Study on Smoke Flow and Temperature Distribution Patterns in Fires at Deeply Buried Subway Stations

Abstract

1. Introduction

2. Full-Scale Fire Experiment

2.1. Experimental Conditions

2.2. Fire Source Setup

2.3. Temperature Measurement System

2.4. Wind Speed Measurement Device

2.5. Video Recording System

2.6. Harmful Gas Monitoring Device

3. Experimental Results and Analysis

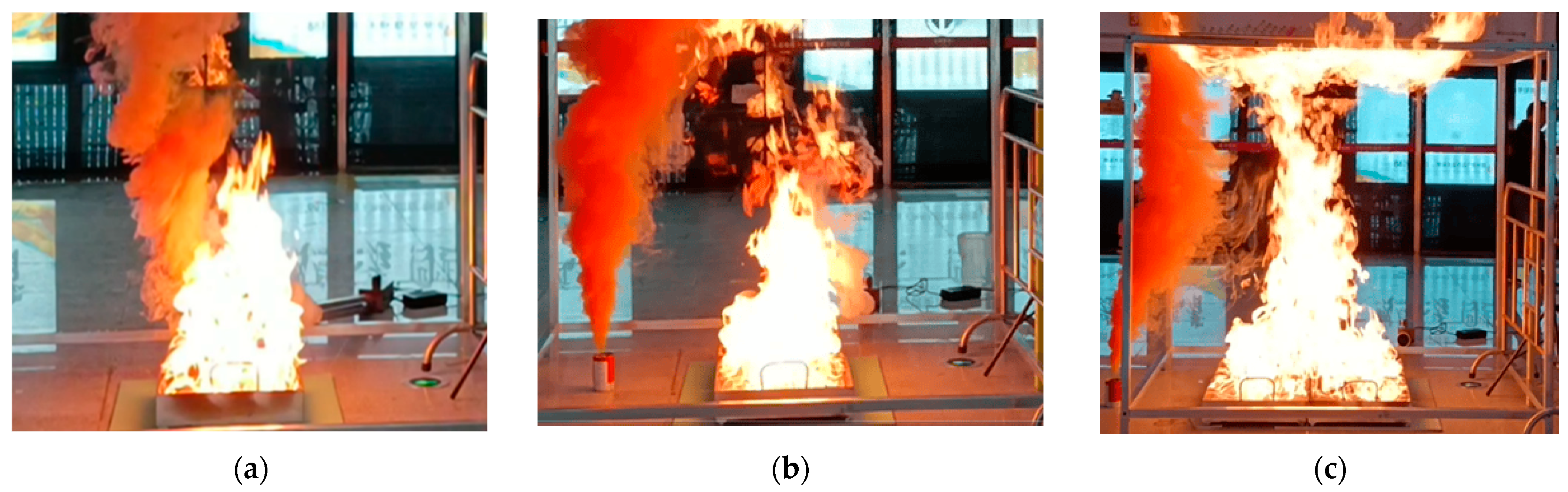

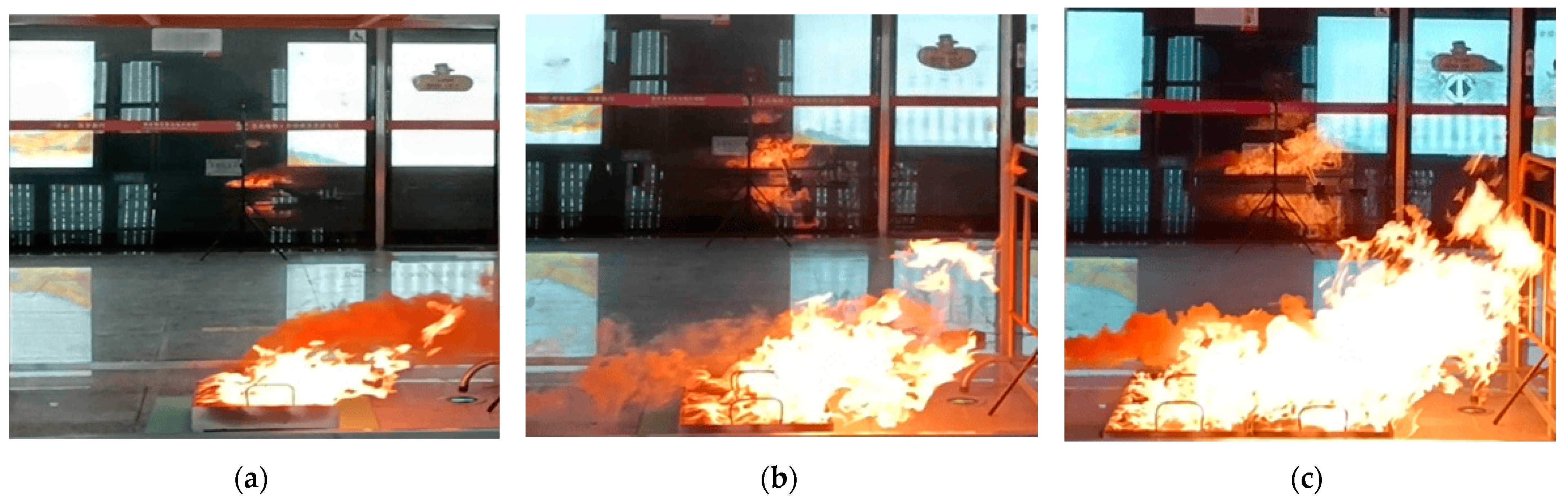

3.1. Fire Source Combustion During the Experiment

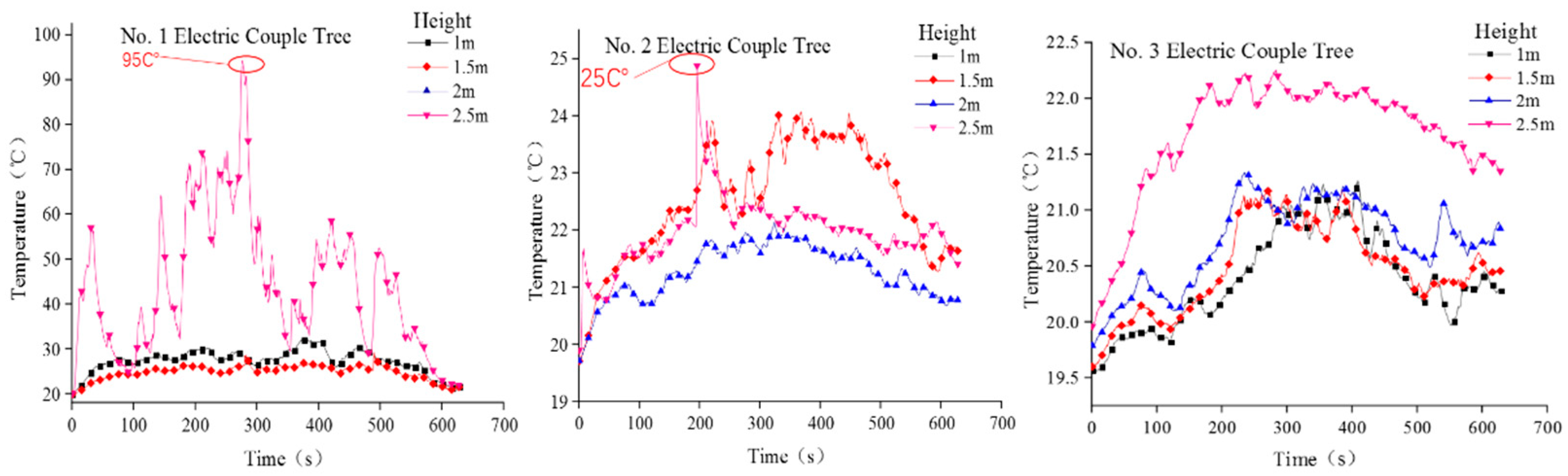

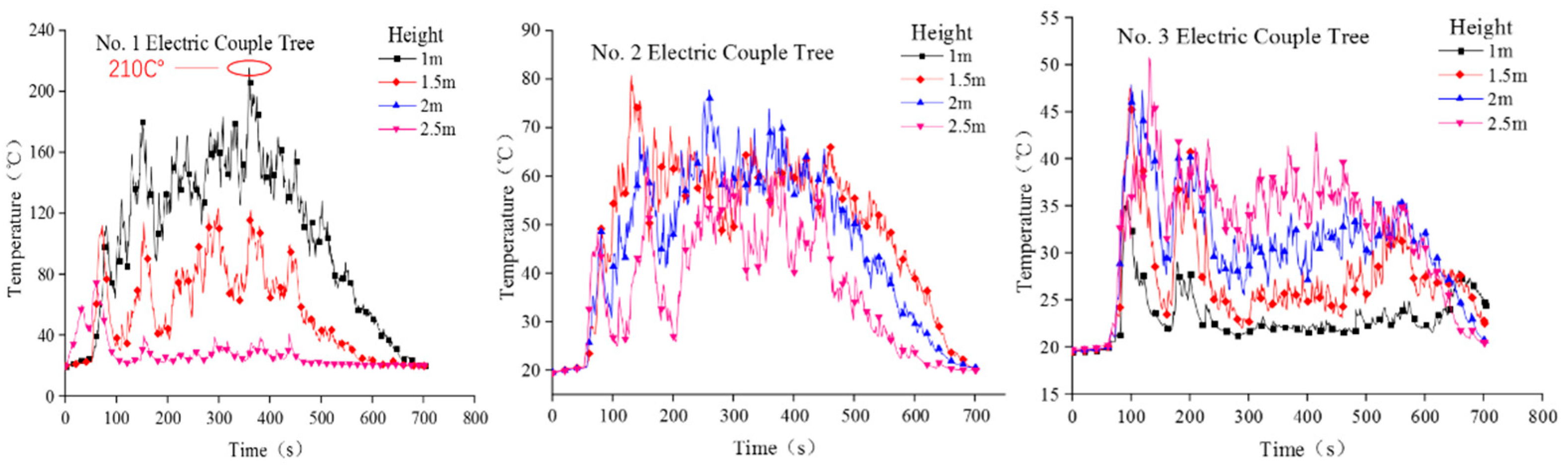

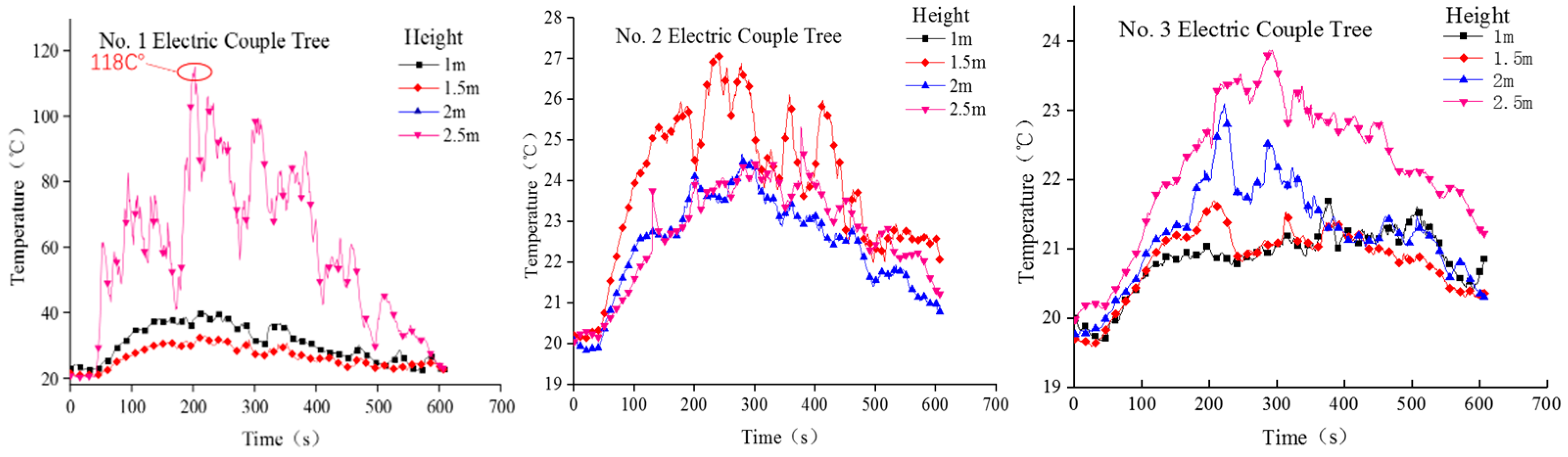

3.2. Temperature Distribution of the Smoke Layer

3.3. Longitudinal Distribution of Ceiling Temperature Field

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.Z. Study on Smoke Movement and Control in Atrium-Style Subway Station Fires. Master’s Thesis, Southwest Jiaotong Universy, Chengdu, China, 2022. [Google Scholar]

- Yang, Y. Simulation Analysis of Smoke in Subway Platform Fires. J. Hefei Univ. (Compr. Ed.) 2021, 38, 121–127. [Google Scholar]

- Nie, C.T.; Chi, X.W.; Xie, Y. Research on the Evaluation Index System of Subway Fire Risk. Urban Mass Transit. 2023, 26, 147–151+156. [Google Scholar]

- Li, Y.F.; Su, Z.H. A Review of Research on Thermal Environment Evolution and Evacuation Safety in Subway Tunnel Fires. Tunn. Undergr. Eng. Disaster Prev. Control. 2024, 6, 1–12. [Google Scholar]

- Xu, D.N. Study on Influencing Factors and Control of Smoke Spread in Rectangular-like Subway Tunnels. Master’s Thesis, Dalian Jiaotong University, Dalian, China, 2023. [Google Scholar]

- Gao, H.H. Study on Smoke Characteristics in Subway Tunnel Fires Considering Train Blockage Effect and Slope Influence. Master’s Thesis, Henan University of Technology, Zhengzhou, China, 2023. [Google Scholar]

- Zhou, D.; Tang, Z.T.; Hu, T.E. Study on the Influence of Tunnel Radius on Smoke Spread Characteristics in Subway Train Fires. J. Railw. Sci. Eng. 2023, 20, 3918–3927. [Google Scholar]

- Chen, S.; Tao, T.; Zhou, X.Y. Simulation Study on Evacuation in Typical Scenarios of Subway Carriage Fires. Urban Mass Transit. 2023, 26, 147–154. [Google Scholar]

- Zahr, T.; Omid, A.; Mahmoud, Y. 3D Simulations of Smoke Exhaust System in Two Types of Subway Station Platforms. Int. J. Vent. 2021, 20, 65–81. [Google Scholar]

- Rie, D.; Ryu, J. Sustainable Urban Planning Technique of Fire Disaster Prevention for Subway. Sustainability 2020, 12, 372. [Google Scholar] [CrossRef]

- Zheng, A.P.; Liu, C.H.; Pang, M.X. Application Research on the Linkage Mode of Subway Tunnel Ventilation System and Interval Fire. Fire Sci. Technol. 2023, 42, 931–934. [Google Scholar]

- Cheng, X. Simulation Study on the Smoke Blocking Performance of Air Curtains in Subway Platforms. Master’s Thesis, Anhui Jianzhu University, Hefei, China, 2024. [Google Scholar]

- Liu, Z.Y.; Li, X.; Zhou, X. Temperature Distribution in Subway Carriage Fires under Air Supply Conditions. J. Tsinghua Univ. (Nat. Sci. Ed.) 2023, 63, 1529–1536. [Google Scholar]

- Chen, K.C.; Xie, J.B.; Yao, Q.H. Simulation and Analysis of Smoke Diffusion in Subway Platform Fires. J. Sun Yat-Sen Univ. (Nat. Sci. Ed.) 2019, 58, 15–22. [Google Scholar]

- Roh, J.S.; Ryou, H.S.; Park, W.H.; Jang, Y.J. CFD simulation and assessment of life safety in a subway train fire. Tunn. Undergr. Space Technol. 2009, 24, 447–453. [Google Scholar] [CrossRef]

- Li, Q.M.; Deng, Y.L.; Liu, C.; Zeng, Q.T.; Lu, Y. Modeling and analysis of subway fire emergency response: An empirical study. Saf. Sci. 2016, 84, 171–180. [Google Scholar] [CrossRef]

- Wang, L. Study on Combustion Characteristics of Transverse Double Fire Sources in Mountain Highway Tunnels. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2023. [Google Scholar]

- Wang, Z.Y.; Li, J.; Fu, M. Evacuation Simulation of Deep-buried Subway Stations Considering Fatigue and Visibility. Fire Sci. Technol. 2019, 38, 1698–1702. [Google Scholar]

- Wen, K.; Ni, T.X.; Peng, J.Z. Calculation Method and Application of Natural Air Supply Pathway Resistance in Deep-buried Subway Stations. Mod. Urban Transit. 2022, 06, 89–93. [Google Scholar]

- Lan, B. Study on Smoke Movement and Evacuation Strategies in Deep-buried Subway Station Fires. Master’s Thesis, Chongqing University of Science and Technology, Chongqing, China, 2021. [Google Scholar]

- Shi, C.L.; Zhong, M.H.; He, L. Full-scale fire experiment research in subway station and tunnel (1): Experimental design. J. Saf. Sci. Technol. 2012, 8, 22–28. [Google Scholar]

| Experimental Condition | Pan Size (m) | Number of Pans | Heat Release Rate (kW/m2) | Fire Source Power (kW) |

|---|---|---|---|---|

| 1. Without exhaust | 0.5 × 0.5 × 0.1 | 1 | 658 | 165 |

| 2. With exhaust | 0.5 × 0.5 × 0.1 | 1 | 658 | 165 |

| 3. Without exhaust | 0.5 × 0.5 × 0.1 | 2 | 696 | 348 |

| 4. With exhaust | 0.5 × 0.5 × 0.1 | 2 | 696 | 348 |

| 5. Without exhaust | 0.5 × 0.5 × 0.1 | 4 | 751 | 751 |

| 6. With exhaust | 0.5 × 0.5 × 0.1 | 4 | 751 | 751 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, H.; Liu, H.; Zhao, Y.; Bian, Z. Study on Smoke Flow and Temperature Distribution Patterns in Fires at Deeply Buried Subway Stations. Fire 2025, 8, 296. https://doi.org/10.3390/fire8080296

Yan H, Liu H, Zhao Y, Bian Z. Study on Smoke Flow and Temperature Distribution Patterns in Fires at Deeply Buried Subway Stations. Fire. 2025; 8(8):296. https://doi.org/10.3390/fire8080296

Chicago/Turabian StyleYan, Huailin, Heng Liu, Yongchang Zhao, and Zirui Bian. 2025. "Study on Smoke Flow and Temperature Distribution Patterns in Fires at Deeply Buried Subway Stations" Fire 8, no. 8: 296. https://doi.org/10.3390/fire8080296

APA StyleYan, H., Liu, H., Zhao, Y., & Bian, Z. (2025). Study on Smoke Flow and Temperature Distribution Patterns in Fires at Deeply Buried Subway Stations. Fire, 8(8), 296. https://doi.org/10.3390/fire8080296