Dry Machining of AISI 316 Steel Using Textured Ceramic Tool Inserts: Investigation of Surface Roughness and Chip Morphology

Abstract

1. Introduction

2. Experimental Details

3. Results and Discussion

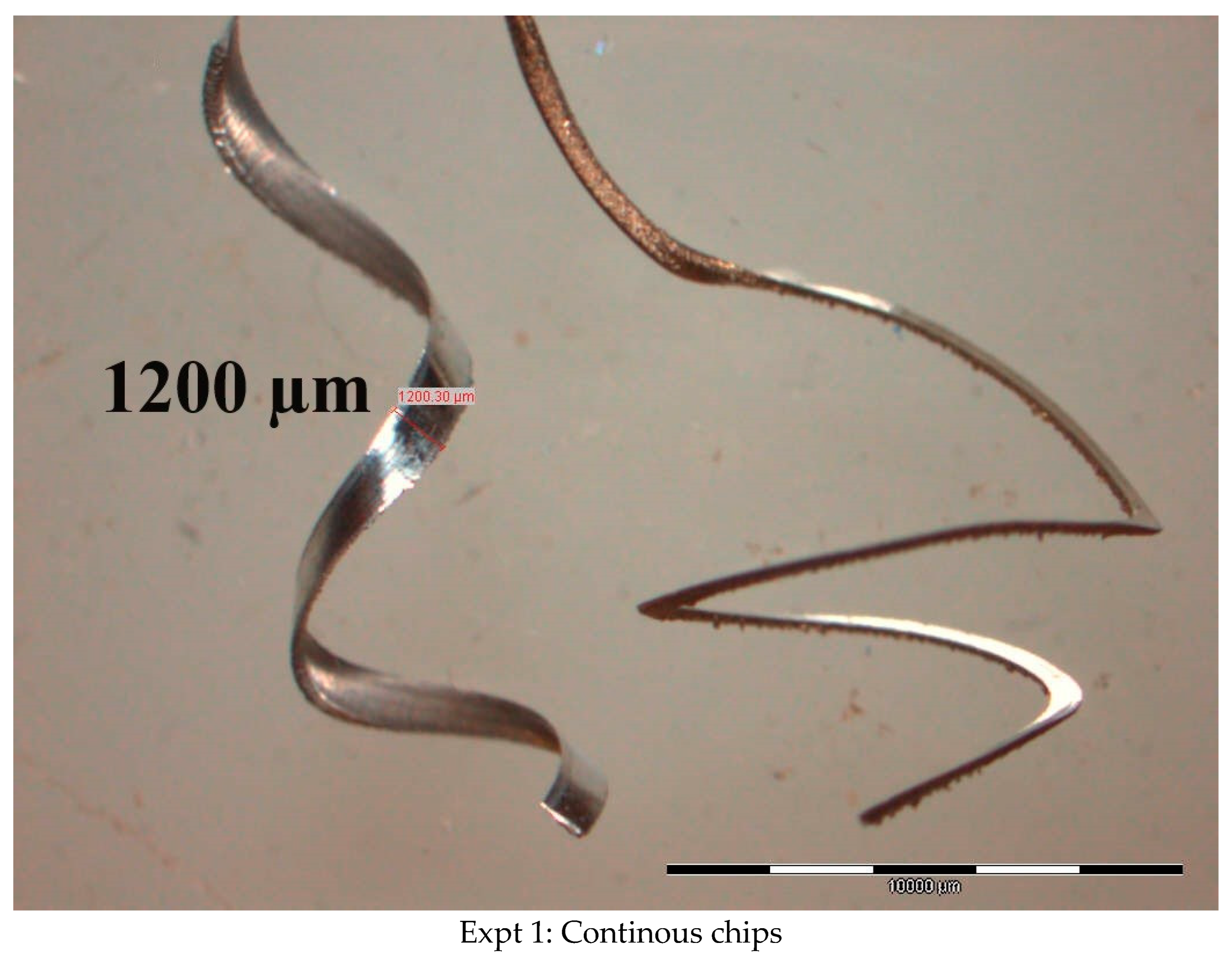

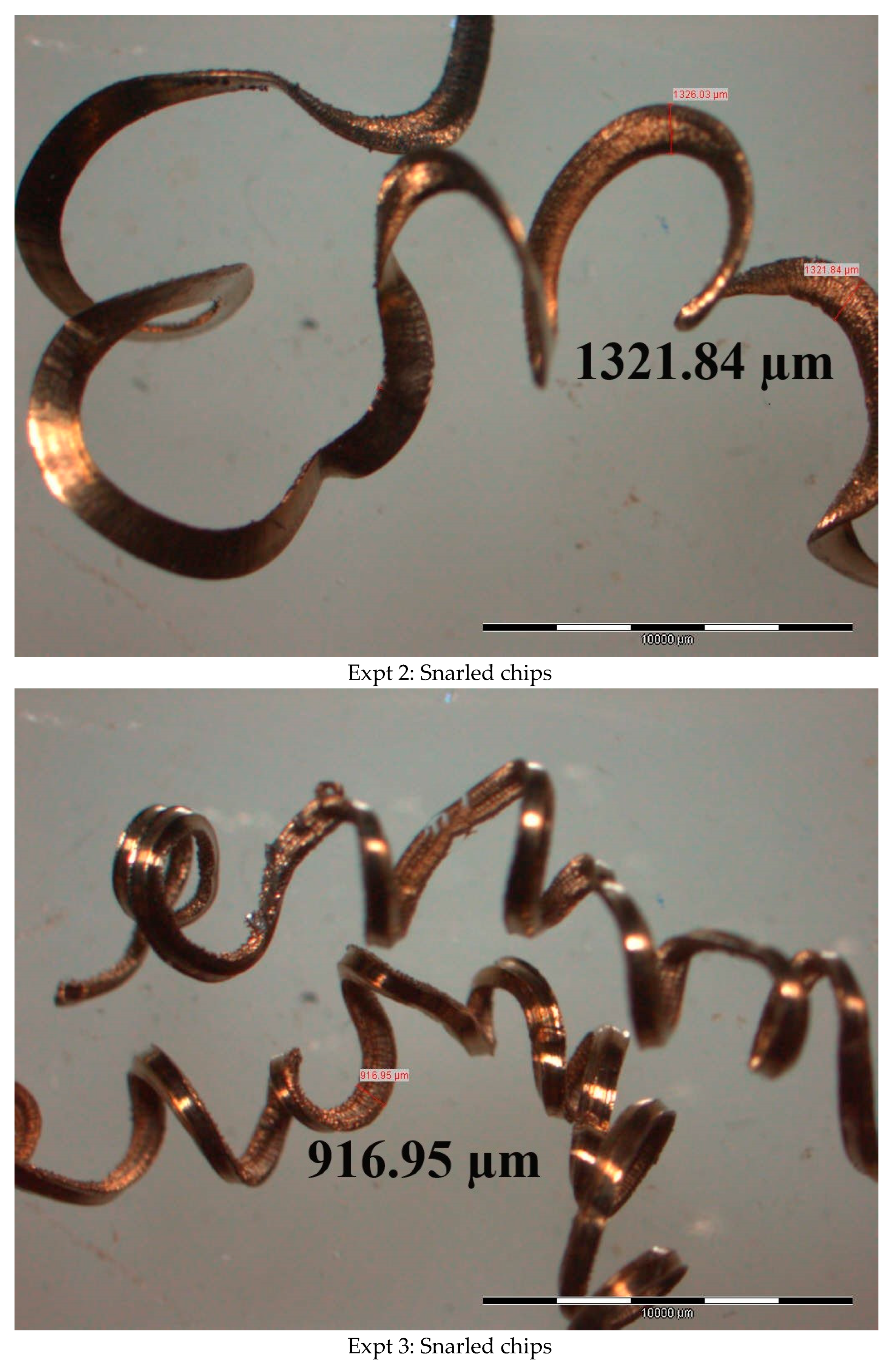

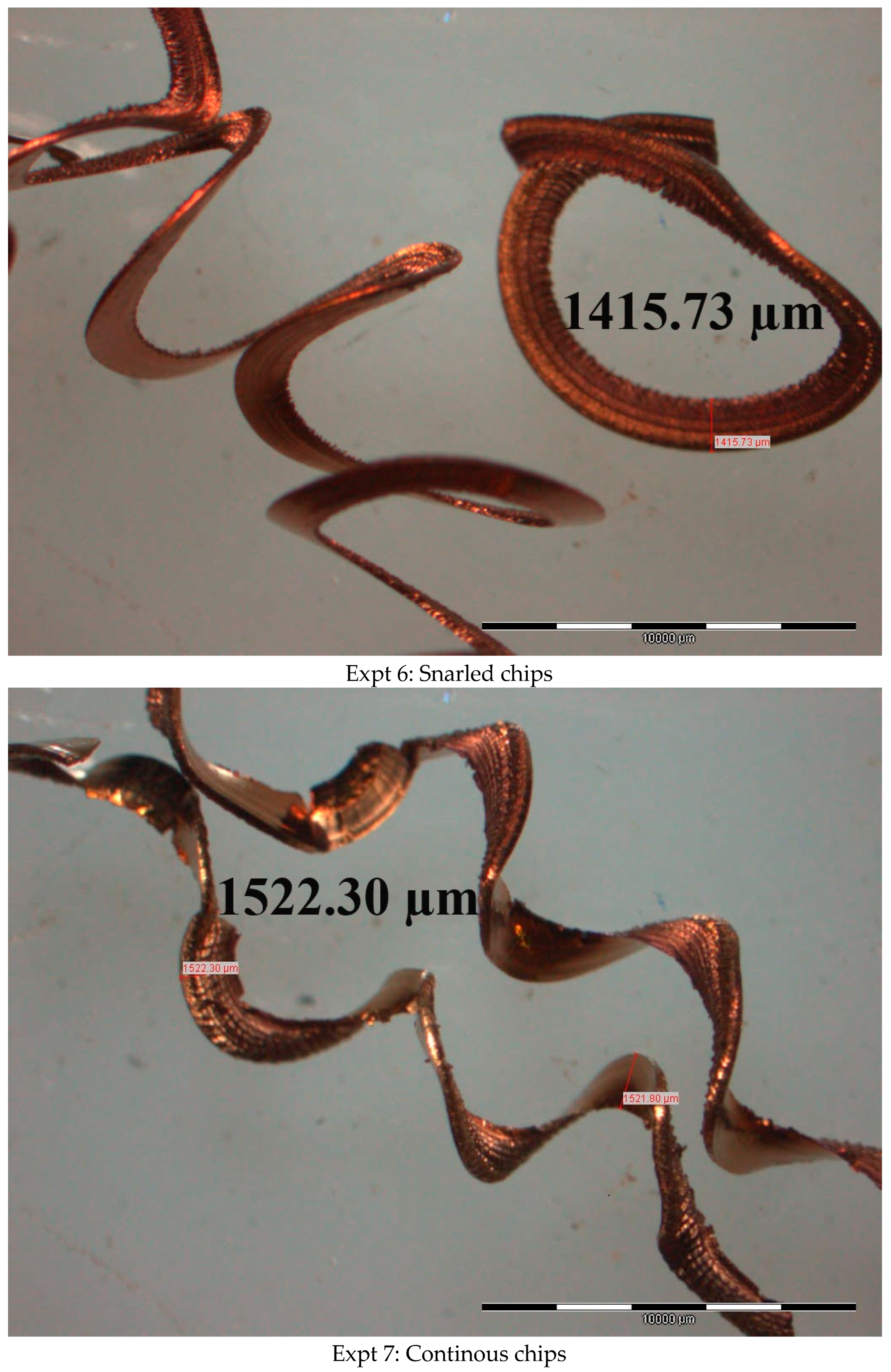

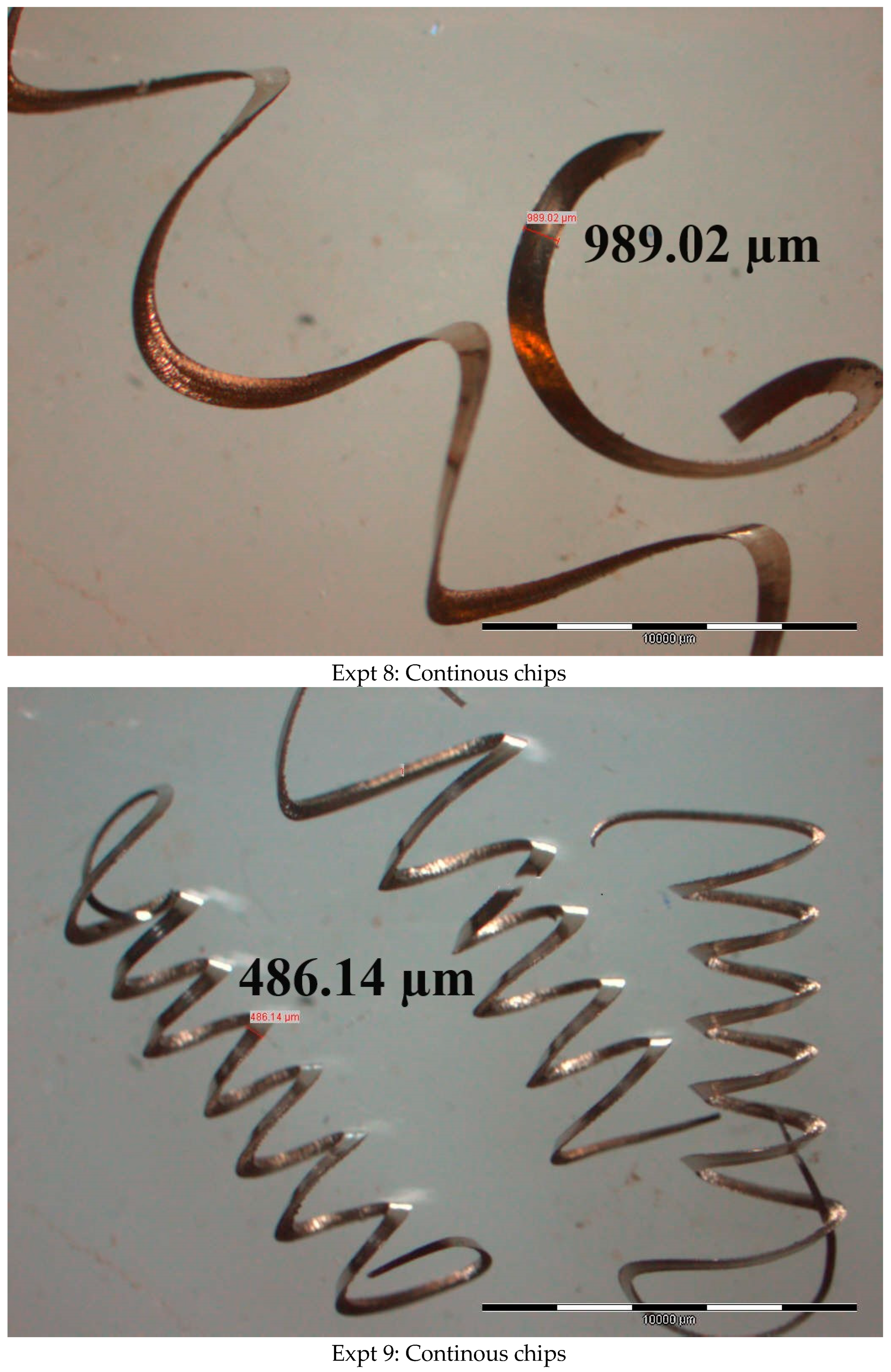

3.1. Chip Morphology

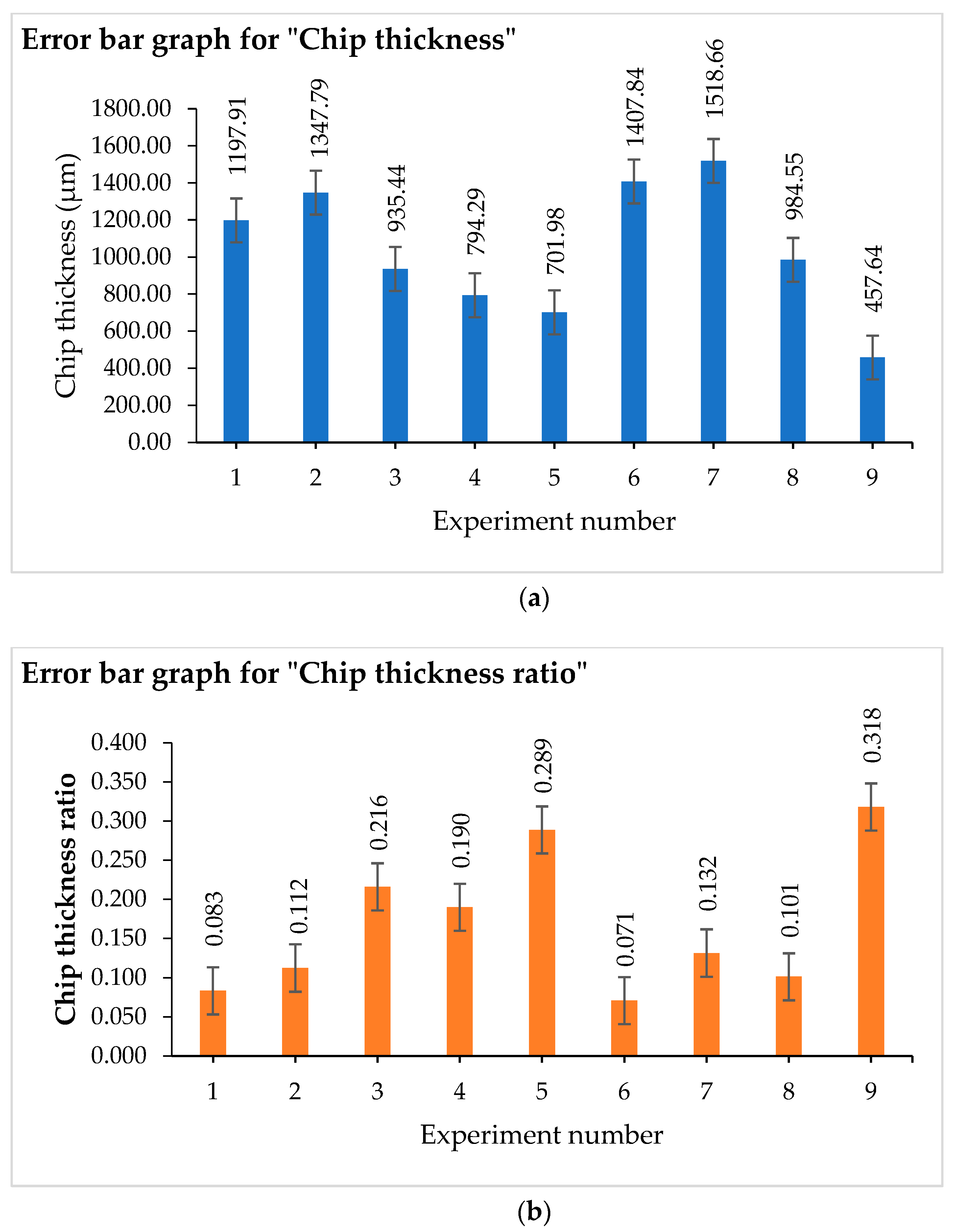

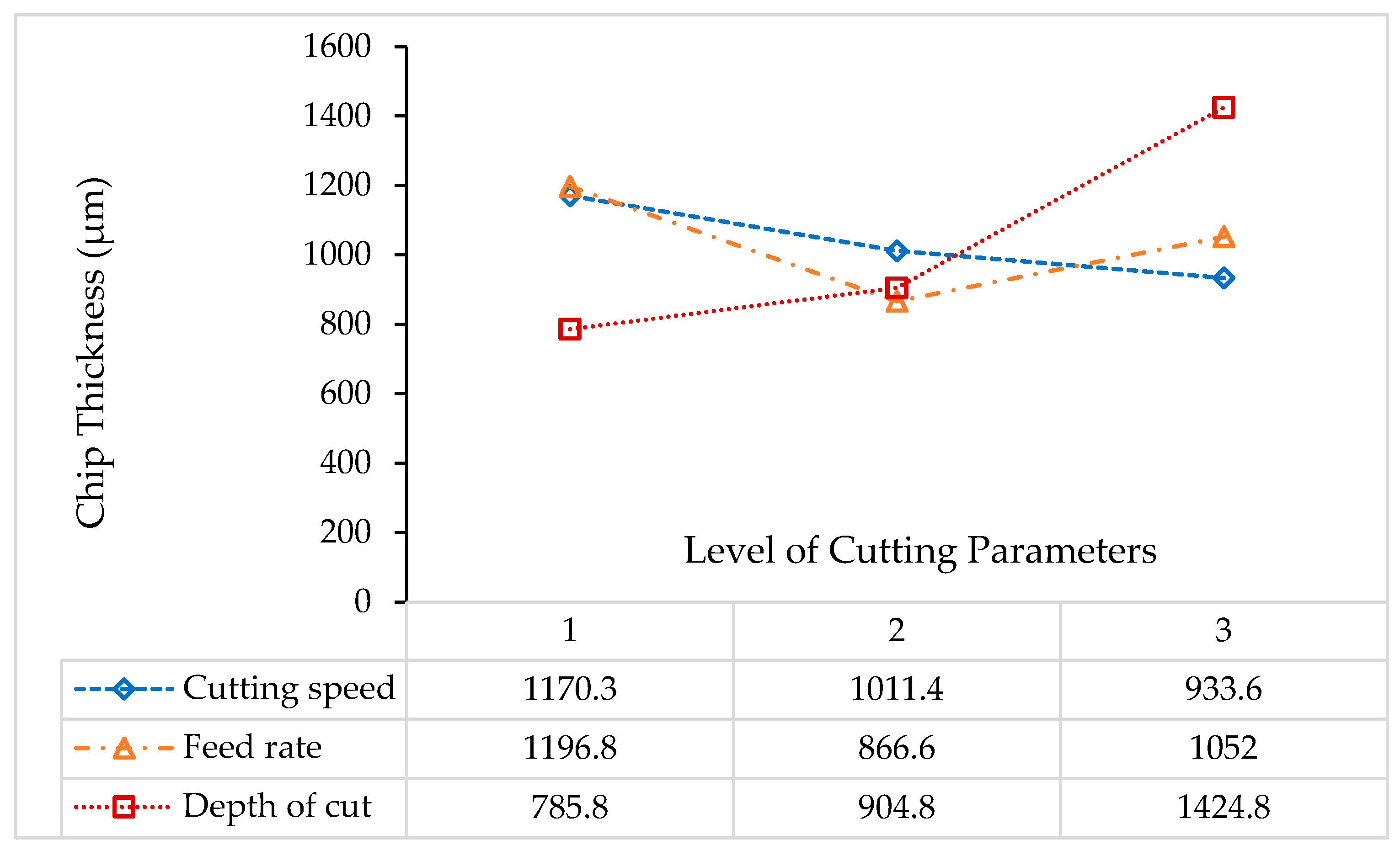

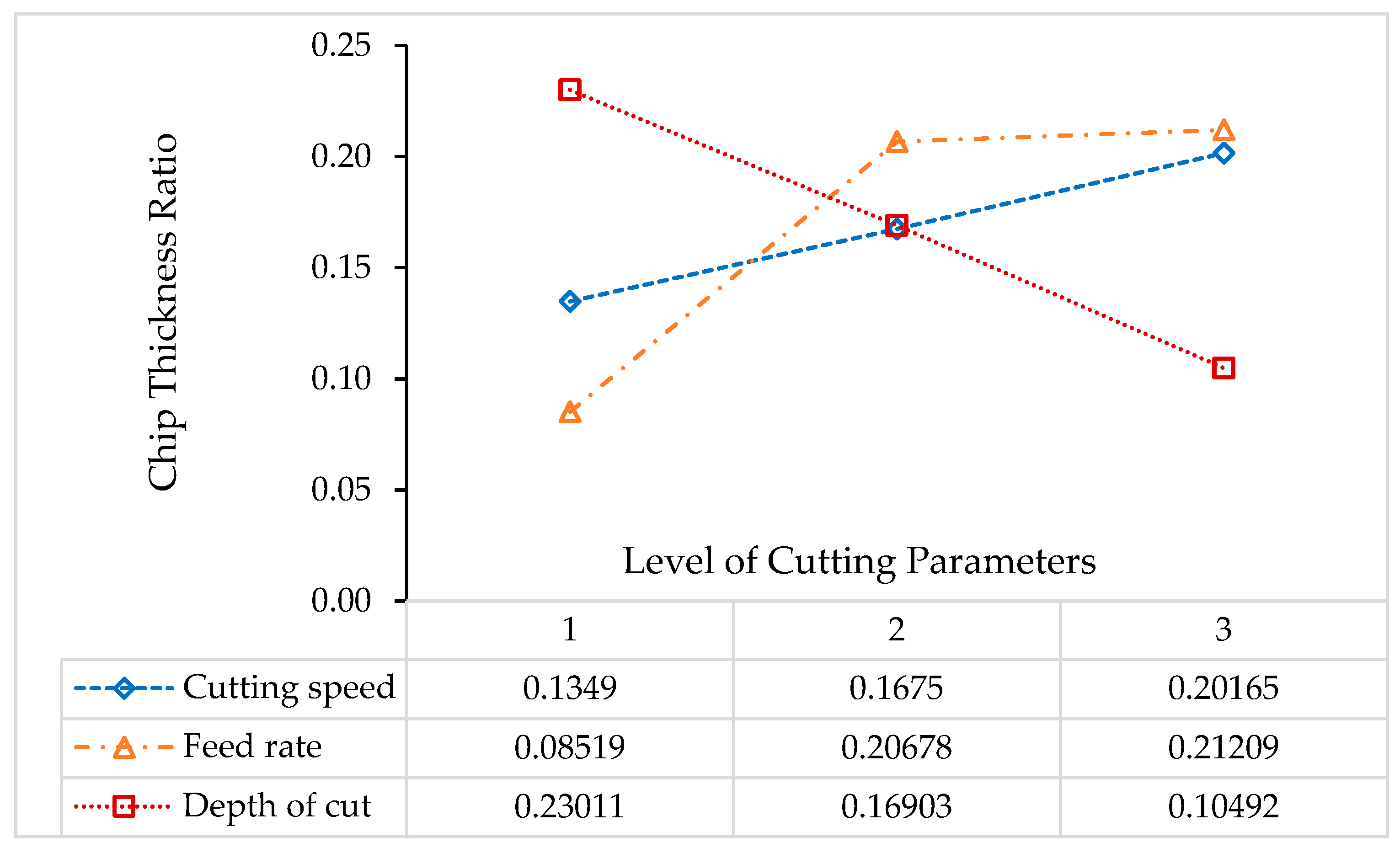

3.2. Chip Thickness and Its Ratio

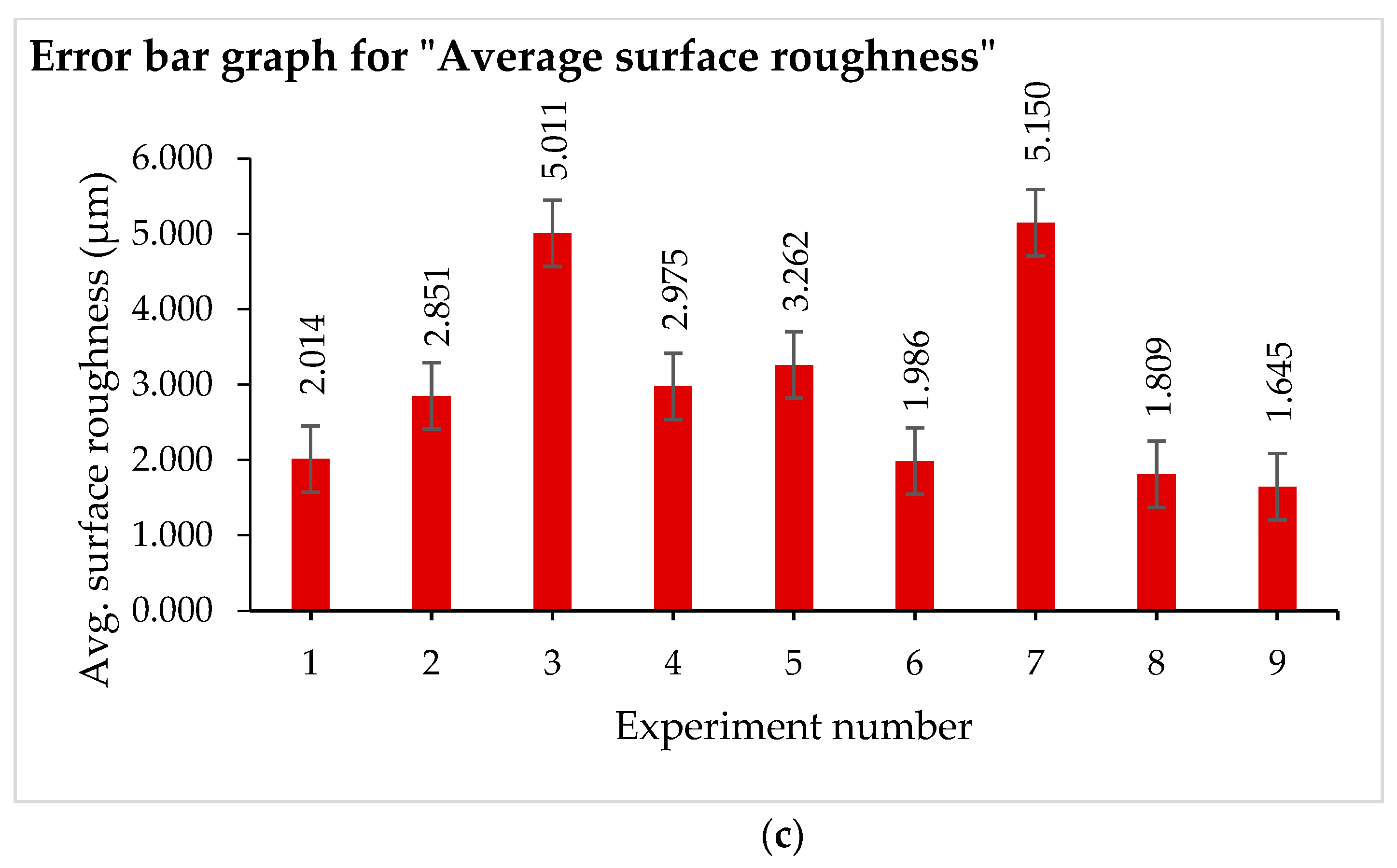

3.3. Surface Roughness Analysis

3.4. Taguchi Based Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mashinini, P.M.; Soni, H.; Gupta, K. Investigation on Dry Machining of Stainless Steel 316 Using Textured Tungsten Carbide Tools. Mater. Res. Express 2020, 7, 016502. [Google Scholar] [CrossRef]

- Guvenc, M.A.; Bilgic, H.H.; Mistikoglu, S. Identification of Chatter Vibrations and Active Vibration Control By Using the Sliding Mode Controller on Dry Turning of Titanium Alloy (Ti6Al4V). Facta Univ. Ser. Mech. Eng. 2023, 21, 307–322. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Mia, M.; Dang, X.P.; Le, C.H.; Packianather, M.S. Green Machining for the Dry Milling Process of Stainless Steel 304. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 234, 881–899. [Google Scholar] [CrossRef]

- Stanojković, J.; Radovanović, M. Influence of the Cutting Parameters on Force, Moment and Surface Roughness in the End Milling of Aluminum 6082-T6. Facta Univ. Ser. Mech. Eng. 2022, 20, 157. [Google Scholar] [CrossRef]

- Siju, A.S.; Jose, S.; Waigaonkar, S.D. Experimental Analysis and Characterisation of Chip Segmentation in Dry Machining of Ti-6Al-4V Alloy Using Inserts with Hybrid Textures. CIRP J. Manuf. Sci. Technol. 2022, 36, 213–226. [Google Scholar] [CrossRef]

- Yuan, J.; Fox-Rabinovich, G.S.; Veldhuis, S.C. Control of Tribofilm Formation in Dry Machining of Hardened AISI D2 Steel by Tuning the Cutting Speed. Wear 2018, 402–403, 30–37. [Google Scholar] [CrossRef]

- Babe, I.B.; Gupta, K.; Chaubey, S.K. Sustainable Dry Machining of Stainless Steel with Microwave-Treated Tungsten Carbide Cutting Tools. Micromachines 2023, 14, 1148. [Google Scholar] [CrossRef] [PubMed]

- Yu, S.; Zhao, G.; Li, C.; Xu, S.; Zheng, Z. Prediction Models for Energy Consumption and Surface Quality in Stainless Steel Milling. Int. J. Adv. Manuf. Technol. 2021, 117, 3777–3792. [Google Scholar] [CrossRef]

- Nagendra Prasad, K.; Ismail, S. Machining Performance of Protruded Textured High-Speed Steel Cutting Tool under Dry Turning Operation. Mater. Today Proc. 2022, 66, 2115–2123. [Google Scholar] [CrossRef]

- Siju, A.S.; Gajrani, K.K.; Joshi, S.S. Dual Textured Carbide Tools for Dry Machining of Titanium Alloys. Int. J. Refract. Met. Hard Mater. 2021, 94, 105403. [Google Scholar] [CrossRef]

- Bertolete, M.; Barbosa, P.A.; Machado, R.; Samad, R.E.; Vieira, N.D.; Vilar, R.; de Rossi, W. Effects of Texturing the Rake Surfaces of Cemented Tungsten Carbide Tools by Ultrashort Laser Pulses in Machining of Martensitic Stainless Steel. Int. J. Adv. Manuf. Technol. 2018, 98, 2653–2664. [Google Scholar] [CrossRef]

- Ma, J.; Duong, N.H.; Lei, S. Numerical Investigation of the Performance of Microbump Textured Cutting Tool in Dry Machining of AISI 1045 Steel. J. Manuf. Process. 2015, 19, 194–204. [Google Scholar] [CrossRef]

- Zhang, K.; Guo, X.; Sun, L.; Meng, X.; Xing, Y. Fabrication of Coated Tool with Femtosecond Laser Pretreatment and Its Cutting Performance in Dry Machining SLM-Produced Stainless Steel. J. Manuf. Process. 2019, 42, 28–40. [Google Scholar] [CrossRef]

- Meng, X.; Zhang, K.; Guo, X.; Wang, C.; Sun, L. Preparation of Micro-Textures on Cemented Carbide Substrate Surface by Plasma-Assisted Laser Machining to Enhance the PVD Tool Coatings Adhesion. J. Mater. Process. Technol. 2021, 288, 116870. [Google Scholar] [CrossRef]

- Fernández-Lucio, P.; Villarón-Osorno, I.; Pereira Neto, O.; Ukar, E.; López de Lacalle, L.N.; Gil del Val, A. Effects of Laser-Textured on Rake Face in Turning PCD Tools for Ti6Al4V. J. Mater. Res. Technol. 2021, 15, 177–188. [Google Scholar] [CrossRef]

- Fatima, A.; Zaheer, A.; Fahad, M. Comparative Performance Analysis of Micro-Structured Carbide Inserts in Machining of EN19 Alloy Steel. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 405. [Google Scholar] [CrossRef]

- Vasumathy, D.; Meena, A. Influence of Micro Scale Textured Tools on Tribological Properties at Tool-Chip Interface in Turning AISI 316 Austenitic Stainless Steel. Wear 2017, 376–377, 1747–1758. [Google Scholar] [CrossRef]

- Roushan, A. Chetan Influence of Texture Patterns and Cryogenic Coolant During Machining of Precipitation-Hardened SS; Springer Proceedings in Materials; Springer: Singapore, 2024; Volume 54, pp. 177–188. [Google Scholar] [CrossRef]

- Roushan, A. Chetan Effect of Discrete and Continuous Texture Geometries on Tool Wear and Derivative Cutting Effect during the Machining. Wear 2025, 568–569, 205964. [Google Scholar] [CrossRef]

- Liu, D.; Wang, W.; Wang, L. Energy-Efficient Cutting Parameters Determination for NC Machining with Specified Machining Accuracy. Procedia CIRP 2017, 61, 523–528. [Google Scholar] [CrossRef]

- Dhage, S.; Jayal, A.D.; Sarkar, P. Effects of Surface Texture Parameters of Cutting Tools on Friction Conditions at Tool-Chip Interface during Dry Machining of AISI 1045 Steel. Procedia Manuf. 2019, 33, 794–801. [Google Scholar] [CrossRef]

- Rajbongshi, S.K.; Sarma, D.K. Performance Parameters Studies in Machining of AISI D2 Steel with Dot-Textured, Groove-Textured & Non-Textured Cutting Tool at the Flank Face. Int. J. Refract. Met. Hard Mater. 2019, 83, 104970. [Google Scholar] [CrossRef]

- Sugihara, T.; Nishimoto, Y.; Enomoto, T. Development of a Novel Cubic Boron Nitride Cutting Tool with a Textured Flank Face for High-Speed Machining of Inconel 718. Precis. Eng. 2017, 48, 75–82. [Google Scholar] [CrossRef]

- Sun, J.; Duan, R.; Wang, Q.; Qu, B.; Wang, M. Effect of Derivative Cutting of Flank-Faced Textured Ceramic Tools on Machined Surface. J. Mater. Eng. Perform. 2024, 34, 13492–13513. [Google Scholar] [CrossRef]

- Fatima, A.; Mativenga, P.T. Performance of Flank Face Structured Cutting Tools in Machining of AISI/SAE 4140 over a Range of Cutting Speeds. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2016, 230, 3–18. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, J.; Wu, F.; Duan, R.; Zhang, X.; Hou, Y. Wear Resistance of Carbide Tools with Textured Flank-Face in Dry Cutting of Green Alumina Ceramics. Wear 2017, 372–373, 91–103. [Google Scholar] [CrossRef]

- Debnath, S.; Reddy, M.M.; Yi, Q.S. Influence of Cutting Fluid Conditions and Cutting Parameters on Surface Roughness and Tool Wear in Turning Process Using Taguchi Method. Measurement 2016, 78, 111–119. [Google Scholar] [CrossRef]

- Bag, R.; Panda, A.; Sahoo, A.K.; Kumar, R. Sustainable High-Speed Hard Machining of AISI 4340 Steel Under Dry Environment. Arab. J. Sci. Eng. 2023, 48, 3073–3096. [Google Scholar] [CrossRef]

- Jurko, J.; Panda, A.; Zaborowski, T. Study of Evaluation Machinability of a Stainless Steels and Accompanying Phenomena in the Cutting Zone During Machining. In Trends in Vital Food and Control Engineering; IntechOpen: London, UK, 2012. [Google Scholar] [CrossRef][Green Version]

- Uysal, A.; Jawahir, I.S. Analysis of Slip-Line Model for Serrated Chip Formation in Orthogonal Machining of AISI 304 Stainless Steel under Various Cooling/Lubricating Conditions. J. Manuf. Process. 2021, 67, 447–460. [Google Scholar] [CrossRef]

- Singh, A.; Thakur, A.; Gangopadhyay, S. Influence of MoS2-Based Nanofluid Minimum Quantity Lubrication on Machining Performance of AISI 316L Stainless Steel. J. Mater. Eng. Perform. 2024, 34, 5184–5195. [Google Scholar] [CrossRef]

- Das, A.; Padhan, S.; Das, S.R.; Alsoufi, M.S.; Ibrahim, A.M.M.; Elsheikh, A. Performance Assessment and Chip Morphology Evaluation of Austenitic Stainless Steel under Sustainable Machining Conditions. Metals 2021, 11, 1931. [Google Scholar] [CrossRef]

- Mahdavinejad, R.A.; Saeedy, S. Investigation of the Influential Parameters of Machining of AISI 304 Stainless Steel. Sadhana Acad. Proc. Eng. Sci. 2011, 36, 963–970. [Google Scholar] [CrossRef]

- Thamizhmanii, S.; Hasan, S. Machinability Study Using Chip Thickness Ratio on Difficult to Cut Metals by Cbn Cutting Tool. Key Eng. Mater. 2012, 504–506, 1317–1322. [Google Scholar] [CrossRef]

- Tamizharasan, T.; Senthilkumar, N.; Selvakumar, V.; Dinesh, S. Taguchi’s Methodology of Optimizing Turning Parameters over Chip Thickness Ratio in Machining P/M AMMC. SN Appl. Sci. 2019, 1, 160. [Google Scholar] [CrossRef]

- Soni, H.; Mashinini, P.M. An Analysis on Tool-Chip Interaction During Dry Machining of SS316 Using Textured Carbide Tools. Arab. J. Sci. Eng. 2021, 46, 7611–7621. [Google Scholar] [CrossRef]

- Abellán-Nebot, J.V.; Vila Pastor, C.; Siller, H.R. A Review of the Factors Influencing Surface Roughness in Machining and Their Impact on Sustainability. Sustainability 2024, 16, 1917. [Google Scholar] [CrossRef]

- Rathod, N.J.; Chopra, M.K.; Shelke, S.N.; Chaurasiya, P.K.; Kumar, R.; Saxena, K.K.; Prakash, C. Investigations on Hard Turning Using SS304 Sheet Metal Component Grey Based Taguchi and Regression Methodology. Int. J. Interact. Des. Manuf. 2024, 18, 2653–2664. [Google Scholar] [CrossRef]

| Workpiece | Stainless steel grade AISI 316 round bars of initial diameter 60 mm and length 200 mm Chemical composition in % weight: 16–18 (Cr), 10–14 (Ni), 2–3 (Mo), 0.045 (P), 0.030 (S), 0.08 (C), 0.10 (N), 2 (Mn), and 0.75 (Si); and the remaining is Fe. |

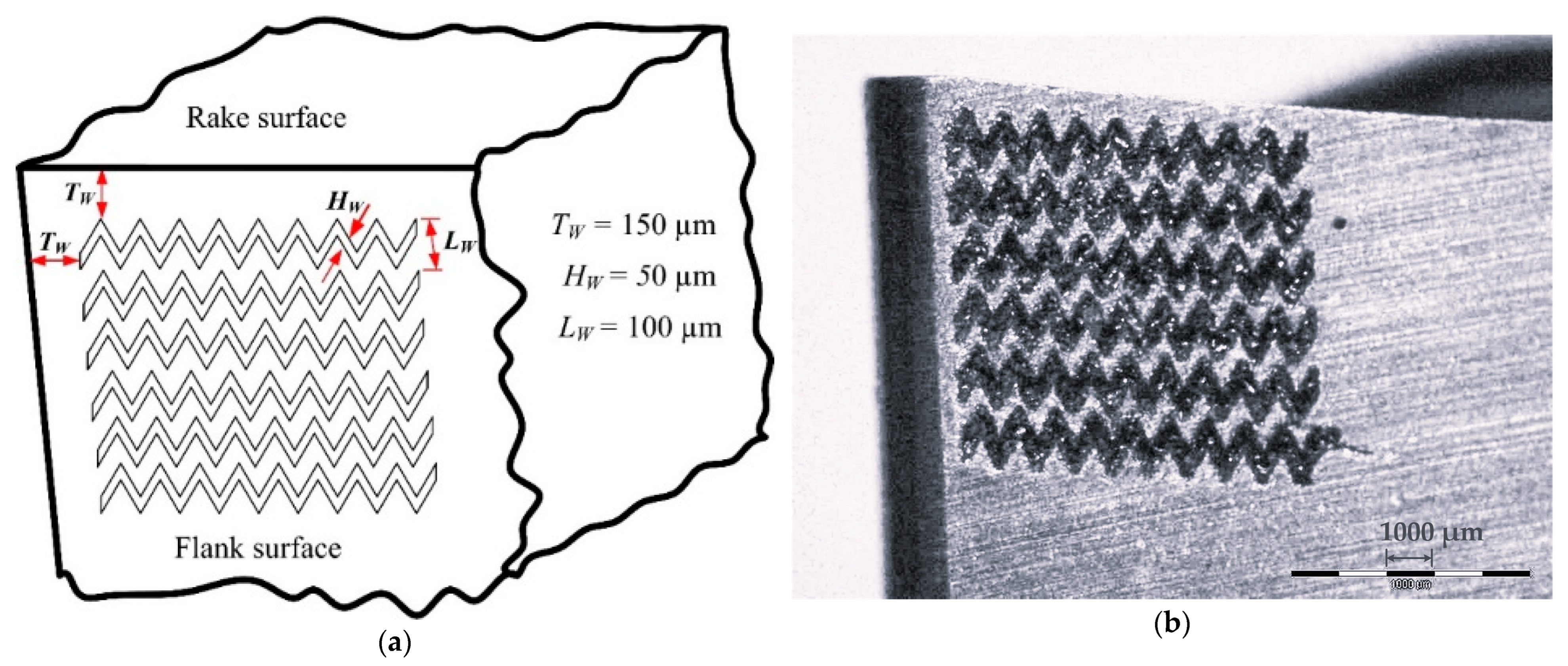

| Cutting tool | Sandvik ISO standard CNMG 120404 uncoated tungsten carbide inserts in rhombic shape with wave textures on the flank face |

| Tool holder | ISO standard DCLNR 2525M12 |

| Basic geometry | Main cutting-edge angle: 95°, rake angles: 6°, and nose radius: 0.4 mm |

| Cutting speed | 70, 120, 170 m/min |

| Feed rate | 0.10, 0.15, 0.20 mm/rev |

| Depth of cut | 0.5, 1.0, 1.5 mm |

| Cutting environment | Dry |

| Design of experiments | Orthogonal array of Taguchi L9 |

| Turning time | 300 s |

| Machine tool | Mascot 1600 lathe machine tool, made by Lathes, Colchester, UK with a maximum RPM of 1600 and a spindle power of 12.5 HP |

| Performance characteristics | Chip analysis: Chip morphology, chip thickness and its ratio, and surface roughness |

| Measuring equipment/devices | Olympus BX-51 fluorescent microscope from Olympus, Tokyo, Japan for measuring chip thickness and the corresponding images TMR200 surface roughness tester manufactured by TMTeck Instrument Co., Ltd., Beijing, China. Used for surface roughness measurement |

| Exp. | vc (m/min) | fr (mm/rev) | dc (mm) | Chip Thickness (µm) | Chip Thickness Ratio | Average Surface Roughness (µm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R1 | R2 | Average | R1 | R2 | Average | R1 | R2 | Average | ||||

| 1 | 70 | 0.10 | 0.50 | 1200.30 | 1195.52 | 1197.91 | 0.083 | 0.083 | 0.083 | 1.993 | 2.034 | 2.014 |

| 2 | 120 | 0.15 | 1.50 | 1321.84 | 1373.73 | 1347.79 | 0.113 | 0.111 | 0.112 | 2.901 | 2.800 | 2.851 |

| 3 | 170 | 0.20 | 1.00 | 916.95 | 953.93 | 935.44 | 0.218 | 0.214 | 0.216 | 5.026 | 4.996 | 5.011 |

| 4 | 70 | 0.15 | 1.00 | 786.52 | 802.06 | 794.29 | 0.191 | 0.189 | 0.190 | 2.948 | 3.001 | 2.975 |

| 5 | 120 | 0.20 | 0.50 | 683.46 | 720.50 | 701.98 | 0.293 | 0.285 | 0.289 | 3.312 | 3.212 | 3.262 |

| 6 | 170 | 0.10 | 1.50 | 1415.73 | 1399.95 | 1407.84 | 0.071 | 0.071 | 0.071 | 1.972 | 2.000 | 1.986 |

| 7 | 70 | 0.20 | 1.50 | 1522.30 | 1515.02 | 1518.66 | 0.131 | 0.132 | 0.132 | 5.100 | 5.200 | 5.150 |

| 8 | 120 | 0.10 | 1.00 | 989.02 | 980.07 | 984.55 | 0.101 | 0.102 | 0.101 | 1.757 | 1.860 | 1.809 |

| 9 | 170 | 0.15 | 0.50 | 486.14 | 429.14 | 457.64 | 0.309 | 0.328 | 0.318 | 1.615 | 1.675 | 1.645 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 3 | 727,751 | 242,584 | 4.27 | 0.076 |

| Linear | 3 | 727,751 | 242,584 | 4.27 | 0.076 |

| vc | 1 | 84,002 | 84,002 | 1.48 | 0.278 |

| fr | 1 | 31,424 | 31,424 | 0.55 | 0.491 |

| dc | 1 | 612,325 | 612,325 | 10.78 | 0.022 * |

| Error | 5 | 284,098 | 56,820 | ||

| Total | 8 | 1,011,849 | |||

| R2: 71.92% | |||||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 3 | 0.054346 | 0.018115 | 8.21 | 0.022 * |

| Linear | 3 | 0.054346 | 0.018115 | 8.21 | 0.022 * |

| vc | 1 | 0.006683 | 0.006683 | 3.03 | 0.142 |

| fr | 1 | 0.024155 | 0.024155 | 10.95 | 0.021 * |

| dc | 1 | 0.023509 | 0.023509 | 10.66 | 0.022 * |

| Error | 5 | 0.011027 | 0.002205 | ||

| Total | 8 | 0.065373 | |||

| R2: 83.13% | |||||

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 3 | 11.6044 | 3.8681 | 8.06 | 0.023 * |

| Linear | 3 | 11.6044 | 3.8681 | 8.06 | 0.023 * |

| vc | 1 | 0.373 | 0.373 | 0.78 | 0.418 |

| fr | 1 | 9.6647 | 9.6647 | 20.13 | 0.006 * |

| dc | 1 | 1.5667 | 1.5667 | 3.26 | 0.131 |

| Error | 5 | 2.401 | 0.4802 | ||

| Total | 8 | 14.0054 | |||

| R2: 82.86% | |||||

| vc | fr | dc | Chip Thickness | S/N Ratios |

|---|---|---|---|---|

| 70 | 0.10 | 0.5 | 1197.91 | −61.5685 |

| 120 | 0.15 | 1.5 | 1347.79 | −62.5924 |

| 170 | 0.20 | 1.0 | 935.44 | −59.4203 |

| 70 | 0.15 | 1.0 | 794.29 | −57.9996 |

| 120 | 0.20 | 0.5 | 701.98 | −56.9265 |

| 170 | 0.10 | 1.5 | 1407.84 | −62.9711 |

| 70 | 0.20 | 1.5 | 1518.66 | −63.6292 |

| 120 | 0.10 | 1.0 | 984.55 | −59.8647 |

| 170 | 0.15 | 0.5 | 457.64 | −53.2105 |

| Cutting Parameters | |||

|---|---|---|---|

| Level | vc | fr | dc |

| 1 | −61.07 | −61.47 | −57.24 * |

| 2 | −59.79 | −57.93 * | 59.79 |

| 3 | −58.53 * | −59.99 | −63.06 |

| Delta () | 2.53 | 3.53 | 5.83 |

| Rank | 3 | 2 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pawanr, S.; Gupta, K. Dry Machining of AISI 316 Steel Using Textured Ceramic Tool Inserts: Investigation of Surface Roughness and Chip Morphology. Ceramics 2025, 8, 97. https://doi.org/10.3390/ceramics8030097

Pawanr S, Gupta K. Dry Machining of AISI 316 Steel Using Textured Ceramic Tool Inserts: Investigation of Surface Roughness and Chip Morphology. Ceramics. 2025; 8(3):97. https://doi.org/10.3390/ceramics8030097

Chicago/Turabian StylePawanr, Shailendra, and Kapil Gupta. 2025. "Dry Machining of AISI 316 Steel Using Textured Ceramic Tool Inserts: Investigation of Surface Roughness and Chip Morphology" Ceramics 8, no. 3: 97. https://doi.org/10.3390/ceramics8030097

APA StylePawanr, S., & Gupta, K. (2025). Dry Machining of AISI 316 Steel Using Textured Ceramic Tool Inserts: Investigation of Surface Roughness and Chip Morphology. Ceramics, 8(3), 97. https://doi.org/10.3390/ceramics8030097