An Experimental Analysis of the Influence of Pyrolytic Oil on the Spray Breakup Process

Abstract

1. Introduction

2. Materials and Methods

2.1. Plastic Material

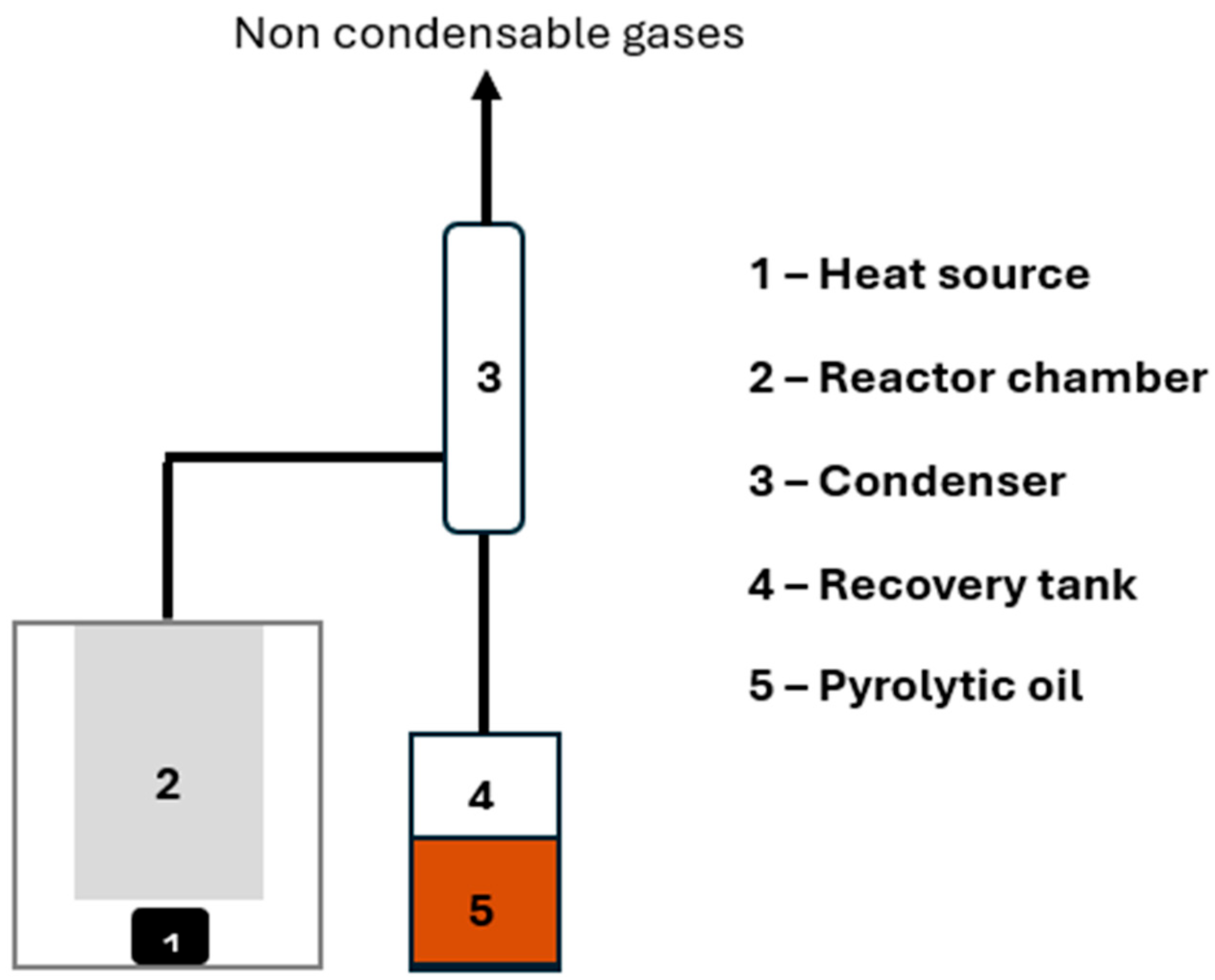

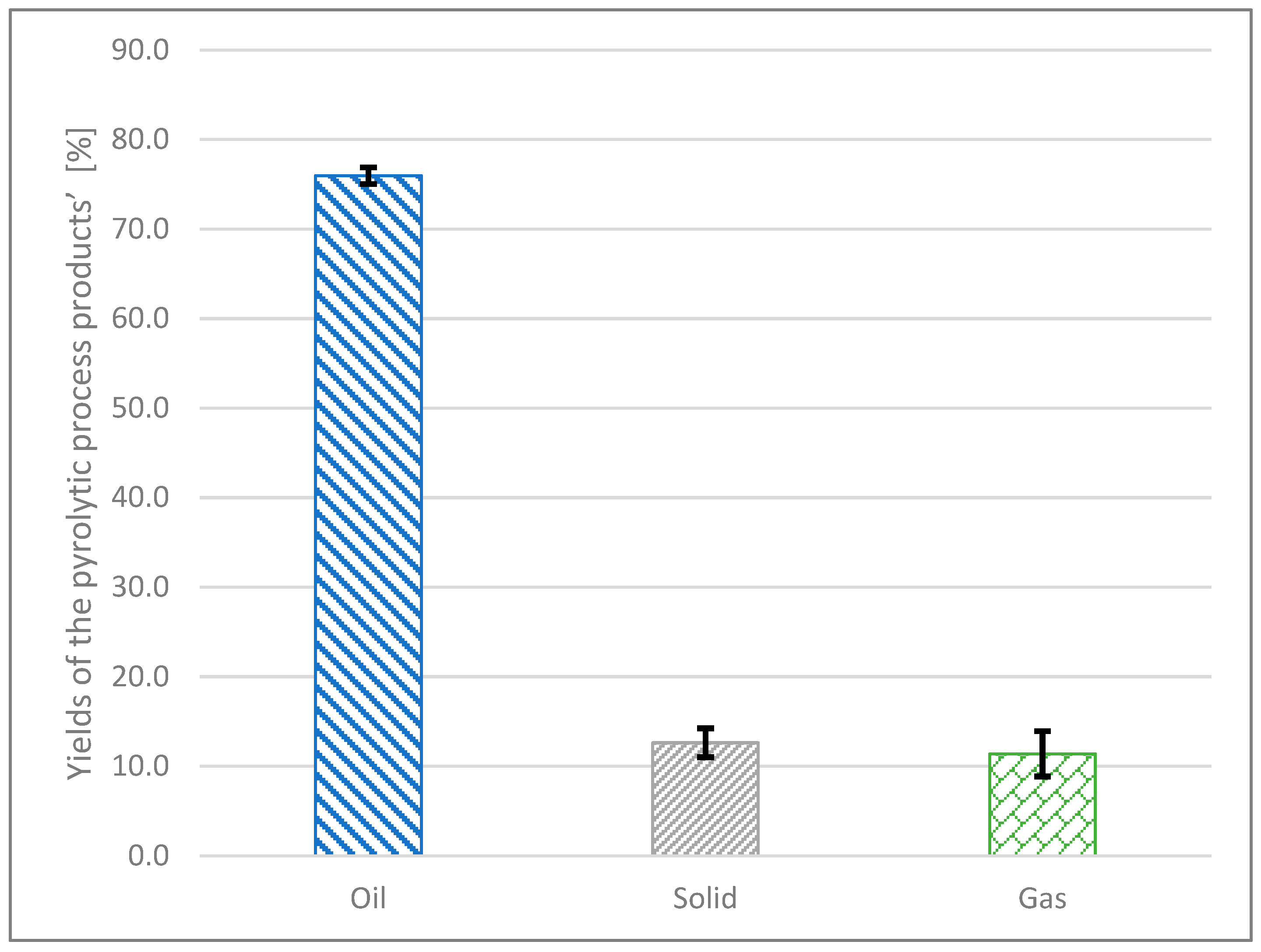

2.2. Pyrolysis Process

2.3. Oil Characterisation

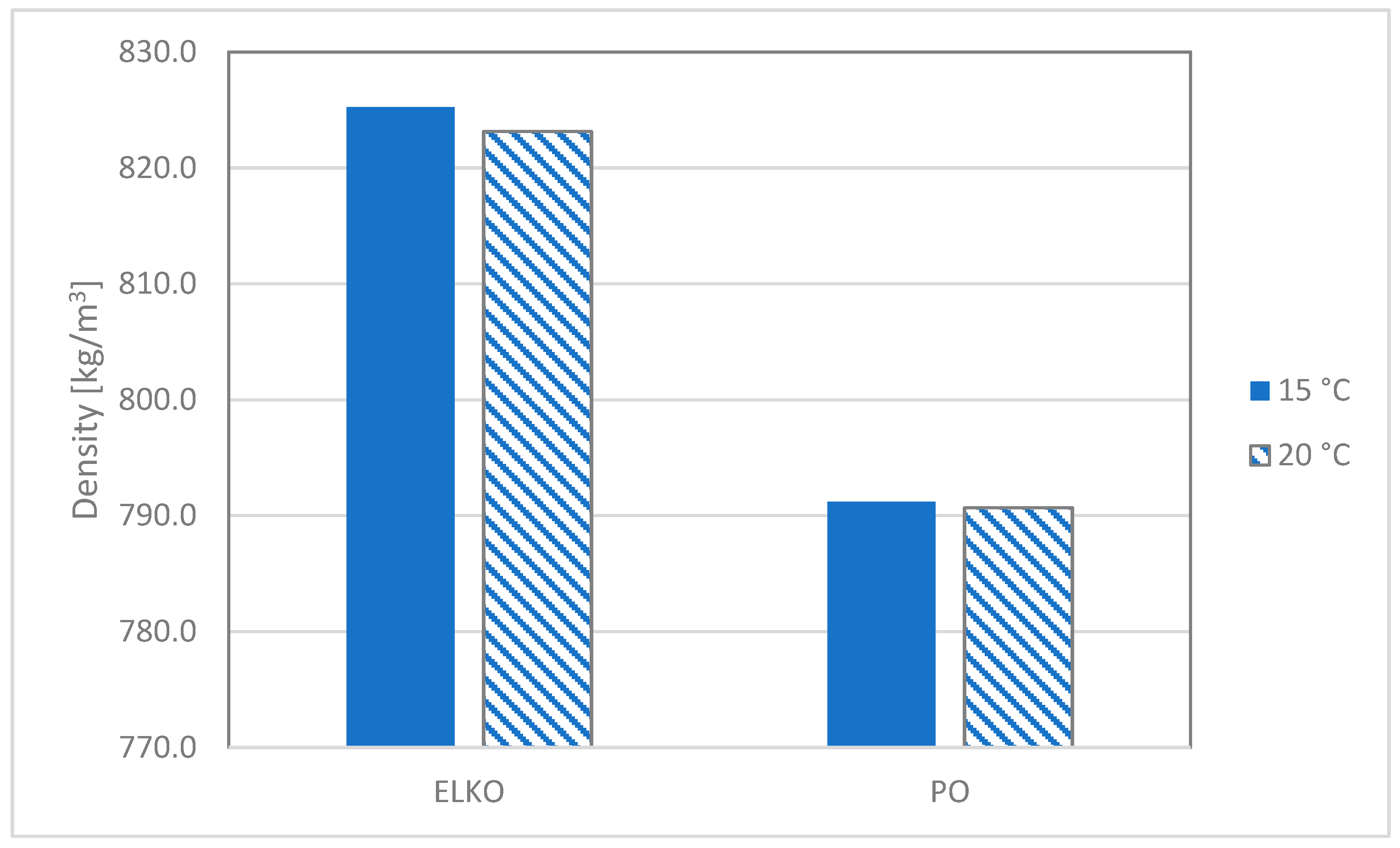

2.4. Density

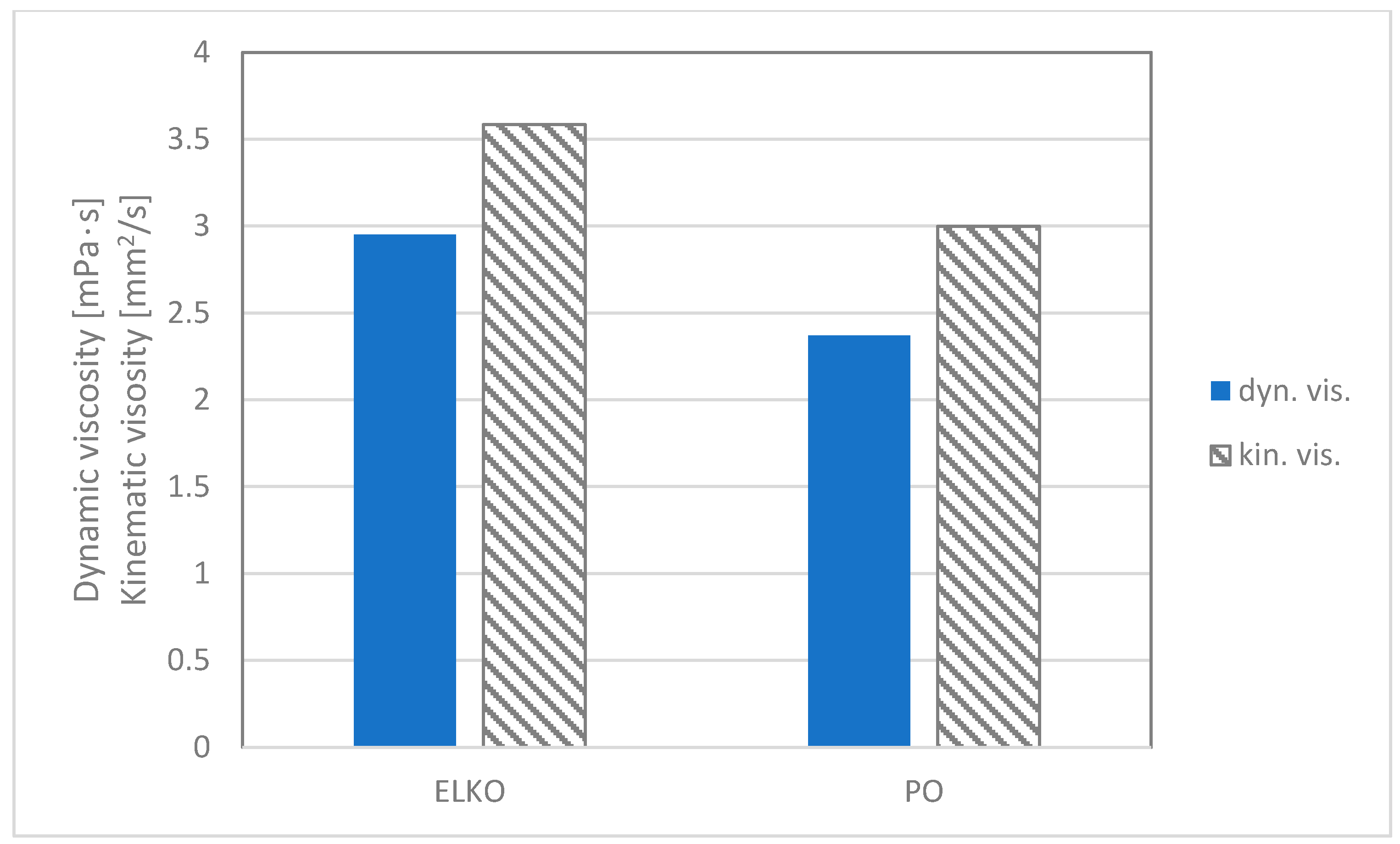

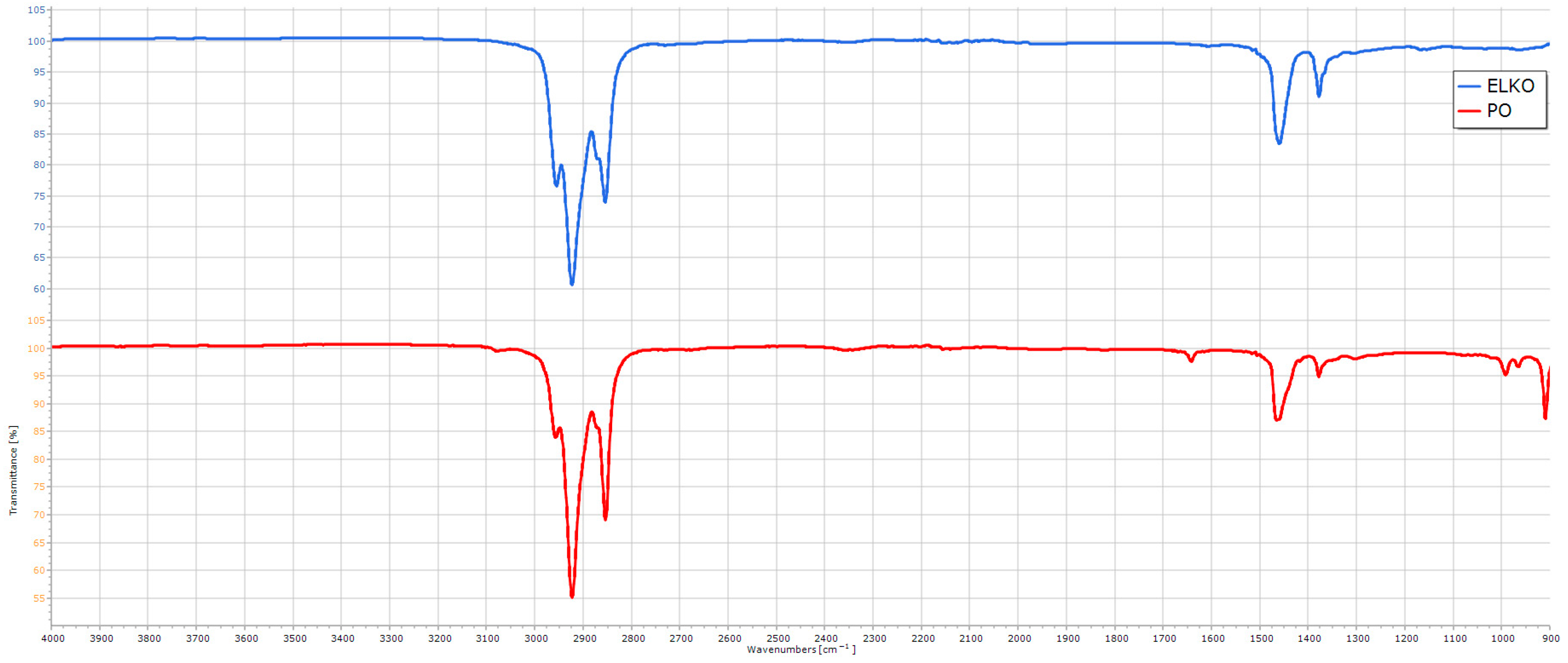

2.5. Viscosity

2.6. Surface Tension

2.7. Calorific Value

2.8. ATR FT-IR Spectroscopy

2.9. Elemental Composition

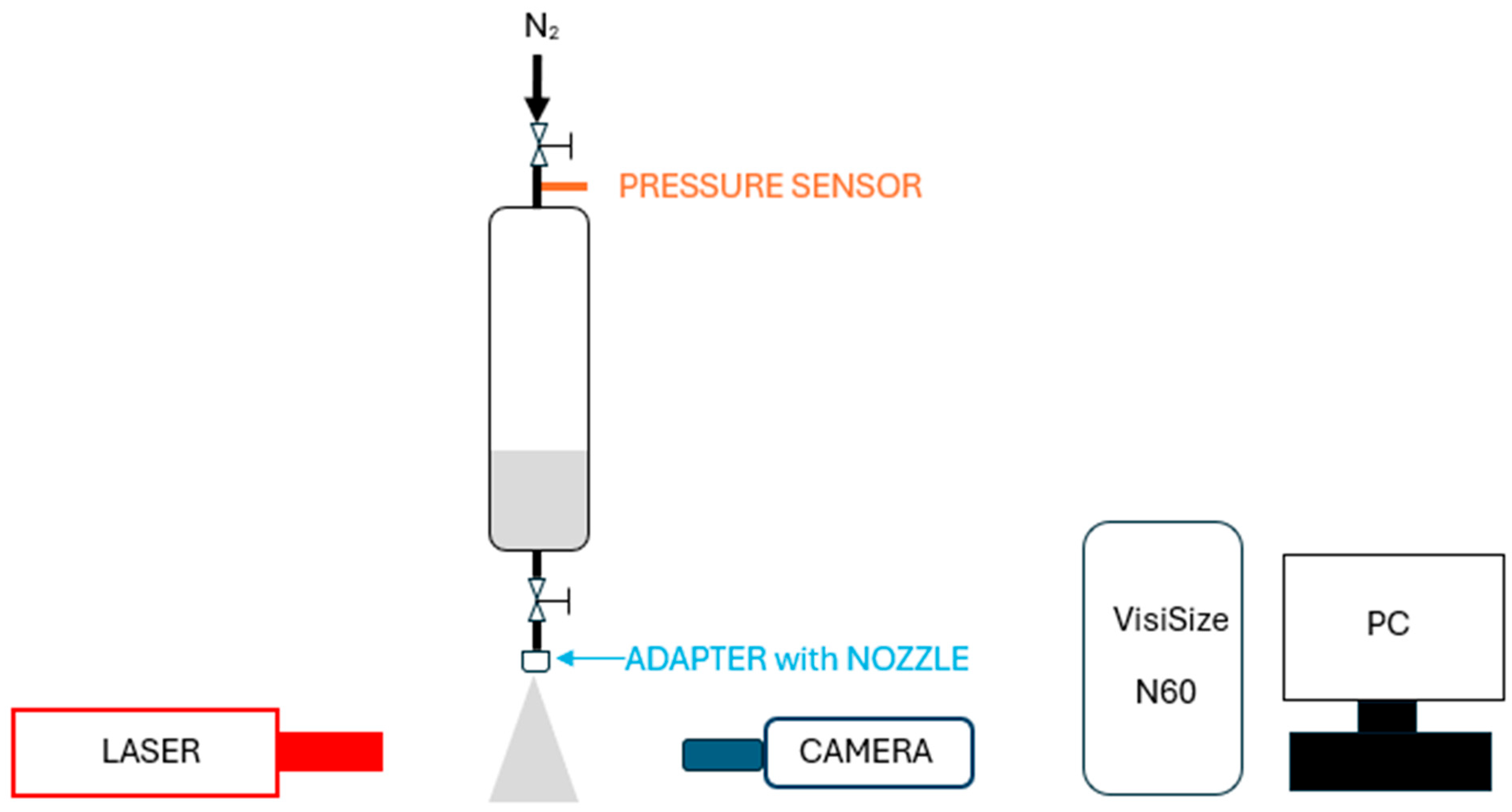

3. Spray Visualisation and Characterisation

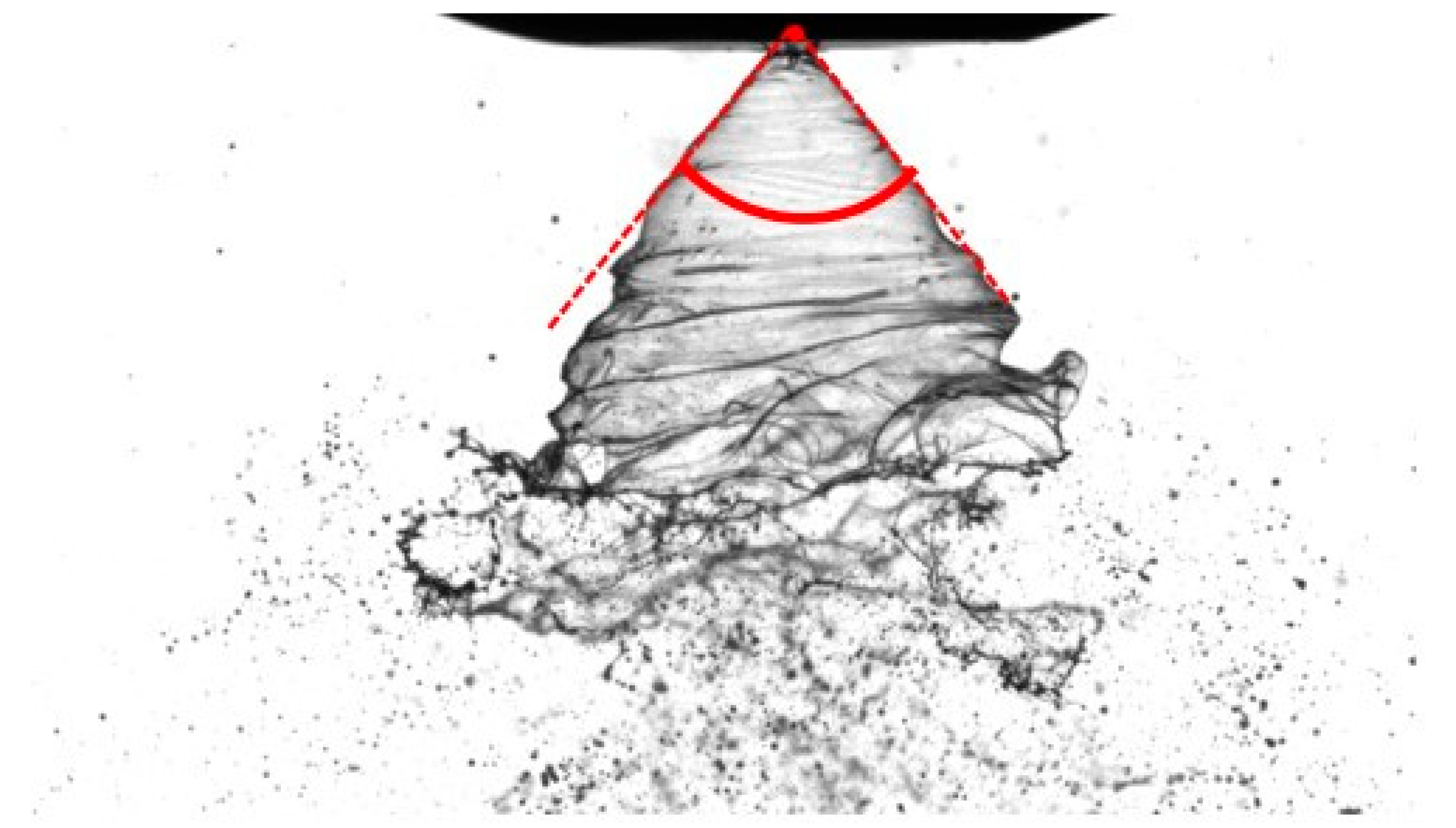

3.1. Spray Angle and Atomisation Intensity

3.2. Experiment Parameters

4. Results and Discussion

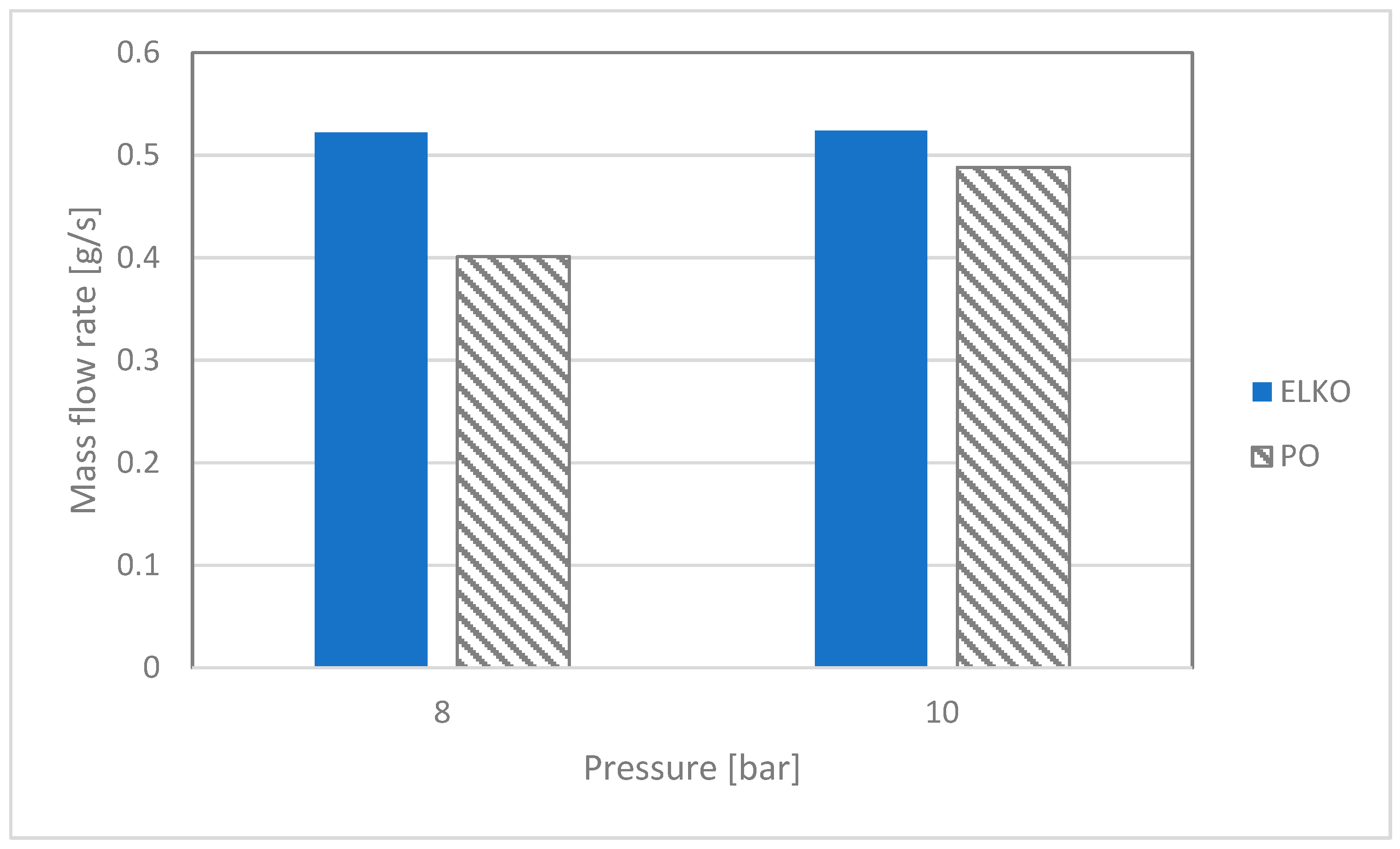

4.1. Mass Flow Rate

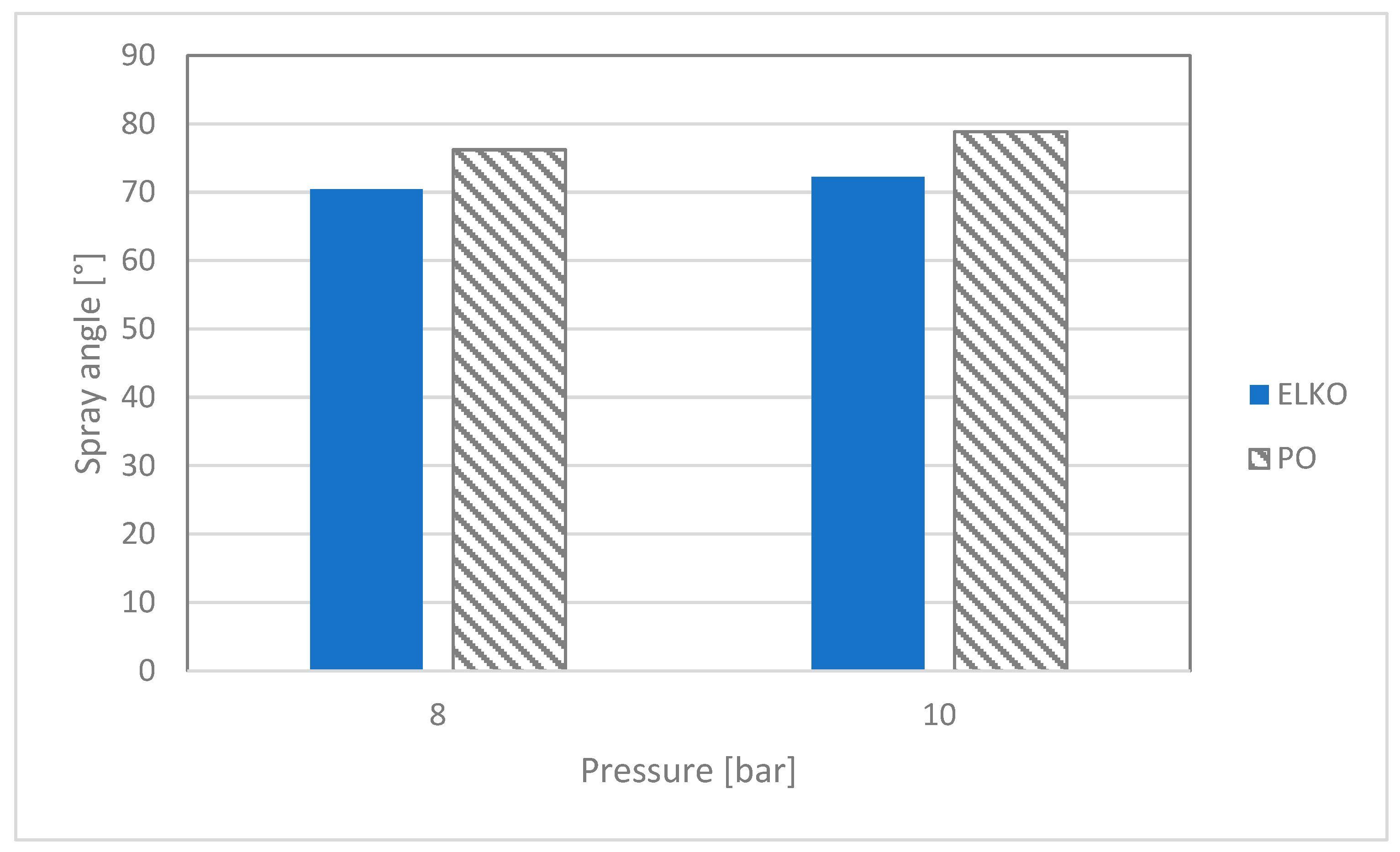

4.2. Spray Angle

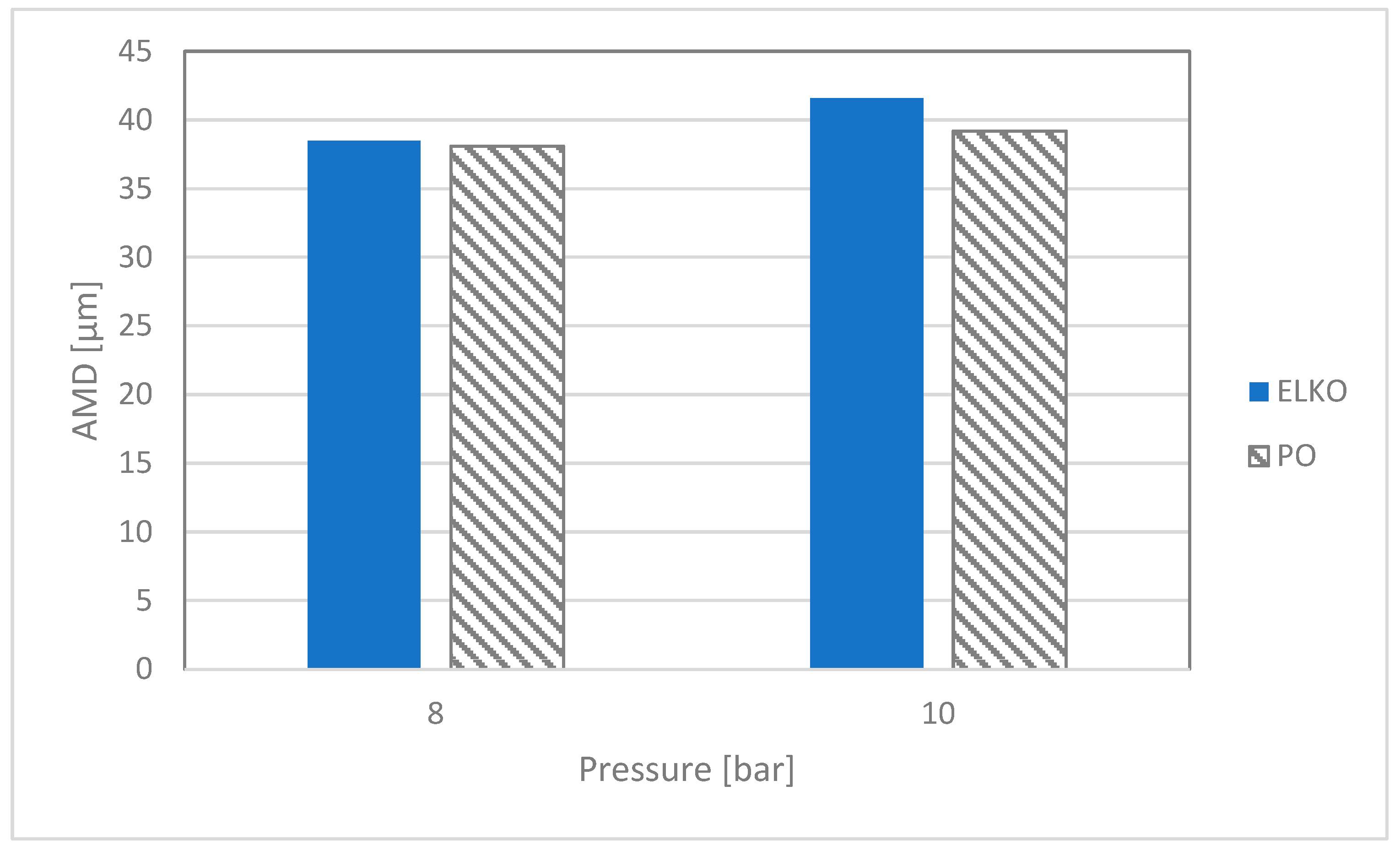

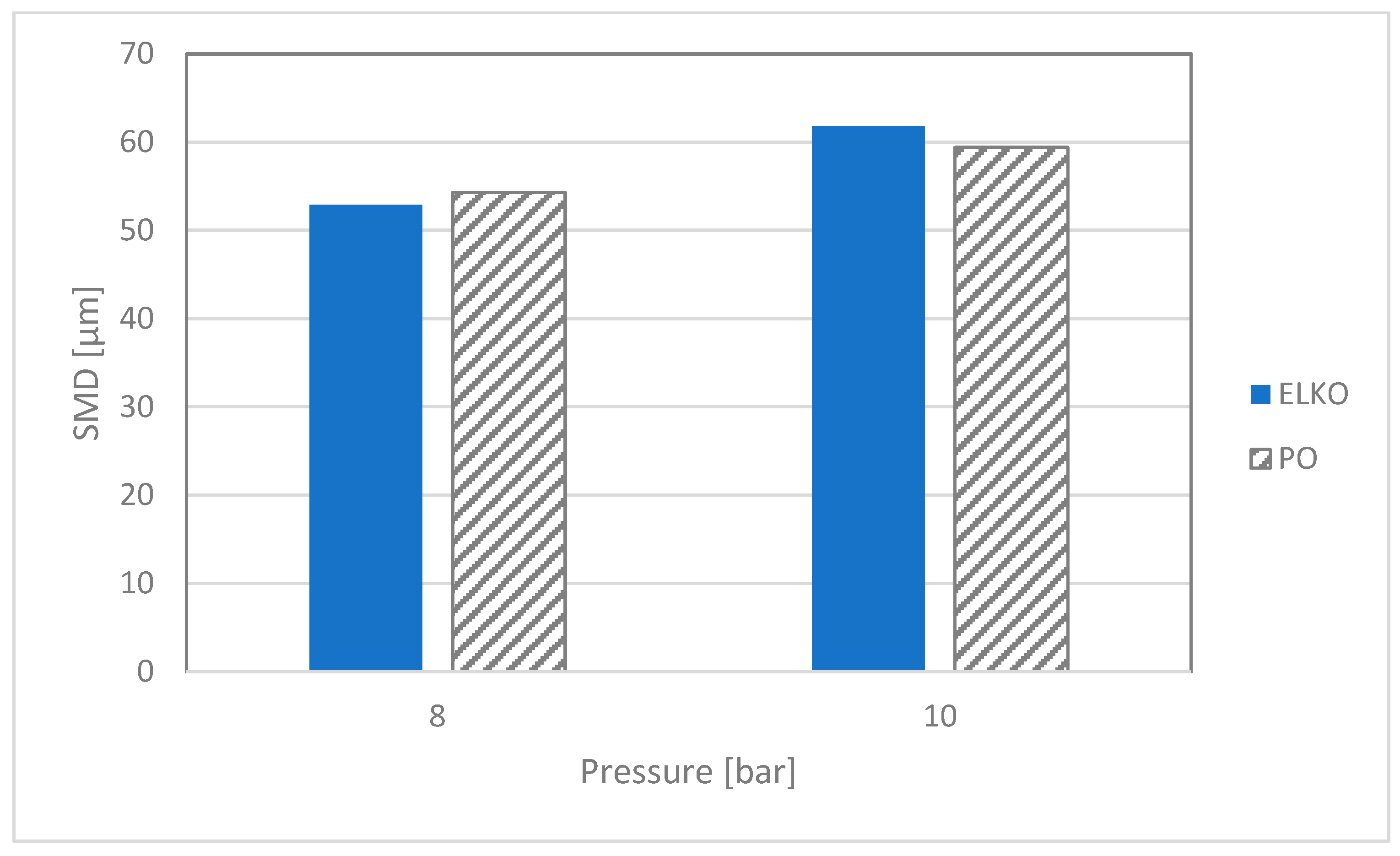

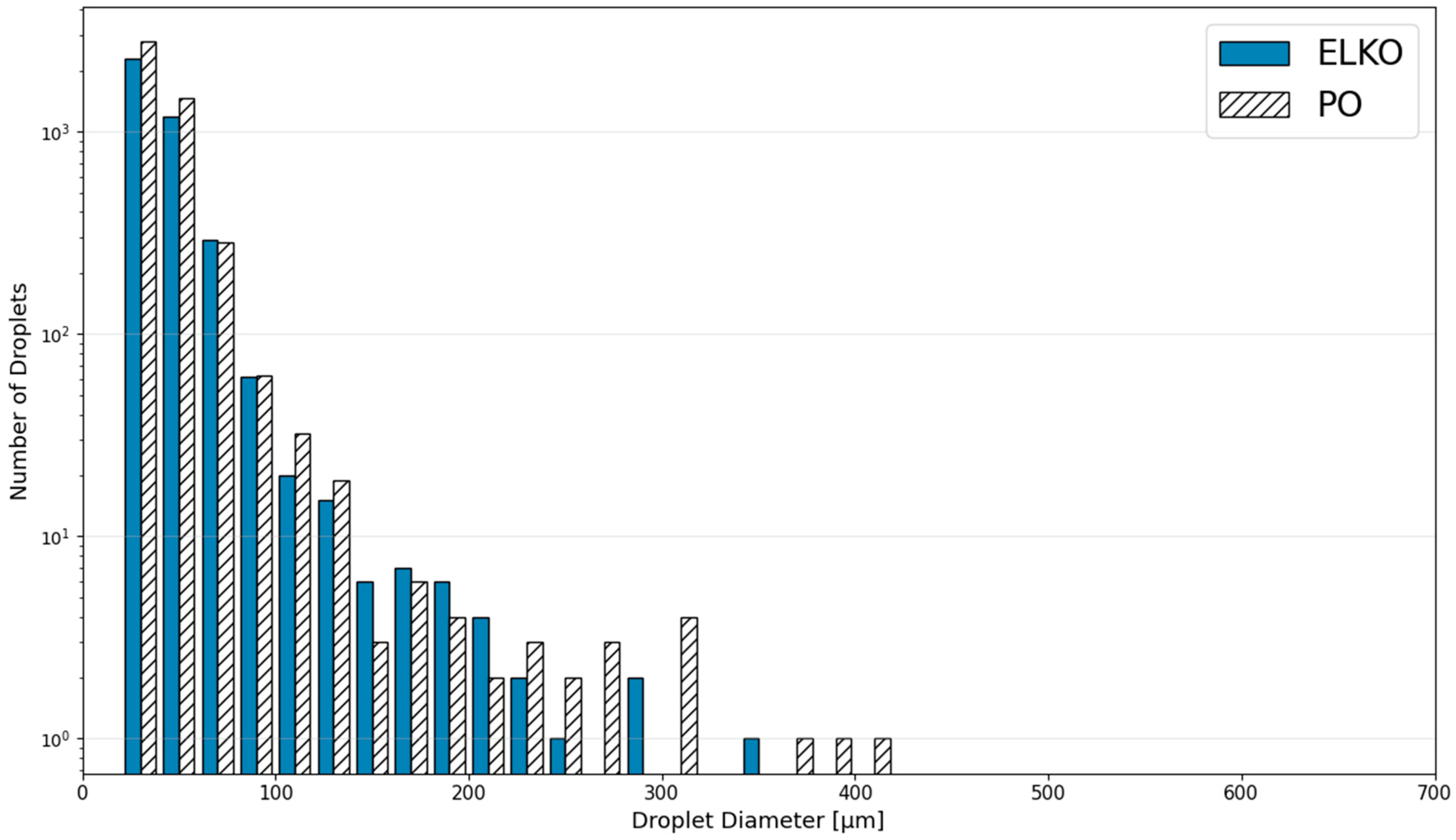

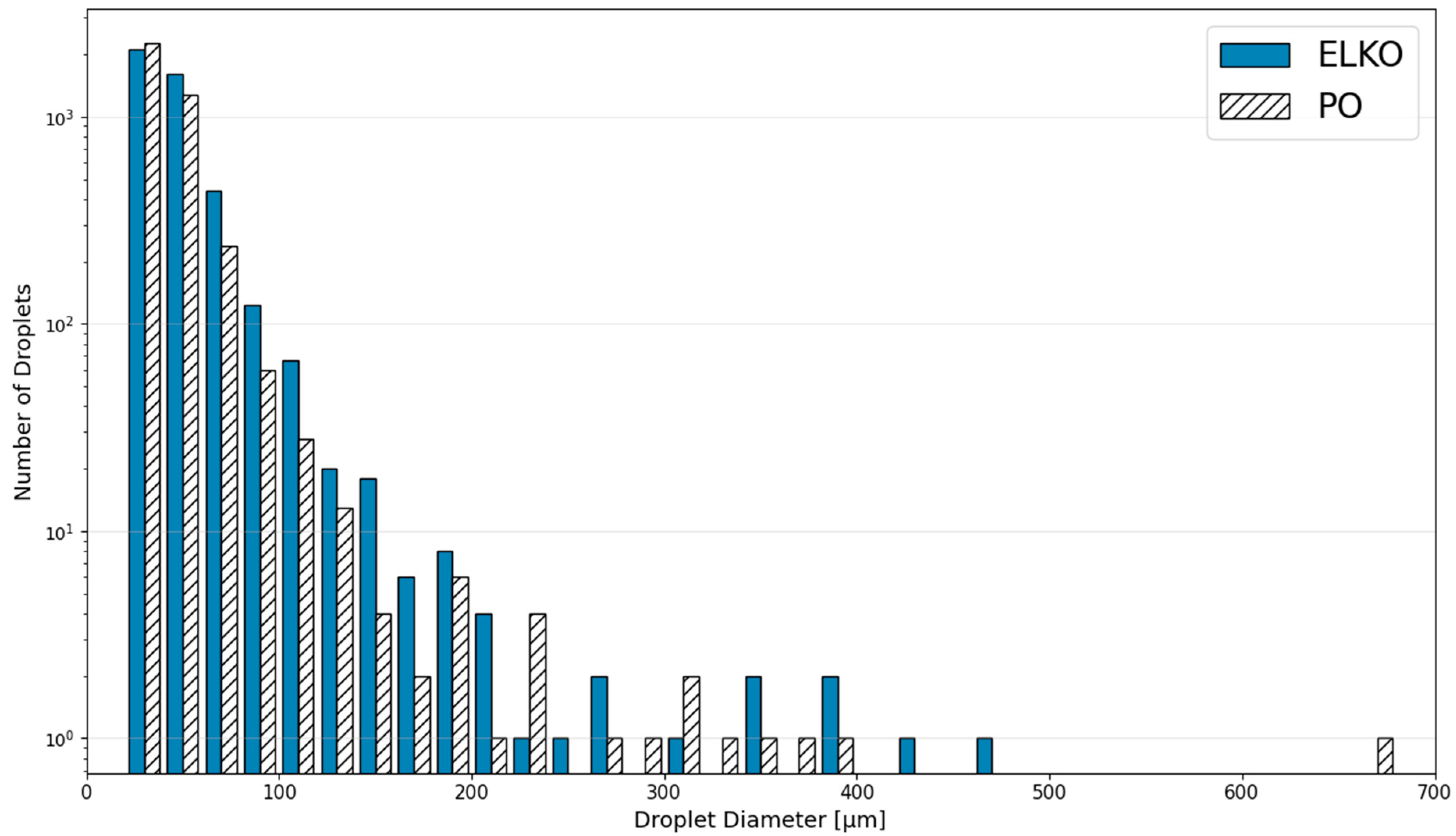

4.3. Droplet Characterisation

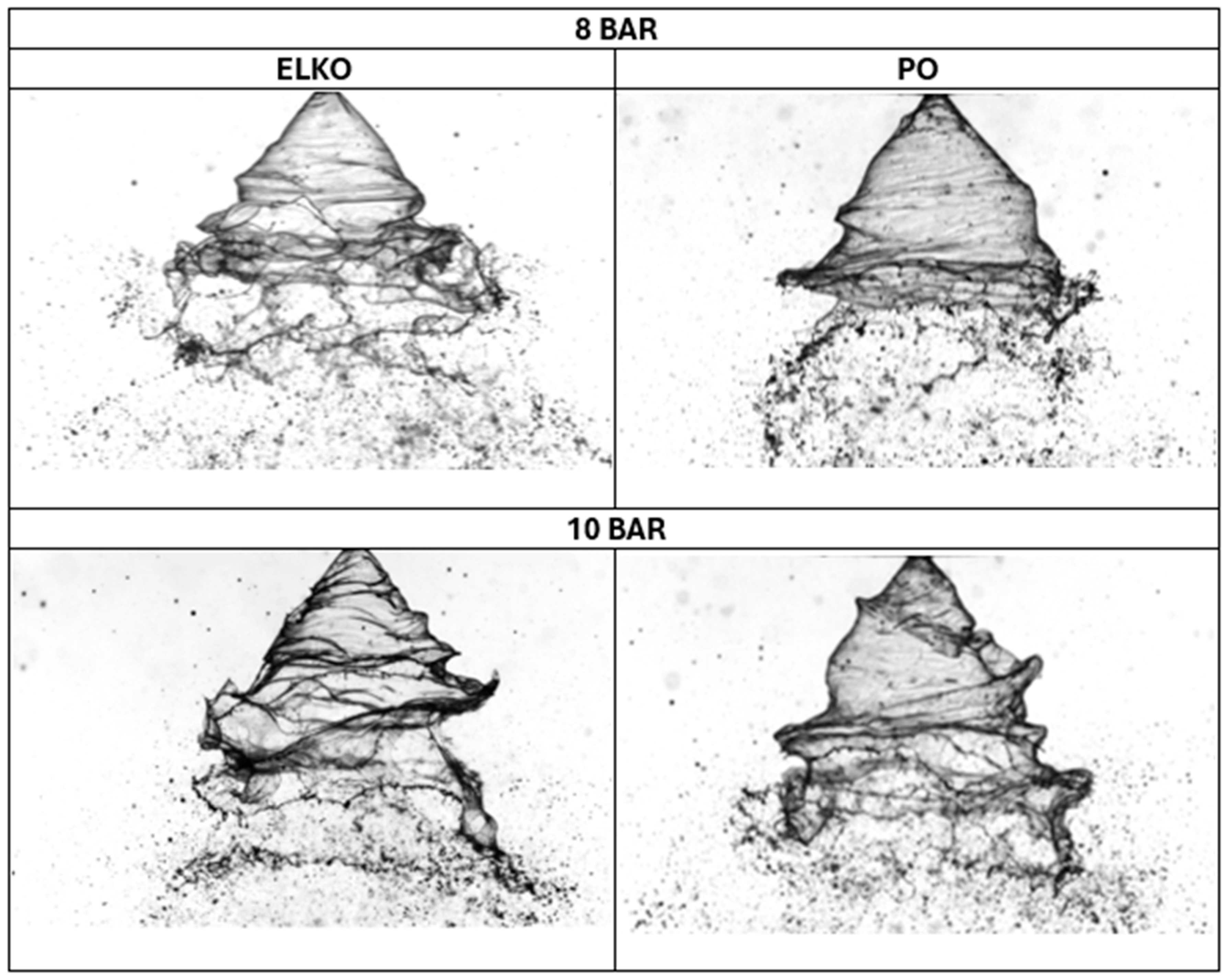

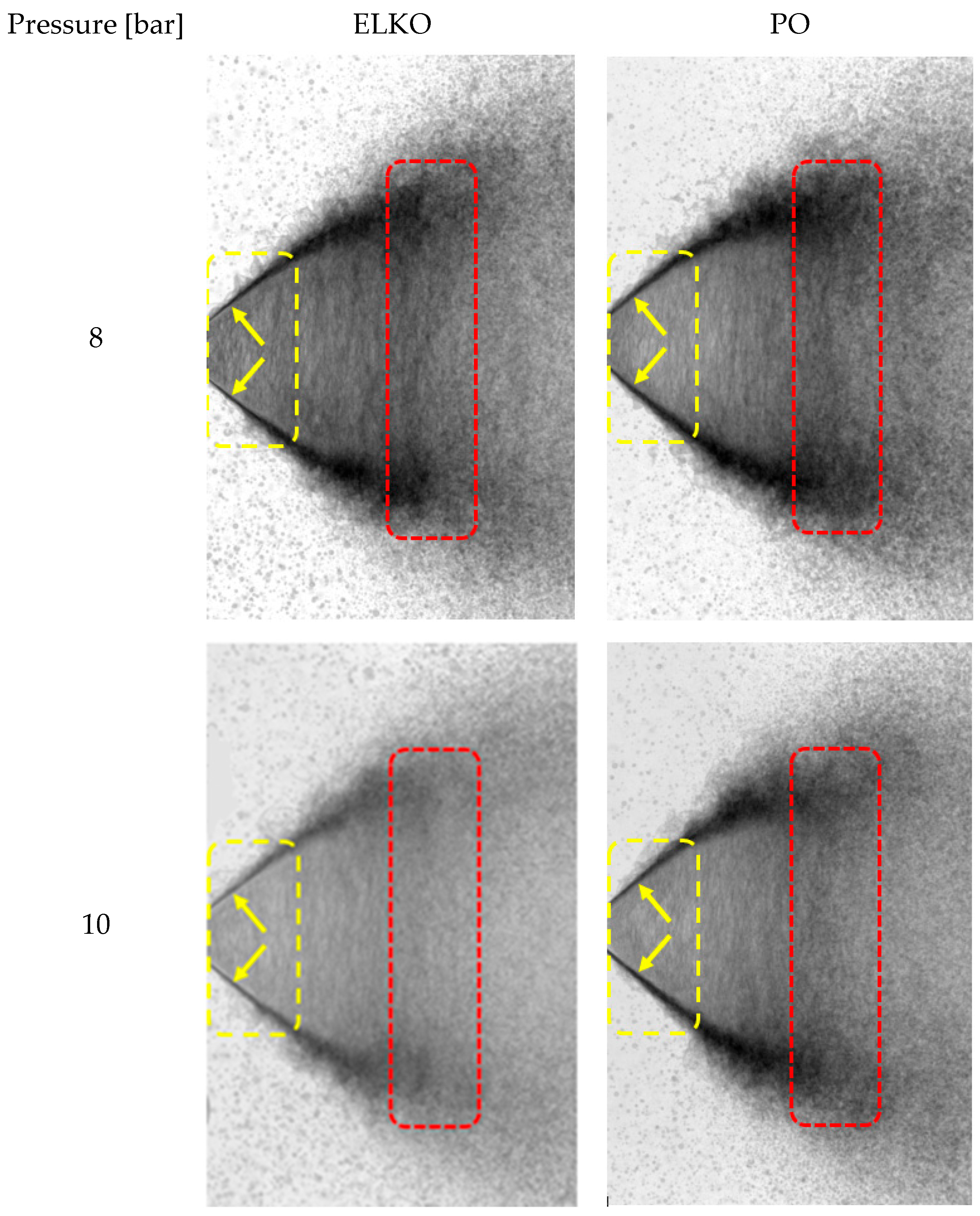

4.4. Spray Breakup

5. Conclusions

- Using the pyrolysis process for the production of synthetic fuels can recover the embedded energy of waste plastic.

- The calorific value of PO was found to be merely 6% lower compared to conventional ELKO oil, which indicates the possible usage of pyrolytic oils in heating applications, but a slight increase in fuel consumption can be expected.

- The obtained pyrolytic oil (PO) has physical properties that are similar to conventional heating oil properties.

- PO has slightly lower density than ELKO, which consequently affects the fuel mass flow rate through the nozzle. In addition to density, the mass flow rate is also influenced by the injection pressure. An increase in mass flow rate through the nozzle also leads to a longer breakup length.

- The viscosity and surface tension of PO are also lower than those of ELKO. Both properties are very important in terms of atomisation as they affect the internal flow conditions within the nozzle, as well as flow conditions at the nozzle inlet. It was found that PO exhibits a larger spray angle due to its lower viscosity, which can be explained by the findings of other researchers showing that lower viscosity leads to reduced viscous dissipation within the swirl chamber, which preserve more of the available pressure and kinetic energy for generating tangential and axial momentum. Moreover, both properties also effect the spray sheet thickness and the rate of sheet breakup.

- Viscosity, surface tension, and injection pressure also influence the arithmetic mean droplet diameter (AMD) and Sauter mean droplet diameter (SMD). At lower pressure, the AMD for ELKO was 1% higher, whereas at higher pressure it was 6% higher. This is attributed to the lower viscosity and surface tension of PO. For SMD, smaller differences were also observed. At lower pressure, a large difference between the mass flow rates of the two oils was detected, indicating that oils operate in different flow regimes. For ELKO, more instabilities were observed on the jet surface, which may suggest that these instabilities contribute to more uniform breakup at lower injection pressure. At higher injection pressure, disturbances on the jet surface were of similar magnitude, so the SMD is slightly lower for PO due to its lower viscosity and surface tension.

- Overall, the droplet diameters of PO were very similar to the droplet diameters of conventional heating oil, which indicates that the combustion process of both oils may be similar regarding fuel evaporation and mixing with air.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Al-Salem, S.M.; Antelava, A.; Constantinou, A.; Manos, G.; Dutta, A. A Review on Thermal and Catalytic Pyrolysis of Plastic Solid Waste (PSW). J. Environ. Manag. 2017, 197, 177–198. [Google Scholar] [CrossRef]

- Cooray, N.; Sena Peires, V.R.; Rasaputra, K. National Action Plan on Plastic Waste Management 2021–2030. 2021. Available online: https://ccet.jp/sites/default/files/2021-08/srilanka_report_web_fin_pw.pdf (accessed on 21 July 2025).

- OECD. Global Plastics Outlook: Policy Scenarios to 2060; OECD: Paris, France, 2022. [Google Scholar] [CrossRef]

- Plastic Europe Trade Association. Plastic—The Fast Facts 2024. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-fast-facts-2024/ (accessed on 21 July 2025).

- Moore, C. Plastic Pollution in Oceans and on Land. Britannica, 18 November 2025. Available online: https://www.britannica.com/science/plastic-pollution/Plastic-pollution-in-oceans-and-on-land (accessed on 24 July 2025).

- Waste Direct. Plastic Waste Statistics and Trends. Available online: https://wastedirect.co.uk/blog/plastic-waste-statistics/ (accessed on 24 July 2025).

- Yu, J.; Sun, L.; Ma, C.; Qiao, Y.; Yao, H. Thermal Degradation of PVC: A Review. Waste Manag. 2016, 48, 300–314. [Google Scholar] [CrossRef]

- Walker, T.R. Policies to Mitigate Climate Change by Addressing Single-Use Plastic Production and Waste Disposal. Available online: https://papers.ssrn.com/sol3/papers.cfm?abstract_id=3857828 (accessed on 19 November 2025).

- Gervet, B. The Use of Crude Oil in Plastic Making Contributes to Global Warming. 2007. Available online: https://www.researchgate.net/publication/266469821_THE_USE_OF_CRUDE_OIL_IN_PLASTIC_MAKING_CONTRIBUTES_TO_GLOBAL_WARMING (accessed on 24 July 2025).

- Engelbeen, F. Plastic—Environmental Aspect. Available online: https://wgbis.ces.iisc.ac.in/envis/plasdoc612.html (accessed on 24 July 2025).

- Marczak, H. Energy Inputs on the Production of Plastic Products. J. Ecol. Eng. 2022, 23, 146–156. [Google Scholar] [CrossRef] [PubMed]

- Zappitelli, J.; Smith, E.; Padgett, K.; Bilec, M.M.; Babbitt, C.W.; Khanna, V. Quantifying Energy and Greenhouse Gas Emissions Embodied in Global Primary Plastic Trade Network. ACS Sustain. Chem. Eng. 2021, 9, 14927–14936. [Google Scholar] [CrossRef]

- Chen, D.; Yin, L.; Wang, H.; He, P. Pyrolysis Technologies for Municipal Solid Waste: A Review. Waste Manag. 2014, 34, 2466–2486. [Google Scholar] [CrossRef] [PubMed]

- Nanda, S.; Berruti, F. Thermochemical Conversion of Plastic Waste to Fuels: A Review. Environ. Chem. Lett. 2020, 19, 123–148. [Google Scholar] [CrossRef]

- Panda, A.K.; Singh, R.K.; Mishra, D.K. Thermolysis of Waste Plastics to Liquid Fuel. A Suitable Method for Plastic Waste Management and Manufacture of Value Added Products-A World Prospective. Renew. Sustain. Energy Rev. 2010, 14, 233–248. [Google Scholar] [CrossRef]

- Khan, S.; Alzahrani, F.M. Gasoline Fuel Spray Dynamics in Direct Injection Systems: A Computational Study Using VOF-DPM Transition Model with AMR. Available online: https://www.researchgate.net/publication/381280900 (accessed on 19 November 2025).

- Kumar, V.; Kumar Nallamothu, S.; Patil, A.; Nakod, P. Spray Characteristics of Elliptical Diesel Nozzles Using Hybrid VOF-to-DPM Transitional Approach in Large Eddy Simulation (LES) Framework. In Proceedings of the International Conference on Liquid Atomization and Spray Systems (ICLASS), Edinburgh, Scotland, 29 August–2 September 2021. [Google Scholar]

- Shi, P.; Zhu, G.; Cheng, J.; Li, J.; Hou, X. Simulation on Atomization Process of Gas–Liquid Pintle Injector in LRE under Periodic Conditions Based on the VOF to DPM Method. Aerosp. Sci. Technol. 2023, 136, 108222. [Google Scholar] [CrossRef]

- Arun Kumar, B.; Kumar, V.; Nakod, P.; Rajan, A.; Schütze, J. Multiscale Modelling of a Doublet Injector Using Hybrid VOF-DPM Method. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; American Institute of Aeronautics and Astronautics Inc. (AIAA): Reston, VA, USA, 2020; Volume 1. Part F. [Google Scholar] [CrossRef]

- Khan, M.Z.H.; Sultana, M.; Al-Mamun, M.R.; Hasan, M.R. Pyrolytic Waste Plastic Oil and Its Diesel Blend: Fuel Characterization. J. Environ. Public Health 2016, 2016, 7869080. [Google Scholar] [CrossRef]

- Jahirul, M.I.; Faisal, F.; Rasul, M.G.; Schaller, D.; Khan, M.M.K.; Dexter, R.B. Automobile Fuels (Diesel and Petrol) from Plastic Pyrolysis Oil—Production and Characterisation. Energy Rep. 2022, 8, 730–735. [Google Scholar] [CrossRef]

- Palomar-Torres, A.; Lesnik, L.; Torres-Jiménez, E.; Bombek, G. Fast Pyrolysis Oil from Plastics Waste as a Fuel for Gas Turbine Power Plants. Renew. Energy Power Qual. J. 2022, 20, 444–448. [Google Scholar] [CrossRef]

- Kumar, S.; Prakash, R.; Murugan, S.; Singh, R.K. Performance and Emission Analysis of Blends of Waste Plastic Oil Obtained by Catalytic Pyrolysis of Waste HDPE with Diesel in a CI Engine. Energy Convers. Manag. 2013, 74, 323–331. [Google Scholar] [CrossRef]

- Güngör, C.; Serin, H.; Özcanl, M.; Serin, S.; Aydin, K. Engine Performance and Emission Characteristics of Plastic Oil Produced from Waste Polyethylene and Its Blends with Diesel Fuel. Int. J. Green Energy 2014, 12, 98–105. [Google Scholar] [CrossRef]

- Nicolae, F.; Molea, A.; Popescu, V. The Effect of Using Pyrolysis Oils from Polyethylene and Diesel on the Pollutant Emissions from a Single Cylinder Diesel Engine. Available online: https://www.researchgate.net/publication/292373913 (accessed on 19 November 2025).

- Kalargaris, I.; Tian, G.; Gu, S. Experimental Characterisation of a Diesel Engine Running on Polypropylene Oils Produced at Different Pyrolysis Temperatures. Fuel 2018, 211, 797–803. [Google Scholar] [CrossRef]

- Venkatesan, H.; Sivamani, S.; Bhutoria, K.; Vora, H.H. Assessment of Waste Plastic Oil Blends on Performance, Combustion and Emission Parameters in Direct Injection Compression Ignition Engine. Int. J. Ambient Energy 2019, 40, 170–178. [Google Scholar] [CrossRef]

- Dobó, Z.; Jakab, Z.; Nagy, G.; Koós, T.; Szemmelveisz, K.; Muránszky, G. Transportation Fuel from Plastic Wastes: Production, Purification and SI Engine Tests. Energy 2019, 189, 116353. [Google Scholar] [CrossRef]

- Jihad, M.; Riayatsyah, T.M.; Bahri, S.; Sofyan, S.E. The Effect of Gasoline-Waste Plastics Oil Blends on SI Engine Performance at High-Speed Rotation. In IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: Bristol, UK, 2020; Volume 463. [Google Scholar] [CrossRef]

- Suchocki, T. Sustainable Energy Application of Pyrolytic Oils from Plastic Waste in Gas Turbine Engines: Performance, Environmental, and Economic Analysis. Sustainability 2024, 16, 8566. [Google Scholar] [CrossRef]

- Suchocki, T.; Kazimierski, P.; Januszewicz, K.; Lampart, P.; Gawron, B.; Białecki, T. Exploring Performance of Pyrolysis-Derived Plastic Oils in Gas Turbine Engines. Energies 2024, 17, 3903. [Google Scholar] [CrossRef]

- Suchocki, T.K.; Kazimierski, P.; Januszewicz, K.; Lampart, P.; Zaniewski, D.; Klimaszewski, P.; Witanowski, Ł. Pyrolysis-Derived Waste Polypropylene Oils in Gas Turbine Engines: A Comprehensive Performance and Emission Study. Arch. Thermodyn. 2023, 44, 157–183. [Google Scholar] [CrossRef]

- Wang, S.; Rodriguez Alejandro, D.A.; Kim, H.; Kim, J.Y.; Lee, Y.R.; Nabgan, W.; Hwang, B.W.; Lee, D.; Nam, H.; Ryu, H.J. Experimental Investigation of Plastic Waste Pyrolysis Fuel and Diesel Blends Combustion and Its Flue Gas Emission Analysis in a 5 KW Heater. Energy 2022, 247, 123408. [Google Scholar] [CrossRef]

- Szwaja, M.; Naber, J.D.; Shonnard, D.; Kulas, D.; Zolghadr, A.; Szwaja, S. Comparative Analysis of Injection of Pyrolysis Oil from Plastics and Gasoline into the Engine Cylinder and Atomization by a Direct High-Pressure Injector. Energies 2023, 16, 420. [Google Scholar] [CrossRef]

- Malode, A.; Tamilarasan, N.; Balaji, K.; Sakthivel, R. High Speed Flow Visualization of Primary Breakup Phenomenon of Pyrolysis Oil-Diesel Blend Using Air-Assisted Atomizer. J. Environ. Nanotechnol. 2024, 13, 484–501. [Google Scholar] [CrossRef]

- SIST 1011:2023; Liquid Petroleum Products—Gas Oil for Heating and Agricultural Machinery—Requirements and Test Methods. Slovenski inštitut za standardizacijo: Ljubljana, Slovenia, 2023.

- SIST ISO 5725-1:2024; Accuracy (Trueness and Precision) of Measurement Methods and Results—Part 1: General Principles and Definitions. Slovenski inštitut za standardizacijo: Ljubljana, Slovenia, 2024.

- Rizk, N.K. Internal Flow Characteristics of Simplex Swirl Atomizers. J. Propuls. Power 1985, 1, 193–199. [Google Scholar] [CrossRef]

- Presser, C. Effect of Fluid Viscosity and Surface Tension on Liquid Sheet Disintegration of a Simplex Pressure-Swirl Atomizer. 1998. Available online: https://www.researchgate.net/publication/280945112 (accessed on 19 November 2025).

- Dafsari, R.A.; Lee, H.J.; Han, J.; Park, D.C.; Lee, J. Viscosity Effect on the Pressure Swirl Atomization of an Alternative Aviation Fuel. Fuel 2019, 240, 179–191. [Google Scholar] [CrossRef]

- Bremond, N.; Clanet, C.; Villermaux, E. Atomization of Undulating Liquid Sheets. J. Fluid Mech. 2007, 585, 421–456. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; Suyari, M. Film Thickness Measurements in a Simplex Swirl Atomizer. J. Propuls. Power 1986, 2, 528–533. [Google Scholar] [CrossRef]

- Chung, I.P.; Presser, C.; Chung, I.P.; Presser, C. Fluid Property Effects on Sheet Disintegration of a Simplex Pressure-Swirl Atomizer. J. Propuls. Power 2001, 17, 212–216. [Google Scholar] [CrossRef]

- Lefebvre, A.H.; McDonell, V.G. Atomization and Sprays, 2nd ed.; CRC Press: Boca Raton, FL, USA; Taylor and Francis Group: Abingdon, UK, 2017. [Google Scholar]

- Oxford Lasers Imaging Division: VisiSize Software Operation Manual VisiSize 6. Oxford Lasers Ltd.: Oxon, UK, 2013.

- Kashdan, J.T.; Shrimpton, J.S.; Whybrew, A. Two-Phase Flow Characterization by Automated Digital Image Analysis. Part 1: Fundamental Principles and Calibration of the Technique. Part. Part. Syst. Charact. 2003, 20, 387–397. [Google Scholar] [CrossRef]

- Kashdan, J.T.; Shrimpton, J.S.; Whybrew, A. Two-Phase Flow Characterization by Automated Digital Image Analysis. Part 2: Application of PDIA for Sizing Sprays. Part. Part. Syst. Charact. 2004, 21, 15–23. [Google Scholar] [CrossRef]

- Kashdan, J.T.; Shrimpton, J.S.; Whybrew, A. A Digital Image Analysis Technique for Quantitative Characterisation of High-Speed Sprays. Opt. Lasers Eng. 2007, 45, 106–115. [Google Scholar] [CrossRef]

- Garai, A.; Gangopadhyay, T.; Mukhopadhyay, A.; Sen, S. Spray Characterisation of Diesel Using a Hybrid Atomizer. Sādhanā 2023, 48, 150. [Google Scholar] [CrossRef]

- Feng, Z.; Tang, C.; Yin, Y.; Zhang, P.; Huang, Z. Time-Resolved Droplet Size and Velocity Distributions in a Dilute Region of a High-Pressure Pulsed Diesel Spray. Int. J. Heat Mass Transf. 2019, 133, 745–755. [Google Scholar] [CrossRef]

- Jiang, Y.; Jeon, H.Y.; Tian, L.; Bode, L.E. Measuring Particle Size Distribution Using LED-Illumination. Int. J. Multiph. Flow 2010, 36, 193–201. [Google Scholar] [CrossRef]

- EN 293:1992; Oil Pressure Atomizing Nozzles—Minimum Requirements—Testing. Slovenski Inštitut za Standardizacijo: Ljubljana, Slovenia, 1992.

- EN 299:2009; Oil Pressure Atomizing Nozzles—Determination of the Angle and Spray Characteristics. Slovenski Inštitut za Standardizacijo: Ljubljana, Slovenia, 2009.

- Laurila, E.; Roenby, J.; Maakala, V.; Peltonen, P.; Kahila, H.; Vuorinen, V. Analysis of viscous fluid flow in a pressure-swirl atomizer using large-eddy simulation. Int. J. Multiph. Flow 2019, 113, 371–388. [Google Scholar] [CrossRef]

- Chen, S.K.; Lefebvre, A.H.; Rollbuhler, J. Factors Influencing the Effective Spray Cone Angle of Pressure-Swirl Atomizers. 1992. Available online: http://ui.adsabs.harvard.edu/abs/1992ATJEG.114...97C/abstract (accessed on 19 November 2025).

- Rizk, N.K.; Lefebvre, A.H. Prediction of Velocity Coefficient and Spray Cone Angle for Simplex Swirl Atomizers. Int. J. Turbo Jet Engines 1987, 4, 65–74. [Google Scholar] [CrossRef]

- Ghaffar, Z.A.; Kasolang, S.; Hamid, A.H.A.; Rashid, M.S.F.M. Effect of Dimensionless Numbers on Air Core Diameter of Pressure Swirl Atomizer. Appl. Mech. Mater. 2019, 899, 22–28. [Google Scholar] [CrossRef]

- Wang, X.F.; Lefebvre, A.H. Mean Drop Sizes from Pressure-Swirl Nozzles. J. Propuls. Power 1987, 3, 11–18. [Google Scholar] [CrossRef]

- Jasuja, A.K.; Lefebvre, A.H. Influence of Ambient Air Pressure on Pressure-Swirl Atomizer Spray Characteristics. 2001. Available online: http://www.researchgate.net/publication/267483260_Influence_of_Ambient_Air_Pressure_on_Pressure-Swirl_Atomizer_Spray_Characteristics (accessed on 19 November 2025).

- Jasuja, A.K. Atomization of Crude and Residual Fuel Oils. 1979. Available online: https://asmedigitalcollection.asme.org/gasturbinespower/article-abstract/101/2/250/402872/Atomization-of-Crude-and-Residual-Fuel-Oils?redirectedFrom=fulltext (accessed on 19 November 2025).

| Product | |

|---|---|

| Oil [%] | 76.0 |

| Solid residue [%] | 12.6 |

| Gas [%] | 11.4 |

| ELKO | 27.66 mN/m |

| PO | 24.78 mN/m |

| ELKO | 48.088 MJ/kg |

| PO | 45.359 MJ/kg |

| ELKO | PO |

|---|---|

| Wavenumber [1/cm] | |

| 2922.8 | 2922.6 |

| 2854.1 | 2853.5 |

| 1459.4 | 1641.9 |

| 1377.3 | 1464.9 |

| 1377.8 | |

| 991.77 | |

| 909.24 | |

| ELKO | PO | |

|---|---|---|

| C [%w/w] | 86.1 | 79.7 |

| H [%w/w] | 13.8 | 13.5 |

| N [%w/w] | 0 | 0.2 |

| O2 [%w/w] | 0 | 6.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jernejc, T.; Bombek, G.; Biluš, I.; Kevorkijan, L.; Lešnik, L. An Experimental Analysis of the Influence of Pyrolytic Oil on the Spray Breakup Process. Clean Technol. 2025, 7, 108. https://doi.org/10.3390/cleantechnol7040108

Jernejc T, Bombek G, Biluš I, Kevorkijan L, Lešnik L. An Experimental Analysis of the Influence of Pyrolytic Oil on the Spray Breakup Process. Clean Technologies. 2025; 7(4):108. https://doi.org/10.3390/cleantechnol7040108

Chicago/Turabian StyleJernejc, Tilen, Gorazd Bombek, Ignacijo Biluš, Luka Kevorkijan, and Luka Lešnik. 2025. "An Experimental Analysis of the Influence of Pyrolytic Oil on the Spray Breakup Process" Clean Technologies 7, no. 4: 108. https://doi.org/10.3390/cleantechnol7040108

APA StyleJernejc, T., Bombek, G., Biluš, I., Kevorkijan, L., & Lešnik, L. (2025). An Experimental Analysis of the Influence of Pyrolytic Oil on the Spray Breakup Process. Clean Technologies, 7(4), 108. https://doi.org/10.3390/cleantechnol7040108