1. Introduction

Gear transmission maintenance is crucial for extending the life and reliability of equipment. However, the unique design and demanding working conditions of gear systems make predicting failure and damage difficult. Transmission errors can cause increased noise and vibration, and defects on the gear teeth can weaken resistance and lead to destruction [

1]. Pitting and cracking are common gear problems that can cause significant failures. It is important to study these issues to monitor the condition of the transmission system and diagnose faults early.

Top of Form

Cracks in the gear teeth affect the bending stiffness due to stress in the root that exceeds the material endurance limit, but do not affect contact stiffness [

2]. Progressive cracks appear at the base of the tooth defect with each rotation of the mechanism, and are particularly visible in thin, heat-hardened stainless steels that are highly stressed.

Pitting can cause the deformation of the teeth and the gear transmission system, resulting in vibration and noise problems.

These crack and pitting defects, when not detected early, significantly influence the vibration behavior of the gear system [

3]. Therefore, researching the mechanism and diagnosing gear defects is crucial to avoid problems.

In the literature, several publications on monitoring and diagnosing gear systems have addressed cracks and pitting separately, with few addressing the vibration signature of coexisting nonlinear cracks and pitting in a two-stage spur gear, which is a difficult problem to diagnose and analyze.

Condition monitoring and fault diagnostics are useful for ensuring the safe running of machines [

4]. To meet the ever-increasing demand for the maintenance of gear systems, industrial companies have traditionally depended on the shutdown of the machines or processing the fault diagnosis. However, online monitoring has proven to be effective in terms of machine state analysis and fault prediction. Vibration-based condition monitoring has become increasingly important in the maintenance of industrial and automotive gearboxes [

5]. Vibration analysis can be used to detect damage in gear systems by analyzing the vibrations produced by the gears as they rotate.

Analysis of the vibration characteristics of cracked gears provides a theoretical basis for diagnosing cracking faults. The potential energy approach was initially developed for calculating gear stiffness by Yang and Lin [

6]. Based on this approach, Wei investigated the calculation of the time-varying meshing stiffness and dynamic characteristics of a two-stage helical gear system [

7]. Hertz’s contact energy, bending deformation energy, and axial compression energy all contributed to the elastic deformation of the gear. The gear is seen as a variable cross-section cantilever beam in this method. Meng created a dynamic model with a cracked first-level spur gear, using the segmental stiffness approach to examine the vibrational response of the crack rupture [

8]. Chen also created a dynamic model to study the dynamic properties of a two-stage planetary gear transmission with a fractured gear [

9].

Yan et al. [

10] used an analytical gear meshing stiffness calculation model with tooth surface crack. Li et al. [

11] considered the axial force of a helical gear as an improved calculation method for TVMS with crack faults.

Methods for diagnosing and identifying gear pitting defects have been divided into two categories in recent years: model-based and data-based [

12].

Ma et al. applied a similar model, but their study focused on the impact of pitting evolution on dynamic gear responses [

13]. Meng et al. created a model to examine the changes in gear meshing stiffness as severe pitting levels grew from healthy gearing, modeling the geometry of the pits as a sphere [

14]. Pitting is caused by friction between the tooth surfaces during the gear meshing process; however, the cracking expands with each setting load and is located at the tooth root. The effective contact area is reduced, the gear teeth are bent, and the gear transmission system’s bearing capacity is reduced because of pitting on the surface of the gear teeth only. Its appearance is due to exceeding the elastic limit in stress at the root of the tooth and on the side of the tooth in tension. Because of the change in the meshing stiffness of the gear, the deformation of the teeth and gear transmission system is more likely to cause vibration in the working process, resulting in system vibration and noise problems.

Hou et al. [

15] used the potential energy approach to solve the TVMS of ideal gears with various levels of pitting severity.

For the diagnosis and analysis of the two defects, time–frequency analysis is a modern diagnostic approach with great sensitivity that gives a good diagnostic capacity for characterizing the dynamic behavior of the gear system [

16,

17,

18]. The set of coexistence defects present on the gear teeth weakens the mechanical resistance, which can lead to their destruction and cause enormous damage. Model-based techniques require a thorough understanding of dynamic modeling as well as precise system condition parameters, and vibration analysis is the most extensively utilized technique [

19].

Indeed, by utilizing the appropriate technology to provide qualitative information on the forces applied to the machine components, this method enables the diagnosis of a possible malfunction. Spectral analysis is the approach used most frequently to investigate mechanical vibration. Furthermore, depending on the critical method of determining the intensity of the damage in local fault detection, the symptoms of the fault can be determined in the experimental instance. However, the application of such a technique in the analysis of multiple combined nonlinear faults is still a subject of study where predicting the maintenance of the gear system and preventing an untimely stoppage in a machine process are concerned. In recent years, based on the method mentioned above, the TVMS of gears without fault has been obtained by many researchers [

20], and many scholars have studied the tooth crack fault of gears [

8,

21]. Tiancheng et al. [

22] used a three-dimensional finite element model to derive and validate the gear mathematical model with pitting–crack coupling faults.

The pitting and cracking of gear teeth can be understood by looking at the mechanics of the gear meshing process. When gears mesh, the teeth meet each other at a specific point, called the contact point. At this point, the gears experience high contact stresses and pressure, as the teeth must conform to each other in order to transmit power.

Pitting can occur when these high contact stresses and pressure cause small surface defects, called pits, to form on the gear teeth. These pits can be caused by a variety of factors, including improper lubrication, high loads, and poor surface finish.

Cracking can occur when the high contact stresses and pressure cause small surface cracks to form on the gear teeth, which can then become larger over time. These cracks can be caused by a variety of factors, including improper heat treatment, high loads, and poor surface finish.

Both pitting and cracking can reduce the strength and durability of the gears and can ultimately lead to gear failure if left unaddressed [

23].

This paper proposes a novel model of tooth-pitting–crack coexistence faults. A method for calculating the stiffness of a spur gear with combined pitting and crack faults is also proposed. The influence of crack and pitting parameters and time-varying mesh stiffness on the vibration characteristics of a gear system is studied. The coexistence of pitting and cracking faults on a two-stage spur gear system is analyzed. The time domain and frequency domain results and the RPM–frequency map are obtained for the 10 degrees of freedom gear system with coexisting defects and compared with experimental results. The results obtained in the first stage serve as the baseline for the second stage of the study, which examines the behavior of the vertical vibrations generated by the gear system.

This paper is divided into the following sections:

Section 2 introduces the proposed calculation model of gear meshing stiffness for a gear with coupled pitting and cracking on the tooth surface.

Section 3 provides a brief overview and the governing equation for the dynamic mathematical modeling of a two-stage spur gear system, while in

Section 4 the description of the test bench and experimental findings for validating the simulated response using the proposed dynamic model are shown.

Section 5 discusses the two-stage gear system fault characteristics in relation to simulation and experiment. The significant findings and conclusions of the work are highlighted in

Section 6.

3. Spur Gear Dynamic Response

Figure 6a shows a two-stage gearbox with six bearings used to support the three shafts—shaft 1 (input), rotating at (T

m) revolution per minute, which carried a pinion of mass 1, a base circle radius 1, and moment of inertia 1 (m

1, R

1, J

1) driven by an electric motor via an input coupling joint, which has the following characteristics: a torsional stiffness (k

p) and a damping coefficient (c

p); shaft 2 (intermediary), which carried a wheel of mass 2, base circle radii 2, within a moment of inertia 2 (m

2, R

2, J

2), and carried a pinion of mass 3, base circle radius 3, and moment inertia 3 (m

3, R

3, J

3); and shaft 2 (output), rotating at (T

L) revolution per minute, which carried a wheel of mass 4, a base circle radius 4, and moment of inertia 4 (m

4, R

4, J

4), and was connected to a torsional stiffness (k

g) and a damping coefficient (c

g) characterizing the load through an output coupling joint, respectively. All bearings are represented by k

1, vertical stiffness, and c

1, vertical damping on the input bearing; k

2 = k

3, vertical stiffness, and c

2 = c

3, vertical damping on the intermediary bearing; and k4, vertical stiffness, and c4, vertical damping on the output bearing.

Figure 6b,c shows two pairs of spur gears, each with a pinion and a gear. The first stage (b) and second stage (c) are properly coupled, and the two-surface gear contact is subjected to torsional stiffness and damping forces generated by the gear meshing stiffness k

t1 and damping coefficient c

t1 in

Figure 6b and the gear meshing stiffness k

t2 and damping coefficient c

t2 in

Figure 6c.

Lagrange dynamics in the inertial coordinate system allows us to develop a model system. More detailed information regarding the consideration of adjustment faults such as pitting and cracking, both combined into one fault in the two-stage spur gear system, is given in the following section.

Figure 6a–c, respectively, show the meshing of a pair of spur gears and the diagram of a two-stage spur gear transmission model. The effective gear meshing stiffness is only addressed when analyzing the coupled torsional–lateral vibrations of pair gearing spurs in a two-stage gearing system to identify pitting and cracking to simplify the stiffness calculation. Cracking and pitting are more likely to develop concurrently and concentrate on the same tooth under heavy load and poor lubrication circumstances, but the mechanism of gear multiple faults is still limited, which presents more obstacles in this study. The model is based on the following premises: (1) the gear body is treated as solid; (2) the shaft is rigid to avoid deformations; (3) engaged teeth are two isotropic elastic bodies; (4) the gear is a standard spur with a pressure angle of 20 degrees; and (6) the root circle is larger than the base circle, or the radius of the circle is greater than the radius of the base (Rr > Rb).

3.1. Motion of Dynamic Model

The model proposed in this paper provides a theoretical basis for studying the coexistence of pitting and cracking faults in a two-stage spur gear system and can be used to analyse the vibration characteristics and diagnose the faults.

During the meshing of the teeth, 1 indicates the first pair and 2 indicates the second pair. Based on the geometry of

Figure 6, the system’s total kinetic energy

T is written as follows:

In the gearing system, the total potential energy

U, which includes the strain energy of rotating gears, is expressed as follows:

Because viscous damping is considered in the gearing system, Rayleigh’s dissipation function D is expressed as follows:

where the driving pinions are 1 and 3 and the driven gears are 2 and 4, respectively.

In this model of the two-stage spur gear system, 10 DOF are considered with four lateral displacements y1, y2, y3, and y4 from the lateral vibrations developed on bearings and six angular rotations as follows: driving motor , pinion , wheel , pinion , wheel , and load from the torsional vibrations.

By using the principle of virtual work, the equation of motion for the two-stage spur gear system can be derived by taking the derivative of the LaGrange function with respect to the lateral and angular displacement of the gears:

Finally, the matrix can be expressed as follows when a pit and crack on the root and surface of a pinion tooth coexist:

3.2. Numerical Analysis of a Two-Stage Gearbox System with Coupled Pitting and Cracking on the Tooth Surface

The advanced RPM–Frequency diagnostic technique will be used in the simulation to effectively identify features of combined faults in a spur gear system [

24]. The equations will be solved using a MATLAB solver with the ode45 subroutine and a Runge-Kutta discretization approach. For this study, slight pitting has been considered negligible at the early stage. The simulation will last for ten seconds for each analysis, and the results will be discussed in terms of the simulated and gear responses:

Figure 7a illustrates the vibration response of a gearbox in good condition with no defects in the lateral displacement. The vibration signal is stable due to the perfect gear transmission.

In

Figure 7b, the frequency of the gear mesh (50.06 Hz) is the dominant amplitude in the frequency spectrum (39.08 Hz) in the healthy gearbox. There are no harmonics or small sideband amplitudes present around either frequency.

Figure 8a illustrates a drastic increase in peak amplitudes over a period of 4 to 10 s. The size of the pitting defect on the tooth root is proportionate to the change in measured peak amplitudes.

In

Figure 8b, there is a noticeable decrease in the amplitude of the gear meshing frequency from 4.6 to 1.839 m/s

2. Additionally, three sub-harmonics, a 25% pitting, and sidebands in the frequency range of 80.08 to 800 Hz are present.

Figure 9a displays the highest fluctuation (between 0 and 10 s), with the primary amplitude peak ranging from 1.5 to 2.48 m/s

2 between 4 and 8 s. The fluctuation in peak amplitudes suggests the onset of crack-induced tooth surface damage at 25%.

In

Figure 9b, the propagation of cracks on the tooth root gear causes a fluctuation and decrease in the amplitudes of the harmonics and sidebands, as well as a variation in the meshing frequency of the gears ranging from 4.6 to 3 m/s

2.

In

Figure 10a, it can be observed that, as the pitting zone increases in size, the depth of the cracks increases significantly, the peak amplitudes of the vibration increase, and the structure becomes unstable within 2 to 10 s.

In

Figure 10b, due to the pitting cracking defect, the presence of three sub-harmonics surrounded by sidebands in the range of 80.08 to 800 Hz is observed. The gear meshing frequency (

fe) increases significantly from 4.6 to 4.839 m/s

2.

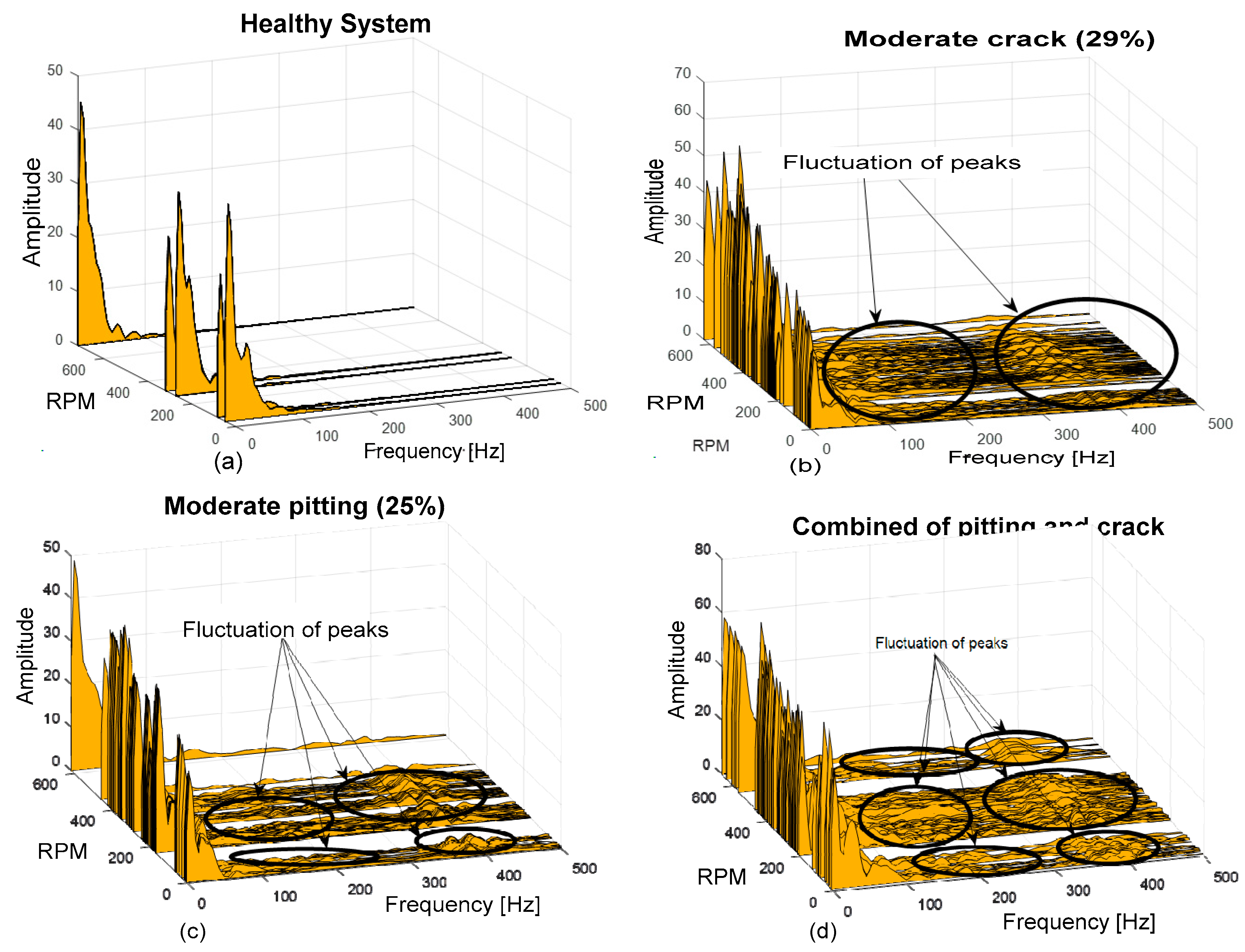

Figure 11a displays a sample spectrum at 600 working speeds, which produces a wide range of vibration frequencies when the gear is in good condition. As gear faults progress, the narrowband components increase in amplitude (fluctuation of peaks) and serve as a useful indicator for detecting suspected gearbox failures such as cracks, as shown in

Figure 11b. In

Figure 11c, the frequency range of vibration, peak size, shape, and the onset of narrow-band processes change in response to the pitting impact on the surface of the tooth. Meanwhile, as shown in

Figure 11d, the coexistence of pitting and cracking causes a significant duplication of energy frequency between 100 Hz and 300 Hz and between 300 Hz and 450 Hz, indicating the evolution of chaotic motion in the spur gear system. As a result, it is observed that the vibration peaks are visible in the spectrum once during each rotation when the faulty gear’s surface and the healthy gear’s surface engage.

4. Experimental Model

In the dynamic analysis of a two-stage spur gear, extensive studies have been conducted with a crack and a pit running at a constant speed, respectively. To evaluate the simulation model for maximum speed conditions, a two-stage spur gear test rig was built. As shown in

Figure 12, the experiments were conducted on a gearbox test bench. The test spur gear was lubricated with grease before being installed on the shafts held by bearings, as specified in the manufacturer’s brochure. The experimental set includes an electric motor with a jaw-type coupling to the gearbox and a speed regulator to control the rotation frequency of the gearbox input shaft. The rotational speed, acceleration, and acting load of the system, which has a maximum speed of 1420 rpm, were measured using the test bench.

A 0.55 kW three-phase induction motor drives a pinion positioned on the input shaft. A resistive torque is provided by the mechanical brake dynamometer, which is coupled to the output shaft of the transfer case, where the reducer is placed, and a power supply with the necessary data-gathering system. Two small piezoelectric accelerometer probe sensors measure vibration signals in the gear system, with lateral and vertical direction (Y) sensitivity of 2.56 mv/ms−2 and an acceleration sensor range of 200 g to 200 g.

For an experimental study, a thin saw cut at the tooth root simulates a cracked gear tooth to determine the crack depth, as shown in

Figure 13a. A scanning electron microscope is used to measure the cracking length pitting in

Figure 13b and the combined fault pitting and crack diameters in

Figure 13c.

To create the comprehensive gear system, the Laboratory Virtual Instrument Engineering Workbench (LabVIEW) was used. LabVIEW-based data acquisition involves building software to collect data from various sensors. The National Instruments (NI) 9234 vibration acquisition card was chosen for the analog input modules. For the experiments, the sampling rate is 10 kHz, and each sample lasts eight seconds to measure the signals within a frequency range of 0 to 15 kHz with a frame rate of 1500.

The specifications of a spur gear system are provided in

Table 1, and these data are used to compute the meshing stiffness and dynamic reactions of the gear system with coupled pitting and cracking on the tooth surface. The effects of coupled pitting and cracking on the tooth surface on mesh stiffness and vibration characteristics are then studied and discussed.

4.1. Experimental Results

The experimental model results on the dynamic properties of pitted and cracked gears are examined to confirm the simulated results using the proposed method. The first test bench is used to evaluate the dynamic behavior of a two-stage spur gear with a moderated crack of 0.5 mm in depth, a moderated pitting gear, and their coexistence in real-world conditions.

Table 600. rpm, a frequency of 10 Hz, and, subsequently, a gear mesh frequency (

fe) of 50.97 Hz make it possible to visualize the evolution of the harmonic amplitude as a function of frequency. The results of the experiments shown in

Figure 14,

Figure 15,

Figure 16 and

Figure 17 demonstrate the capability of diagnosing gear failures in real machines using large amplitude fluctuations in fault frequencies caused by sidebands. The vibration of the healthy gear at rest contains a noise component due to the impact behavior of the teeth and other mechanical components such as shafts and bearings, as shown in

Figure 14a,b.

The vibration signals measured during the meshing of the pitted spur gear are shown in

Figure 15a. In comparison to a normal state, as shown in

Figure 14a, it is observed that the vibration’s amplitude is higher.

Figure 15b illustrates the spectra of the measured signals, which show the appearance of a peak near 588 Hz, which indicates the presence of pitting. As seen in

Figure 15b, the sidebands surrounding the gear meshing frequency (

fe) are quite noticeable compared to the normal state, which implies that a gear tooth has been damaged and helps us to understand the root cause of the increased vibration.

Figure 16a depicts the vibration signals measured during the meshing of the cracked spur gear. In comparison to a normal state, as shown in

Figure 14a, it is observed that the vibration’s amplitude is higher.

Figure 16b depicts the spectra of the measured signals, which show the appearance of a peak near 588 Hz, which indicates the presence of pitting. There is a noticeable increase in the amplitude of the sidebands surrounding the gear meshing frequency (

fe) and along the frequency range of 100 to 588 Hz compared to the pitting case in

Figure 15b.

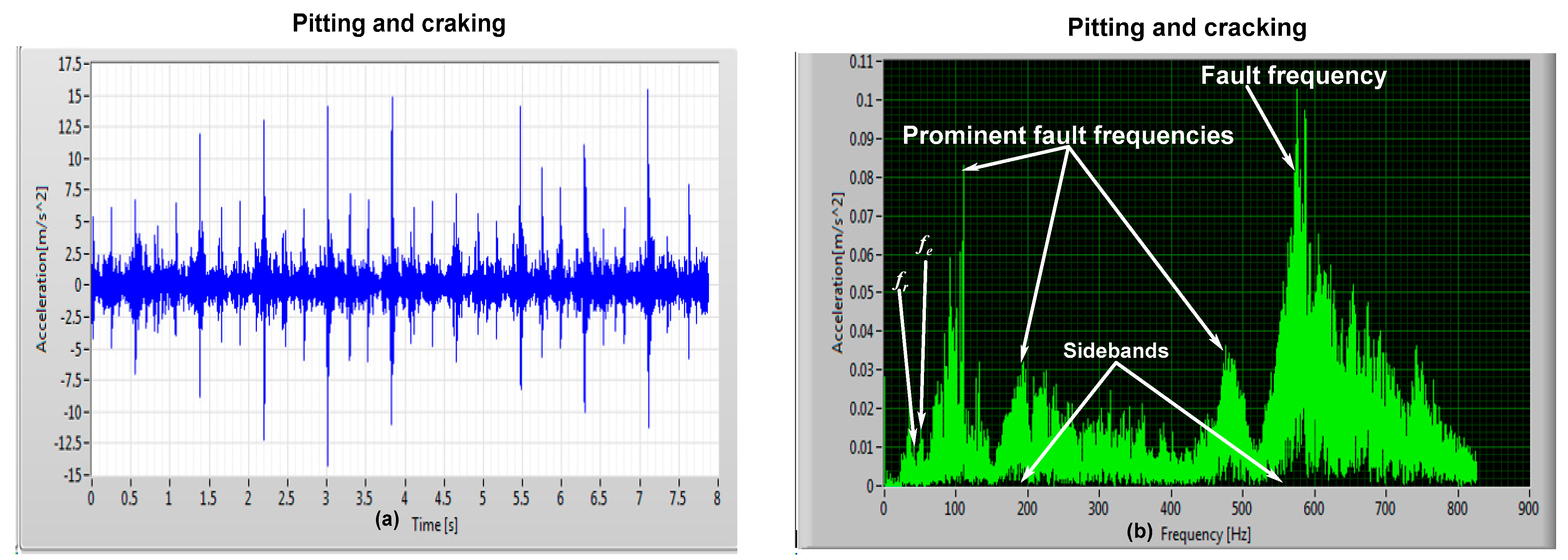

The result of vibration acceleration measurement for a gear with pitting and cracking coexistence conditions (

Figure 17a) demonstrates a considerable increase in vibration amplitude compared to the results of

Figure 14a,

Figure 15a and

Figure 16a independently. The coexistence of a 0.5-mm crack defect and 13 pits significantly impacts the vibration signal amplitude, as shown in

Figure 17b. However, as shown in

Figure 18, the frequency plot of the experimental results obtained using the 3-D waterfall frequency shows a sample spectral for 50,000 operating speeds, indicating that a wide range of vibration frequencies is generated.

Due to the high number of erroneous peaks and signal leaks, spectral and time analysis of the waveform alone are insufficient for diagnosing the problem. This deficiency is addressed by extracting non-stationary data from the experimental test using the RPM–frequency mapping technique.

4.2. Feature Extraction of Experimental Results

In

Figure 18a, the spectrogram shows that the energy bands have a small amplitude, which indicates that the gear is not broken. In the presence of a crack endangering the tooth root,

Figure 18b shows how the size and shape of the bands alter, and the narrow-band process begins. Three bands with high amplitudes and frequencies ranging from 0 to 900 Hz are depicted in

Figure 18c. In

Figure 18d, the RPM range is divided into four dominant band segments used to monitor the evolution of vibration signal amplitudes, identify pitting and cracking features, and distinguish the most dominant fault.

In

Figure 18d, the RPM range is divided into four dominant band segments that are used to monitor the evolution of vibration signal amplitudes, identify pitting and cracking features, and distinguish the most dominant fault.

To further analyze the impact of coexisting pitting and cracking on the dynamic response of gear systems, the vibration signal of the damaged gear system has been denoised, as shown in

Figure 19.

Figure 19a shows how the gear vibration signals have changed. Because of the simultaneous occurrence of the tooth surface pits and root cracks, the three indicated periodic impulses in the time domain can be identified.

The modulation effect of the fluctuating vibration signal impacted by the coexistence of pitting and cracking can be noticed from the FFT spectrum in

Figure 19b, and it is observed that the characteristic frequencies (

fr and

fe) are significantly affected. It has been observed that the sidebands and harmonic amplitudes of pitted and cracked gears can be directly identified from the RPM–frequency map, as shown in

Figure 19c.

6. Conclusions

In summary, this study proposes a novel model of tooth pitting–crack coexistence faults in gear transmission systems and a method of calculating the stiffness of a spur gear with a combined pitting and crack fault. The influence of the crack and pitting parameters and time-varying mesh stiffness on the vibration characteristics of a gear system is studied. The coexistence of pitting and cracking faults on a two-stage spur gear system is analyzed. Both the time domain and frequency domain results and the RPM-frequency map are obtained for the 10 degrees of freedom gear system with coexistence defects and compared with experimental results. Based on the operating condition of a 10 Hz input frequency, several conclusions are obtained:

(1) Cracking predominates in terms of meshing stiffness when the crack is moderate (29%) and the pitting is moderate (25%).

(2) By observing the vibration mutation in the acceleration time domain, the vibration peaks can be used to identify a defect; for the acceleration signal in the frequency domain, the sideband frequency rise can indicate the nature of the defect.

(3) The sideband in the RPM–frequency map responses is more sensitive to cracking and pitting coupled faults affecting the gear tooth surface than the time domain and FFT responses of the dynamics spur gear transmission system. The surface crack fault is easier to diagnose than the surface pit fault because the side frequencies of the dynamics spur gear transmission system increase and change more quickly and drastically during the surface crack propagation.

(4) According to the simulation results for a two-stage spur gear transmission system with a tooth cracking and pitting couple, complex sidebands form close to the gear mesh frequency, and their harmonics and amplitudes rise as the severity of the cracking and pitting couple increases. The experimental results indicate cracking and pitting on the teeth with detailed defect characteristics which qualitatively assess the accuracy of the modeling results.