Abstract

Rigid polyurethane foams (RPUFs) are essential polymeric materials, prized for their low density, high mechanical strength, and superior thermal insulation, making them indispensable in construction, refrigeration, and transportation. Despite these advantages, their highly porous, carbon-rich structure renders them intrinsically flammable, promoting rapid flame spread, intense heat release, and the generation of toxic smoke. Traditional strategies to reduce flammability have primarily focused on incorporating additive or reactive flame retardants into the foam matrix, which can effectively suppress combustion but often compromise mechanical integrity, suffer from migration or compatibility issues, and involve complex synthesis routes. Despite recent progress, the long-term stability, scalability, and durability of surface flame-retardant coatings for RPUFs remain underexplored, limiting their practical application in industrial environments. Recent advances have emphasized the development of surface-engineered flame-retardant coatings, including intumescent systems, inorganic–organic hybrids, bio-inspired materials, and nanostructured composites. These coatings form protective interfaces that inhibit ignition, restrict heat and mass transfer, promote char formation, and suppress smoke without altering the intrinsic properties of RPUFs. Emerging deposition methods, such as layer-by-layer assembly, spray coating, ultraviolet (UV) curing, and brush application, enable precise control over thickness, uniformity, and adhesion, enhancing durability and multifunctionality. Integrating bio-based and hybrid approaches further offers environmentally friendly and sustainable solutions. Collectively, these developments demonstrate the potential of surface-engineered coatings to achieve high-efficiency flame retardancy while preserving thermal and mechanical performance, providing a pathway for safe, multifunctional, and industrially viable RPUFs.

1. Introduction

Rigid polyurethane foams (RPUFs) are among the most widely used polymeric foams, valued for their lightweight cellular structure, versatile chemistry, and superior thermal and mechanical performance [1,2,3,4,5,6,7]. Produced through the polyaddition of polyols and isocyanates, RPUFs form a highly cross-linked three-dimensional network that delivers structural rigidity alongside low density and closed-cell morphology [8,9,10]. These characteristics translate into exceptional thermal insulation, high specific strength, and ease of processing, making RPUFs indispensable in building insulation panels, refrigeration appliances, and transportation systems ranging from automobiles to aerospace structures [11,12]. Their versatility and cost-effectiveness ensure that RPUFs continue to play a pivotal role in energy-efficient technologies and infrastructure.

Despite their widespread utility, the intrinsic fire hazard of RPUFs remains a formidable impediment to broader adoption [13,14]. The chemically organic backbone and highly porous cellular structure, together with the large specific surface area, endow the material with an alarming propensity to ignite and sustain combustion [15,16]. Once ignited, RPUFs exhibit rapid flame spread and release substantial amounts of heat, thereby accelerating fire development and reducing the effectiveness of suppression efforts [17,18,19,20]. Equally concerning is the generation of dense smoke and toxic gases, particularly carbon monoxide and hydrogen cyanide, which intensify the lethality of fires by impairing visibility and posing severe risks to human health [21,22,23,24]. These dangers are not confined to controlled laboratory studies but are consistently observed in real-world fire incidents where RPUFs have contributed to greater fire severity and higher casualty rates [25,26,27,28,29,30,31]. As a result, meeting the increasingly strict fire safety standards while developing innovative flame-retardant strategies has become a major challenge for their application in critical fields including building insulation, automotive manufacturing, and aerospace engineering.

Over the past several decades, significant efforts have been directed toward reducing the inherent flammability of RPUFs by incorporating flame-retardant additives into the bulk polymer matrix. Halogenated flame retardants were initially the most widely employed due to their high efficiency in suppressing combustion and slowing flame propagation. Growing environmental and health concerns have, however, led to their gradual replacement, as halogen-containing compounds release corrosive and toxic byproducts during thermal decomposition [32,33,34]. To address these issues, alternative phosphorus- and nitrogen-based flame-retardant systems have been developed, offering improved environmental compatibility while maintaining effective fire suppression [35,36]. Despite these improvements, challenges persist, including additive migration, leaching, and detrimental effects on essential foam properties such as compressive strength and dimensional stability. Inorganic fillers, including aluminum hydroxide (APP) [37,38], expandable graphite (EG) [39,40,41], 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) [42,43,44] and melamine (MEL) [45,46,47], have also been explored as either additive-type or reactive flame retardants, enhancing thermal stability and promoting char formation. Collectively, these strategies demonstrate the ongoing balance between achieving effective flame retardancy and preserving the intrinsic mechanical and thermal properties of RPUFs, emphasizing the need for innovative and sustainable approaches that maintain the core advantages of these materials.

Recent developments in surface coatings have shown that they provide an effective and adaptable approach to improving the fire safety of RPUFs while maintaining their inherent lightweight, insulating, and mechanical characteristics [48,49,50,51]. Various coating types, such as intumescent, non-intumescent inorganic and organic, hybrid, and bio-inspired green systems, function at the foam surface to form protective layers that reduce heat transfer, restrict oxygen diffusion, delay ignition, and facilitate the formation of stable char [49]. Intumescent coatings generate self-expanding char for enhanced thermal protection, whereas aerogel and hydrogel coatings offer lightweight, thermally insulating, and mechanically robust alternatives [52,53,54,55]. Hybrid coatings integrate inorganic fillers with polymeric matrices to achieve combined effects of flame retardancy, smoke suppression, and structural reinforcement. Bio-inspired and green coatings utilize renewable materials and hierarchical architectures to provide multifunctional performance with greater environmental compatibility. Together, these strategies highlight how thoughtful material design and innovation can produce sustainable, high-performance, and multifunctional flame-retardant RPUFs applicable across a wide range of industrial and construction contexts.

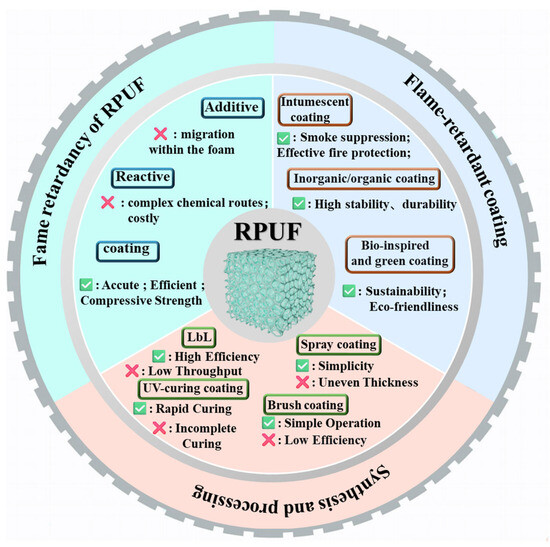

Building on the detailed discussion of individual techniques, it is clear that the development of flame-retardant coatings for RPUFs involves a careful balance between laboratory innovation and industrial scalability. Techniques such as Layer-by-Layer (LbL) assembly, spray coating, UV-curing, and brush coating each offer distinct advantages in terms of coating uniformity, adhesion, flame-retardant efficiency, and environmental compatibility. LbL assembly provides precise nanoscale control and multifunctional performance but faces significant throughput and cost limitations at scale. Spray coating and UV-curing methods offer rapid, scalable, and environmentally friendly routes suitable for industrial adoption, though challenges remain in achieving uniform deposition and complete curing on highly porous foam structures. Brush coating, while labor-intensive, enables targeted application, deep penetration, and strong adhesion, particularly for prototyping, repair, or specialized components, with automation offering potential for broader industrial use. Collectively, these methods reveal the trade-offs between performance, process complexity, and scalability, emphasizing the need for continuous optimization and integration of advanced coating technologies. Therefore, this review aims to comprehensively summarize recent progress in flame-retardant coatings for RPUFs, analyze their mechanisms and fabrication strategies, and provide critical insights into future research directions toward durable, efficient, and industrially applicable flame-retardant systems.

2. Fame Retardancy of RPUF

The high flammability of RPUF arises from its carbon-rich composition and porous structure, both of which accelerate thermal transport, volatile generation and fire growth [17,56]. To mitigate these risks, research has increasingly shifted from internal modification of the polymer to interfacial engineering at the foam surface, where ignition first occurs.

2.1. Flame-Retardant Mechanism

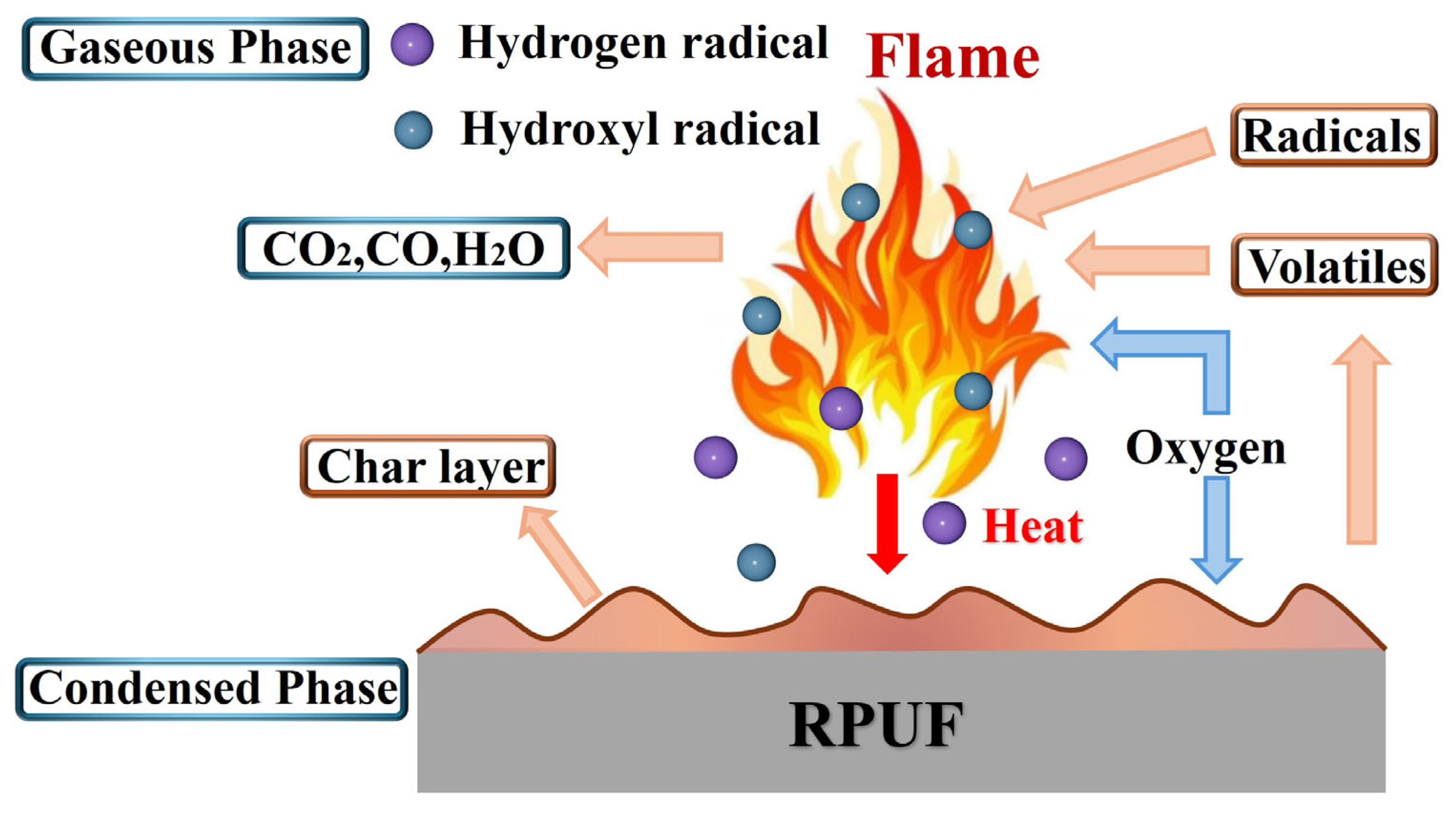

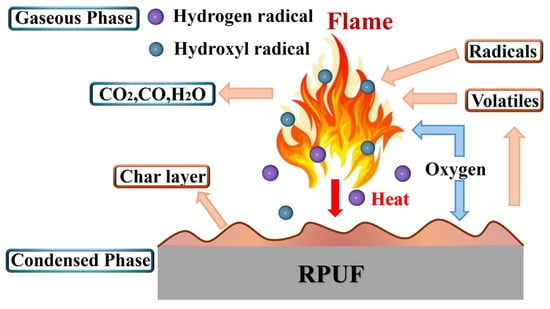

The flame-retardant mechanism of RPUF typically involves a combination of physical and chemical processes. As portrayed in Figure 1, in the condensed phase, flame retardants can promote char formation on the surface of the foam, developing a thermal barrier that slows heat release and mass loss. In the gas phase, certain flame retardants release non-combustible gases or radicals that dilute combustible volatiles and interrupt the free radical chain reactions of combustion. Together, these mechanisms reduce flame propagation, smoke generation, and heat release, thereby improving the fire safety of RPUF materials.

Figure 1.

Schematic illustration of the flame-retardant mechanism in RPUF.

To enhance the flame retardancy of RPUF, three main strategies are commonly employed: additive, reactive, and coating-type flame retardants. Additive flame retardants are physically mixed into the foam matrix, providing flame resistance without altering the polymer backbone. Reactive flame retardants are chemically incorporated into the polyurethane network during synthesis, offering more durable and often more effective flame-retardant performance. Coating-type flame retardants are applied to the surface of the foam, forming a protective layer that can char, swell, or insulate during combustion. By selecting and combining these approaches, the flame-retardant properties of RPUF can be tailored to meet specific safety requirements and application demands.

2.2. Additive Flame Retardant

The most common approach to improving the fire resistance of RPUFs has been the direct physical incorporation of flame retardants into the polyol before the foaming process [57]. A wide variety of materials have been explored within this framework, ranging from inorganic fillers such as expandable graphite [58,59,60], nanoclays [61] and layered double hydroxides [62] to phosphorus- and nitrogen-based compounds and their synergistic blends [63]. By introducing these additives, the combustion behavior of the foam can be altered through multiple mechanisms. In the gas phase, certain species act as radical scavengers that suppress flame-propagating reactions. In the condensed phase, others undergo endothermic decomposition that absorbs heat, while many promote the formation of protective char layers that insulate the underlying material. The combination of these effects provides a versatile means of retarding ignition and slowing flame spread, highlighting why this dispersed additive approach has remained the most widely adopted strategy for RPUF flame retardancy.

Additive flame-retardant systems are often favored because they can be introduced with relative ease during formulation, provide broad flexibility in design, and remain economically viable for large-scale applications. Their practicality has made them the backbone of early efforts to enhance the fire resistance of RPUFs. Despite these advantages, their physical rather than chemical association with the polymer matrix presents a fundamental drawback. Without covalent anchoring, many additives are susceptible to migration within the foam, leaching under environmental exposure. Such processes can gradually diminish the concentration of active flame-retardant species at critical sites, thereby undermining long-term protection.

2.3. Reactive Flame Retardant

Reactive strategies introduce flame-retardant functionalities directly into the polymer backbone by employing specially designed polyols or modified isocyanates during synthesis [64,65]. This approach ensures that the flame-retardant elements become an integral part of the network structure rather than existing as separate phases. Among the most widely investigated functionalities are phosphorus-, nitrogen- and silicon-containing groups, each contributing distinct mechanisms to the overall fire resistance [66]. By covalently binding these groups within the polymer chains, reactive systems eliminate the risks of migration, leaching or phase separation, thereby providing long-lasting flame retardancy. In addition to improved stability, this approach opens opportunities for multifunctionality, as the incorporation of reactive flame-retardant units can simultaneously influence mechanical reinforcement, thermal insulation or chemical resistance, offering a more holistic pathway for the design of advanced RPUF materials.

Despite these benefits, the synthesis of reactive flame-retardant monomers often involves complex chemical routes and can be costly, limiting large-scale adoption. The introduction of additional functional groups may also interfere with foaming kinetics, affecting the uniformity of cell formation and overall morphology. As a result, achieving an optimal balance between fire performance and structural integrity remains a central challenge. Continued research is needed to develop reactive systems that provide robust flame retardancy while maintaining the desired physical and mechanical characteristics of RPUFs (Table 1).

Table 1.

Comparative analysis of additive, reactive, and coating flame-retardant strategies for RPUF composites.

2.4. Flame Retardant Coating

The latest advancement in flame-retardant strategies focuses on confining active functionality to the surface of RPUFs, targeting the precise region where ignition first occurs [75]. Surface-applied coatings, which include intumescent polymer films, sol–gel-derived layers, layer-by-layer assembled nanostructures, and bio-based hybrid materials, form a continuous protective barrier that slows the release of flammable volatiles and limits mass transport [18,76]. In addition to serving as a physical shield, these coatings can facilitate the development of stable, insulating char or ceramic-like residues during combustion, thereby delaying ignition, reducing flame propagation, and mitigating the release of toxic smoke and gases. By focusing protection at the interface rather than throughout the bulk, surface-confined approaches achieve high flame-retardant efficiency with minimal impact on the intrinsic mechanical and thermal properties of the foam.

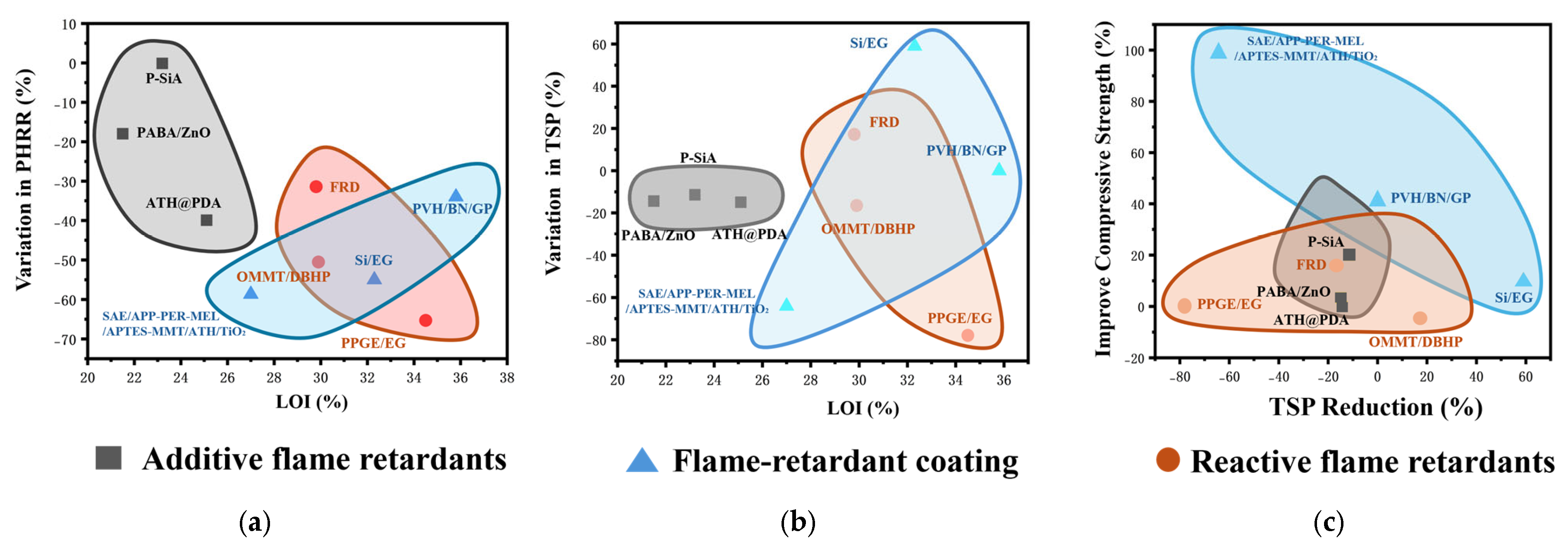

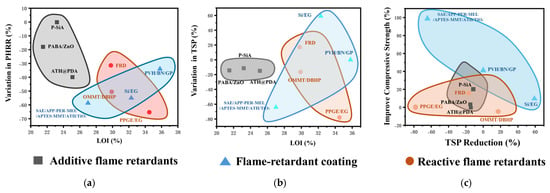

From the results presented in Table 1 and Figure 2, it is evident that coating-type and reactive flame retardants exhibit superior effectiveness in reducing the peak heat release rate (PHRR) compared with additive-type flame retardants. Moreover, when considering mechanical performance, the coating-type flame-retardant systems for RPUF demonstrate a distinct advantage, indicating that surface modification not only enhances fire safety but also better preserves the structural integrity of the foam. One of the primary advantages of surface coatings is their ability to enhance flame retardancy without compromising the intrinsic properties of the foam, allowing high performance to be achieved with relatively low material consumption. In addition to their protective function, interfacial coatings provide opportunities for multifunctional improvements. Despite these promising attributes, several challenges remain. The long-term durability of coatings under mechanical stress, their adhesion to substrates with low surface energy and the practical scalability of fabrication processes have yet to be fully addressed.

Figure 2.

Flame-retardant performance of RPUFs incorporating additive, reactive, and coating-type flame retardants: (a) comparison of changes in PHRR and LOI (%), (b) comparison of changes in TSP and LOI (%), and (c) comparison of improvements in compressive strength (%) and reductions in TSP (%). Flame-retardant systems include P-SiA [67], PABA/ZnO [68], ATH@PDA [69], OMMT/DBHP [70], FRD [65], PPGE/EG [71], Si/EG [72], PVH/BN/GP [73], SAE/APP-PER-MEL/APTES-MMT/ATH/TiO2 [74].

3. The Design Principles and Evolution of Flame-Retardant Coating

3.1. Intumescent Coating

Intumescent coatings provide a powerful strategy to mitigate the high flammability of RPUFs, which are otherwise valued for their exceptional insulation and lightweight characteristics [77,78]. Upon exposure to heat, these coatings undergo a self-activated transformation, expanding into a voluminous char layer that effectively shields the underlying foam from heat flux, oxygen diffusion, and volatile release. The process typically integrates an acid source, a carbon-rich substrate, and a gas-releasing component, enabling simultaneous char formation and thermal insulation [79]. Unlike additive or reactive flame-retardant systems that often compromise the intrinsic properties of RPUF, intumescent coatings maintain the mechanical and thermal performance of the foam while providing substantial improvements in fire safety. Advances in formulation, including the incorporation of bio-based carbon sources, phosphorus-nitrogen compounds, and nanostructured reinforcements, have further improved expansion dynamics, durability, and environmental compatibility. These developments highlight intumescent coatings as a promising route toward multifunctional, sustainable, and fire-safe RPUF materials.

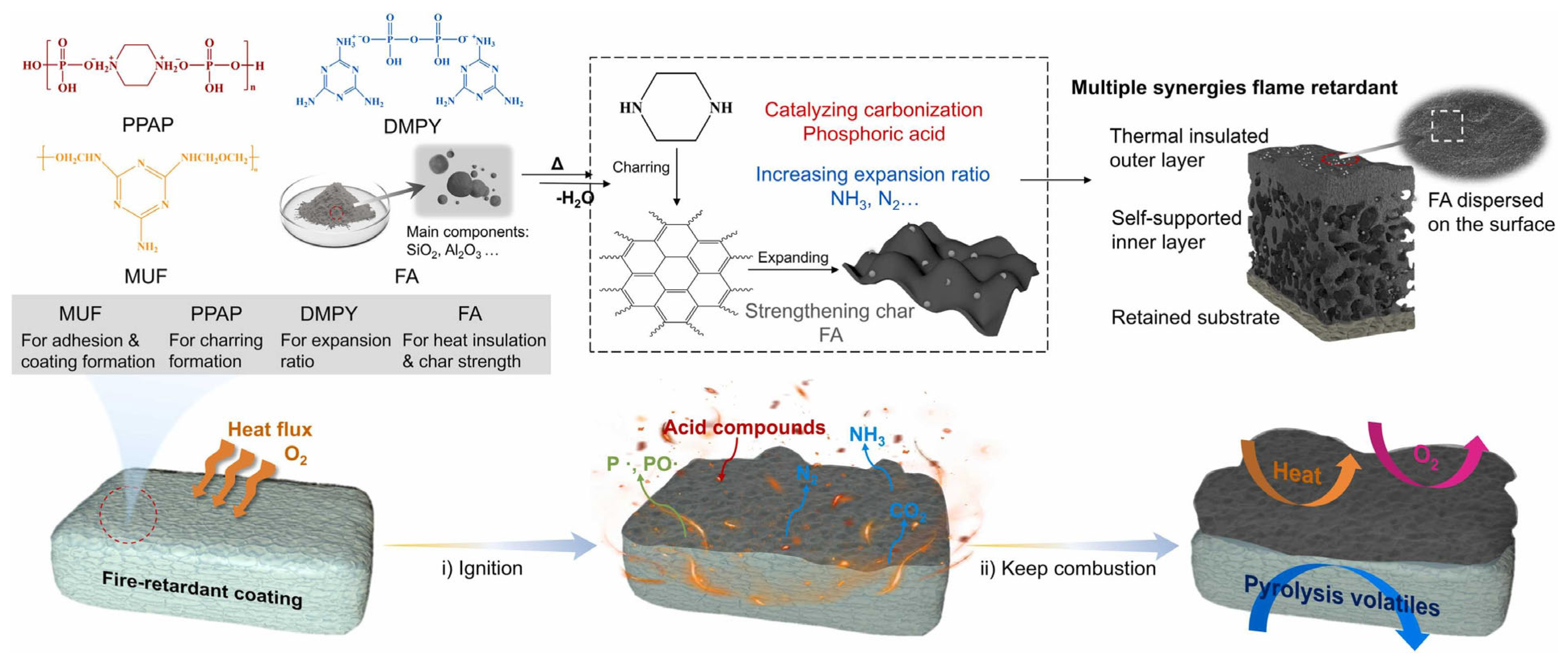

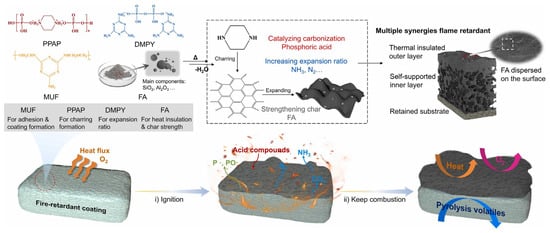

As illustrated in Figure 3, Xu et al. [80] developed an organic-inorganic hybrid intumescent coating (MPDF5), formulated with melamine–urea–formaldehyde resin, piperazine pyrophosphate, dimelamine pyrophosphate, and industrial waste fly ash, which significantly enhanced the flame retardancy of RPUF. The coated foam (RPUF@MPDF5) with a thickness of only 100 µm exhibited remarkable self-extinguishing ability and achieved a UL-94 V-0 rating. Compared with uncoated RPUF, the total heat release and total smoke production were reduced by 89.1% and 76.4%, respectively, demonstrating excellent suppression of both heat and smoke. The enhanced performance was attributed to the rapid decomposition of the coating into viscous char precursors, the release of non-flammable gases facilitating intumescence, and the incorporation of porous fly ash that reinforced the external char layer and improved thermal insulation. Beyond RPUF, the MPDF5 coating was also effective in enhancing the fire resistance of wood and steel, underscoring its versatility and practical potential in construction applications.

Figure 3.

Component and combustion process of multiple synergistic organic-inorganic hybrid fire-retardant coatings [80]. Copyright 2025. Reproduced with permission from Elsevier Science Ltd.

Tong et al. [74] developed an environmentally friendly intumescent flame-retardant coating for RPUF to effectively suppress ignition and flame spread. Compared with uncoated RPUF, the coated samples exhibited superior fire resistance, achieving a limiting oxygen index above 27% and rapid self-extinguishing in vertical combustion tests without droplet formation. Thermogravimetric analysis revealed that the coating increased the carbon residue from 16.9% to 44.3%, while cone calorimetry demonstrated significant reductions in peak heat release rate (from 227.4 to 93.9 kW/m2) and total heat release (from 18.9 to 4.9 MJ/m2). In addition, the peak smoke production rate and the total smoke production were significantly reduced, confirming the smoke suppression capability of the coating. The enhanced flame retardancy was attributed to the APP-PER-MEL intumescent system that generated a protective char layer, combined with the synergistic effect of modified montmorillonite and aluminum hydroxide, which reinforced the barrier and improved thermal stability. These results highlight that intumescent coatings enhance the fire safety of RPUFs, reduce toxic emissions, and, at the same time, expand their potential for sustainable applications in thermal insulation and construction materials.

3.2. Non-Intumescent Inorganic/Organic Coating

Non-intumescent inorganic and organic coatings have emerged as a promising approach to improve the fire safety of RPUFs, providing effective thermal shielding without relying on expansion mechanisms [81,82,83]. Aerogel coatings, with ultra-low thermal conductivity and high porosity, function as lightweight insulating barriers that resist heat transfer while maintaining the structural and insulating performance of RPUFs [84,85]. Hydrogel coatings utilize high water content and endothermic dehydration to create a cooling effect and form protective residues that limit flame spread and smoke generation. Additional systems based on layered silicates, ceramic oxides, or polymer–inorganic hybrids produce dense and stable barriers that inhibit oxygen penetration and volatile release [86]. Compared with conventional intumescent layers prone to collapse during extended heating, non-intumescent coatings offer greater structural stability, durability, and multifunctionality, including enhanced water resistance, mechanical reinforcement, and environmental adaptability. Collectively, hydrogel, aerogel, and hybrid coatings provide a versatile and sustainable strategy for endowing RPUFs with superior fire protection while preserving their lightweight insulation advantages.

3.2.1. Aerogel Coating

Aerogel coatings represent a promising approach to enhance the fire safety of RPUFs while maintaining their lightweight and insulating nature. With ultralow density, high porosity, and very low thermal conductivity, these coatings develop stable, lightweight barriers that restrict heat transfer and safeguard the structural and mechanical integrity of foams. In contrast to intumescent layers that rely on expansion and may degrade under prolonged exposure, aerogels remain intact, ensuring reliable resistance to flames, heat, and smoke. Both inorganic systems, such as silica and alumina aerogels, and organic-inorganic hybrids with improved adhesion and flexibility, have demonstrated multifunctional performance.

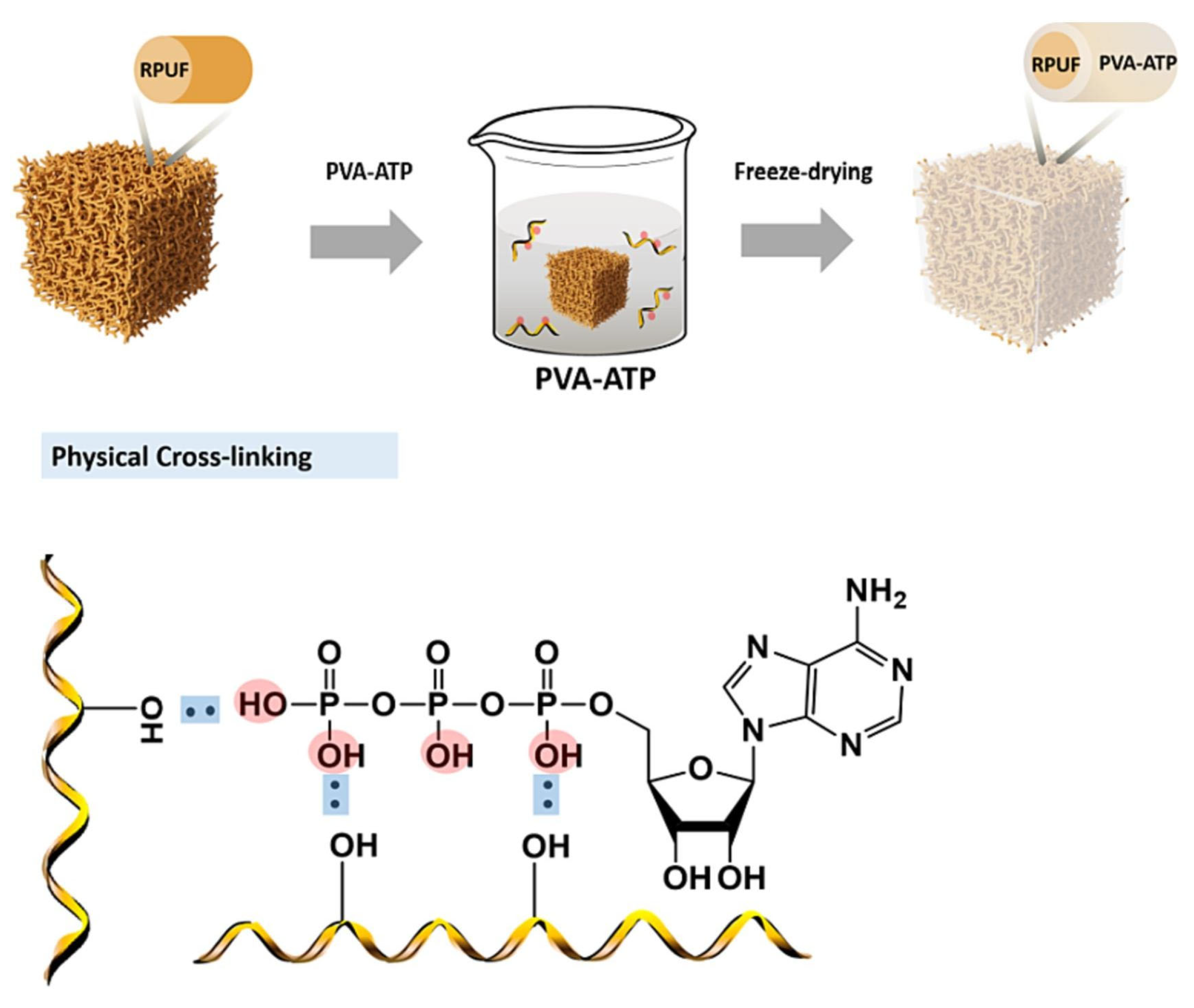

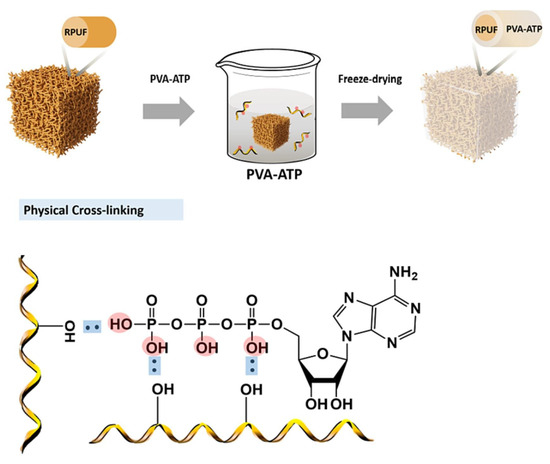

Li et al. [87] developed an innovative organic P-N aerogel strategy to enhance the flame retardancy, thermal insulation, and mechanical performance of RPUFs by integrating polyvinyl alcohol (PVA) with adenosine triphosphate (ATP). As illustrated in Figure 4, RPUF samples were immersed in PVA-ATP solutions of varying concentrations and subsequently freeze-dried. The resulting RPUF/PVA-ATP composites exhibited markedly improved compressive strength, with the RPUF/PVA-ATP7 sample reaching 338 kPa, a 74.2% increase over unmodified RPUF, while maintaining ultralow thermal conductivity of 0.020 W/(m·K), lower than that of air. Flame-retardant tests showed that RPUF/PVA-ATP5 and RPUF/PVA-ATP7 passed the UL-94 V-0 rating with limiting oxygen indices of 30.0% and 36.5%, respectively. Cone calorimetry revealed reductions of 40.7% in peak heat release rate and 61.6% in peak CO production for RPUF/PVA-ATP7, demonstrating effective suppression of heat and smoke hazards.

Figure 4.

Preparation process of RPUF/PVA-ATP [87]. Copyright 2023. Reproduced with permission from Elsevier Science Ltd.

Silica aerogels provide an effective approach to enhance fire safety and thermal insulation in RPUFs. Rao et al. [67] developed phosphorus-modified silica aerogels (P-SiA) by combining a phosphorus-containing diol with ammonium polyphosphate and tetraethyl orthosilicate, forming a hierarchically porous network with strong compatibility in the RPUF matrix. The dual hydroxyl groups enabled uniform APP dispersion and improved interfacial adhesion, leading to a 46.4% increase in compressive strength for RPUF/P-SiA-5 compared with pristine RPUF. The system synergistically combined physical insulation from silica aerogel with chemical flame-retardant activity, promoting dense char formation and suppressing heat and smoke release. Limiting oxygen index reached 23.2% for RPUF/P-SiA-15, while residual char at 700 °C increased to 36.1 wt%, demonstrating enhanced thermal stability and flame retardancy. Mechanistic analysis indicated that a phosphorus-silica hybrid char layer inhibited combustion, and hierarchical porosity improved insulation. This study highlights a rational design strategy integrating inorganic aerogels with reactive phosphorus species to produce RPUFs with outstanding fire safety, smoke suppression, thermal insulation, and mechanical performance.

3.2.2. Hydrogel Coating

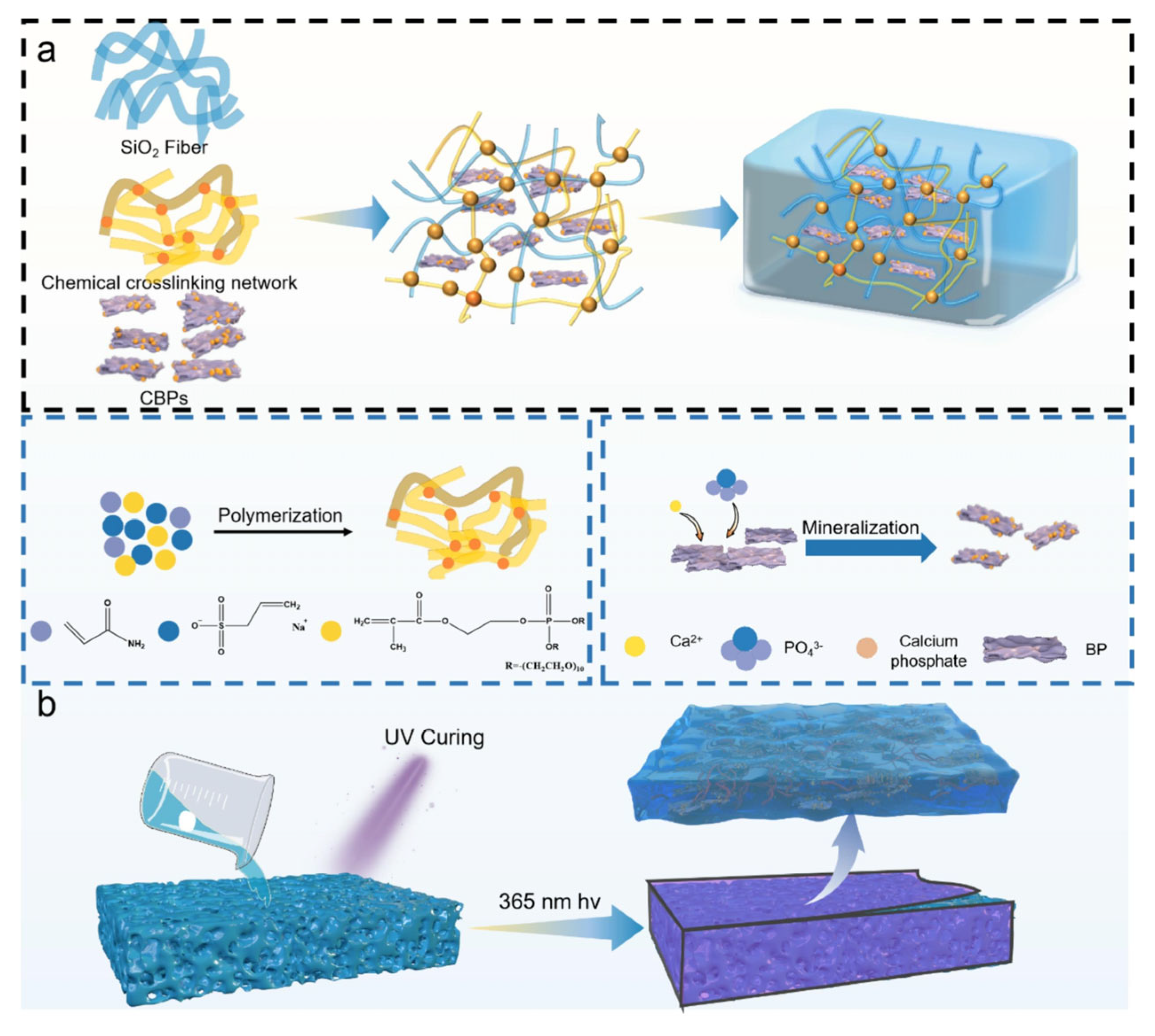

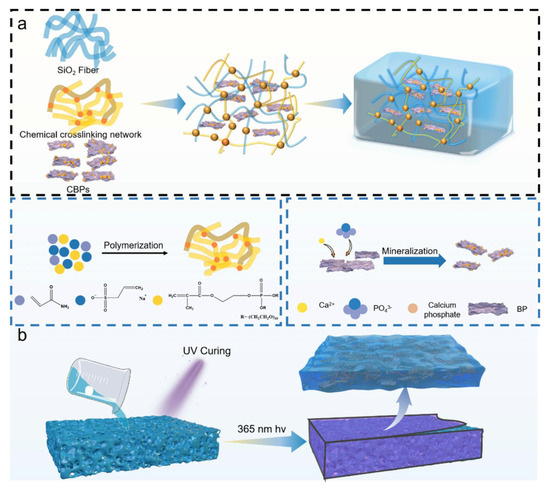

Hydrogel coatings have emerged as a multifunctional strategy to enhance the fire resistance of RPUFs while maintaining mechanical performance. As shown in Figure 5, Wang et al. [88] designed a multiscale hydrogel by integrating calcium phosphate nanocrosslinked points, silica nanofiber networks, and black phosphorus sheets, combined with intrinsic flame-retardant precursors to overcome the low thermal stability and weak adhesion typical of conventional hydrogels. When applied to RPUF, the hydrogel-coated composites exhibited a 23.6% reduction in peak heat release rate, a 45% decrease in total smoke production, and a 27-s delay in time to ignition. The incorporation of mineralized black phosphorus nanosheets and silica nanofibers via UV-curing produced strong adhesion, high mechanical robustness, and self-extinguishing behavior. This work highlights a rational design of hydrogel coatings that provide sustained fire protection, mechanical reinforcement, and multifunctionality, offering a versatile approach for flame-retardant applications in construction, casting, and mining industries.

Figure 5.

Schematic illustration of the hydrogel flame retardant coating design and its application in RPUF. (a) Synthesis of the hydrogel flame retardant coating. (b) Schematic of the preparation process of flame retardant RPUF with a hydrogel coating [88]. Copyright 2024. Reproduced with permission from Elsevier Science Ltd.

Shi et al. [89] developed an eco-friendly double-network hydrogel coating composed of polyacrylic and polydopamine (PAAm-PDA) using a simple casting and curing method, producing a uniform and strongly adherent protective layer on the RPUF surface. The hydrogel provided high water retention and effective thermal management, enabling multiple flame-retardant mechanisms, which led to rapid self-extinguishing behavior, a six-fold extension in time to ignition, and reductions of 39.7 percent and 42.2 percent in mean heat release rate and total smoke production compared with uncoated foam. The coating also exhibited excellent mechanical performance, including a compression strain of 85 percent and resistance to repeated scratching, ensuring durability under practical conditions. This study presents a green and straightforward strategy to fabricate multifunctional hydrogel coatings that integrate fire protection, mechanical reinforcement, and sustainability, offering a promising approach for developing safe and high-performance structural materials.

3.2.3. Other Hybrid Coatings

Other hybrid coatings have emerged as an effective strategy to enhance fire safety, mechanical strength, and environmental resilience in RPUFs. These coatings combine inorganic fillers such as layered silicates, ceramic oxides, or metal hydroxides with polymeric matrices, creating dense, thermally stable barriers that restrict oxygen penetration and volatile release [90]. The synergy between physical insulation provided by inorganic components and chemical flame-retardant activity from polymeric or phosphorus-based additives enhances both flame retardancy and smoke suppression.

Ceramifiable organic-inorganic hybrid coatings have emerged as a promising strategy to enhance the fire safety of RPUFs. Song et al. [73] developed a lava-inspired, micro/nano-structured hybrid coating by integrating low-melting glass powders as ceramic precursors, boron nitride nanosheets as synergists, and a fire-retardant polymer matrix. Upon exposure to flame, this coating transforms into a lava-like, noncombustible ceramic char layer with a porous interior, providing a robust thermal shield for underlying substrates. Applied at a thickness of only 200 μm, the coating enabled RPUF to self-extinguish, reduced heat and smoke release, achieved a high limiting oxygen index of 35.8 vol%, passed the UL-94 V-0 rating, and enhanced compressive strength, outperforming conventional fire-retardant PU foams. Beyond RPUFs, the hybrid coating offered effective fire and thermal protection for solid wood and steel while demonstrating good friction and UV resistance. This bioinspired design provides a cost-effective, multifunctional, and durable approach for fire-retardant coatings with broad applicability in construction, transportation, plumbing, and electrical systems.

3.3. Bio-Inspired Flame-Retardant Coating

Bio-based flame-retardant polyurethane materials have attracted significant attention as a sustainable alternative to petroleum-based systems, combining environmental friendliness with enhanced fire safety. In recent years, various renewable resources such as lignin, tannic acid, phytic acid, cardanol, and vanillin have been utilized to synthesize flame-retardant polyols or incorporated as reactive or additive flame retardants in polyurethane matrices. Liu et al. [91] developed a bio-based waterborne polyurethane incorporating a phosphorus–nitrogen–silicon flame retardant, which significantly improved limiting oxygen index and reduced peak heat release through synergistic gas-phase radical quenching and condensed-phase char formation. These bio-based components introduce heteroatoms (e.g., P, N, Si, and S) and aromatic structures that promote char formation, inhibit the release of combustible gases, and improve thermal stability during combustion [92,93].

Bio-inspired and green coatings represent a sustainable approach to improving the fire safety of RPUFs [85,94,95]. Inspired by natural structures such as nacre, plant cuticles, and intumescent shells, these coatings adopt hierarchical designs that combine multifunctionality with resilience under extreme conditions, enabling simultaneous flame retardancy, smoke suppression, and mechanical reinforcement while limiting hazardous additives. Renewable resources have been employed as coating precursors, functioning as char promoters while also contributing hydrophilicity control, biocompatibility, and biodegradability [96,97,98,99]. When integrated with inorganic nanosheets or catalytic components, bio-derived coatings form hybrid interfaces that enhance thermal barrier properties and promote the stabilization of combustion products, thereby extending the performance of RPUFs. The convergence of bio-inspired principles with green chemistry provides a pathway to coatings that not only meet stringent fire safety requirements but also advance ecological responsibility, offering a promising route to next-generation flame-retardant solutions for polymer foams.

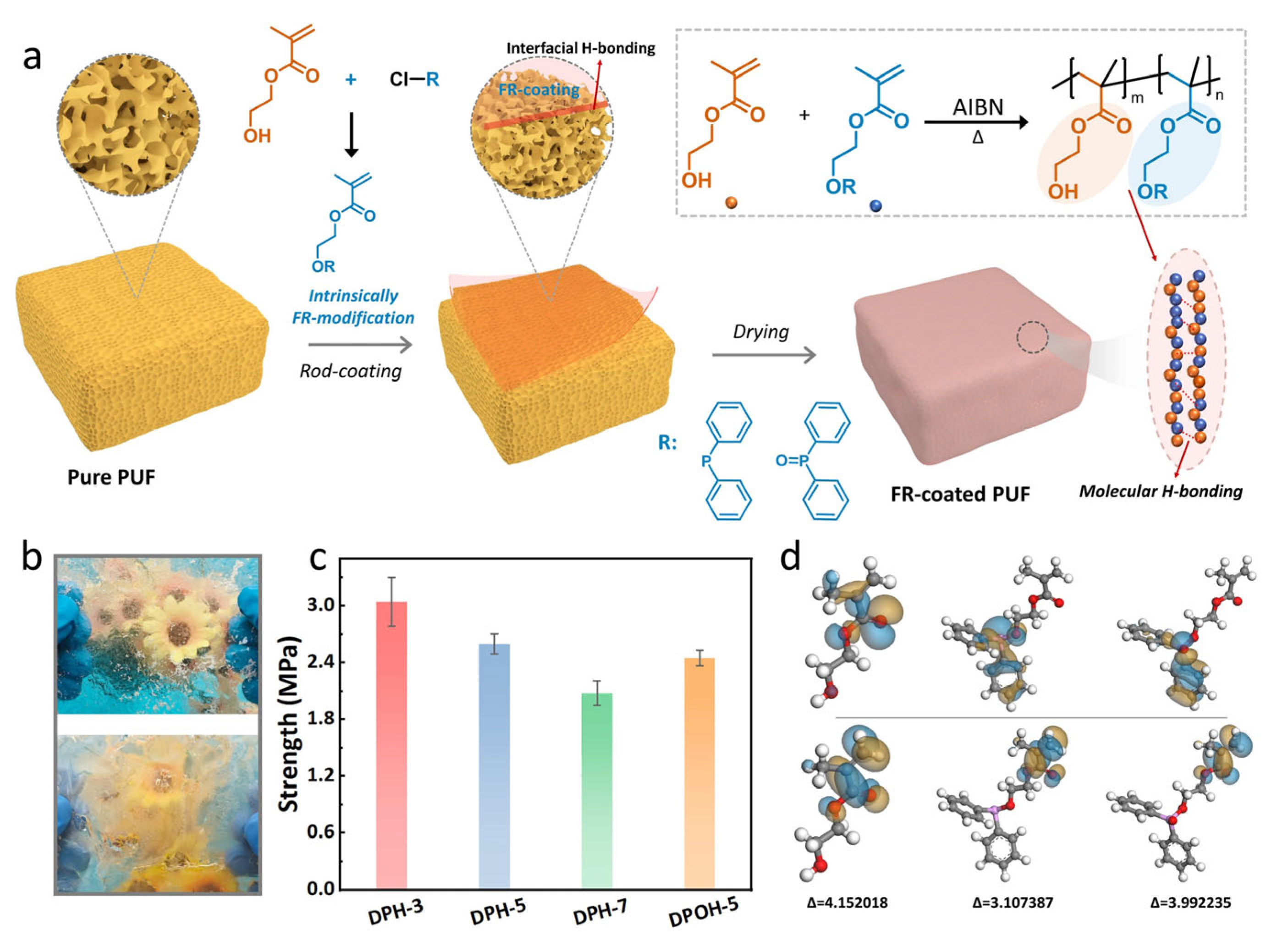

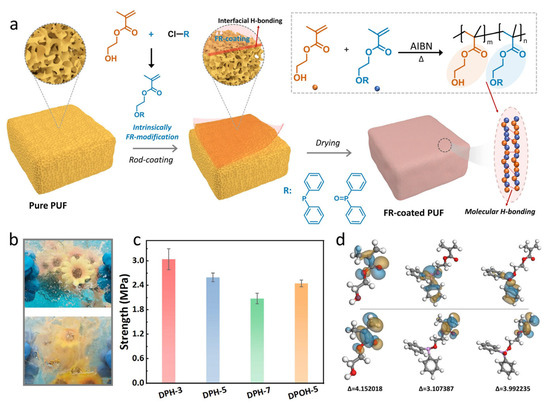

Bio-inspired coatings have recently gained attention as an effective strategy to overcome the inherent flammability and poor interfacial adhesion of RPUFs. Drawing inspiration from the strong adhesion of marine algae, Yu et al. [100] developed an intrinsically flame-retardant acrylic copolymer coating incorporating multiple hydrogen bonding interactions, which provided excellent interfacial adhesion to RPUF and other substrates while delivering efficient flame protection, as illustrated in Figure 6. The coated foams exhibited high char-forming ability, achieved self-extinguishing behavior, and reached the UL-94 V-0 rating, demonstrating superior performance compared to conventional coatings. Building on this concept, further work has reported bio-inspired flame-retardant coatings with additional functionalities such as rapid water-mediated self-healing, robust adhesion strength of up to 1.6 MPa, and enhanced thermal stability. These coatings enabled RPUFs to achieve both UL-94 V-0 ratings and elevated LOI values, while significantly reducing peak heat release rates by more than 30%. The improved performance was attributed to the synergistic action of diphenyl and hydroxyethyl groups, which promoted the formation of dense and cohesive char layers, enhancing condensed-phase protection. Collectively, these studies highlight how bio-inspired design principles can be translated into practical, multifunctional, and sustainable flame-retardant coatings, expanding the potential of RPUFs in applications ranging from building insulation to transportation and electronics.

Figure 6.

(a) Schematic of the preparation of bionic flame retardant polyurethane foam coating. (b) Digital photo of copolymer DPH and DPOH. (c) Tensile strength of copolymers. (d) ΔE of flame retardant monomers calculated by DFT simulation [100]. Copyright 2025. Reproduced with permission from Elsevier Science Ltd.

Xu et al. [101] developed phytate-based flame retardants, including aluminum phytate (PA-Al) and iron phytate (PA-Fe), through a simple ionic reaction between phytic acid and metal salts, and incorporated them into RPUF by a one-step water-blown process. The resulting composites exhibited markedly improved fire resistance, with RPUF/PA-Fe30 achieving a char residue of 22.1 wt% compared with only 12.4 wt% for pristine RPUF. Cone calorimetry confirmed that RPUF/PA-Al30 achieved the lowest fire risk, with a 17.0% reduction in total heat release and a 22.0% reduction in total smoke release, while TG-FTIR analysis showed that PA-Fe was particularly effective in suppressing the release of flammable gases (hydrocarbons, esters) and toxic products (isocyanates, CO, HCN, and aromatics). Moreover, the phytate additives demonstrated good compatibility with the RPUF matrix and enhanced its thermal stability, smoke suppression, and toxicity reduction performance. These findings highlight the potential of phytate-based systems as a sustainable and efficient strategy for designing bio-inspired flame-retardant coatings for RPUFs.

4. Synthesis and Processing: From Laboratory Innovation to Industrial Scalability

The movement from laboratory-scale experiments to full industrial production continues to represent one of the greatest challenges in the development of flame-retardant coatings for RPUFs. Although research laboratories have produced a range of sophisticated and highly effective coating strategies, translating these innovations into commercially viable processes is complicated by practical limitations related to production speed, material cost, and manufacturing feasibility. In this section, we provide a detailed overview of representative processing techniques, examining their performance and versatility at the laboratory level, the specific obstacles they face when scaled up for industrial use, and the potential avenues for overcoming these challenges to enable broader application.

4.1. LbL Assembly and Dip-Coating Techniques

LbL assembly has emerged as one of the most sophisticated and effective strategies for constructing nanoscale flame-retardant coatings [102,103,104,105]. This technique relies on the sequential deposition of oppositely charged species, including polyelectrolytes, nanoparticles, or other functional materials such as chitosan/ammonium polyphosphate and phytic acid/polyethylenimine, directly onto the foam substrate. By precisely controlling the number of layers, their composition, and overall architecture, LbL assembly can achieve outstanding flame-retardant performance while requiring minimal additive content. The use of water as a primary solvent enhances the environmental compatibility of the process, further increasing its appeal for sustainable applications.

Dip-coating, a more generalized deposition strategy to which LbL belongs, offers a scalable and straightforward route for the fabrication of flame-retardant surfaces. In dip-coating, RPUFs are immersed in a flame-retardant solution or suspension, withdrawn at a controlled speed, and dried to achieve a uniform layer. By repeating the immersion cycles, multilayered coatings can be constructed, enabling tunable surface chemistry and thickness. Dip-coated RPUFs benefit from the incorporation of reactive or additive flame retardants, as well as hybrid coatings that combine inorganic nanoparticles, phosphorus–nitrogen compounds, or bio-based materials.

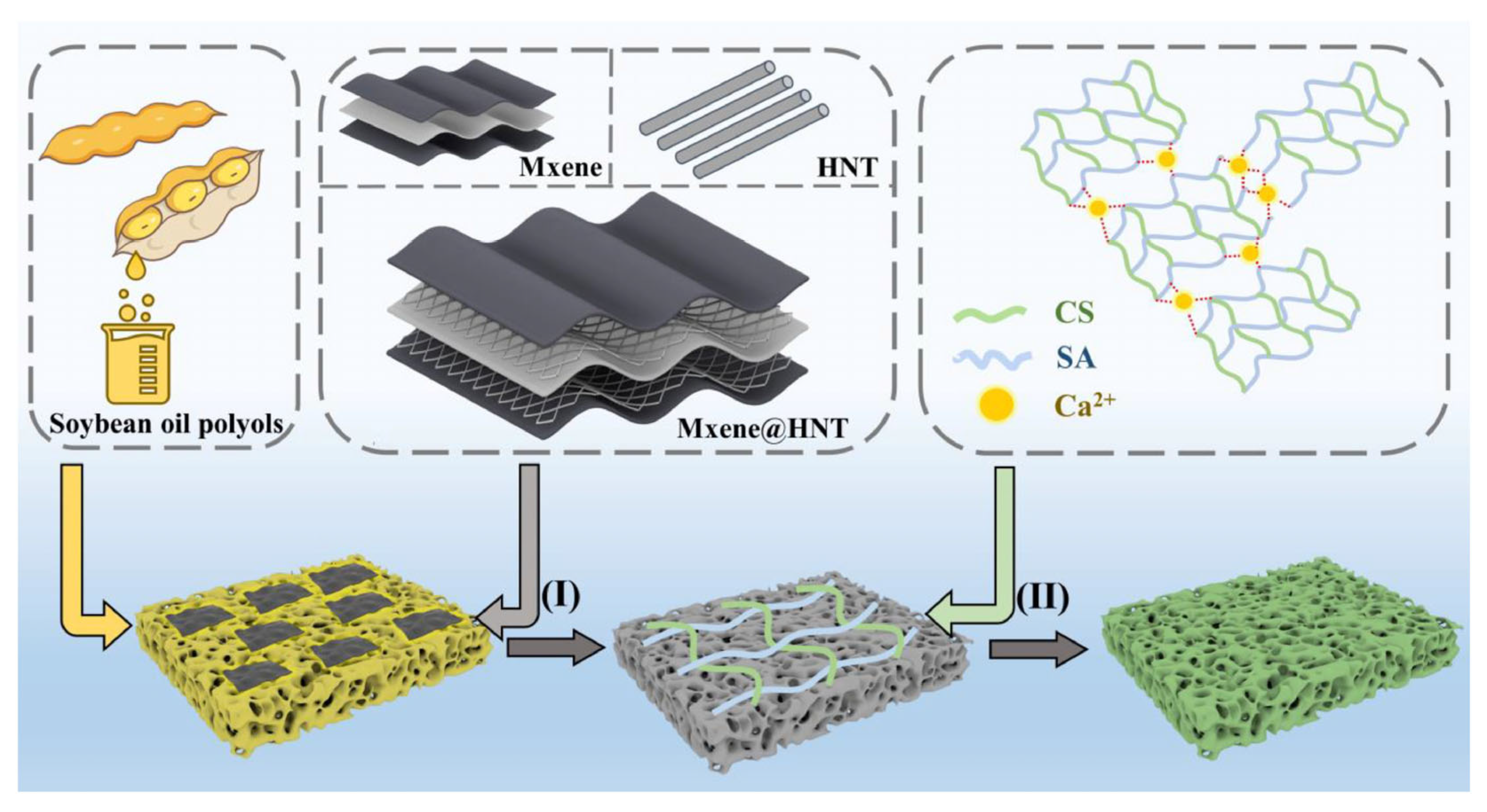

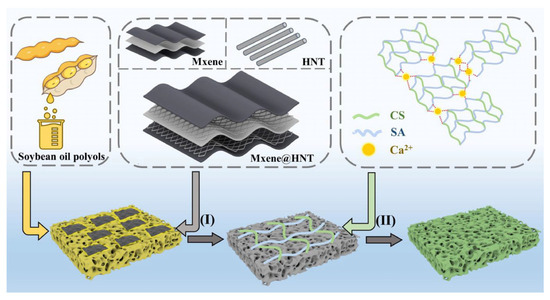

Fan et al. [106] prepared Mxene@HNT composites and employed an LBL deposition method using a dual hydrogel (DH) to immobilize Mxene@HNT onto RPUF surfaces, developing the RPUF/M@H/DH flame-retardant system (Figure 7). Utilizing vegetable oil as a sustainable polyol, this system significantly improved fire safety, achieving a UL-94 V-0 rating and a limiting oxygen index of 30.5%. Cone calorimetry revealed reductions of 29.34% in peak heat release rate and 14.95% in peak smoke production rate, along with a 151.5% increase in carbonization yield compared to unmodified RPUF. Additionally, the LBL approach enhanced interfacial adhesion between the coating and RPUF, ensuring long-term durability and synergistic interaction between DH and Mxene@HNT. The mechanical properties of RPUF remained largely unaffected, demonstrating that LBL coatings can provide multifunctional, environmentally friendly, and mechanically robust flame-retardant solutions suitable for a wide range of industrial applications.

Figure 7.

Schematic diagram of preparation of eco-friendly fire-retardant RPUF/M@H/DH. (I) Mxene@HNT was integrated onto the surface of RPUF to yield a flame-retardant inner layer; (II) DH wrapped and immobilized flame-retardant material on the outermost layer to yield flame-retardant outer layer [106]. Copyright 2024. Reproduced with permission from Elsevier Science Ltd.

Despite its notable advantages at the laboratory scale, LbL assembly faces significant challenges in terms of industrial implementation. The inherently sequential nature of the dipping and rinsing steps makes it slow and incompatible with high-speed, continuous foam production. Although automated systems have been developed, their throughput remains far below that of conventional roll-to-roll or conveyor-based coating lines. In addition, the low viscosity of typical LbL solutions often leads to excessive penetration into the open-cell structure of RPUF, causing material waste and reducing the efficiency of the surface coating. The construction and maintenance of a production line with multiple dipping, rinsing, and drying baths further increase capital and operational costs, limiting the economic feasibility of large-scale adoption.

4.2. Spray Coating

Spray coating is a commonly employed method for applying flame-retardant coatings to polymers, where a formulation containing a polymer binder, flame-retardant fillers, and a solvent or water is atomized and evenly deposited onto the surface [107,108,109]. Its simplicity, speed, and versatility have made it a common choice in laboratory studies, where rapid screening of formulations and layer properties is often required. Beyond the laboratory, spray coating is one of the most immediately scalable methods for industrial implementation.

Hu et al. [110] demonstrated this concept on wood, where MXene sheets were simply sprayed onto the substrate to form a conductive network, achieving high electrical conductivity and excellent EMI shielding effectiveness (31.1 dB at 8.2–12.4 GHz), while also providing fire-retardant behavior through MXene oxidation to titanium dioxide. A subsequent coating of waterborne acrylic (WA) resin enhanced adhesion, water resistance, and durability, preventing MXene delamination and maintaining functional performance after water-soaking and drying cycles. This facile, scalable, and environmentally friendly spray approach can be readily adapted to RPUFs, enabling the fabrication of lightweight, fire-retardant, and water-resistant foams with the added potential for EMI shielding, thus extending their utility in safety-critical, energy-efficient, and harsh-environment applications.

Although publications specifically addressing spray-applied flame-retardant coatings on RPUF remain limited, this approach has already been successfully applied to a variety of other polymeric materials, suggesting that further optimization and systematic study could significantly expand its use in foam-based applications. Despite these advantages, spray coating presents several technical challenges. Formulations must be carefully optimized to achieve appropriate viscosity for efficient atomization while preventing filler sedimentation, as abrasive or large particles such as expandable graphite can clog nozzles and interrupt production. Ensuring uniform coating thickness on highly porous substrates is difficult, and excess material can infiltrate the foam pores, resulting in uneven curing and waste of expensive additives. Moreover, while water-based formulations are environmentally preferred, many high-performance coatings still require organic solvents, which necessitate complex and costly vapor recovery systems to meet regulatory standards.

4.3. UV-Curing Coating

UV curing technology has emerged as a rapid and energy-efficient approach for the fabrication of flame-retardant coatings on RPUF, offering significant potential for industrial-scale production [111,112,113]. The process involves the application of a liquid, solvent-free resin formulation that typically contains unsaturated oligomers, such as urethane acrylates, reactive diluents, photo initiators, and flame-retardant additives. Upon exposure to UV light, the formulation polymerizes and crosslinks within seconds to form a solid, uniform film. The principal advantage of this approach is its extremely fast curing speed, which allows for high-throughput coating and immediate handling of treated products, significantly reducing the factory footprint compared to conventional thermal drying ovens. Additionally, fully UV-curable systems generally contain minimal volatile organic compounds (VOCs), addressing critical environmental and occupational safety concerns. The resulting crosslinked networks often exhibit enhanced chemical resistance, surface hardness, and long-term durability, making them particularly attractive for protective coatings.

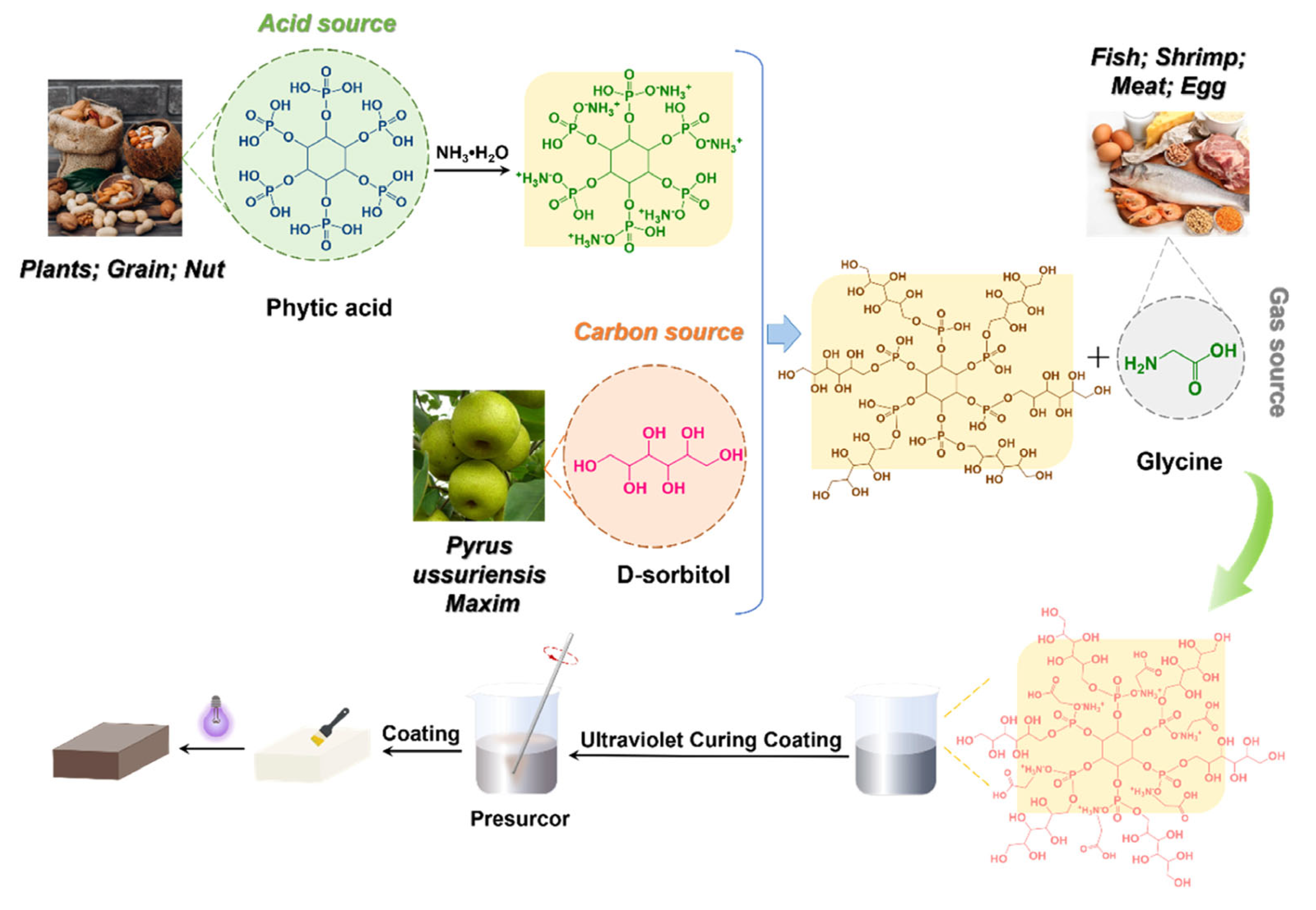

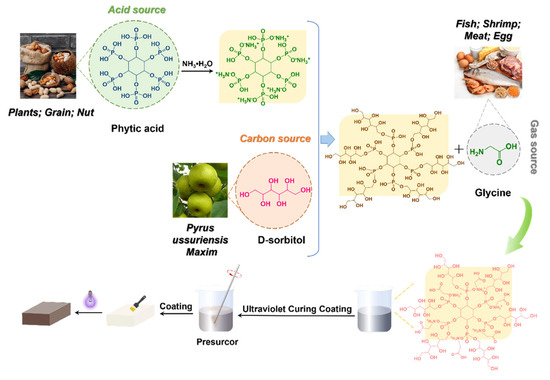

Liu et al. [112] reported a green, biomass-derived flame-retardant coating, synthesized from phytic acid as an acid source, D-sorbitol as a carbon source, and glycine as a gas source, which was applied to RPUF surfaces using a simple and cost-effective UV-curing technique (Figure 8). This coating enabled the RPUF to achieve a limiting oxygen index of 39.7% and successfully pass UL-94 testing with a V-0 rating. Compared with uncoated foam, the coated RPUF exhibited a prolonged ignition time by 3 s, a 60% reduction in peak heat release rate, and notable smoke suppression. Mechanistic analysis revealed that during combustion, the coating rapidly formed a dense, expanding char layer while releasing inert gases, which effectively hindered mass and heat transfer, protecting the foam substrate. The facile, scalable, and eco-friendly UV-curing method demonstrates that such coatings can be readily applied to RPUFs, offering an efficient, sustainable, and high-performance solution for flame-retardant polymer foams in building, transportation, and other industrial applications.

Figure 8.

The preparation route of coated RPUF [112]. Copyright 2024. Reproduced with permission from Elsevier Science Ltd.

Despite these advantages, UV-curable flame-retardant coatings for RPUF face several challenges. The highly porous, three-dimensional structure of RPUF can create shadowed regions that are shielded from direct UV exposure, leading to incomplete curing in recessed areas. Formulation design must therefore ensure adequate UV penetration, which may involve the use of specialized photo initiators or UV-LED systems emitting longer wavelengths. The incorporation of solid flame-retardant fillers can further scatter UV light, reducing curing efficiency and necessitating surface modification of fillers.

4.4. Brush Coating

Brush coating, which involves the manual application of a coating formulation using a brush, is one of the most fundamental and accessible techniques for imparting flame retardancy to RPUF [114]. In laboratory settings, it is particularly valuable due to its simplicity, minimal equipment requirements, and the exceptional control it offers over the placement of thick or highly viscous coatings on targeted areas. The mechanical action of brushing allows the coating to penetrate the complex and porous surface of RPUF, enhancing initial adhesion and ensuring uniform coverage over intricate geometries, which is especially useful during prototyping and small-scale sample preparation.

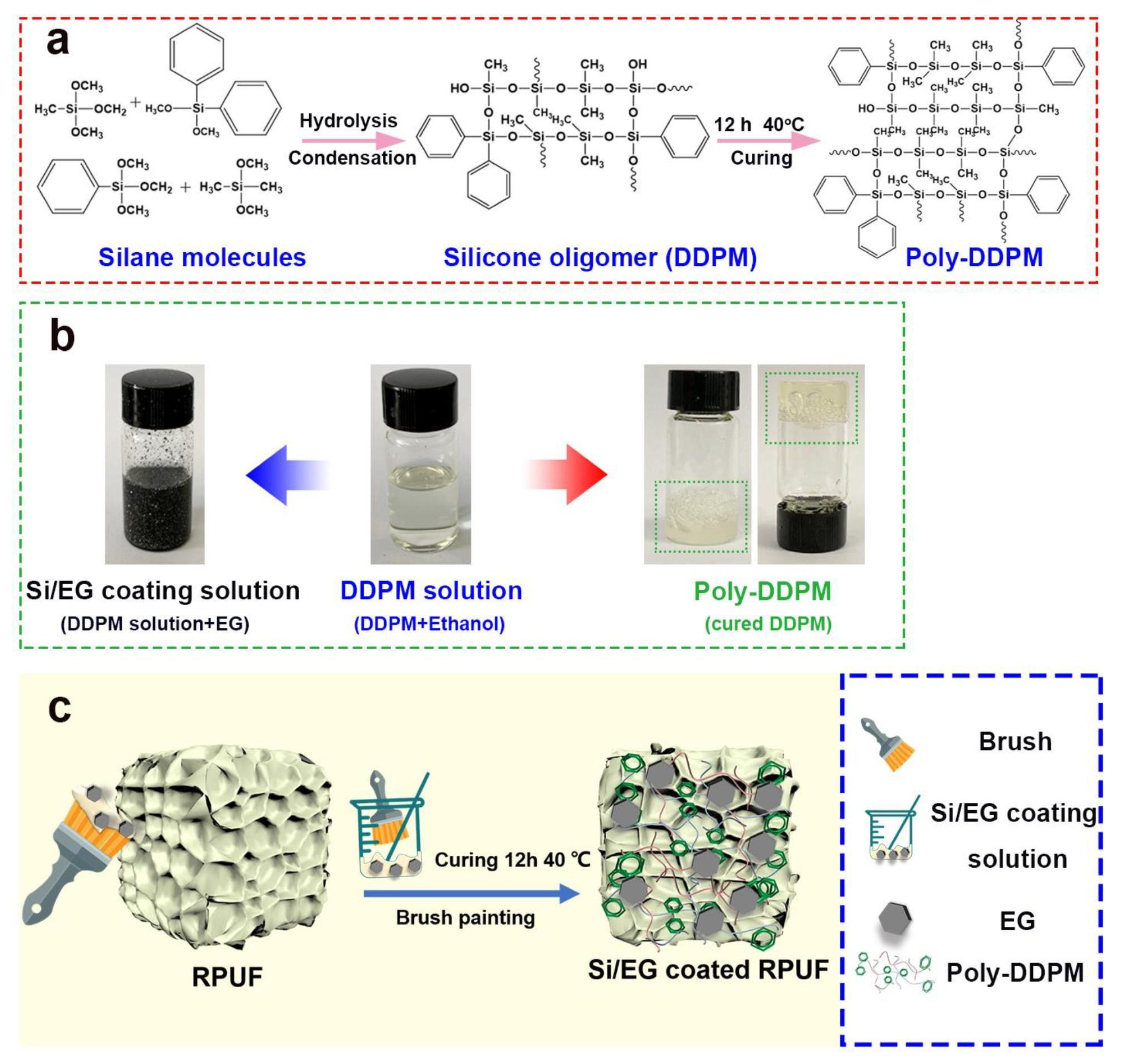

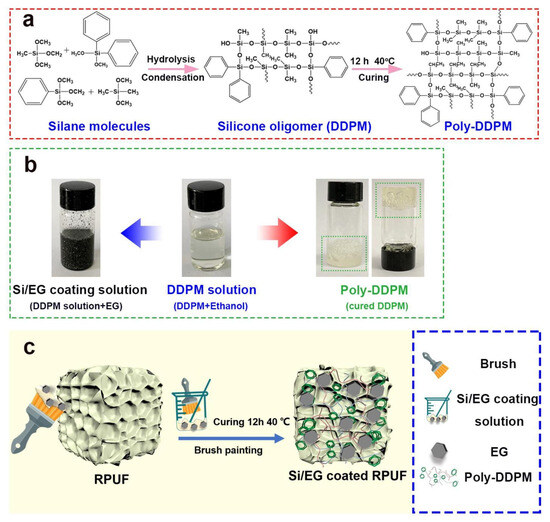

As shown in Figure 9, Zhang et al. [72] synthesized a silicone oligomer (poly-DDPM) and combined it with expandable graphite (EG) to develop a flame-retardant system applied to RPUF surfaces via brush painting. The resulting poly-DDPM/EG coating, with an average add-on of 8.5 mg/cm2, markedly improved fire resistance, raising the limiting oxygen index (LOI) from 18 to 32.3 and achieving a UL-94 V-0 rating. Cone calorimetry revealed that peak heat release rate and peak smoke release rate were reduced by 55% and 59%, respectively, while the coated foam resisted ignition even under direct exposure to a butane burner for 10 min. Remarkably, the compressive strength of the coated RPUF increased by 10%, and the coating maintained durability under harsh artificial weathering conditions.

Figure 9.

Schematic illustration for the preparation of the Si/EG coated RPUF sample. (a) Schematic illustration for the synthesis route of DDPM and the curing process of DDPM to poly-DDPM. (b) Digital photos of DDPM solution, Si/EG coating solution and cured poly-DDPM. (c) Schematic illustration for the preparation of the Si/EG coated RPUF sample [72]. Copyright 2020. Reproduced with permission from Elsevier Science Ltd.

From an industrial perspective, conventional manual brush coating is severely constrained by its labor-intensive nature and low throughput. The process depends heavily on operator skill, resulting in significant variations in coating thickness and uniformity across large panels and making it unsuitable as a primary method for mass-produced RPUF products such as insulation boards or structural foam panels. Nevertheless, brush coating maintains a valuable niche in specialized industrial applications. It is ideally suited for on-site application, maintenance, repair, and the customization of high-value components.

The future of brush coating in industrial settings may be enhanced through automation. Robotic brush coating systems have the potential to combine the advantages of mechanical manipulation, which ensures deep penetration and strong adhesion within the foam pores, with the consistency and speed associated with automated processes. Such developments could expand the applicability of brush coating to finishing complex or low-volume specialty foam products, providing a reliable method for high-precision flame-retardant protection in contexts where conventional large-scale coating techniques are impractical.

4.5. Spin Coating

Spin coating offers a rapid and controllable method for depositing uniform flame-retardant layers onto RPUFs. In this process, a solution or suspension containing flame-retardant agents is applied to the foam surface, which is then rotated at high speed to spread the coating via centrifugal force. The resulting thin film exhibits precise control over thickness, homogeneity, and surface morphology, enabling the fine-tuning of flame-retardant performance. Spin-coated layers can incorporate a variety of functional additives, including phosphorus- or nitrogen-based compounds, inorganic nanoparticles, and bio-based macromolecules, which contribute to char formation, thermal insulation, and reduced flammability during combustion.

Beyond its precision, spin coating allows the formation of multilayer architectures through sequential deposition cycles, facilitating synergistic interactions between different flame-retardant components. Compared with bulk modifications, spin-coated RPUFs retain their intrinsic mechanical flexibility and porosity while achieving enhanced surface-dominated flame-retardant effects. As such, spin coating provides a versatile platform for the design of high-performance flame-retardant foams.

The transition from laboratory innovation to industrial scalability remains a central challenge in developing flame-retardant coatings for RPUFs. Among various strategies, LbL assembly and dip-coating enable precise nanoscale control and excellent fire protection but face scalability limits due to their sequential, time-consuming processes and high operational costs. Spray coating, by contrast, offers speed, simplicity, and compatibility with continuous production lines, representing one of the most promising routes toward industrial application, though issues of coating uniformity and solvent management persist. UV-curing coatings provide a rapid, energy-efficient, and solvent-free alternative, achieving durable, high-performance flame-retardant layers within seconds, yet are constrained by incomplete curing in the porous foam structure. Brush coating, while simple and effective in laboratory or repair contexts, remains labor-intensive, with future potential in robotic automation for niche, high-precision uses. Spin coating offers fine control over coating thickness and uniformity, maintaining the foam’s mechanical integrity and enabling multifunctional surface engineering, but is currently restricted to small-scale applications. Collectively, these methods highlight the trade-offs between performance, cost, and scalability, underscoring the need for integrated, eco-efficient processes to realize practical, high-throughput production of flame-retardant RPUFs.

5. Concluding Remarks and Future Aspects

RPUFs continue to occupy a central role in advanced materials engineering due to their combination of low density, excellent thermal insulation, and impressive mechanical properties. Decades of research have highlighted that the inherent flammability of RPUFs, arising from their porous, carbon-rich structure, remains a critical limitation for applications where fire safety is paramount. Conventional strategies, encompassing both additive and reactive flame-retardant approaches, have offered significant mitigation, yet each comes with trade-offs. Additive systems are convenient and cost-effective but are prone to migration and leaching, whereas reactive systems provide long-lasting flame retardancy while introducing synthetic complexity and potential disruptions to foam morphology. These constraints underscore the ongoing need for innovative solutions capable of enhancing fire safety without compromising the intrinsic performance of RPUFs.

The development and assessment of flame-retardant RPUFs must consider not only their fire performance but also safety, regulatory compliance, and environmental sustainability. Standardized testing protocols such as ISO 5660 and ASTM E1354 [115,116], which employ cone calorimetry, are widely used to measure parameters including heat release rate, total heat release, and smoke production rate, providing a quantitative assessment of a material’s fire behavior. The limiting oxygen index determined according to ISO 4589 is another critical metric that reflects the minimum oxygen concentration required to sustain combustion [117]. These standardized methods enable consistent evaluation and facilitate comparison of fire performance across different materials and formulations. Regulatory frameworks such as REACH in the European Union and the Restriction of Hazardous Substances (RoHS) directive increasingly restrict the use of halogenated or persistent flame retardants due to their potential toxicity and environmental persistence. Consequently, halogen-free and bio-based alternatives have gained growing attention for their ability to meet fire safety requirements while reducing ecological and human health risks.

Recent life cycle assessment (LCA) and toxicity studies have highlighted that flame-retardant coatings derived from renewable resources, including lignin, cellulose, and phytic acid, can significantly reduce the carbon footprint and environmental burden associated with conventional phosphorus- or bromine-based systems. For instance, LCA analyses demonstrate that bio-based coatings generally exhibit lower energy consumption and greenhouse gas emissions throughout their production and disposal stages. Furthermore, toxicity evaluations have shown that these systems release fewer volatile organic compounds and produce less corrosive or carcinogenic smoke during combustion. The integration of such environmentally responsible materials aligns with global sustainability objectives and supports the transition toward safer polymeric foams. By incorporating LCA methodologies and regulatory standards into the design process, researchers can ensure that the next generation of flame-retardant RPUFs delivers enhanced fire performance, lower toxicity, and improved environmental compatibility across their entire life cycle.

Surface-confined flame-retardant coatings have emerged as a highly promising alternative. By localizing protective functionality at the interface, these coatings can delay ignition, restrict volatile release, suppress flame propagation, and reduce toxic smoke emission, all while preserving the mechanical and thermal characteristics of the foam. Recent advances include intumescent, inorganic/organic hybrid, aerogel, hydrogel, nanocarbon-based, and bio-inspired systems. Each employs distinct mechanisms, from char formation and thermal shielding to radical scavenging and synergistic interfacial interactions, demonstrating that multifunctionality and sustainability can be achieved in parallel with flame retardancy. In particular, bio-inspired and hybrid coatings exemplify the potential to align ecological responsibility with high-performance material design.

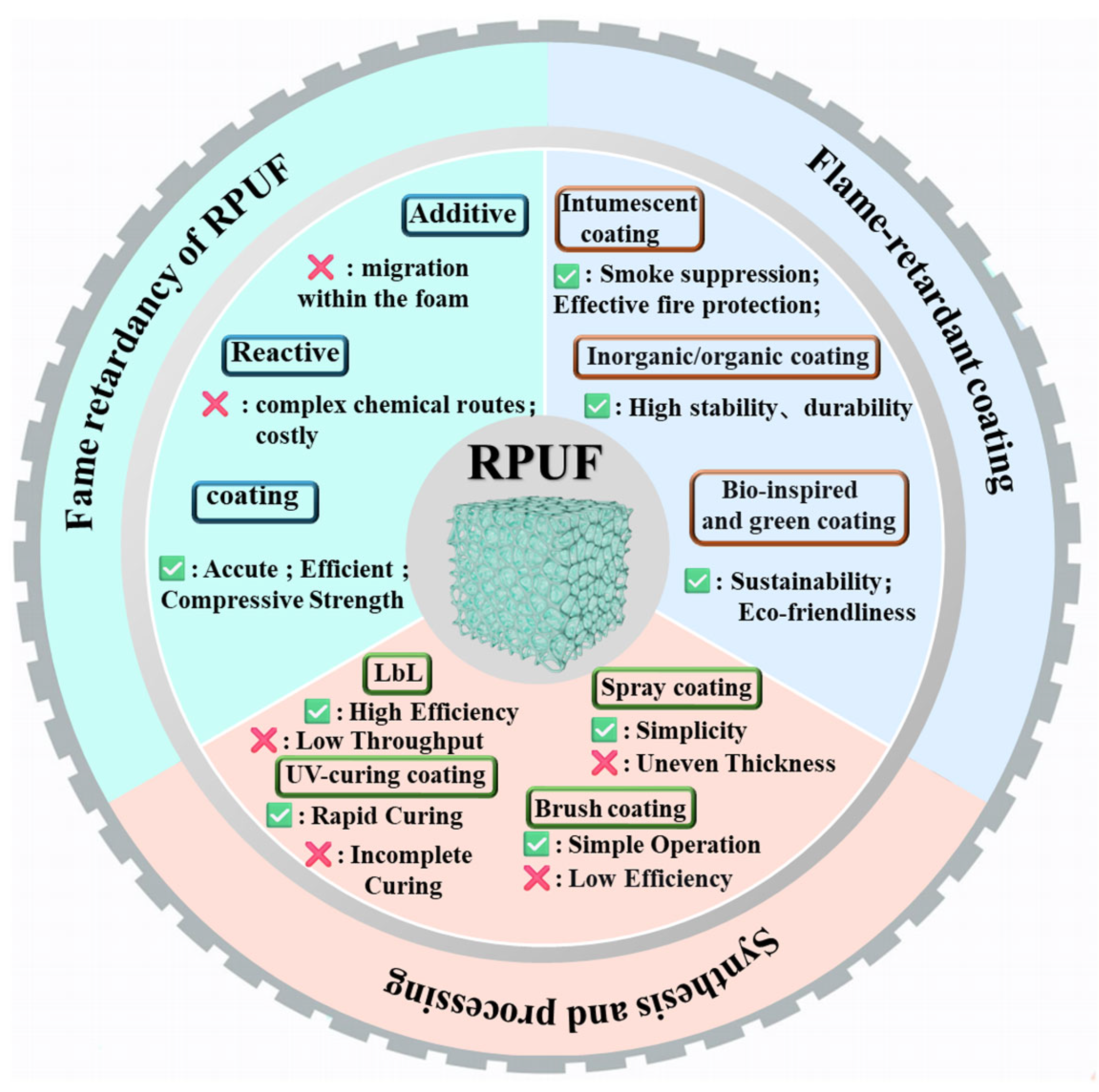

Despite these advances, several challenges must be addressed before widespread industrial adoption can be realized. Key limitations include scalability, long-term mechanical and thermal stability, adhesion to complex or low-surface-energy substrates, and overall process cost. Techniques such as layer-by-layer assembly, UV-curing, spray, dip, and brush coating offer complementary advantages, but optimization is required to balance throughput, uniformity, and resource efficiency. The integration of automation, rational formulation design, and compatibility with industrial coating lines will be essential for translating laboratory achievements into commercially viable solutions. Figure 10 outlines representative strategies for improving the flame retardancy of RPUF, highlighting coating technologies as promising alternatives to traditional additive-based methods, which are often limited by additive migration within the foam matrix. Both inorganic and organic coatings are considered, ranging from complex chemical approaches to bio-inspired and environmentally friendly systems. Each processing route presents distinct trade-offs: layer-by-layer and spray coatings deliver high efficiency, although spray application can result in uneven film thickness; brush coating is easy to implement but has low efficiency; and UV-curing provides rapid processing, although incomplete curing may occur. Collectively, these innovations aim to enhance flame-retardant effectiveness, improve compressive strength, simplify application, and advance sustainability, thereby addressing the growing demand for eco-friendly and high-performance polymeric materials.

Figure 10.

Advanced flame-retardant strategies for RPUF: coating developments and processing approaches.

Looking ahead, the next generation of flame-retardant RPUFs is expected to arise from the convergence of interfacial engineering, nanostructured materials, and bio-derived chemistries. Approaches that enable synergistic flame retardancy, smoke suppression, and multifunctionality, while minimizing environmental impact, are likely to define the future of polymer foam fire safety. Enhanced mechanistic understanding across multiple scales, from molecular interactions to macroscopic char formation, will guide the rational design of coatings capable of enduring real-world fire scenarios. With continued interdisciplinary effort, flame-retardant coatings can not only improve the safety and sustainability of RPUFs, but their use can also be expanded across energy-efficient construction, transportation, electronics, and other critical sectors, establishing a new paradigm for high-performance, multifunctional polymer foams.

Author Contributions

Conceptualization, Y.Y. and W.W.; methodology, Y.Y. and Q.G.; software, J.C.; validation, Y.Y., J.C. and Y.Z.; formal analysis, M.C., Y.Y. and L.X.; investigation, Y.Y. and W.W.; resources, Y.Y.; writing—original draft preparation, Q.G.; writing—review and editing, Y.Y., L.X. and W.W.; visualization, Y.X., K.N. and L.X.; supervision, Y.Y. and W.W.; project administration, Y.Y.; funding acquisition, Y.Y. and W.W. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by the National Natural Science Foundation of China (No. 22305202), open fund of Fujian Provincial Key Laboratory of Functional Materials and Applications (Xiamen University of Technology) (No. fma2024001). This research was also supported under the Australian Research Council/Discovery Early Career Researcher Award (DECRA) funding scheme (project number DE230100180).

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest. The authors declare that they do not have any competing financial interests or personal relationships that might influence their work.

References

- Fu, Y.; Qiu, C.; Ni, L.; Ye, H.; Zou, H.; Luo, Y.; Liang, M. Cell structure control and performance of rigid polyurethane foam with lightweight, good mechanical, thermal insulation and sound insulation. Constr. Build. Mater. 2024, 447, 138068. [Google Scholar] [CrossRef]

- Haridevan, H.; Evans, D.A.; Ragauskas, A.J.; Martin, D.J.; Annamalai, P.K. Valorisation of technical lignin in rigid polyurethane foam: A critical evaluation on trends, guidelines and future perspectives. Green. Chem. 2021, 23, 8725–8753. [Google Scholar] [CrossRef]

- Iqbal, N.; Mubashar, A.; Ahmed, S.; Arif, N.; Din, E.-U. Investigating relative density effects on quasi-static response of high-density Rigid Polyurethane Foam (RPUF). Mater. Today Commun. 2022, 31, 103320. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Liu, L.; Zheng, H.; Dai, J.; Tang, L.-C.; Song, P. A highly fire-retardant rigid polyurethane foam capable of fire-warning. Compos. Commun. 2022, 29, 101046. [Google Scholar] [CrossRef]

- Kim, H.J.; Jin, X.; Choi, J.W. Investigation of bio-based rigid polyurethane foams synthesized with lignin and castor oil. Sci. Rep. 2024, 14, 13490. [Google Scholar] [CrossRef]

- Ma, C.; Qiu, S.; Xiao, Y.; Zhang, K.; Zheng, Y.; Xing, W.; Hu, Y. Fabrication of fire safe rigid polyurethane foam with reduced release of CO and NOx and excellent physical properties by combining phosphine oxide-containing hyperbranched polyol and expandable graphite. Chem. Eng. J. 2022, 431, 133347. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Z.; Ding, S.; Wang, Z.; Xie, X. Improved thermal insulation, mechanical properties, energy absorption and flame retardancy of bio-based rigid polyurethane foam modified with calcium hydroxystannate. Constr. Build. Mater. 2024, 456, 139251. [Google Scholar] [CrossRef]

- Andersons, J.; Grūbe, R.; Vēvere, L.; Cābulis, P.; Kirpluks, M. Anisotropic thermal expansion of bio-based rigid low-density closed-cell polyurethane foams. J. Mater. Res. Technol. 2022, 16, 1517–1525. [Google Scholar] [CrossRef]

- Prociak, A.; Kucała, M.; Kurańska, M.; Barczewski, M. Effect of selected bio-components on the cell structure and properties of rigid polyurethane foams. Polymers 2023, 15, 3660. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Ma, H.; Song, C.; Zhou, Z.; Xu, W.; Song, Q.; Ren, F. Preparation and performance of melamine-formaldehyde rigid foams with high closed cell content. Cell. Polym. 2021, 40, 183–197. [Google Scholar] [CrossRef]

- Alsuhaibani, A.M.; Refat, M.S.; Qaisrani, S.A.; Jamil, F.; Abbas, Z.; Zehra, A.; Baluch, K.; Kim, J.-G.; Mubeen, M. Green buildings model: Impact of rigid polyurethane foam on indoor environment and sustainable development in energy sector. Heliyon 2023, 9, e14451. [Google Scholar] [CrossRef]

- Barszczewska-Rybarek, I.; Jaszcz, K.; Chladek, G.; Grabowska, P.; Okseniuk, A.; Szpot, M.; Zawadzka, M.; Sokołowska, A.; Tarkiewicz, A. Characterization of changes in structural, physicochemical and mechanical properties of rigid polyurethane building insulation after thermal aging in air and seawater. Polym. Bull. 2022, 79, 3061–3083. [Google Scholar] [CrossRef]

- Yuan, Y.; Yu, B.; Shi, Y.; Ma, C.; Song, L.; Hu, W.; Hu, Y. Highly efficient catalysts for reducing toxic gases generation change with temperature of rigid polyurethane foam nanocomposites: A comparative investigation. Compos. Part A Appl. Sci. Manuf. 2018, 112, 142–154. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Shi, Y.; Song, L.; Ma, C.; Hu, Y. The influence of highly dispersed Cu2O-anchored MoS2 hybrids on reducing smoke toxicity and fire hazards for rigid polyurethane foam. J. Hazard. Mater. 2020, 382, 121028. [Google Scholar] [CrossRef] [PubMed]

- Tian, F.; Wu, Y.; Xu, H.; Wang, B.; She, Y.; Chen, H.; Liu, Y.; Wang, S.; Xu, X. Enhancing Rigid Polyurethane Foam Properties with Lignin-Based Core–Shell Intumescent Flame Retardants. ACS Sustain. Chem. Eng. 2024, 12, 18126–18135. [Google Scholar] [CrossRef]

- Bu, F.-Y.; Fu, Z.-C.; Dong, Q.-X.; Wang, T.; An, W.-L.; Deng, J.-N.; Deng, C.; Yan, Y.-W.; Chen, M.-J. Flame-Retardant and Mechanical Strong Polyurethane Foam Enabled by Hydrogen-Bonded Phosphonate Networks. ACS Appl. Polym. Mater. 2025, 7, 8186–8198. [Google Scholar] [CrossRef]

- Zheng, L.; Zhan, J.; Wang, J.; Xu, Z.; Mu, X. Highly efficient flame retardancy and fire spread behavior of rigid polyurethane foams with extremely low content of flame retardant. Polym. Degrad. Stab. 2024, 230, 111039. [Google Scholar] [CrossRef]

- Muhammed Raji, A.; Hambali, H.U.; Khan, Z.I.; Binti Mohamad, Z.; Azman, H.; Ogabi, R. Emerging trends in flame retardancy of rigid polyurethane foam and its composites: A review. J. Cell. Plast. 2023, 59, 65–122. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, S.G.; Lee, J.S.; Ma, B.C. Understanding the flame retardant mechanism of intumescent flame retardant on improving the fire safety of rigid polyurethane foam. Polymers 2022, 14, 4904. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, N.; Yuan, H.; Chen, H.; Xie, X.; Zhang, L.; Rein, G. Smouldering and its transition to flaming combustion of polyurethane foam: An experimental study. Fuel 2022, 309, 122249. [Google Scholar] [CrossRef]

- Yuan, Y.; Wang, W.; Xiao, Y.; Yuen, A.C.Y.; Mao, L.; Pan, H.; Yu, B.; Hu, Y. Surface modification of multi-scale cuprous oxide with tunable catalytic activity towards toxic fumes and smoke suppression of rigid polyurethane foam. Appl. Surf. Sci. 2021, 556, 149792. [Google Scholar] [CrossRef]

- Tang, G.; Guan, M.; Yang, S.; Fang, Y.; Liu, X.; Dai, K.; Wang, W. Highly thermally stable MOF-based flame retardant system for fire-safe and toxicity-suppressing rigid polyurethane foam. Constr. Build. Mater. 2025, 477, 141382. [Google Scholar] [CrossRef]

- Lee, T.; Kim, J.-H.; Tsang, Y.F.; Chen, W.-H.; Lee, D.; Jung, M.-W.; Jung, S.; Kwon, E.E. Conversion of toxic chemicals into flammable gases through the thermolysis of polyurethane foam using CO2. Chem. Eng. J. 2023, 457, 141291. [Google Scholar] [CrossRef]

- Qu, J.; Tong, Y.; Bi, Y.; Sun, W.; Shi, Y.; Zhao, Z.; Liu, Z.; Wang, S.; Liu, L.; Chen, X. P-N hybrids modified with MXene encapsulation significantly improve fire safety properties of rigid polyurethane foams. Polym. Degrad. Stab. 2025, 241, 111590. [Google Scholar] [CrossRef]

- Huang, X.; Wang, C.; Gao, J.; Zhou, Z.; Tang, G.; Wang, C. Research on two sides horizontal flame spread over rigid polyurethane with different flame retardants. J. Therm. Anal. Calorim. 2021, 146, 2141–2150. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, H.; Luo, Y.; Zhang, R.; Sun, J.; Liu, X.; Zong, Z.; Tang, G. Rigid polyurethane foam composites based on iron tailing: Thermal stability, flame retardancy and fire toxicity. Cell. Polym. 2022, 41, 189–207. [Google Scholar] [CrossRef]

- Lu, D.; Wang, Y. Mesoporous Heat-Trapping and Smoke-Adsorbing Fe-MOFs Improve Fire Safety and Compression Resistance of Rigid Polyurethane Foam. Langmuir 2025, 41, 24995–25014. [Google Scholar] [CrossRef]

- Bo, G.; Xu, X.; Tian, X.; Yan, J.; Su, X.; Yan, Y. Bio-based rigid polyurethane foams modified with C-MOF/MWCNTs and TBPBP as building insulation materials: Synergistic effect and corresponding mechanism for enhancing fire and smoke safety. Polymers 2022, 14, 3630. [Google Scholar] [CrossRef]

- Chen, Z.; Yuan, S.; Xu, X. Synergistic Effect of Amino-Modified Co-MOF and APP on Improvement of the Fire Safety of the Rigid Polyurethane Foam. ACS Omega 2024, 10, 892–903. [Google Scholar] [CrossRef]

- Luo, W.; Wang, T.; Gou, X.; Luo, J.; An, W.; Fu, Z.-C.; Deng, J.; Zhao, H.-B.; Chen, M.-J. In Situ Assembly of Nanostructured Polyelectrolyte Coatings by Aqueous Phase Separation toward Outstanding Thermal Insulation and Fire Resistance. ACS Mater. Lett. 2024, 6, 5418–5428. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, S.-A. Preparation and fire behavior of rigid polyurethane foams synthesized from modified urea–melamine–formaldehyde resins. RSC Adv. 2018, 8, 17879–17887. [Google Scholar] [CrossRef]

- Yuan, Y.; Lin, W.; Xiao, Y.; Yu, B.; Wang, W. Advancements in flame-retardant systems for rigid polyurethane foam. Molecules 2023, 28, 7549. [Google Scholar] [CrossRef] [PubMed]

- Kondaveeti, S.; Patel, P.; de Souza, F.M.; Gupta, R.K. Exploring soybean oil-based polyol and the effect of non-halogenated flame retardants in rigid polyurethane foam. J. Polym. Environ. 2024, 32, 5873–5887. [Google Scholar] [CrossRef]

- Cui, Z.; Han, J.; Sun, J.; Chen, Y.; Wang, X.; Gu, X.; Zhang, S. Preparation of aliphatic bio-based polyester polyols for water-blown and halogen-free flame retardant rigid polyurethane foam. Polym. Degrad. Stab. 2024, 226, 110832. [Google Scholar] [CrossRef]

- Yuan, Y.; Yang, H.; Yu, B.; Shi, Y.; Wang, W.; Song, L.; Hu, Y.; Zhang, Y. Phosphorus and nitrogen-containing polyols: Synergistic effect on the thermal property and flame retardancy of rigid polyurethane foam composites. Ind. Eng. Chem. Res. 2016, 55, 10813–10822. [Google Scholar] [CrossRef]

- Son, T.; Nguyen, H.T.; Phan, H.T.; Pham, C.T.; Nguyen, B.T.; Pham, L.H.; Do, T.V.V.; Vothi, H.; Kim, J.; Hoang, D.Q. Phosphorus/phosphorus-nitrogen flame retardants applied to polyurethane/rice husk eco-composites: Thermal behavior, flame retardancy, and physico-mechanical properties. Polym. Bull. 2021, 78, 2727–2743. [Google Scholar] [CrossRef]

- Lu, W.; Li, Q.; Zhang, Y.; Yu, H.; Hirose, S.; Hatakeyama, H.; Matsumoto, Y.; Jin, Z. Lignosulfonate/APP IFR and its flame retardancy in lignosulfonate-based rigid polyurethane foams. J. Wood Sci. 2018, 64, 287–293. [Google Scholar] [CrossRef]

- Luo, F.; Wu, K.; Li, Y.; Zheng, J.; Guo, H.; Lu, M. Reactive flame retardant with core-shell structure and its flame retardancy in rigid polyurethane foam. J. Appl. Polym. Sci. 2015, 132. [Google Scholar] [CrossRef]

- Shi, L.; Li, Z.M.; Xie, B.H.; Wang, J.H.; Tian, C.R.; Yang, M.B. Flame retardancy of different-sized expandable graphite particles for high-density rigid polyurethane foams. Polym. Int. 2006, 55, 862–871. [Google Scholar] [CrossRef]

- Acuña, P.; Li, Z.; Santiago-Calvo, M.; Villafañe, F.; Rodríguez-Perez, M.Á.; Wang, D.-Y. Influence of the characteristics of expandable graphite on the morphology, thermal properties, fire behaviour and compression performance of a rigid polyurethane foam. Polymers 2019, 11, 168. [Google Scholar] [CrossRef]

- Acuña, P.; Santiago-Calvo, M.; Villafañe, F.; Rodríguez-Perez, M.A.; Rosas, J.; Wang, D.Y. Impact of expandable graphite on flame retardancy and mechanical properties of rigid polyurethane foam. Polym. Compos. 2019, 40, E1705–E1715. [Google Scholar] [CrossRef]

- Qian, X.; Liu, Q.; Zhang, L.; Li, H.; Liu, J.; Yan, S. Synthesis of reactive DOPO-based flame retardant and its application in rigid polyisocyanurate-polyurethane foam. Polym. Degrad. Stab. 2022, 197, 109852. [Google Scholar] [CrossRef]

- Zhan, Z.; Shi, Q.; Shen, J.; Bao, T.; Weng, S.; Li, L.; Meng, F. Novel multifunctional DOPO-containing polyaniline for highly efficient flame retardance and static electricity control for rigid polyurethane foam. Compos. Commun. 2024, 48, 101951. [Google Scholar] [CrossRef]

- Tang, G.; Zhang, Z.; Wang, R.; Xu, Z.; Guan, M.; Deng, D.; Wu, S.; Dai, K.; Liu, X. Improvements in the flame retardancy, smoke suppression, mechanical strength and thermal insulating properties of rigid polyurethane foams modified with DOPO-grafted cyclosiloxane and diatomite. Constr. Build. Mater. 2025, 495, 143620. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, S. Preparation of flame-retardant rigid polyurethane foams by combining modified melamine-formaldehyde resin and phosphorus flame retardants. ACS Omega 2020, 5, 9658–9667. [Google Scholar] [CrossRef] [PubMed]

- Jia, D.; Yang, J.; He, J.; Li, X.; Yang, R. Melamine-based polyol containing phosphonate and alkynyl groups and its application in rigid polyurethane foam. J. Mater. Sci. 2021, 56, 870–885. [Google Scholar] [CrossRef]

- Liu, M.; Gong, Z.; Wang, G.; Liu, X.; Hou, Y.; Tang, G. Melamine resin coordinated cobalt@ piperazine pyrophosphate microcapsule: An innovative strategy for imparting long-lasting fire safety to rigid polyurethane foams. Polym. Degrad. Stab. 2024, 219, 110605. [Google Scholar] [CrossRef]

- Yin, S.; Du, Y.; Liang, X.; Xie, Y.; Xie, D.; Mei, Y. Surface coating of biomass-modified black phosphorus enhances flame retardancy of rigid polyurethane foam and its synergistic mechanism. Appl. Surf. Sci. 2023, 637, 157961. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, S.; Liang, R.; Liao, Z.; You, G. A green highly-effective surface flame-retardant strategy for rigid polyurethane foam: Transforming UV-cured coating into intumescent self-extinguishing layer. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105534. [Google Scholar] [CrossRef]

- Liu, H.; Yang, H.; Chen, M.; Jiang, Y.; Wan, C. An effective approach to reducing fire hazards of rigid polyurethane foam: Fire protective coating. J. Coat. Technol. Res. 2019, 16, 257–261. [Google Scholar] [CrossRef]

- Fang, Y.; Ma, Z.; Wei, D.; Yu, Y.; Liu, L.; Shi, Y.; Gao, J.; Tang, L.C.; Huang, G.; Song, P. Engineering sulfur-containing polymeric fire--retardant coatings for fire-safe rigid polyurethane foam. Macromol. Rapid Commun. 2024, 45, 2400068. [Google Scholar] [CrossRef]

- Yang, Y.; Dang, B.; Wang, C.; Chen, Y.; Chen, K.; Chen, X.; Li, Y.; Sun, Q. Ultrastrong lightweight nanocellulose-based composite aerogels with robust superhydrophobicity and durable thermal insulation under extremely environment. Carbohydr. Polym. 2024, 323, 121392. [Google Scholar] [CrossRef]

- Zhang, K.; Li, C.; Liu, L.; Wang, X.; Li, N.; Yang, C.; Huang, Y.; Lu, H.; Liu, H.; Li, J. Developing lightweight silanized cellulose ultramaterials as the strongest engineered aerogel. Adv. Funct. Mater. 2025, 35, 2415963. [Google Scholar] [CrossRef]

- Guo, W.; Chen, S.; Liang, F.; Jin, L.; Ji, C.; Zhang, P.; Fei, B. Ultra-light-weight, anti-flammable and water-proof cellulosic aerogels for thermal insulation applications. Int. J. Biol. Macromol. 2023, 246, 125343. [Google Scholar] [CrossRef]

- Gu, J.; Fu, R.; Kang, S.; Yang, X.; Song, Q.; Miao, C.; Ma, M.; Wang, Y.; Sai, H. Robust composite aerogel beads with pomegranate-like structure for water-based thermal insulation coating. Constr. Build. Mater. 2022, 341, 127722. [Google Scholar] [CrossRef]

- Ciecierska, E.; Jurczyk-Kowalska, M.; Bazarnik, P.; Gloc, M.; Kulesza, M.; Kowalski, M.; Krauze, S.; Lewandowska, M. Flammability, mechanical properties and structure of rigid polyurethane foams with different types of carbon reinforcing materials. Compos. Struct. 2016, 140, 67–76. [Google Scholar] [CrossRef]

- Xu, W.; Wang, G.; Zheng, X. Research on highly flame-retardant rigid PU foams by combination of nanostructured additives and phosphorus flame retardants. Polym. Degrad. Stab. 2015, 111, 142–150. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.; Naik, Y. Effect of expandable graphite on the properties of intumescent flame-retardant polyurethane foam. J. Appl. Polym. Sci. 2008, 110, 2586–2594. [Google Scholar] [CrossRef]

- Strąkowska, A.; Członka, S.; Konca, P.; Strzelec, K. New flame retardant systems based on expanded graphite for rigid polyurethane foams. Appl. Sci. 2020, 10, 5817. [Google Scholar] [CrossRef]

- Acuña, P.; Lin, X.; Calvo, M.S.; Shao, Z.; Pérez, N.; Villafañe, F.; Rodríguez-Pérez, M.Á.; Wang, D.-Y. Synergistic effect of expandable graphite and phenylphosphonic-aniline salt on flame retardancy of rigid polyurethane foam. Polym. Degrad. Stab. 2020, 179, 109274. [Google Scholar] [CrossRef]

- Dzulkifli, M.H.; Majid, R.A.; Yahya, M.Y. Influence of sodium-montmorillonite nanoclay on flammability, thermal stability, morphology, and mechanical properties of rigid water-blown palm oil-based polyurethane foam. Cell. Polym. 2023, 42, 140–155. [Google Scholar] [CrossRef]

- Gao, L.; Zheng, G.; Zhou, Y.; Hu, L.; Feng, G.; Xie, Y. Synergistic effect of expandable graphite, melamine polyphosphate and layered double hydroxide on improving the fire behavior of rosin-based rigid polyurethane foam. Ind. Crops Prod. 2013, 50, 638–647. [Google Scholar] [CrossRef]

- Yuan, Y.; Xu, L.; Wang, W. Tri-phase flame retardant system towards advanced energy-saving building materials with highly efficient fire and smoke toxicity reductions. Constr. Build. Mater. 2024, 433, 136719. [Google Scholar] [CrossRef]

- Yang, R.; Hu, W.; Xu, L.; Song, Y.; Li, J. Synthesis, mechanical properties and fire behaviors of rigid polyurethane foam with a reactive flame retardant containing phosphazene and phosphate. Polym. Degrad. Stab. 2015, 122, 102–109. [Google Scholar] [CrossRef]

- Cui, Z.; Chen, Y.; Meng, D.; Wang, S.; Sun, T.; Sun, J.; Li, H.; Gu, X.; Zhang, S. Reactive flame-retardants prepared by transesterification between erythritol and dimethyl methyl phosphonate for rigid polyurethane foams. Polym. Degrad. Stab. 2023, 208, 110238. [Google Scholar] [CrossRef]

- Sun, X.; Deng, L.; Fu, J.; Zhao, Z.; Xu, C.; Hao, M.; Bussemaker, M.; Jiang, J.; Liu, L.X.; Zhou, R. Innovative flame-retardant systems for rigid polyurethane foam: Synergistic effects of nitrogen and phosphorus polyols. React. Funct. Polym. 2025, 211, 106215. [Google Scholar] [CrossRef]

- Cao, J.; Tao, J.; Yang, M.; Liu, C.; Yan, C.; Zhao, Y.; Yu, C.; Zhao, H.-B.; Rao, W. A novel phosphorus-modified silica aerogel for simultaneously improvement of flame retardancy, mechanical and thermal insulation properties in rigid polyurethane foam. Chem. Eng. J. 2024, 485, 149909. [Google Scholar] [CrossRef]

- Zhang, X.; Qu, X.; Guan, Q.; Li, R.; Wang, Z.; Xie, H. Rigid polyurethane foam with improved thermal stability and flame retardancy modified by barium phytate and zinc oxide. Case Stud. Therm. Eng. 2025, 72, 106261. [Google Scholar] [CrossRef]

- Liu, X.; Sui, Y.; Guo, P.; Chen, R.; Mu, J. A flame retardant containing biomass-based polydopamine for high-performance rigid polyurethane foam. New J. Chem. 2022, 46, 11985–11993. [Google Scholar] [CrossRef]

- Han, S.; Zhu, X.; Chen, F.; Chen, S.; Liu, H. Flame-retardant system for rigid polyurethane foams based on diethyl bis (2-hydroxyethyl) aminomethylphosphonate and in-situ exfoliated clay. Polym. Degrad. Stab. 2020, 177, 109178. [Google Scholar] [CrossRef]

- Wu, N.; Niu, F.; Lang, W.; Yu, J.; Fu, G. Synthesis of reactive phenylphosphoryl glycol ether oligomer and improved flame retardancy and mechanical property of modified rigid polyurethane foams. Mater. Des. 2019, 181, 107929. [Google Scholar] [CrossRef]

- Wang, S.; Wang, X.; Wang, X.; Li, H.; Sun, J.; Sun, W.; Yao, Y.; Gu, X.; Zhang, S. Surface coated rigid polyurethane foam with durable flame retardancy and improved mechanical property. Chem. Eng. J. 2020, 385, 123755. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, J.; Maluk, C.; Yu, Y.; Seraji, S.M.; Yu, B.; Wang, H.; Song, P. A lava-inspired micro/nano-structured ceramifiable organic-inorganic hybrid fire-extinguishing coating. Matter 2022, 5, 911–932. [Google Scholar] [CrossRef]

- Zhang, W.; Tong, M.; Xing, F.; Zheng, H.; Zhu, C. Enhanced flame-retardant performance of rigid polyurethane foam by using aptes--mmt and ath mixed intumescent coatings. J. Appl. Polym. Sci. 2024, 141, e54836. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Li, J.; Zhang, J.; Wang, T.; Fu, Z.; An, W.; Sun, G.; Chen, M.; Deng, J. Rigid polyurethane foam with durable hydrophobicity and flame retardancy endowed by novel functional surfactants. Constr. Build. Mater. 2024, 451, 138815. [Google Scholar] [CrossRef]

- Xu, W.; Zhong, D.; Chen, R.; Cheng, Z.; Qiao, M. Boron phenolic resin/silica sol coating gives rigid polyurethane foam excellent and long-lasting flame-retardant properties. Polym. Adv. Technol. 2021, 32, 4029–4040. [Google Scholar] [CrossRef]

- Zhan, W.; Li, L.; Chen, L.; Kong, Q.; Chen, M.; Chen, C.; Zhang, Q.; Jiang, J. Biomaterials in intumescent fire-retardant coatings: A review. Prog. Org. Coat. 2024, 192, 108483. [Google Scholar] [CrossRef]

- Yang, H.; Yu, B.; Song, P.; Maluk, C.; Wang, H. Surface-coating engineering for flame retardant flexible polyurethane foams: A critical review. Compos. Part B-Eng. 2019, 176, 107185. [Google Scholar] [CrossRef]