Effects of the Processing Technology of CVD-ZnSe, Cr2+:ZnSe, and Fe2+:ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively Pulsed Laser at 2.1 µm

Abstract

:1. Introduction

2. Materials: ZnSe, Cr2+:ZnSe and Fe2+:ZnSe

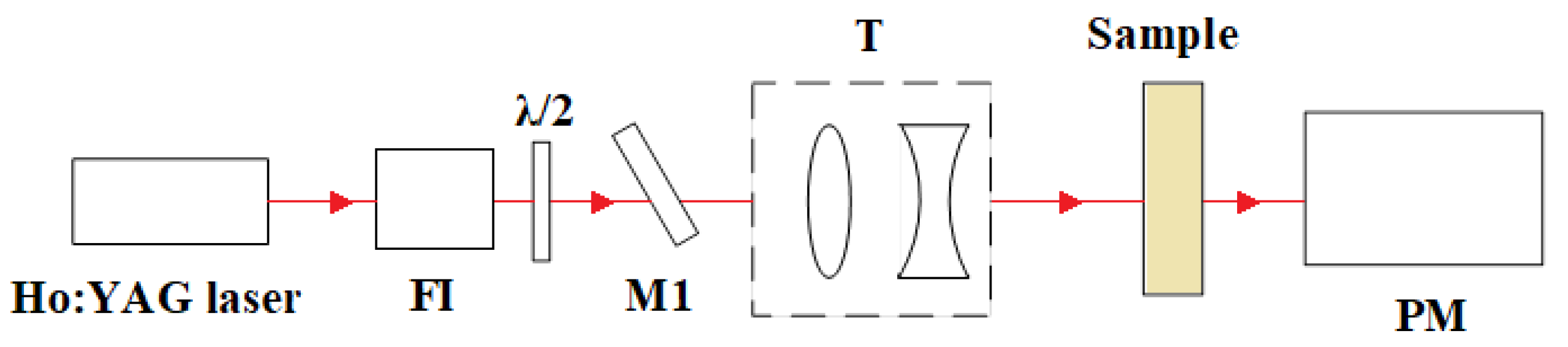

3. Experimental Setup

4. LIDT Test Method

5. Results

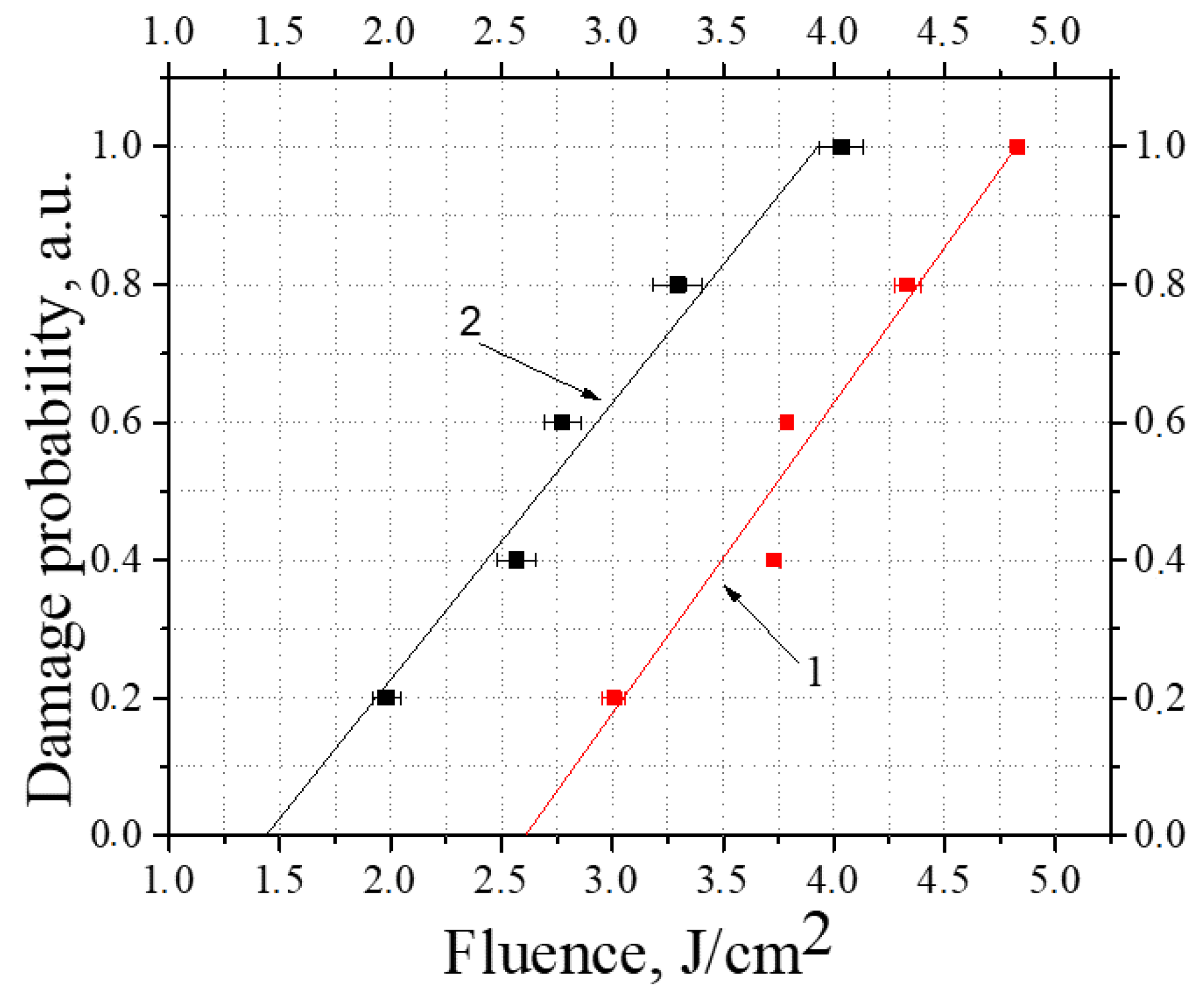

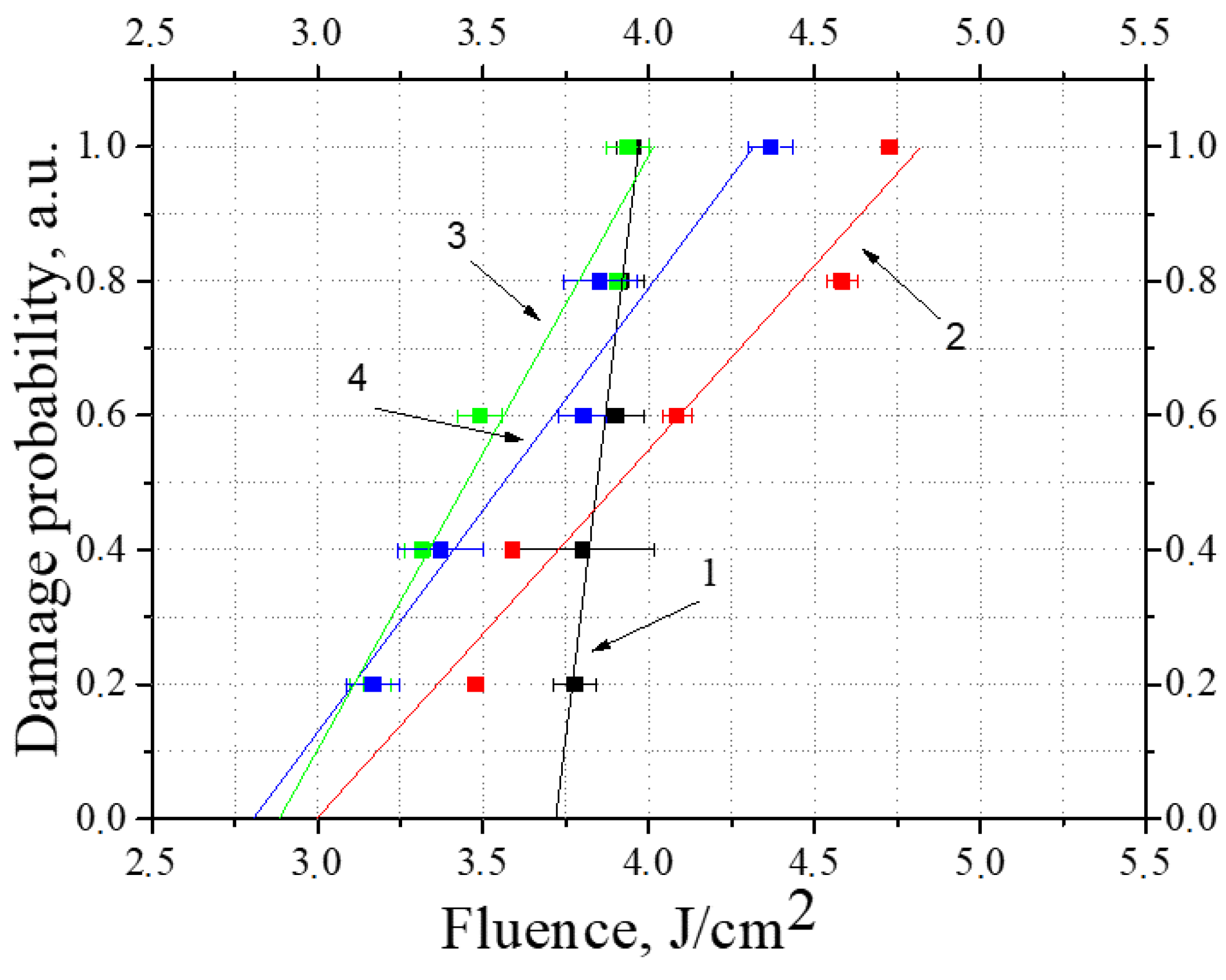

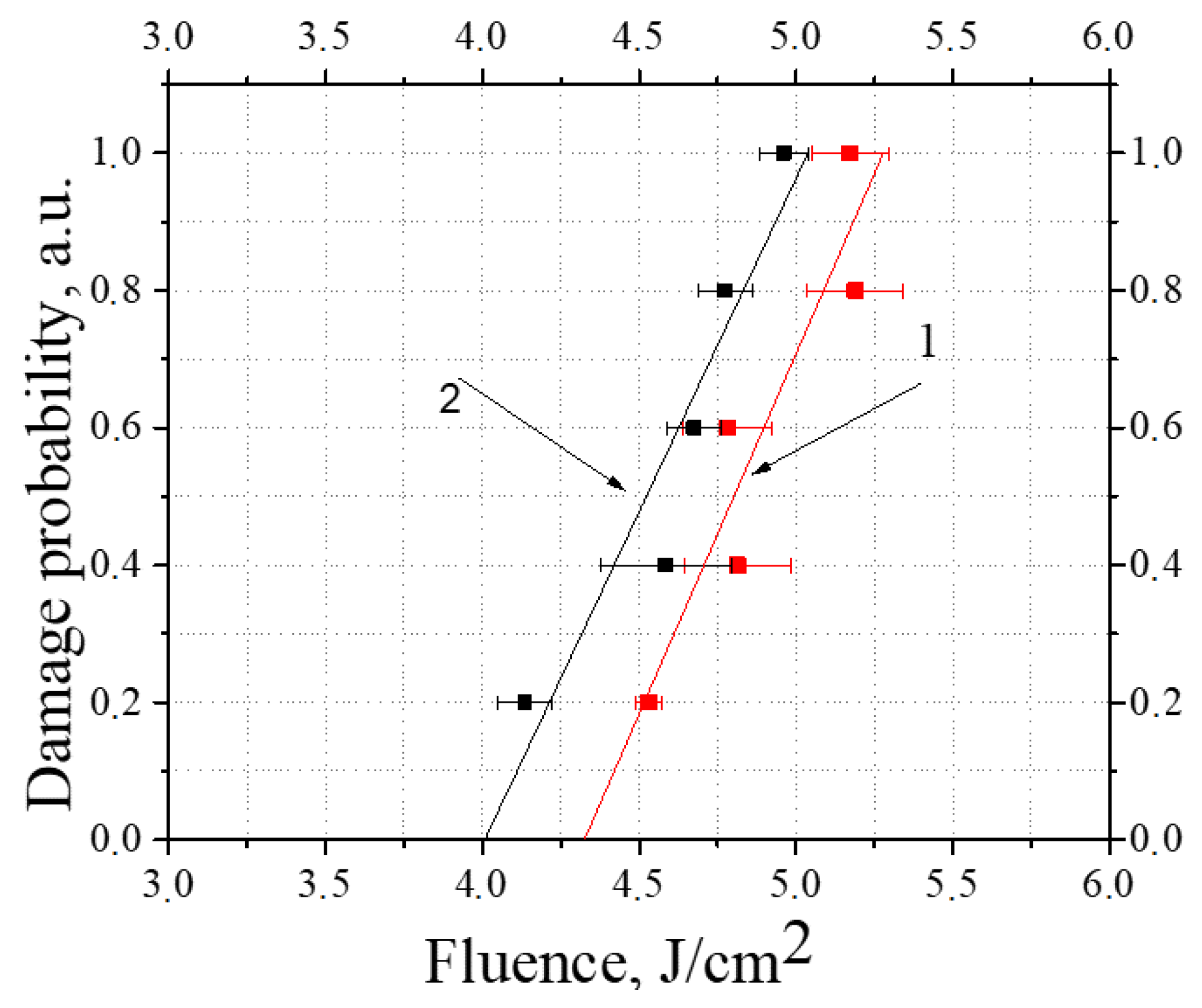

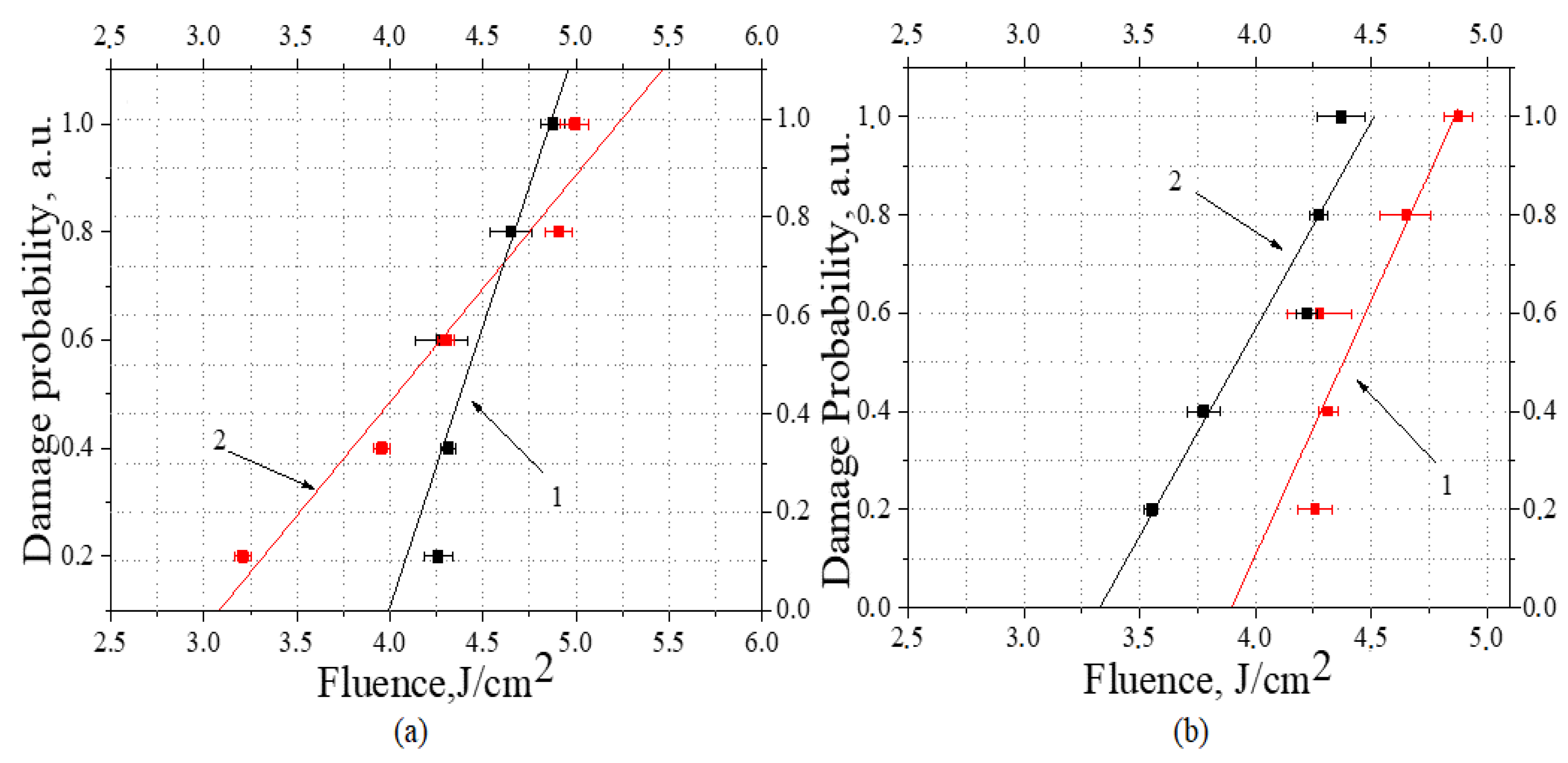

5.1. Optical Damage of ZnSe

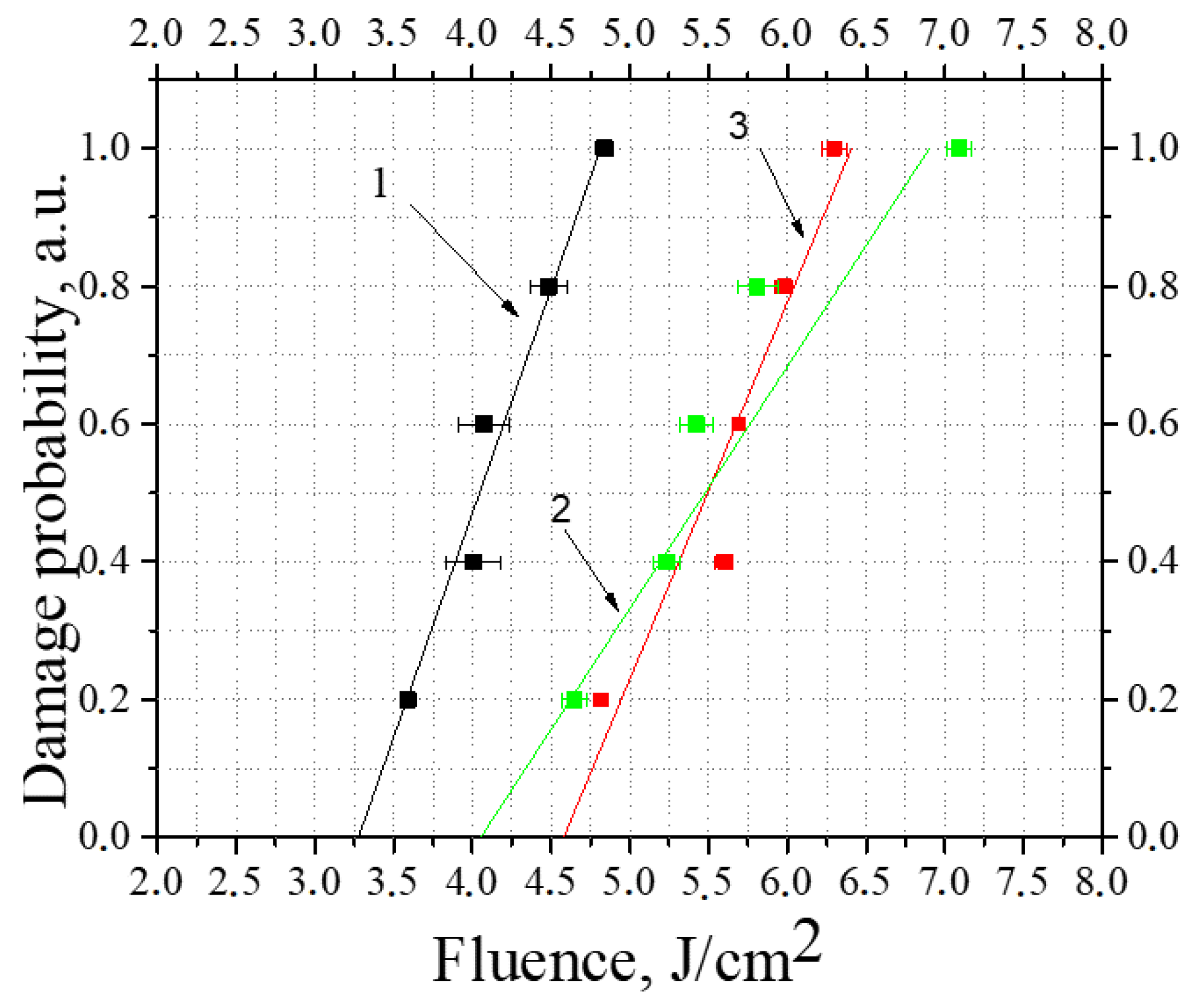

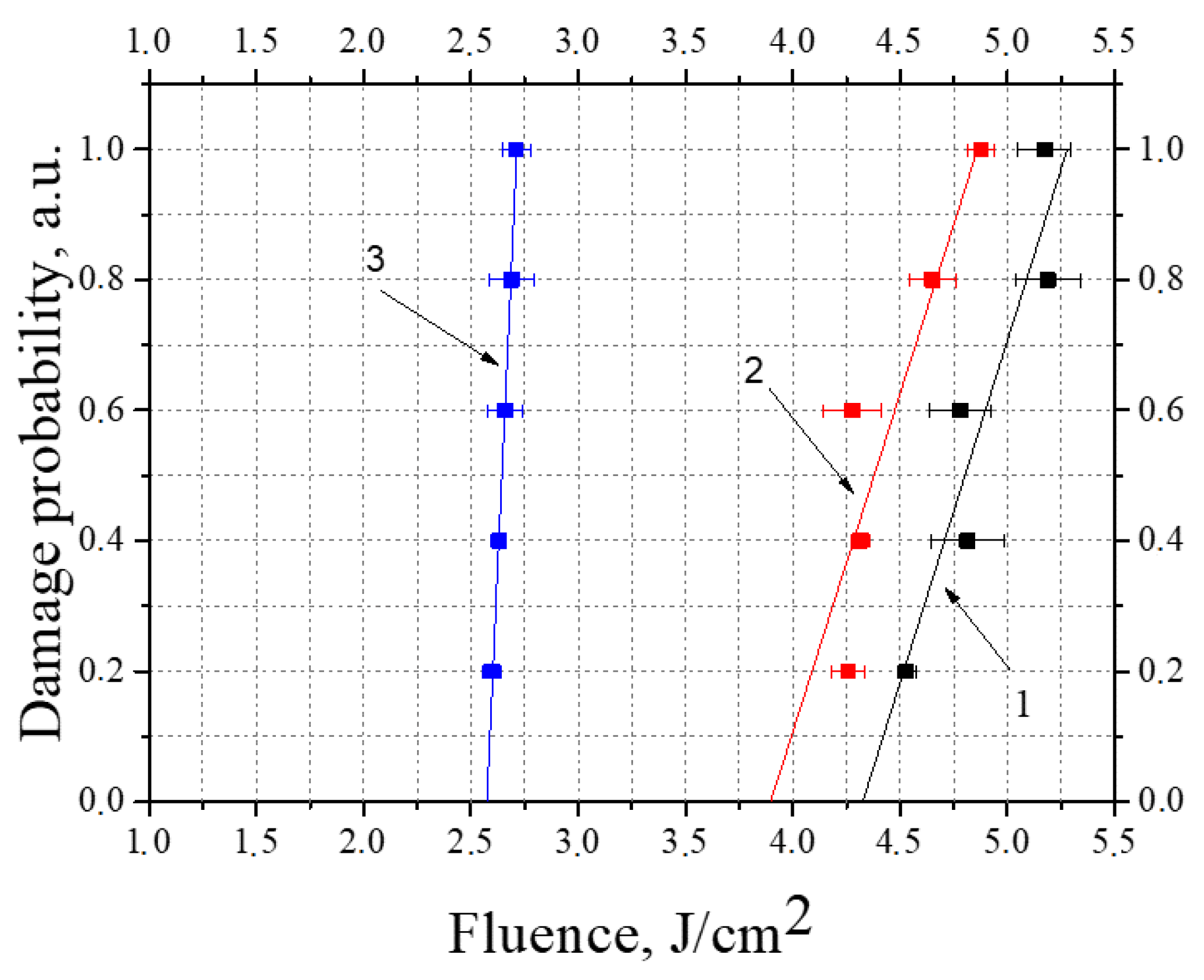

5.2. Optical Damage of Cr2+:ZnSe and Fe2+:ZnSe

6. Discussion

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Harris, D.C. Development of Hot-Pressed and Chemical-Vapor-Deposited Zinc Sulfide and Zinc Selenide in the United States for Optical Windows; Tustison, R.W., Ed.; SPIE: Bellingham, WA, USA, 2007; p. 654502. [Google Scholar]

- DeLoach, L.D.; Page, R.H.; Wilke, G.D.; Payne, S.A.; Krupke, W.F. Transition metal-doped zinc chalcogenides: Spectroscopy and laser demonstration of a new class of gain media. IEEE J. Quantum Electron. 1996, 32, 885–895. [Google Scholar] [CrossRef]

- Lewis, K.L.; Arthur, G.S. Surface and Free Carrier Absorption Processes in CVD Zinc Selenide. In Laser Induced Damage in Optical Materials: 1982; Bennett, H.E., Ed.; U.S. Government Printing Office Washington: Boulder, CO, USA, 1984; pp. 86–101. [Google Scholar]

- Gavrushchuk, E.M. Polycrystalline Zinc Selenide for IR Optical Applications. Inorg. Mater. 2003, 39, 883–899. [Google Scholar] [CrossRef]

- Mirov, S.B.; Moskalev, I.S.; Vasilyev, S.; Smolski, V.; Fedorov, V.V.; Martyshkin, D.; Peppers, J.; Mirov, M.; Dergachev, A.; Gapontsev, V. Frontiers of Mid-IR Lasers Based on Transition Metal Doped Chalcogenides. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 1–29. [Google Scholar] [CrossRef]

- Taylor, R.L.; Goela, J.S. Specification Of Infrared Optical Materials For Laser Applications; Fischer, R.E., Smith, W.J., Eds.; SPIE: Bellingham, WA, USA, 1986; p. 22. [Google Scholar] [CrossRef]

- Ristau, D. (Ed.) Laser-Induced Damage in Optical Materials; CRC Press: Boca Raton, FL, USA, 2014; ISBN 9781439872178. [Google Scholar] [CrossRef]

- Manenkov, A.A.; Prokhorov, A.M. Laser-induced damage in solids. Sov. Phys. Uspekhi 1986, 29, 104–122. [Google Scholar] [CrossRef]

- Kovalev, V.I.; Faizullov, F.S. Investigation of surface breakdown mechanism in IR-optical materials. In Laser Induced Damage in Optical Materials; ASTM International: West Conshohocken, PA, UA, 1978; p. 318. [Google Scholar]

- Benson, S.; Szarmes, E.; Hooper, B.; Dottery, E.; Madey, J. Laser Damage on Zinc Selenide and Cadmium Telluride Using the Stanford Mark III Infrared Free Electron Laser. In Laser Induced Damage in Optical Materials: 1987; ASTM International: West Conshohocken, PA, USA, 1988; pp. 41–49. [Google Scholar] [CrossRef]

- Haas, C.R.; Kreutz, E.-W.; Wesner, D.A. Damage to Coated ZnSe Optical Components by High-Power CO2 Laser Radiation; Bennett, H.E., Chase, L.L., Guenther, A.H., Newnam, B.E., Soileau, M.J., Eds.; SPIE: Bellingham, WA, USA, 1994; p. 732. [Google Scholar] [CrossRef]

- Lefranc, S.; Kudriavtsev, E.M.; Autric, M.L. Pulsed-Laser-Induced Damage in Semiconductors Ge, ZnS, and ZnSe at 10.6 um; Exarhos, G.J., Guenther, A.H., Kozlowski, M.R., Soileau, M.J., Eds.; SPIE: Bellingham, WA, USA, 1998; p. 605. [Google Scholar] [CrossRef]

- Krol, H.; Grèzes-Besset, C.; Gallais, L.; Natoli, J.-Y.; Commandré, M. Study of Laser-Induced Damage at 2 Microns on Coated and Uncoated ZnSe Substrates; Exarhos, G.J., Guenther, A.H., Lewis, K.L., Ristau, D., Soileau, M.J., Stolz, C.J., Eds.; SPIE: Bellingham, WA, USA, 2006; p. 640316. [Google Scholar] [CrossRef]

- Hobbs, D.; Macleod, B.; Sabatino, E.; Mirov, S.; Martyshkin, D.; Mirov, M.; Tsoi, G.; McDaniel, S.; Cook, G. Laser testing of anti-reflection micro-structures fabricated in ZnSe and chromium-ion doped ZnSe laser gain media. Opt. Mater. Express 2017, 7, 3377. [Google Scholar] [CrossRef]

- Hobbs, D.S.; MacLeod, B.D.; Sabatino, E.; Mirov, S.B.; Martyshkin, D.V. Laser Damage Resistant Anti-Reflection Microstructures for Mid-Infrared Metal-Ion Doped ZnSe Gain Media; Exarhos, G.J., Gruzdev, V.E., Menapace, J.A., Ristau, D., Soileau, M.J., Eds.; SPIE: Bellingham, WA, USA, 2012; p. 85300P. [Google Scholar] [CrossRef]

- McDaniel, S.; Hobbs, D.; MacLeod, B.; Sabatino, E.; Berry, P.; Schepler, K.; Mitchell, W.; Cook, G. Cr:ZnSe laser incorporating anti-reflection microstructures exhibiting low-loss, damage-resistant lasing at near quantum limit efficiency. Opt. Mater. Express 2014, 4, 2225. [Google Scholar] [CrossRef]

- Timofeeva, N.A.; Gavrishchuk, E.M.; Savin, D.V.; Rodin, S.A.; Kurashkin, S.V.; Ikonnikov, V.B.; Tomilova, T.S. Fe2+ Diffusion in CVD ZnSe during Annealing in Different (Ar, Zn, and Se) Atmospheres. Inorg. Mater. 2019, 55, 1201–1205. [Google Scholar] [CrossRef]

- Yudin, N.; Antipov, O.; Eranov, I.; Gribenyukov, A.; Verozubova, G.; Lei, Z.; Zinoviev, M.; Podzvalov, S.; Slyunko, E.; Voevodin, V.; et al. Laser-Induced Damage Threshold of Single Crystal ZnGeP2 at 2.1 µm: The Effect of Crystal Lattice Quality at Various Pulse Widths and Repetition Rates. Crystals 2022, 12, 652. [Google Scholar] [CrossRef]

- ISO 11146-1:2021. Lasers and Laser-Related Equipment—Test Methods for Laser Beam Widths, Divergence Angles and Beam Propagation Ratios. International Organization for Standardization: Geneva, Switzerland, 2005; p. 11146-2.

- Hue, J.; Garrec, P.; DiJon, J.; Lyan, P. R-on-1 Automatic Mapping: A New Tool for Laser Damage Testing; Bennett, H.E., Guenther, A.H., Kozlowski, M.R., Newnam, B.E., Soileau, M.J., Eds.; SPIE: Bellingham, WA, USA, 1996; p. 90. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Kieleck, C.; Tyazhev, A.; Marchev, G.; Stöppler, G.; Eichhorn, M.; Schunemann, P.G.; Panyutin, V.L.; Petrov, V. Laser damage of the nonlinear crystals CdSiP2 and ZnGeP2 studied with nanosecond pulses at 1064 and 2090 nm. Opt. Eng. 2014, 53, 122511. [Google Scholar] [CrossRef]

- Yudin, N.N.; Antipov, O.L.; Gribenyukov, A.I.; Eranov, I.D.; Podzyvalov, S.N.; Zinoviev, M.M.; Voronin, L.A.; Zhuravleva, E.V.; Zykova, M.P. Effect of postgrowth processing technology and laser radiation parameters at wavelengths of 2091 and 1064 nm on the laser-induced damage threshold in ZnGeP2 single crystal. Quantum Electron. 2021, 51, 306–316. [Google Scholar] [CrossRef]

- ISO 2602:1980. Statistical Interpretation of Test Results—Estimation of the Mean—Confidence Interval. International Organization for Standardization: Geneva, Switzerland, 1980.

- Sun, Z.; Lenzner, M.; Rudolph, W. Generic incubation law for laser damage and ablation thresholds. J. Appl. Phys. 2015, 117, 073102. [Google Scholar] [CrossRef]

- Chen, M.; Cui, H.; Li, W.; Kou, H.; Li, J.; Pan, Y.; Jiang, B. Reparative effect of diffusion process on host defects in Cr2+ doped ZnS/ZnSe. J. Alloys Compd. 2014, 597, 124–128. [Google Scholar] [CrossRef]

- Gladilin, A.A.; Chentsov, S.I.; Mironov, S.A.; Uvarov, O.V.; Ilichev, N.N.; Studenikin, M.I.; Gavrischuk, E.M.; Timofeeva, N.A.; Aminev, D.F.; Kalinushkin, V.P. Effect of Zinc Atmosphere upon Doping ZnSe: Fe Crystals on the Composition and Distribution of Impurity-Defect Centers. Bull. Lebedev Phys. Inst. 2020, 47, 237–243. [Google Scholar] [CrossRef]

- Morozova, N.K.; Karetnikov, I.A.; Blinov, V.V.; Gavrishchuk, E.M. A study of luminescence centers related to copper and oxygen in ZnSe. Semiconductors 2001, 35, 24–32. [Google Scholar] [CrossRef]

- Brodyn, M.S.; Degoda, V.Y.; Alizadeh, M.; Podust, G.P.; Pavlova, N.Y.; Kozhushko, B.V. Deep traps concentrations in ZnSe single crystals. Mater. Sci. Eng. B 2020, 258, 114570. [Google Scholar] [CrossRef]

- Degoda, V.Y.; Podust, G.P.; Doroshenko, I.Y.; Pavlova, N.Y. Phosphorescence and conduction current relaxation in ZnSe crystals. Opt. Mater. 2022, 129, 112460. [Google Scholar] [CrossRef]

- Fürtjes, P.; Tomm, J.W.; Griebner, U.; Steinmeyer, G.; Balabanov, S.S.; Gavrishchuk, E.M.; Elsaesser, T. Kinetics of excitation transfer from Cr2+ to Fe2+ ions in co-doped ZnSe. Opt. Lett. 2022, 47, 2129. [Google Scholar] [CrossRef]

- Hexkicberg, M.M.; Stevexsok, A. Self-diffusion of Zn and Se in ZnSe. Phys. Status Solidi 1971, 48, 255–269. [Google Scholar] [CrossRef]

- Mironov, E.A.; Palashov, O.V.; Balabanov, S.S. High-purity CVD-ZnSe polycrystal as a magneto-active medium for a multikilowatt Faraday isolator. Opt. Lett. 2021, 46, 2119. [Google Scholar] [CrossRef]

- Klein, C.A.; Miller, R.P.; Stierwalt, D.L. Surface and bulk absorption characteristics of chemically vapor-deposited zinc selenide in the infrared. Appl. Opt. 1994, 33, 4304. [Google Scholar] [CrossRef]

- Balabanov, S.S.; Gavrishchuk, E.M.; Gladilin, A.A.; Ikonnikov, V.B.; Il’ichev, N.N.; Kalinushkin, V.P.; Mironov, S.A.; Savin, D.V.; Studenikin, M.I.; Timofeeva, N.A.; et al. Spatial Distribution of Impurity Defect Centers in Fe-Doped Polycrystalline Zinc Selenide. Inorg. Mater. 2019, 55, 423–431. [Google Scholar] [CrossRef]

- Gavrishchuk, E.M.; Gladilin, A.A.; Danilov, V.P.; Ikonnikov, V.B.; Il’ichev, N.N.; Kalinushkin, V.P.; Ryabova, A.V.; Studenikin, M.I.; Timofeeva, N.A.; Uvarov, O.V.; et al. Distribution of luminescence centers in the bulk of undoped, Fe-doped, and Cr-doped CVD ZnSe polycrystals studied by two-photon confocal microscopy. Inorg. Mater. 2016, 52, 1108–1114. [Google Scholar] [CrossRef]

| Sample | f, kHz | N | <ΔWav2 > 1/2 J/cm2 | K | Wav, J/cm2 | W0d, J/cm2 |

|---|---|---|---|---|---|---|

| ZnSe_org | 12 | 5 | 0.05 | 2.8 | (4.2 ± 0.14) | (3.28 ± 0.06) |

| ZnSe_Se | 12 | 5 | 0.09 | 2.8 | (4.9 ± 0.3) | (3.6 ± 0.3) |

| ZnSe_Zn | 12 | 5 | 0.01 | 2.8 | (3.45 ± 0.03) | (3.01 ± 0.03) |

| ZnSe_Ar | 12 | 5 | 0.02 | 2.8 | (4.89 ± 0.06) | (4.32 ± 0.06) |

| Sample | f, kHz | N | <ΔWav2 > 1/2, J/cm2 | K | Wav, J/cm2 | W0d, J/cm2 |

|---|---|---|---|---|---|---|

| ZnSe_Ar | 12 | 5 | 0.02 | 2.8 | (4.89 ± 0.06) | (4.32 ± 0.06) |

| ZnSe_Ar | 16 | 5 | 0.02 | 2.8 | (4.63 ± 0.06) | (4.01 ± 0.06) |

| ZnSe_org | 12 | 5 | 0.02 | 2.8 | (4.19 ± 0.04) | (3.43 ± 0.04) |

| ZnSe_org | 16 | 5 | 0.02 | 2.8 | (4.46 ± 0.02) | (4.044 ± 0.02) |

| ZnSe_Se | 12 | 5 | 0.02 | 2.8 | (4.85 ± 0.06) | (3.78 ± 0.06) |

| ZnSe_Se | 16 | 5 | 0.02 | 2.8 | (4.86 ± 0.02) | (4.5 ± 0.02) |

| ZnSe_Zn | 12 | 5 | 0.02 | 2.8 | (3.44 ± 0.02) | (3.09 ± 0.02) |

| ZnSe_Zn | 16 | 5 | 0.02 | 2.8 | (3.51 ± 0.03) | (2.99 ± 0.03) |

| Sample | f, kHz | N | <ΔWav2 > 1/2, J/cm2 | K | WD, J/cm2 | W0d, J/cm2 |

|---|---|---|---|---|---|---|

| ZnSe_Ar | 12 | 5 | 0.02 | 2.8 | (4.89 ± 0.06) | (4.32 ± 0.06) |

| Fe2+:ZnSe_Ar | 12 | 5 | 0.02 | 2.8 | (4.47 ± 0.06) | (3.89 ± 0.06) |

| Cr2+:ZnSe_Ar | 12 | 5 | 0.001 | 2.8 | (2.658 ± 0.001) | (2.577 ± 0.001) |

| Cr2+:ZnSe_Se | 12 | 5 | 0.03 | 2.8 | (2.31 ± 0.03) | (1.82 ± 0.08) |

| Cr2+:ZnSe_Zn | 12 | 5 | 0.01 | 2.8 | (2.82 ± 0.03) | (2.6 ± 0.03) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yudin, N.; Antipov, O.; Balabanov, S.; Eranov, I.; Getmanovskiy, Y.; Slyunko, E. Effects of the Processing Technology of CVD-ZnSe, Cr2+:ZnSe, and Fe2+:ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively Pulsed Laser at 2.1 µm. Ceramics 2022, 5, 459-471. https://doi.org/10.3390/ceramics5030035

Yudin N, Antipov O, Balabanov S, Eranov I, Getmanovskiy Y, Slyunko E. Effects of the Processing Technology of CVD-ZnSe, Cr2+:ZnSe, and Fe2+:ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively Pulsed Laser at 2.1 µm. Ceramics. 2022; 5(3):459-471. https://doi.org/10.3390/ceramics5030035

Chicago/Turabian StyleYudin, Nikolay, Oleg Antipov, Stanislav Balabanov, Ilya Eranov, Yuri Getmanovskiy, and Elena Slyunko. 2022. "Effects of the Processing Technology of CVD-ZnSe, Cr2+:ZnSe, and Fe2+:ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively Pulsed Laser at 2.1 µm" Ceramics 5, no. 3: 459-471. https://doi.org/10.3390/ceramics5030035

APA StyleYudin, N., Antipov, O., Balabanov, S., Eranov, I., Getmanovskiy, Y., & Slyunko, E. (2022). Effects of the Processing Technology of CVD-ZnSe, Cr2+:ZnSe, and Fe2+:ZnSe Polycrystalline Optical Elements on the Damage Threshold Induced by a Repetitively Pulsed Laser at 2.1 µm. Ceramics, 5(3), 459-471. https://doi.org/10.3390/ceramics5030035