193–206. [Google Scholar]

- Tasca, G. Intonaci e concotti nella preistoria: Tecniche di rilevamento e problemi interpretativi. In Introduzione All’archeologia Degli Spazi Domestici; Comune di Como: Como, Italy, 1998; pp. 77–87. [Google Scholar]

- Moffa, C. L’organizzazione dello spazio sull’acropoli di Broglio di Trebisacce. In Grandi Contesti e Problemi Della Protostoria Italiana; All’Insegna del Giglio: Firenze, Italy, 2002; pp. 19–31. [Google Scholar]

- Peinetti, A. Analisi tecnologica di resti strutturali in terra: Variabilità delle tecniche di costruzione e osservazioni in sezione levigata per la caratterizzazione di concotti e conglomerati architettonici. IpoTESI di Preist. 2016, 8, 103–138. [Google Scholar] [CrossRef]

- Cappuccini, L.; Mohr, M. Strutture a Spina nel IV sec. a. C. In Spina—Neue Perspektiven der Archäologischen Erforschung; Tagung an der Universität Zürich 4./5. Mai 2012; Verlag Marie Leidorf GmbH: Zurigo, Switzerland, 2017; pp. 21–26. [Google Scholar]

- Zamboni, L. Spina Città Liquida: Gli Scavi 1977–1981 Nell’abitato e i Materiali Tardo-Arcaici e Classici; VML Verlag Marie Leidorf: Rahden, Germany, 2016. [Google Scholar]

- Munsell Color Company. Munsell Soil Color Charts (Year 2000 Revised Washable Edition); Munsell Color Company: New Windsor, NY, USA, 2000. [Google Scholar]

- Cuomo di Caprio, N. Ceramica in Archeologia 2: Antiche Tecniche di Lavorazione e Moderni Metodi di Indagine; L’Erma di Bretschneider: Roma, Italy, 2007. [Google Scholar]

- Akyuz, S.; Akyuz, T.; Basaran, S.; Bolcal, C.; Gulec, A. Analysis of ancient potteries using FT-IR, micro-Raman and EDXRF spectrometry. Vib. Spectrosc. 2008, 48, 276–280. [Google Scholar] [CrossRef]

- De Benedetto, G.E.; Laviano, R.; Sabbatini, L.; Zambonin, P. Infrared spectroscopy in the mineralogical characterization of ancient pottery. J. Cult. Herit. 2002, 3, 177–186. [Google Scholar] [CrossRef]

- Müller, C.M.; Pejcic, B.; Esteban, L.; Piane, C.D.; Raven, M.; Mizaikoff, B. Infrared Attenuated Total Reflectance Spectroscopy: An Innovative Strategy for Analyzing Mineral Components in Energy Relevant Systems. Sci. Rep. 2014, 4, 6764. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ravisankar, R.; Kiruba, S.; Eswaran, P.; Senthilkumar, G.; Chandrasekaran, A. Mineralogical Characterization Studies of Ancient Potteries of Tamilnadu, India by FT-IR Spectroscopic Technique. E-J. Chem. 2010, 7, S185–S190. [Google Scholar] [CrossRef]

- Annamalai, G.R.; Ravisankar, R.; Naseerutheen, A.; Chandrasekaran, A.; Rajan, K. Application of various spectroscopic techniques to characterize the archaeological pottery excavated from Manaveli, Puducherry, India. Optik 2014, 125, 6375–6378. [Google Scholar] [CrossRef]

- Ramasamy, V.; Suresh, G. Mineral characterization and crystalline nature of quartz in Ponnaiyar River sediments, Tamilnadu, India. Am. J. Sci. Res. 2009, 4, 103–107. [Google Scholar]

- Velraj, G.; Janaki, K.; Musthafa, A.M.; Palanivel, R. Spectroscopic and porosimetry studies to estimate the firing temperature of some archaeological pottery shreds from India. Appl. Clay Sci. 2009, 43, 303–307. [Google Scholar] [CrossRef]

- Djomgoue, P.; Njopwouo, D. FT-IR Spectroscopy Applied for Surface Clays Characterization. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 275–282. [Google Scholar] [CrossRef] [Green Version]

- Madejová, J. FTIR techniques in clay mineral studies. Vib. Spectrosc. 2003, 31, 1–10. [Google Scholar] [CrossRef]

- Alver, B.E.; Dikmen, G. Investigation of the Influence of Heat Treatment on the Structural Properties of Illite-Rich Clay Mineral Using FT-IR, 29Si MAS NMR, TG AND DTA Methods. Anadolu Univ. J. Sci. Technol. Appl. Sci. Eng. 2016, 17, 823–829. [Google Scholar] [CrossRef]

- Ricci, G.; Caneve, L.; Pedron, D.; Holesch, N.; Zendri, E. A multi-spectroscopic study for the characterization and definition of production techniques of German ceramic sherds. Microchem. J. 2016, 126, 104–112. [Google Scholar] [CrossRef]

- Gane, P.A.C.; Ridgway, C.J.; Schoelkopf, J. Absorption Rate and Volume Dependency on the Complexity of Porous Network Structures. Transp. Porous Media 2004, 54, 79–106. [Google Scholar] [CrossRef]

- Ridgway, C.J.; Gane, P.A. Correlating pore size and surface chemistry during absorption into a dispersed calcium carbonate network structure. Nord. Pulp Pap. Res. J. 2006, 21, 563–568. [Google Scholar] [CrossRef]

- Caner, E.; Güney, B.A. Characterization of ceramic ware fragments from Aizanoi-Turkey by micro Raman, XRPD and SEM-EDX spectrometry. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2017, 177, 135–139. [Google Scholar] [CrossRef] [PubMed]

- Leach, F.; Davidson, J.; Claridge, G.; Ward, G.; Craib, J. The Physical and Mineralogical Characteristics of Pottery from Mochong, Rota, Mariana Islands. In Islands of Inquiry: Colonisation, Seafaring and the Archaeology of Maritime Landscapes; ANU Press: Camberra, Australia, 2008; pp. 435–452. [Google Scholar] [CrossRef]

- Moropoulou, A.; Bakolas, A.; Bisbikou, K. Thermal analysis as a method of characterizing ancient ceramic technologies. Thermochim. Acta 1995, 269–270, 743–753. [Google Scholar] [CrossRef]

- Bakolas, A.; Biscontin, G.; Moropoulou, A.; Zendri, E. Physico-chemical characteristics of traditional mortars in Venice. Trans. Built Environ. 1995, 15, 187–194. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, S. Thermal and spectroscopic characterization of archeological pottery from Ambari, Assam. J. Archaeol. Sci. Rep. 2016, 5, 557–563. [Google Scholar] [CrossRef]

- Aouba, L.; Bories, C.; Coutand, M.; Perrin, B.; Lemercier, H. Properties of fired clay bricks with incorporated biomasses: Cases of Olive Stone Flour and Wheat Straw residues. Constr. Build. Mater. 2016, 102, 7–13. [Google Scholar] [CrossRef] [Green Version]

| Site | Groups | Pieces | Color (Munsell Chart Code) |

|---|---|---|---|

| SB83 | A | 14 | Extremely heterogeneous |

| SB83 | C1 | 18 | Light red (2.5YR 6/6) |

| SB83 | C2 | 31 | Light brown (7.5YR 6/4) |

| SB83 | G | 16 | Pieces presenting a twisted decoration cord on one side |

| AER16 | 1 | 16 | Light red (2.5YR 6/6) and reddish yellow (5YR 6/6) |

| AER16 | 2 | 14 | Light reddish-brown (2.5YR 6/4) with tones of pale yellow (2.5Y 8/2) |

| AER16 | 3 | 20 | Pink (7.5YR 7/4) and very pale brown (10YR 7/3) |

| AER16 | 4 | 19 | Light brownish grey (10YR 6/2) with some tones of light grey (2.5Y 7/1) |

| AER16 | 5 | 22 | Red (2.5YR 5/6) with some tones of light reddish brown (2.5YR 6/4) |

| AER16 | 6 | 13 | Extremely heterogeneous with efflorescence on the surface |

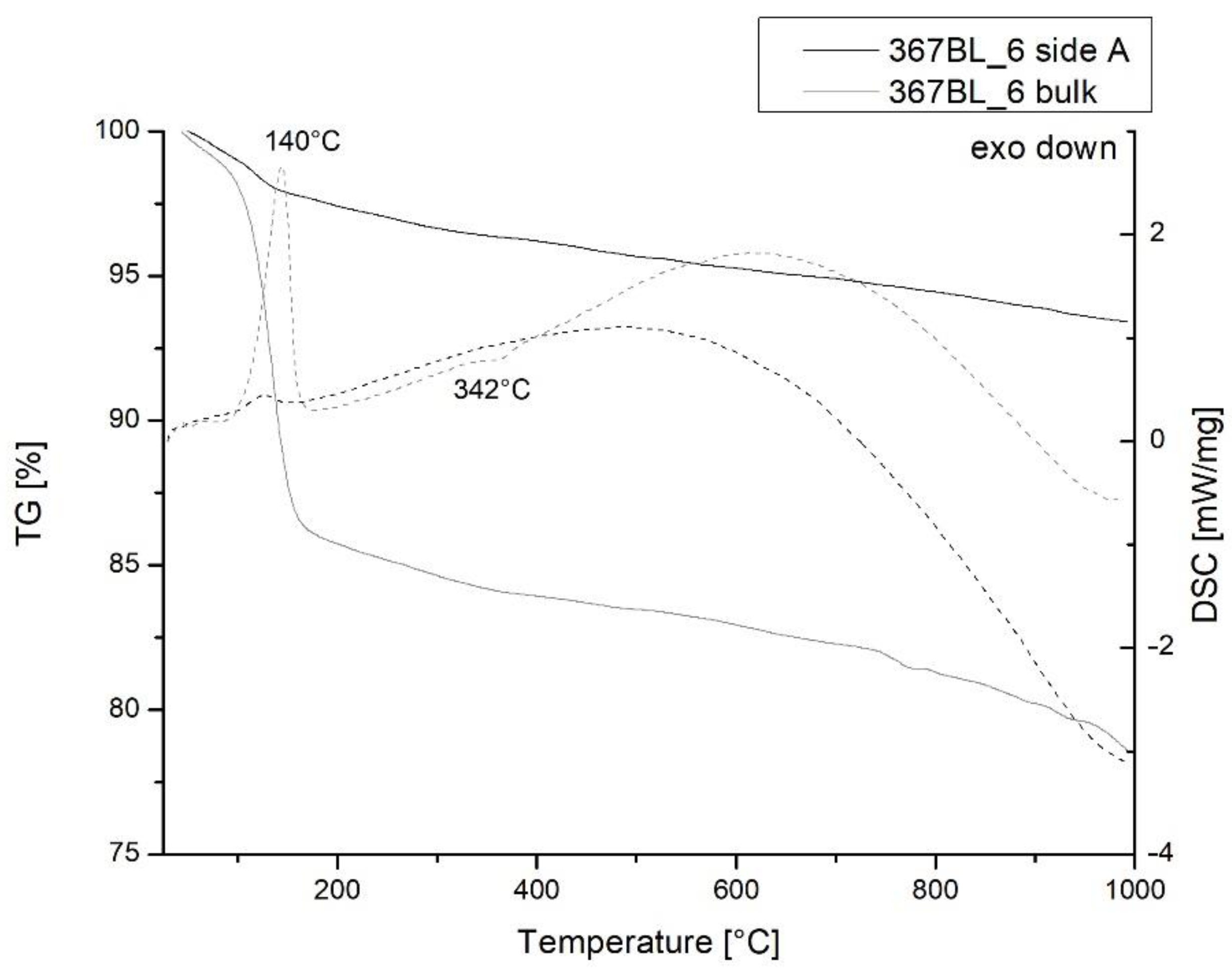

| Sample | <100 °C | 100 ÷ 200 °C | 200 ÷ 400 °C | 400 ÷ 600 °C | >600 °C | Total Weight Loss |

|---|---|---|---|---|---|---|

| 367BL_6 (side A) | 2.4% | 12.6% | 1.8% | 1.0% | 4.5% | 22.3% |

| 367BL_6 (bulk) | 1.0% | 1.6% | 1.3% | 0.9% | 1.7% | 6.5% |

| 2P_C1 (side A) | 1.1% | 1.7% | 1.7% | 0.7% | 1.6% | 6.8% |

| 303Y_1 + 5 (side A) | 3.0% | 1.4% | 2.7% | 1.7% | 0.9% | 9.7% |

| 309P_1 + 5 (bulk) | 1.1% | 0.1% | 0.5% | 0.7% | 0.4% | 2.7% |

| 41W_A (bulk) | 0.2% | 0.6% | 0.7% | 0.4% | 0.8% | 2.6% |

| 106P_G (bulk) | 1.0% | 0.2% | 0.8% | 1.9% | 1.8% | 5.7% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cantelli, M.; Cimino, D.; Facchi, A.; Phaneuf, R.J.; Zendri, E. Non-Vascular Ceramic Sherds Coming from Two Italian Etruscan Settlements: Peculiarities and Interpretation of Their Possible Use. Heritage 2022, 5, 1433-1448. https://doi.org/10.3390/heritage5030075

Cantelli M, Cimino D, Facchi A, Phaneuf RJ, Zendri E. Non-Vascular Ceramic Sherds Coming from Two Italian Etruscan Settlements: Peculiarities and Interpretation of Their Possible Use. Heritage. 2022; 5(3):1433-1448. https://doi.org/10.3390/heritage5030075

Chicago/Turabian StyleCantelli, Margherita, Dafne Cimino, Alberta Facchi, Raymond J. Phaneuf, and Elisabetta Zendri. 2022. "Non-Vascular Ceramic Sherds Coming from Two Italian Etruscan Settlements: Peculiarities and Interpretation of Their Possible Use" Heritage 5, no. 3: 1433-1448. https://doi.org/10.3390/heritage5030075

APA StyleCantelli, M., Cimino, D., Facchi, A., Phaneuf, R. J., & Zendri, E. (2022). Non-Vascular Ceramic Sherds Coming from Two Italian Etruscan Settlements: Peculiarities and Interpretation of Their Possible Use. Heritage, 5(3), 1433-1448. https://doi.org/10.3390/heritage5030075