Classification and Prevention of Electrical Fires: A Comprehensive Review

Abstract

1. Introduction

2. Electrical Fire

2.1. Electrical Wiring Fire

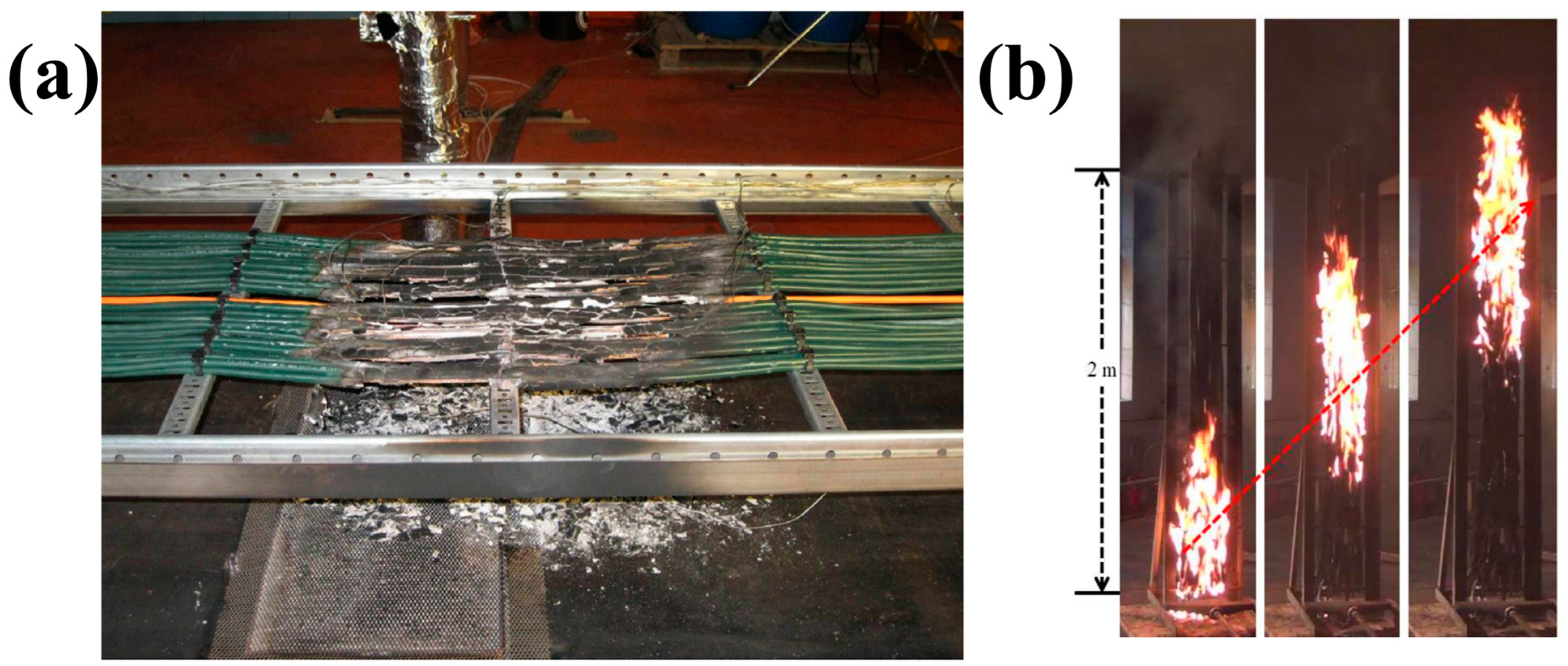

2.1.1. Cable Fire

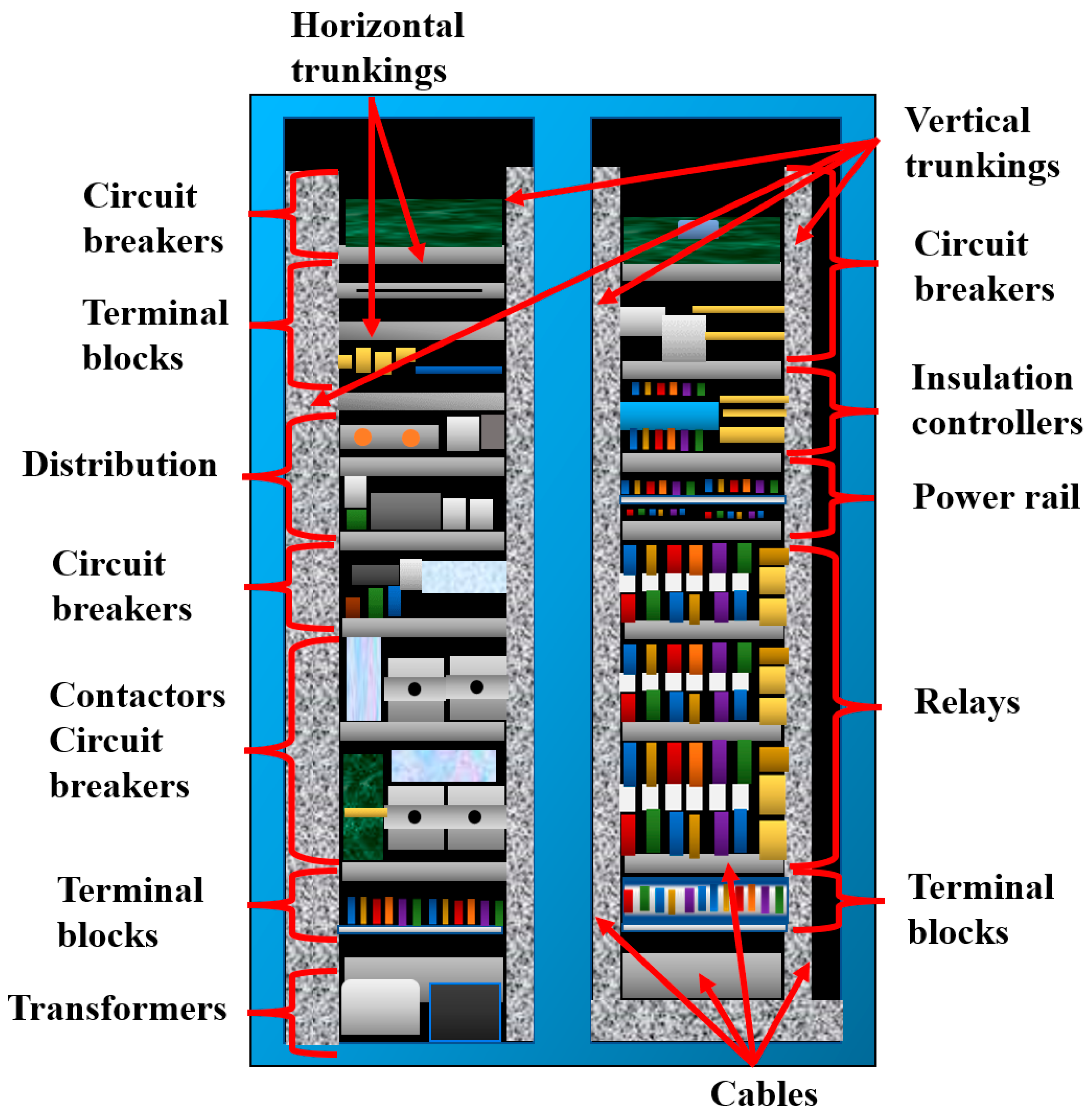

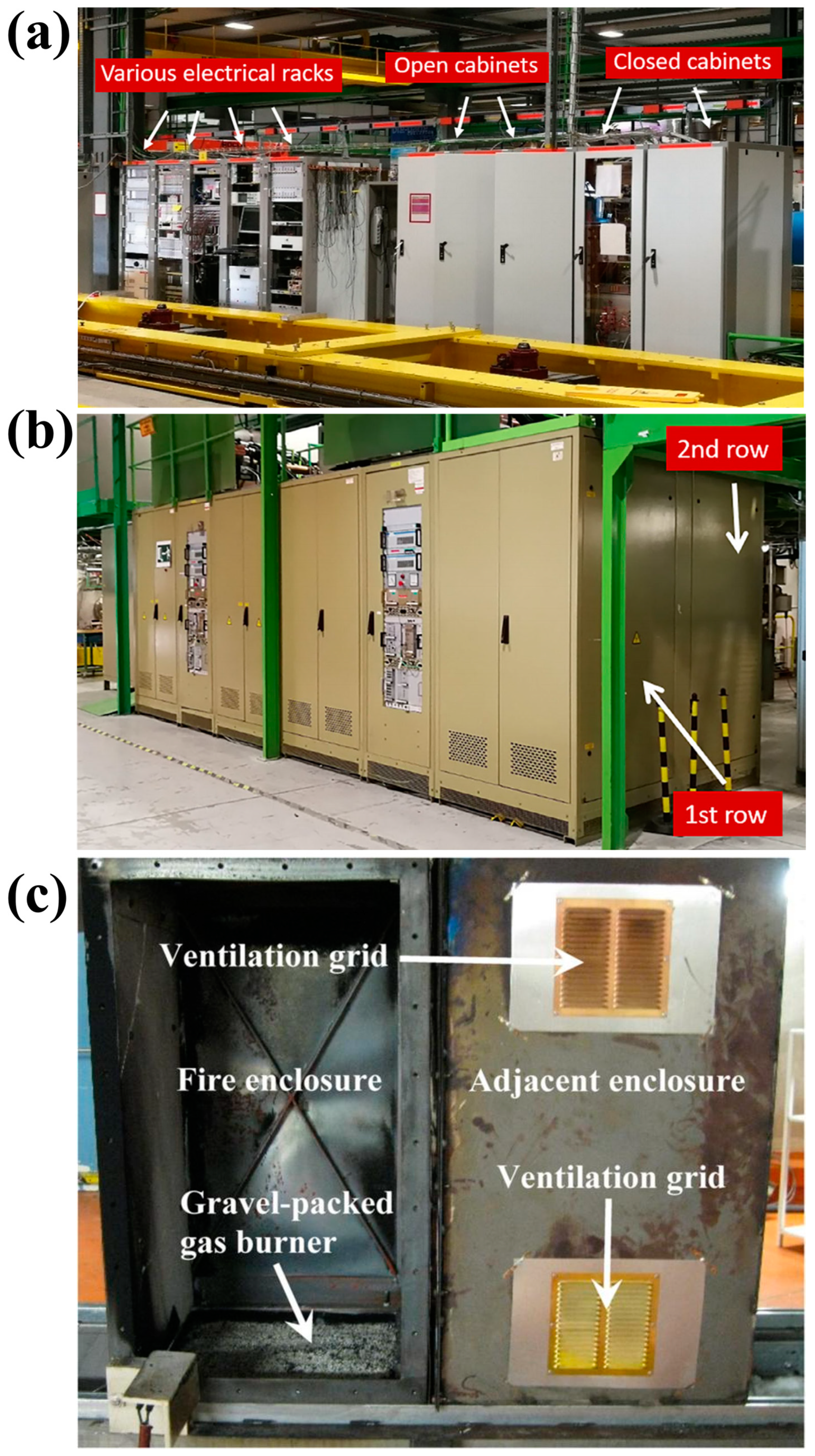

2.1.2. Electrical Cabinet Fire

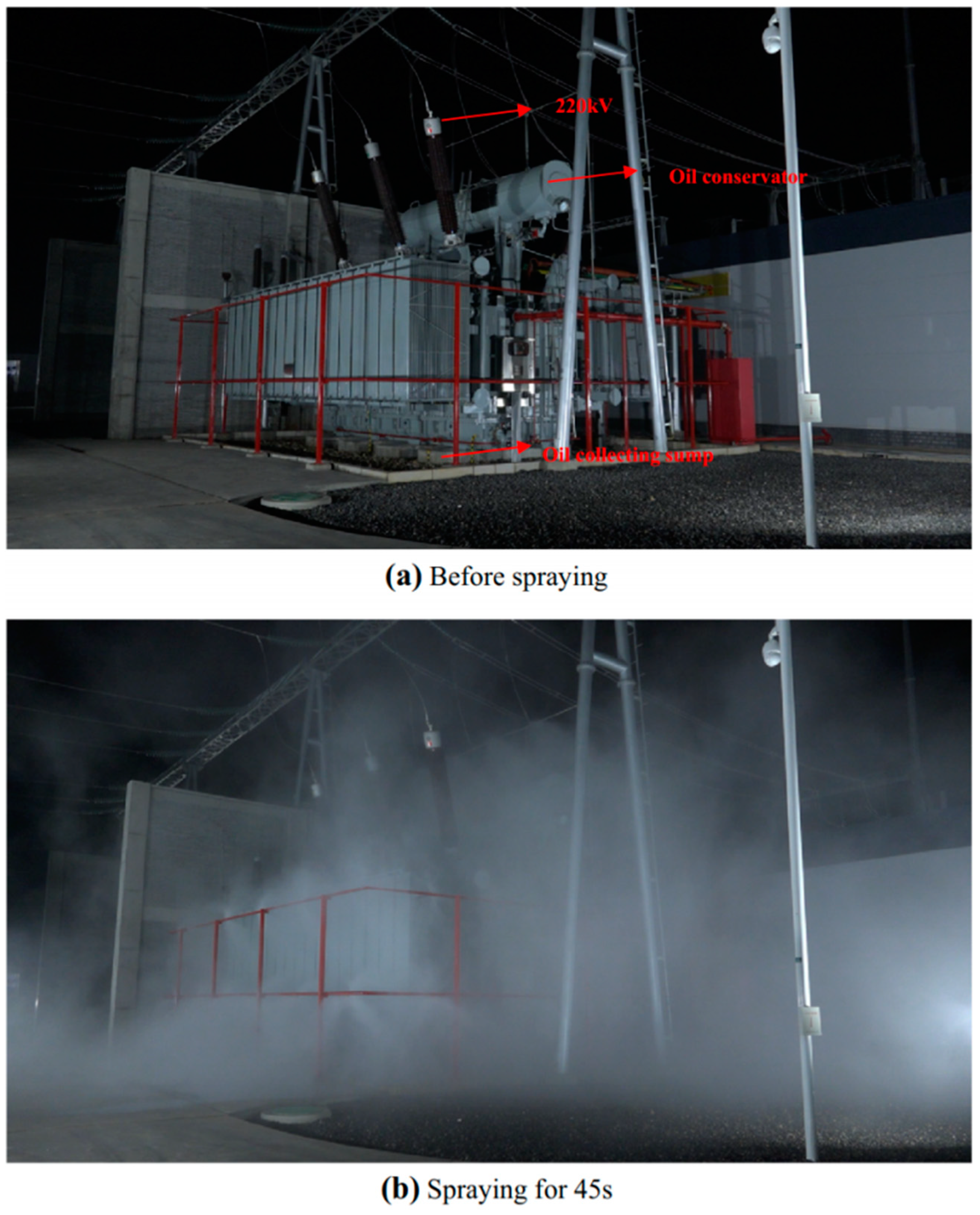

2.1.3. Transformer Fire

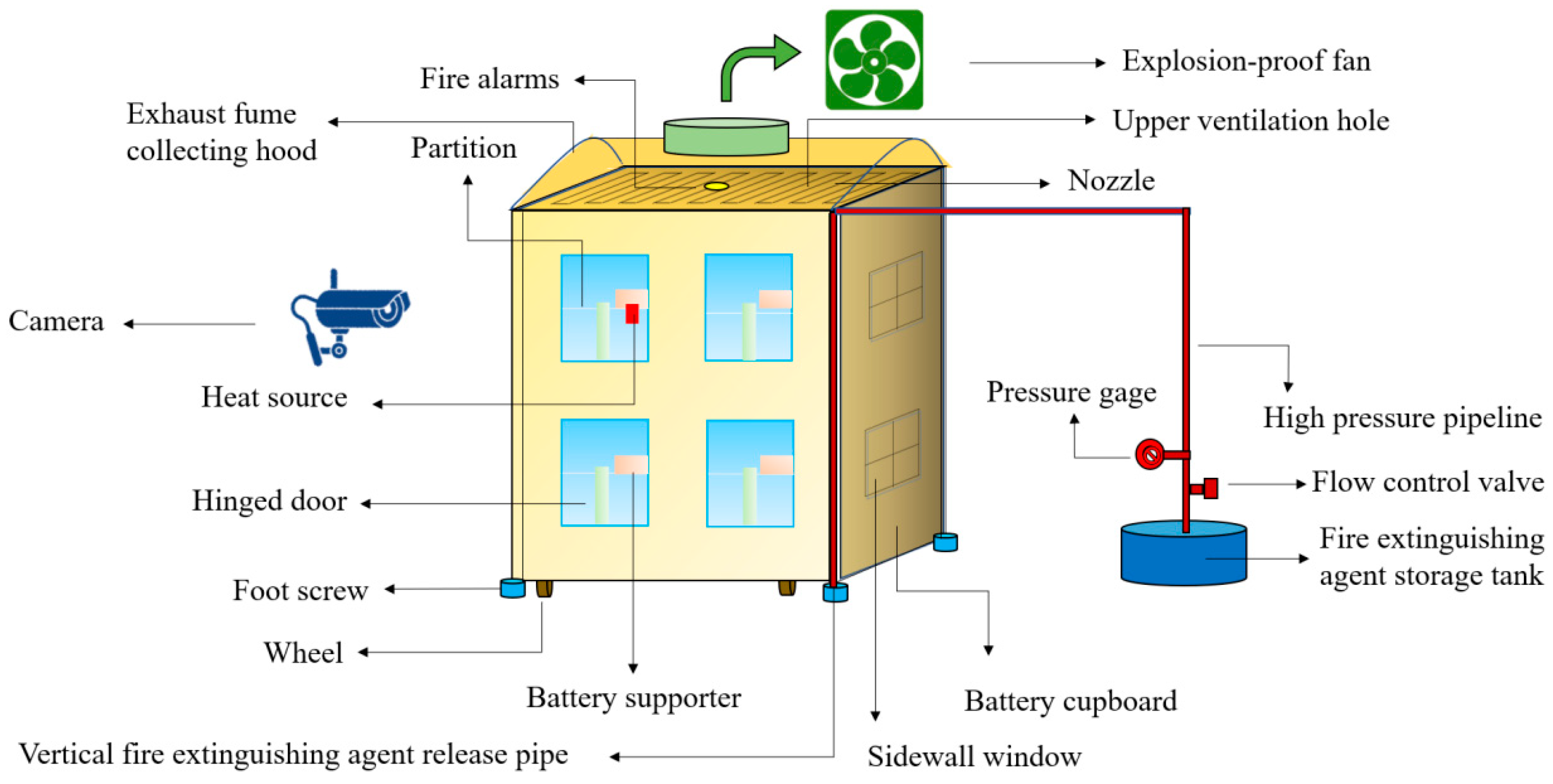

2.1.4. Battery Fires

2.1.5. Data Center Fires

2.1.6. Household Fires

2.2. Scenario-Specific Electrical Fires

2.2.1. Submarine Electrical Fire

2.2.2. Electrical Fire on Surface Ships

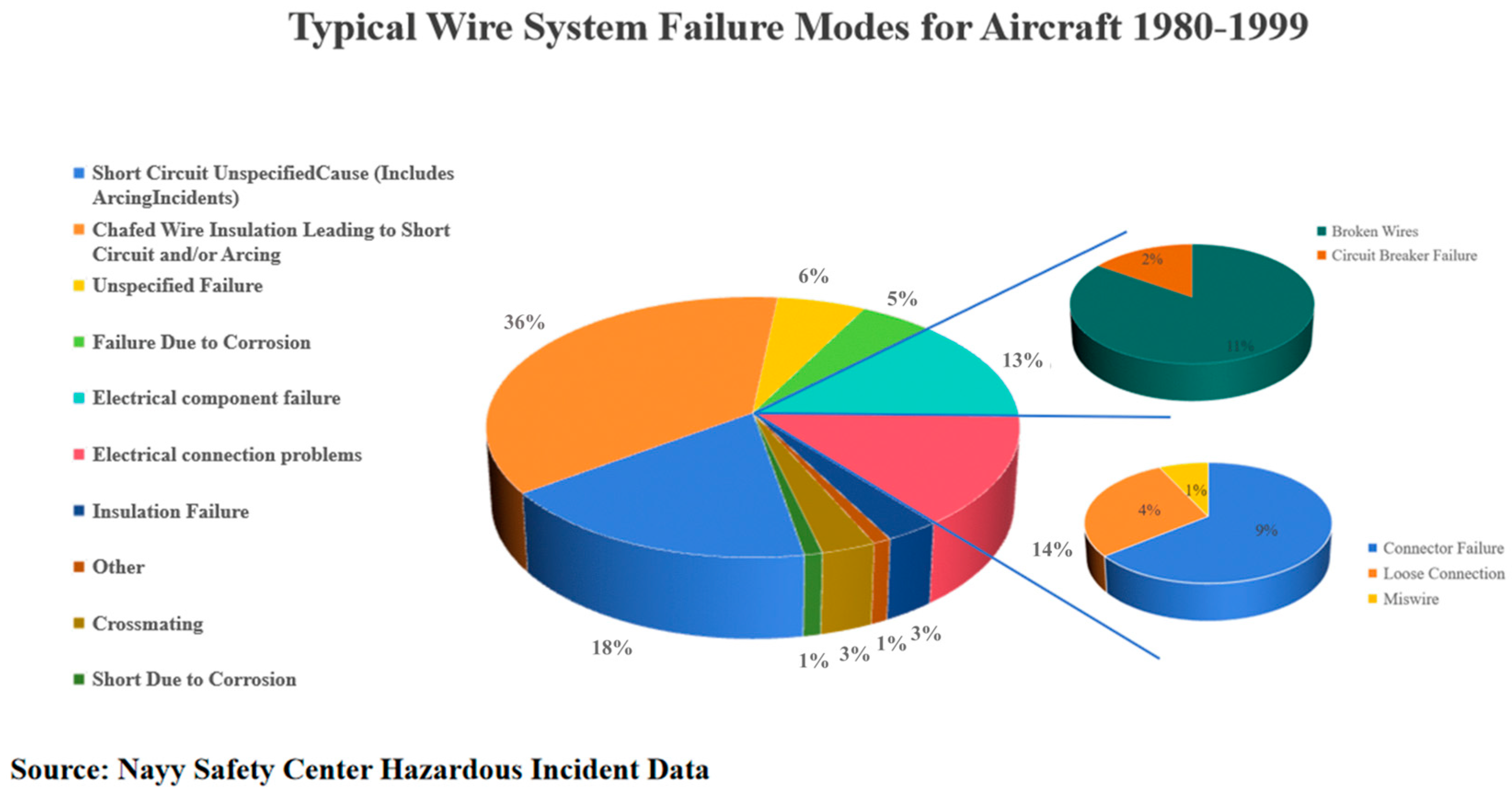

2.2.3. Aircraft Electrical Fire

2.3. Summary

3. Electric Fire Prevention and Control Technology

3.1. Electrical Fire Detection

3.1.1. Sensor Detection Technology

Traditional Sensor Detection Technology

Video Detection Technology

3.1.2. Infrared Thermal Imaging Detection Technology

3.1.3. Arc Detection Technique

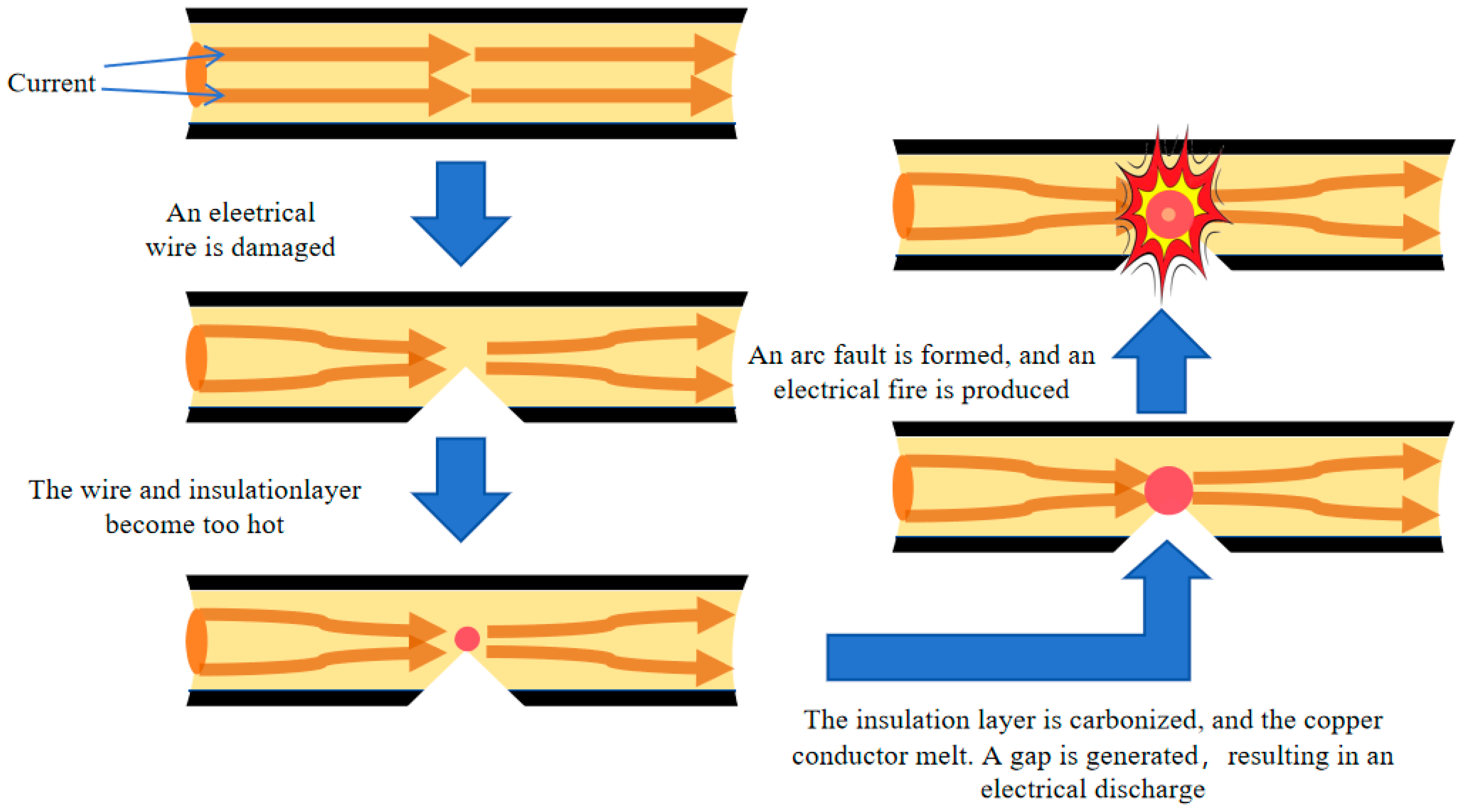

3.1.4. Optical Fiber Detection Technology

3.1.5. Exploration Technology Selection

3.2. Electrical Fire Extinguishing

3.2.1. Electrical Fire Extinguishing Agent

| Properties | C6F-ketone |

|---|---|

| Chemical formula | CF3CF2C(O)CF(CF3)2 |

| Molecular weight | 316.04 |

| Boiling point at 1 atm (°C) | 49.2 |

| Freezing point (°C) | −108.0 |

| Critical temperature (°C) | 168.7 |

| Critical pressure (bar) | 18.65 |

| Critical volume (cc/mole) | 494.5 |

| Critical density (kg/m3) | 639.1 |

| Density, sat. liquid (g/mL) | 1.60 |

| Density, gas at 1 atm (g/mL) | 0.0136 |

| Specific volume, gas at 1 atm (g/mL) | 0.0733 |

| Specific heat, vapor at 1 atm (kJ/kg·K) | 1.103 |

| Specific heat, liquid (kJ/kg·K) | 0.891 |

| Heat of vaporization at boiling point (kJ/kg) | 88.0 |

| Relative dielectric strength, 1 atm (N2 = 1.0) | 2.3 |

3.2.2. Electrical Fire Extinguishing Technology

3.2.3. Selection of Fire Fighting Technology

4. Research Gaps and Prospects for Electrical Fire Prevention and Control

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Abbreviations

| ITER | International Thermonuclear Experimental Reactor |

| NPP | Nuclear power plant |

| CERN | European Organization for Nuclear Research |

| PM | Permanent magnet |

| SSPCs | Solid-state power controllers |

| USNSC | U.S. Navy Safety Center |

| TWA | Trans World Airlines |

| NTSB | National Transportation Safety Board |

| AAIB | Air Accidents Investigation Branch |

| BFU | Bundesamt für Flugunfalluntersuchung |

| CIGRE | International Conference on Large Electricity Grids |

| IEEE | Institute of Electrical and Electronics Engineers |

| NFPA | National Fire Protection Association |

| AFFF | Aqueous film-forming foam |

| IT | Insulation transformer |

| NREL | National Renewable Energy Laboratory |

| FAA | Federal Aviation Administration |

| DO-160 | Environmental Conditions and Test Procedures for Airborne Equipment |

| WMA | Water mist additive |

| DTS | Distributed temperature sensing |

| Raman | Raman scattering |

| OTDR | Optical time-domain reflectometry |

| ARC | Accelerating rate calorimetry |

| CO2 | Carbon dioxide |

| C6F-ketone | Dodecafluoro-2-methylpentan-3-one |

| WMA | Water mist additives |

| CO | Carbon monoxide |

| CH4 | Methane |

| H2 | Hydrogen |

| HF | Hydrogen fluoride |

| Novec 1230 | Dodecafluoro-2-methylpentan-3-one |

| DTS | Distributed temperature sensing |

| EPA | Environmental Protection Agency |

| MIL-STD | Military standard |

| ARINC | Aeronautical radio, incorporated |

| RTCA | Radio Technical Commission for Aeronautics |

| ARL | Aerospace research laboratory |

References

- National Fire and Rescue Administration. National Fire and Rescue Administration Held a Press Conference on the National Fire Safety Situation from January to August This Year [EB/OL]. Available online: http://www.china.com.cn/app/template/amucsite/web/webLive.html#3697 (accessed on 4 December 2024).

- Zhang, Y. Design and Implementation of Fire Safety Assessment and Early Warning System for High Rise Buildings. In Smart Infrastructures in the IoT Era; Al-Turjman, F., Ed.; Springer Nature: Cham, Switzerland, 2025; pp. 245–257. [Google Scholar] [CrossRef]

- Shelby Hall. Fire Loss in the United States [EB/OL]. Available online: https://www.nfpa.org/education-and-research/research/nfpa-research/fire-statistical-reports/fire-loss-in-the-united-states?os=httpswww.google.com&ref=app (accessed on 4 December 2024).

- Jia, F.; Patel, M.K.; Galea, E.R.; Grandison, A.; Ewer, J. CFD fire simulation of the Swissair flight 111 in-flight fire—Part 1: Prediction of the pre-fire air flow within the cockpit and surrounding areas. Aeronaut. J. 2006, 110, 41–52. [Google Scholar] [CrossRef]

- Huang, W.; Zhou, C.; Wang, X.Q. Fire Statistic and Prevention Measures for Cables in Power Plant. Adv. Mater. Res. 2013, 614–615, 1949–1952. [Google Scholar] [CrossRef]

- Keski-Rahkonen, O.; Mangs, J. Electrical ignition sources in nuclear power plants: Statistical, modelling and experimental studies. Nucl. Eng. Des. 2002, 213, 209–221. [Google Scholar] [CrossRef]

- Mcgrattan, K.B.; Dreisbach, J. (Eds.) Cable Response to Live Fire (CAROLFIRE) Volume 3: Thermally-Induced Electrical Failure (THIEF) Model; Office of Nuclear Regulatory Research: Rockville, MD, USA, 2008. [Google Scholar] [CrossRef]

- Hirschler, M.M. Survey of fire testing of electrical cables. Fire Mater. 1992, 16, 107–118. [Google Scholar] [CrossRef]

- BS EN 50399:2022; Common Test Methods for Cables Under Fire Conditions. British Standards Institution: London, UK, 2022.

- Magalie, C.; Anne-Sophie, C.; Rodolphe, S.; Laurent, F.; Emmanuelle, G.; Christian, L. Fire behaviour of electrical cables in cone calorimeter: Influence of cables structure and layout. Fire Saf. J. 2018, 99, 12–21. [Google Scholar] [CrossRef]

- Huang, X.; Nakamura, Y. A Review of Fundamental Combustion Phenomena in Wire Fires. Fire Technol. 2020, 56, 315–360. [Google Scholar] [CrossRef]

- Grigorieva, M.M.; Ivanova, E.V.; Strizhak, P.A. Forecasting investigation of mode fire hazard of electrical overload of cable lines. EPJ Web Conf. 2015, 82, 1031. [Google Scholar] [CrossRef]

- Sarazin, J.; Bachelet, P.; Bourbigot, S. Fire behavior of simulated low voltage intumescent cables with and without electric current. J. Fire Sci. 2017, 35, 179–194. Available online: https://journals.sagepub.com/doi/abs/10.1177/0734904117698843 (accessed on 4 December 2024). [CrossRef]

- Hirschler, M.M. Flame retardants and heat release: Review of traditional studies on products and on groups of polymers. Fire Mater. 2015, 39, 207–231. [Google Scholar] [CrossRef]

- Zhang, B.-S.; Zhang, J.-Q.; Li, Q.; Wang, L.-F.; Xie, H.; Fan, M.-H. Effects of Insulating Material Ageing on Ignition Time and Heat Release Rate of the Flame Retardant Cables. Procedia Eng. 2018, 211, 972–978. [Google Scholar] [CrossRef]

- Martinka, J.; Rantuch, P.; Sulová, J.; Martinka, F. Assessing the fire risk of electrical cables using a cone calorimeter. J. Therm. Anal. Calorim. 2019, 135, 3069–3083. [Google Scholar] [CrossRef]

- Polanský, R.; Polanská, M. Testing of the fire-proof functionality of cable insulation under fire conditions via insulation resistance measurements. Eng. Fail. Anal. 2015, 57, 334–349. [Google Scholar] [CrossRef]

- Courty, L.; Garo, J. External heating of electrical cables and auto-ignition investigation. J. Hazard. Mater. 2017, 321, 528–536. [Google Scholar] [CrossRef]

- McGrattan, K.B.; Lock, A.J.; Marsh, N.D.; Nyden, M.R. (Eds.) Cable Heat Release, Ignition, and Spread in Tray Installations During Fire (CHRISTIFIRE): Phase 1—Horizontal Trays; Contractor Report; NUREG/CR-7010; Office of Nuclear Regulatory Research: Rockville, MD, USA, 2012. [Google Scholar]

- Mcgrattan, K.; Bareham, S. (Eds.) Cable Heat Release, Ignition, and Spread in Tray Installations During Fire (CHRISTIFIRE) Phase 2: Vertical Shafts and Corridors; NUREG/CR-7010; Office of Nuclear Regulatory Research: Rockville, MD, USA, 2013; Volume 2. [Google Scholar]

- Huang, X.; Wang, Y.; Ren, Z.; Li, Z.; Cheng, C.; Chow, W. Experimental investigation on maximum ceiling jet temperature generated by a vertically spreading cable fire. Fire Saf. J. 2021, 120, 103125. [Google Scholar] [CrossRef]

- Passalacqua, R.; Cortes, P.; Taylor, N.; Beltran, D.; Zavaleta, P.; Charbaut, S. Experimental characterisation of ITER electric cables in postulated fire scenarios. Fusion Eng. Des. 2013, 88, 2650–2654. [Google Scholar] [CrossRef]

- Huang, X.; Ren, Z.; Zhu, H.; Peng, L.; Cheng, C.; Chow, W. A modified zone model on vertical cable tray fire in a confined compartment in the nuclear power plant. J. Fire Sci. 2018, 36, 472–493. [Google Scholar] [CrossRef]

- Yang, Y.-C.; Li, Q.; Zhang, J.-Q.; Fan, M.-H. The Study of the Cable Failure Criteria Used in Fire PSA. Procedia Eng. 2016, 135, 510–514. [Google Scholar] [CrossRef][Green Version]

- Avidor, E.; Joglar-Billoch, F.J.; Mowrer, F.W.; Modarres, M. Hazard Assessment of Fire in Electrical Cabinets. Nucl. Technol. 2003, 144, 337–357. [Google Scholar] [CrossRef]

- Coutin, M.; Plumecocq, W.; Zavaleta, P.; Audouin, L. Characterisation of open-door electrical cabinet fires in compartments. Nucl. Eng. Des. 2015, 286, 104–115. [Google Scholar] [CrossRef]

- Woodward, R. (Ed.) The Organisation for Economic Co-Operation and Development (OECD), 1st ed.; Taylor & Francis: London, UK, 2009. [Google Scholar] [CrossRef]

- Chavez, J.M. An Experimental Investigation of Internally Ignited Fires in Nuclear Power Plant Control Cabinets: Part 1: Cabinet Effects Tests; No. NUREG/CR-4527-1; SAND-86-0336; Sandia National Labs.: Albuquerque, NM, USA; Nuclear Regulatory Commission: Washington, DC, USA, 1987. [Google Scholar]

- Chavez, J.M.; Nowlen, S.P. An Experimental Investigation of Internally Ignited Fires in Nuclear Power Plant Control Cabinets: Part 2, Room Effects Tests; No. NUREG/CR-4527-Vol. 2; SAND-86-0336-Vol. 2; Sandia National Labs.: Albuquerque, NM, USA; Nuclear Regulatory Commission: Washington, DC, USA, 1988. [Google Scholar]

- Mangs, J.; Keski-Rahkonen, O. Full Scale Fire Experiments on Electronic Cabinets; Technical Research Centre of Finland: Espoo, Finland, 1996. [Google Scholar]

- Mangs, J.; Paananen, J.; Keski-Rahkonen, O. Calorimetric fire experiments on electronic cabinets. Fire Saf. J. 2003, 38, 165–186. [Google Scholar] [CrossRef]

- Plumecocq, W.; Coutin, M.; Melis, S.; Rigollet, L. Characterization of closed-doors electrical cabinet fires in compartments. Fire Saf. J. 2011, 46, 243–253. [Google Scholar] [CrossRef]

- Bruynooghe, C.; Noël, M. European clearinghouse: Contributing factors to incidents related to reactivity management. Prog. Nucl. Energy 2010, 52, 523–526. [Google Scholar] [CrossRef]

- Perović, D.; Van Hees, P.; Madsen, D.; Malmborg, V.; Gren, L.; Pagels, J.; Rios, O.; La Mendola, S. Identification and characterization of design fires and particle emissions to be used in performance-based fire design of nuclear facilities. Fire Mater. 2021, 45, 1008–1024. [Google Scholar] [CrossRef]

- Zavaleta, P.; Bouygues, O.; Lapuerta, C. Electrical component ignition in a closed enclosure adjacent to a controlled fire. Fire Mater. 2021, 45, 331–344. [Google Scholar] [CrossRef]

- Zavaleta, P.; Suard, S.; Audouin, L. Fire spread from an open-doors electrical cabinet to neighboring targets in a confined and mechanically ventilated facility. Fire Mater. 2019, 43, 466–485. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Liu, H.; Yan, G.; Kou, W. Infrared identification of internal overheating components inside an electric control cabinet by inverse heat transfer problem. Proc. SPIE-Int. Soc. Opt. Eng. 2014, 9300, 293–298. [Google Scholar] [CrossRef]

- El-Harbawi, M.; Al-Mubaddel, F. Risk of Fire and Explosion in Electrical Substations Due to the Formation of Flammable Mixtures. Sci. Rep. 2020, 10, 6295. [Google Scholar] [CrossRef]

- Morandi, A.; Trevisani, L.; Ribani, P.L.; Fabbri, M.; Martini, L.; Bocchi, M. Superconducting transformers: Key design aspects for power applications. J. Phys. Conf. Ser. 2008, 97, 12318. [Google Scholar] [CrossRef]

- Hao, Y.; Zhang, Y.; Wang, Z.; Liu, X.; Chen, M.; Yang, L. Analysis and design of an intelligent fire alarm system for UHV Substation. IOP Conf. Ser. Mater. Sci. Eng. 2019, 677, 42023. [Google Scholar] [CrossRef]

- Land, H.B. Determination of the Cause of Arcing Faults in Low-Voltage Switchboards. IEEE Trans. Ind. Appl. 2008, 44, 430–436. [Google Scholar] [CrossRef]

- Ma, G.-L.; Xie, Q. Seismic Analysis of a 500-kV Power Transformer of the Type Damaged in the 2008 Wenchuan Earthquake. J. Perform. Constr. Facil. 2018, 32, 4018007. [Google Scholar] [CrossRef]

- Ziomek, W. Transformer Electrical Insulation [Editorial]. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1841–1842. [Google Scholar] [CrossRef]

- Christin, A.J.; Salam, M.A.; Rahman, Q.M.; Wen, F.; Ang, S.P.; Voon, W. Causes of transformer failures and diagnostic methods—A review. Renew. Sustain. Energy Rev. 2018, 82, 1442–1456. [Google Scholar] [CrossRef]

- Metwally, I.A. Failures, Monitoring and New Trends of Power Transformers. IEEE Potentials 2011, 30, 36–43. [Google Scholar] [CrossRef]

- Bossi, A.; Dind, J.E.; Frisson, J.M.; Khoudiakov, U.; Light, H.F.; Narke, D.V.; Tournier, Y.; Verdon, J. An international survey of failures in large power transformers in service. Cigré Electra 1983, 88, 21–48. [Google Scholar]

- Valenta, L.; Černý, I.; Maternik-Demontoux, A. Power Transformers and Environmental Protection. IFAC-Pap. 2016, 49, 18–22. [Google Scholar] [CrossRef]

- Oommen, T. Vegetable oils for liquid-filled transformers. IEEE Electr. Insul. Mag. 2002, 18, 6–11. [Google Scholar] [CrossRef]

- Pawel Rozga, P.; Beroual, A.; Przybylek, P.; Jaroszewski, M.; Strzelecki, K. A Review on Synthetic Ester Liquids for Transformer Applications. Energies 2020, 13, 6429. [Google Scholar] [CrossRef]

- Muller, S.; Brady, R.; De Bressy, G.; Magnier, P.; Pe’rigaud, G. Prevention of Transformer Tank Explosion: Part 1—Experimental Tests on Large Transformers. In Proceedings of the ASME 2008 Pressure Vessels and Piping Conference, Chicago, IL, USA, 27–31 July 2008. [Google Scholar] [CrossRef]

- Muller, S.; Boiarciuc, M.P.; Perigaud, G. Protection of oil-filled transformer against explosion: Numerical simulations on a 200 MVA transformer. In Proceedings of the 2009 IEEE Bucharest PowerTech, Bucharest, Romania, 28 June–2 July 2009. [Google Scholar] [CrossRef]

- Claassen, M.; Bingham, B.; Chow, J.C.; Watson, J.G.; Chu, P.; Wang, Y.; Wang, X. Characterization of Lithium-Ion Battery Fire Emissions—Part 2: Particle Size Distributions and Emission Factors. Batteries 2024, 10, 366. [Google Scholar] [CrossRef]

- Clark, K. Battery Storage Fire in Arizona Is Under Investigation [EB/OL]. Available online: https://www.power-eng.com/energy-storage/batteries/cause-of-battery-storage-fire-in-arizona-under-investigation/ (accessed on 4 December 2024).

- Li, M.; Xu, L.; Wang, X.; Mo, D.; Hu, Y.; Wang, N.; Yang, K.; Deng, K. Multifunctional diluent regulated flame-retardant localized high concentration electrolyte boosting Li||NCM811 batteries. Chem. Eng. J. 2025, 504, 158923. [Google Scholar] [CrossRef]

- Guo, X.; Guo, S.; Wu, C.; Li, J.; Liu, C.; Chen, W. Intelligent Monitoring for Safety-Enhanced Lithium-Ion/Sodium-Ion Batteries. Adv. Energy Mater. 2023, 13, 2203903. [Google Scholar] [CrossRef]

- Han-joo, K. (LEAD) Kakao, Naver Suffer Service Disruption due to Fire at Data Center [EB/OL]. Available online: https://en.yna.co.kr/view/AEN20221015002451315 (accessed on 4 December 2024).

- Shi, P.; Zhu, H.; Dong, X.; Hai, B. Research Progress on Thermal Runaway Warning Methods and Fire Extinguishing Technologies for Lithium-Ion Batteries. World Electr. Veh. J. 2025, 16, 81. [Google Scholar] [CrossRef]

- Gragnaniello, D.; Greco, A.; Sansone, C.; Vento, B. Fire and smoke detection from videos: A literature review under a novel taxonomy. Expert Syst. Appl. 2024, 255, 124783. [Google Scholar] [CrossRef]

- Sousa, M.J.; Moutinho, A.; Almeida, M. Thermal Infrared Sensing for Near Real-Time Data-Driven Fire Detection and Monitoring Systems. Sensors 2020, 20, 6803. [Google Scholar] [CrossRef]

- Lee, S.-Y.; Park, I.-C.; Park, J.-H.; Jung, H.-S. Evaluation of Initial Fire Extinguishing System for Marine ESS. J. Mar. Sci. Eng. 2024, 12, 877. [Google Scholar] [CrossRef]

- Farrell, K.; Hassan, K.; Hossain, D.; Ahmed, B.; Rahnamayiezekavat, P.; Douglas, G.; Saha, S. Water Mist Fire Suppression Systems for Building and Industrial Applications: Issues and Challenges. Fire 2023, 6, 40. [Google Scholar] [CrossRef]

- Military Wiki. Soviet Submarine K-278 Komsomolets [EB/OL]. Available online: https://military-history.fandom.com/wiki/Soviet_submarine_K-278_Komsomolets (accessed on 4 December 2024).

- Intelligencer Staff. What We Know About the Deadly Bronx Apartment-Building Fire 17 People Were Killed, Including Eight Children. [EB/OL]. Available online: https://nymag.com/intelligencer/2022/01/bronx-apartment-building-fire-kills-at-least-19-updates.html (accessed on 4 December 2024).

- Takano, M.; Romanova, V.; Yamazawa, H.; Sivintsev, Y.; Compton, K.; Novikov, V.; Parker, F. Reactivity Accident of Nuclear Submarine near Vladivostok. J. Nucl. Sci. Technol. 2001, 38, 143–157. [Google Scholar] [CrossRef]

- Land, H.B. Sensing Switchboard Arc Faults. IEEE Power Eng. Rev. 2002, 22, 18–27. [Google Scholar] [CrossRef]

- Depetro, A.; Gamble, G.; Moinuddin, K. Fire Safety Risk Analysis of Conventional Submarines. Appl. Sci. 2021, 11, 2631. [Google Scholar] [CrossRef]

- Tingle, C. Submarine Accidents A 60-year Statistical Assessment. Prof. Saf. 2009, 54, 31–39. Available online: https://www.jstor.org/stable/48687573 (accessed on 4 December 2024).

- Military Wiki. List of Submarine and Submersible Incidents Since 2000 [EB/OL]. Available online: https://military-history.fandom.com/wiki/List_of_submarine_and_submersible_incidents_since_2000 (accessed on 4 December 2024).

- Tripathi, A. WHY AN INDIAN SUBMARINE ‘INS Sindhuratna’ STUCK IN RUSSIA? [EB/OL]. Available online: https://world-defence.com/why-an-indian-submarine-ins-sindhuratna-stuck-in-russia/ (accessed on 4 December 2024).

- Fang, T.; Pan, L.; Guofeng, C.; Jianghui, X. An Estimation Method of Fire Extinguishing Time in Closed Ship Cabin. E3S Web Conf. 2020, 165, 6007. [Google Scholar] [CrossRef]

- Griffin, L.; Bollan, H. Review and Rationalisation of Post-Fire Monitoring for Atmosphere Control in Submarines. In Proceedings of the 44th International Conference on Environmental Systems, Tucson, AZ, USA, 13–17 July 2014. [Google Scholar]

- Land, H.B.; Eddins, C.L.; Klimek, J.M. Evolution of Arc Fault Protection Technology at APL. Johns Hopkins APL Tech. Dig. 2004, 25, 140–153. [Google Scholar]

- Szymborski, J. Lead-acid batteries for use in submarine applications. In Proceedings of the 2002 Workshop on Autonomous Underwater Vehicles, San Antonio, TX, USA, 21 June 2002. [Google Scholar] [CrossRef]

- Skjong, E.; Rodskar, E.; Molinas, M.; Johansen, T.A.; Cunningham, J. The Marine Vessel’s Electrical Power System: From its Birth to Present Day. Proc. IEEE 2015, 103, 2410–2424. [Google Scholar] [CrossRef]

- Wu, S.B.; Chen, X.Q.; Chen, H.X.; Lu, J.Q. Intelligent fire early warning and monitoring system for ship bridge based on WSN. Int. J. Sci. 2020, 7, 248–255. [Google Scholar]

- Zong, L.; Wang, Y.; Wu, B. Risk assessment framework for fire accidents in the ship engine room. In Proceedings of the 2017 4th International Conference on Transportation Information and Safety (ICTIS), Banff, AB, Canada, 8–10 August 2017; pp. 1093–1098. [Google Scholar]

- Dutta, B.B.; Kar, A.R. Simulation Techniques for Ship Onboard Fire Safety. In Proceedings of the ASME 2009 28th International Conference on Ocean, Offshore and Arctic Engineering, Volume 2: Structures, Safety and Reliability, Honolulu, HI, USA, 31 May–5 June 2009; pp. 641–649. [Google Scholar] [CrossRef]

- Garri, G. Fire on board ship. In The Management of Mass Burn Casualties and Fire Disasters: Proceedings of the First International Conference on Burns and Fire Disasters; Masellis, M., Gunn, S., Eds.; Springer: Dordrecht, The Netherlands, 1992; pp. 93–105. [Google Scholar] [CrossRef]

- Ben, D.-F.; Ma, B.; Chen, X.-L.; Zhu, S.-H.; Tang, H.-T.; Lu, W.; Xia, Z.-F. Burn injuries caused by ship fire: A 12-year study in Shanghai. Burns 2010, 36, 576–580. [Google Scholar] [CrossRef] [PubMed]

- Baalisampang, T.; Abbassi, R.; Garaniya, V.; Khan, F.; Dadashzadeh, M. Review and analysis of fire and explosion accidents in maritime transportation. Ocean Eng. 2018, 158, 350–366. [Google Scholar] [CrossRef]

- Uğurlu, Ö. Analysis of fire and explosion accidents occurring in tankers transporting hazardous cargoes. Int. J. Ind. Ergon. 2016, 55, 1–11. [Google Scholar] [CrossRef]

- Casals-Torrens, P.; Castells, M. Upotreba niskodimnih bezhalogenih kabela u dizajnu protupožarne zaštite na brodu. Nase More 2018, 65, 12–17. [Google Scholar] [CrossRef]

- Tao, J.; Liu, G.; Lam, K. Design Optimization of Marine Engine-Mount System. J. Sound Vib. 2000, 235, 477–494. [Google Scholar] [CrossRef]

- Su, S.; Wang, L. Three dimensional reconstruction of the fire in a ship engine room with multilayer structures. Ocean Eng. 2013, 70, 201–207. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, S.; He, J.; Xu, D.; Abdou, S.N.; Ibrahim, M.M.; Sun, S.; Chen, Y.; Li, H.; Xu, B.B.; et al. Experimental design of paraffin/methylated melamine-formaldehyde microencapsulated composite phase change material and the application in battery thermal management system. J. Mater. Sci. Technol. 2023, 169, 124–136. [Google Scholar] [CrossRef]

- Constable, S. Marine electromagnetic methods—A new tool for offshore exploration. Lead. Edge 2006, 25, 438–444. [Google Scholar] [CrossRef]

- Mikhailov, V.M.; Sen’kov, A.P. The Use of Permanent-Magnet Machines in Ship Electrical Systems. Russ. Electr. Eng. 2017, 88, 814–817. [Google Scholar] [CrossRef]

- Shichuan, S.; Liang, W.; Yuhong, N.; Xiang, G. Numerical computation and characteristic analysis on the center shift of fire whirls in a ship engine room fire. Saf. Sci. 2012, 50, 12–18. [Google Scholar] [CrossRef]

- Lehr, W.; Simecek-Beatty, D. Comparison of hypothetical LNG and fuel oil fires on water. J. Hazard. Mater. 2004, 107, 3–9. [Google Scholar] [CrossRef]

- International Conference on Applications of Statistics and Probability in Soil and Structural Engineering ICASP-4: Florence, Italy, 1983. J. Appl. Probab. 1981, 18, 791. [CrossRef]

- Tarnapowicz, D. Reduction of the fire risk in the aspect of ground currents in ship electrical grid LV type IT. In Proceedings of the 2016 International Conference on Information and Digital Technologies (IDT), Rzeszow, Poland, 5–7 July 2016. [Google Scholar] [CrossRef]

- Ward, T.A.; Ykema, J.I. Fire Protective Coating System for Shipboard Electrical Cables. Nav. Eng. J. 1990, 102, 154–161. [Google Scholar] [CrossRef]

- Reed, J.W. TWA Flight 800, explosion airblast unexplained. J. Acoust. Soc. Am. 2003, 114, 2442. [Google Scholar] [CrossRef]

- Jia, F.; Patel, M.K.; Galea, E.R.; Grandison, A.; Ewer, J. CFD fire simulation of the Swissair flight 111 in-flight fire—Part II: Fire spread analysis. Aeronaut. J. 2006, 110, 303–314. [Google Scholar] [CrossRef]

- Foo, S. A machine vision approach to detect and categorize hydrocarbon fires in aircraft dry bays and engine compartments. IEEE Trans. Ind. Appl. 2000, 36, 459–466. [Google Scholar] [CrossRef]

- Parise, G.; Hesla, E.; Mardegan, C.S.; Parise, L.; Capaccini, E.B. Measures to Minimize Series Faults in Electrical Cords and Extension Cords. IEEE Trans. Ind. Appl. 2019, 55, 4551–4556. [Google Scholar] [CrossRef]

- Cunningham, J.C.; Davidson, W.M. A-C and D-C Short-Circuit Tests on Aircraft Cable. Trans. Am. Inst. Electr. Eng. 1944, 63, 961–969. [Google Scholar] [CrossRef]

- Goraj, R. Novel coupled model for power loss prediction in a record-breaking electric aircraft motor. Aircr. Eng. Aerosp. Technol. 2018, 92, 345–354. [Google Scholar] [CrossRef]

- Lewis, J.; Lloyd, E. The airworthiness and reliability of aircraft electrical systems. Proc. IEEE Part A Power Eng. 1956, 103, 34–49. [Google Scholar] [CrossRef]

- Walkinshaw, D.S.; Preston, K.F. Controlling Cabin and Envelope Air Flows and Pressure Differentials to Prevent Envelope Condensation, Enable Cabin Humidification, Improve Fire Safety, and Decrease Fuel Use. SAE Int. J. Aerosp. 2011, 4, 1243–1253. [Google Scholar] [CrossRef]

- Bryant, J.M.; Newman, M.M.; Robb, J.D. Aircraft protection from thunderstorm discharges to antennas. Trans. Am. Inst. Electr. Eng. Part II Appl. Ind. 1953, 72, 248–254. [Google Scholar] [CrossRef]

- Song, T.; Li, Y.; Song, J.; Zhang, Z. Airworthiness Considerations of Supply Chain Management from Boeing 787 Dreamliner Battery Issue. Procedia Eng. 2014, 80, 628–637. [Google Scholar] [CrossRef]

- Brusso, B.C. History of Aircraft Wiring Arc-Fault Protection [History]. IEEE Ind. Appl. Mag. 2017, 23, 6–11. [Google Scholar] [CrossRef]

- Werfelman, L. Battery Rules. AeroSafety World 2010, 5, 44–46. [Google Scholar]

- Furse, C.; Haupt, R. Down to the wire [aircraft wiring]. IEEE Spectr. 2001, 38, 34–39. [Google Scholar] [CrossRef]

- Lebbin, P. Review of Canadian Flight Deck and Cabin Smoke and Fire Incidents: 2001–2010. SAE Int. J. Aerosp. 2013, 6, 286–298. [Google Scholar] [CrossRef]

- Zhang, J.; Lu, C.; Guan, Y.; Liu, W. Thermodynamic properties and transport coefficients of air thermal plasmas mixed with ablated vapors of Cu and polytetrafluoroethylene. Phys. Plasmas 2015, 22, 103518. [Google Scholar] [CrossRef]

- Yaramasu, A.; Cao, Y.; Liu, G.; Wu, B. Aircraft electric system intermittent arc fault detection and location. IEEE Trans. Aerosp. Electron. Syst. 2015, 51, 40–51. [Google Scholar] [CrossRef]

- Elkalashy, N.I.; Lehtonen, M.; Darwish, H.A.; Izzularab, M.A.; Taalab, A.-M.I. Modeling and experimental verification of high impedance arcing fault in medium voltage networks. IEEE Trans. Dielectr. Electr. Insul. 2007, 14, 375–383. [Google Scholar] [CrossRef]

- Carvou, E.; Le Garrec, J.L.; Pérez, J.; Praquin, J.; Djeddi, M.; Mitchell, J.B.A. Small angle x-ray scattering and electron microscopy of nanoparticles formed in an electrical arc. AIP Adv. 2013, 3, 32139. [Google Scholar] [CrossRef]

- Naidu, M.; Schoepf, T.; Gopalakrishnan, S. Arc fault detection scheme for 42-V automotive DC networks using current shunt. IEEE Trans. Power Electron. 2006, 21, 633–639. [Google Scholar] [CrossRef]

- McDougall, J.L.; Klepacki, D.G.; Stevenson, M.E.; Kenner, M.T. Post-fire Structural Integrity Evaluation of an Aircraft Utilizing ASTM E 1004-02. J. Fail. Anal. Prev. 2015, 15, 3–6. [Google Scholar] [CrossRef]

- Stavnes, M.; Hammoud, A. Assessment of safety in space power wiring systems. IEEE Aerosp. Electron. Syst. Mag. 1994, 9, 21–27. [Google Scholar] [CrossRef]

- Wileman, A.; Aslam, S.; Perinpanayagam, S. A road map for reliable power electronics for more electric aircraft. Prog. Aerosp. Sci. 2021, 127, 100739. [Google Scholar] [CrossRef]

- Gregory, G.; Wong, K.; Dvorak, R. More About Arc-Fault Circuit Interrupters. IEEE Trans. Ind. Appl. 2004, 40, 1006–1011. [Google Scholar] [CrossRef]

- Momoh, J.; Button, R. Design and analysis of aerospace DC arcing faults using fast fourier transformation and artificial neural network. In Proceedings of the 2003 IEEE Power Engineering Society General Meeting (IEEE Cat No03CH37491), Toronto, ON, Canada, 13–17 July 2003. [Google Scholar] [CrossRef]

- Wu, Y.; Li, M.; Rong, M.; Yang, F.; Murphy, A.B.; Wu, Y.; Yuan, D. Experimental and theoretical study of internal fault arc in a closed container. J. Phys. D Appl. Phys. 2014, 47, 505204. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, J.; Wang, J.; Zhang, Y.; Song, L. Lower pressure dripping limits of inclined polyethylene-insulated wires during flame spreading under different oxygen concentrations. Fire Saf. J. 2021, 120, 103108. [Google Scholar] [CrossRef]

- Fonollosa, J.; Solórzano, A.; Marco, S. Chemical Sensor Systems and Associated Algorithms for Fire Detection: A Review. Sensors 2018, 18, 553. [Google Scholar] [CrossRef] [PubMed]

- De Tommasi, F.; Massaroni, C.; Presti, D.L.; Grasso, R.F.; Carassiti, M.; Fong, Y.; Schena, E. Temperature monitoring during thermal treatment by thermocouples and thermistors: Current status and perspectives. In The Application of Heat in Oncology: Principles and Practice; Wiley: Hoboken, NJ, USA, 2023; pp. 107–119. [Google Scholar] [CrossRef]

- Sulthana, S.F.; Wise, C.T.A.; Ravikumar, C.V.; Anbazhagan, R.; Idayachandran, G.; Pau, G. Review Study on Recent Developments in Fire Sensing Methods. IEEE Access 2023, 11, 90269–90282. [Google Scholar] [CrossRef]

- Nikolic, M.V.; Milovanovic, V.; Vasiljevic, Z.Z.; Stamenkovic, Z. Semiconductor Gas Sensors: Materials, Technology, Design, and Application. Sensors 2020, 20, 6694. [Google Scholar] [CrossRef] [PubMed]

- Hangauer, A.; Chen, J.; Strzoda, R.; Fleischer, M.; Amann, M.C. Performance of a fire detector based on a compact laser spectroscopic carbon monoxide sensor. Opt. Express 2014, 22, 13680–13690. [Google Scholar] [CrossRef] [PubMed]

- Kong, S.G.; Jin, D.; Li, S.; Kim, H. Fast fire flame detection in surveillance video using logistic regression and temporal smoothing. Fire Saf. J. 2016, 79, 37–43. [Google Scholar] [CrossRef]

- Töreyin, B.U.; Dedeoğlu, Y.; Güdükbay, U.; Çetin, A.E. Computer vision based method for real-time fire and flame detection. Pattern Recognit. Lett. 2006, 27, 49–58. [Google Scholar] [CrossRef]

- Hackner, A.; Oberpriller, H.; Ohnesorge, A.; Hechtenberg, V.; Müller, G. Heterogeneous sensor arrays: Merging cameras and gas sensors into innovative fire detection systems. Sens. Actuators B Chem. 2016, 231, 497–505. [Google Scholar] [CrossRef]

- Kanwal, K.; Liaquat, A.; Mughal, M.; Abbasi, A.R.; Aamir, M. Towards Development of a Low Cost Early Fire Detection System Using Wireless Sensor Network and Machine Vision. Wirel. Pers. Commun. 2017, 95, 475–489. [Google Scholar] [CrossRef]

- Krüger, S.; Despinasse, M.-C.; Raspe, T.; Nörthemann, K.; Moritz, W. Early fire detection: Are hydrogen sensors able to detect pyrolysis of house hold materials? Fire Saf. J. 2017, 91, 1059–1067. [Google Scholar] [CrossRef]

- Jelicic, V.; Magno, M.; Brunelli, D.; Paci, G.; Benini, L. Context-Adaptive Multimodal Wireless Sensor Network for Energy-Efficient Gas Monitoring. IEEE Sens. J. 2013, 13, 328–338. [Google Scholar] [CrossRef]

- Vidas, S.; Moghadam, P. HeatWave: A handheld 3D thermography system for energy auditing. Energy Build. 2013, 66, 445–460. [Google Scholar] [CrossRef]

- Mahdipour, E.; Dadkhah, C. Automatic fire detection based on soft computing techniques: Review from 2000 to 2010. Artif. Intell. Rev. 2014, 42, 895–934. [Google Scholar] [CrossRef]

- Çetin, A.E.; Dimitropoulos, K.; Gouverneur, B.; Grammalidis, N.; Günay, O.; Habiboǧlu, Y.H.; Töreyin, B.U.; Verstockt, S. Video fire detection—Review. Digit. Signal Process. 2013, 23, 1827–1843. [Google Scholar] [CrossRef]

- Kang, M.; Tung, T.X.; Kim, J.-M. Efficient video-equipped fire detection approach for automatic fire alarm systems. Opt. Eng. 2013, 52, 17002. [Google Scholar] [CrossRef]

- Gunay, O.; Toreyin, B.U.; Kose, K.; Cetin, A.E. Entropy-Functional-Based Online Adaptive Decision Fusion Framework with Application to Wildfire Detection in Video. IEEE Trans. Image Process. 2012, 21, 2853–2865. [Google Scholar] [CrossRef] [PubMed]

- Jenifer, P. Notice of Violation of IEEE Publication Principles: Effective visual fire detection in video sequences using probabilistic approach. In Proceedings of the 2011 International Conference on Emerging Trends in Electrical and Computer Technology, Nagercoil, India, 23–24 March 2011. [Google Scholar] [CrossRef]

- Chen, L.-H.; Huang, W.-C. Fire Detection Using Spatial-temporal Analysis. In Proceedings of the World Congress on Engineering 2013 Vol III (WCE 2013), London, UK, 3–5 July 2013. [Google Scholar]

- Kuo, J.-Y.; Lai, T.-Y.; Fanjiang, Y.-Y.; Huang, F.-C.; Liao, Y.-H. A behavior-based flame detection method for a real-time video surveillance system. J. Chin. Inst. Eng. 2015, 38, 947–958. [Google Scholar] [CrossRef]

- Oghabi, E.; Moghaddam, R.K.; Kobravi, H. A new strategy for fire detection based on analyzing the irregularity pattern of image contour. Signal Image Video Process. 2024, 18, 6143–6155. [Google Scholar] [CrossRef]

- Wang, T.; Bu, L.; Yang, Z.; Yuan, P.; Ouyang, J.; Shi, L. A new fire detection method using a multi-expert system based on color dispersion, similarity and centroid motion in indoor environment. IEEE/CAA J. Autom. Sin. 2020, 7, 263–275. [Google Scholar] [CrossRef]

- Lv, C.; Zhou, H.; Chen, Y.; Fan, D.; Di, F. A lightweight fire detection algorithm for small targets based on YOLOv5s. Sci. Rep. 2024, 14, 14104. [Google Scholar] [CrossRef]

- Zhu, D.; Ahmad, K.A.; Chen, A. Research on flame recognition technology based on local complex features. J. Phys. Conf. Ser. 2022, 2246, 12074. [Google Scholar] [CrossRef]

- Chen, J.; He, Y.; Wang, J. Multi-feature fusion based fast video flame detection. Build. Environ. 2010, 45, 1113–1122. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.; Wang, Y.; Wang, W.; Duan, Y.; Liu, J. Video flame recognition based on LGATP texture feature and sparse representation. Signal Image Video Process. 2024, 18, 8911–8923. [Google Scholar] [CrossRef]

- Shahid, M.; Virtusio, J.J.; Wu, Y.-H.; Chen, Y.-Y.; Tanveer, M.; Muhammad, K.; Hua, K.-L. Spatio-Temporal Self-Attention Network for Fire Detection and Segmentation in Video Surveillance. IEEE Access 2021, 10, 1259–1275. [Google Scholar] [CrossRef]

- Zhao, E.; Liu, Y.; Zhang, J.; Tian, Y. Forest Fire Smoke Recognition Based on Anchor Box Adaptive Generation Method. Electronics 2021, 10, 566. [Google Scholar] [CrossRef]

- Lu, P.; Zhao, Y.; Xu, Y. A Two-Stream CNN Model with Adaptive Adjustment of Receptive Field Dedicated to Flame Region Detection. Symmetry 2021, 13, 397. [Google Scholar] [CrossRef]

- Zheng, S.; Zou, X.; Gao, P.; Zhang, Q.; Hu, F.; Zhou, Y.; Wu, Z.; Wang, W.; Chen, S. A Forest Fire Recognition Method Based on Modified Deep CNN Model. Forests 2024, 15, 111. [Google Scholar] [CrossRef]

- Rosadi, D.; Andriyani, W.; Arisanty, D.; Agustina, D. Prediction of Forest Fire using Hybrid SOM-AdaBoost Method. J. Phys. Conf. Ser. 2021, 2123, 12030. [Google Scholar] [CrossRef]

- Ma, S.; Li, W.; Wan, L.; Zhang, G. A Lightweight Fire Detection Algorithm Based on the Improved YOLOv8 Model. Appl. Sci. 2024, 14, 6878. [Google Scholar] [CrossRef]

- Dong, Y.; Yang, H.; Yin, M.; Li, M.; Qu, Y.; Jia, X. Research on Lightweight Method of Segment Beam Point Cloud Based on Edge Detection Optimization. Buildings 2024, 14, 1221. [Google Scholar] [CrossRef]

- Gade, R.; Moeslund, T.B. Thermal cameras and applications: A survey. Mach. Vis. Appl. 2013, 25, 245–262. [Google Scholar] [CrossRef]

- Huda, A.; Taib, S. Suitable features selection for monitoring thermal condition of electrical equipment using infrared thermography. Infrared Phys. Technol. 2013, 61, 184–191. [Google Scholar] [CrossRef]

- Pareek, S.; Sharma, R.; Maheshwari, R. Application of artificial neural networks to monitor thermal condition of electrical equipment. In Proceedings of the 2017 3rd International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Rupnagar, India, 16–18 November 2017. [Google Scholar] [CrossRef]

- Almeida, C.A.L.; Braga, A.P.; Nascimento, S.; Paiva, V.; Martins, H.J.A.; Torres, R.; Caminhas, W.M. Intelligent Thermographic Diagnostic Applied to Surge Arresters: A New Approach. IEEE Trans. Power Deliv. 2009, 24, 751–757. [Google Scholar] [CrossRef]

- Joshi, D.D.; Kumar, S.; Patil, S.; Kamat, P.; Kolhar, S.; Kotecha, K. Deep learning with ensemble approach for early pile fire detection using aerial images. Front. Environ. Sci. 2024, 12, 1440396. [Google Scholar] [CrossRef]

- Sun, W.; Liu, Y.; Wang, F.; Hua, L.; Fu, J.; Hu, S. A Study on Flame Detection Method Combining Visible Light and Thermal Infrared Multimodal Images. Fire Technol. 2024, 1–22. [Google Scholar] [CrossRef]

- Lee, R.H. The Other Electrical Hazard: Electric Arc Blast Burns. IEEE Trans. Ind. Appl. 1982, IA-18, 246–251. [Google Scholar] [CrossRef]

- Yang, K.; Zhang, R.; Yang, J.; Liu, C.; Chen, S.; Zhang, F. A Novel Arc Fault Detector for Early Detection of Electrical Fires. Sensors 2016, 16, 500. [Google Scholar] [CrossRef]

- Gregory, G.; Scott, G. The arc-fault circuit interrupter, an emerging product; In Proceedings of the 1998 IEEE Industrial and Commercial Power Systems Technical Conference. Conference Record. Papers Presented at the 1998 Annual Meeting (Cat. No.98CH36202), Edmonton, AB, Canada, 3–8 May 1998. [Google Scholar] [CrossRef]

- Maroni, C.-S.; Cittadini, R.; Cadoux, Y.; Serpinet, M. Series arc detection in low voltage distribution switchboard using spectral analysis. In Proceedings of the Sixth International Symposium on Signal Processing and Its Applications (CatNo01EX467), Kuala Lumpur, Malaysia, 13–16 August 2001. [Google Scholar] [CrossRef]

- Pulkkinen, J.P. Commercial arc fault detection devices in military electromagnetic environment. IEEE Electromagn. Compat. Mag. 2018, 7, 49–52. [Google Scholar] [CrossRef]

- Phipps, K.; Cooke, T.; Dorr, D.; Keebler, P. Frequency phenomenon and algorithms for arc detection. In Proceedings of the 2010 IEEE International Symposium on Electromagnetic Compatibility, Fort Lauderdale, FL, USA, 25–30 July 2010. [Google Scholar] [CrossRef]

- Sidhu, T.; Sagoo, G.; Sachdev, M. On-line detection and location of low-level arcing in dry-type transformers. IEEE Trans. Power Deliv. 2002, 17, 135–141. [Google Scholar] [CrossRef]

- Sidhu, T.; Sagoo, G.; Sachdev, M. Multisensor secondary device for detection of low-level arcing faults in metal-clad MCC switchgear panel. IEEE Trans. Power Deliv. 2002, 17, 129–134. [Google Scholar] [CrossRef]

- Liu, Y.-J.; Chen, C.-I.; Fu, W.-C.; Lee, Y.-D.; Cheng, C.-C.; Chen, Y.-F. A Hybrid Approach for Low-Voltage AC Series Arc Fault Detection. Energies 2023, 16, 1256. [Google Scholar] [CrossRef]

- Jiang, R.; Wang, Y.; Gao, X.; Bao, G.; Hong, Q.; Booth, C.D. AC Series Arc Fault Detection Based on RLC Arc Model and Convolutional Neural Network. IEEE Sens. J. 2023, 23, 14618–14627. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, F.; Zhang, S. A New Methodology for Identifying Arc Fault by Sparse Representation and Neural Network. IEEE Trans. Instrum. Meas. 2018, 67, 2526–2537. [Google Scholar] [CrossRef]

- Qin, Y.-W.; Zhang, P.-H.; Song, R.-N.; Zhu, M.-N. Arc fault diagnosis technology and trend of development in novel power system. Electr. Meas. Instrum. 2024, 61, 1–9. [Google Scholar] [CrossRef]

- Tumialis, P.; Skierkowski, M.; Przychodny, J.; Obszarski, P. The Impact of 8- and 4-Bit Quantization on the Accuracy and Silicon Area Footprint of Tiny Neural Networks. Electronics 2025, 14, 14. [Google Scholar] [CrossRef]

- Shatarah, I.S.; Olbrycht, R. Distributed temperature sensing in optical fibers based on Raman scattering: Theory and applications. Meas. Autom. Monit. 2017, 63, 41–44. [Google Scholar]

- Yaodong, Z.; Yi, K.; Xiaopo, M.; Xueming, Z.; Zhiqiang, F.; Zeqi, H.; Xiang, R.; Tianru, S.; Jianjin, F.; Junjie, H. Analysis of Current Carrying Capacity of Power Cable Based on DTS. J. Phys. Conf. Ser. 2020, 1639, 12029. [Google Scholar] [CrossRef]

- Bian, H.; Zhu, Z.; Zang, X.; Luo, X.; Jiang, M. A CNN Based Anomaly Detection Network for Utility Tunnel Fire Protection. Fire 2022, 5, 212. [Google Scholar] [CrossRef]

- Blöcher, G.; Regenspurg, S.; Kranz, S.; Lipus, M.; Pei, L.; Norden, B.; Reinsch, T.; Henninges, J.; Siemon, R.; Orenczuk, D.; et al. Best practices for characterization of High Temperature-Aquifer Thermal Energy Storage (HT-ATES) potential using well tests in Berlin (Germany) as an example. Geothermics 2024, 116, 102830. [Google Scholar] [CrossRef]

- National Fire Protection Association. NFPA 10: Standard for Portable Fire Extinguishers; NFPA: Quincy, MA, USA, 2022. [Google Scholar]

- GB/T 4968-2008; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China, & Standardization Administration of China. Classification of Fires. Standards Press of China: Beijing, China, 2008.

- Sheng, Y.; Zhang, S.; Ma, W.; Peng, Y.; Ma, L.; Wang, Q.; Hu, D. Tuning stability, rheology, and fire-extinguishing performance of advanced firefighting foam material by inorganic nanoparticle flame retardants. J. Colloid Interface Sci. 2024, 677, 378–389. [Google Scholar] [CrossRef]

- Zhang, J.; Shang, F.; Zhang, S.; Wang, L.; Ke, Y.; Huang, J.; Su, W.; Liu, R.; Sheng, Y. Research on Key Parameters and Fire Extinguishing Effectiveness of Compressed Air Foam System Used for UHV Substation. In Fire Technology; Springer: Berlin/Heidelberg, Germany, 2024; pp. 1–22. [Google Scholar] [CrossRef]

- Liu, Y.; Chen, R.; Zhixuan, W.; Zhang, R.; Jing, H.; Yu, D.; Pan, R. Effects of thermal aging on the performance of ordinary and novel superhydrophobic and oleophobic ultra-fine dry powder extinguishing agent. Sci. Rep. 2025, 15, 3668. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Du, S.; Zhou, Z.; Guo, Y.; Yang, Q.; Yao, S.; Zhang, H. Enhanced Fire-Extinguishing Performance and Synergy Mechanism of HM/DAP Composite Dry Powder. Materials 2025, 18, 533. [Google Scholar] [CrossRef] [PubMed]

- Cao, F.-C.; Ma, X.-Y.; Zhou, H.-L.; Tang, Y.; Dong, X.-L.; Huang, A.-C. Enhanced suppression of metal combustion processes using a compound expansible graphite extinguishing agent: Experimental study and mechanistic insights. J. Loss Prev. Process Ind. 2023, 85, 105154. [Google Scholar] [CrossRef]

- Lee, C.W.; Venkatachalapathy, R.; Prakash, J. A Novel Flame-Retardant Additive for Lithium Batteries. Electrochem. Solid-State Lett. 2000, 3, 63–65. [Google Scholar] [CrossRef]

- E Hyung, Y.; Vissers, D.R.; Amine, K. Flame-retardant additives for lithium-ion batteries. J. Power Sources 2003, 119, 383–387. [Google Scholar] [CrossRef]

- Aurbach, D.; Talyosef, Y.; Markovsky, B.; Markevich, E.; Zinigrad, E.; Asraf, L.; Gnanaraj, J.S.; Kim, H.-J. Design of electrolyte solutions for Li and Li-ion batteries: A review. Electrochim. Acta 2004, 50, 247–254. [Google Scholar] [CrossRef]

- Yim, T.; Park, M.-S.; Woo, S.-G.; Kwon, H.-K.; Yoo, J.-K.; Jung, Y.S.; Kim, K.J.; Yu, J.-S.; Kim, Y.-J. Self-Extinguishing Lithium Ion Batteries Based on Internally Embedded Fire-Extinguishing Microcapsules with Temperature-Responsiveness. Nano Lett. 2015, 15, 5059–5067. [Google Scholar] [CrossRef]

- Kim, G.-H.; Smith, K.; Ireland, J.; Pesaran, A. Fail-safe design for large capacity lithium-ion battery systems. J. Power Sources 2012, 210, 243–253. [Google Scholar] [CrossRef]

- Sahraei, E.; Meier, J.; Wierzbicki, T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells. J. Power Sources 2014, 247, 503–516. [Google Scholar] [CrossRef]

- Nakayama, M.; Iizuka, K.; Shiiba, H.; Baba, S.; Nogami, M. Asymmetry in anodic and cathodic polarization profile for LiFePO4 positive electrode in rechargeable Li ion battery. J. Ceram. Soc. Jpn. 2011, 119, 692–696. [Google Scholar] [CrossRef]

- Capasso, C.; Veneri, O. Experimental analysis on the performance of lithium based batteries for road full electric and hybrid vehicles. Appl. Energy 2014, 136, 921–930. [Google Scholar] [CrossRef]

- Summer, S. Flammability Assessment of Lithium-Ion and Lithium-Ion Polymer Battery Cells Designed for Aircraft Power Usage; US Department of Transportation, Federal Aviation Administration: Washington, DC, USA, 2010.

- Doughty, D.H. Vehicle Battery Safety Roadmap Guidance [EB/OL]. Available online: https://www.osti.gov/biblio/1055366/ (accessed on 4 December 2024).

- Park, O. Best Practices for Emergency Response to Incidents Involving Electric Vehicles Battery Hazards: A Report on Full-Scale Testing Results; (1205174.000): F0F; The Fire Protection Research Foundation: Quincy, MA, USA, 2013. [Google Scholar]

- Zhang, L.; Jin, K.; Sun, J.; Wang, Q. A Review of Fire-Extinguishing Agents and Fire Suppression Strategies for Lithium-Ion Batteries Fire. Fire Technol. 2024, 60, 817–858. [Google Scholar] [CrossRef]

- Xu, J.; Guo, P.; Duan, Q.; Yu, X.; Zhang, L.; Liu, Y.; Wang, Q. Experimental study of the effectiveness of three kinds of extinguishing agents on suppressing lithium-ion battery fires. Appl. Therm. Eng. 2020, 171, 115076. [Google Scholar] [CrossRef]

- Wang, Q.; Li, K.; Wang, Y.; Chen, H.; Duan, Q.; Sun, J. The Efficiency of Dodecafluoro-2-Methylpentan-3-One on Suppressing the Lithium Ion Battery Fire. J. Electrochem. Energy Convers. Storage 2018, 15, 41001. [Google Scholar] [CrossRef]

- Wang, Q.; Shao, G.; Duan, Q.; Chen, M.; Li, Y.; Wu, K.; Liu, B.; Peng, P.; Sun, J. The Efficiency of Heptafluoropropane Fire Extinguishing Agent on Suppressing the Lithium Titanate Battery Fire. Fire Technol. 2016, 52, 387–396. [Google Scholar] [CrossRef]

- Kim, A.; Crampton, G.P. Performance of Novec1230 in Electronic Facility Fire Protection; NRCC-53526; National Research Council Canada: Ottawa, ON, Canada, 2022. [Google Scholar]

- Mawhinney, J.R.; Back, G.G. Water Mist Fire Suppression Systems. In SFPE Handbook of Fire Protection Engineering; Hurley, M.J., Gottuk, D., Hall, J.R., Harada, K., Kuligowski, E., Torero, J., Watts, J.M., Wieczorek, C., Eds.; Springer: New York, NY, USA, 2016; pp. 1587–1645. [Google Scholar] [CrossRef]

- Xiaomeng, Z.; Guangxuan, L.; Bo, C. Improvement of water mist’s fire-extinguishing efficiency with MC additive. Fire Saf. J. 2006, 41, 39–45. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, A.K. A review of water mist fire suppression systems—Fundamental studies. J. Fire Prot. Eng. 1999, 10, 32–50. [Google Scholar]

- Shi, X.; Li, Y.; Ren, X.; Zhang, X.; Zhang, Y.; Zhang, Y.; Jiao, F.; Zhang, Y.; Yu, Y.; Cao, W. Smoldering characteristic and energy utilization for regulating coal dust with moisture and non-combustible substances. Int. Commun. Heat Mass Transf. 2025, 162, 108570. [Google Scholar] [CrossRef]

- Li, S.; Chen, R.; Zhang, Y.; Cheng, S.; Li, X.; Zhang, T.; Zhang, X.; Zhou, W.; Shi, X.; Cao, W. The effect of NH3 concentration on explosion venting characteristics and combustion mechanism. Int. J. Hydrogen Energy 2025, 101, 1172–1182. [Google Scholar] [CrossRef]

- Zhao, Y.; Xiao, X.; Zhang, X.; Wang, B.; Wu, C.; Chu, Z.; Shi, X.; Yu, Y.; Zhao, H.; Jiao, F.; et al. Experiment study on the explosion suppressing characteristics and mechanism of melamine cyanurate and ammonium dihydrogen phosphate for lignite dust. Powder Technol. 2024, 448, 120246. [Google Scholar] [CrossRef]

- Liu, Z.; Kim, A.K.; Carpenter, D.; Kanabus-Kaminska, J.M.; Yen, P.-L. Extinguishment of Cooking Oil Fires by Water Mist Fire Suppression Systems. Fire Technol. 2004, 40, 309–333. [Google Scholar] [CrossRef]

- Hansen, R.L.; Back, G.G. Water Spray Protection of Machinery Spaces. Fire Technol. 2001, 37, 317–326. [Google Scholar] [CrossRef]

- Hills, A.T.; Simpson, T.; Smith, D.P. Water mist fire protection systems for telecommunication switch gear and other electronic facilities. In Proceedings of the Water Mist Fire Suppression Workshop, Gaithersburg, MD, USA, 1–2 March 1993; pp. 123–142. [Google Scholar]

- Mawhinney, J.R.; Taber, B. Findings of experiments using water mist for fire suppression in an electronic equipment room. In Proceedings of the Halon Alternatives Technical Working Conference, Albuquerque, NM, USA, 7–9 May 1996; p. 15. [Google Scholar]

- Liu, Z.; Kim, A.K.; Carpenter, D. A study of portable water mist fire extinguishers used for extinguishment of multiple fire types. Fire Saf. J. 2007, 42, 25–42. [Google Scholar] [CrossRef]

- Joseph, P.; Nichols, E.; Novozhilov, V. A comparative study of the effects of chemical additives on the suppression efficiency of water mist. Fire Saf. J. 2013, 58, 221–225. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, J. Fire extinct experiments with water mist by adding additives. J. Therm. Sci. 2011, 20, 563–569. [Google Scholar] [CrossRef]

- Cao, X.; Ren, J.; Zhou, Y.; Wang, Q.; Gao, X.; Bi, M. Suppression of methane/air explosion by ultrafine water mist containing sodium chloride additive. J. Hazard. Mater. 2015, 285, 311–318. [Google Scholar] [CrossRef]

- Hiltz, J. Additives for Water Mist Fire Suppression Systems; DRDC Atlantic TM 2012-236 2012; Defence R&D Canada-Atlantic: Halifax, NS, Canada, 2012. [Google Scholar] [CrossRef]

- Man, C.; Shunbing, Z.; Litao, J.; Xiaoli, W. Surfactant-containing Water Mist Suppression Pool Fire Experimental Analysis. Procedia Eng. 2014, 84, 558–564. [Google Scholar] [CrossRef]

- LeFort, G.; Marshall, A.W.; Pabon, M. Evaluation of Surfactant Enhanced Water Mist Performance. Fire Technol. 2009, 45, 341–354. [Google Scholar] [CrossRef]

- Lu, J.; Chen, B.-H.; Wu, C.; Liu, X.; Zhou, T.; Tan, Y. A multi-additive suppressant agent–based low-flow and long-distance firefighting approach for suppressing wildfires near electrical transmission lines. J. Fire Sci. 2016, 34, 398–415. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, H.; Li, M.; Wang, X.; Das, O.; Han, Z.X.; Jiang, L. Al-Mg@PVDF and Al-Si@PVDF composites with enhanced combustion and energy release characteristics. Def. Technol. 2024; in press. [Google Scholar] [CrossRef]

- Zhao, S.; Li, M.; Jiang, L. Exploring the influence of metal oxides on the pyrolytic behavior and decomposition mechanism of the green gas generating agent 5-Aminotetrazole. J. Loss Prev. Process. Ind. 2024, 92, 105481. [Google Scholar] [CrossRef]

- Cheng, X.-N.; Xu, G.-Z.; Liu, H.; Han, Z.-X.; Li, M.; Jiang, L. Thermal safety characteristics of nanoscale nitrocellulose/stabilizer composite materials. Cellulose 2024, 31, 9623–9643. [Google Scholar] [CrossRef]

- Yang, X.; Jiang, L.; Li, M. Experimental and simulated study on continuous laser ablation of glass fiber epoxy resin plate. Int. Commun. Heat Mass Transf. 2023, 148, 107088. [Google Scholar] [CrossRef]

- Li, M.; Zhang, D.; Han, Z.-X.; Jiang, L. Thermal oxidation characteristics of polystyrene with different particle sizes based on the traditional kinetic approaches and distributed activation energy model. J. Therm. Anal. Calorim. 2024, 149, 993–1001. [Google Scholar] [CrossRef]

- Liu, H.; Li, M.; Zhao, S.; Jiang, L.; Xu, Q.; Majlingová, A. Applications of distributed activation energy model on the pyrolysis of green renewable wood. Fuel 2024, 359, 130457. [Google Scholar] [CrossRef]

- Zhao, S.-N.; Li, M.; Liu, H.; Han, Z.-X.; Chen, J.; Jiang, L. Insights into oxidant matching with green gas generator 5-aminotetrazole from aspects of thermal decomposition behavior, kinetics and combustion mechanism. Renew. Energy 2024, 224, 120156. [Google Scholar] [CrossRef]

- Xu, G.; Li, M.; Mensah, R.A.; Jiang, L.; Das, O. A strategic approach to thermal stability enhancement of nitrocellulose. J. Therm. Anal. Calorim. 2024, 1–17. [Google Scholar] [CrossRef]

- Yao, Y.; Tan, L.; Chen, F.; Pan, A.; Ma, Q.; Zhao, J.; Kang, R. Hydrogen energy industry in China: The current status, safety problems, and pathways for future safe and healthy development. Saf. Sci. 2025, 186, 106808. [Google Scholar] [CrossRef]

- Lu, J.; Chen, B.-H.; Liang, P.; Sun, Y.; Fang, Z.; Huang, S. Experimental Evaluation of Protecting High-Voltage Electrical Transformers Using Water Mist with and without Additives. Fire Technol. 2019, 55, 1671–1690. [Google Scholar] [CrossRef]

| Aviation Investigation Report Number | The Cause of the Accident |

|---|---|

| TSB 2009b | Arcing caused by damaged braiding can cause smoke in the cockpit windshield heater wiring terminals |

| TSB 1997b | Suspected broken copper braided wires causing arcing |

| TSB 2007a | Improperly routed wiring in the turbine engine and friction in the core caused high-voltage power to surge back into the flight deck electronics box, creating flames and smoke behind the electrical circuit breaker panel |

| TSB 1997a | Avionics relays-related failures |

| TSB 2003 | Electric arcs from the wires ignited flammable insulation blankets, spreading the fire above the flight deck ceiling |

| TSB 2007b | The electric arc of the light switch failed and ignited dust that had accumulated nearby, causing the fire |

| TSB 2000a | An unconnected battery cable ran through the battery compartment, igniting flammable nylon lifebags in the adjacent baggage compartment |

| TSB 2009a | An electric arc was generated on one of the engines, which likely damaged a nearby fuel line, causing damage to the helicopter’s hull |

| TSB 2010a | The fire was caused by an electric arc between the connector and the lighting source of the cabin panel |

| TSB 2002b | The internal switch regulator in one IFE controller generates excessive heat that causes the process board to ignite. Despite the loss of power, the system battery continued to power the IFE processor board, likely prolonging the duration of the fire |

| NTSB 2009a | A short circuit near the oxygen hose released oxygen and spread the fire |

| NTSB 2009b | The plane’s weather radar system is suspected of causing the cabin fire |

| AAIB 2000 | Arcing and associated heat damage in the case of improper installation of kitchen chillers |

| BFU 2009 | An electrical short circuit caused by wear on the wire loom caused a fire in the insulating pad behind the cargo hold cladding |

| AAIB 2009 | As the plane was preparing to taxi, an internal fault in the main circuit relay caused an electric arc and molten metal droplets fell, igniting the cabin insulation blanket |

| Characteristics | Shortcomings |

|---|---|

| Space | More suitable for confined space fire detection, difficult to effectively apply to large spaces, such as shopping malls |

| Distance | Before particles or gases arrive at the sensor used to detect them, the alarm will not start, so the sensor must be close to the fire source. For example, smoke sensors require smoke from the fire source for the sensor’s movement time, and gas concentration sensors require more CO release |

| Information | No details were given on the nature of the fire or its size |

| Detector | More protection of potential sources requires more sensors to be installed. In addition, the accuracy and speed of fire detection requires a combination of sensors, such as smoke sensors and temperature sensors |

| Accuracy | There are often false positives. For example, photosensitive sensors can be misled by sunlight and artificial lighting; smoke sensors can be affected by a variety of gases; and temperature sensors can be influenced by their own position, requiring minimal heat to trigger them; |

| Cost | Many sensors are expensive to use, and complex system configurations add to the budget |

| Power | The installed sensors require radio sources |

| Technical Type | Technical Characteristics | Advantages | Limitations |

|---|---|---|---|

| Traditional Sensor Detection Technology | Multi-dimensional perception of physical and chemical parameter changes during a fire | Early warning and real-time monitoring | Obvious limitations, such as the single temperature parameter’s inability to identify the type of burning material |

| Video Detection Technology | Direct identification of smoke and fire source image features within the monitored area | Long detection range, wide protection area, high sensitivity, and fast response speed | Need to consider adaptability to complex environments, such as light changes and smoke obscuration |

| Infrared Thermal Imaging Detection Technology | Observes the thermal state of electrical equipment and detects subtle temperature changes in components | Early fire warning, suitable for various complex environments and long-distance monitoring | Image processing methods need optimization |

| Arc Detection Technology | Multi-dimensional physical signal analysis and intelligent algorithm identification of arc faults | Identifies arc faults | Need to balance computational complexity and hardware costs |

| Optical Fiber Detection Technology | Based on the Raman scattering effect and optical time-domain reflectometry principle for distributed measurement | High precision and resolution, suitable for long distances and complex environments | Unable to achieve continuous distributed monitoring |

| Fire Suppression Agent | Experimental Conditions | Extinguishing Effects | Advantages/Disadvantages | Service Restrictions |

|---|---|---|---|---|

| Water Mist | Spray time: 5–10 min; Droplet size: <1000 μm | Effective cooling, but may not fully suppress lithium-ion battery reignition | Pros: Widely available, low cost; Cons: High conductivity, potential damage to electrical equipment | Suitable for non-conductive environments, not suitable for high-density electrical equipment locations, may cause equipment damage |

| CO2 | Spray time: 1–2 min; Concentration: 30–40% | Rapid extinguishing, but limited cooling effect; may not prevent reignition | Pros: Non-conductive, suitable for electrical equipment; Cons: High environmental impact, potential health hazards | Suitable for use in high-density electrical equipment locations, not suitable for use in enclosed or poorly ventilated environments as this may result in health hazards |

| C6F-ketone | Spray time: 30 s; Concentration: 5–7%; Ambient | Rapid extinguishing, effective suppression of reignition, significant cooling effect | Pros: Non-conductive, environmentally friendly (ODP = 0, GWP = 1); Cons: High cost | Suitable for lithium battery fires, but the cost is high |

| Dry Powder | Spray time: 1–3 min; Concentration: 10–15% | Significant extinguishing effect, but limited cooling; may not prevent reignition | Pros: Suitable for multiple fire types; Cons: Potential damage to electrical equipment, difficult to clean up | Suitable for a wide range of electrical fires, not suitable for use in places with delicate electrical equipment as this may result in damage to the equipment |

| Aqueous Film-Forming Foam (AFFF) | Spray time: 2–5 min; Concentration: 5–10% | Effective cooling and isolation of oxygen, mainly used to extinguish liquid fires | Pros: Highly efficient fire suppression; good burnback resistance; Cons: May leave residue, requires cleanup | Suitable for use in non-conductive environments, not suitable for use in high-density electrical equipment locations where residues may be left behind |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, G.; Guo, J.; Kang, Y.; Huang, Q.; Zhao, J.; Liu, C. Classification and Prevention of Electrical Fires: A Comprehensive Review. Fire 2025, 8, 154. https://doi.org/10.3390/fire8040154

Li G, Guo J, Kang Y, Huang Q, Zhao J, Liu C. Classification and Prevention of Electrical Fires: A Comprehensive Review. Fire. 2025; 8(4):154. https://doi.org/10.3390/fire8040154

Chicago/Turabian StyleLi, Guohui, Jiapu Guo, Yanhao Kang, Que Huang, Junchao Zhao, and Changcheng Liu. 2025. "Classification and Prevention of Electrical Fires: A Comprehensive Review" Fire 8, no. 4: 154. https://doi.org/10.3390/fire8040154

APA StyleLi, G., Guo, J., Kang, Y., Huang, Q., Zhao, J., & Liu, C. (2025). Classification and Prevention of Electrical Fires: A Comprehensive Review. Fire, 8(4), 154. https://doi.org/10.3390/fire8040154