Prospects of Waste Incineration for Improved Municipal Solid Waste (MSW) Management in Ghana—A Review

Abstract

1. Introduction

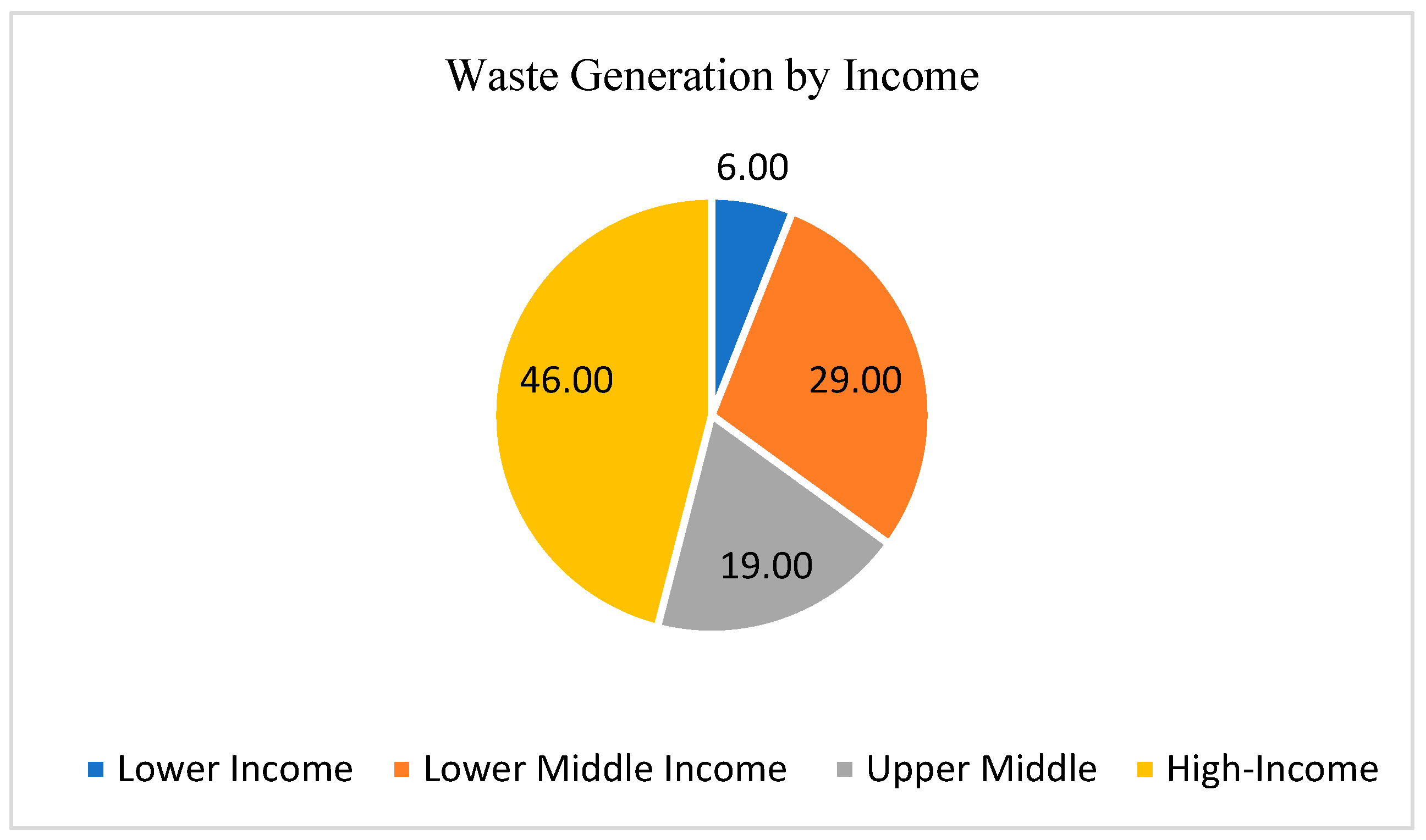

2. Overview of Waste and WtE Technologies

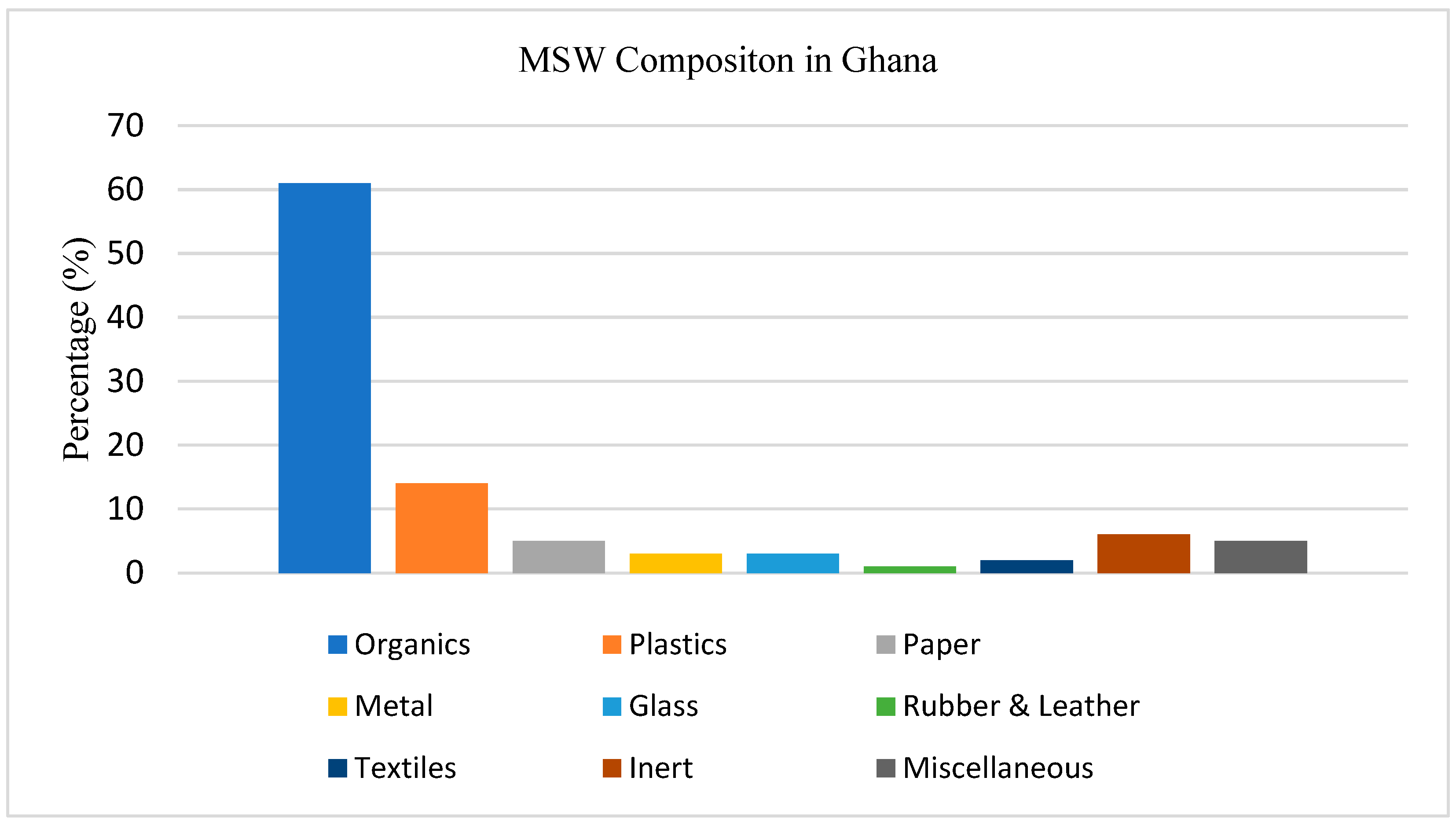

2.1. Overview of Waste

- ➢

- Organics—which consist of food waste, wood, yard waste, and animal droppings;

- ➢

- Paper—cardboards, newsprints, tissue, and office papers;

- ➢

- Plastics—polyethylene terephthalate (PET), low-density polyethylene (LDPE), high-density polyethylene (HDPE), polyvinyl chloride (PVC), polystyrene (PS), polypropylene (PP), and other plastics;

- ➢

- Metals—scrap and cans/tins;

- ➢

- Glass—both coloured and plain ones;

- ➢

- Leather and rubber;

- ➢

- Textiles;

- ➢

- Inert (fine organics, ash, and sand);

- ➢

- Miscellaneous (paints, demolition and construction waste, batteries, any other fraction that does not fall into the above categories).

- Residential—The report identified single and multifamily dwellings as typical waste generators and identified food waste, e-waste, paper, plastics, household hazardous waste, leather, glass, etc.

- Commercial—Another source of MSW identified by the report is the solid waste from commercial sources. Under this category, markets, stores, hotels, restaurants, and office buildings are typical waste generators. Some of the types of solid waste identified include paper, cardboard, food waste, e-waste, etc.

- Institutional—Schools, government buildings, airports, prisons, and hospitals (non-medical wastes) were identified as typical waste generators. The same types of solid waste listed under commercial sources were also identified for institutional sources.

- Industrial—Typical waste generators under this source of MSW include construction sites, fabrication, chemical plants, light and heavy manufacturing, and power plants. Some types of solid waste given under this section include hazardous wastes, packaging, food wastes, housekeeping wastes, etc.

- Construction and demolition—Solid waste from construction and demolition sources including that from new building sites, road maintenance, renovation sites, and the pulling down of buildings are identified as typical construction and demolition waste generators. Some types of solid waste under this section include bricks, tiles, wood, steel, concrete, and dirt.

- Municipal services—Under this category of MSW source, street cleaning, landscaping, recreational zones, water, and effluent treatment plants were identified as typical waste generators, while landscape and tree trimmings, street sweepings, general waste from recreational areas, and sludge were identified as other types of solid waste.

- Process—Refineries, power plants, chemical plants, processing and mineral extraction, and processing constitute some typical waste generators, while materials such as slag, tailings, industrial process waste, and scrap materials are some examples of typical processed solid waste.

- Medical waste—Under this category of MSW source, hospitals, nursing homes, and clinics were identified as typical waste generators, while pharmaceutical waste, infectious waste such as hand gloves, bandages, cultures, and hazardous waste, i.e., chemicals and sharp objects, were identified as typical solid waste.

- Agricultural—Typical waste generators identified under this category include crops, dairies, orchards, feedlots, and farms, while spoiled food waste and hazardous waste such as pesticides were identified as typical agricultural solid waste.

- Evaluate past consumption—This can be achieved through assessing the true use and need of everything, after which ones which are deemed unnecessary are pared down.

- To limit present and future consumption in terms of amount and size—This can be achieved through minimising shopping activities to conserve valuable resources which are used to make new things and through making used items available to others. Areas that can be considered include home sizes, reducing packaging, personal effects, etc.

- Decreasing activities that may support or lead to consumption.

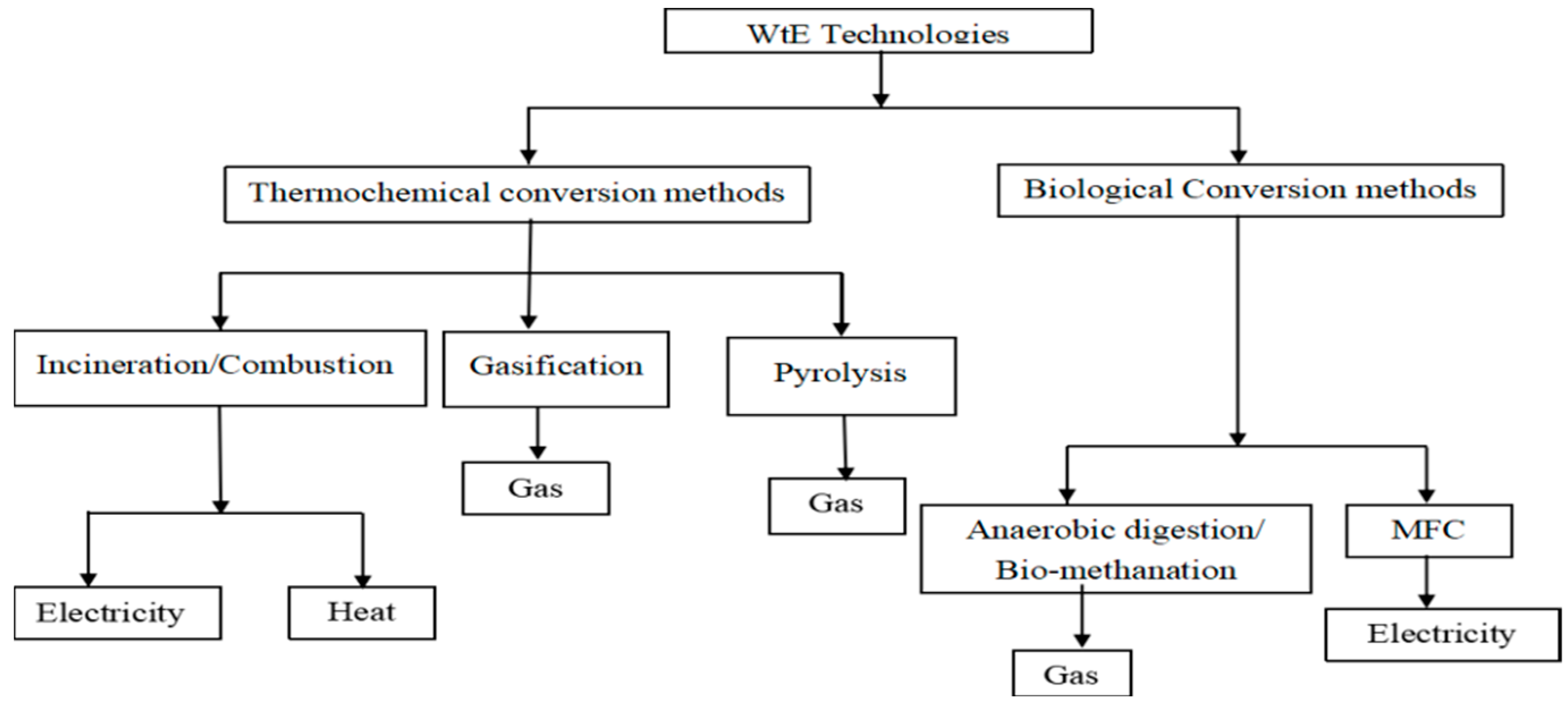

2.2. WtE Technologies

2.2.1. Thermochemical Conversion Methods

2.2.2. Biological Conversion Methods

3. Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a Waste 2.0: A Global Snapshot of Solid Waste Management to 2050; Urban Development; World Bank: Washington, DC, USA, 2018; Available online: https://openknowledge.worldbank.org/handle/10986/30317 (accessed on 3 December 2022).

- World Energy Council 2016, World Energy Resources Council. Available online: https://www.worldenergy.org/assets/images/imported/2016/10/World-Energy-Resources-Full-report-2016.10.03.pdf (accessed on 20 April 2021).

- Solheimslid, T.; Harneshaug, H.K.; Lümmen, N. Calculation of first-law and second -law efficiency of a Norwegian combined heat and power facility driven by municipal waste incineration: A case study. Energy Convers. Manag. 2015, 95, 149–159. [Google Scholar] [CrossRef]

- Ni, M.; Leung DY, C.; Leung MK, H.; Sumathy, K. An overview of hydrogen production from biomass. Fuel Process. Technol. 2006, 87, 461–472. [Google Scholar] [CrossRef]

- Patwa, A.; Parde, D.; Dohare, D.; Vijay, R.; Kumar, R. Solid waste characterization and treatment technologies in rural areas: An Indian and international review. Environ. Technol. Innov. 2020, 20, 101066. [Google Scholar] [CrossRef]

- Han, Z.; Liu, Y.; Zhong, M.; Shi, G.; Li, Q.; Zeng, D.; Zhang, Y.; Fei, Y.; Xie, Y. Influencing factors of domestic waste characteristics in rural areas of developing countries. Waste Manag. 2018, 72, 45–54. [Google Scholar] [CrossRef]

- Global Waste Management Outlook. 2015. Available online: https://www.uncclean.org/wp-content/uploads/library/unep23092015.pdf (accessed on 20 May 2021).

- Energy Commission of Ghana. Energy (Supply and Demand) Outlook for Ghana: Final. 2016. Available online: http://energycom.gov.gh/files/Energy%20Commission%20-%202016Energy%20Outlook%20for%20Ghana_final.pdf (accessed on 24 January 2022).

- Dong, J.; Tang, Y.; Nzihou, A.; Chi, Y.; Weiss-Hortala, E.; Ni, M.; Zhou, Z. Comparison of waste-to-energy technologies of gasifification and incineration using life cycle assessment: Case studies in Finland, France and China. J. Clean. Prod. 2018, 203, 287–300. [Google Scholar] [CrossRef]

- Executive Summary, Solid Waste Conversion/Waste to Energy Technology Options June 2020, Pre-Feasibility Study Technology Assessment Waste to Energy Options. Available online: https://www.muni.org/Departments/Assembly/Documents/WTE%20Executive%20Summary%20Technology%20Assesmment%20Version%203.pdf (accessed on 21 March 2022).

- Waste-to-Energy Plants in Europe in 2015. Available online: http://www.cewep.eu/2017/09/07/waste-toenergy-plants-in-europe-in-2015/ (accessed on 20 July 2022).

- Tan, S.T.; Ho, W.S.; Hashim, H.; Lee, C.T.; Taib, M.R.; Ho, C.S. Energy, economic and environmental (3E) analysis of waste-to-energy (WTE) strategies for municipal solid waste (MSW) management in Malaysia. Energy Convers. Manag. 2015, 102, 111–120. [Google Scholar] [CrossRef]

- Moya, D.; Aldás, C.; López, G.; Kaparaju, P. Municipal solid waste as a valuable renewable energy resource: A worldwide opportunity of energy recovery by using waste-to-energy technologies. Energy Proc. 2017, 134, 286–295. [Google Scholar] [CrossRef]

- Maisarah, M.; Bong, C.P.C.; Ho, W.S.; Lim, J.S.; Ab Muis, Z.; Hashim, H.; Elagroudy, S.; Teck, G.L.H.; Ho, C.S. Review on the suitability of waste for appropriate waste-to-energy technology. Chem. Eng. Trans. 2018, 63, 187–192. [Google Scholar] [CrossRef]

- Acheampong, M.; Yu, Q.; Cansu Ertem, F.; Deba Enomah Ebude, L.; Tanim, S.; Eduful, M.; Vaziri, M.; Ananga, E. Is Ghana Ready to Attain Sustainable Development Goal (SDG) Number 7?—A Comprehensive Assessment of Its Renewable Energy Potential and Pitfalls. Energies 2019, 12, 408. [Google Scholar] [CrossRef]

- Akolgo, G.A.; Essandoh, E.O.; Gyamfi, S.; Atta-Darkwa, T.; Kumi, E.N.; de Freitas Maia, C.M.B. The potential of a dual purpose improved cookstove for low income earners in Ghana—Improved cooking methods and biochar production. Renew. Sustain. Energy Rev. 2018, 82, 369–379. [Google Scholar] [CrossRef]

- Danquah, J.A.; Roberts, C.O.; Appiah, M. Elephant Grass (Pennisetum purpureum): A Potential Source of Biomass for Power Generation in Ghana. Curr. J. Appl. Sci. Technol. 2018, 30, 1–12. [Google Scholar] [CrossRef]

- Duku, M.H.; Gu, S.; Hagan, E.B. A comprehensive review of biomass resources and biofuels potential in Ghana. Renew. Sustain. Energy Rev. 2011, 15, 404–415. [Google Scholar] [CrossRef]

- Gomaa, M.R.; Mustafa, R.J.; Al-Dmour, N. Solar thermochemical conversion of carbonaceous materials into syngas by Co-Gasification. J. Clean. Prod. 2020, 248, 119185. [Google Scholar] [CrossRef]

- Gyamfi, S.; Modjinou, M.; Djordjevic, S. Improving electricity supply security in Ghana—The potential of renewable energy. Renew. Sustain. Energy Rev. 2015, 43, 1035–1045. [Google Scholar] [CrossRef]

- Kemausuor, F.; Kamp, A.; Thomsen, S.T.; Bensah, E.C.; Østergård, H. Assessment of biomass residue availability and bioenergy yields in Ghana. Resour. Conserv. Recycl. 2014, 86, 28–37. [Google Scholar] [CrossRef]

- Ofori-Boateng, C.; Lee, K.T.; Mensah, M. The prospects of electricity generation from municipal solid waste (MSW) in Ghana: A better waste management option. Fuel Process. Technol. 2013, 110, 94–102. [Google Scholar] [CrossRef]

- Mohammed, Y.S.; Mokhtar, A.S.; Bashir, N.; Saidur, R. An overview of agricultural biomass for decentralized rural energy in Ghana. Renew. Sustain. Energy Rev. 2013, 20, 15–22. [Google Scholar] [CrossRef]

- Ulrike, D.; Karl-Heinz, P.; Nayina, S.G. Biogas in Ghana—Sub-Sector Analysis of Potential and Framework Conditions 2014, Retrieve 28 January 2017. Available online: http://www.renewables-made-in-germany.com (accessed on 15 December 2022).

- Hoornweg, D.; Bhada-Tata, P. What a Waste: A Global Review of Solid Waste Management; Urban Development Series; Knowledge Papers No. 15. World Bank: Washington, DC, USA, 2012. Available online: https://openknowledge.worldbank.org/entities/publication/1a464650-9d7a-58bb-b0ea-33ac4cd1f73c (accessed on 2 March 2022).

- Tchobanoglous, G.; Kreith, F. Handbook of Solid Waste Management, 2nd ed.; McGraw Hill Handbook; The McGraw-Hill Companies, Inc.: New York, NY, USA, 2002. [Google Scholar]

- Pérez-Gimeno, A.; Navarro-Pedreño, J.; Almendro-Candel, M.B.; Gómez, I.; Zorpas, A.A. The use of wastes (organic and inorganic) in land restoration in relation to their characteristics and cost. Waste Manag. Res. 2019, 37, 502–507. [Google Scholar] [CrossRef]

- Geevarghese, R.; Sajjadi, S.S.; Hudecki, A.; Sajjadi, S.; Jalal, N.R.; Madrakian, T.; Ahmadi, M.; Włodarczyk-Biegun, M.K.; Ghavami, S.; Likus, W.; et al. Biodegradable and Non-Biodegradable Biomaterials and Their Effect on Cell Differentiation. Int. J. Mol. Sci. 2022, 23, 16185. [Google Scholar] [CrossRef]

- Available online: https://www.epa.sa.gov.au/files/8437_food_waste.pdf) (accessed on 20 March 2023).

- Available online: https://www.lawinsider.com/dictionary/combustible-waste (accessed on 30 March 2023).

- National Research Council. Waste Incineration and Public Health; The National Academies Press: Washington, DC, USA, 2000. [Google Scholar] [CrossRef]

- Daura, L.A. Electricity Generation Potential of Municipal Solid Waste in Kano Metropolis. J. Sci. Eng. Res. 2016, 3, 157–161. [Google Scholar]

- Jin, J.; Wang, Z.; Ran, S. Solid waste management in Macao: Practices and challenges. Waste Manag. 2006, 26, 1045–1051. [Google Scholar] [CrossRef] [PubMed]

- United States Environmental Protection Agency. 2022. Available online: https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/national-overview-facts-and-figures-materials (accessed on 10 February 2023).

- Meiza, K.; Obiri-Danso, K.; Kadar, Z.; Fei-Baffoe, B.; Mensah, M.Y. Municipal solid waste characterization and quantification as a measure towards effective waste management in Ghana. Waste Manag. 2015, 46, 15–27. [Google Scholar]

- Best Practices for Solid Waste Management: A Guide for Decision-Makers in Developing Countries 2020. Available online: https://www.epa.gov/sites/default/files/2020-10/documents/master_swmg_10-20-20_0.pdf (accessed on 20 December 2020).

- Hezri, A.A. Toward 3R-Based Waste Management: Policy Change in Japan, Malaysia and the Philippines. In 3R Policies for Southeast and East Asia. ERIA Research Project Report 2009–2010; Kojima, M., Ed.; ERIA: Jakarta, Indonesia, 2010; pp. 274–290. [Google Scholar]

- Johnson, B. Zero Waste Home: The Ultimate Guide to Simplifying Your Life by Reducing Your Waste; Scribner: New York, NY, USA, 2013. [Google Scholar]

- Agamuthu, P. Landfilling in developing countries. Waste Manag. Res. 2013, 31, 1–2. [Google Scholar] [CrossRef]

- Georgieva, K.; Varma, K. Municipal Solid Waste Incineration; World Bank Technical Guidance Report; The International Bank for Reconstruction and Development/The World Bank: Washington, DC, USA, 1999. [Google Scholar]

- Zhang, C.; Xu, T.; Feng, H.; Chen, S. Greenhouse gas emissions from landfills: A Review and Bibliometric Analysis. Sustainability 2019, 11, 2282. [Google Scholar] [CrossRef]

- Han, Z.; Cui, B. Performance of macrophyte indicators to eutrophication pressure in ponds. Ecol. Eng. 2016, 96, 8–19. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Abalo, E.M.; Peprah, P.; Nyonyo, J.; Ampomah-Sarpong, R.; Agyemang-Duah, W. A Review of the Triple Gains of Waste and the Way Forward for Ghana. Hindawi J. Renew. Energy 2018, 2018, 9737683. [Google Scholar] [CrossRef]

- Oduro-Kwarteng, S. Private Sector Involvement in Urban Solid Waste Collection. Ph.D. Thesis, Erasmus University, Rotterdam, The Netherlands, 2010. [Google Scholar]

- Rosen, M.A.; Dincer, I. On exergy and environmental impact. Int. J. Energy Res. 1997, 21, 643–654. [Google Scholar] [CrossRef]

- Sikarwar, V.S.; Zhao, M.; Clough, P.; Yao, J.; Zhong, X.; Memon, M.Z.; Shah, N.; Anthony, E.J.; Fennell, P.S. An overview of advances in biomass gasification. Energy Env. Sci. 2016, 9, 2939–2977. [Google Scholar] [CrossRef]

- Vuppaladadiyam, A.K.; Vuppaladadiyam, S.S.V.; Sahoo, A.; Murugavelh, S.; Anthony, E.; Bhaskar, T.; Zheng, Y.; Zhao, M.; Duan, H.; Zhao, Y.; et al. Bio-oil and biochar from the pyrolytic conversion of biomass: A current and future perspective on the trade-off between economic, environmental, and technical indicators. Sci. Total Environ. 2023, 857, 159155. [Google Scholar] [CrossRef]

- Velghe, I.; Carleer, R.; Yperman, J.; Schreurs, S. Study of the pyrolysis of municipal solid waste for the production of valuable products. J. Anal. Appl. Pyrolysis 2011, 92, 366–375. [Google Scholar] [CrossRef]

- Mohan, D.; Pittman, C.U., Jr.; Steele, P.H. Pyrolysis of wood/biomass for bio-oil: A critical review. Energy Fuels 2006, 20, 848–889. [Google Scholar] [CrossRef]

- Katyal, S. Effect of carbonization temperature on combustion reactivity of bagasse char. Energy Sources Part A 2007, 29, 1477–1485. [Google Scholar] [CrossRef]

- Final Report 2003, an Introduction to Anaerobic Digestion of Organic Wastes. Available online: http://report4_final.doc (accessed on 20 November 2022).

- Vázquez-Fernández, A.; Suárez-Ojeda, M.E.; Carrera, J. Review about bioproduction of Volatile Fatty Acids from wastes and wastewaters: Influence of operating conditions and organic composition of the substrate. J. Environ. Chem. Eng. 2022, 10, 107917. [Google Scholar] [CrossRef]

- Elango, D.; Pulikesi, M.; Baskaralingam, P.; Ramamurthi, V.; Sivanesan, S. Production of biogas from municipal solid waste with domestic sewage. J. Hazard. Mater. 2007, 141, 301–304. [Google Scholar] [CrossRef]

- Beylier, M.R.; Balaguer, M.D.; Colprim, J.; Pellicer-Nàcher, C.; Ni, B.J.; Smets, B.F.; Sun, S.P.; Wang, R.C. 6.22—Biological Nitrogen Removal from Domestic Wastewater. In Comprehensive Biotechnology, 3rd ed.; Moo-Young, M., Ed.; Elsevier: Pergamon, Turkey, 2011; pp. 285–296. ISBN 9780444640475. [Google Scholar] [CrossRef]

- Hu, Y.; Cheng, H.; Tao, S. The growing importance of waste-to-energy (WTE) incineration in China’s anthropogenic mercury emissions: Emission inventories and reduction strategies. Renew. Sustain. Energy Rev. 2018, 97, 119–137. [Google Scholar] [CrossRef]

- Waste-to-Energy Plants in Europe in 2017. Available online: https://www.cewep.eu/waste-to-energy-plants-in-europe-in-2017/ (accessed on 20 July 2022).

- Available online: https://www.bbva.com/en/sustainability/5-best-recycling-practices-from-around-the-world/ (accessed on 10 March 2023).

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions: The Role of Waste-to-Energy in the Circular Economy. 2017. Available online: https://ec.europa.eu/docsroom/documents/27321/attachments/1/translations/en/renditions/native (accessed on 30 March 2022).

- Michaels, T.; Krishnan, K.; Energy Recovery Council. Directory of Waste to Energy Facilities 2019. Available online: http://energyrecoverycouncil.org/wp-content/uploads/2019/01/ERC-2018-directory.pdf (accessed on 22 January 2023).

- Available online: https://www.statista.com/statistics/689771/japan-power-density-generated-by-waste-incineration/#statisticContainer (accessed on 11 February 2023).

- Han, Z.; Ma, H.; Shi, G.; He, L.; Wei, L.; Shi, Q. A review of groundwater contamination near municipal solid waste landfill sites in China. Sci. Total Environ. 2016, 569, 1255–1264. [Google Scholar] [CrossRef]

- Ji, L.; Lu, S.; Yang, J.; Du, C.; Chen, Z.; Buekens, A.; Yan, J. Municipal solid waste incineration in China and the issue of acidification: A review. Waste Manag. Res. 2016, 34, 280–297. [Google Scholar] [CrossRef]

- China Electricity Council (2019) China Annual Statistic Report on Electricity. Available online: https://cec.org.cn/detail/index.html?3-292822 (accessed on 11 January 2023).

- National Bureau of Statistics of China (2020) China Statistical Yearbook. 2020. Available online: http://www.stats.gov.cn/tjsj/ndsj/2020/indexch.htm (accessed on 3 April 2023).

- Lino, F.A.M.; Ismail, K.A.R. Evaluation of the treatment of municipal solid waste as renewable energy resource in Campinas, Brazil. Sustain. Energy Technol. Assess. 2018, 29, 19–25. [Google Scholar] [CrossRef]

- Mia, S.; Uddin, M.E.; Kader, M.A.; Ahsan, A.; Mannan, M.A.; Hossain, M.M.; Solaiman, Z.M. Pyrolysis and co-composting of municipal organic waste in Bangladesh: A quantitative estimate of recyclable nutrients, greenhouse gas emissions, and economic benefits. Waste Manag. 2018, 75, 503–513. [Google Scholar] [CrossRef]

- Starostina, V.; Damgaard, A.; Eriksen, M.K.; Christensen, T.H. Waste management in the Irkutsk region, Siberia, Russia: An environmental assessment of alternative development scenarios. Waste Manag. Res. 2018, 36, 373–385. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.esi-africa.com/industry-sectors/generation/400kw-hybrid-waste-to-energy-power-plant-a-first-for-ghana/#:~:text=Ghana%20will%20soon%20be%20getting,Nwabiagya%20South%20Municipality%20in%20Ashanti (accessed on 20 January 2023).

- Available online: www.seas.columbia.edu/earth/wtert/pressreleases/Guidebook_WTE_v5_July25_2013.pdf (accessed on 20 February 2023).

- Dos Santos, R.E.; Dos Santos, I.F.S.; Barros, R.M.; Bernal, A.P.; Tiago Filho, G.L.; da Silva, F.D.G.B. Generating electrical energy through urban solid waste in Brazil: An economic and energy comparative analysis. J. Environ. Manag. 2019, 231, 198–206. [Google Scholar] [CrossRef] [PubMed]

- Soares, R.R.; Miyamaru, E.S.; Martins, G. Environmental performance of the allocation and urban solid waste treatment with energetic reuse through life cycle assessment at CTR—Caieiras. Eng. Sanitária Ambient. 2017, 22, 993–1003. [Google Scholar] [CrossRef][Green Version]

- Sellitto, M.A.; Murakami, F.K.; Butturi, M.A.; Marinelli, S.; Kadel, N., Jr.; Rimini, B. Barriers, drivers, and relationships in industrial symbiosis of a network of Brazilian manufacturing companies. Sustain. Prod. Consum. 2021, 26, 443–454. [Google Scholar] [CrossRef]

- Ihsanullah, I.; Alam, G.; Jamal, A.; Shaik, F. Recent advances in applications of artificial intelligence in solid waste management: A review. Chemosphere 2022, 309, 136631. [Google Scholar] [CrossRef]

- Abbasi, M.; El Hanandeh, A. Forecasting municipal solid waste generation using artificial intelligence modelling approaches. Waste Manag. 2016, 56, 13–22. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yakah, N.; Samavati, M.; Akuoko Kwarteng, A.; Martin, A.; Simons, A. Prospects of Waste Incineration for Improved Municipal Solid Waste (MSW) Management in Ghana—A Review. Clean Technol. 2023, 5, 997-1011. https://doi.org/10.3390/cleantechnol5030050

Yakah N, Samavati M, Akuoko Kwarteng A, Martin A, Simons A. Prospects of Waste Incineration for Improved Municipal Solid Waste (MSW) Management in Ghana—A Review. Clean Technologies. 2023; 5(3):997-1011. https://doi.org/10.3390/cleantechnol5030050

Chicago/Turabian StyleYakah, Noah, Mahrokh Samavati, Augustine Akuoko Kwarteng, Andrew Martin, and Anthony Simons. 2023. "Prospects of Waste Incineration for Improved Municipal Solid Waste (MSW) Management in Ghana—A Review" Clean Technologies 5, no. 3: 997-1011. https://doi.org/10.3390/cleantechnol5030050

APA StyleYakah, N., Samavati, M., Akuoko Kwarteng, A., Martin, A., & Simons, A. (2023). Prospects of Waste Incineration for Improved Municipal Solid Waste (MSW) Management in Ghana—A Review. Clean Technologies, 5(3), 997-1011. https://doi.org/10.3390/cleantechnol5030050