Abstract

Solar panels are an environmentally friendly alternative to fossil fuels; however, their useful life is limited to approximately 25 years, after which they become a waste management issue. Proper management and recycling of end-of-life (EOL) solar panels are paramount. It protects the environment because of the high energy consumption of silicon production. We can effectively decrease energy and cost requirements by recovering silicon from recycled solar panels. This is one-third of those needed for manufacturing silicon directly. Moreover, solar panels include heavy metals, such as lead, tin, and cadmium, which pose risks to human health and the environment. Empirical evidence suggests that the costs of mining materials can exceed those of recycled materials, thereby making recycling a more cost-effective means of resource harvesting. This review paper focuses on the techniques developed to delaminate solar panels, which are considered a crucial step in the recycling of EOL solar panels. Initially, various classifications of solar panels are given. Subsequently, an analysis of the diverse methods of solar panel delamination and their efficacy in the retrieval of valued materials is presented. This investigation has identified three primary modes of delamination, namely mechanical, thermal, and chemical. Among these, mechanical delamination is deemed to be a sustainable and cost-effective option when compared to thermal and chemical delamination. The current most popular method of thermal delamination is characterized by its high energy consumption and potential emission, and the chemical delamination generates hazardous liquids that pose their own threat to the environment. This study emphasizes the mechanical delamination techniques, characterized by their environmentally friendly nature, minimal ecological footprint, and capacity to retrieve entire glass panels intact. This paper also discusses the current gaps and potential enhancements for mechanical delamination techniques. For example, some delamination techniques result in crushed materials. Thus, the handling and recovery of materials such as glass and silicon cells require the implementation of an appropriate sorting technique. Also, the value obtained from recovering crushed materials is lower than that of intact glass and silicon cells.

1. Introduction

There is currently an increasing focus on the greenhouse gases being released into the atmosphere, underscoring the need for renewable energies. Solar panels assume a pivotal role as a substitute for fossil fuel-based energy generation [1]. However, the environment is still susceptible to the adverse effects of the disposal of waste solar panels. The end-of-life (EOL) solar panels are expected to make a significant contribution to the accumulation of environmentally hazardous materials. This underscores the importance of recycling EOL solar panels. Researchers have considered decreasing the harmful effects of recycling them, designing an economical method to recycle them, and increasing the metal enrichment rate to manage EOL solar panels sustainably. Si is one of the raw materials that can be provided by recycling EOL solar panels to be used in other industries. The lowest environmental harm, energy consumption, and waste minimization are crucial criteria in selecting effective methods for recycling solar panels [2]. Solar radiation as a renewable energy source is critical in reducing carbon emissions during power generation. The solar panel market capacity was the fastest growing industry in 2021, which has grown 850 GWs. However, cumulative EOL solar panels will account for 10% of the total electrical and electronic equipment (WEEE) generation in 2050, which will require recycling. The solar and semiconductor industries can benefit from recycling rare metals from EOL solar panels. Recycling EOL solar panels is a sustainable option because the energy required for recycling is much less than the production energy. The EOL solar panels contain heavy metals, which can pose risks to human health and the environment, so recycling and recovering heavy metals are critical subjects [3].

Considerable efforts have been devoted to the management of EOL solar panels with various techniques, such as panel repairing, module separation, and silicon and rare metal material recovery. A key stage of the EOL solar panel recycling is delamination, whereby the junction box, cables, and aluminum frames are removed, and the EVA/cell/backsheet is delaminated, resulting in metal enrichment. Subsequently, the copper cables and EVA/cell/backsheet can be subjected to individual recycling processes to recover copper and silver. Ultimately, the metal enrichment can be recycled to retrieve elements such as silicon, cadmium, selenium, tellurium, gallium, molybdenum, and indium [4]. Figure 1 shows a deframed EOL solar panel (left) and a partially delaminated solar panel (right).

Figure 1.

The solar panel situated on the left-hand side has reached its end of life, while the solar panel located on the right-hand side has undergone partial delamination.

We have furnished a comprehensive table, Table 1, comprising abbreviations of professional terms that can prove to be beneficial in comprehending the text.

Table 1.

Professional terms and their abbreviations.

There exist several excellent review articles in the literature covering different aspects of recycling of solar panels through delamination [5,6]. These papers give a great overview of the recycling of PV modules, the energy consumption of these recycling processes, and the environmental effects of different recycling methods. These papers, however, do not discuss the different types of solar panels and each delamination method in detail.

Mulazzani et al. [5] examined only c-Si solar panels, the recycling of PV modules, and the energy consumption of these recycling processes, and they did not discuss each delamination technique in detail. However, we discussed the different types of solar panels and each method in detail. Hasan et al. [7] discussed the environmental effects of different recycling methods for c-Si and CdTe, and briefly examined the delamination of solar panels. However, we provided a more comprehensive insight into the delamination techniques and covered eco-friendliness and economic aspects. Wang et al. [6] examined only c-Si solar panels, the recycling of PV modules, and the energy consumption of these recycling processes, and they did not discuss each delamination technique in detail. However, we discussed the different types of solar panels and each method in detail.

This paper, on the other hand, covers an up-to-date review of the process of EOL solar panel delamination, the associated environmental impacts, sustainability considerations, relevant policies, and details of each method. Great efforts are dedicated to the extraction of particular materials, such as glass, silicon, or rare metals [4,8]. The present paper investigates the management of EOL solar panels and scrutinizes the methodologies employed for their retrieval. Apart from benefiting researchers and the industry, this information can also assist policymakers, enabling them to effectively regulate the recycling of waste solar panels [4].

Investigating the delamination process in the recycling of EOL solar panels is of high importance as it serves as the initial step in the extraction of materials from such panels. The efficacy of this step can significantly impact the efficiency of the overall recycling process. This literature review paper aims to examine the various types of solar panels, evaluate the advantages and disadvantages of the latest delamination techniques, analyze their ecological impact, assess the costs involved, and determine the efficiencies in recovering materials.

2. Types of Solar Panels

The performance of solar (photovoltaic) panels is subject to the variation in their classifications, namely crystalline silicon, thin film, concentrator photovoltaics, and emerging technologies.

2.1. Crystalline Silicon (c-Si) Solar Panels

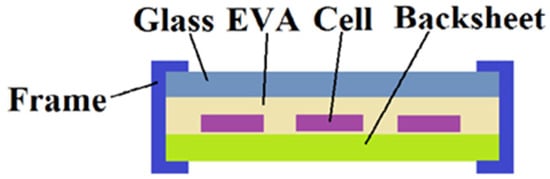

The dominant variety of solar panels is the crystalline silicon solar panels, which account for approximately 85% of the total of solar panels in use. These panels are composed of multiple layers, as depicted in Figure 2. The layers encompass glass, ethyl vinyl acetate (EVA), electrical contacts (comprising copper and silver), silicon cells (either monocrystalline or polycrystalline), aluminum frames, a junction box, and a backsheet [9].

Figure 2.

Structure of crystalline silicon solar panels.

Aluminum frames serve as a protective barrier for the various components of the solar panels while also exhibiting excellent conductivity. Furthermore, these frames offer protection against lightning strikes during thunderstorms. The junction box facilitates the conduction of electricity to the exterior, and electrical cables are utilized to connect solar panels in a series configuration. The backsheets of a solar panel serve as the outermost layer and act as the primary barrier for safeguarding the solar cells. Their pivotal function is shielding the solar panels against the detrimental effects of fluctuating environmental conditions throughout their operational lifespan. EVA, or ethylene vinyl acetate, is a thermoplastic polymer that exhibits favorable characteristics, such as high radiation transmission and low susceptibility to degradation from sunlight. Its application as an encapsulating agent in solar modules is attributed to its ability to form a sealing and insulating film around the solar cells upon exposure to heat. The encapsulation of solar cells by the EVA binder is a challenge in the recovery of the solar panel materials given the high cost of silicon wafers. The EVA binder serves to bind the backsheet, solar cells, and glass together. Tempered glass, utilized as a protective layer for solar panels, functions to safeguard the photovoltaic cells from the detrimental effects of environmental factors such as vapors, water, and dirt [10].

The production of electronic devices that incorporate silicon wafers, like crystalline solar cells, has relied on monocrystalline silicon. This material is typically of high purity, although it may contain trace amounts of other elements that serve to modify its semiconducting properties. The Czochralski process is the primary method employed for the growth of monocrystalline silicon, yielding specimens that are typically several hundred kilograms in weight and up to 2 m in length. These specimens are subsequently sliced into thin, delicate wafers. The majority of solar cells in the photovoltaic market are polycrystalline, which are typically produced using the Siemens process. This process has broad applications across various sectors of the electronics industry [11].

Glass/backsheet PV modules have been the established norm in the industry for a considerable period. However, there is a noticeable surge in the popularity of glass/glass modules because they are a potential solution for cost reduction in PV panels. The glass/glass structure can increase energy yield by utilizing albedo (scattered light from the ground and surroundings) in real-world outdoor conditions. In other words, they can generate more electrical power by absorbing photons from both sides of the device [12,13].

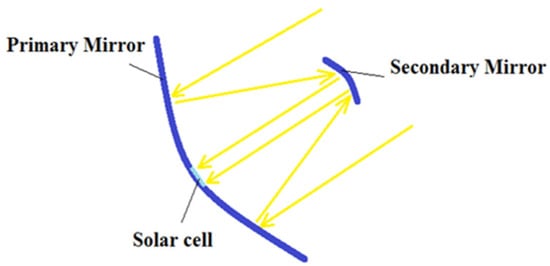

Concentrated photovoltaic (CPV) panels are another type of c-Si solar panel that utilize lenses and curved mirrors to concentrate sunlight into small areas, and their efficiency can be improved through the implementation of a cooling system. The CPV structure illustrated in Figure 3 represents a primary mirror that reflects light towards a secondary mirror, which in turn concentrates the light towards a solar cell. Technological advancements have led to an increase in the efficiency of CPV panels. However, these panels have yet to achieve widespread adoption in comparison to the crystalline silicon solar panels [11].

Figure 3.

CPV structure.

2.2. Thin-Film Solar Panels

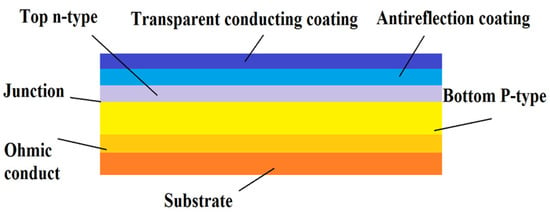

Thin-film solar cells are a type of photovoltaic technology that involves the deposition of thin layers onto a substrate, such as glass, metal, or plastic. The structure of a thin-film solar panel is depicted in Figure 4, which includes various layers, such as the transparent conducting coating, anti-reflection coating, top n-type, bottom P-type, ohmic conduct, and substrate. These layers can be produced using different technologies, including amorphous silicon, cadmium telluride (CdTe), and copper indium gallium selenide (CIGS), with layer thicknesses ranging from several nanometers to several micrometers. Compared to crystalline silicon solar cells, thin-film solar cells are lighter. The thickness of the thin-film solar panels ranges from a few nanometers (nm) to tens of micrometers (μm) [11]. Thin-film solar cells offer a significant benefit in terms of cost-effective production. By utilizing large-area deposition techniques with affordable materials, the manufacturing cost of the solar modules is reduced [14]. The compound annual growth rate (CAGR) of thin-film solar modules has exhibited a gradual decrease from 13% in 2010 to 4.5% in 2019. Among the various types of thin-film solar modules, CdTe has consistently maintained the highest share of production [15]. Copper indium gallium selenide (CIGS) and cadmium telluride (CdTe) are poised to assume significant roles in the realm of thin-film technology. These materials are expected to exhibit efficiencies that are comparable to those of crystalline solar cells. Given the increasing module efficiency of these two thin-film technologies, their market share is expected to expand in the coming years, as long as the production cost remains lower than that of crystalline Si. However, the reliability of these technologies in relation to temperature poses a concern. Furthermore, the availability of materials may play a crucial role in determining which technologies will dominate the majority of the PV demand in the future [16]. The copper indium selenium or copper indium gallium selenium CI(G)Se-based thin-film solar cells (TFSCs) have garnered significant interest in the photovoltaic industry. This is primarily due to their ability to achieve high efficiency levels in solar cells and modules, all while maintaining a relatively low cost. The optimized efficiencies for CISe, CIGSe, and CIGSe bilayer TFSCs were 22.81%, 27.32%, and 27.99%, respectively [17].

Figure 4.

Structure of thin-film solar panels.

2.3. Emerging Solar Panels

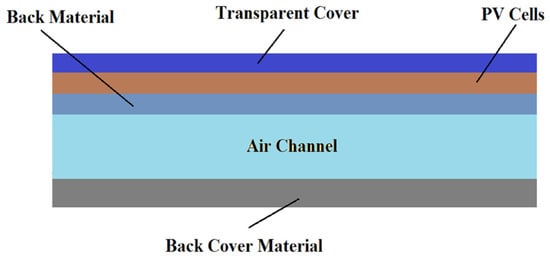

The dye-sensitized solar cells (DSSC) represent a third-generation technology capable of generating electricity from both natural and synthetic light sources. While DSSC are less expensive than crystalline silicon solar panels, their efficiency in converting light into electricity is inferior. Additionally, the recycling of rare metals such as platinum and ruthenium that are present in DSSC poses a significant challenge [11]. Organic solar panels as emerging solar panels applied onto polyethylene terephthalate (PET) substrates are a viable option. Despite their lower efficiency in comparison to crystalline silicon solar panels, they possess the advantage of being able to be installed on non-uniform surfaces [18]. Hybrid solar panels possess the unique ability to generate both electrical and thermal power. In comparison to crystalline silicon solar panels, they exhibit a superior electrical performance of approximately 7%. This enhanced electrical output is attributed to the production and transfer of thermal power, which results in lower temperatures of the photovoltaic (PV) cells. Hybrid solar panels can be classified as either air-based or liquid-based. The structure of an air-based hybrid solar panel is depicted in Figure 5, comprising a transparent cover, PV cells, back material, air channel, and back cover material [19].

Figure 5.

Air-based hybrid solar panel structure.

3. Delamination Techniques

The delamination of a solar panel refers to the separation of its internal components. Delamination can be classified into three primary categories: mechanical delamination, thermal delamination, and chemical delamination.

3.1. Mechanical Delamination

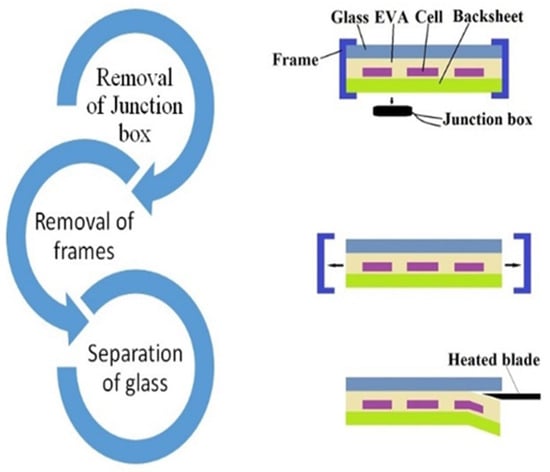

Mechanical delamination is a common method used to separate the various components of EOL solar panels. This process typically involves the removal of the junction box and frames and separation of the glass from the backsheet/EVA/cell. A popular mechanical technique used for delaminating EOL solar panels is the hot-knife technology, which involves three steps. First, the junction box is removed, followed by the removal of the aluminum frames. Finally, the glass and EVA/cell/backsheet are separated by specific types of machines and heated blades. Specific machines are employed for each step of the delamination process. The hot-knife delamination technology is a critical stage of the recycling process. In the nest stage, the copper cables and the laminate, comprising the cell and ethylene vinyl acetate (EVA) backsheet, are vendored to an external recycling facility, commonly referred to as a refinery. At this facility, the EVA plastic is incinerated, allowing for the retrieval of copper and silver. The disassembly and delamination process encompasses economical treatment service, material recovery, and component extraction. Increasing the transportation distance of EOL solar panels from refineries can lead to a substantial increase of 60% to 90% in affecting the environment, so the logistics of the EOL solar panels are significant in the environmental effect of the delamination process. Module delamination, which refers to the separation of glass and EVA components, is shown in Figure 6. Although various types of machines have been used for delaminating distorted EOL solar panels, the efficiency of this technique remains a challenge [20]. Figure 7 illustrates the delamination process through the utilization of the hot-knife technique.

Figure 6.

Module delamination involves glass and EVA separating equipment (Photo courtesy of NPC Incorporated) [20].

Figure 7.

Delamination process by the hot-knife technique.

The complete procedure for the disposal of EOL solar panels is accomplished through mechanical means. Initially, the electrical components, such as cables and junction boxes, are manually extracted. Subsequently, the expander machine is employed to separate the frame, followed by the utilization of the shearing machine to cut the panel into 100 × 100 mm2 fragments [21]. Despite the notable environmental advantages, the economic aspect of the method was not addressed in their discussion.

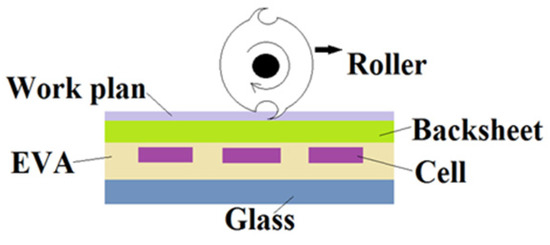

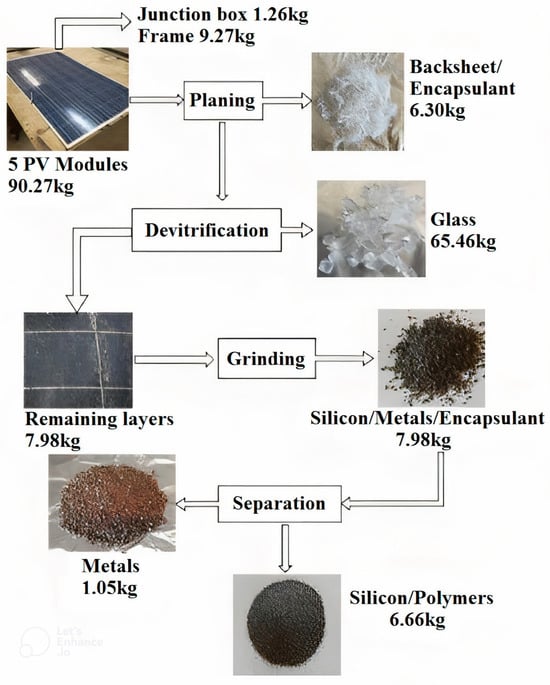

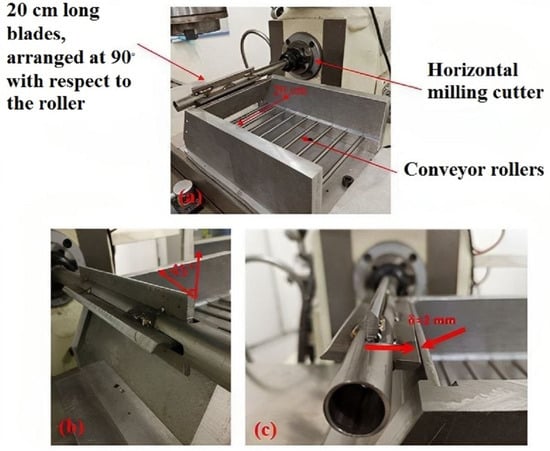

In recent times, efforts have been made to segregate glass and EVA, as depicted in Figure 8. A pioneering mechanical approach has been suggested for the recycling of solar panels, which involves surface delamination, grinding, and densimetric recycling. This innovative technology is characterized by lower energy consumption and reduced environmental impact. The glass is claimed to be retrieved in substantial fragments with a high degree of purity (99%wt), thereby generating minimal dust and environmental harm. According to evaluations, this technique has the potential to retrieve materials with superior purity levels in comparison to the conventional process. The block diagram in Figure 9 describes the processes of surface delamination, grinding, and densimetric recycling used to manage photovoltaic (PV) modules that have reached their end of life. The specifications of the devitrifying machine depicted in Figure 10 include a horizontal cutter and conveyor rollers, the blade profile set at 45 degrees, and the distance between the roller blades and the inclined stator set at 2 mm [22]. However, there are significant environmental and economic advantages, like producing less dust, low energy expenditure for grinding, and low loss of materials, respectively, but they did not discuss the metal enrichment rate, which is important for the next stages of recycling.

Figure 8.

A side view of the surface delamination, grinding, and densimetric recycling technique.

Figure 9.

Management of photovoltaic (PV) solar panels that have reached their end of life [22].

Figure 10.

Specifications of the devitrifying machine. (a) A horizontal cutter and conveyor rollers. (b) Blade profile set at 45 degrees. (c) Distance between the roller blades and the inclined stator is 2 mm [22].

The utilization of hot-knife technology has been found to be effective in the recovery of glass with a remarkably high degree of purity, reaching up to 100%, and it has been observed that this process results in a reduction in CO2 emissions [23].

In the study conducted by [24], a water jet technology was employed to recover solar panel materials. The application of water jet technology for silicon and EVA scrubbing leads to the preservation of glass. Subsequently, a crushed amalgamation of silicon and EVA was subjected to processing to facilitate the retrieval of pure materials and rare metals.

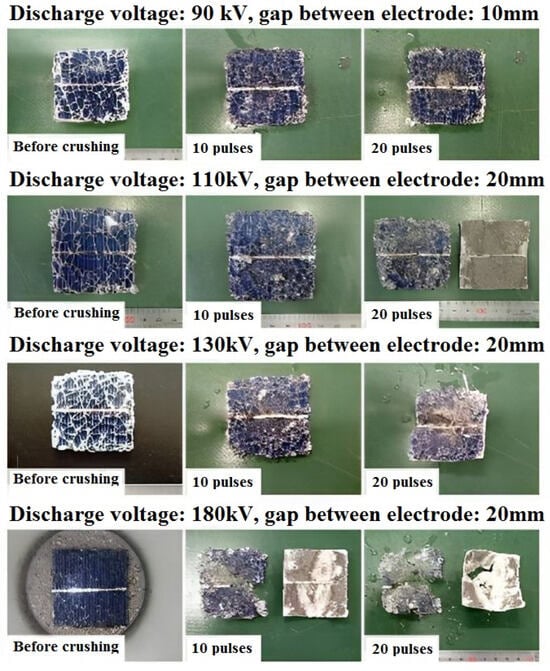

Another study proposed a method for recycling EOL solar panels utilizing a combination of two rotor crushing and hammer crushing. The objective of the study was to achieve high purity and recovery rates. To this end, thermal treatment was employed for coarse fractions with a diameter higher than 1mm subsequent to the initial crushing process using two blade rotors and hammers. The coarse fractions were then subjected to a specific sieve with a diameter of 0.08 mm. The proposed method resulted in the recovery of 80–85% of glass with high purity [25]. However, there are significant environmental and economic advantages, like a significant reduction of energy and chemical consumption as well as a reduction in equipment size, but they did not discuss the metal enrichment rate, which is important in the next stages of recycling. The high-voltage pulse crushing method presents a viable option for the recovery of glass. The process involves the application of microexplosions or shock waves to the aluminum electrode and silicon substrate, which effectively separates the glass and backsheet layers. Subsequently, a high-voltage pulse is applied to the glass layer, resulting in the separation of the glass and electrode. Further application of high-voltage pulses can facilitate the separation of the electrodes and backsheet. The resulting glass fractions typically range between 45 and 850 μm with a minor impurity of Si that can be eliminated through dense medium separation. The products derived from the initial stage of high-voltage pulse crushing under different conditions are depicted in Figure 11 [26]. They could recover glass with small impurities of Si that can be removed by dense medium separation, but they did not discuss the economic and environmental aspects.

Figure 11.

The products derived from the initial stage of high-voltage pulse crushing are subject to diverse conditions [26].

Glass can be mechanically separated in addition to other methods. Once the electrical components have been separated and fragmented into smaller pieces by the Expander machine, they are subsequently transported to another machine for grinding and sifting. To optimize the recycling process of glass, an optical micro-sorting machine is utilized for further refinement [21]. The full recovery end of life photovoltaic (FRELP) method involves the utilization of a vibrating knife and infrared lamp to effectively separate glass and EVA [2].

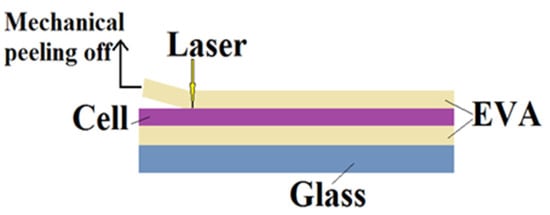

The backsheet/EVA/cell separation process can be effectively executed through the utilization of hot-knife technology, which is facilitated by specialized machinery [20]. Chemical dissolution and pyrolysis have been found to be ineffective methods for recycling EVA due to their negative impact on the environment. To address this issue, a novel approach involving laser irradiation has been proposed. This method involves the removal of the junction box, aluminum frame, and backsheet, followed by the application of laser radiation. The aluminum and silver electrodes present in the EVA absorb the pulsed energy from the laser, leading to an increase in the temperature of the EVA/cell. This increase in temperature results in a weakening of the adhesive strength at the back of the EVA [27]. The delamination induced by laser irradiation has been visually demonstrated in Figure 12.

Figure 12.

Delamination via laser irradiation.

Another study proposes a novel method for separating polymeric and metallic contents, namely the crush and sieve technique, which offers a viable alternative to pyrolysis. This technique enables the production of metal-rich fractions through size selection while minimizing the environmental impact. Specifically, four distinct particles of varying size and composition were selected using size-selective separation, and their properties were investigated to enhance the efficiency of the recovery process and promote eco-friendly solutions [28].

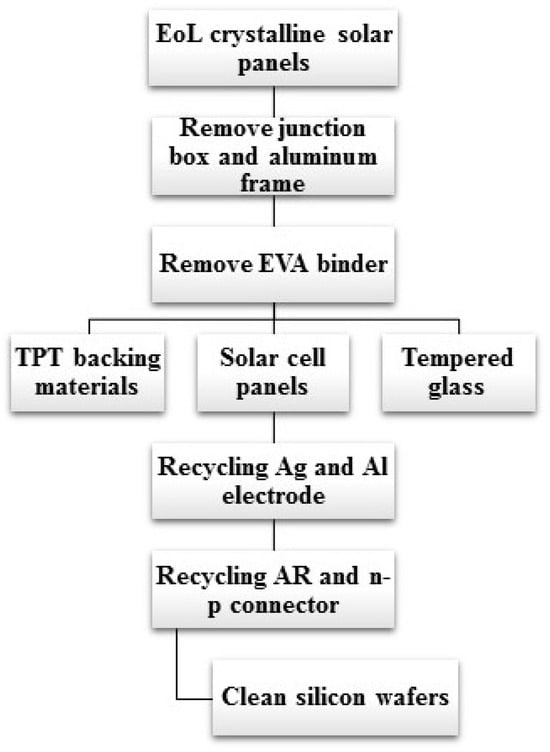

3.2. Thermal Delamination

The recycling process for EOL solar panels is shown in Figure 13. The presented flowchart shows the sequential steps involved in the recycling process of crystalline silicon solar panels. First, the junction box and aluminum frame are separated. Subsequently, the EVA binder is removed, followed by the elimination of the tedlar polyester tedlar (TPT) backing materials, solar cell panels, and tempered glass. The electrodes of silver and aluminum are recycled, and the anti-reflection (AR) coating and n-p connector are removed. The clean silicon wafers can then be extracted. Pyrolysis is employed to enhance the efficiency of the recycling process. For instance, a two-step thermal method has been proposed to recycle waste crystalline silicon solar panels. The backsheet was removed by heating at 150 °C for 5 min, and the EVA binder was eliminated by heating at 500 °C. This method has been found to reduce the production of toxic gases, such as fluorinated gases [10]. This method decreased the production of toxic gases like fluorinated gases, but they did not discuss the economic aspect, which is critical in thermal methods.

Figure 13.

Recycling procedure for EOL solar panel [10].

In present times, the recycling of solar panels has become a complex process due to the thinness of solar cells, which poses a significant challenge in the recovery of silicon and metals from glass. However, combinational methods have emerged as a potential solution to these difficulties. The recycling of thin-film solar panels can be achieved through mechanical, thermal, and chemical processes. Initially, the elimination of the junction box and aluminum frame is necessary. Subsequently, the backsheet is removed at a temperature of 100 °C, followed by the removal of EVA at 130 °C using mechanical force. Finally, the remaining materials are cut into small pieces using a diamond cutter, and chemical solvents are employed to recover rare metals [3].

The solvothermal swelling with thermal decomposition (SSTD) technique has been proposed as a means of improving the efficacy of silicon recovery. This method has yielded a silicon recovery rate of 86.11%, which is ten times greater than that achieved through the use of thermal methods alone. The recovery of backsheets has been accomplished through the use of toluene–ethanol [29]. They could recover 86.11% of Si, but they did not discuss the economic and environmental aspects. The implementation of an eco-sustainable approach for the management of end-of-life photovoltaic (PV) modules is of utmost importance. The utilization of heat treatment for Si-PV modules has demonstrated the ability to recover glass. This process has been carried out in a two-step procedure at a temperature of 500 °C, resulting in the successful removal of backsheet polymers without the generation of hazardous fluorinated compounds or low volatile organic compounds [30]. The pyrolytic elimination of EVA has been the subject of investigation, revealing a polymer recovery rate of 99% at a temperature of 500 °C. Through the utilization of thermogravimetric analysis (TGA), it has been demonstrated that the optimal temperature for this process is approximately 500 °C [31]. They could recover 99% of polymers at 500 °C, but they did not discuss the economic and environmental aspects. The elevation of temperature has been observed to have a negative impact on the duration of the recycling process. This phenomenon is exemplified by the fact that the recycling process, when conducted at a temperature of 500 °C, requires 65 min to complete, whereas at 600 °C, the process is completed in 30 min. It is noteworthy that the quality of performance remains consistent across both temperature conditions. Furthermore, it has been found that the removal of the backsheet prior to the thermal process can result in a reduction in the procedure time by approximately 45% [32].

A mechanical/thermal approach has been proposed to effectively isolate polymers and rare metals. Initially, a mechanical technique is employed to eliminate fluorinated polymers. Subsequently, the thermal technique is utilized to completely separate rare metals from the remaining polymers. This methodology is characterized by its energy efficiency and minimal environmental impact [33]. This method has less harmful effects on the environment and is energy-efficient, but they did not discuss the metal enrichment rate, which is important for the next recycling stages. Hydrothermal methodologies have the potential to be employed for the purpose of recycling. In particular, a composite of glucose and phosphate, subjected to a temperature of 190 °C for a duration of ten hours, has been successfully employed for the recycling of end-of-life solar panels [34]. The elimination of EVA was achieved through a heating process at a temperature of 650 °C for a duration of 30 min within a furnace. Subsequently, a solution of hydrofluoric acid (HF) and nitric acid (HNO3) was employed to facilitate the separation of silicon and metals [35].

3.3. Chemical Delamination

Recycling procedures that enable the retrieval of photovoltaic cells without incurring damage are currently available with the aim of mitigating carbon emissions and reducing the production costs of new solar panels. The utilization of organic solvents presents a promising avenue towards achieving this objective. Specifically, hexane, an organic solvent, has been employed to recover silicon photovoltaics with minimal damage. The efficacy of pure hexane in dissolving EVA has been demonstrated. Furthermore, X-ray diffraction (XRD) analysis has indicated that hexane does not cause damage to the front surface of photovoltaic cells [36]. The utilization of trichloroethylene in conjunction with microwave recycling of EOL solar panels has been found to accelerate the separation of distinct layers. This approach offers a more environmentally friendly alternative as it minimizes the impact on the ecosystem [37]. The environment is less affected by this technique, but they did not discuss the economic aspect.

O-dichlorobenzene is an organic solvent that exhibits high efficiency in the recovery of photovoltaic cells. The ultrasonic irradiation technique can be employed to dissolve the EVA entirely using this solvent. Conversely, trichloroethylene (TCE) and benzene exhibit poor efficiency in dissolving EVA, and an increase in temperature results in a decrease in the dissolving rate [38]. Photovoltaic cells have been recovered with high efficiency, and the entire EVA has been dissolved, but they did not discuss the economic and environmental aspects. The utilization of ScCO2 in conjunction with toluene has been found to be effective in the recovery of foil, glass, and rare metals with a notable degree of purity, estimated to be approximately 96%. Furthermore, the recovery rate of EVA and solar cells was observed to be approximately 85% [39]. This method can recover back foil, glass, and rare metals with a high purity of approximately 96%, and the recovery rate of EVA and solar cells was approximately 85%, but they did not discuss the economic and environmental aspects. Upon recovery of Si, it has been observed that the utilization of a KOH–ethanol solution is a more ecologically sound alternative to the use of benzene and trichloroethylene. The process of Si recovery can be accomplished within a span of three hours with the added benefit of a regulated oxidation rate [40].

The complete dissolution of EVA can be achieved within a span of 60 min by employing a toluene solvent at a temperature of 60 °C [41]. The separation of glass, silicon, and EVA from EOL solar panels can be achieved through the utilization of an acetone solvent. Furthermore, the dissolution of wafers can be accomplished by employing solvents such as nitric acid. The incorporation of oxalate has been shown to facilitate the recovery of Cu with a reported efficiency of 98.9%. Additionally, the recovery of Al can be achieved by introducing glucose and phosphate at a temperature of 190 °C for a duration of ten hours [34]. They could recover 98.9% of Cu. Al, but they did not discuss the economic and environmental aspects. Transparent conducting oxides (TCOs) have been widely employed as electrode materials in the fabrication of thin-film photovoltaic (PV) panels. The separation of glass and TCO is typically achieved through the use of 1 M NaOH and 1 M KOH solutions [3]. They could separate glass and TCO effectively, but they did not discuss the economic and environmental aspects. At a temperature of 50 °C, a cyclohexane solvent was employed to separate ethylene-vinyl acetate (EVA) and glass for a duration of one hour. The recovery rate of glass was determined to be 52 wt% [42]. They could separate EVA and glass effectively, but they did not discuss the economic and environmental aspects, and the recovery rate of glass is low.

4. Discussion

The disposal of EOL solar panels poses a significant environmental concern due to the potential for the waste to cause harm to the environment. However, the solar panel waste contains valuable materials that can be reused to reduce the cost of producing new solar panels and other products. Therefore, the recycling of EOL solar panels is a crucial task that offers numerous environmental and economic benefits. This review paper focused on the key stage of recycling EOL solar panels, namely delamination, which is considered the most critical step. Efficient delamination techniques can enhance the purity of the extracted materials and reduce their adverse effects on the environment. The reviewed delamination techniques include mechanical, thermal, and chemical methods, each with varying efficiency rates in extracting specific materials. However, combining these techniques may significantly increase their efficiency. For instance, pyrolysis has been utilized in different mechanical and chemical delamination stages. Mechanical delamination is gaining popularity due to its affordability and environmental friendliness. The surface delamination, grinding, and densimetric recycling technique can extract glass with 100% purity and produce less dust, which is environmentally friendly. The hot-knife technology can recover glass with 100% purity and decrease CO2 emissions, thereby reducing its environmental impact.

The solvothermal swelling with thermal decomposition (SSTD) technique, employed as a thermal delamination method, has been found to be capable of recovering 86.11% of silicon, a significant improvement over the conventional method, which takes ten times longer. In a separate study, the optimal temperature for the recovery of 99% of the polymer was identified. While pyrolysis is an effective means of dissolving EVA adhesion, it is not economically viable due to its high energy consumption.

The utilization of ScCO2 in conjunction with toluene as a chemical delamination technique has resulted in the successful recovery of 96% of glass, 85% of solar cells, and the ethylene-vinyl acetate (EVA) component. The KOH–ethanol solution as a chemical delamination technique is eco-friendlier than previous chemical methods. This method effectively extracts rare metals but produces toxic liquids that are harmful to the environment. Hexane, as an organic solvent method for recycling PV cells, is effective in recycling without damage and reduces carbon production. Trichloroethylene, as another chemical method, increases the separation speed of different layers in the EOL solar panels and has less harmful effects on the environment. The efficiency of delamination techniques is of utmost importance in the extraction of rare metals, as end-of-life solar panels contain only a small proportion of these metals. Increasing the metal enrichment rate will result in a higher purity of extracted rare metals.

The hot-knife technology can decrease the energy and costs of EOL solar panel recycling. The surface delamination, grinding, and densimetric method consumes less energy for grinding, and it has minimal material loss. The two rotor crusher plus hammer crushing method effectively reduces energy and chemical material consumption and decreases equipment size. The mechanical/thermal method is significantly energy efficient. Furthermore, as an organic solvent method, hexane can reduce the production costs associated with manufacturing new solar panels.

The environmental damage caused by the hot-knife technology is relatively insignificant when compared to the adverse effects resulting from the production of panels. This technology reduced CO2 emissions. The surface delamination, grinding, and densimetric method has resulted in the generation of less dust, thereby minimizing its environmental impact.

Solar panels provide a sustainable and eco-friendly energy solution. It is essential to address the environmental impact of solar panels at the end of their life cycle to ensure a truly sustainable energy future by implementing effective recycling methods. Developing a strong solar panel recycling infrastructure requires ongoing research, investment in recycling technologies, and the implementation of appropriate regulations. Additionally, raising public awareness about the importance of recycling solar panels is critical. By combining these elements, we can create a robust and sustainable system for recycling solar panels.

Table 2 compares the efficiency of recent works, including the methods utilized, year of publication, country of origin, solar panel types, material recovery yields, scale, and whether the method is economical and eco-friendly. Based on the data presented in the table, it can be inferred that the employment of hot-knife technology as well as the surface delamination, grinding, and densimetric method can restore the glass to its original state. Furthermore, these techniques are both environmentally friendly and cost-effective. In contrast to other thermal methods, the mechanical/thermal approach is highly energy efficient and has minimal negative impact on the environment. Additionally, the utilization of hexane, an organic solvent, is both economical and results in reduced carbon emissions.

Table 2.

Summary of works conducted to delaminate EOL solar panels.

5. Conclusions

Solar panels are classified into three main types with the crystalline silicon solar panel being the most widely used and possessing the largest global market share. The recycling of waste solar panels involves several steps with delamination being the most crucial step. This review paper explored the latest solar panel delamination techniques. The three types of delamination techniques are applied to recover materials such as glass, silicon, and rare metals with the highest efficiency, the least harm to the environment, and economic viability. While thermal delamination is effective in recovering glass and silicon, its high energy consumption makes it less economically friendly. Chemical delamination is economical and efficient in recovering silicon cells, but it produces toxic liquids that are harmful to the environment. Mechanical delamination, on the other hand, is eco-friendly and economical. The hot-knife technology and surface delamination, grinding, and densimetric recycling mechanical methods can recover glass without causing damage, resulting in less dust and harm to the environment, and these methods are economical. On the other hand, there is a need to improve mechanical delamination techniques to increase the recovery rate of glass and silicon; it is a challenge to recycle them from crushed materials. One of the objectives of delamination is to increase the metal enrichment rate to facilitate the recycling of metals in subsequent steps, making it a viable option for future research. The future holds great potential for the advancement of EOL solar panel recycling. With the increasing number of solar panel farms, the management of EOL solar panels poses a significant challenge. Failing to address this issue can have detrimental effects on the environment. Therefore, recycling them to produce solar panels or repairing them seems economical and eco-friendly.

Author Contributions

Conceptualization, A.G., S.D.A., M.N., S.Y.K. and A.Z.K.; methodology, A.G., S.D.A., M.N., S.Y.K. and A.Z.K.; formal analysis, A.G.; investigation, A.G.; writing—original draft preparation, A.G.; writing—review and editing, A.G., S.D.A., M.N., S.Y.K. and A.Z.K.; visualization, A.G.; supervision, S.D.A., M.N., S.Y.K. and A.Z.K.; resources, A.Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data analyzed during this study are included in this published article.

Acknowledgments

The authors thank the NSW Environment Protection Authority, KGM Services Pty Limited/as The Solar Professionals, Anderson Services Group Pty Ltd., and Apex Greenhouses (Australia).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Singh, R. Solar-city plans with large-scale energy storage: Metrics to assess the ability to replace fossil-fuel based power. Sustain. Energy Technol. Assess. 2021, 44, 101065. [Google Scholar] [CrossRef]

- Riahi, S.; Mckenzie, J.A.; Sandhu, S.; Majewski, P. Towards net zero emissions, recovered silicon from recycling PV waste panels for silicon carbide crystal production. Sustain. Mater. Technol. 2023, 36, e00646. [Google Scholar] [CrossRef]

- Kumar, S. Extraction and analysis of TCO coated glass from waste amorphous silicon thin film solar module. Sol. Energy Mater. Sol. Cells 2023, 253, 112227. [Google Scholar]

- Xu, Y.; Li, J.; Tan, Q.; Peters, A.L.; Yang, C. Global status of recycling waste solar panels: A review. Waste Manag. 2018, 75, 450–458. [Google Scholar] [CrossRef]

- Mulazzani, A.; Eleftheriadis, P.; Leva, S. Recycling c-Si PV modules: A review, a proposed energy model and a manufacturing comparison. Energies 2022, 15, 8419. [Google Scholar] [CrossRef]

- Hasan, A.A.; Ahmed Alkahtani, A.; Shahahmadi, S.A.; Nur, E.; Alam, M.; Islam, M.A.; Amin, N. Delamination-and electromigration-related failures in solar panels—A review. Sustainability 2021, 13, 6882. [Google Scholar] [CrossRef]

- Wang, X.; Tian, X.; Chen, X.; Ren, L.; Geng, C. A review of end-of-life crystalline silicon solar photovoltaic panel recycling technology. Sol. Energy Mater. Sol. Cells 2022, 248, 111976. [Google Scholar] [CrossRef]

- Tembo, P.M.; Subramanian, V. Current trends in silicon-based photovoltaic recycling: A technology, assessment, and policy review. Solar Energy 2023, 259, 137–150. [Google Scholar] [CrossRef]

- Dias, P.R.; Benevit, M.G.; Veit, H.M. Photovoltaic solar panels of crystalline silicon: Characterization and separation. Waste Manag. Res. 2016, 34, 235–245. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Song, E.; Zhang, C.; Zhuang, X.; Ma, E.; Bai, J.; Yuan, W.; Wang, J. Pyrolysis-based separation mechanism for waste crystalline silicon photovoltaic modules by a two-stage heating treatment. RSC Adv. 2019, 9, 18115–18123. [Google Scholar] [CrossRef] [PubMed]

- Bagher, A.M.; Vahid, M.M.A.; Mohsen, M. Types of solar cells and application. Am. J. Opt. Photonics 2015, 3, 94–113. [Google Scholar] [CrossRef]

- ibne Mahmood, F.; Kumar, A.; Afridi, M.; TamizhMani, G. Potential induced degradation in c-Si glass-glass modules after extended damp heat stress. Sol. Energy 2023, 254, 102–111. [Google Scholar] [CrossRef]

- Singh, J.P.; Guo, S.; Peters, I.M.; Aberle, A.G.; Walsh, T.M. Comparison of glass/glass and glass/backsheet PV modules using bifacial silicon solar cells. IEEE J. Photovolt. 2015, 5, 783–791. [Google Scholar] [CrossRef]

- Paul, R.; Arulkumar, S.; Jenifer, K.; Parthiban, S. Al-Diffused ZnO Transparent Conducting Oxide Thin Films for Cadmium Telluride Superstrate Solar Cells: A Comprehensive Study. J. Electron. Mater. 2023, 52, 130–139. [Google Scholar] [CrossRef]

- Efaz, E.T.; Rhaman, M.M.; Al Imam, S.; Bashar, K.L.; Kabir, F.; Mourtaza, M.E.; Sakib, S.N.; Mozahid, F.A. A review of primary technologies of thin-film solar cells. Eng. Res. Express 2021, 3, 032001. [Google Scholar] [CrossRef]

- Lee, T.D.; Ebong, A.U. A review of thin film solar cell technologies and challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297. [Google Scholar] [CrossRef]

- Adhikari, A.; Vallejo, O.R.; Diaz, J.E.C.; Martinez-Reyes, J.; Cano, F.J.; Amador, M.d.l.L.O.; Subramaniam, V. A computational study for understanding the effect of various parameters on the performance of three different CI (G) Se-based thin film solar cells. Opt. Laser Technol. 2024, 169, 110102. [Google Scholar] [CrossRef]

- Tempesta, A.G.; Mariano, L.C.; Pacheco, K.R.M.; dos Santos, T.R.C.; Rocco, M.L.M.; Roman, L.S. Organic photovoltaic solar panels (OPV) applied to a tubelike bus station. Braz. J. Phys. 2022, 52, 16. [Google Scholar] [CrossRef]

- Fine, J.P.; Dworkin, S.B.; Friedman, J. A methodology for predicting hybrid solar panel performance in different operating modes. Renew. Energy 2019, 130, 1198–1206. [Google Scholar] [CrossRef]

- Frischknecht, R.; Komoto, K.; Doi, T. Life Cycle Assessment of Crystalline Silicon Photovoltaic Module; International Energy Agency (IEA): Paris, France; The National Renewable Energy Laboratory and the University of New South Wales (UNSW Sydney): Sydney, Austrilia, 2023. [Google Scholar]

- Del Pero, F.; Delogu, M.; Berzi, L.; Escamilla, M. Innovative device for mechanical treatment of End of Life photovoltaic panels: Technical and environmental analysis. Waste Manag. 2019, 95, 535–548. [Google Scholar] [CrossRef]

- Fiandra, V.; Sannino, L.; Andreozzi, C. Photovoltaic waste as source of valuable materials: A new recovery mechanical approach. J. Clean. Prod. 2023, 385, 135702. [Google Scholar] [CrossRef]

- Ito, M. Development of Recycling Technology of Glass and Metals from Photovoltaic Panels by Separation with a Heated Cutter. NPC Incorporated Japan 2016. Available online: https://www.nedo.go.jp/content/100806683.pdf (accessed on 10 August 2023).

- Deng, R.; Zhuo, Y.; Shen, Y. Recent progress in silicon photovoltaic module recycling processes. Resour. Conserv. Recycl. 2022, 187, 106612. [Google Scholar] [CrossRef]

- Granata, G.; Pagnanelli, F.; Moscardini, E.; Havlik, T.; Toro, L. Recycling of photovoltaic panels by physical operations. Sol. Energy Mater. Sol. Cells 2014, 123, 239–248. [Google Scholar] [CrossRef]

- Akimoto, Y.; Iizuka, A.; Shibata, E. High-voltage pulse crushing and physical separation of polycrystalline silicon photovoltaic panels. Miner. Eng. 2018, 125, 1–9. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; You, J.; Diao, H.; Zhao, L.; Wang, W. Back EVA recycling from c-Si photovoltaic module without damaging solar cell via laser irradiation followed by mechanical peeling. Waste Manag. 2022, 137, 312–318. [Google Scholar] [CrossRef] [PubMed]

- Sim, Y.; Tay, Y.B.; Pham, H.K.; Mathews, N. A facile crush-and-sieve treatment for recycling end-of-life photovoltaics. Waste Manag. 2023, 156, 97–106. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Lai, D.; Wang, G.; Wang, Y. Nondestructive silicon wafer recovery by a novel method of solvothermal swelling coupled with thermal decomposition. Chem. Eng. J. 2021, 418, 129457. [Google Scholar] [CrossRef]

- Fiandra, V.; Sannino, L.; Andreozzi, C.; Graditi, G. End-of-life of silicon PV panels: A sustainable materials recovery process. Waste Manag. 2019, 84, 91–101. [Google Scholar] [CrossRef] [PubMed]

- Dias, P.; Javimczik, S.; Benevit, M.; Veit, H. Recycling WEEE: Polymer characterization and pyrolysis study for waste of crystalline silicon photovoltaic modules. Waste Manag. 2017, 60, 716–722. [Google Scholar] [CrossRef]

- Dobra, T.; Vollprecht, D.; Pomberger, R. Thermal delamination of end-of-life crystalline silicon photovoltaic modules. Waste Manag. Res. 2022, 40, 96–103. [Google Scholar] [CrossRef]

- Fiandra, V.; Sannino, L.; Andreozzi, C.; Corcelli, F.; Graditi, G. Silicon photovoltaic modules at end-of-life: Removal of polymeric layers and separation of materials. Waste Manag. 2019, 87, 97–107. [Google Scholar] [CrossRef]

- Han, Q.; Gao, Y.; Su, T.; Qin, J.; Wang, C.; Qu, Z.; Wang, X. Hydrometallurgy recovery of copper, aluminum and silver from spent solar panels. J. Environ. Chem. Eng. 2023, 11, 109236. [Google Scholar] [CrossRef]

- Riech, I.; Castro-Montalvo, C.; Wittersheim, L.; Giácoman-Vallejos, G.; González-Sánchez, A.; Gamboa-Loira, C.; Acosta, M.; Méndez-Gamboa, J. Experimental methodology for the separation materials in the recycling process of silicon photovoltaic panels. Materials 2021, 14, 581. [Google Scholar] [CrossRef] [PubMed]

- Tembo, P.; Heninger, M.; Subramanian, V. An investigation of the recovery of silicon photovoltaic cells by application of an organic solvent method. ECS J. Solid State Sci. Technol. 2021, 10, 025001. [Google Scholar] [CrossRef]

- Pang, S.; Yan, Y.; Wang, Z.; Wang, D.; Li, S.; Ma, W.; Wei, K. Enhanced separation of different layers in photovoltaic panel by microwave field. Sol. Energy Mater. Sol. Cells 2021, 230, 111213. [Google Scholar] [CrossRef]

- Kim, Y.; Lee, J. Dissolution of ethylene vinyl acetate in crystalline silicon PV modules using ultrasonic irradiation and organic solvent. Sol. Energy Mater. Sol. Cells 2012, 98, 317–322. [Google Scholar] [CrossRef]

- Lovato, E.S.; Donato, L.M.; Lopes, P.P.; Tanabe, E.H.; Bertuol, D.A. Application of supercritical CO2 for delaminating photovoltaic panels to recover valuable materials. J. CO2 Util. 2021, 46, 101477. [Google Scholar] [CrossRef]

- Yan, Y.; Wang, Z.; Wang, D.; Cao, J.; Ma, W.; Wei, K.; Yun, L. Recovery of silicon via using KOH-ethanol solution by separating different layers of end-of-life PV modules. JOM 2020, 72, 2624–2632. [Google Scholar] [CrossRef]

- Azeumo, M.F.; Germana, C.; Ippolito, N.M.; Franco, M.; Luigi, P.; Settimio, S. Photovoltaic module recycling, a physical and a chemical recovery process. Sol. Energy Mater. Sol. Cells 2019, 193, 314–319. [Google Scholar] [CrossRef]

- Pagnanelli, F.; Moscardini, E.; Altimari, P.; Padoan, F.C.; Atia, T.A.; Beolchini, F.; Amato, A.; Toro, L. Solvent versus thermal treatment for glass recovery from end of life photovoltaic panels: Environmental and economic assessment. J. Environ. Manag. 2019, 248, 109313. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).