Real-Time Sensor-Controlled Coagulant Dosing and Pressure in a Novel Sludge Dewatering System

Abstract

1. Introduction

2. Materials and Methods

2.1. Sludge Characteristics and Conditioning Agents

2.2. Sensor-Integrated Filter Press System

- Total Solids (TS) Sensor (Valmet, Espoo, Finland): An inline microwave absorption sensor, calibrated via gravimetric methods, was used to measure feed sludge solids content in real time prior to each run.

- Viscosity Assessment (Brookfield, Middleboro, MA, USA): Offline viscosity measurements were conducted on ~100 mL sludge samples using a rotational viscometer (20 °C, shear rate 100 s−1). The results were used to categorize sludge as low, medium, or high viscosity in the control logic.

- Temperature Sensor (Hanna Instruments, Woonsocket, RI, USA): A Pt-100 resistance thermometer measured sludge temperature, ensuring the reading reflected the sludge itself. The sensor was immersed in the sludge to record the actual sludge temperature. Cold sludge conditions were simulated via pre-cooling.

- pH Sensor (Endress+Hauser, Greenwood, IN, USA): A glass electrode pH probe installed in the mixing tank provided continuous monitoring during coagulant dosing. The resulting pH change (ΔpH) was used to evaluate charge neutralization effectiveness.

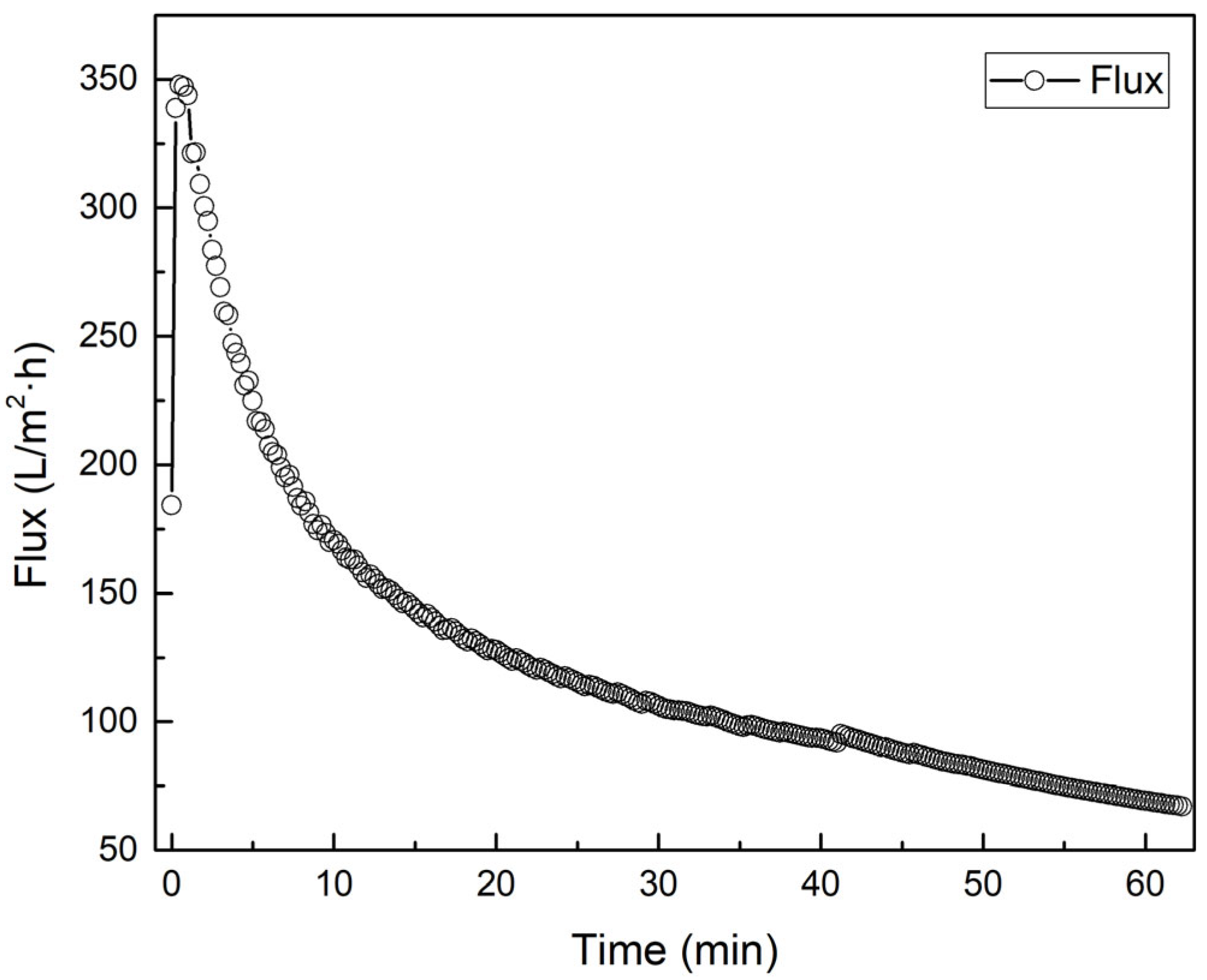

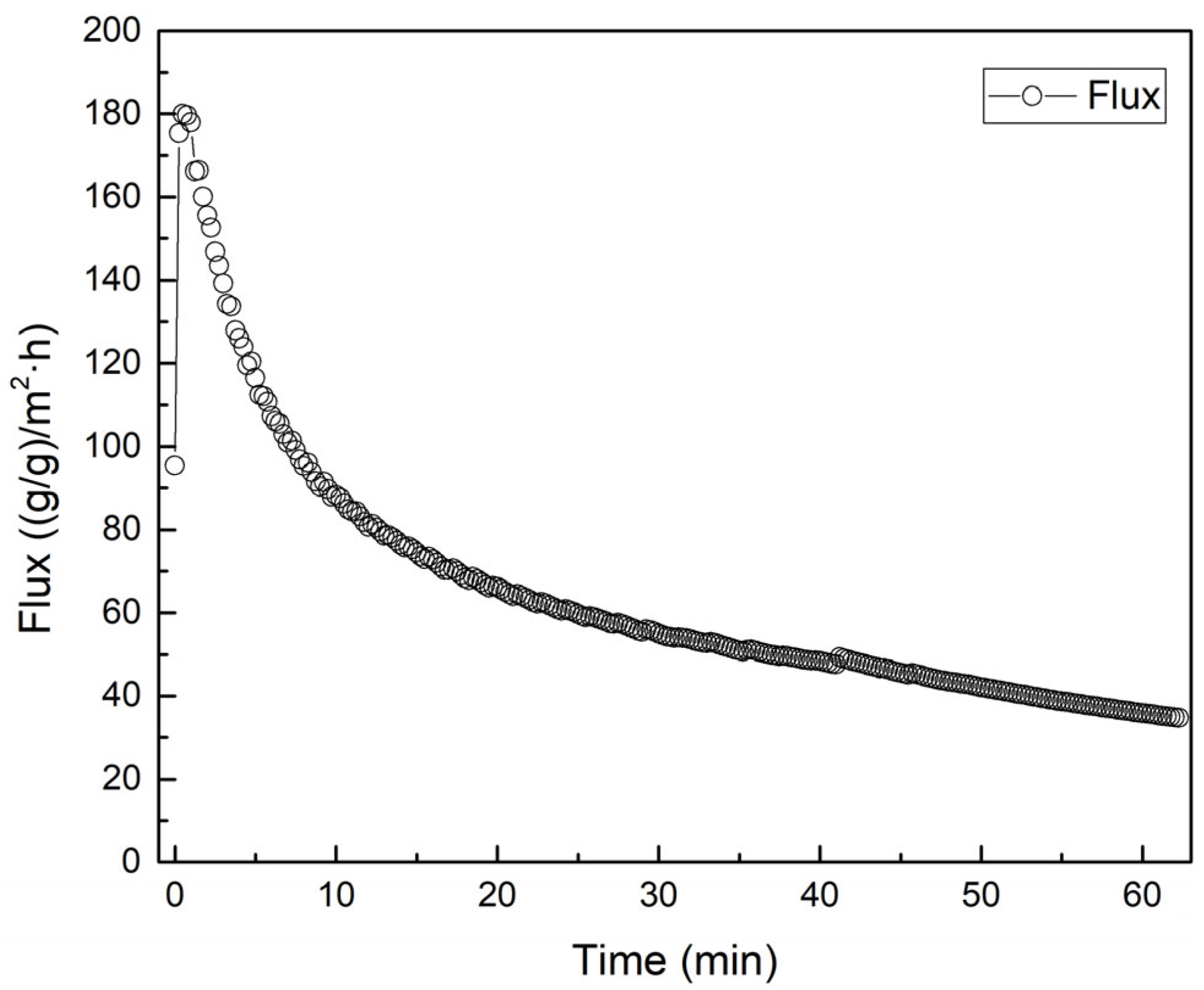

- Filtrate Mass Sensor (Flow Monitoring) (Mettler Toledo, Greifensee, Switzerland): An electronic balance placed below the press outlet recorded filtrate mass continuously. These data were used to calculate instantaneous filtration flux (L/m2·h), serving as a decision variable for pressure modulation.

- Pressure Sensor (WIKA, Klingenberg am Main, Germany): Hydraulic pressure was monitored using a transducer to verify target pressures and ensure operational safety.

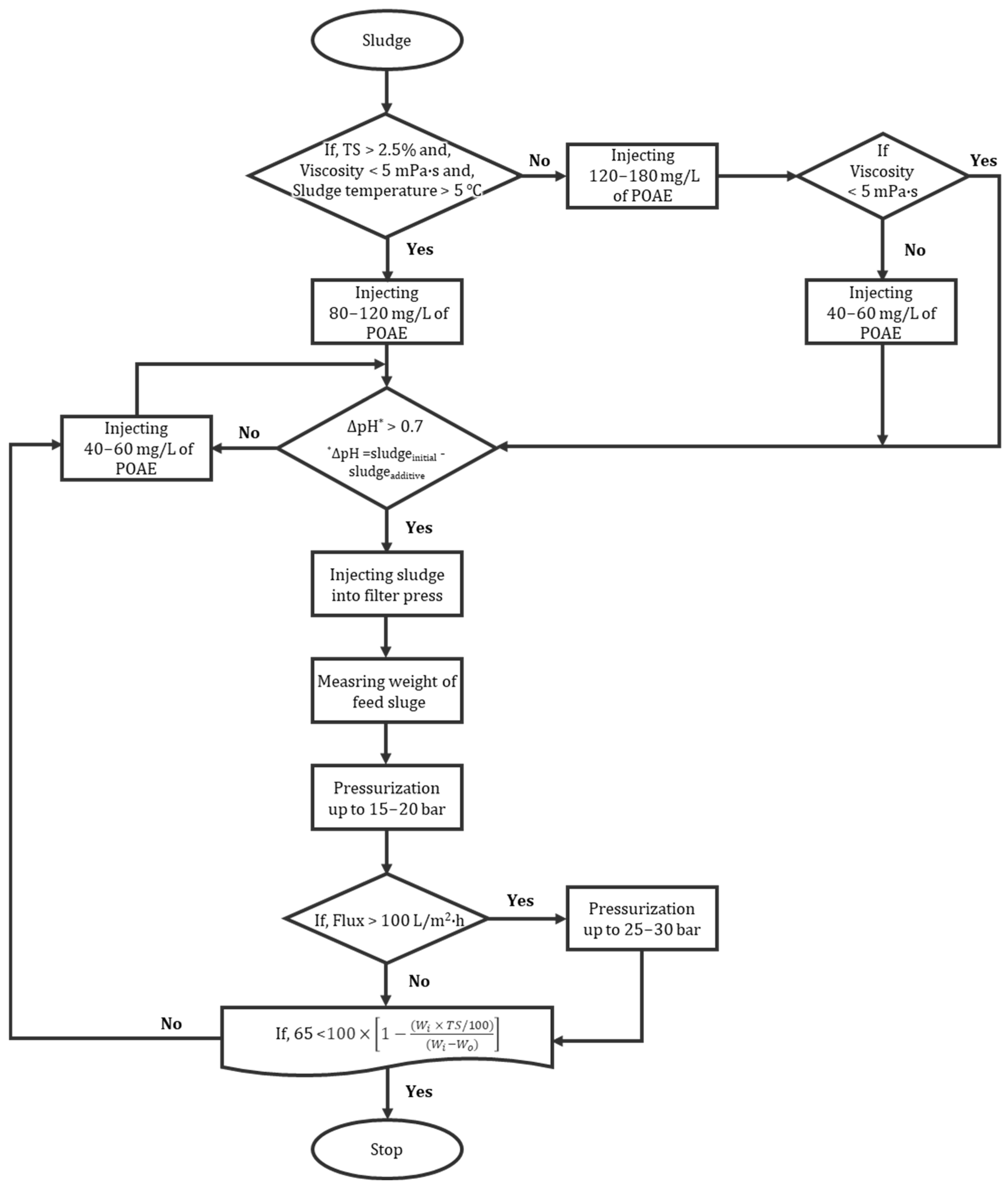

2.3. Control Algorithm for Real-Time Dosing and Pressure Adjustment

2.3.1. Initial Sludge Assessment

- Low-viscosity sludge (viscosity < 5 mPa·s), typically associated with low solids and high water content, receives an initial reduced POAE dose of 40–60 mg/L. The rationale is to prevent overdosing while sufficiently destabilizing fewer suspended solids.

- High-viscosity sludge (viscosity ≥ 5 mPa·s), often characterized by higher solids or increased colloidal content, initially receives a higher POAE dose (120–180 mg/L) to ensure effective flocculation.

2.3.2. Polymer Injection and Mixing

2.3.3. Filtration Initiation

2.3.4. Flux Monitoring and Pressure Adjustment

2.3.5. Cake Moisture Calculation and Termination

2.4. Experimental Procedure

3. Results and Discussion

3.1. Influence of Sludge Properties on Dewaterability

3.1.1. Total Solids (TS)

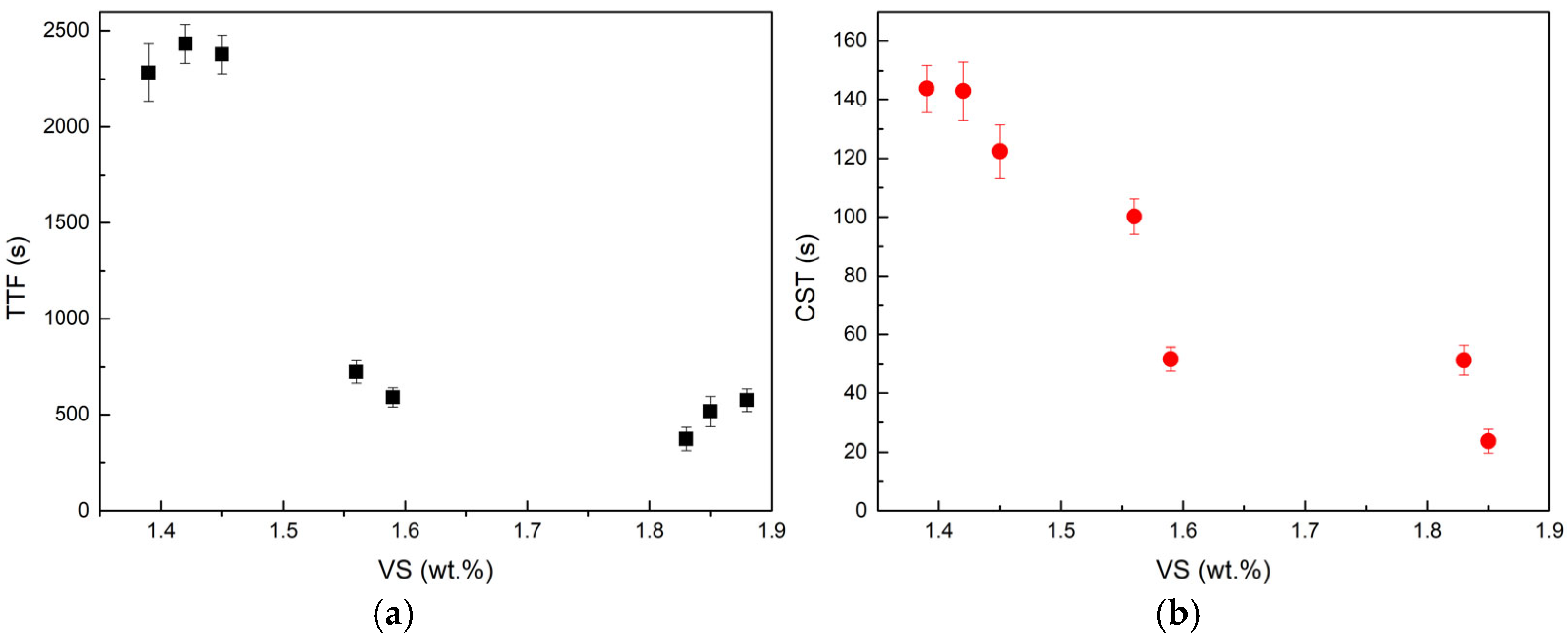

3.1.2. Volatile Solids (VS)

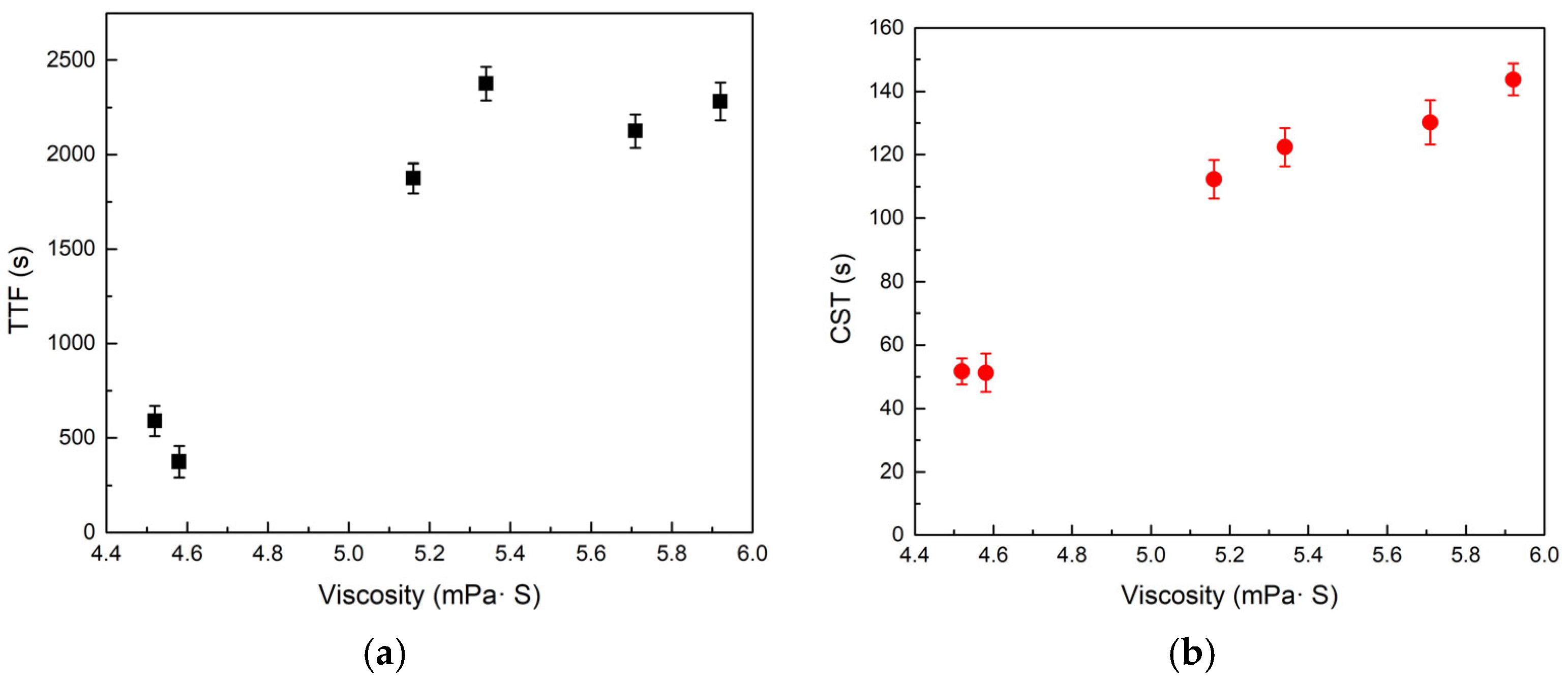

3.1.3. Viscosity

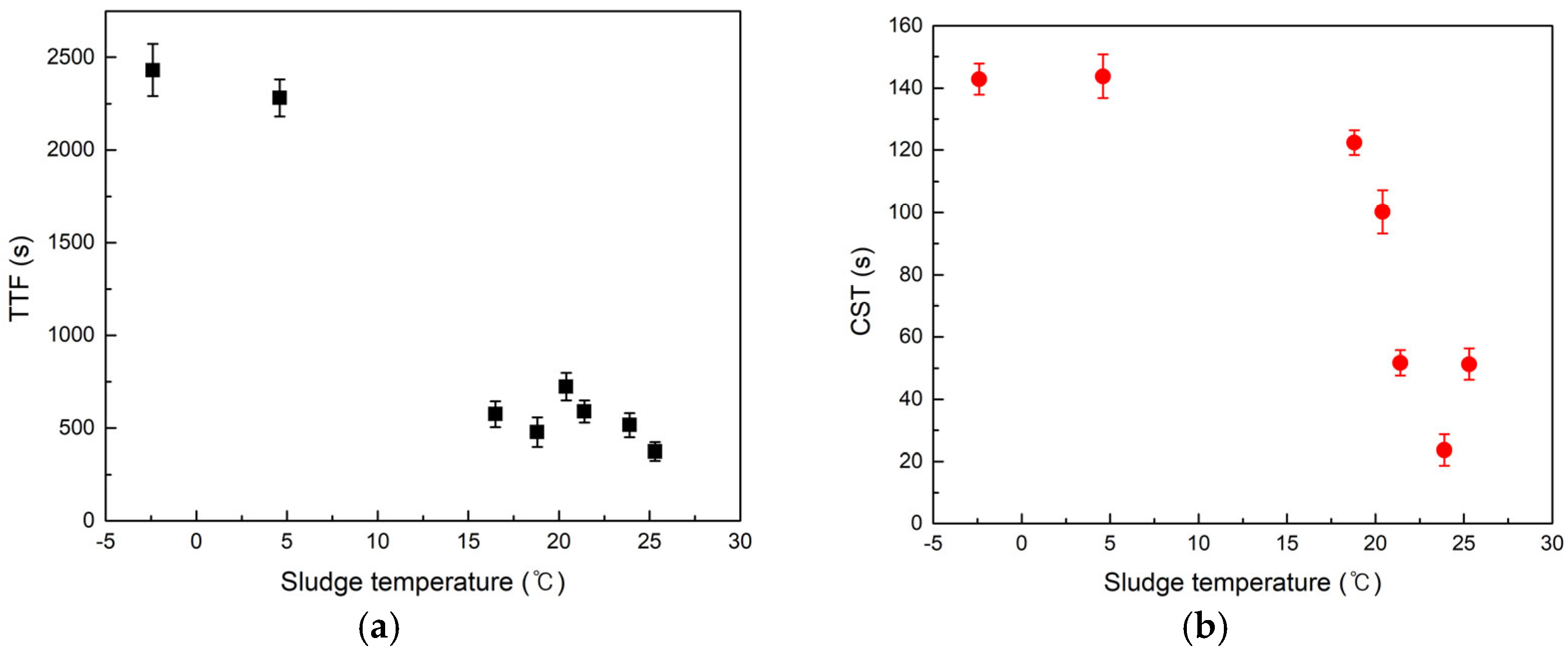

3.1.4. Temperature

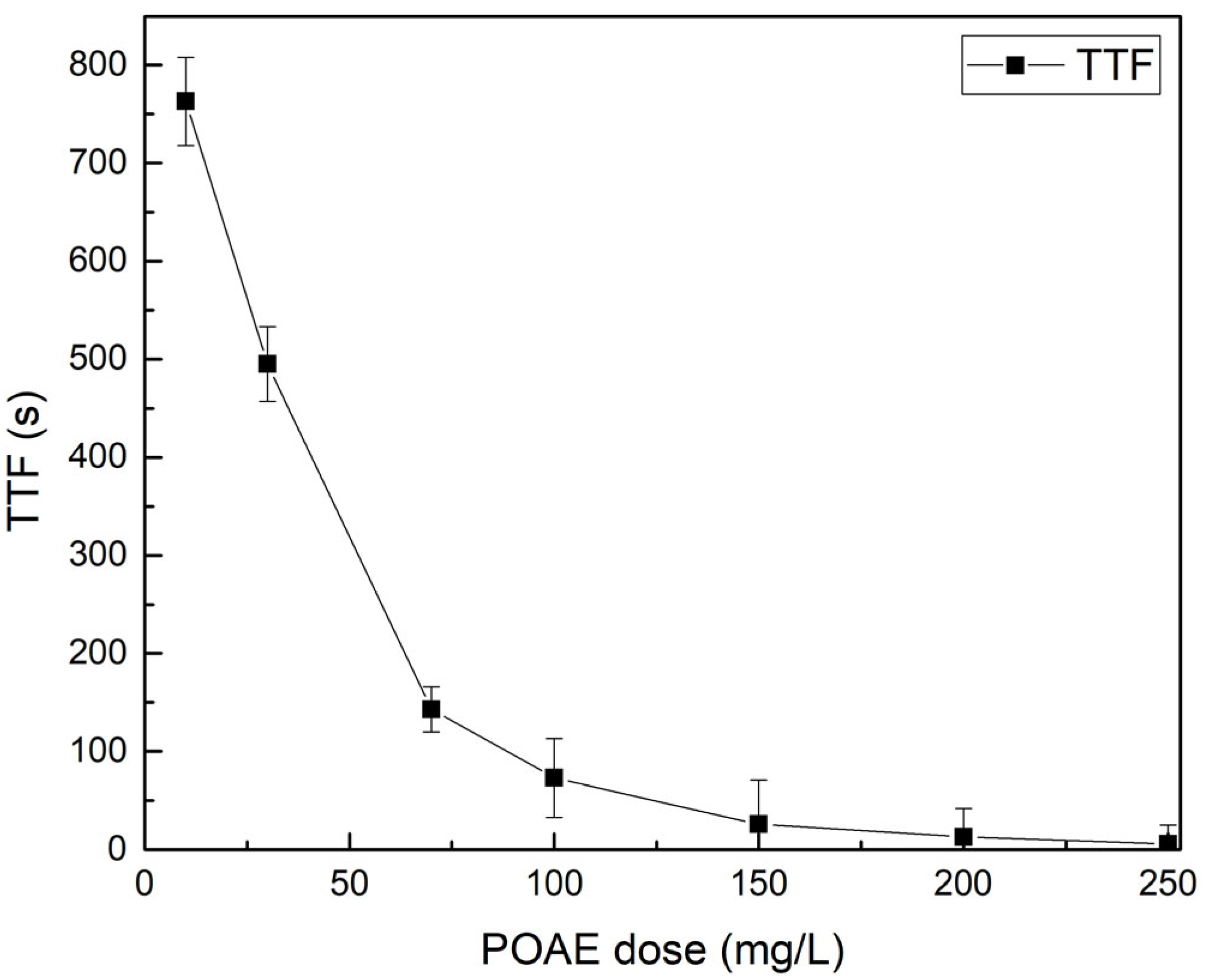

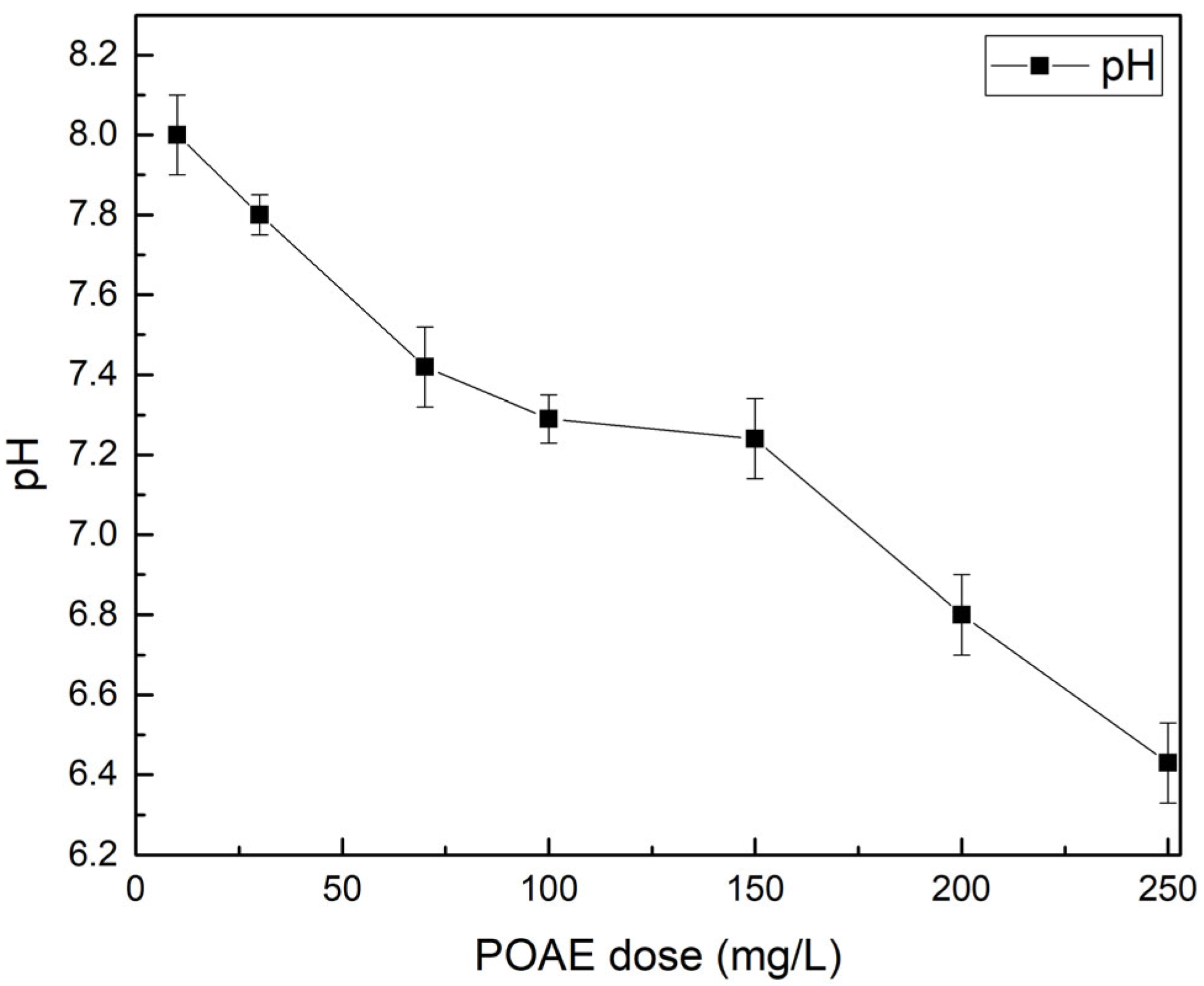

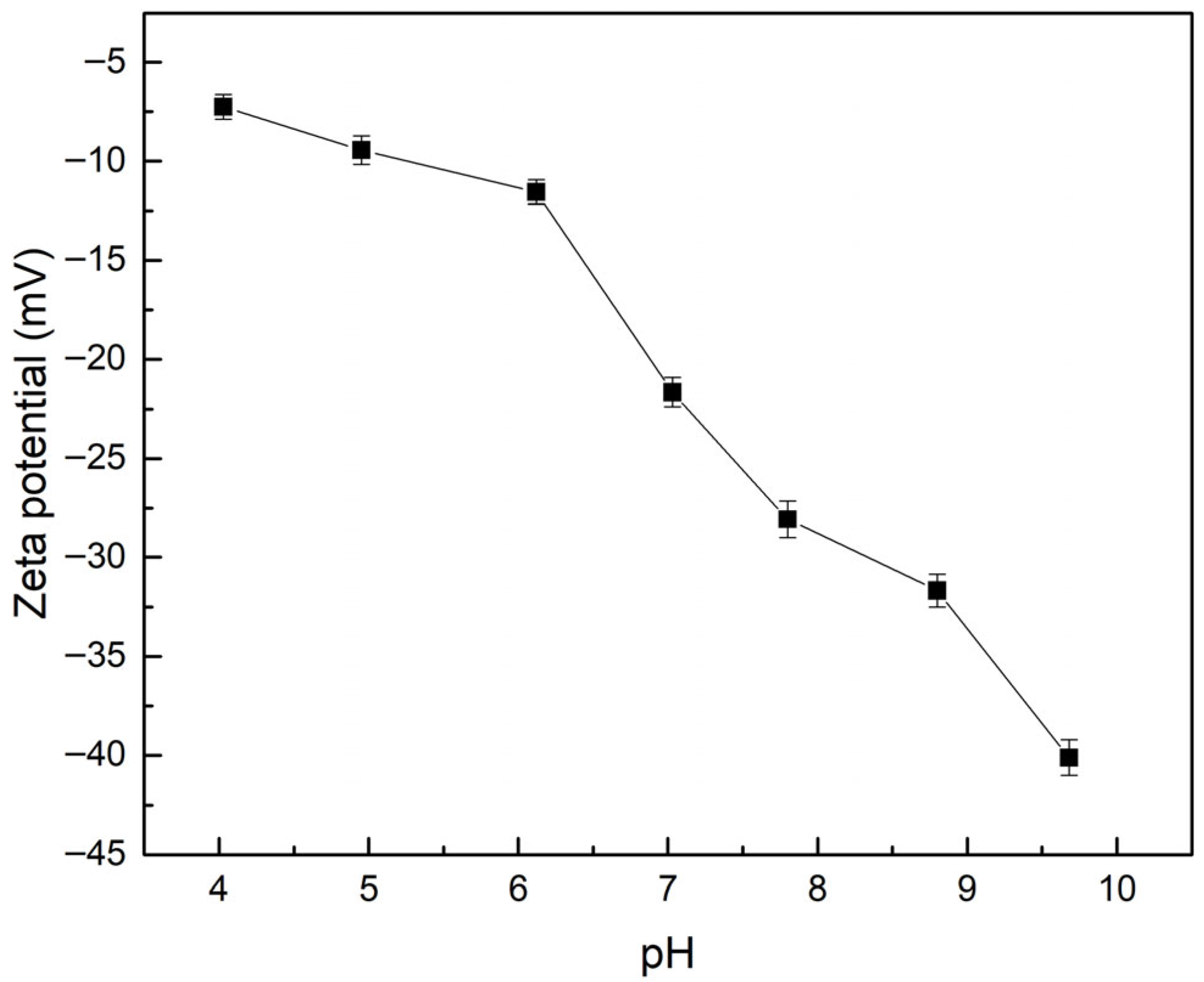

3.2. Coagulant (POAE) Dose and Indicators

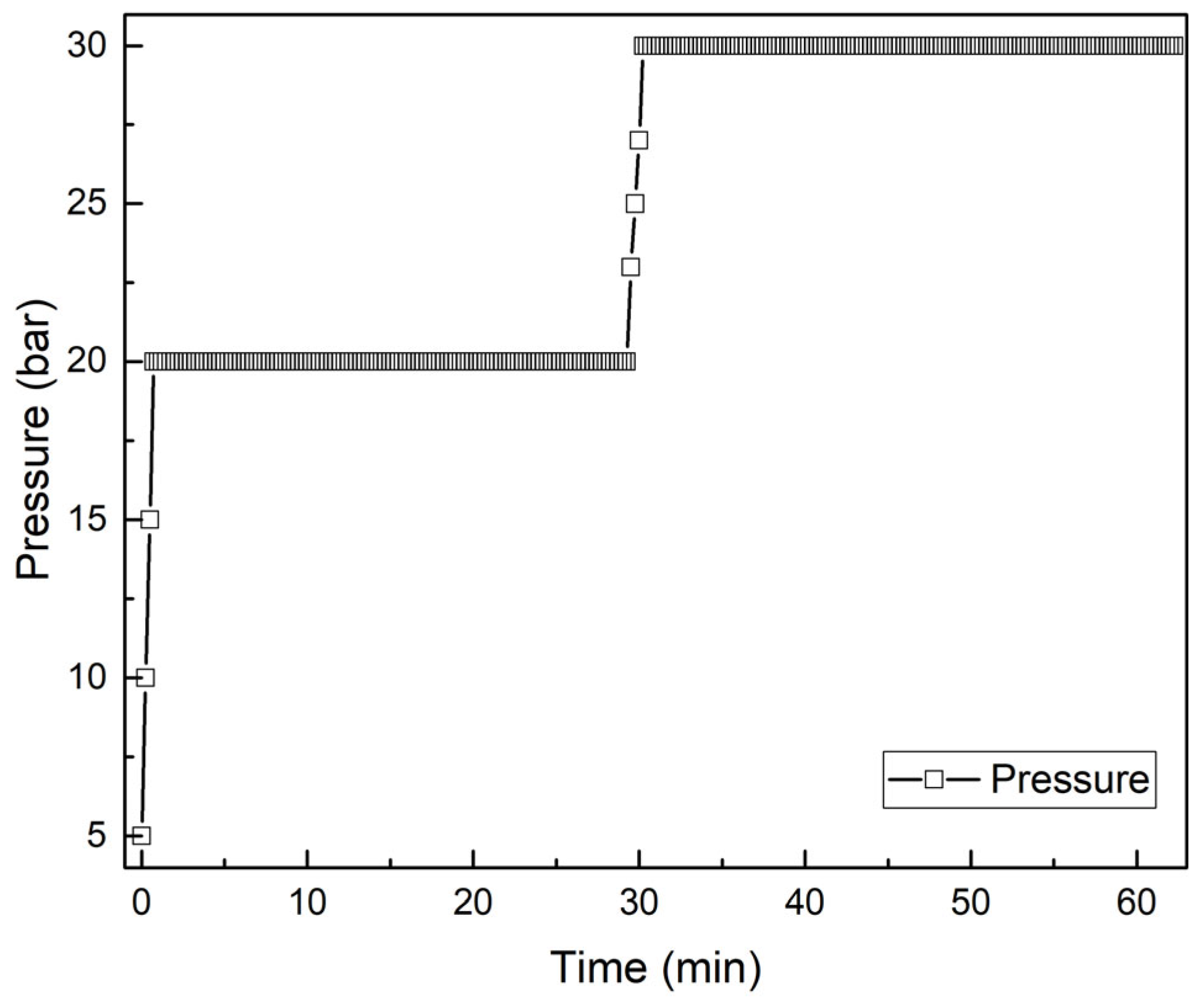

3.3. System Performance Under Integrated Real-Time Control

4. Conclusions

- A sensor-integrated feedback control system was developed to adapt coagulant dosing and filter press pressure in real time, significantly improving sludge dewatering performance over conventional static operation.

- Optimal polymer dosing was achieved in the range of ~100–150 mg/L POAE; within this range, the sludge pH dropped by ~0.7 units and zeta potential approached neutral, indicating effective charge neutralization and flocculation.

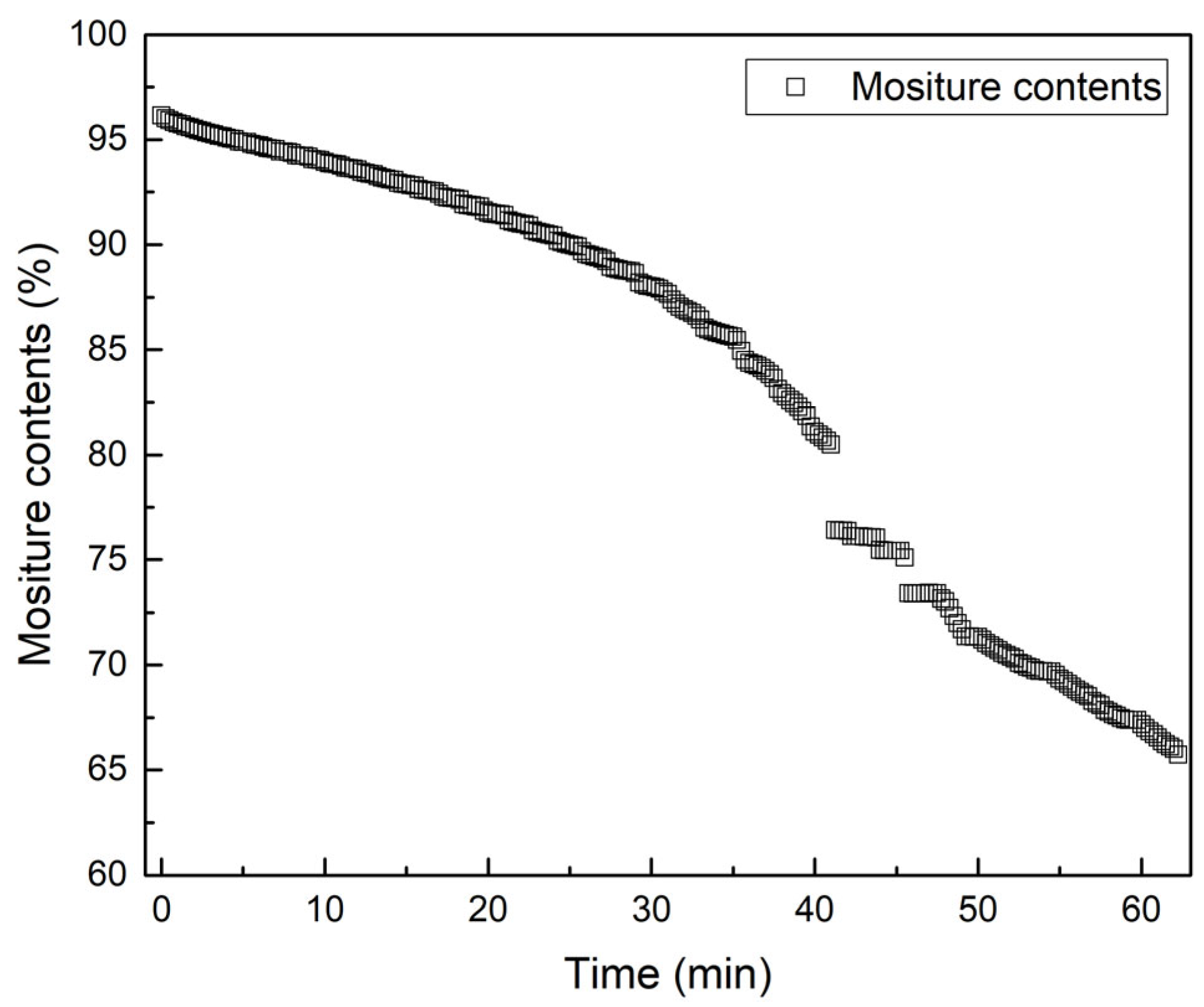

- Dynamic pressure control (stepping from 20 to 30 bar based on filtrate flux feedback) produced a final cake moisture of ~65%, markedly drier than the ~75–80% achieved under constant-pressure conditions. The adaptive pressure ramp prevented premature cake compression and maintained higher filtration rates.

- Combining chemical and mechanical control minimized polymer waste while avoiding excessive cake compaction. The result was more consistent and efficient dewatering, with lower chemical consumption (thus reduced operating cost) compared to a fixed-dose, fixed-pressure approach.

- The study demonstrates the potential for closed-loop, sensor-based dewatering systems to replace static, heuristic operations in wastewater treatment. This approach can lead to more sustainable and cost-effective biosolids management; future work should explore full-scale implementation and additional control parameters (e.g., streaming current or turbidity sensors).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| WWTP | Wastewater Treatment Plant |

| TS | Total Solids |

| TTF | Time-to-Filter |

| CST | Capillary Suction Time |

| EPS | Extracellular Polymeric Substances |

| PE | Population Equivalent |

| POAE | Polyoxyethylene Alkyl Ether |

| PLC | Programmable Logic Controller |

| VS | Volatile Solids |

| SRF | Specific Resistance to Filtration |

References

- Neyens, E.; Baeyens, J. A review of classic Fenton’s peroxidation as an advanced oxidation technique. J. Hazard. Mater. 2003, 98, 33–50. [Google Scholar] [CrossRef]

- Lee, J.; Kim, Y.M. Enhanced dewaterability of digested sludge using Fenton oxidation and cationic polymer. Chemosphere 2019, 222, 695–702. [Google Scholar]

- Song, E.; Kim, E.; Kim, G.W.; Jeong, C.J.; Lee, W.; Han, S.K. Dewaterability Enhancement of Anaerobic Sludge Using Polymeric Aluminum Chloride and Polyoxyethylene Alkyl Ether Surfactants. Water 2024, 16, 2303. [Google Scholar] [CrossRef]

- Jin, B.; Wilén, B.M.; Lant, P. Impacts of morphological, physical and chemical properties of sludge flocs on dewaterability of activated sludge. Chem. Eng. J. 2004, 98, 115–126. [Google Scholar] [CrossRef]

- Novak, J.T.; Sadler, M.E.; Murthy, S.N. Mechanisms of floc destruction during anaerobic and aerobic digestion and the effect on conditioning and dewatering of biosolids. Water Res. 2003, 37, 3136–3144. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Luo, Y.; Qiao, W. Possible solutions for sludge dewatering in China. Front. Environ. Sci. Eng. China 2010, 4, 102–107. [Google Scholar] [CrossRef]

- Liu, H.; Yang, J.; Zhu, N.; Zhang, H.; Li, Y.; He, S.; Yang, C.; Yao, H. A comprehensive insight into the combined effects of Fenton’s reagent and skeleton builders on sludge deep dewatering performance. J. Hazard. Mater. 2013, 258, 144–150. [Google Scholar] [CrossRef] [PubMed]

- Ke, M.Y. Probe into advanced sludge dewatering technology in Jimei Wastewater Treatment Plant. Water Wastewater 2011, 37, 40–43. [Google Scholar]

- Cao, B.; Zhang, W.; Wang, Q.; Huang, Y.; Meng, C.; Wang, D. Wastewater sludge dewaterability enhancement using hydroxyl aluminum conditioning: Role of aluminum speciation. Water Res. 2016, 105, 615–624. [Google Scholar] [CrossRef] [PubMed]

- Sorensen, P.B.; Christensen, J.R.; Bruus, J.H. Effect of small-scale solids migration in filter cakes during filtration of wastewater solids suspensions. Water Environ. Res. 1995, 67, 25–32. [Google Scholar] [CrossRef]

- Hach, RTC Sludge Dewatering Improves Efficiency, Optimizes Polymer Feed at Bowling Green. Available online: www.at.hach.com/cms/documents/Claros/DOC043.53.30393.Apr17.pdf#:~:text=Solution%20The%20plant%20installed%20the,Benefits%20Continuous%20analysis%20provided%20by (accessed on 24 July 2025).

- Fukasawa, A.; Yamato, T.; Watanabe, S. Automatic control of polymer dosage using floc images in sludge dewatering plant. Environ. Process. 2024, 11, 29. [Google Scholar] [CrossRef]

- Novak, J.; Knocke, W.; Burgos, W.; Schuler, P. Predicting the dewatering performance of belt filter presses. Water Sci. Technol. 1993, 28, 11–19. [Google Scholar] [CrossRef]

- Yousefi, S.A.; Nasser, M.S.; Hussein, I.A.; Judd, S. Influence of polyelectrolyte architecture on the electrokinetics and dewaterability of industrial membrane bioreactor activated sludge. J. Environ. Manag. 2019, 233, 410–416. [Google Scholar] [CrossRef] [PubMed]

- Parker, D.G. Factors Affecting the Filtration Characteristics of Aerobically Digested Sludge; Virginia Polytechnic Institute and State University: Blacksburg, VA, USA, 1970. [Google Scholar]

- Lousada-Ferreira, M.; van Lier, J.B.; van der Graaf, J.H. Impact of suspended solids concentration on sludge filterability in full-scale membrane bioreactors. J. Membr. Sci. 2015, 476, 68–75. [Google Scholar] [CrossRef]

- Gray, N.F. Capillary suction time (CST). In Progress in Filtration and Separation; Academic Press: Cambridge, MA, USA, 2015; pp. 659–670. [Google Scholar]

- Capodici, M.; Mannina, G. The sludge dewaterability in membrane bioreactors. In Proceedings of the SIDISA: X International Symposium on Sanitary and Environmental Engineering, Rome, Italy, 19–23 June 2016; pp. 19–23. [Google Scholar]

- Hyder, U.S.; Kakar, F.; Okoye, F.; Elbeshbishy, E. Management of digestate from anaerobic digestion of municipal sludge. In Anaerobic Digestate Management; Tyagi, V.K., Aboudi, K., Eskicioglu, C., Eds.; IWA Publishing: London, UK, 2022; pp. 75–110. [Google Scholar]

- Yan, C.; Zhan, M.; Xv, K.; Zhang, S.; Liang, T.; Yu, R. Sludge dewaterability enhancement under low temperature condition with cold-tolerant Bdellovibrio sp. CLL13. Sci. Total Environ. 2022, 820, 153269. [Google Scholar] [CrossRef]

- Duan, J.; Gregory, J. Coagulation by hydrolysing metal salts. Adv. Colloid Interface Sci. 2003, 100, 475–502. [Google Scholar] [CrossRef]

- Gao, B.Y.; Chu, Y.B.; Yue, Q.Y.; Wang, B.J.; Wang, S.G. Characterization and coagulation of a polyaluminum chloride (PAC) coagulant with high Al13 content. J. Environ. Manag. 2005, 76, 143–147. [Google Scholar] [CrossRef]

- Fitria, D.; Scholz, M.; Swift, G.M.; Al-Faraj, F. Impact of temperature and coagulants on sludge dewaterability. Int. J. Technol. 2022, 13, 596–605. [Google Scholar] [CrossRef]

- Rodrigues, A.C.; Boroski, M.; Shimada, N.S.; Garcia, J.C.; Nozaki, J.; Hioka, N. Treatment of paper pulp and paper mill wastewater by coagulation–flocculation followed by heterogeneous photocatalysis. J. Photochem. Photobiol. A Chem. 2008, 194, 1–10. [Google Scholar] [CrossRef]

- Inam, M.A.; Khan, R.; Lee, K.H.; Wie, Y.M. Removal of arsenic oxyanions from water by ferric chloride—Optimization of process conditions and implications for improving coagulation performance. Int. J. Environ. Res. Public Health 2021, 18, 9812. [Google Scholar] [CrossRef]

- Verrelli, D.I.; Dixon, D.R.; Scales, P.J. Effect of coagulation conditions on the dewatering properties of sludges produced in drinking water treatment. Colloids Surf. A Physicochem. Eng. Asp. 2009, 348, 14–23. [Google Scholar] [CrossRef]

- Ahmed, T.; Kanwal, R.; Hassan, M.; Ayub, N.; Scholz, M.; McMinn, W. Coagulation and disinfection in water treatment using Moringa. In Proceedings of the Institution of Civil Engineers-Water Management; Thomas Telford Ltd.: London, UK, 2010; Volume 163, pp. 381–388. [Google Scholar]

- Chia-Hung, H.; Kung-Cheh, L. Assessment of sludge dewaterability using rheological properties. J. Chin. Inst. Eng. 2003, 26, 221–226. [Google Scholar] [CrossRef]

- Buyukkamaci, N.; Kucukselek, E. Improvement of dewatering capacity of petrochemical sludge. J. Hazard. Mater. 2006, 144, 323–327. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.F.; Qi, H.Y.; Du, K.; Ran, D.D.; Liu, W.H.; Shen, X.F.; Zeng, R.J. Reinterpretation of the mechanism of coagulation and its effects in waste activated sludge treatment. Sep. Purif. Technol. 2022, 291, 120958. [Google Scholar] [CrossRef]

- Liang, Y.; Wang, R.; Sun, W.; Sun, Y. Advances in chemical conditioning of residual activated sludge in China. Water 2023, 15, 345. [Google Scholar] [CrossRef]

- Sun, Y.; Fan, W.; Zheng, H.; Zhang, Y.; Li, F.; Chen, W. Evaluation of dewatering performance and fractal characteristics of alum sludge. PLoS ONE 2015, 10, e0130683. [Google Scholar] [CrossRef]

- Abu-Orf, M.M.; Dentel, S.K. Automatic control of polymer dose using the streaming current detector. Water Environ. Res. 1998, 70, 1005–1018. [Google Scholar] [CrossRef]

- Sørensen, P.B.; Moldrup, P.; Hansen, J. Filtration and expression of compressible cakes. Chem. Eng. Sci. 1996, 51, 967–979. [Google Scholar] [CrossRef]

- Sveegaard, S.G.; Keiding, K.; Christensen, M.L. Compression and swelling of activated sludge cakes during dewatering. Water Res. 2012, 46, 4999–5008. [Google Scholar] [CrossRef] [PubMed]

- Kowalczyk, M. The Influence of the Addition of Cement and Zeolite on the Increase in the Efficiency of Sewage Sludge Dewatering in the Pressure Filtration Process. Energies 2024, 17, 685. [Google Scholar] [CrossRef]

- La Heij, E.; Kerkhof, P.; Herwijn, A.; Coumans, W. Fundamental aspects of sludge filtration and expression. Water Res. 1996, 30, 697–703. [Google Scholar] [CrossRef]

- Zhao, Y.; Bache, D. Integrated effects of applied pressure, time, and polymer doses on alum sludge dewatering behaviour. Waste Manag. 2002, 22, 813–819. [Google Scholar] [CrossRef]

- Wu, R.; Lee, D.; Wang, C.; Chen, J.; Tan, R. Novel cake characteristics of waste-activated sludge. Water Res. 2001, 35, 1358–1362. [Google Scholar] [CrossRef]

- Rashmi, H.R.; Devatha, C.P. Review on solid-liquid separation using various conditioning methods. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1166, 012002. [Google Scholar] [CrossRef]

- Lee, C.; Liu, J. Enhanced sludge dewatering by dual polyelectrolytes conditioning. Water Res. 2000, 34, 4430–4436. [Google Scholar] [CrossRef]

- Mahmoud, A.; Olivier, J.; Vaxelaire, J.; Hoadley, A.F. Electro-dewatering of wastewater sludge: Influence of the operating conditions and their interactions effects. Water Res. 2011, 45, 2795–2810. [Google Scholar] [CrossRef] [PubMed]

| Sludge Parameter | Threshold | Low Condition (Poor Dewatering) TTF: >2000 s CST: >130 s | High Condition (Much Faster) TTF: <800 s CST: <80 s |

|---|---|---|---|

| Total solids | 2.5% | At below | At above |

| Volatile solids | 1.6% | At below | At above |

| Viscosity | 5 mPa·S | At above | At below |

| Temperature | 5 °C | At below | At above |

| Metric | Real-Time Control | Static Operation |

|---|---|---|

| Final cake moisture | <65% | >75–80% |

| Total filtrate collected | >450 g | 300–400 g |

| Coagulant dose | Adaptive | Fixed |

| Pressure application | Stepped: 20→30 bar at 30 min (flux-triggered) | Constant (20 or 30 bar) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, E.; Han, S.K. Real-Time Sensor-Controlled Coagulant Dosing and Pressure in a Novel Sludge Dewatering System. Clean Technol. 2025, 7, 82. https://doi.org/10.3390/cleantechnol7030082

Song E, Han SK. Real-Time Sensor-Controlled Coagulant Dosing and Pressure in a Novel Sludge Dewatering System. Clean Technologies. 2025; 7(3):82. https://doi.org/10.3390/cleantechnol7030082

Chicago/Turabian StyleSong, Eunhye, and Seong Kuk Han. 2025. "Real-Time Sensor-Controlled Coagulant Dosing and Pressure in a Novel Sludge Dewatering System" Clean Technologies 7, no. 3: 82. https://doi.org/10.3390/cleantechnol7030082

APA StyleSong, E., & Han, S. K. (2025). Real-Time Sensor-Controlled Coagulant Dosing and Pressure in a Novel Sludge Dewatering System. Clean Technologies, 7(3), 82. https://doi.org/10.3390/cleantechnol7030082