1. Introduction

Given that pottery has always been one of the main fields of study of archaeological material, seen from many different viewpoints (art historical, economic, daily-life related etc.), the application of material analysis to the investigation of compositions and production technologies of archaeological pottery and glazes has been a growing research field during the last decade stemming from the discipline of archaeometry. Despite the increasing interest in archaeological pottery technologies in recent years, Byzantine glazed pottery has received scant attention. This article aims at filling this gap, to a small extent at least. What appears to be more crucial is the combination of the traditional archaeological research with the archaeometric research, as in this case the literature is limited about Chalkis in Euboea during the Byzantine and Early Modern periods.

Chalkis served as the port of call in the Aegean for nearby Thebes (

Figure 1) [

1,

2,

3]. This city was the harbour of Byzantine Thebes and later a Venetian hub with the name of Negroponte [

4]. Historical documents for Chalkis within the Byzantine administrative system are rather scarce.

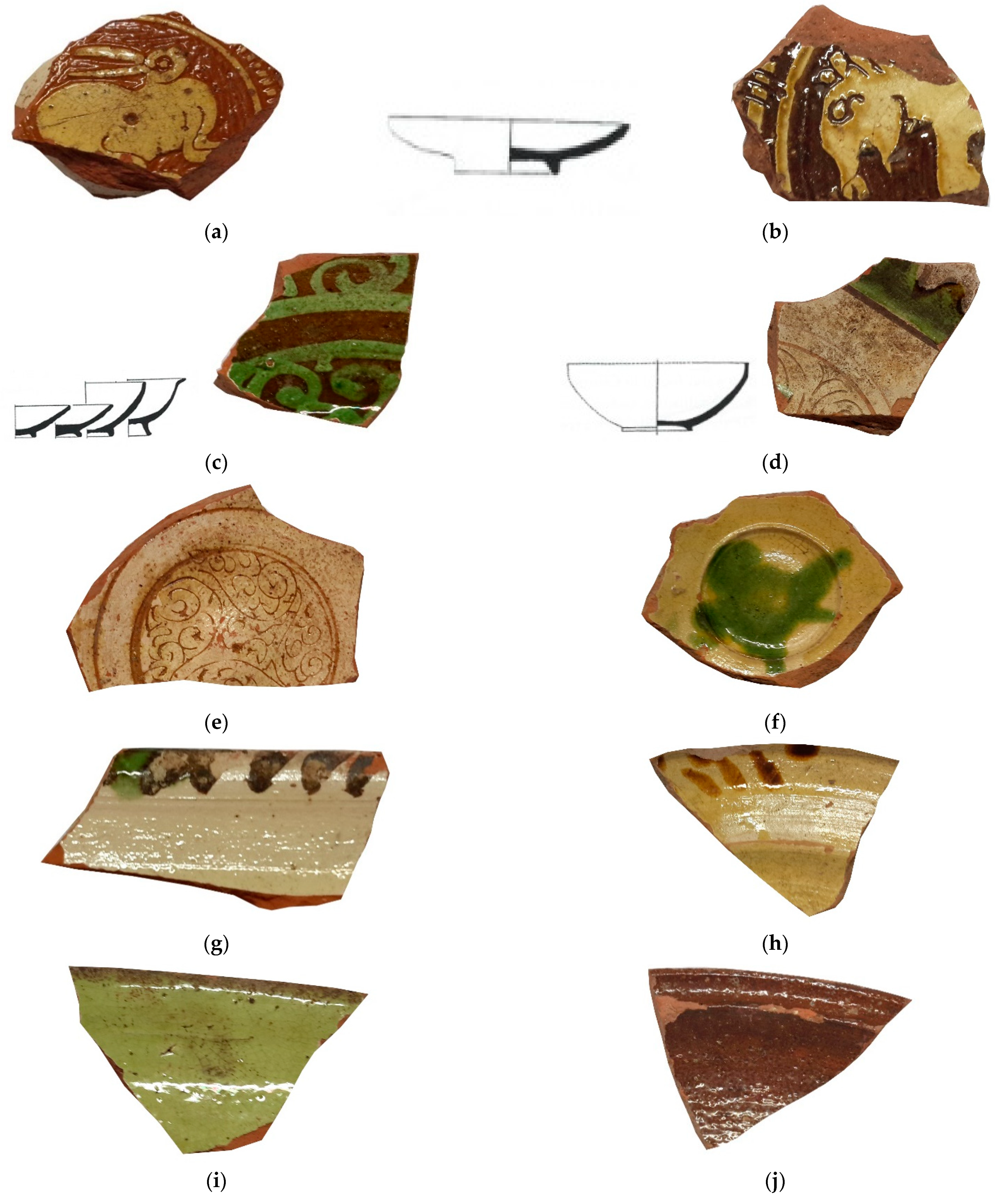

During the Byzantine period and mainly in the 12th and 13th centuries, several categories of Byzantine glazed table wares were manufactured in Chalkis. However, the city contained a production area and because of its port was also an important distribution centre for pottery (Waksman et al. 2014). Towards the end of the Middle Byzantine period, one may notice the emergence of new glazed pottery types in the local ceramic repertoire of the city. The majority of these wares appear to have been locally made as part of a large-scale production, which were grouped together in the so-called ‘main Middle Byzantine Production (MBP)’ [

5,

6,

7,

8,

9,

10,

11]. The pottery types manufactured in Chalkis included ‘Slip-Painted Ware’, ‘Green and Brown Painted Ware’, ‘Fine Sgraffito Ware, ‘Painted Fine Sgraffito Ware’, ‘Incised Sgraffito Ware’, and ‘Champlevé Ware’ (

Figure 2). During the 12th and 13th centuries, MBP had a wide distribution in the Mediterranean and beyond: from Marseilles to the Levantine coast and from Crimea to Cyprus [

12,

13,

14,

15]. The 13th century is characterized by political disintegration, which led to the creation of more regional workshops where ceramic products were mostly manufactured for local markets (without the predominance of one influential centre). Regardless that the manufacture of earlier glazed products continued, new types were introduced, e.g., ‘Sgraffito Ware with Concentric Circles’ (which is also known as ‘Zeuxippus Ware’).

In general, the glazed pottery from Chalkis ranges from the Middle Byzantine Period to Ottoman/Venetian times. However, the majority of the pottery material that was studied from the Orionos Street excavation can rather be dated to the Middle Byzantine and the Late Byzantine periods, especially in the late 12th to early 13th centuries. In this article, the production technology and surface treatment of glazed pottery have been investigated on the basis of 56 ceramic fragments from the Orionos Street excavation. The examined 56 fragments included Champlevé Ware (20), Incised Sgraffito Ware (13), Monochrome Glazed Ware (8), Slip Painted Ware (4), Plain Glazed Ware (3), Painted Fine Sgraffito Ware (2), Green and Brown Painted Ware (2), Splashed Ware (2), Fine Sgraffito Ware (1), and Painted Ware (1) (

Table 1).

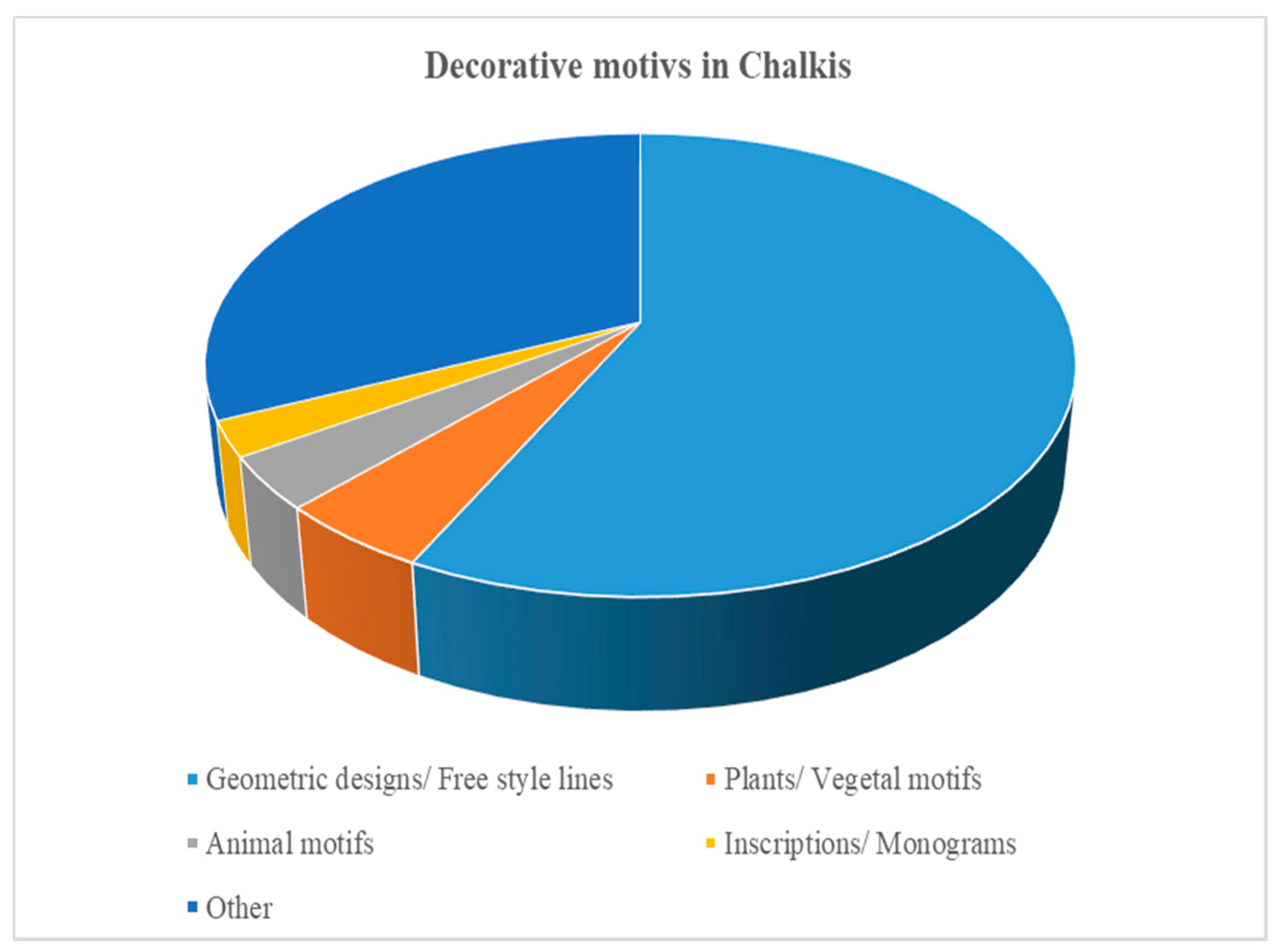

Firstly, the decoration of the 56 ceramic fragments was studied firstly, which included ‘Champlevé Ware’, ‘Incised Sgraffito Ware’, ‘Monochrome Glazed Ware’, ‘Slip Painted Ware’, ‘Plain Glazed Ware’, ‘Painted Fine Sgraffito Ware’, ‘Green and Brown Painted Ware’, ‘Splashed Ware’, ‘Fine Sgraffito Ware’, and ‘Painted Ware’. Decoration with geometric designs or free style lines (57%), plants or vegetal motifs (5%), animal motifs (4%), and inscriptions or monograms (3%). The remaining 31% represented monochrome glazed wares (

Figure 3). The pottery from Chalkis presented a high variety of. Furthermore, the pottery from Chalkis had a standard variety of colours among which green, yellow, and brown (either single-coloured or bi-coloured). We noticed in Chalkis’ pottery was mainly single coloured and, to a lesser extent, bi-coloured examples, which bore a decoration marked by intense green hue or olive and light ochre hue. Yellow was the most common pigment followed by green and brown. The chronology, characteristics (typology, style, colour), and quantities of the samples were the criteria for the selection of the samples.

In addition, this paper focuses on the manufacture of glazed ceramics within the local pottery repertoire of Chalkis while trying to contextualise the pottery typology and to consider issues of technology. We were interested in the decoration and in the iconographical implications of artifacts in this region because many influences existed in a broader Mediterranean and Near Eastern perspective. The compositional variation of the ceramic body and glaze was investigated by non-invasive EDXRF and Scanning electron microscopy (SEM-EDS) as part of a larger study of manufacturing techniques of Byzantine ceramics. Furthermore, the manufacturing technology was investigated by SEM-EDS and XRD, providing general conclusions concerning the clay preparation, the microstructure of the body and surface, and the firing technology. These analyses of glazed ceramics may characterize and reflect important parameters to study culture and society because pottery was used in various ways, e.g., food preparation, storage and transport, providing thus insights into trade and commerce, as well as connections with other societies (regarding dietary habits or accumulation of goods). The aim here is to recognize technological practices and the decorative elements of Byzantine pottery. This article attempts to investigate the Byzantine glazed pottery techniques at this aforementioned site in more detail. This was achieved through sampling of glazed pottery and applying an analytical methodology that takes into account compositional data of both ceramic bodies and their glazes.

2. Analytical Approach

The 56 samples were studied under a stereoscope in order to describe their fabrics, slips, and glaze structure. This examination was mainly focused on the composition and the thickness of the layers. Furthermore, prior to coating with carbon, the cross-sections were observed under a binocular polarising microscope. Another aspect was the microstructure of the clay, in terms of characteristics such as coherence, inclusions or porosity. The elemental compositions of the ceramic bodies and glazes of the 56 glazed fragments were examined in situ with energy dispersive X-ray fluorescence spectroscopy (EDXRF). For this, a handheld portable Thermo Scientific™ Niton™ XL3t XRF Analyzer (pXRF) (Waltham, MA, USA) was used with a measurement time of 120 s under a standard atmosphere. Depending on the specific questions, two different methods were applied: ‘mining’ providing major and minor concentrations of elements with Z > 13 (Al) and ‘soil’ providing concentrations of elements with Z > 16 (S) for a larger suite of trace elements [

16].

Twelve fresh break samples were examined under a polarizing and Scanning electron microscope (SEM-EDS). Additionally, eight fragments were selected from the same fragments for the preparation and investigation of cross sections: ‘Champlevé Ware (four samples), Monochrome Glazed Ware (one sample), Slip Painted Ware (one sample), Plain Glazed Ware (one sample), and Splashed Ware (one sample)’. The SEM examination of the fresh breaks provided a clearer image of the micromorphology of the ceramic body in view of the degree of vitrification, thus allowing for assessing the firing conditions. The sections, which included all layers (ceramic body, slip, glaze), were embedded in polyester resin, polished with a 0.25 μm diamond paste, and then coated with a layer of carbon. Then, they were examined under an FEI, Quanta Inspect D8334 SEM-EDS. The EDS was operating with a voltage of 25 kV, and spectra with a live time of 100 s were recorded in order to obtain the optimum excitation of the low-energy and low-concentration elements. Analytical totals, typically in the range of 95–99%, were normalized to 100%. The spectra were calibrated using a cobalt standard and deconvoluted with the phi-rho-z correction procedure using Oxford Instruments SEM Quant software. Elemental compositions were determined by EDS of polished samples. Additionally, in some cases, element maps were recorded in order to investigate the distribution of inclusions in the ceramic body and pigments in the glaze layers. Concentrations are presented as the average of three to five measurements on different zones selected within the regions of interest, avoiding altered areas and body interfaces.

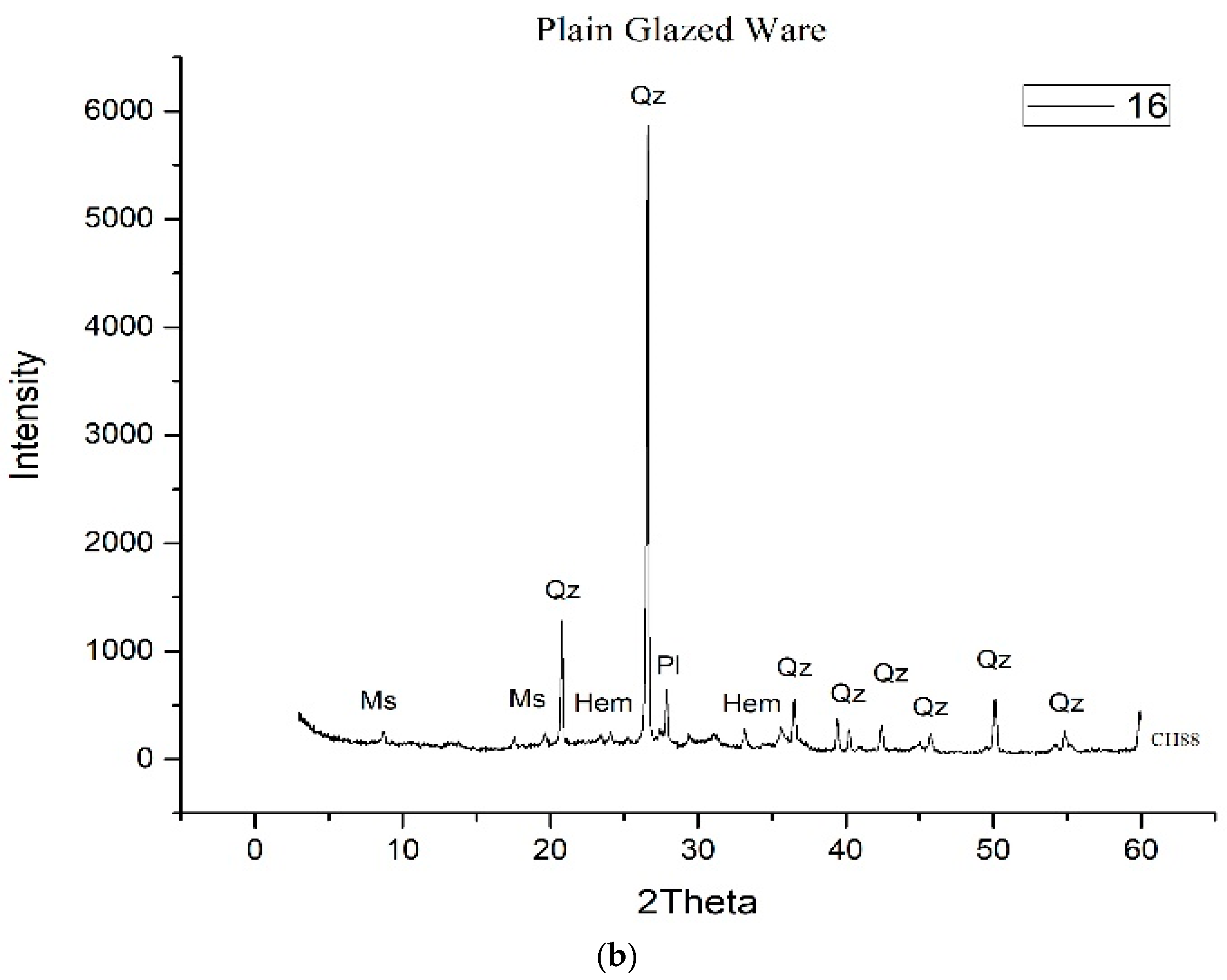

Furthermore, seven bulk samples ‘Champlevé Ware (four samples), Slip Painted Ware (one sample), Plain Glazed Ware (one sample), and Splashed Ware (one sample)’ were analysed for their mineralogical composition using a SIEMENS X-ray diffractometer of the National Recearch center ‘NCSR Demokritos’. The quantity of the Monochrome Glazed Ware (CH137) was not sufficient for XRD analysis. The diffractometer is equipped with Cu–Ka radiation and has a system of single-chroming/monochromatic application of a secondary beam of pyrolytic graphite operating at 40 kV and 35 mA. The system of fractures/slashes in the course of the initial and the diffracted beam was 1.0°. Bulk samples were scanned from 3 to 60° 2θ, with a scanning angle step of 0.03/2θ and a step time of 0.1 s for 1 h and 30 min. Qualitative analysis was performed using DIFFRACplus EVA software (Bruker-AXS, Billerica, Massachusetts, USA) based on the ICDD Powder Diffraction File (2006 version). The XRD investigation was focused on investigating the presence or absence of main clay and ceramic phases providing supplementary information concerning the firing conditions. Representative fragments of the most common glazed wares in Chalkis were selected for SEM (polished samples) and XRD analyses.

3. Results

pXRF was applied for measurement of the elemental composition of ceramic bodies and glazes.

Table 2 presents the average compositions of the ceramic bodies, which were measured in ‘soil’ mode while the average compositions of the glazes, measured in ‘mining’ mode, are presented in

Table 3. The pXRF measurements of these glazed fragments indicated a comparably homogeneous composition without considerable variation or distinct patterns. An obvious exception was the large variation determined for S, Cu, and Pb concentrations. High Pb and Cu contents in the ceramic bodies are assumedly related to intrusion by the lead glaze in some cases, including copper-bearing pigments during firing. On the other hand, S K lines were potentially interfered by Pb M lines, indicating falsely enhanced S contents. Nevertheless, based on the remaining elements contents, it can be concluded that the examined glazed pottery was manufactured apparently with the same or very similar raw materials.

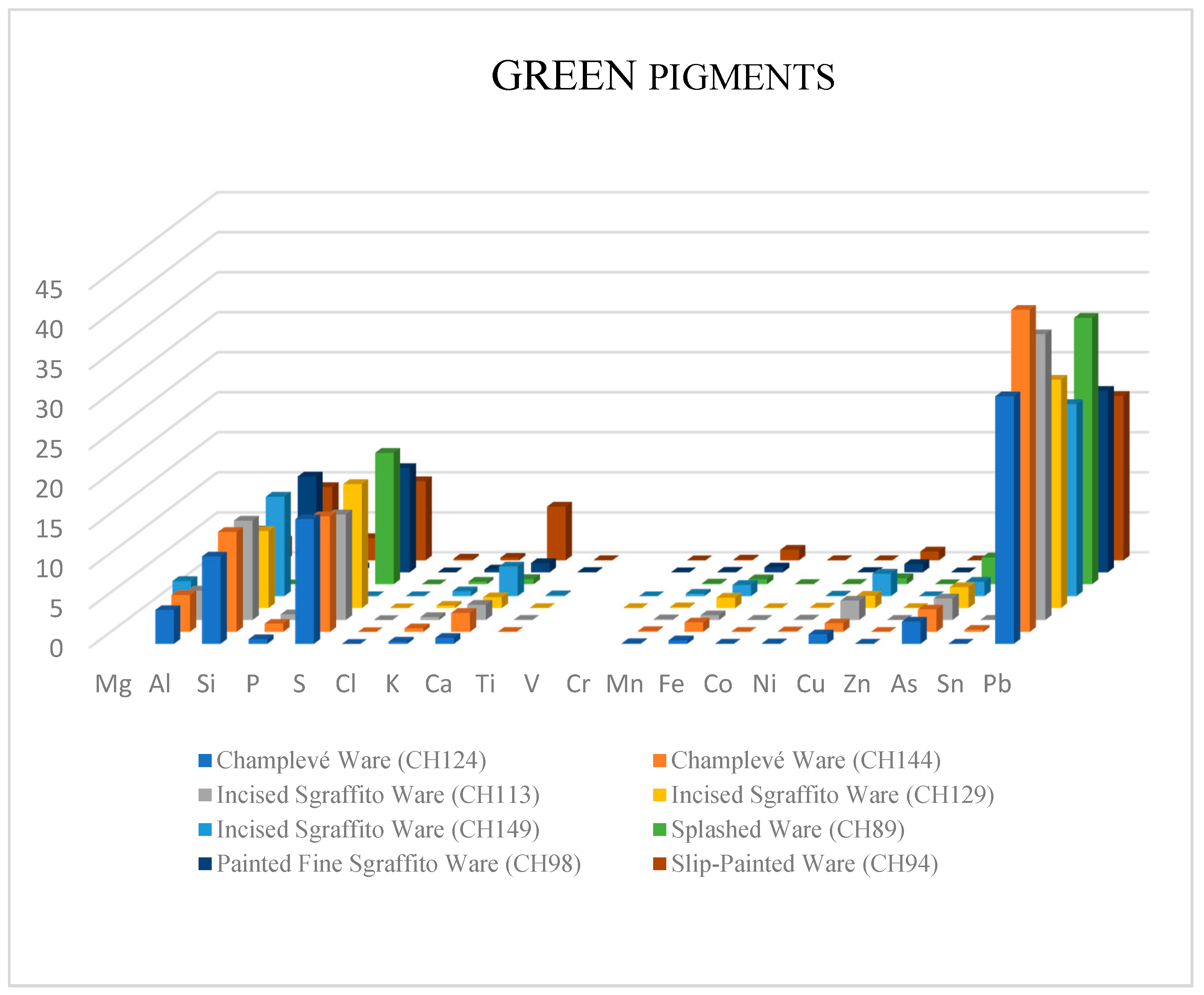

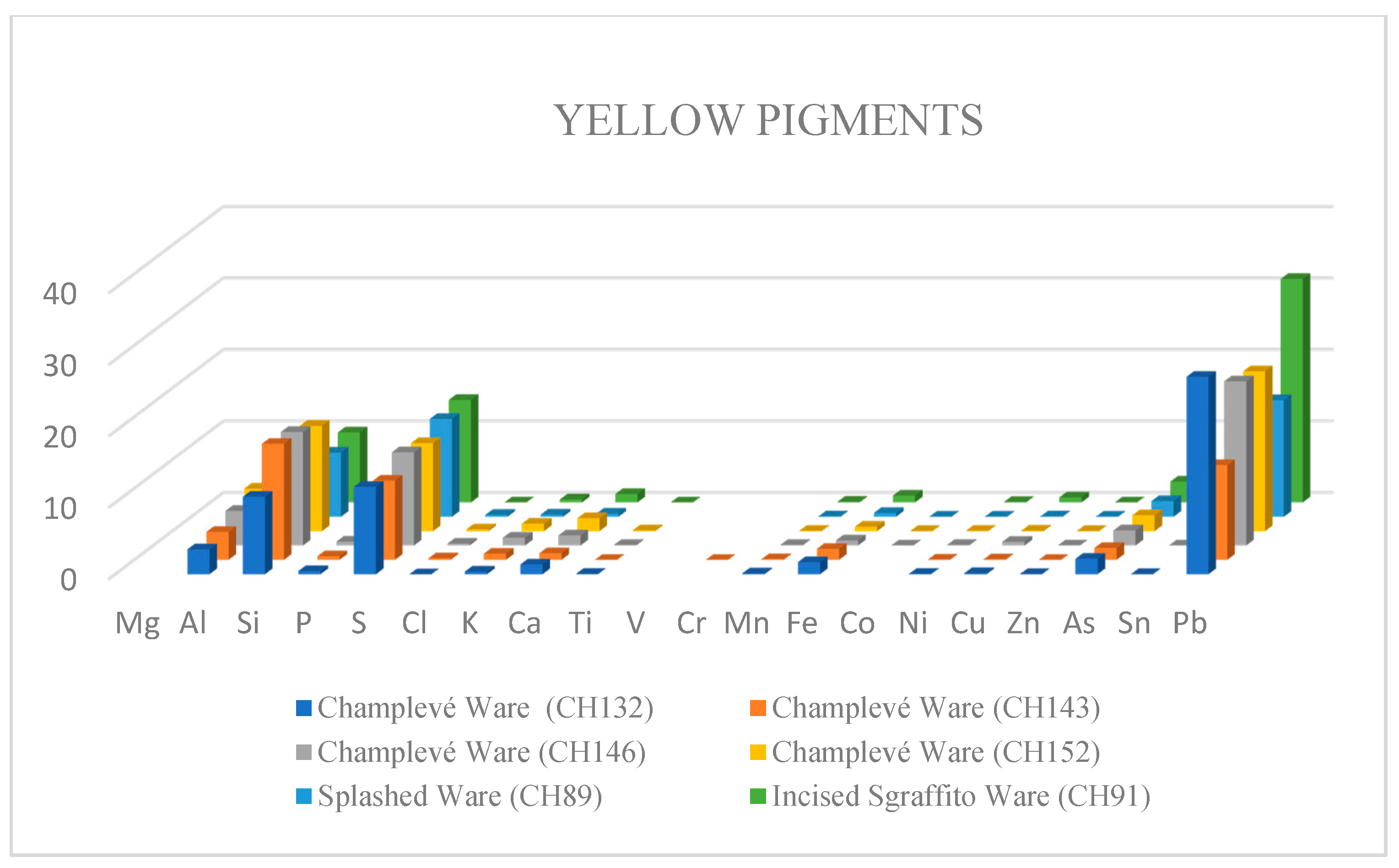

The green pigments, which were studied, were found in fragments of Champlevé Ware (CH124, CH144), Incised Sgraffito Ware (CH113, CH129, CH149), Splashed Ware (CH89), Painted Fine Sgraffito Ware (CH98), and Slip-Painted Ware (CH94). The Splashed Ware (CH89) presented a Cu content of c. 0.8%, which was apparently the main colorant of this green pigment. Furthermore, the Incised Sgraffito Ware sherds (CH113, CH129, CH149) had Cu 1.6–2.9%. All the other samples had Cu 1–1.2%. Finally, all the samples had Fe 0.5–1.4% (

Figure 4). The yellow pigments came from the sherds of Champlevé Ware (CH132, CH143, CH146, CH152), Splashed Ware (CH89), and Incised Sgraffito Ware (CH91). The Champlevé Wares (CH132, CH143, CH146, CH152) consisted of the main colorant Fe 1.1% in combination with Cu 0.2% and Mn 0.1%. However, the Splashed Ware (CH89) and the Incised Sgraffito Ware (CH91) contained Fe < 1% (

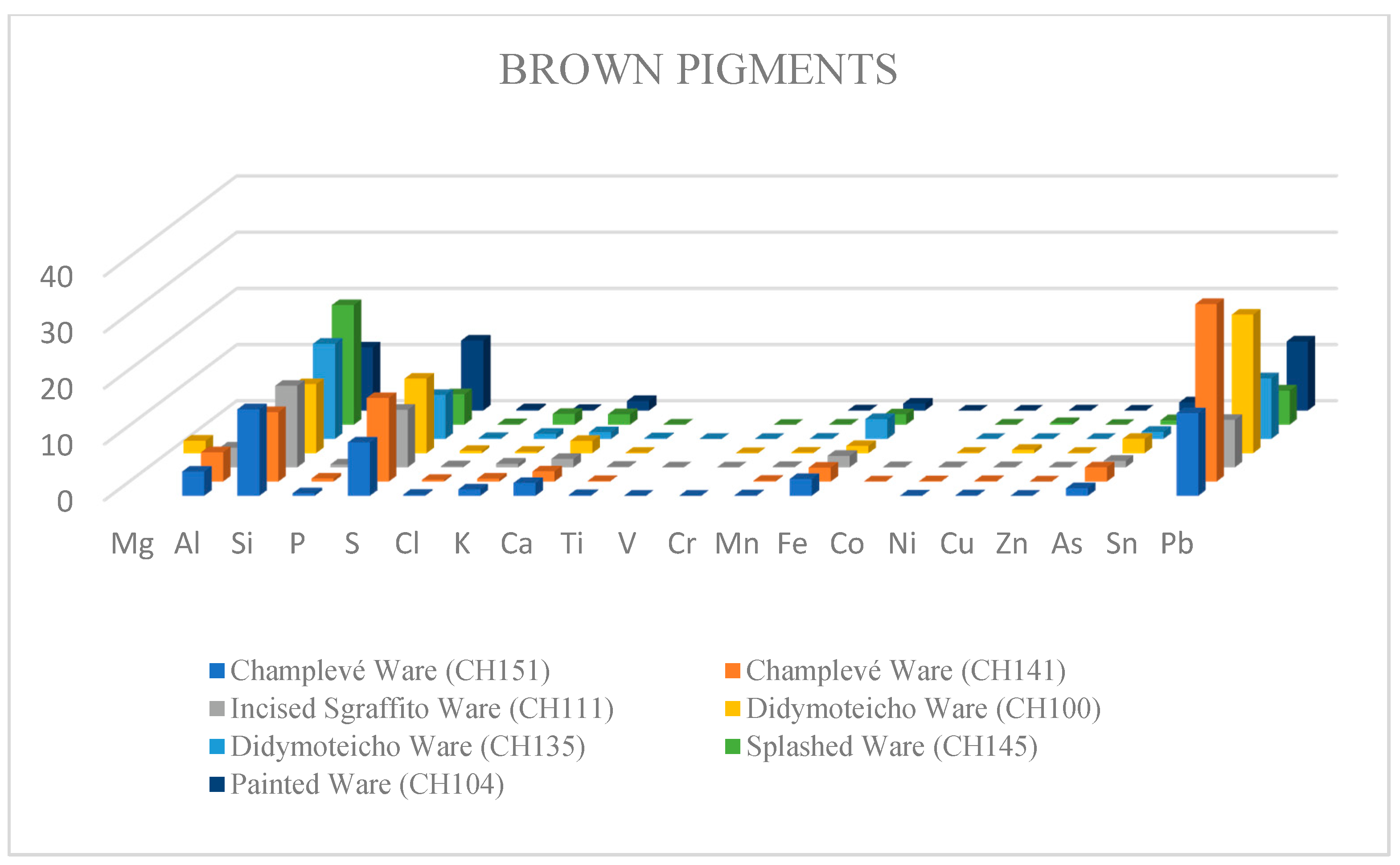

Figure 5). The brown pigments were present in fragments of Champlevé Ware (CH151, CH141), Incised Sgraffito Ware (CH111), Splashed Ware (CH145), and the Painted Ware (CH104). The Splashed Ware (CH145) and the Painted Ware (CH104) had the main colorant Fe < 2% in combination with Cu < 0.6% and Mn < 0.08%. The pieces of Champlevé Ware (CH151) and Incised Sgraffito Ware (CH111) had Fe 2–3% in combination with Cu < 0.1% and Mn < 0.1%. Lastly, the Champlevé Ware (CH141) had about Fe 2.5% with Cu < 0.1% and Mn 0.2% (

Figure 6). One dark pigment was also analysed in the Incised Sgraffito Ware (CH139), and it contained Fe 3.1% and Mn 0.1% (

Table 4).

According to Scanning electron microscopy (SEM-EDS), the glazes consisted of NaO

2: 0.3%, MgO: 0.9%, Al

2O

3: 7%, SiO

2: 26.3%, SO

3: 20%, K

2O: 1%, CaO: 1.5%, Fe

2O

3: 1.8%, and PbO: 40.6%. The Champlevé Ware (CH141) and the Slip Painted Ware (CH94) had a small amount of CuO due to greenish to green decoration. The Champlevé Ware (CH148) had also TiO

2 0.4% (

Table 5). Moreover, the chemical composition of the slip layers was not that different from the chemical composition of the clays. The slips consisted of NaO

2: 1.1%, MgO: 1.5%, Al

2O

3: 16.4%, SiO

2: 56.2%, SO

3: 4.4%, K

2O: 3.5%, CaO: 3.2%, TiO

2: 0.5%, Fe

2O

3: 4.2%, and PbO: 8.4% (

Table 6). Furthermore, the fabrics consisted of NaO

2: 1.2%, MgO:2.4%, Al

2O

3:18.7%, SiO

2: 60%, K

2O:3.9%, CaO: 5.2%, TiO

2:1%, and Fe

2O

3: 7.6% (

Table 7). The percentage of SO

3 is due to the interference of Pb lines in S Ka lines. The measured compositions of each layer were quite similar and no significant differences among the samples were observed.

According to the analyses of the polished glazes on fragments of Champlevé Ware, Monochrome Glazed Ware, Splashed Ware, Slip Painted Ware, and Plain Glazed Ware, the results were the following: PbO~41%, CaO 1.5%, K2O 1%, and Na2O 0.3%. Furthermore, the correlation of SiO2, AlO3, and CaO for the glazes from Chalkis proved the similar chemical composition of the glazes in the local pottery. All the pottery samples from Chalkis are typically lead glazes with a small amount of alkali and earth alkaline metals (CaO, K2O, Na2O).

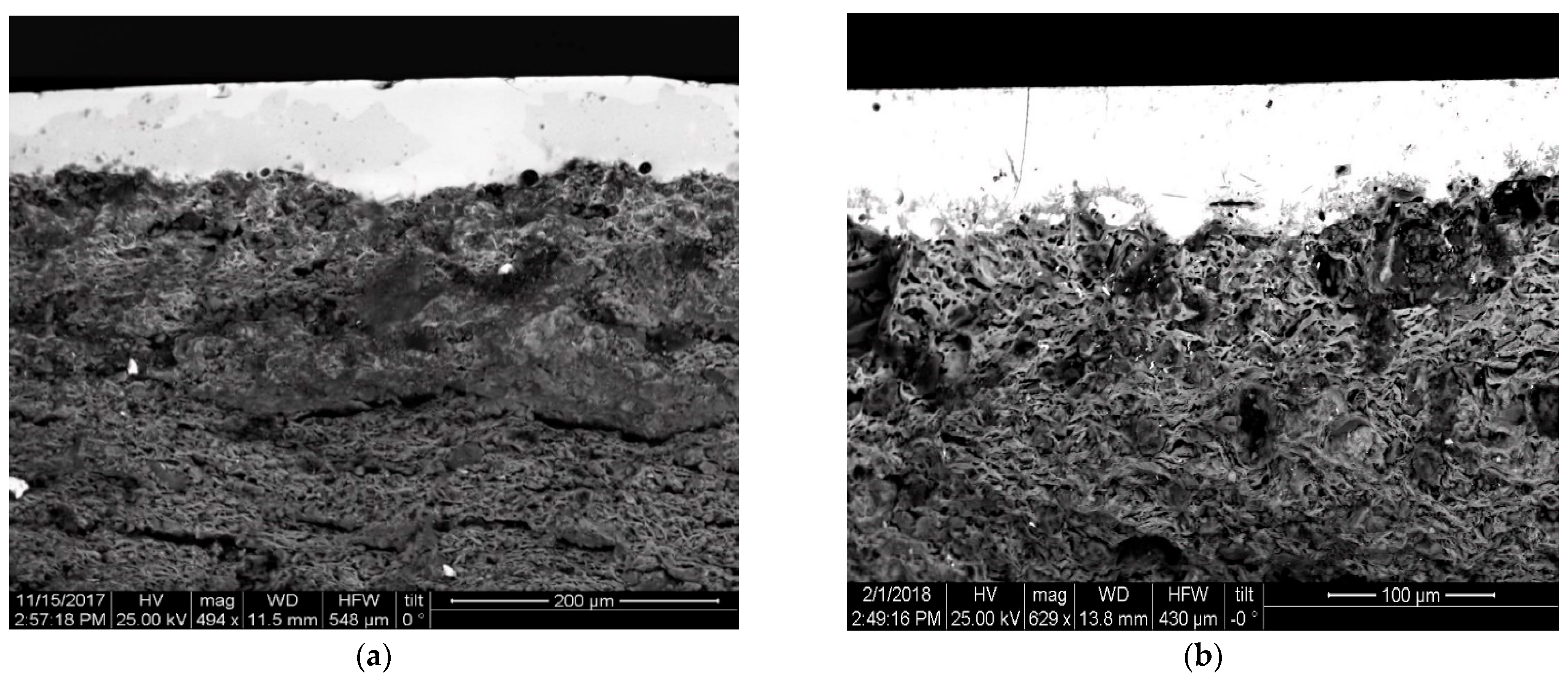

The slip had various functions in pottery construction and in the decoration of the ceramics studied. Slip was used as an adhesive for attaching appendages to the body of a vessel. Likewise, it was applied as decoration to the surface of a vessel. When it was used as decoration, slip was applied like paint with a brush or similar tool. Unlike paint, however, slip had the advantage of bonding with the surface of the clay vessel and, for this reason, it was more durable than paint. Separate slip layers below the glaze were observed in fragments of all ware types with glaze diffusing into the slip layers apart from the Plain Glazed Ware sample (CH88) that did not have a slip layer. The slip layers were more compact and vitrified compared to the porous ceramic bodies applied assumedly as a fluid suspension. The optical microscopy images suggested that the thicknesses of the surface layers were not uniform and they ranged from 100 to 600 μm (

Figure 7). Slip layers were observed not only on open wide surfaces but also on inner curved surfaces. These data clearly indicate that finer slip, with or no colorant and more fluxes, was used in the production of the slip compared with that utilized for the body. Additionally, no cracks were observed on the samples, which showed there was no mismatch between the thermal expansion coefficients of the bodies and the slip. In addition, it could easily be seen that the colour of the slip on all samples was different from the colour of the body, as it was a quite pure white colour with few impurities of Fe. The iron content of the slip slayer was typically lower than that in the ceramic bodies. For this, it can be assumed that either a different raw material was used or that iron inclusions were effectively removed from the clay during suspension. According to the examined slips, the percentage of Fe was quite low, about 4%. The Ca:Fe ratio was 3:4 and the percentage was 0.8%. In addition, the Na and K values of the slip were similar to those of the bodies. This indicates that Ca-, Na-, and K-bearing minerals (such as Na

2O and K

2O) were used as deflocculants during the preparation of the suspension for the surface application. In addition, oxides of Na and K acted as a flux in the batch, helping to form the sintered and slip. The fluxes Ca, K, and Na had a ratio of 3:4:1 and the percentage was 0.8%. The optical microscopic images of the slip obtained from all samples indicated that a very compact and uniform structure, with a larger degree of sintering compared to the body, formed over the vessels. The difference between the colours of these layers and of the bodies clearly indicates that finer clay fluxes and sometimes colorants were used in the production of the slip compared with the bodies.

To sum up, regarding the decoration, the motifs were designed on the slip, and the pigment oxides were added to the glaze of Champlevé Ware, Monochrome Glazed Ware and Plain Ware, but for the other pottery typologies, the pigments were added on the slip. All of them seemed to have underglaze decoration (

Figure 7).

Quantitative analysis, carried out on the polished samples with the SEM-EDS, indicated a calcareous clay (Ca content c. 5%) used for the manufacture of the ceramic body. The calcareous clays, containing this amount of CaO in a fine calcium carbonate form, exhibited a characteristic cellular structure with a high porosity. This characteristic microstructure remained constant for 200 °C (850–1050 °C), and above this temperature there was a progressive increase of vitrification. Vitrification results in different features depending on its degree in the samples. In a first degree/phase, it appears in continuous filaments, joining the edges of the parallel aligned clay particles. In a second degree/phase, when the filaments from several clay layers fuse together, vitrification appears as wavy glassy strips [

17]. Quantitative analysis indicated a CaO content of c. 5% and a FeO content of c. 8%. The CaO that appeared from the dissociation of calcium carbonate above about 750–800 °C reacted strongly with the iron oxides and broke them down. The final colour depended on the amount of calcium carbonate in the clay [

18]. The final colour of the understudied fabrics was an intense red colour. According to the fresh break samples, vitrification at different stages was observed in all pottery types: Champlevé Ware, Monochrome Glazed Ware, Splashed Ware, Slip Painted Ware, and Plain Glazed Ware (

Figure 8). Specifically, the fragments of Champlevé Ware and Incised Sgraffito Ware had intermediate to total vitrification. The pieces of Splashed Ware, Slip-Painted Ware, and Monochrome Glazed Ware had extensive to intermediate vitrification. Finally, the Plain Glazed Ware had extensive vitrification. These ceramics were fired in two firing stages in an oxidizing atmosphere with high temperatures. This study indicates that different ware types of local pottery from Chalkis had almost the same chemical composition, as can also be observed in the ternary diagram of CaO+MgO/Al

2O

3/SiO

2 (

Figure 9).

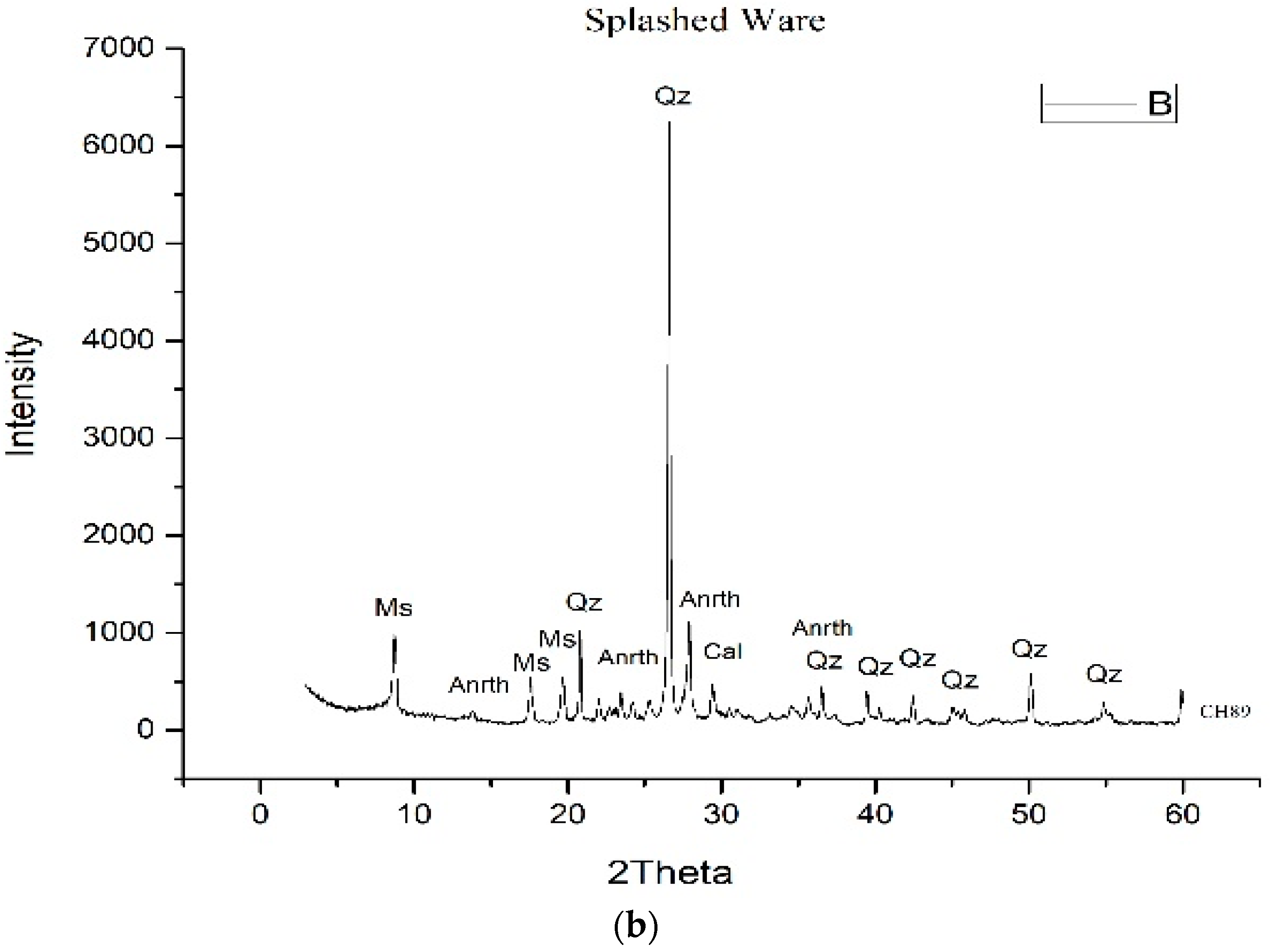

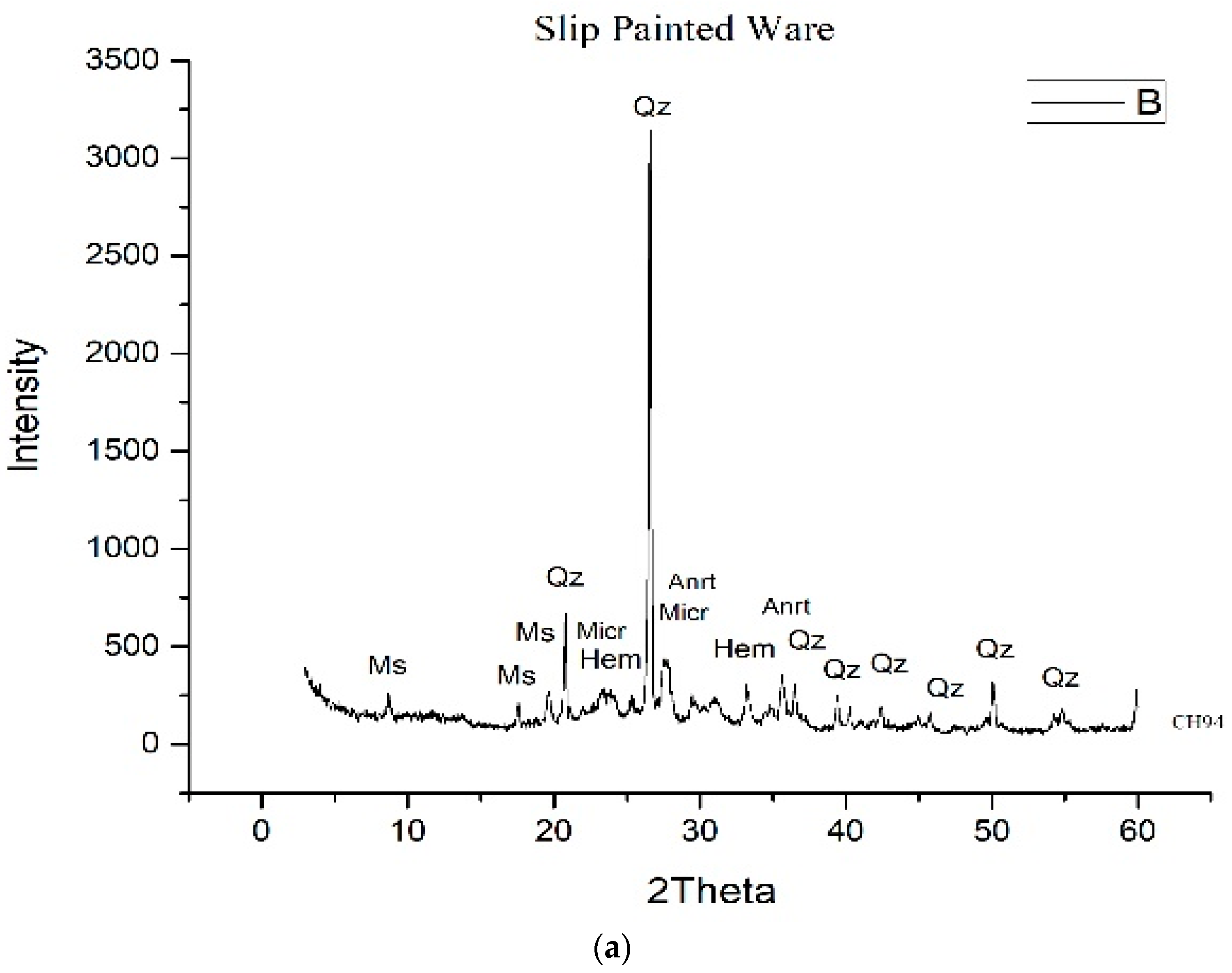

The XRD spectroscopy data were significant, and many conclusions were extracted [

19,

20,

21,

22,

23,

24,

25]. The fragments of Champlevé Ware from Chalkis consisted of Quartz, Plagioclase, K-Feldspars, and Diopside. In addition, the presence of Hematite was observed apart from one sample (CH148). Finally, a small amount of Muscovite/Illite was detected in the samples CH84, CH92, and CH124. The Slip Painted Ware (CH94) contained Quartz, K-Feldspars, Plagioclase, Hematite, and Muscovite/Illite. The Splashed Ware CH89 from Chalkis was composed of Quartz, Plagioclase, Calcite, and Muscovite/Illite. The Plain Glazed Ware CH88 from Chalkis contained Quartz, Plagioclase, Hematite, and Muscovite/Illite (

Table 8;

Figure 10 and

Figure 11). The Champlevé Ware sherds were fired at a high temperature, T > 950 °C, due to the presence of Diopside. The pieces of Splashed Ware CH89, the Plain Glazed Ware CH88, and the Slip Painted Ware were fired at a temperature of about 800–950 °C due to the presence of Muscovite/Illite (

Table 8 and

Table 9;

Figure 10 and

Figure 11).

Moreover, all of the minerals in the samples that were analysed by XRD were crossed with the minerals that were analysed by scanning electron microscopy. As a result, all of them confirmed the use of both techniques. In conclusion, after the combination of the stages of vitrification that were observed by SEM with the minerals that were detected by XRD, the temperature was determined. The fragments of Champlevé Ware were fired at a temperature of 1050–1150 °C, but the Slip Painted Ware, Splashed Ware, and Plain Glazed Ware were fired at a lower temperature, between 850 and 1150 °C (

Table 10). The main results are presented in

Table 11,

Table 12 and

Table 13.

4. Conclusions

In the present paper, 56 samples of glazed pottery finds were studied from the Orionos Street excavations in Chalkis, Euboea, in Greece, dated to the late 12th to early 13th centuries. The selected assemblage of Byzantine pottery fragments included primarily Champlevé Ware, Incised Sgraffito Ware, and Monochrome Glazed Ware and to a lesser extent, small numbers of Slip Painted Ware, Plain Glazed Ware, Painted Fine Sgraffito Ware, Green and Brown Painted Ware, Splashed Ware, Fine Sgraffito Ware, and Painted Ware. The findings from the Orionos Street excavations in Chalkis showed a large variety of motifs (geometric designs or free style lines, plants or vegetal motifs, animals, inscriptions or monograms) and a standard repertoire of colours (green, yellow, and brown). The decoration and the iconographical aspects of these artifacts were mainly single-coloured and, to a lesser extent, bi-coloured decoration (showing an intense green hue or olive and light ochre hue). Yellow was the most common pigment followed by green and brown. Nevertheless, many different hues were observed due to the different combination of metal oxides or the different ratios of them. The analytical examination indicated that Cu was the main component of green colours while yellow and brown colours were achieved by Fe mixed with smaller amounts of Cu and Mn. Concerning the glaze layer, the application of lead glazes with small amounts of alkaline metals (CaO, K2O, Na2O) on a slipped preparation layer appeared to be the common technology in Chalkis.

Regarding the micromorphology, different degrees of vitrification were observed in samples of all the pottery types studied with Scanning electron microscopy (SEM-EDS): Champlevé Ware, Monochrome Glazed Ware, Splashed Ware, Slip Painted Ware, and Plain Glazed Ware. The general picture presented extensive to intermediate vitrification and in some cases almost total vitrification. The Champlevé Ware fragments were fired at a temperature of 1050–1150 °C, but the sherds of Slip Painted Ware, Splashed Ware, and Plain Glazed Ware were fired at a lower temperature between 850 and 1150 °C. It is evident that two firing stages in oxidizing atmosphere were used with high temperatures. Based on the compositional analysis, this study indicated a rather similar chemical composition of the body fabrics of the local pottery finds from the Orionos Street excavations in Chalkis This is most probably due to the use of the same raw material sources. In conclusion, the glazed pottery from Chalkis was manufactured with a considerably high level of technology and was fired at comparably high temperatures. Potters followed a standard to high level of pottery production technology while they experimented with the decoration.