1. Introduction

Ceramic materials have been widely used as structural materials across multiple industrial sectors, including architecture, aerospace, biomedical, and industrial manufacturing, among others [

1]. Their popularity is due to their outstanding thermal, mechanical, morphological, and piezoelectric properties [

2,

3]. However, the fabrication of complex ceramic components presents significant challenges, particularly during the sintering process, which has limited their applications in certain fields such as the automotive industry, medicine (biomedical implants), and aerospace [

4].

In response to these challenges, the emerging technology of three-dimensional (3D) printing is gaining recognition as a promising solution to overcome the manufacturing limitations of ceramic components with intricate geometries, porous structures, thin walls, or designs featuring precise and specific details that are difficult to produce using conventional methods such as pressing, casting, or extrusion. This technology enables the creation of innovative designs with specific properties that are hard to achieve through traditional manufacturing methods [

1,

5]. Additionally, its manufacturing flexibility and high material-use efficiency make it ideal for small-batch production of ceramic pieces with complex geometries [

3].

To achieve a successful printing process, it is essential that the ceramic pastes used possess properties that allow for consolidated structures with high-quality finishes [

6,

7]. According to Mohamed N. Rahaman in his book

Ceramic Processing and Sintering, low thermal conductivity in a ceramic paste can be beneficial during post-curing (such as air drying or kiln firing), as it enables uniform curing of the material, minimizing the development of internal stresses that could lead to cracking or deformation [

8].

In this context, diatomite—a natural material known for its filtration, filler, insecticidal, abrasive, and thermal insulation properties—offers significant potential for improving ceramic pastes [

9]. Its porous and absorbent nature, along with its ability to act as a thermal insulator, suggests it could play a crucial role in modulating the thermal conductivity of ceramic pastes used in 3D printing [

9,

10,

11].

Nevertheless, despite advances in research on porous ceramics made with kaolin and diatomite, there are still significant limitations in understanding the specific effect of diatomite on the thermal conductivity and extrusion behavior of these ceramics. In the study by Leal Quintero [

12], the effective thermal conductivity of porous ceramics made from kaolins and diatomaceous earth from Boyacá was investigated, but the individual impact of diatomite on thermal properties was not isolated. Furthermore, although Fonseca Páez [

13] produced and characterized ceramic membranes based on kaolin and diatomaceous earth, focusing the analysis on microstructure and heavy metal removal efficiency, the extrusion process and the specific role of diatomite in this context were not addressed in detail. These gaps highlight the need for studies that specifically analyze how the incorporation of diatomite affects the thermal conductivity and extrusion behavior of ceramics in order to optimize their properties and manufacturing processes.

While previous studies have explored the use of diatomite in porous ceramics and membranes, most have focused on filtration or structural properties without isolating its impact on thermal conductivity or extrusion behavior in additive manufacturing contexts.

Therefore, this study seeks to address a specific gap in current ceramic manufacturing research: understanding how different amounts of diatomite influence both the thermal conductivity and extrusion behavior of ceramic pastes designed for 3D printing. By systematically analyzing pastes with different diatomite contents, we aim to determine their suitability for additive manufacturing processes, especially where thermal management and extrudability are crucial. Complementary analyses using X-ray diffraction (XRD), thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), energy-dispersive spectroscopy (EDS), and scanning electron microscopy (SEM) will help correlate structural and thermal behaviors, providing a comprehensive basis for optimizing ceramic formulations for advanced and sustainable manufacturing applications.

2. Materials and Methods

2.1. Materials

The diatomite, which had a silica content of approximately 85–90%, and kaolin were supplied by Caolines Boyacá (Colombia). Feldspar (aluminum and potassium silicate, K2O·Al2O3·6SiO2) with a minimum purity of 95% for SiO2 and Al2O3 combined, was provided by Caolines La Pirámide, Bogotá D.C. (Colombia). Carboxymethyl cellulose (CMC) was obtained from PRODESCO S.L., Manises, Valencia (Spain). Sodium silicate was supplied by Comercial Fox, Bogotá D.C. (Colombia). Water was provided by Globaldentt SAS, Bogotá D.C. (Colombia).

2.2. Preparation of Ceramic Pastes

The ceramic pastes were prepared from a liquid mixture composed of 144 mL of water, 1 g of sodium silicate, and 1 g of CMC. The solid composition consisted of diatomite, feldspar, and kaolin, combined in different weight percentages, as shown in

Table 1. The total weight of the solid mixture was 100 g.

All components were initially mixed at 300 rpm using a 30 mm magnetic stirrer hot plate mixer at 20 °C. The mixing speed was then gradually increased to 1300 rpm and maintained for 10 min to obtain a homogeneous and lump-free ceramic paste. Once the solid and liquid mixtures were prepared separately, they were combined in a glass beaker according to the sample compositions.

Subsequently, each ceramic paste sample was compacted in a centrifuge (Laboratory Centrifuge 800-1, 4000 RPM + 20 mL × 12, 110 V, White) at 700 rpm to ensure the complete removal of any remaining air bubbles. Finally, each paste was stored and protected from light for 12 h before conducting the thermal conductivity test, considering that for the 3D printing process, the ceramic paste must rest for 12 h in airtight containers.

Table 1 presents the experimental design, showing the quantity of each component used in the samples.

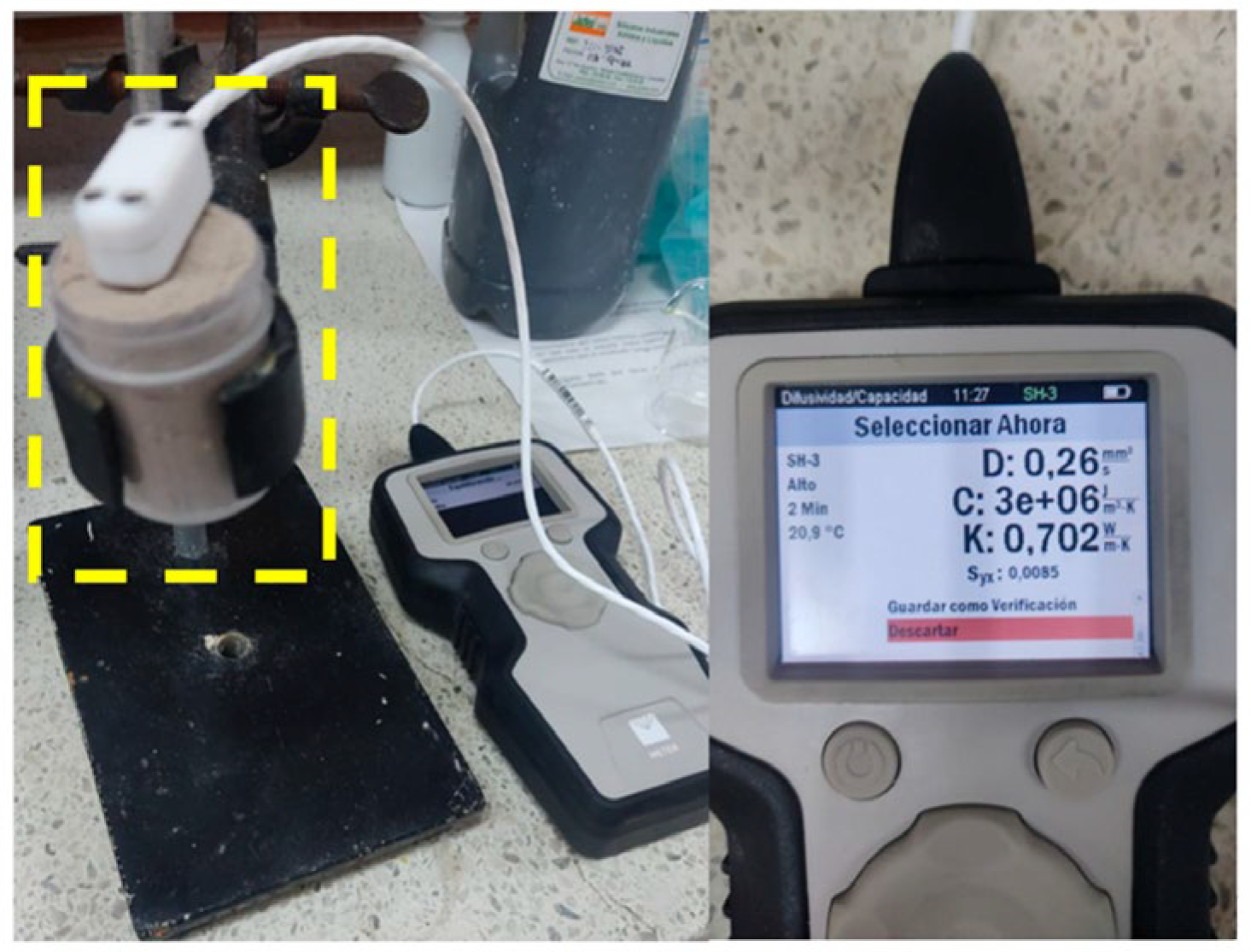

2.3. Thermal Conductivity Testing of Ceramic Pastes

Thermal conductivity was measured for the P0, P1, P2, and P3 pastes using the TEMPO thermal properties analyzer with the SH3 device from METER Group, Pullman, WA, USA, which operates under the principle of linear heat flow. The two needles were inserted into the ceramic paste, as shown in the yellow rectangle in

Figure 1.

2.4. Extrusion Test

The extrusion test, also referred to as a capillary rheometer test, is used to evaluate the extrudability of materials and was conducted following the methodology proposed by Varela H. and Barluenga G. [

14]. A universal testing machine equipped with a 5 kN load cell was employed to apply force to a ram-type extrusion system. This system consisted of a steel cylinder measuring 120 mm in height and 31 mm in internal diameter, fitted with a Teflon-tipped plunger of 30 mm × 31.5 mm, and a conical nozzle with an inlet diameter of 31.5 mm and an outlet diameter of 2 mm. The barrel was filled with 120 mm of ceramic paste, and a piston attached to the testing machine was placed at the top to apply a constant vertical displacement rate of 5 mm/s.

According to the criteria established by Varela H. and Barluenga G. [

14], two characteristic behaviors are identified through this test. A material exhibits deficient extrusion when the stress–displacement curve, following the linear elastic phase, shows an increasing trend in applied force, indicating frictional resistance. In contrast, adequate extrusion is characterized by a peak in force followed by a decrease, corresponding to reduced frictional forces as extrusion progresses. These behaviors are illustrated in

Figure 2.

2.5. Characterization of Ceramic Paste

The thermal conductivity of each ceramic paste was determined using the TEMPOS SH3 device. It utilizes a single-sided heat reflectance sensor operating under the principle of linear heat flow by applying a constant, momentary heat source to the sample.

To thermally characterize the ceramic pastes, differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) were performed using an SDT Q600 TA instrument from New Castle, DE, USA. Tests were conducted from 30 to 1000 °C at a heating rate of 10 °C/min.

Morphological characterization of the ceramic pastes was performed using scanning electron microscopy (SEM). The chemical composition was determined by energy-dispersive X-ray spectroscopy (EDS). Both techniques were carried out using a ZEISS EVO MA10 system from Oberkochen, Baden-Württemberg, Germany.

2.6. Rheological Analysis

The rheological analysis was conducted using an REO-OSC-MCR-01 device from Graz, Austria, an oscillatory rheometer (amplitude sweep) in which viscoelastic materials are deformed or flow in response to applied forces or stresses. The equipment consists of two plates: a larger one at the bottom (platform) and a smaller one at the top. The viscous sample is placed between the two plates, and either an oscillatory rotation or stress is applied. Shear stress and strain are then measured.

Rheology provides insight into how materials behave in terms of deformation or flow under applied forces or stresses. Characterizing this material reveals the extrusion behavior of the paste for ceramic printing. The storage modulus (G′) represents the elastic component of the material—i.e., the energy stored and recovered after deformation—while the loss modulus (G″) indicates the viscous component, i.e., the energy dissipated as heat during deformation.

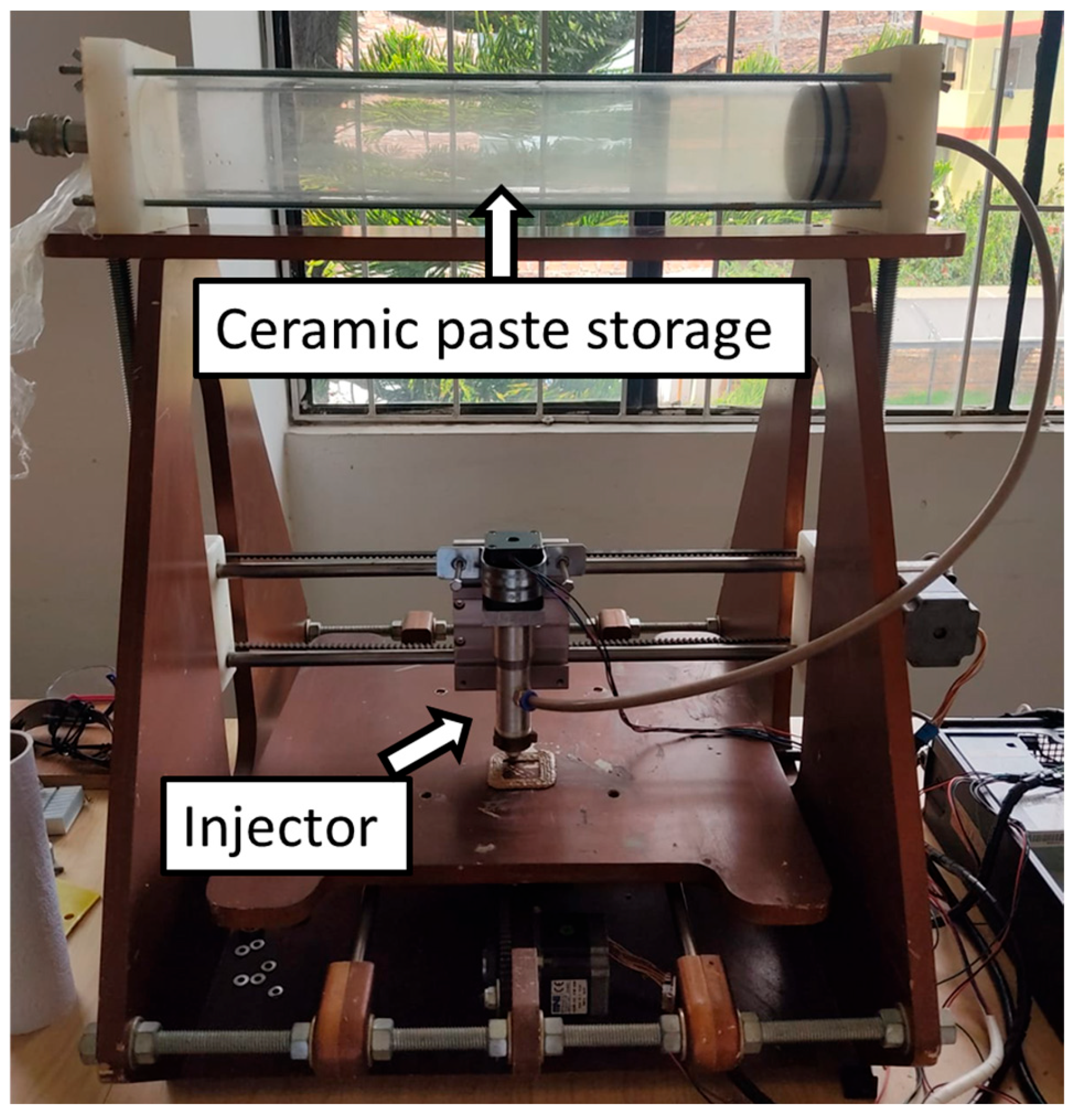

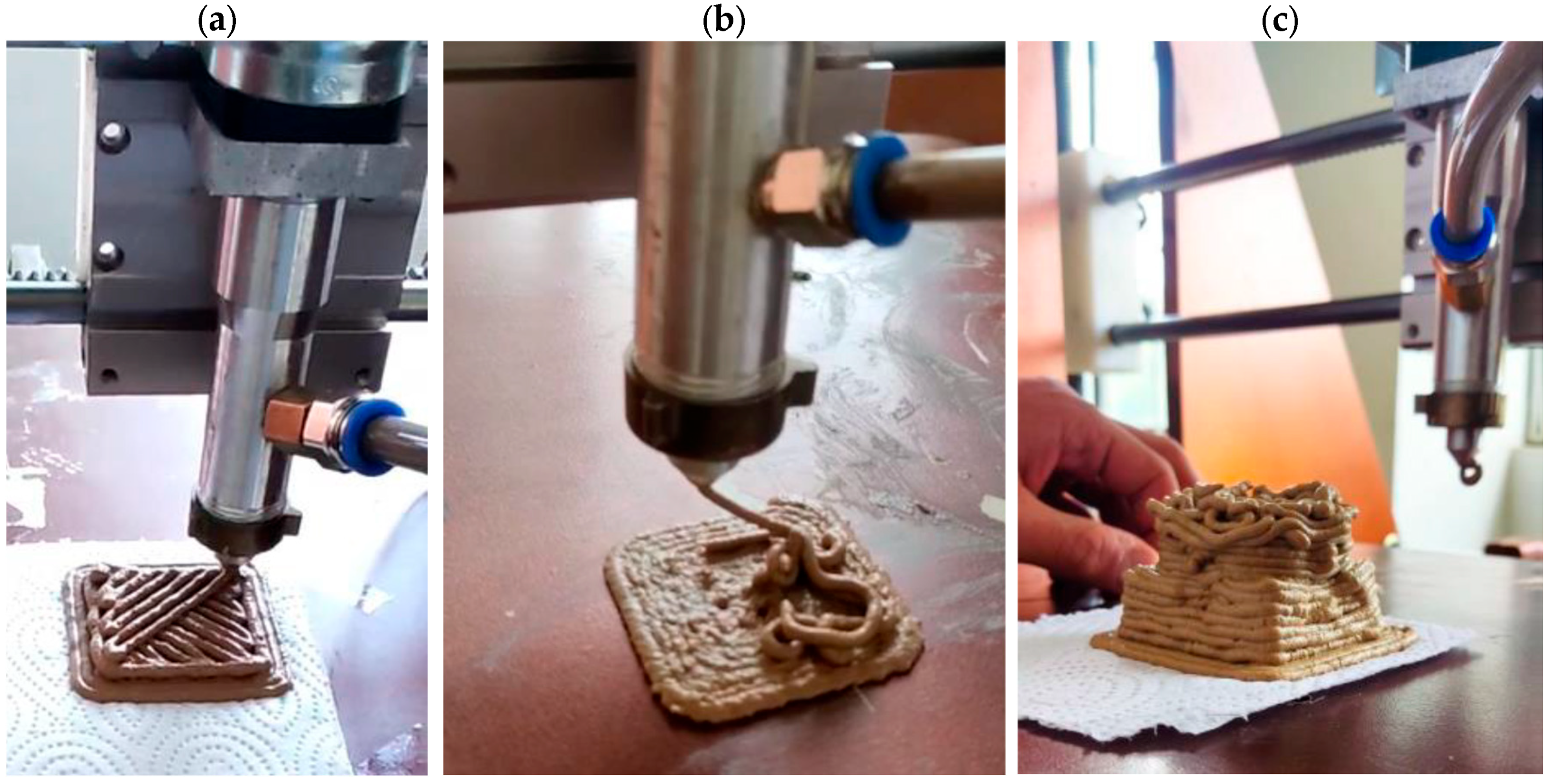

2.7. 3D Printing

The printing of the developed ceramic pastes was carried out using a printer built by the GENTE research group from the School of Electromechanical Engineering at UPTC, Duitama campus, as shown in

Figure 3. The printing test was performed using a 2 mm nozzle.

Table 2 presents the constant printing parameters used for ceramic pastes P0, P1, P2, and P3.

3. Results

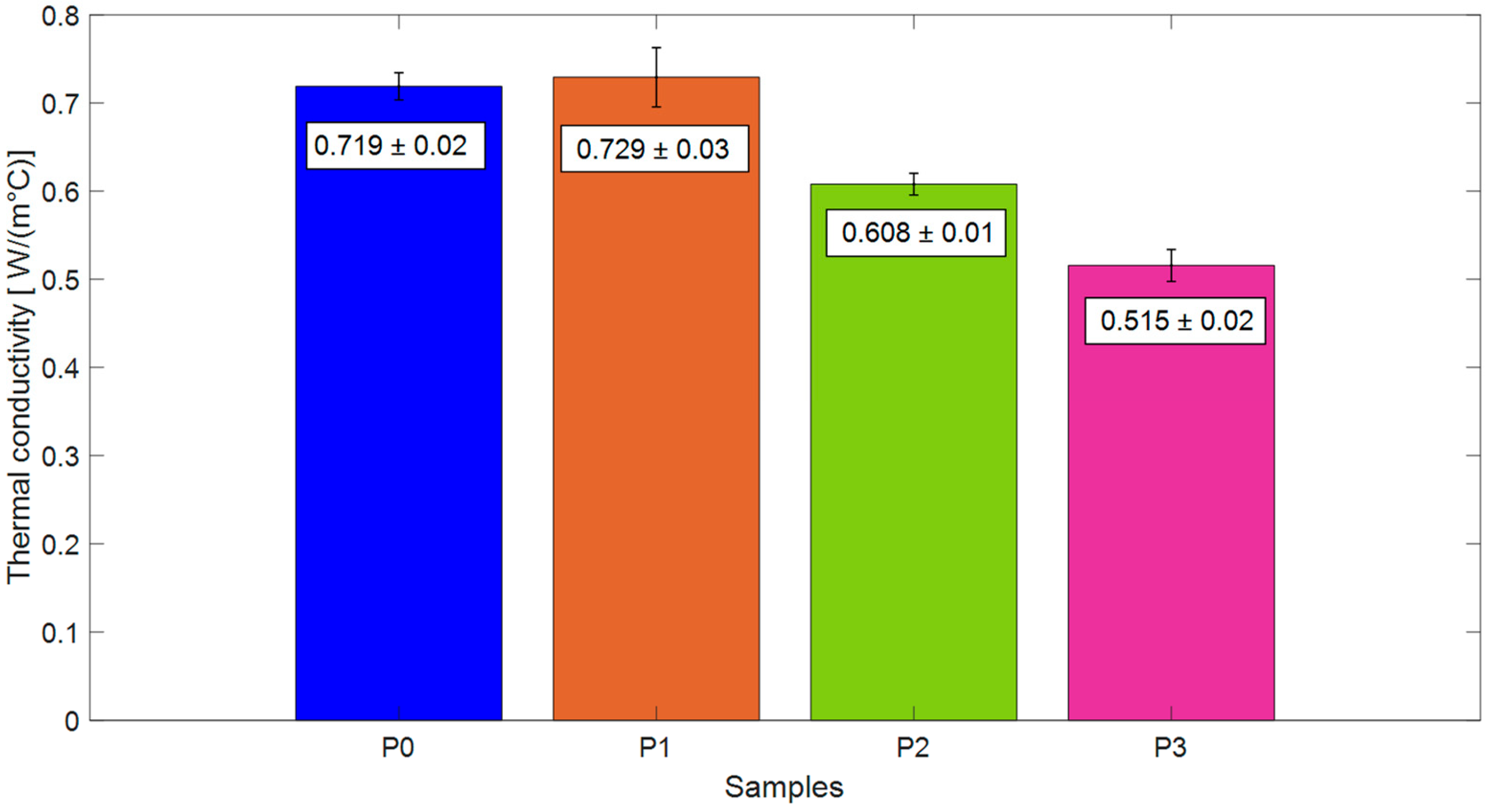

3.1. Thermal Conductivity Analysis of Ceramic Pastes

The effective thermal conductivity results obtained using the TEMPO device with the SH3 sensor are shown in

Table 3.

Table 3 shows the thermal conductivity values for the ceramic pastes developed for additive manufacturing. Here, kP0 corresponds to the sample with 0% diatomite, kP1 to 10% diatomite, kP2 to 30% diatomite, and kP3 to 60% diatomite. The measured thermal conductivities range from 0.515 W/(m·°C) to 0.719 W/(m·°C). Paste P1 (10% diatomite) had the highest thermal conductivity within the experimental range, although without a significant difference from sample P0 (0% diatomite), suggesting that at low contents, diatomite does not have a noticeable reducing effect on thermal conductivity. The P3 sample (60% diatomite) recorded the lowest average thermal conductivity, at 0.515 W/(m·°C).

Based on these results, a bar graph was created to illustrate the thermal conductivity values of each ceramic paste sample, as shown in

Figure 4.

The ceramic paste without diatomite (P0) exhibited a thermal conductivity of 0.719 ± 0.02 W/(m·°C). The incorporation of 10% diatomite by weight (P1) did not result in a significant change, although diatomite typically lowers thermal conductivity due to its high porosity; the slight increase observed in sample P1 (10% diatomite) compared to the control (P0) may be attributed to several factors. At this low concentration, the insulating effect of diatomite may not be dominant. Additionally, early-stage interactions between diatomite and the ceramic matrix could promote a more compact microstructure, reducing the air volume and temporarily increasing thermal conductivity. This effect diminishes with higher diatomite content, as the porosity becomes more prevalent and leads to the expected decrease in thermal conductivity. However, when the diatomite content was increased to 30% (P2), the thermal conductivity decreased to 0.608 ± 0.01 W/(m·°C) and further declined to 0.515 ± 0.02 W/(m·°C) at 60% diatomite (P3). These results indicate that diatomite effectively reduces the thermal conductivity of the ceramic paste, an essential attribute for additive manufacturing applications. Lower thermal conductivity facilitates improved control over thermal gradients during the printing and sintering stages, thereby minimizing internal stresses, reducing the risk of cracking and deformation in the final product. Furthermore, it enhances the energy efficiency of the process and promotes the dimensional stability of the printed components [

15,

16,

17].

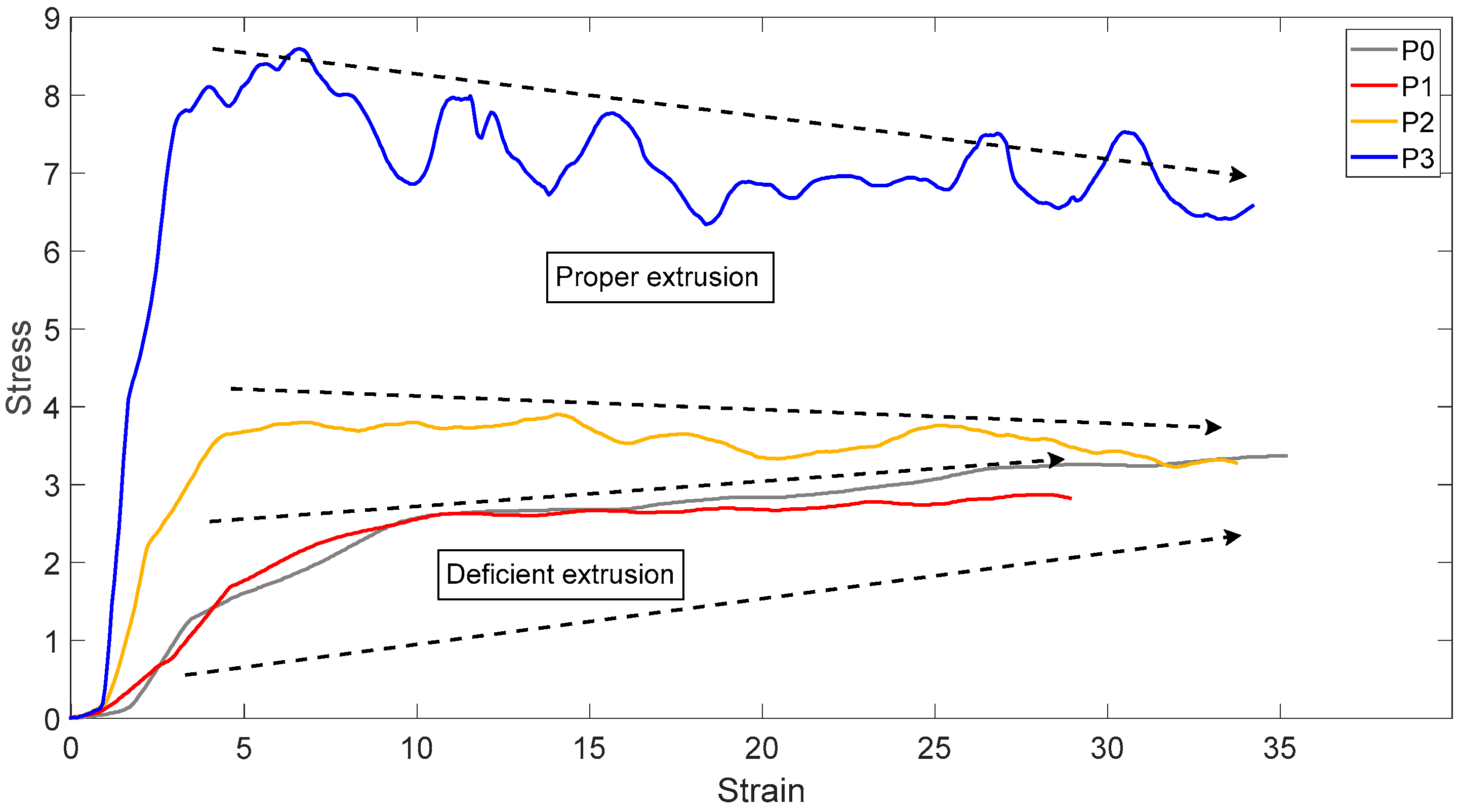

3.2. Extrusion Test (Capillary Rheometer Test)

Figure 5 presents the extrusion stress and displacement of ceramic paste samples P0, P1, P2, and P3 after 10 min. Two characteristic behavioral patterns were identified, as described in

Figure 2. Adequate extrusion is characterized by an initial peak in stress, followed by a decrease, attributed to a reduction in frictional surface area. In contrast, deficient extrusion displays a marked increase in stress after the initial peak, indicating friction-dominated behavior. These patterns may be associated with the cohesive properties of the paste [

14], as well as extrusion issues such as water drainage (liquid phase migration) and die blockage [

14].

Samples P0 and P1 exhibit deficient extrusion behavior. In contrast, the incorporation of diatomite in samples P2 and P3 enhances the extrusion performance, resulting in adequate extrusion. These formulations are less likely to clog the printer nozzle or form agglomerates during the process. Among all samples, P0—formulated without diatomite—shows the weakest extrusion performance. The results confirm that sample P2, containing 30% diatomite, demonstrates superior extrusion behavior compared to the other formulations.

Table 4 presents the maximum stress recorded for each paste (in MPa), as well as the extrusion behavior, categorized as either adequate or deficient.

These results indicate that pastes P2 and P3 are suitable for additive manufacturing, as they exhibit extrusion stress above 3 MPa—necessary for the material to be printable. Furthermore, it is evident that increasing diatomite content significantly increases extrusion resistance.

3.3. Thermogravimetric Analysis (TGA) and Differential Scanning Calorimetry (DSC)

Temperature increases during thermogravimetric analysis can have a significant impact on the sintering of ceramic pastes. The TGA test results are shown in

Figure 6.

The thermogravimetric curve decreases as temperature increases. From room temperature to 150 °C, there is a sharp drop in the curve, corresponding primarily to moisture evaporation from the pastes. As the temperature rises from 200 °C to 500 °C, the paste begins to decompose, and the curve drops gradually. However, the weight loss in this range is minimal—about 0.2%—indicating that the mass of the green body remains relatively unchanged above 600 °C. The total weight loss of the ceramic green body is approximately 30% to 50% between 60 °C and 110 °C.

Figure 7 shows the DSC results for the ceramic pastes. An endothermic peak appears between 30 °C and 200 °C, corresponding to the release of hydration products. Following this, the curves decline due to the sintering process of the ceramic paste. The intensity of the peaks reflects the enthalpy, which increases at 100 °C as the diatomite content increases—as seen in sample P3, which contains 60% diatomite. This suggests a greater amount of adsorbed water or hydrated compounds in the diatomite.

Additionally, a prominent endothermic peak is observed around 520 °C, which is attributed to the dehydroxylation of kaolinite present in the paste. This process involves the release of structural water (-OH groups) and the transformation of kaolinite into metakaolinite, an amorphous phase. This thermal event is typical for kaolinite-based ceramics and plays a key role in the structural evolution of the material before sintering.

3.4. Energy-Dispersive X-Ray Spectoscopy

The chemical composition of the samples was analyzed using energy-dispersive X-ray spectroscopy (EDS), identifying the elements present in sample P3 at 5.00 KX magnification. As shown below, the analysis revealed the presence of silica and alumina as major components, as well as iron and potassium. The presence of potassium is associated with the feldspar content in the ceramic formulation, while iron can be present as natural mineralogical components of kaolin or diatomite, or in smaller proportions as a natural impurity in the raw materials.

Figure 8b shows sample P3, in which silicon is the predominant element, followed by alumina. Smaller amounts of iron and potassium were also detected. The presence of silicon and alumina suggests that the ceramic paste may exhibit good thermal and mechanical resistance [

18], and depending on the applied temperature change, these components could favor the formation of a glassy phase, which can be evidenced by changes in morphology observed by SEM, loss of crystallinity in XRD patterns, or typical thermal signals in DSC analysis. The presence of iron and potassium may influence the sintering temperature, porosity, and final color of the material [

18].

3.5. Scanning Electron Microscopy (SEM) Analysis

To observe the morphology and distribution of the components in the ceramic pastes, scanning electron microscopy (SEM) was used.

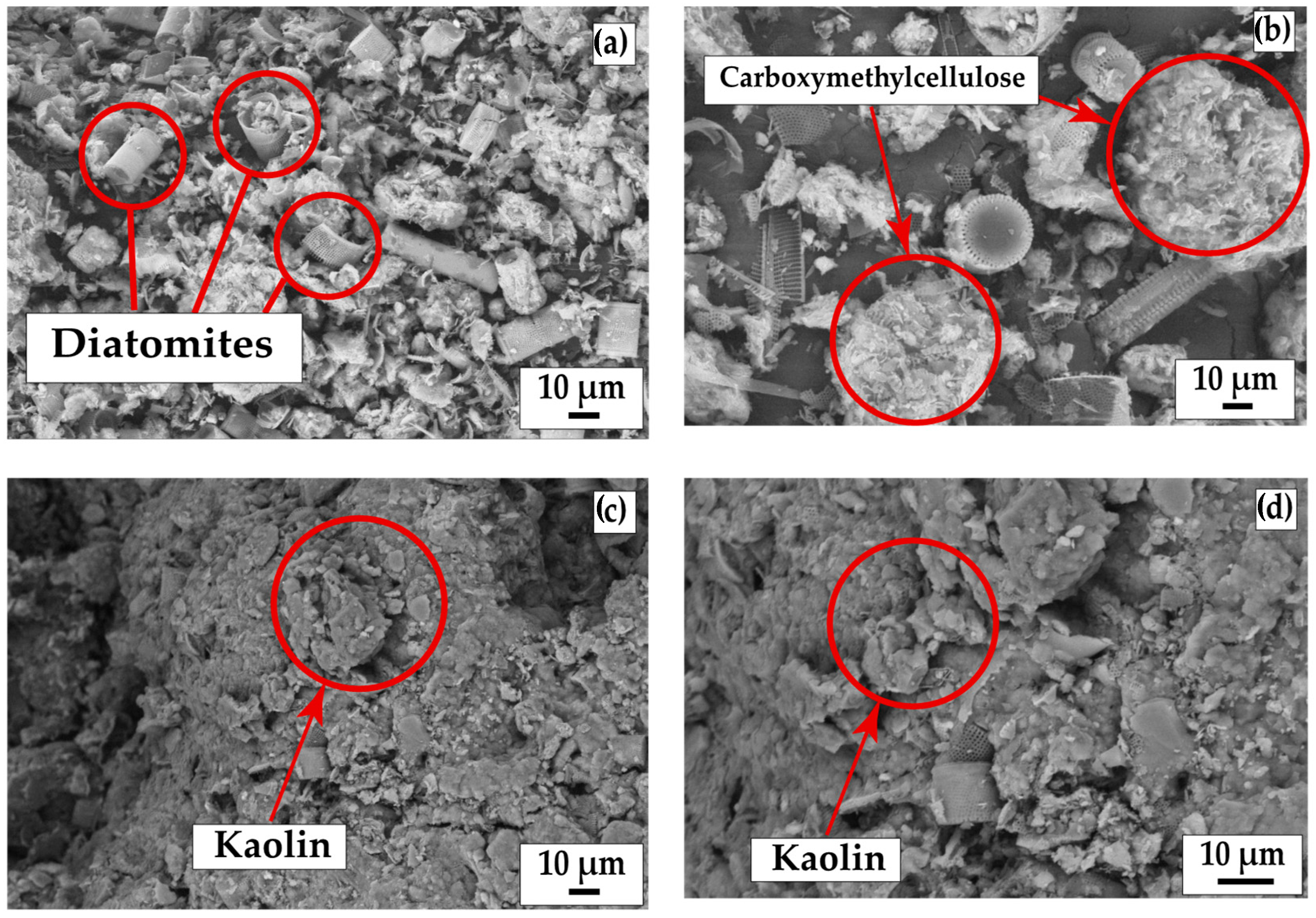

In

Figure 9, two morphological groups of diatomites present in the ceramic pastes can be clearly identified. The radial type (

Figure 10a) has a diameter of approximately 10 to 12 μm, and the radiate naviculoid type (

Figure 10b), belonging to the species Aulacoseira granulata, shows diameters in the range of 14 to 18 μm [

19,

20].

The SEM images in

Figure 9 show the hard, porous cell walls of the diatomites, known as frustules, for each morphological type present in the ceramic pastes. These structures display an organized architecture, including striations, which may influence the thermal properties of the material.

Figure 10a presents the prepared ceramic paste P3, which contains 60% diatomite, 13.3% kaolin, 13.3% feldspar, and 13.3% carboxymethyl cellulose. The red circles highlight the notable presence of radial diatomites that remain intact despite the milling process.

Figure 10b shows agglomerates of carboxymethyl cellulose, which, due to its gelling nature, clusters into granules within the ceramic paste.

Figure 10c,d show grouped particles and laminar shapes typical of kaolinite, with an approximate size of 3 μm. In

Figure 10b, the very white, small particles are likely feldspar. Voids are observed between the different structures, creating porosity in the mixture that can lead to material fracture, as these pores may act as stress concentrators. Moreover, the high porosity induced by the diatomite will reduce thermal conductivity, enhancing the material’s insulating properties. The addition of kaolin and CMC may improve extrudability, but it is essential to adjust the water ratio to avoid defects in the extruded paste.

3.6. Rheological Analysis

Figure 11 presents the results of the oscillatory amplitude sweep test, showing the shear stress versus strain for sample P2. The diagram displays the storage modulus (G′) ■ and the loss modulus (G″) ▲ plotted against shear strain. The vertical axis initially shows that G′ is greater than G″, indicating a predominantly elastic behavior. The horizontal axis shows shear strain as a percentage. As the strain increases, a crossover point is observed where both moduli intersect, indicating the transition of the material from solid-like to liquid-like behavior.

The data highlighted in red in

Figure 11 show the yield stress (

τy), the minimum shear stress required for the paste to begin flowing, which in this case is 0.25%—50 Pa, and the flow stress (

τf), the shear stress required to maintain the flow once the paste has started moving, which is 6.2%—20.63 Pa.

Based on the research conducted by Gyawali et al. [

21], which highlights the importance of rheological characterization in 3D printing, this type of analysis helps resolve key questions, such as whether the material can be printed, whether the prepared paste is too liquid, whether the printed structure can maintain its shape, or whether the paste is too viscous to flow through the nozzle. The material formulation must fall within an optimal range for extrusion, ensuring structural integrity as layers are built on top of one another. Therefore, material characteristics such as the yield stress (

) and storage modulus (G′) at a given shear rate (

) play a crucial role in 3D printing applications [

21]. In this case, the evaluated paste demonstrates a suitable viscoelastic behavior for 3D printing.

3.7. Printing of Ceramic Pastes

Ceramic paste P2 (30% diatomite) was selected for the printing test due to its optimal balance between extrusion behavior and thermal conductivity. As shown in the previous sections, P2 demonstrated adequate extrusion performance at moderate stress levels (3.8 MPa), as well as good filament flow and integrity. In contrast, P1 exhibited poor extrusion behavior (2.62 MPa), resulting in uneven flow and nozzle clogging during preliminary printing attempts. While P3 (60% diatomite) showed even better extrusion resistance (8.59 MPa), its high viscosity resulted in increased surface roughness and required higher printing pressures, complicating the process.

Preliminary printing tests were conducted with pastes P1 and P3; however, only P2 maintained uniform layer deposition and dimensional stability throughout the printed structure. Therefore, only P2 is presented in detail in this section.

The extrusion of paste P2 is shown in

Figure 12. The material extrudes uniformly, and both its elasticity and interlayer adhesion are evident. The elastic nature of the extruded filament ensures it does not break, allowing the printing process to continue smoothly. In addition to the nozzle diameter (2 mm), initial layer height (2.8 mm), and printing speed (5.0 mm/s), several other parameters were kept constant to ensure comparability across samples. The ambient temperature during printing was maintained at 22 ± 2 °C, and relative humidity ranged from 45 to 55%. The ceramic paste was extruded using a pneumatic system with an applied pressure of 0.4 MPa, and the build platform was not heated. Layer height and infill speed were optimized to prevent collapse of the extruded structure, ensuring dimensional accuracy and interlayer bonding. Nozzle cleaning and paste degassing were performed before each print to avoid clogging and improve consistency.

The composite material filament extrudes consistently and forms a stable structure during buildup, enabling the successful printing of ceramic objects.

Figure 13 illustrates a comparative analysis of printed pastes P0 and P2, with the left images showing the wet state and the right images depicting the same specimens after drying. The drying behavior reveals that, in the absence of diatomite (P0), the material develops visible cracks. However, when 30% diatomite is incorporated (P2), the structure remains intact, demonstrating improved dimensional stability.

4. Discussion

The ceramic pastes developed for additive manufacturing applications were evaluated and characterized using various techniques, which allowed observation of the behavior of the pastes as the diatomite content increased.

Thermal conductivity tests showed that as the diatomite content increased, the thermal conductivity of the ceramic pastes decreased. This is consistent with the study conducted by Liu Z., Jin X., and Jiang J., which indicated that the addition of diatomite reduces the overall thermal conductivity of ceramic pastes and that increasing the diatomite mass in ceramic pastes lowers the overall thermal conductivity of cement-based materials [

22].

The present study determined that the inclusion of diatomite enhances the extrusion performance of ceramic pastes. This was evidenced by comparing sample P0, which lacked diatomite and exhibited poor extrusion behavior, with other samples. These results align with the findings of Zhihui Zhao and Mingxu Chen, who demonstrated that diatomite plays a key role in improving the thixotropic behavior of 3D-printed magnesium and potassium phosphate cement compounds, thereby simultaneously enhancing the extrusion process and the post-deposition structural stability [

23]. Similarly, research conducted by Qiang Liu and Quan Jiang indicated that while diatomite significantly improves the printability of concrete, excessive amounts may increase the surface roughness of 3D-printed samples. Notably, when the diatomite content reaches 30%, the deformability of the printed structure is minimized, and the overall print quality is optimized [

24]. These findings correspond with the present study, in which a 30% diatomite composition yielded optimal consistency, flowability, and filament integrity, facilitating the successful construction of 3D-printed ceramic structures.

Furthermore, the data corroborate the inadequacy of sample P0, which exhibited poor extrusion behavior, as indicated by the stress–strain curve profile. The results suggest that increasing diatomite content progressively improves extrusion behavior, transitioning from deficient to adequate performance. This improvement is attributed to the highly porous structure and low density of diatomite, which enhance the rheological properties of the ceramic paste. Such improvements were particularly evident in samples P2 and P3, where the enhanced rheology ensured that the ceramic paste could be extruded without generating excessive resistance or causing nozzle clogging.

The highly porous structure of diatomite is also evident in the SEM micrographs, which provide a detailed view of the internal structure of the ceramic paste samples. The images display the morphologies and compositions of the ceramic pastes, highlighting the interaction between diatomite and the ceramic matrix.

In the study by Wu C. and Li Z. [

7], SEM images revealed diatomites distributed throughout the ceramic matrix with uniform dispersion. A similar distribution was observed in the present study, where diatomites are spread throughout the ceramic paste, with a well-established interfacial bond between the ceramic matrix and the diatomites.

The SEM micrographs shown in

Figure 10 reveal a homogeneous distribution and strong interface between the diatomites and the ceramic matrix, indicating that the mixture was well-processed both before and during extrusion. Good dispersion promotes continuous and uniform extrusion, which is essential for producing parts with consistent dimensions and no structural defects. Regarding thermal conductivity, the homogeneous distribution of diatomites also influences heat transfer through the material. Due to their porous structure and silica content, diatomites tend to reduce the thermal conductivity of ceramic materials. When well-distributed, this reduction is uniform throughout the piece, avoiding localized thermal buildup or weak spots. Furthermore, strong interfacial bonding prevents the formation of microcracks or voids that could act as unwanted thermal barriers or points of mechanical failure.

5. Conclusions

This study evaluated the effect of diatomite content on ceramic pastes with 0%, 10%, 30%, and 60% by weight, focusing on thermal conductivity and extrusion behavior for additive manufacturing applications. Extrusion behavior was observed to depend on both diatomite content and mixture cohesion. Pastes P0 and P1 showed poor performance, while P2 and P3 presented adequate extrusion, with extrusion stresses of 3.8 MPa and 8.59 MPa, respectively. However, despite the high strength of P3, its high viscosity hampered the printing process, increasing surface roughness and the required pressure. In contrast, paste P2 achieved a favorable balance between fluidity and dimensional stability. Regarding thermal conductivity, sample P0 (0% diatomite) showed an average value of 0.719 W/(m °C), while P1 (10%) showed a slightly higher value of 0.729 W/(m °C), which could be explained by experimental variability or particle distribution at low diatomite contents. From P2 onwards, the thermal conductivity decreased markedly, reaching 0.608 W/(m °C) and 0.515 W/(m °C) in P2 and P3, respectively, confirming the insulating effect of diatomite due to its porous structure. DSC analysis revealed a marked endothermic peak around 520 °C, corresponding to the dehydroxylation of kaolinite, a key structural process prior to sintering. EDS analysis showed the presence of silica and alumina as main components, along with iron and potassium. Potassium is attributed to the feldspar content, while iron could be derived from both natural impurities and mineralogical components of kaolin and diatomite. Furthermore, SEM analysis identified radial diatoms (10–12 μm) and naviculoid diatoms (Aulacoseira granulata) with diameters between 14 and 18 μm, values corrected after a review of the micrographs. Preliminary 3D printing tests were performed with pastes P1 and P3, where P1 presented nozzle obstructions and unstable flow, and P3 showed high resistance and poor surface finish. Only P2 achieved uniform filament deposition and dimensional stability during printing, displaying the best overall performance in terms of thermal conductivity, extrudability, and printability, positioning it as the most suitable formulation for development in additive manufacturing applications.

Author Contributions

Investigation, P.A.R.C., A.F.R.-N. and Y.T.-P.; Writing—original draft, P.A.R.C. and A.F.R.-N.; Writing—review and editing, Y.T.-P. and E.Y.G.-P. The authors contributed to all phases of the research from conception to experimental development, analysis of results, and writing of the article. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Pedagogical and Technological University of Colombia (UPTC), grant number SGI 3712.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to express their gratitude to Technological Development Research Institute-CIMADI from the Technological and Pedagogical University of Colombia (UPTC).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Wang, Y.; Wu, T.; Huang, G. State-of-the-art research progress and challenge of the printing techniques, potential applications for advanced ceramic materials 3D printing. Mater. Today Commun. 2024, 40, 110001. [Google Scholar] [CrossRef]

- Filho, E.A.S.; Luna, C.B.B.; Silva, A.L.; Ferreira, E.S.B.; Araújo, E.M.; Costa, A.C.F.M. Effect of kaolin waste annealing on the structural and thermal behavior of poly(ε−caprolactone). Momento 2022, 2022, 66–82. [Google Scholar] [CrossRef]

- Bonilla-Cruz, J.; Ávila-López, M.A.; Rodríguez, F.E.L.; Aguilar-Elguezabal, A.; Lara-Ceniceros, T.E. 3D printable ceramic pastes design: Correlating rheology & printability. J. Eur. Ceram. Soc. 2022, 42, 6033–6039. [Google Scholar] [CrossRef]

- Zhu, N.; Hou, Y.; Zhang, L.; Wen, G. Preparation of h-BN/SiCO ceramic matrix composites with high thermal conductivity and strength by vat photopolymerization 3D printing. J. Eur. Ceram. Soc. 2024, 44, 5885–5895. [Google Scholar] [CrossRef]

- Vishnu, R.; Prabhakaran, K. Porous eco-ceramics of low thermal conductivity and high EMI shielding effectiveness from sawdust and sucrose by paste molding. Ceram. Int. 2021, 47, 34595–34610. [Google Scholar] [CrossRef]

- Romanczuk-Ruszuk, E.; Sztorch, B.; Pakuła, D.; Gabriel, E.; Nowak, K.; Przekop, R.E. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics 2023, 6, 364–385. [Google Scholar] [CrossRef]

- Wu, C.; Li, Z.; Li, Y.; Wu, J.; Zhao, Y.; Liao, Y. Effect of starch on pore structure and thermal conductivity of diatomite-based porous ceramics. Ceram. Int. 2023, 49, 383–391. [Google Scholar] [CrossRef]

- Rahaman, M.N. Ceramic Processing and Sintering, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 1–875. [Google Scholar]

- Soleimanpour, S.; Sadrameli, S.M.; Mousavi, S.A.H.S.; Jafaripour, M. Preparation and characterization of high temperature shape stable NaNO3/diatomite phase change materials with nanoparticles for solar energy storage applications. J. Energy Storage 2022, 45, 103735. [Google Scholar] [CrossRef]

- El Ouardi, Y.; Lenoble, V.; Branger, C.; Laatikainen, K.; Angeletti, B.; Ouammou, A. Enhancing clay adsorption properties: A comparison between chemical and combined chemical/thermal treatments. Groundw. Sustain. Dev. 2021, 12, 100544. [Google Scholar] [CrossRef]

- El-Kordy, A.; Elgamouz, A.; Abdelhamid, A.; Kawde, A.N.; Tijani, N.; Lemdek, E.M. Manufacturing of novel zeolite-clay composite membrane from natural clay and diatomite, an electrochemical study of the surface and application towards heavy metals removal. J. Environ. Chem. Eng. 2024, 12, 112143. [Google Scholar] [CrossRef]

- Allen, A.E.; Dupont, C.L.; Oborník, M.; Horák, A.; Nunes-Nesi, A.; McCrow, J.P.; Zheng, H.; Johnson, D.A.; Hu, H.; Fernie, A.R.; et al. Determinación de conductividad térmica efectiva en cerámicas porosas con caolines y diatomeas de Boyacá. Nature 2018, 473, 203–207. [Google Scholar] [CrossRef] [PubMed]

- Páez, F.; Luis, A. Elaboración y Caracterización de Prototipos de Membranas Cerámicas a Base de Caolin y Tierras Diatomáceas de la Región de Boyacá. Ph.D. Thesis, Universidad Pedagógica y Tecnológica de Colombia, Tunja, Colombia, 2019. [Google Scholar]

- Varela, H.; Barluenga, G.; Perrot, A. Extrusion and structural build-up of 3D printing cement pastes with fly ash, nanoclays and VMAs. Cem. Concr. Compos. 2023, 142, 105217. [Google Scholar] [CrossRef]

- Przybyła, S.; Kwiatkowski, M.; Kwiatkowski, M.; Hebda, M. Optimization of Ceramic Paste Composition for 3D Printing via Robocasting. Materials 2024, 17, 4560. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zheng, L.; Luo, X.; Xie, Z.; Han, L.; Pei, J.; Liu, F. Preparation of low thermal conductivity hierarchically porous diatomite ceramics by doped with ZrSiO4 opacifier-based foam-gelcasting method. J. Mater. Sci. 2022, 57, 4941–4951. [Google Scholar] [CrossRef]

- Alvarado, C.; Alvarado-Quintana, H.; Siche, R. Ceramic Thermal Insulator Based on Diatomite Obtained by Starch Consolidation Casting. Materials 2023, 16, 4028. [Google Scholar] [CrossRef] [PubMed]

- Yang, R.; Zhao, W.; Sun, S.; Yang, J.; Jiao, J. Effect of thermal exposure on the microstructure and strength of an alumina-silica ceramic fiber. Int. J. Appl. Ceram. Technol. 2023, 20, 3064–3072. [Google Scholar] [CrossRef]

- Montoya, A.R. Caracterización Mecánica y Microestructural de Diatomeas y Evaluación de su Potencial uso Como Abrasivo en Piezas Precolombinas de Aleación Oro-Platino. Universidad de los Andes. 2017. Available online: https://hdl.handle.net/1992/39584 (accessed on 20 July 2025).

- Caballero, P.; Zuni, D. Elaboración de Filtros de Diatomita Activada con Adición de Quitosano para la Descontaminación de las Aguas del Rio Chili a Nivel de Laboratorio; Universidad Nacional de San Agustín de Arequipa: Arequipa, Peru, 2017. [Google Scholar]

- Gyawali, B.; Haghnazar, R.; Akula, P.; Alba, K.; Nasir, V. A review on 3D printing with clay and sawdust/natural fibers: Printability, rheology, properties, and applications. Results Eng. 2024, 24, 103024. [Google Scholar] [CrossRef]

- Liu, Z.; Jin, X.; Zhang, Y.; Jiang, J. Numerical simulation of the effective thermal conductivity of cement-based composites: Microscopic insights into diatomite/silica aerogel. Mater. Des. 2023, 233, 112281. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, M.; Zhong, X.; Huang, Y.; Yang, L.; Zhao, P.; Wang, S.; Lu, L.; Cheng, X. Effects of bentonite, diatomite and metakaolin on the rheological behavior of 3D printed magnesium potassium phosphate cement composites. Addit. Manuf. 2021, 46, 102184. [Google Scholar] [CrossRef]

- Liu, Q.; Jiang, Q.; Zhao, H.; Yu, Y.; Zhao, T. Porous diatomite promotes lightweight and low-carbon concrete 3D printing: An exploratory study. J. Build. Eng. 2025, 103, 112071. [Google Scholar] [CrossRef]

Figure 1.

TEMPO thermal properties analyzer with the SH3 device.

Figure 1.

TEMPO thermal properties analyzer with the SH3 device.

Figure 2.

Extrusion system and curve behavior according to the study by Varlea H. and Barulenga G. [

14].

Figure 2.

Extrusion system and curve behavior according to the study by Varlea H. and Barulenga G. [

14].

Figure 3.

Three-dimensional printer for ceramic paste.

Figure 3.

Three-dimensional printer for ceramic paste.

Figure 4.

Thermal conductivity graph of each developed ceramic paste.

Figure 4.

Thermal conductivity graph of each developed ceramic paste.

Figure 5.

Extrusion stress and displacement of ceramic paste samples P0, P1, P2, and P3.

Figure 5.

Extrusion stress and displacement of ceramic paste samples P0, P1, P2, and P3.

Figure 6.

Thermogravimetric analysis of samples P0, P1, P2 and P3.

Figure 6.

Thermogravimetric analysis of samples P0, P1, P2 and P3.

Figure 7.

Differential scanning calorimetry analysis of samples P0, P1, P2 and P3.

Figure 7.

Differential scanning calorimetry analysis of samples P0, P1, P2 and P3.

Figure 8.

(a) EDS spectrum of sample P3 and (b) SEM of sample P3.

Figure 8.

(a) EDS spectrum of sample P3 and (b) SEM of sample P3.

Figure 9.

SEM analysis results: (a) radial-type diatomite and (b) naviculoid-type diatomite.

Figure 9.

SEM analysis results: (a) radial-type diatomite and (b) naviculoid-type diatomite.

Figure 10.

SEM analysis results for ceramic paste P3 (a) micrograph of sample P3, (b) agglomerates of carboxymethyl cellulose, (c,d) grouped particles and laminar shapes typical of kaolinite.

Figure 10.

SEM analysis results for ceramic paste P3 (a) micrograph of sample P3, (b) agglomerates of carboxymethyl cellulose, (c,d) grouped particles and laminar shapes typical of kaolinite.

Figure 11.

Rheological results: shear stress vs. strain.

Figure 11.

Rheological results: shear stress vs. strain.

Figure 12.

Extrusion of ceramic paste P2: (a) initial layer formation, (b) continued layering, (c) completed structure.

Figure 12.

Extrusion of ceramic paste P2: (a) initial layer formation, (b) continued layering, (c) completed structure.

Figure 13.

Comparison between printed pieces P0 and P2.

Figure 13.

Comparison between printed pieces P0 and P2.

Table 1.

Preparation of ceramic pastes. Experimental design.

Table 1.

Preparation of ceramic pastes. Experimental design.

| Sample | Solid Mixture |

|---|

| Diatomite (% By Weight) | Kaolin (% By Weight) | Feldspar (% By Weight) |

|---|

| P0 | 0 | 50 | 50 |

| P1 | 10 | 45 | 45 |

| P2 | 30 | 35 | 35 |

| P3 | 60 | 20 | 20 |

Table 2.

Printing parameters.

Table 2.

Printing parameters.

| Parameter | Value |

|---|

| Printing speed | 5.0 mm/s |

| Infill speed | 8.0 mm/s |

| Travel speed | 120 mm/s |

| Initial layer height | 2.8 mm |

Table 3.

Thermal conductivity of the developed ceramic pastes.

Table 3.

Thermal conductivity of the developed ceramic pastes.

| | [] | [] | [] | [] |

|---|

| Replica 1 | 0.702 | 0.768 | 0.617 | 0.523 |

| Replica 2 | 0.723 | 0.713 | 0.594 | 0.495 |

| Replica 3 | 0.732 | 0.707 | 0.613 | 0.529 |

| Average | 0.719 ± 0.01 | 0.729 ± 0.03 | 0.608 ± 0.01 | 0.515 ± 0.01 |

Table 4.

Extrusion behavior and stress (MPa) in the EXT test.

Table 4.

Extrusion behavior and stress (MPa) in the EXT test.

| Sample | Adequate Extrusion | Stress (MPa) |

|---|

|

P0

|

No

|

2.53

|

|

P1

|

No

|

2.62

|

|

P2

|

Yes

|

3.8

|

|

P3

|

Yes

|

8.59

|

| Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).