1. Introduction

The need for producing biodiesel from algae arises from a combination of factors, such as the search for sustainable energy sources, reducing dependence on fossil fuels, and increasing awareness of climate change. Numerous scientific studies have identified algae as a promising energy source due to their high productivity, ability to grow on non-arable land, and potential to reduce greenhouse gas emissions [

1,

2,

3,

4]. However, the economic and technical feasibility of algae-based biodiesel production depends on the synergy of environmental, technological, and political factors.

Microalgae have a significantly higher yield of biomass and lipids per unit area compared to traditional energy crops such as rapeseed. The oil yield from algae can reach up to 30–40% of dry mass, making them a superior feedstock for biodiesel compared to plant crops like soybean or palm [

3,

5,

6,

7]. This high productivity allows for greater biodiesel production on a smaller land area, which is particularly important for sustainability and reducing pressure on agricultural land.

Algae cultivation does not require agricultural land, thus avoiding the conflict between food and fuel production. This is especially important for countries with limited resources [

1,

8].

Microalgae have an exceptional capacity for CO

2 sequestration (1.8–2.0 kg of CO

2 per kg of biomass) through photosynthesis, making them a key solution for reducing the carbon footprint of the energy sector [

9,

10,

11,

12]. Their application in wastewater treatment enables the removal of up to 98.48% phosphorus and 90.6% nitrogen while producing lipid-rich feedstock for biodiesel production [

8,

9,

13,

14]. Analyses show that algae-based biodiesel (especially as an additive to conventional diesel) reduces particulate emissions by 30–50% compared to fossil diesel, with a sulphur content of almost zero [

2,

5,

6,

10]. Life cycle assessments show that algae biodiesel could reduce greenhouse gas emissions by 50–70% compared to fossil diesel, despite slightly lower energy efficiency [

2,

15].

In addition to biodiesel, algae can yield other valuable products such as bioethanol, biogas, and high-value compounds for the food, pharmaceutical, and cosmetic industries. These co-products contribute to the circular economy and enhance the economic viability of algae-based production [

11].

Policies promoting renewable energy development and circular economy practices further boost interest in algae-derived biodiesel, particularly through integration with wastewater treatment systems and industrial CO

2 sequestration efforts [

11].

The history of algae biodiesel research, though not long, is linked to important projects and technological advancements. Below is a brief overview of the most significant achievements related to algae biodiesel. Interest in algae biodiesel began with the Aquatic Species Program (ASP), launched in 1978 by the United States Department of Energy (DOE). The program initially focussed on hydrogen production from algae, but in the 1980s, the focus shifted to biodiesel due to its greater energy potential [

16]. Laboratory experiments identified algae with a high lipid content (up to 40%), leading to the testing of open algae cultivation systems in arid regions. High costs resulted in the closure of the program in 1996. The rise in oil prices spurred new research between 2006 and 2015. Publications on algae biodiesel increased from 1 paper in 1990 to 101 papers in 2015, with an annual growth rate of 14.76% [

1]. Institutions such as the NREL (United States) and the CSIRO (Australia) played an important role during this period, focussing on genetic modification of algae and photobioreactor optimisation [

1,

17]. Since 2015, the focus has shifted to reducing the energy footprint and costs through innovations in algae cultivation, extraction, and integration with industrial processes. Key advancements in algae biodiesel production technology include the following:

Hybrid photobioreactor (PBR) systems, which combine open ponds and closed PBRs to improve control over cultivation conditions (light, pH, nutrients) while reducing contamination risks [

5]. These systems enable algae growth in controlled environments with optimised resource use. Biofilm-based systems feature modular 3D structures. Experiments show biomass productivity increased from 5.7 g m

−2 d

−1 to 70.9 g m

−2 d

−1 after implementation, alongside a 40% reduction in biomass separation energy cost [

18,

19]. These systems use natural materials like bamboo and pine sawdust to enhance surface area for algae growth [

18,

20].

Lipid induction technologies include the use of stress factors and genetic engineering. Stress factors such as nitrogen deprivation, high light intensity (up to 500 µmol/m

2/s), and salinity shock increase the lipid content in algae (e.g.,

Chlorella spp. up to 45% of dry mass) [

5]. Suparmaniam et al. [

21] reported in their study that the lipid yield of Chlorella vulgaris cultures increased to 0.163, 0.381, and 0.182 g/L when they were stressed with a nutrient limitation of 4%

v/

v, 15 g/L salinity, and 2 g/L bicarbonate, compared to the non-stressed culture (0.139 g/L). In addition, cultivation under combined stress conditions, i.e., salinity (15 g/L) and bicarbonate addition (2 g/L), increased lipid yield and the carbon dioxide (CO

2) fixation rate by 68.26% and 16.64%, respectively, compared to the control culture. With the help of genetic engineering (CRISPR-Cas9 technology), the metabolism of the algae was modified (e.g., by increasing the expression of the ACCase gene) in order to optimise tri-glyceride synthesis [

22,

23].

More efficient algae harvesting methods are sought through the application of electro flocculation and magnetic separation. Electro flocculation using an electric field (0.5–2 V/cm) reduces energy consumption by 40% compared to traditional centrifugation [

5]. Magnetic separation employing magnetite nanoparticles (Fe

3O

4) enables rapid biomass separation, with a 95% utilisation rate [

24].

Innovative methods for algae oil extraction involve supercritical fluids and nanotechnology. Supercritical CO

2 (scCO

2) extraction of

Nannochloropsis oculata at 550 bar and 75 °C achieved a 26.2% lipid yield (0.262 g lipids/g biomass). The addition of n-hexane as a co-solvent increased the yield to 40%, although pure scCO

2 remained the main solvent to avoid residual waste [

25]. The method is emphasised as energy-efficient and environmentally friendly. The use of TiO

2 nanoparticles (10–50 nm) (nanotechnology) increased the reaction surface area during transesterification and reduced the need for catalysts by 20% [

10]. Replacing hexane with less toxic alternatives like limonene could lower production costs by 15–20%, improving sustainability [

17,

26].

Hydrothermal liquefaction (HTL) is a technology (300–350 °C, 10–20 MPa) that enables direct conversion of wet algae into biofuel without energy-intensive drying, reducing total production costs by 25–30% [

27,

28].

Integration with the circular economy is a key approach that combines wastewater treatment and CO

2 fixation from industrial emissions. Microalgae remove up to 98.48% phosphorus and 90.6% nitrogen from wastewater while generating lipid-rich feedstock for biodiesel [

5]. Through CO

2 fixation, algae absorb up to 1.8 kg of CO

2 per kg of biomass, making them vital for decarbonising the energy sector [

29,

30]. Models integrating fuel production with wastewater remediation or industrial CO

2 capture reduce raw material costs by 40–60% [

9,

13]. For example, an Egyptian project aiming for 0.25 million tonnes of biodiesel annually highlights competitiveness at USD 2000 per tonne with government incentives, though scalability depends on cost optimisation and policy alignment [

13].

Co-products reduce the economic and environmental burdens of microalgal biodiesel. Residual biomass after lipid extraction contains 30–60% proteins and 10–30% carbohydrates, depending on algal species and cultivation conditions. Co-products of algae biodiesel include nutraceuticals used in the production of dietary supplements and other pharmaceutical products, dyes, colorants, etc. These are, for example, compounds such as carotenoids (e.g., β-carotene), omega-3 polyunsaturated fatty acids (docosahexaenoic acid and eicosahexaenoic acid), astaxanthin, squalene, and phycobiliprotein, which have become increasingly popular in the pharmaceutical industry in recent years. They are also used as feed for aquaculture, as raw materials for the production of ethanol and hydrogen, and as an organic additive to improve soil structure [

31].

Previous research on algae-based biodiesel has looked in detail at the technical potential, environmental benefits (such as CO2 capture and wastewater treatment), and challenges in terms of production costs and scalability. Numerous studies have detailed advances in algae cultivation, harvesting, lipid extraction, and integration into the circular economy. However, most studies have focussed on qualitative assessments or isolated technical, economic, or environmental aspects. A comprehensive, quantitative assessment that incorporates these dimensions to inform strategic decisions is often lacking. For example, there is a lack of studies that systematically combine a SWOT (strengths, weaknesses, opportunities, and threats) analysis with the analytical hierarchy process (AHP) to quantitatively prioritise the key factors influencing the adoption and future prospects of algae-based biodiesel. The previous literature to date has rarely provided a structured, weighted assessment of the relative importance of technical, economic, and environmental factors, nor does it forecast the likely scenarios for algal biodiesel adoption in the short and long term. This study is the first to conduct a comprehensive SWOT-AHP analysis, which enables a quantitative ranking of the internal and external factors influencing the development and deployment of algae biodiesel. By integrating these methods, the study not only identifies critical strengths, weaknesses, opportunities, and threats, but also assigns them a relative weighting, enabling a more strategic and actionable understanding of the sector’s prospects. Furthermore, based on this systematic analysis, the study provides short-term (2030) and long-term (2050) projections for the adoption of algal biodiesel—something that has not been achieved with this level of methodological rigour in previous literature.

2. Materials and Methods

This study uses a systematic, quantitative methodology that combines SWOT analysis (strengths, weaknesses, opportunities, and threats) with the analytical hierarchy process (AHP). SWOT analysis has become an increasingly popular tool for strategic assessment in engineering, especially in the energy sector. By systematically identifying and evaluating internal (strengths and weaknesses) and external (opportunities and threats) influencing factors, SWOT analysis provides a comprehensive framework for understanding the dynamics affecting the systems and technologies under consideration [

32,

33]. The analytic hierarchy process (AHP) was selected to prioritise the most influential coefficients by quantifying their relative importance. Developed by Thomas L. Saaty in 1977 and further refined in 1987 [

34], the AHP is a multi-criteria decision-making method designed to facilitate complex decisions involving multiple conflicting criteria [

35].

The main objective is to assess the prospects for algae-based biodiesel production by quantitatively evaluating technical, economic, and environmental factors and categorising their impact. The investigation began with an extensive literature search to gather comprehensive information on algal biodiesel. Initially, a targeted search was conducted using the keywords “algae” and “biodiesel” in the Web of Science (WoS) and PubMed databases, covering the period from 2015 to 2025, to capture the latest developments in the field. This initial search found 276 articles in the WoS and 106 articles in PubMed.

A more targeted search was then conducted using Boolean operators. The query (“algal biodiesel”) AND (“SWOT”) returned 3 results, while the combination (“algae biodiesel”) AND (“SWOT”) AND (“AHP”) returned only one relevant article. To supplement the literature data, additional information was extracted from relevant technical reports and studies published by organisations such as the International Renewable Energy Agency (IRENA), the National Renewable Energy Laboratory (NREL), the International Energy Agency (IEA-PVPS), and various EU reports.

This study adheres strictly to scientific and ethical standards and uses only data from published peer-reviewed literature and credible institutional reports. The data collection included a wide range of materials, including the following:

A historical overview of the development of algae-based biodiesel;

Data on algal biodiesel yields, energy consumption in production, emerging technology trends, and environmental impact assessments;

Industry reports and regulatory documents that provide insight into the market and policy framework;

Statistical summaries with information on global biodiesel production volumes and price trends.

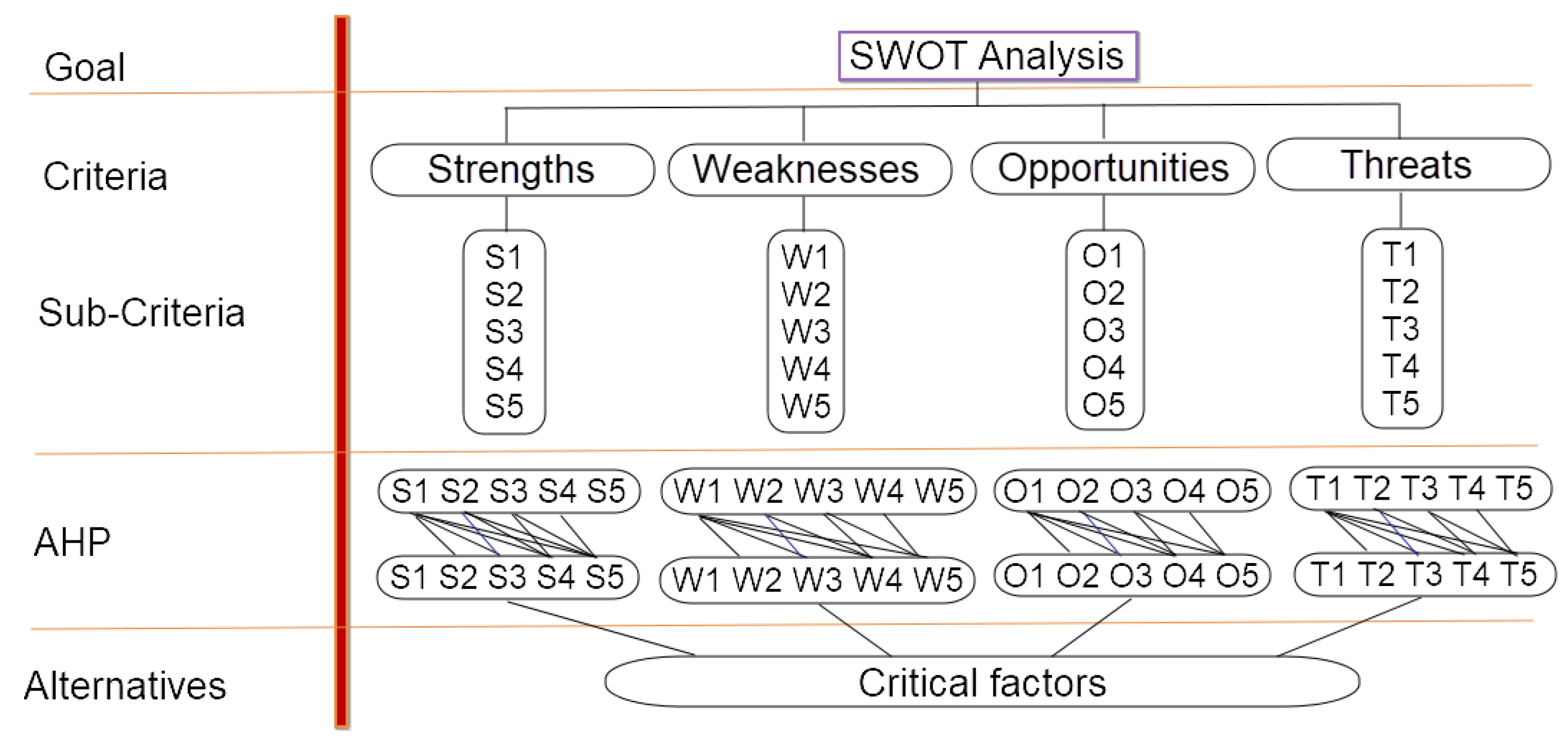

The introduction gives a brief historical overview of the development of algae-based biodiesel. Since the production and application of biodiesel depend on a number of technical, economic, and environmental factors, historical numerical indicators on these aspects are presented first. These numerical indicators point to trends in technological development. On this basis and based on the literature review, the key factors within each SWOT category were identified in the study. Each factor was clearly defined and underpinned with references to established methodologies commonly used in energy sector research. Based on the authors’ expert judgement, the four most important factors in each SWOT category were selected. The factors were prioritised using the analytic hierarchy process (AHP). The SWOT-AHP model is shown in

Figure 1.

Goal: To determine the algae biodiesel deployment perspective;

Criteria: SWOT categories (S, W, O, T);

Sub-criteria: 16 identified factors;

Alternatives: Critical factors.

To quantitatively prioritise SWOT factors, a structured AHP was conducted by the authors of this study with the following steps:

Creation of pairwise comparison matrices for the SWOT categories and their respective factors using the Saaty scale (1–9) to express relative importance;

Perform all AHP calculations—including matrix normalisation, derivation of eigenvectors, and CR assessment—using standard mathematical procedures, as described by Saaty.

In the final phase, the overall priority vector is calculated by multiplying the local weightings of the factors by the specific group weighting to determine the priority ranking of the SWOT factors.

So, as result of process, we obtained the following:

The Saaty scale has nine levels of importance:

1 stands for equal importance;

3 stands for medium importance;

5 stands for high importance;

7 stands for very high importance;

9 stands for extreme importance;

2, 4, 6, and 8 stand for intermediate values.

The calculation of the priority of the model elements begins with the construction of the matrix A with the dimensions

n ×

n, where

n is the number of elements on a certain level (in our case, n = 4). The numbers above the diagonal

aij =

wi/

wj are an estimate of the importance of the i-th element compared to the j-th element (pairwise comparison) and were determined by the authors of this study based on the previously explained Saaty scale. The numbers on the diagonal

aij = 1, and the numbers below the diagonal are the inverse of the numbers above the diagonal (a

ji = 1/

aij). Below is an example of a matrix with three elements:

The normalised matrix was obtained from the matrix

A. The

n-dimensional column vector, denoted by

W, represents the weighting vector (priority) for the compared factors and is determined by calculating the average of the entries in each row of the normalised matrix:

where

ālk represents entries of the normalised matrix.

It is important to emphasise that the reliability of the AHP results depends directly on the consistency of the pairwise comparison judgments. If the pairwise comparisons are perfectly consistent, the matrix A reaches rank 1 and the maximum eigenvalue (

λmax) is equal to the matrix size (

n). In practical applications, however, it is extremely rare for perfect consistency to be achieved. Instead, the actual

λmax is calculated using the expression (3):

Deviations between the actual matrix

A and the ideal matrix

A are considered acceptable if they are up to 10%. The consistency is defined by the relationship between the entries of

A:

aij ×

ajk =

aik. The consistency index (

CI) is calculated, using the expression (4) [

36]:

The final consistency ratio (

CR) can be used to determine whether the estimates are sufficiently consistent. The

CR is calculated as the ratio between the

CI and the random index (

RI—see

Table 1) [

36]:

The generally accepted upper limit for the CR is 0.1. In cases where the final consistency ratio exceeded 0.1 in the calculation, the authors repeated the estimation procedure with modified factors in the pairwise comparison matrix to improve consistency.

Table 1.

Random index (

RI) [

34].

Table 1.

Random index (

RI) [

34].

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

At the end of the Discussion Section, a sensitivity analysis of the AHP model applied to the results obtained is carried out.

3. Results

The prospects for the production and application of biodiesel depend on a number of factors related to technical, economic, and environmental aspects, as well as the policies of individual countries. In order to gain insight into this issue, the results of research on certain indicators of the competitiveness of algae biodiesel are presented below. The first interesting indicator is the amount of biodiesel produced from algae in the last 10 years (

Table 2). It should be emphasised that the data are mostly estimated due to the lack of globally standardized statistical sources. The data are derived from indirect sources (e.g., production plant capacities and assumptions about biomass-to-biodiesel conversion (30% lipid content → 0.33 t of biodiesel per tonne of dry biomass)) [

6,

37,

38,

39,

40]).

It can generally be said that the United States dominates in production thanks to support from programs such as the

Aquatic Species Program and significant investments in research. Norway and Canada are focussed on cultivating macroalgae in cold water [

37,

41], while China and India are exploring the combination of microalgae and wastewater [

6].

Another important indicator of improvements in algae biodiesel production technology is the increase in the amount of biodiesel per tonne of dry biomass, as shown in

Table 3. The amount of biodiesel is calculated based on lipid content, assuming 90% transesterification efficiency and a biodiesel density of approximately 0.88 kg/L.

Table 3 clearly shows the increasing trend in lipid content and the amount of biodiesel produced from algae per tonne of dry mass. The key factors contributing to these improvements are the following:

The third important indicator of improvements in algae biodiesel production technology is reflected in the reduction in energy consumption during the biodiesel production process from algae.

Table 4 presents the energy consumption per amount of algae biodiesel produced from 2013 to 2025.

For the production of conventional diesel, the energy consumption (well-to-tank, WTT, including extraction, transport, processing, and distribution) averages 14–18 MJ/kg of diesel. This value covers all stages of the fuel’s life cycle up to delivery to the user, and not just the energy content of the fuel itself (which is about 42 MJ/kg). These values are confirmed by the latest European and international fuel life cycle analyses.

The JEC Well-to-Wheels Study (v5, 2020) states that the total energy consumption for producing conventional diesel in the EU ranges between 14 and 18 MJ/kg, depending on refining technology and logistics [

53].

New life cycle assessment studies also confirm that the production of 1 kg of fossil diesel requires 1.2 MJ of primary energy for each MJ of diesel, which, with a calorific value of diesel of 42–43 MJ/kg, leads to 50–52 MJ/kg [

53], which corresponds to an energy efficiency of ~83%.

An important aspect of biodiesel production is the emission of greenhouse gasses (GHG) and other environmental impacts.

Table 5 shows the impact of improving the technology for producing biodiesel from algae on reducing emissions to the environment.

Tu et al. [

54] emphasise that applying HTL technology (converting wet biomass without drying) reduces CO

2 emissions by 40–50% and energy consumption by ~35%. Particulate matter (PM) reductions are achieved by eliminating drying processes and using nanoparticles for lipid extraction. Leveraging waste resources (CO

2, wastewater), HTL adoption, genetic engineering, and circular economy integration drive substantial emission cuts.

Greenhouse gas emissions from conventional diesel production (well-to-tank phase, WTT—from extraction to fuel distribution, excluding combustion in engines) amount to 18.2 gCO

2e/MJ of diesel, according to the European average [

58]. This corresponds to approximately 745–760 kg CO

2e per tonne of diesel produced and delivered to the market before combustion. These values are confirmed by the latest European fuel life cycle studies, including the JEC Well-to-Wheels v5 (2021) and the European Commission report, which cite a WTT phase emission range of 17–19 gCO

2e/MJ for diesel in the EU [

53]. These emissions relate solely to the production chain (WTT) and exclude tailpipe emissions from diesel combustion (TTW), which add ~74 gCO

2e/MJ. Total well-to-wheel (WTW) emissions for diesel thus exceed 90 gCO

2e/MJ.

For North America, the average is ~12–14 gCO

2e/MJ [

59], and for the rest of the world, the NTM (Network for Transport Measures) 2025 review provides an “international diesel” WTT baseline of 13 gCO

2e/MJ [

60].

The price of biodiesel compared to conventional diesel is an important factor in the market placement of biodiesel.

Table 6 shows the price trends for the period from 2010 to 2024. The prices are estimated based on various sources such as [

39,

61,

62,

63]. The price ranges reflect differences between laboratory, pilot, and commercial plants.

The price of algae-based biodiesel is still higher than that of conventional biodiesel (for example, USD 1200–1800 per tonne in 2024 for biodiesel from soybean or rapeseed) [

64], but the gap is steadily narrowing. The largest price drop is the result of increased cultivation efficiency, optimisation of lipid extraction, and integration with other industries (biorefinery approach) [

39].

Table 6 shows the long-term downward trend in the price of algae biodiesel, but also highlights ongoing challenges for full market competitiveness with fossil fuels.

3.1. SWOT-AHP Analysis of Biodiesel Production from Algae

3.1.1. SWOT Analysis

The first step is a SWOT analysis, i.e., identifying the most important strengths, weaknesses, opportunities, and threats. The most important strengths include the following:

High lipid yield and rapid algae growth.

The oil yield of algae can be up to 30–40% of the dry weight, which makes it a better source of feedstock for biodiesel compared to plant-based feedstocks such as soybeans or palm oil [

5,

6,

65].

Cultivation in photobioreactors enables continuous production without seasonal restrictions [

14].

Non-requirement of agricultural land.

Algae are cultivated in wastewater or salt lakes or near industrial CO

2 emissions and therefore do not compete with food plants [

14,

32].

Environmental benefits.

Reduction of PM (up to 27%), CO

2 (

Table 5), CO (up to 23.5%), and HC emissions (up to 30%) compared to fossil diesel [

56,

66,

67].

Absorption of CO

2 from industrial plants (up to 1.8 kg CO

2 per kg biomass) [

14].

Integrated circular production.

Recycling of nutrients from wastewater and the use of biomass residues for biogas production or as organic fertilizer [

14,

68].

Among the most important weaknesses, the following can be included:

Among the most important opportunities, the following can be included:

Technological innovations.

Expansion into niches that are inaccessible to electric vehicles.

Applications in heavy transport, maritime, and aviation, where BEVs are unsuitable [

32]. Electric ships currently make up only a very small part of the global maritime fleet (less than 1%), and their use is limited to smaller passenger and local vessels [

76]. The electrification of heavy road freight transport is still in its infancy, with sales shares of 1.6% in Europe, 2.8% in China, and only 0.1% in other countries [

77].

Use of waste streams.

Integration with wastewater treatment plants and thermal power plants for CO

2 recycling [

11].

Production of high-value co-products.

Use of biomass proteins as feed in aquaculture, for the production of pharmaceutical ingredients, for nutraceutical products, for dyes, and as organic fertilizers [

14,

31,

68,

78]. Succinic acid can be synthesized from the carbohydrate fractions of algae, with a yield of 0.3–0.5 g/g of biomass. It is used in the bioplastics industry and in pharmaceuticals [

79]. The price of succinic acid is 2 to 3 USD/kg. Beta-carotene and astaxanthin from

Dunaliella salina and

Haematococcus pluvialis are extracted in parallel with the lipids and have a market value of 2000–7000 USD/kg [

80].

Among the most important threats, the following can be included:

The dominance of electric vehicles (BEVs).

According to Concawe’s analysis [

81], mass electrification scenarios predict a reduction in liquid fuel consumption of around 60% by 2050 compared to today, while liquid fuel volumes are expected to fall by around 25–40% by 2035, depending on the speed of BEV adoption and the efficiency of existing internal combustion engine vehicles.

The reduction in battery prices from USD 132/kWh in 2021 to USD 70/kWh by 2030 further decreases the attractiveness of biodiesel [

82]. According to Bloomberg, lithium iron phosphate (LFP) batteries are significantly increasing their market share, and their price in China fell to just USD 53/kWh in 2024 [

83].

The dominance of BEVs is confirmed by data on the increase in vehicles sold worldwide. Global sales amounted to around 330,000 BEVs in 2015, around 1,260,000 BEVs in 2018, and around 4,600,000 BEVs in 2021, and estimates for 2024 assume sales of between 10 and 11 million BEVs [

84]. The forecast for 2030 is global sales of 30 to 38 million BEVs.

Regulatory restrictions.

Competition from other renewable fuels.

Hydrogen and synthetic e-fuels are gaining an advantage in transport sectors with high energy demands [

87,

88,

89].

The risks of irresponsible algae farming.

Open farming systems can disrupt ecosystems and have low productivity (0.06–0.231 g/L/day) [

90,

91].

The analysis makes it clear that future progress will depend on the ability to reduce costs through technological innovation and adaptation to the regulatory framework, while exploiting niches where biodiesel has comparative advantages.

3.1.2. AHP Analysis

Step 1: Defining a pairwise comparison matrix for the main SWOT categories (

Table 7).

Explanation of comparisons:

Threats vs. strengths = 7—The high ratio is due to the discontinuation of diesel vehicle production (Volkswagen, Volvo) and traffic bans in some cities (Paris, Amsterdam).

Weaknesses vs. strengths = 3—Technical limitations in engines are considered three times more important than the environmental benefits of algae-based biodiesel.

Opportunities vs. strengths = 3—The potential in heavy transport outweighs the strength in emission reduction.

Step 2: Defining the normalised matrix (

Table 8). To do this, we must first sum the column members and then divide each column member by the column sum. For example, the sum of the members of the “Threats” column is 1 + 0.5 + 0.5 + 0.1429 = 2.1429. The normalised value of this member is 1/2.1429 = 0.4667. The amounts for the other categories are calculated in the same way.

Step 3: Defining the priority vector (

Table 9). It is calculated as the average of the row element values in the normalised matrix.

Step 4: Consistency check.

The consistency vector is calculated as the ratio of the weighted sum to the priority vector (Weighted sum = Original matrix × Priority vector). See

Table 10.

Lambda max:

λmax = (4.064 + 4.079 + 4.079 + 4.027)/4 = 4.062.

Consistency index (CI):

CI = (λmax − n)/(n − 1) = (4.062 − 4)/3 = 0.021.

Consistency ratio (CR) with RI = 0.9 acc.

Table 1:

CR = CI/RI = 0.021/0.9 = 0.023, CR = 2.3% < 10% → The matrix is consistent.

The key influences on weighting are as follows:

Cessation of diesel vehicle production—major manufacturers (e.g., Volkswagen) are planning full electrification by 2030.

Traffic bans in cities—London and Berlin have banned diesel vehicles in city centres until 2025.

Growing share of hybrid vehicles—hybrid vehicles account for 40% of new registrations in the EU (2025).

We repeated the procedure according to steps 1, 2, 3, and 4 for each of the SWOT categories. Below you will find the results of the analysis for each of the categories (

Table 11,

Table 12,

Table 13,

Table 14,

Table 15,

Table 16,

Table 17 and

Table 18). First, let us define the criteria for the threats category:

T1: Competition with EVs;

T2: Regulatory constraints;

T3: Cessation of diesel vehicle production;

T4: Unstable prices for raw materials.

Table 11.

Pairwise comparison matrix for “threats” category.

Table 11.

Pairwise comparison matrix for “threats” category.

| | T1 | T2 | T3 | T4 |

|---|

| T1 | 1 | 2 | 3 | 5 |

| T2 | 1/2 | 1 | 2 | 3 |

| T3 | 1/3 | 1/2 | 1 | 2 |

| T4 | 1/5 | 1/3 | 1/2 | 1 |

The previously calculated global weighting for threats was 47.2%. The global weighting of the criteria results from the multiplication of the global weighting of the category and the local weighting of the criteria.

Table 12.

Local and global weights of the criteria for the “threats” category.

Table 12.

Local and global weights of the criteria for the “threats” category.

| | Local Weight | Global Weighting | Explanation |

|---|

| T1 | 47.6% | 22.5% | BEVs will account for 40% of the EU market by 2030. |

| T2 | 26.9% | 12.7% | The EU bans biodiesel made from crops that threaten food security. |

| T3 | 15.5% | 7.3% | Volkswagen and Volvo will stop producing diesel cars by 2030. |

| T4 | 8.7% | 4.1% | Fluctuations in the prices of chemicals for algae cultivation (±25% per year). |

Manufacturers such as Volkswagen, Volvo, and Mercedes plan a complete transition to electric vehicles by 2030.

Example: Volkswagen’s “Electric First” strategy includes ending diesel engine production in Europe by 2026.

The next category is weaknesses. The criteria in this category are as follows:

W1: High operating costs;

W2: Lack of commercially viable large-scale production;

W3: Technical issues with the fuel (oxidation, sedimentation, high viscosity);

W4: Potential negative environmental impacts (increased NOx emissions, wastewater pollution).

Table 13.

Pairwise comparison matrix for “weaknesses” category.

Table 13.

Pairwise comparison matrix for “weaknesses” category.

| | W1 | W2 | W3 | W4 |

|---|

| W1 | 1 | 1/3 | 2 | 3 |

| W2 | 3 | 1 | 5 | 7 |

| W3 | 1/2 | 1/5 | 1 | 2 |

| W4 | 1/3 | 1/7 | 1/2 | 1 |

Table 14.

Local and global weights of the criteria for the “weaknesses” category.

Table 14.

Local and global weights of the criteria for the “weaknesses” category.

| | Local Weight | Global Weighting |

|---|

| W2 | 58.6% | 13.3% |

| W1 | 21.8% | 4.95% |

| W3 | 12.3% | 2.79% |

| W4 | 7.3% | 1.66% |

The global weighting for the weaknesses category is 22.7%.

The lack of commercial production remains the most important sub-criterion (58.6%) due to the following:

Strategic recommendations to address the lack of commercial production (13.3%) are as follows:

The next category is opportunities. The criteria in this category are as follows:

O1: Production of high-value co-products;

O2: Utilisation of waste streams;

O3: Expansion into niches inaccessible to BEVs;

O4: Technological innovations.

Table 15.

Pairwise comparison matrix for “opportunities” category.

Table 15.

Pairwise comparison matrix for “opportunities” category.

| | O1 | O2 | O3 | O4 |

|---|

| O1 | 1 | 5 | 3 | 8 |

| O2 | 1/5 | 1 | 0.5 | 2 |

| O3 | 1/3 | 2 | 1 | 3 |

| O4 | 1/8 | 1/2 | 1/3 | 1 |

Table 16.

Local and global weights of the criteria for the “opportunities” category.

Table 16.

Local and global weights of the criteria for the “opportunities” category.

| | Local Weight | Global Weighting |

|---|

| O1 | 59.6% | 22.7% × 59.6% = 13.5% |

| O2 | 12.1% | 22.7% × 21.4% = 4.86% |

| O3 | 21.4% | 22.7% × 12.1% = 2.75% |

| O4 | 6.9% | 22.7% × 6.9% = 1.57% |

The next category is strengths. The criteria in this category are as follows:

S1: High lipid yield;

S2: No requirement for agricultural land;

S3: Environmental benefits;

S4: Integrated circular production.

Table 17.

Pairwise comparison matrix for “strengths” category.

Table 17.

Pairwise comparison matrix for “strengths” category.

| | S1 | S2 | S3 | S4 |

|---|

| S1 | 1 | 5 | 8 | 5 |

| S2 | 1/5 | 1 | 2 | 1 |

| S3 | 1/8 | 1/2 | 1 | 1 |

| S4 | 1/5 | 1 | 1 | 1 |

Table 18.

Local and global weights of the criteria for the “strengths” category.

Table 18.

Local and global weights of the criteria for the “strengths” category.

| | Local Weight | Global Weighting |

|---|

| S1 | 65.4% | 7.3% × 65.4% = 4.77% |

| S2 | 13.9% | 7.3% × 13.9% = 1.01% |

| S3 | 8.9% | 7.3% × 11.8% = 0.86% |

| S4 | 11.8% | 7.3% × 8.9% = 0.65% |

4. Discussion

The noticeable and continuous growth in algal biodiesel production from 15–30 thousand tonnes in 2015 to an estimated 1700–2000 thousand tonnes in 2024 (

Table 2) speaks directly to the importance of factors O1 and S1. At the same time, the leading countries are increasing their investments and diversifying their approaches, so that the possibility of synergies with different sectors (waste utilisation, circular economy) is also supported by this trend (factors S4 and O3).

However, despite the growth, much of the production is still in the pilot phase, which exacerbates the weakness of W2 (lack of commercially viable large-scale production) and suggests that further technological and economic breakthroughs are needed before full commercialisation.

The trend of increasing lipid content in algae from 20–30% (2014) to up to 75% in hybrid strains in 2024 and the associated increase in biodiesel per tonne of biomass (

Table 3) is the result of the application of advanced technologies—genetic modification and process optimisation. These data support factor S1 (high efficiency of resources and raw materials) and strengthen the thesis about the possibilities of technological improvement and the development of high-quality by-products, which is emphasised by factors O1 and O4. At the same time,

Table 4 shows that the energy consumption per kilogramme of biodiesel has decreased from 120–150 MJ (2013) to 20 MJ (2023), with a forecast of 15–18 MJ in 2025. These improvements result from the introduction of new technologies such as hybrid PBR systems, nanomaterials, and AI process management. Despite this reduction in energy consumption for biodiesel production, less energy is required to produce conventional diesel (factor W1).

However, the challenges of scaling and capital investment remain, which means that the weaknesses W1, W2, and W4 are still relevant (high cost, technical complexity, and the higher price of biodiesel).

Table 5 shows a significant reduction in CO

2 emissions (from 25–30% to up to 90% for the latest technologies), an almost complete elimination of SO

2, and a significant reduction in NO

x and PM emissions. These results emphasise the importance of factor S3. In view of stricter legal requirements (e.g., bans, EU directives), the positive environmental properties of algae biodiesel are becoming a strategic advantage.

However, factors such as increasing competition from electric vehicles (BEVs) and regulatory restrictions (factors T1 and T2) remain a threat to the long-term sustainability and economic viability of algae biodiesel. This is evidenced by the increasing presence of BEVs in the market and the announcement of the discontinuation of the production of diesel vehicles, reducing the potential users of biodiesel.

Based on the previous analysis, five globally important AHP criteria can be identified (

Table 19).

Based on the data from

Table 2,

Table 3,

Table 4,

Table 5 and

Table 6 and the prioritisation where the AHP methodology highlights competition from BEVs (T1), by-products and sustainability (O1), commercial viability (W2), and regulatory constraints (T2) as key factors, the following can be concluded:

Technological progress and growing production significantly strengthen the long-term opportunities and benefits.

The main barriers remain market uncertainties, the high price of algae biodiesel, and regulatory pressure, which is closely linked to the trends towards the electrification of transport.

The integration of algae biodiesel into the circular economy and innovation offers the best scenario to overcome the identified weaknesses and threats.

4.1. Sensitivity Analysis

Let us assume that the sensitivity of the AHP model presented depends primarily on the evaluation of the influencing factors of the main SWOT categories, since the local weighting factors are multiplied by the weighting factors of the main categories. For this purpose, two further scenarios were analysed in addition to the presented Scenario 1 (which could be described as pessimistic to a certain extent). In Scenario 2, all influencing factors are equally important (optimistic scenario), and in Scenario 3 (slightly optimistic), slightly less importance is attached to threats and opportunities and greater importance to strengths and weaknesses. The pairwise comparison matrices and weightings for scenarios 2 and 3 can be found in

Table 20 and

Table 21.

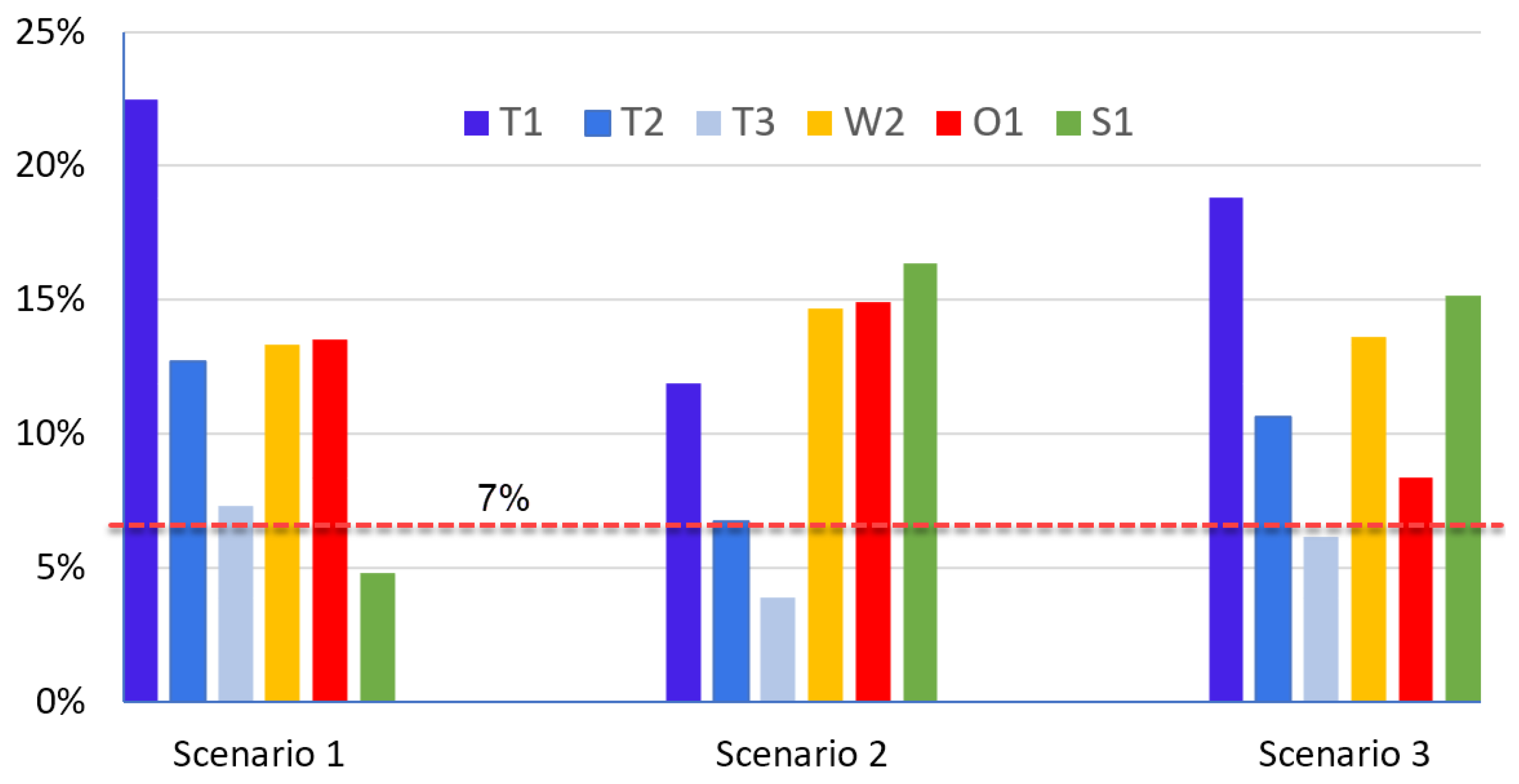

The most influential factors according to the global weightings for all three scenarios are shown graphically in

Figure 2.

It is easy to see from

Figure 2 that in all three scenarios, T1, T2, W2, and O1 are among the five most influential factors (above line 7%). In Scenario 2 and Scenario 3, the factor S1 is among the five most influential factors instead of factor T3.

This analysis leads to the conclusion that the authors’ subjectivity does not play a major role in determining the importance of the main SWOT categories. It also follows that factors T1 and W2 play a very important role in all three scenarios, which gives them strategic importance. On the other hand, the prioritisation of the factors within the categories can obviously be of great importance. In this context, analysing data from the literature relating to different aspects of the production and use of biodiesel from algae obviously plays an important role.

4.2. Strategic Priorities and Activities (According to AHP Weights)

The recommended priorities are as follows:

Investment in technologies to increase algae productivity.

Development of co-products for additional revenue.

Focus on niches where EVs are not competitive (maritime transport).

The recommended activities are as follows:

Reducing the impact of BEV competition.

Focus on the maritime and heavy transport sectors where BEVs are not competitive.

Development of hybrid systems that combine biodiesel with electric propulsion for smaller ships (e.g., diesel–electric hybrid ships).

Develop co-products for additional income. Produce proteins for aquaculture feed (price up to USD 15/kg). Produce omega-3 fatty acids (price up to USD 50/kg) with lipids extracted from algae.

The recommended cost optimisation strategies are as follows:

Use of genetically modified algae with lipid yields of over 80% (e.g., Botryococcus braunii).

Use of cheaper catalysts (e.g., Fe2O3 nanocatalyst) for transesterification.

5. Assessment of the Perspective of Biodiesel from Algae

Based on the SWOT-AHP analysis, the short- and long-term prospects of biodiesel from algae are assessed as follows.

5.1. Short-Term Perspectives (Until 2030)

Key trends are as follows:

- (a)

Market growth with technological innovations.

The global market for biodiesel from algae is expected to grow at a compound annual growth rate (CAGR) of 10.1% until 2030, with a focus on reducing production costs through the optimisation of photobioreactors and genetic engineering of algae [

40].

Application of integrated biorefineries for the production of co-products (e.g., food proteins, omega-3 acids) will reduce net production costs by 30–40% [

9,

39].

- (b)

Use of biodiesel from algae as an additive to fossil diesel (blending), which improves its ecological properties (reduction of PM, CO, and HC emissions). In their study, Gupta and Gangwar [

93] analyse the combustion, performance, and emission characteristics of algal biodiesel blends from B10 to B100 and conclude that B20 is the most optimal blend under different engine conditions due to its diesel-like combustion and performance characteristics and lower exhaust emissions.

- (c)

Focus on niches where BEVs have difficulty competing.

Biodiesel will be used in heavy road and maritime transportation where BEVs are not competitive. It is expected that by 2030, 15% of biodiesel in the EU will be destined for shipping [

40,

94].

- (d)

Regulatory support and subsidies.

The main challenges are as follows:

5.2. Long-Term Perspectives (Until 2050)

The key trends are as follows:

- (a)

Reduction in demand for traditional biodiesel.

The increase in BEV sales and the development of hydrogen technology will reduce the demand for biofuels in the EU by 50% by 2050 [

94].

Biodiesel from algae will only be relevant in niches for which BEVs are unsuitable (e.g., aviation, heavy road freight transport, maritime transport).

- (b)

Integration with the circular economy.

The production of biodiesel from algae will be based on the recycling of waste streams (CO

2 from industrial emissions, wastewater), which will reduce costs by 25–35% and improve sustainability [

9].

- (c)

Advances in synthetic biology.

Strategies for sustainable development are as follows:

- (a)

Combination of biodiesel production with high-value co-products.

Production of pharmaceutical ingredients (e.g., astaxanthin) and bioplastics could generate additional revenue of USD 15–25/kg, funding biodiesel development.

Algae-derived co-products like omega-3 fatty acids (up to USD 50/kg) and aquaculture proteins (up to USD 15/kg) enhance economic viability.

- (b)

Industry partnerships.

Collaboration with thermoelectric plants and municipal enterprises to utilise waste streams (e.g., CO2 emissions, wastewater) for algae cultivation.

Example: Algae systems can capture up to 80% of CO2 from power plants while producing biomass.

- (c)

Biomass conversion innovations.

Hydrothermal liquefaction (HTL) converts entire biomass into biofuel with 70–80% efficiency, reducing energy consumption.

High-pressure hydrogenation reactors improve reaction efficiency, enabling faster processing and higher yields (e.g., Fe2O3 nanocatalysts).

6. Conclusions

This study systematically evaluates the prospects of biodiesel production from algae as a sustainable energy source through a combination of SWOT analysis and the analytical hierarchy process (AHP). Algal biodiesel offers significant environmental benefits, including high lipid productivity, utilisation of uncultivable land, effective CO2 sequestration, and the potential for integration into circular economy models such as wastewater treatment. These strengths make algae a promising feedstock for renewable biofuels that could make a significant contribution to climate change mitigation and energy security.

Despite these advantages, however, there are also some limitations that stand in the way of widespread acceptance. The most pressing challenges are the current high production and operating costs, technical limitations in terms of fuel performance in conventional engines, insufficient production capacity at a commercial scale, and regulatory uncertainties. In addition, the market potential for algae biodiesel is further limited by strong competition from increasingly cost-efficient battery-powered electric vehicles and other renewable energy alternatives.

The AHP analysis categorises competition from battery electric vehicles and the lack of commercially viable large-scale production as the main factors influencing the future development of the sector. Opportunities such as the production of high-value by-products and the utilisation of waste streams to increase resource efficiency promise to improve the economic viability and sustainability of algae biodiesel.

The sensitivity analysis shows that the influence of subjectivity in the quantification of the influencing factors of the AHP method is not large.

Short-term forecasts (up to 2030) indicate increasing market growth focussed on niche sectors—such as heavy-duty transport and maritime applications—where electrification is reaching its limits. In these areas, blending algal biodiesel with fossil fuels can bring environmental benefits while maintaining operational feasibility.

In the long term (2050), algae-based biodiesel is likely to be particularly important in specialised sectors integrated into circular economy systems, supported by advances in genetic engineering, photobioreactor technologies, and innovations in biomass conversion.

To achieve these results, strategic investments are needed to increase algal productivity, reduce production costs, develop markets for high-value by-products, and foster partnerships with industry. Regulatory frameworks should also be adapted to incentivise renewable liquid fuels that complement electrification, especially in the hard-to-decarbonise transport sectors.

To summarise, although algal biodiesel currently still faces significant economic and technological hurdles, it can nevertheless make a promising contribution to a diversified and sustainable energy portfolio. Future research and policy efforts focussed on overcoming these challenges will be crucial to fully unlock the potential of algae as a biofuel feedstock.