Unconventional Materials Processing Using Spark Plasma Sintering

Abstract

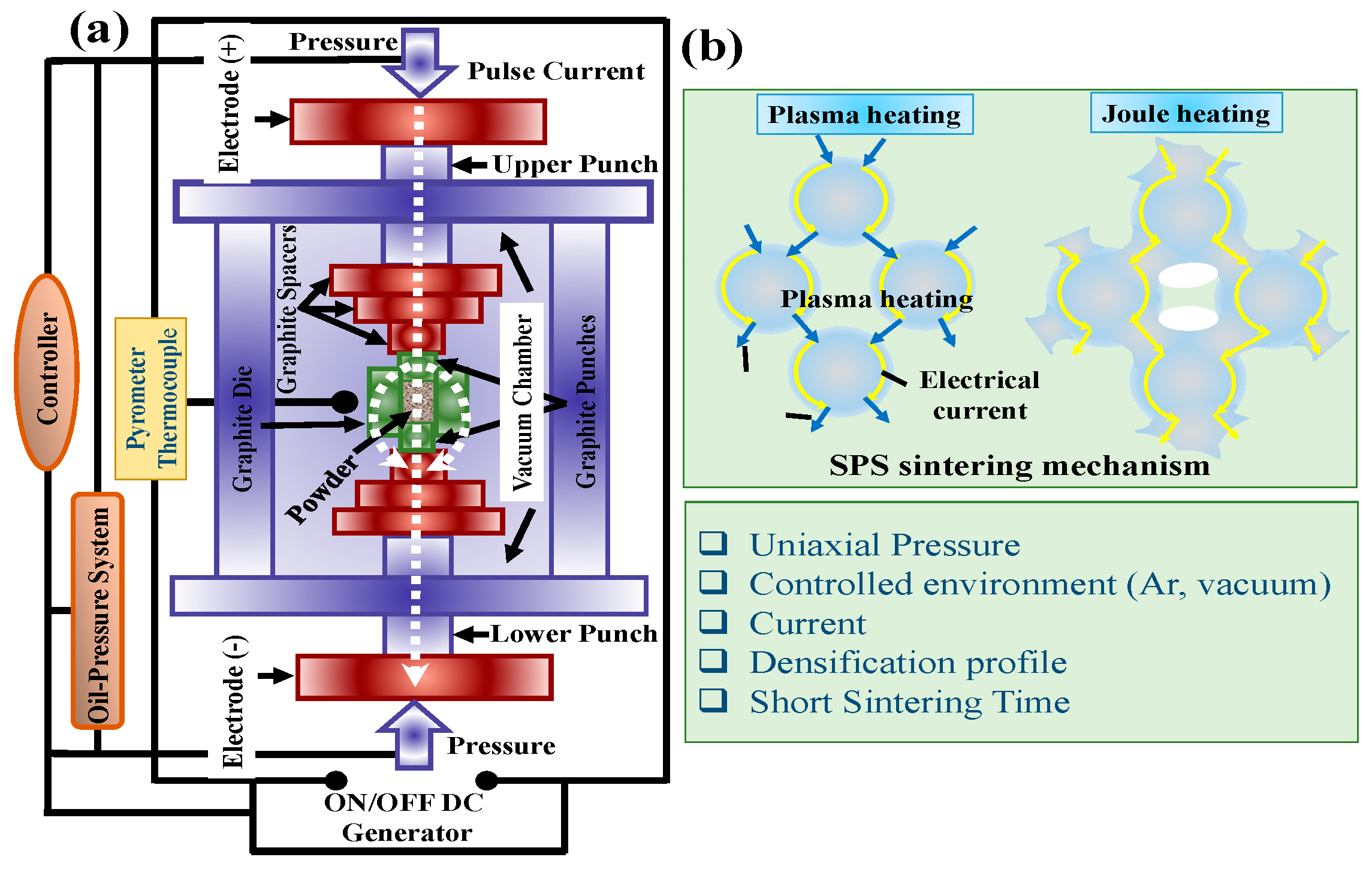

1. Introduction

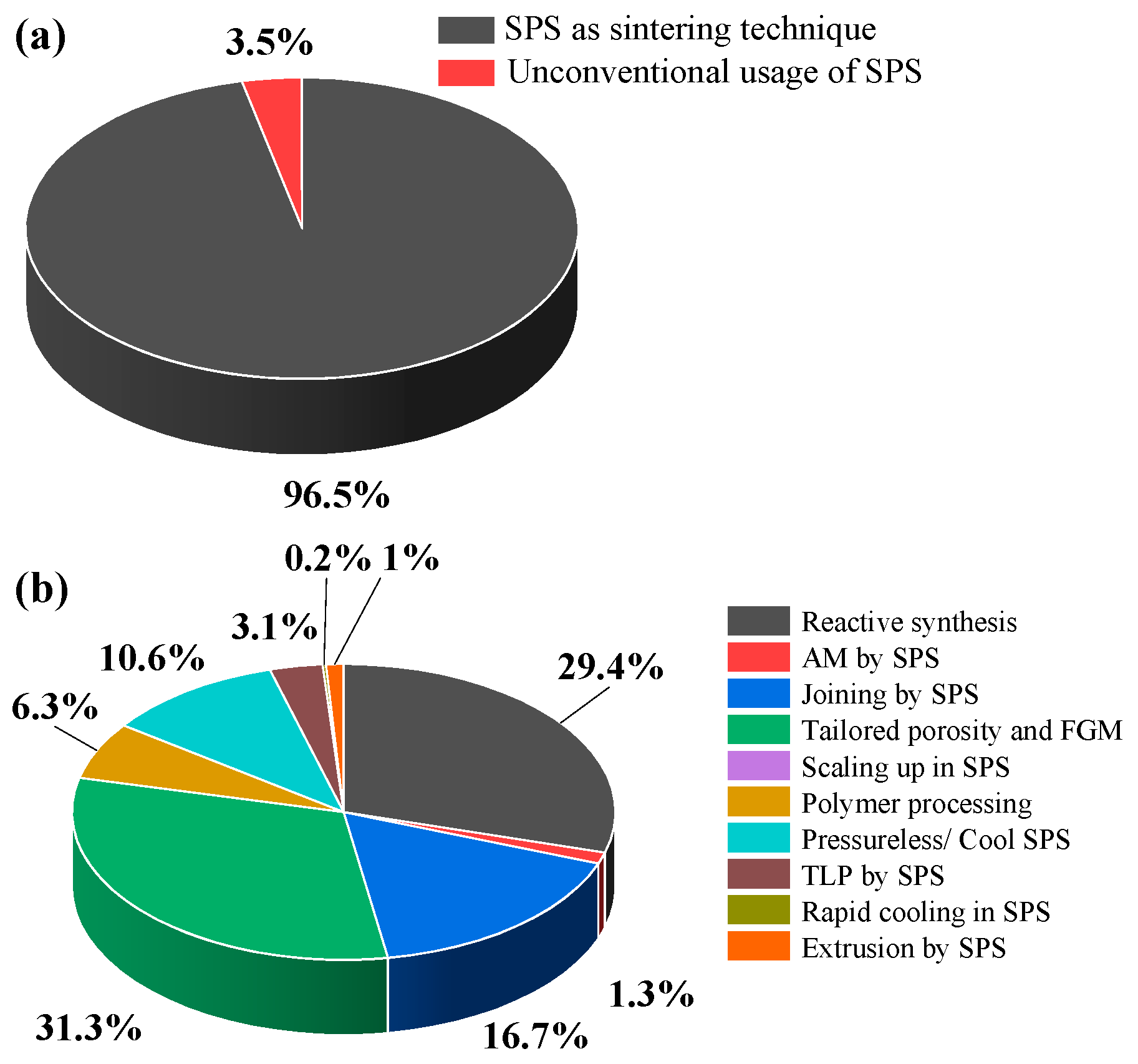

2. Unconventional Applications of SPS

2.1. Reactive Synthesis by SPS

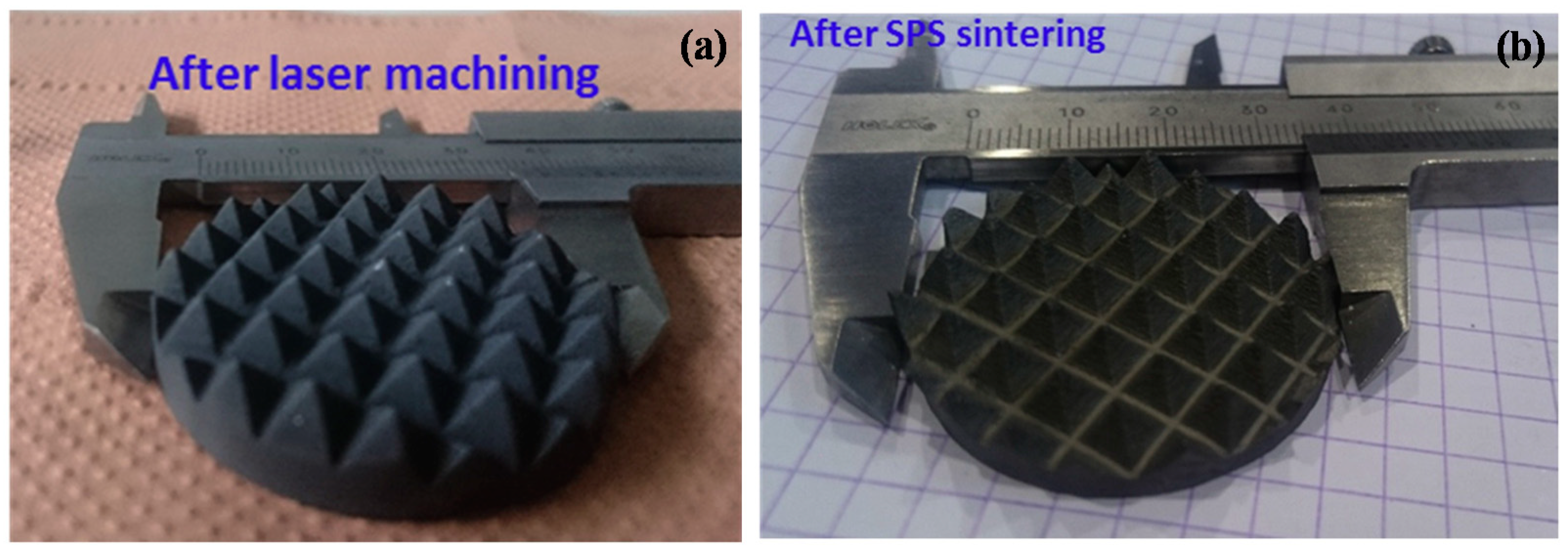

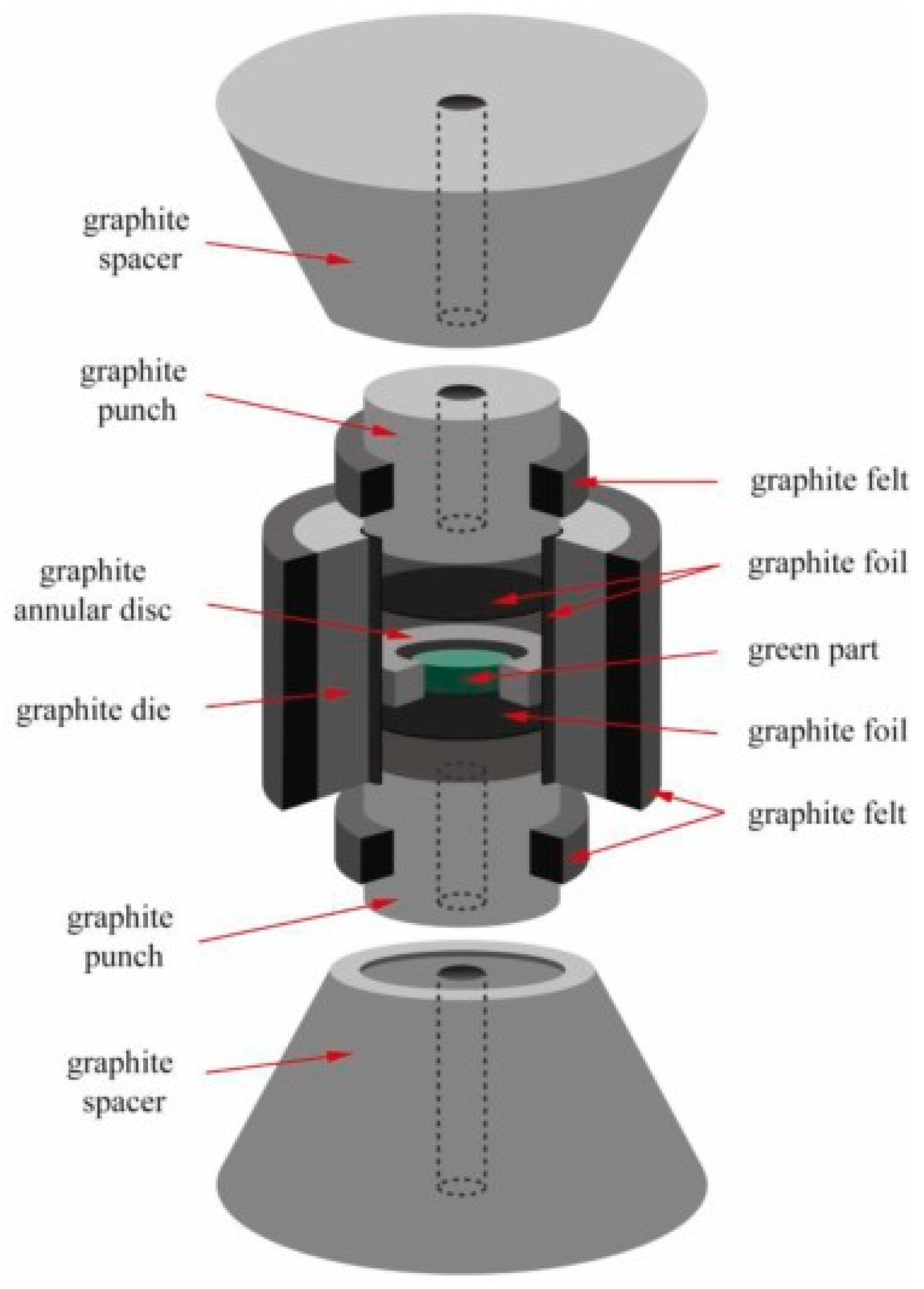

2.2. Additive Manufacturing by SPS

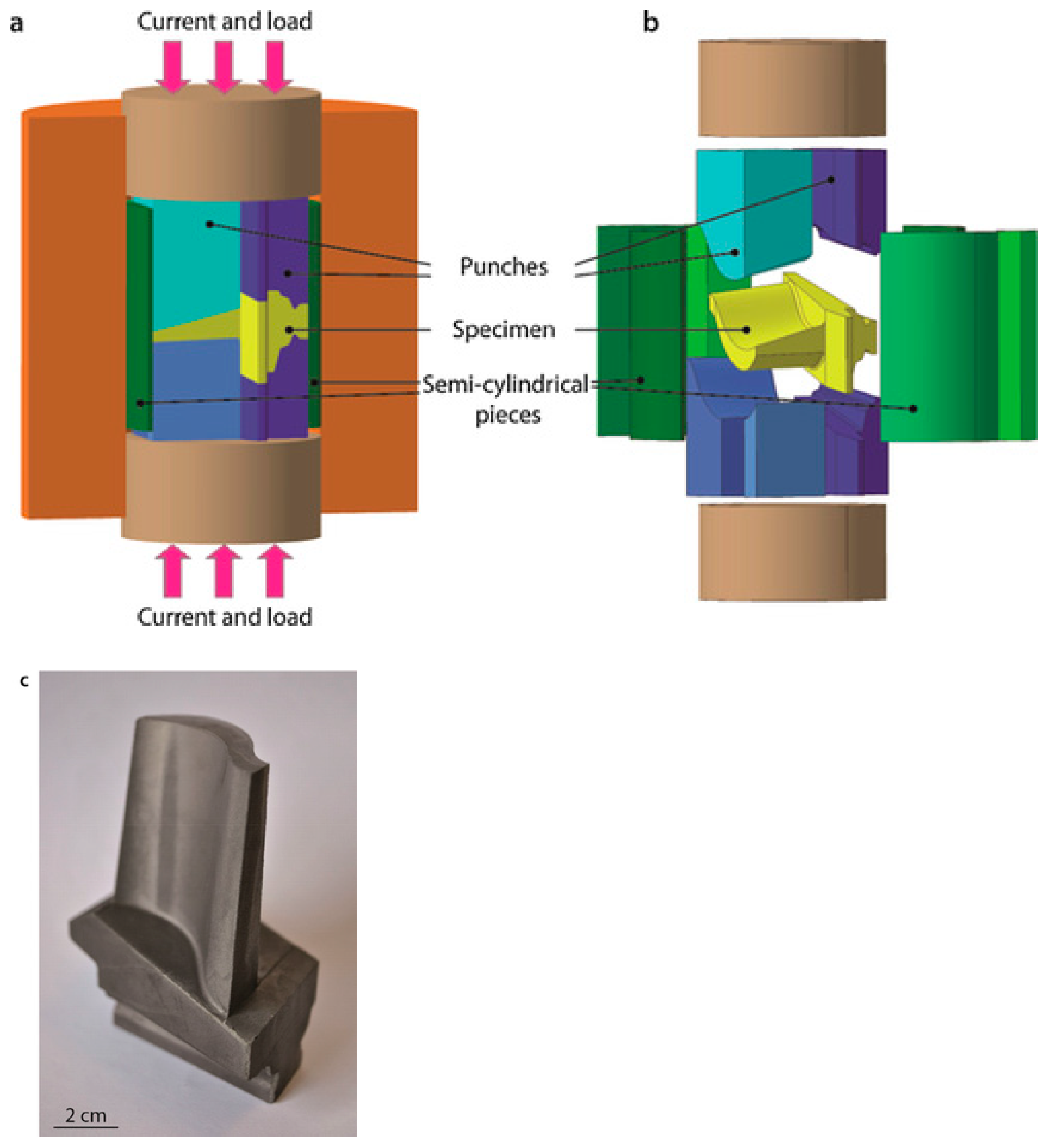

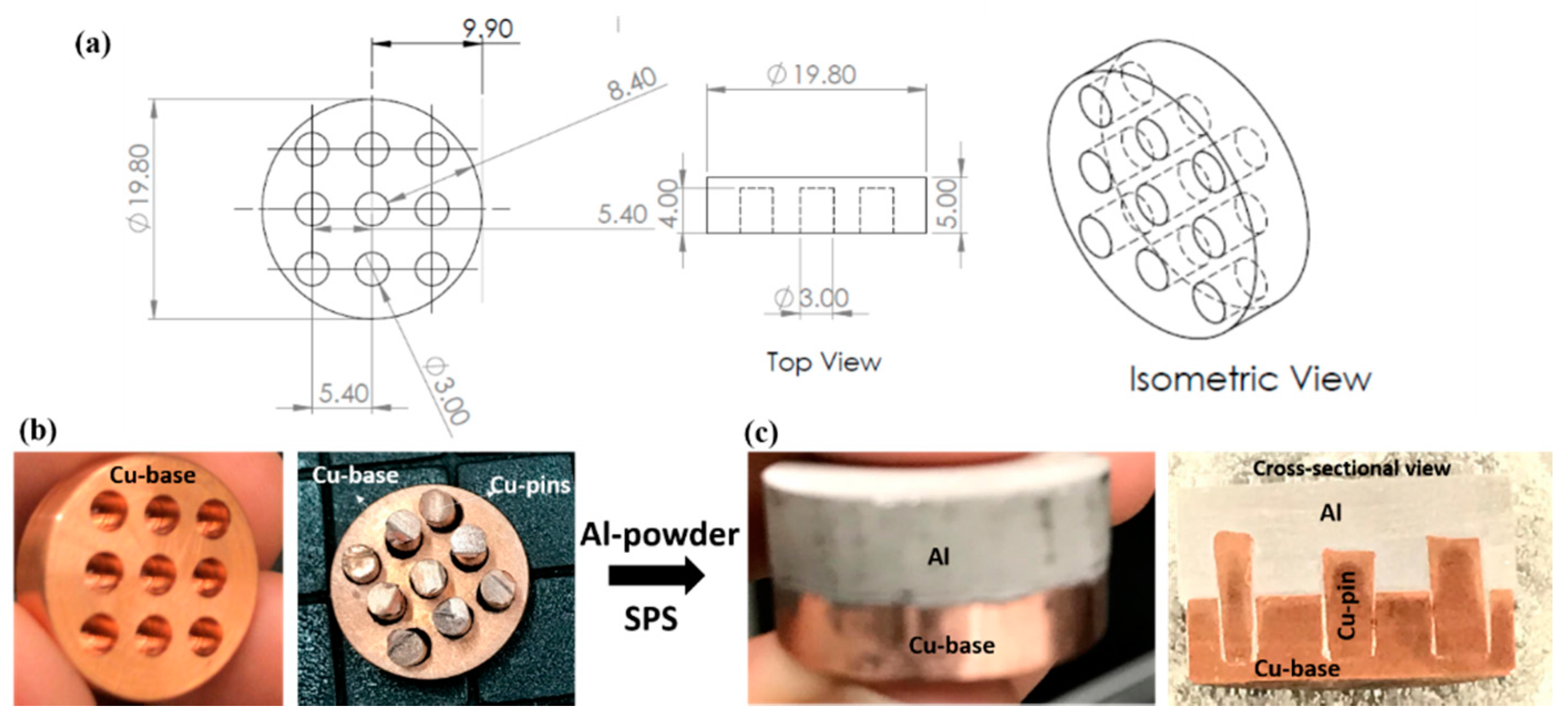

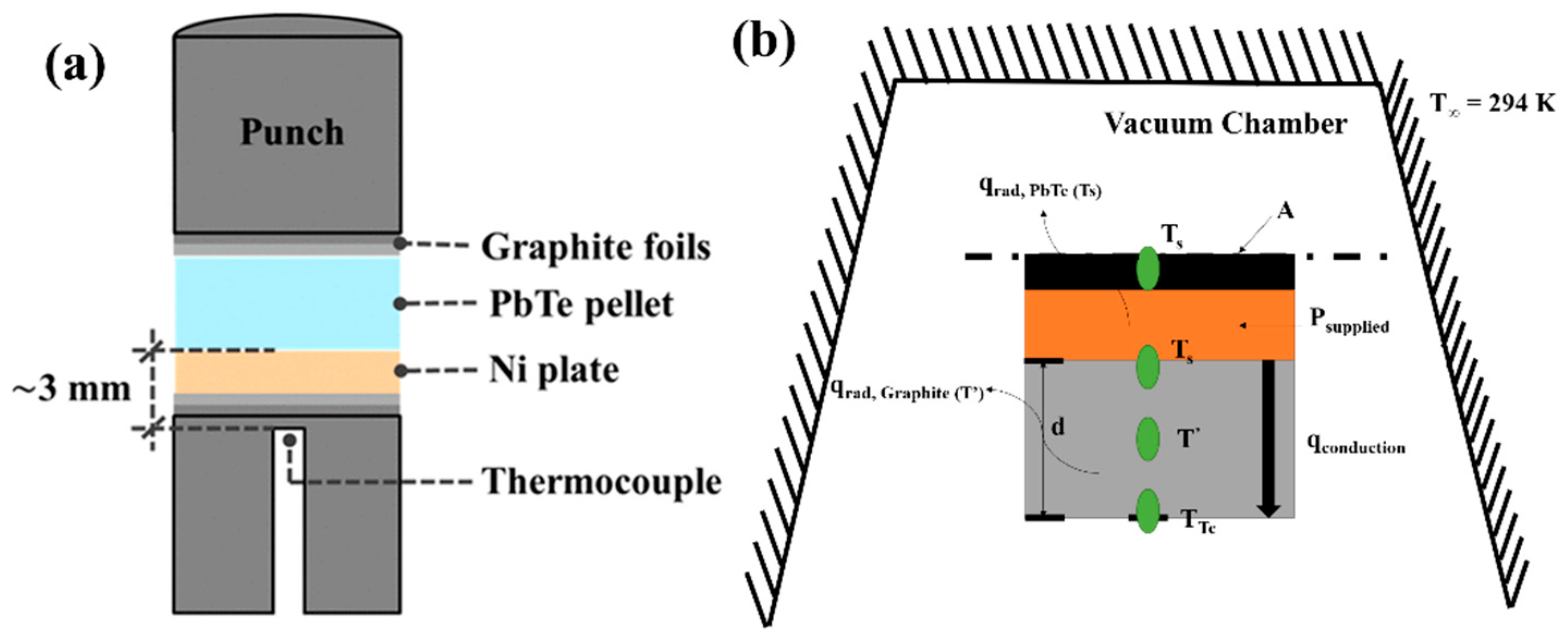

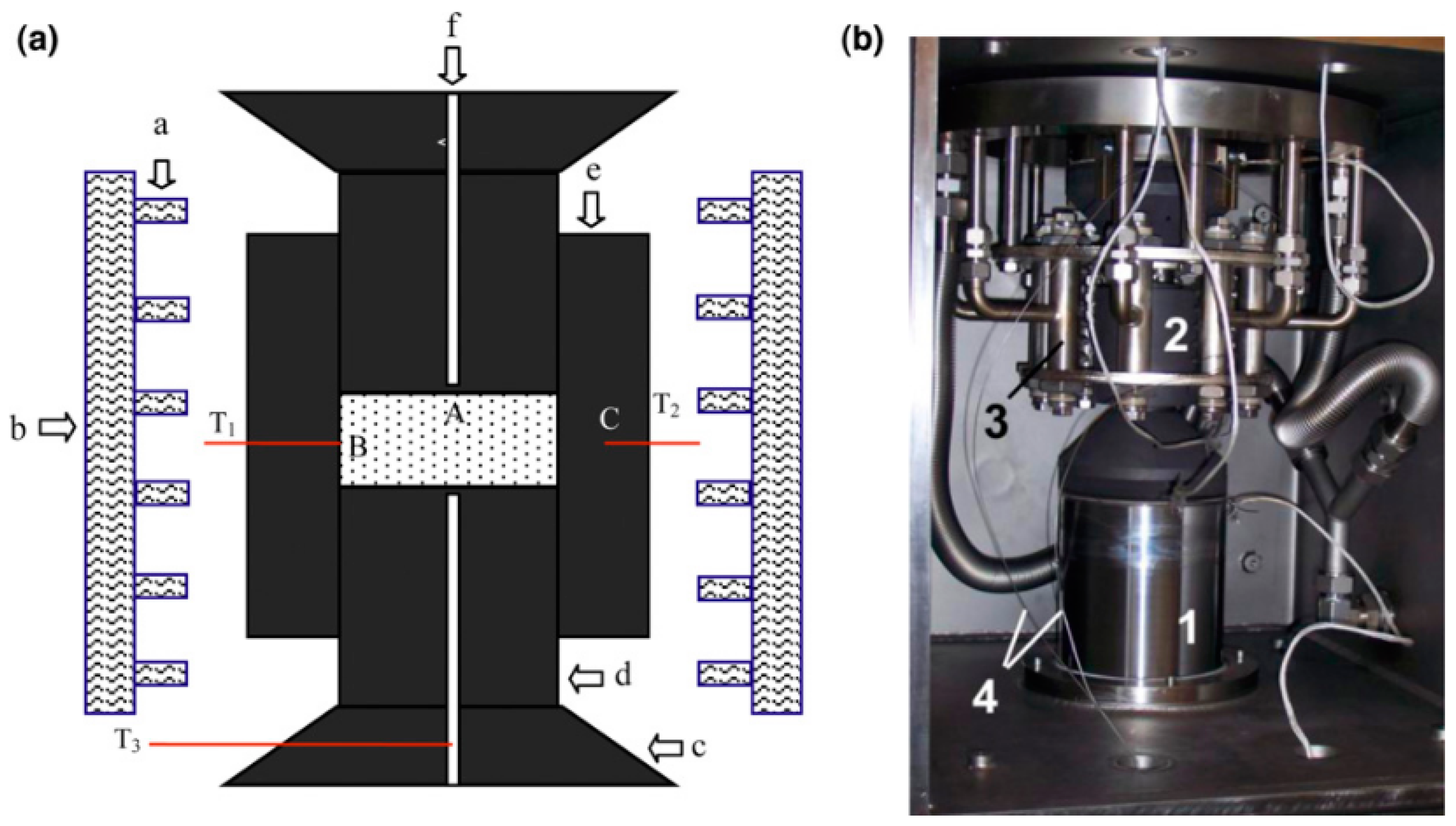

3. Joining of Materials

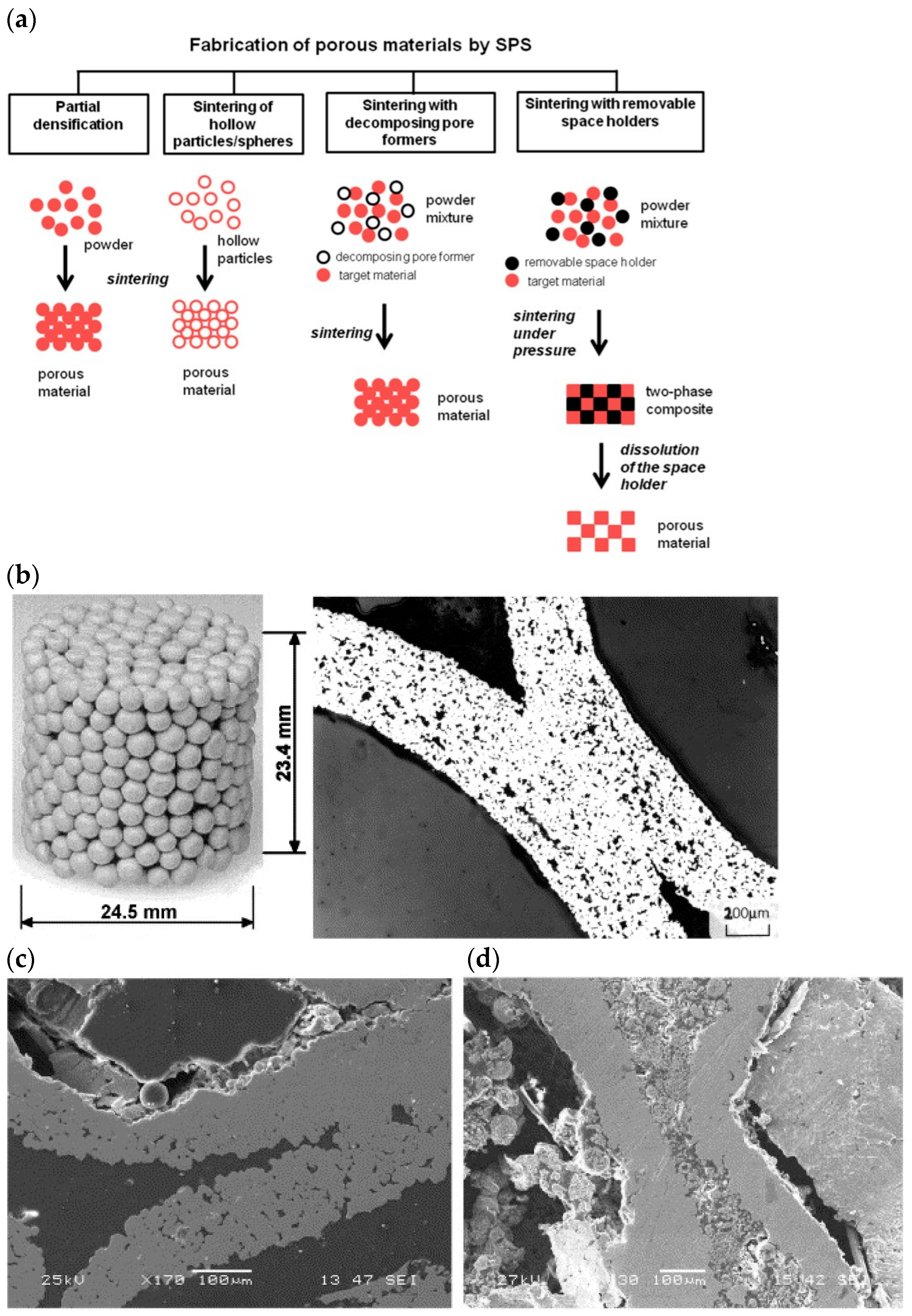

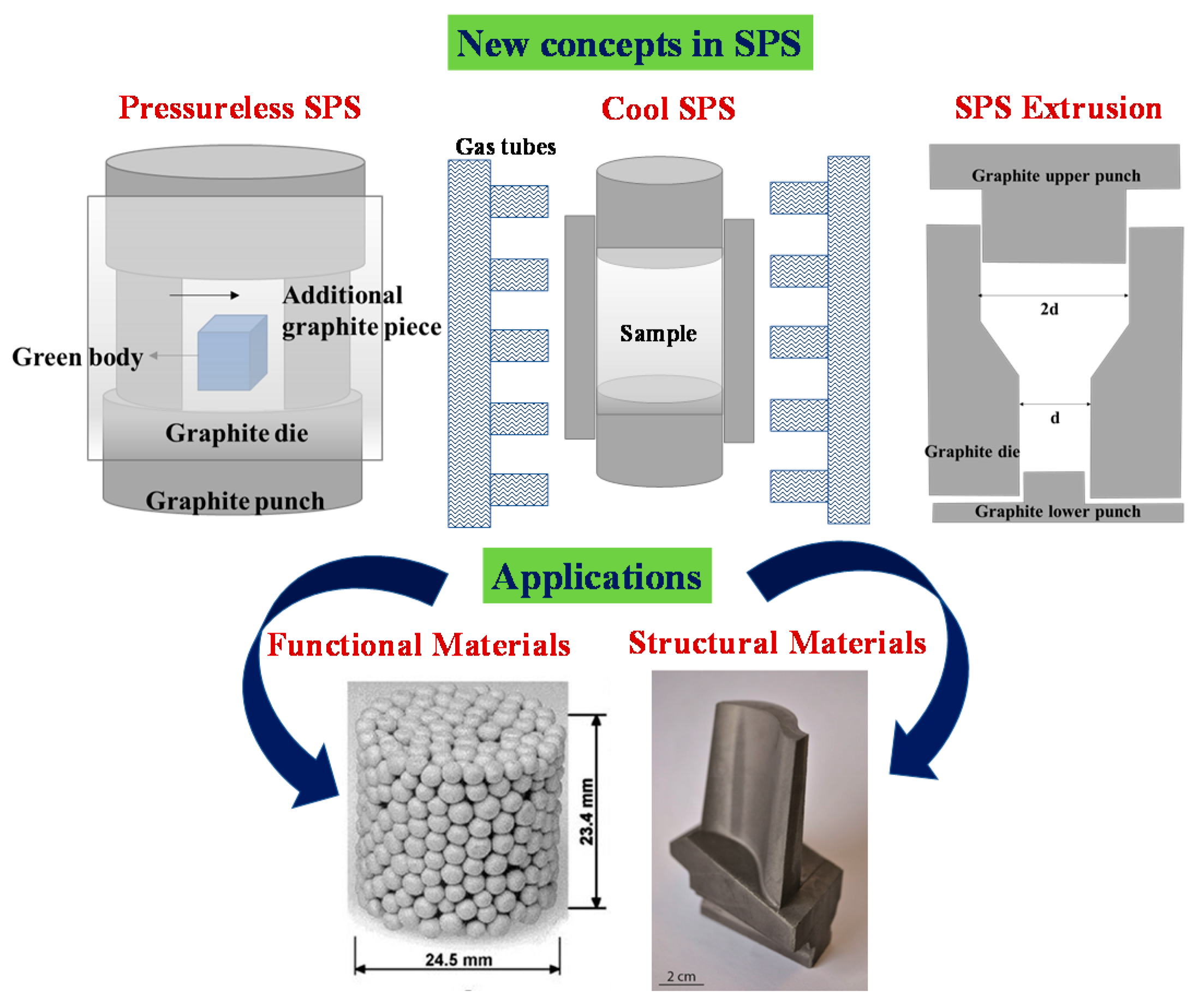

4. Tailored Porosity by SPS

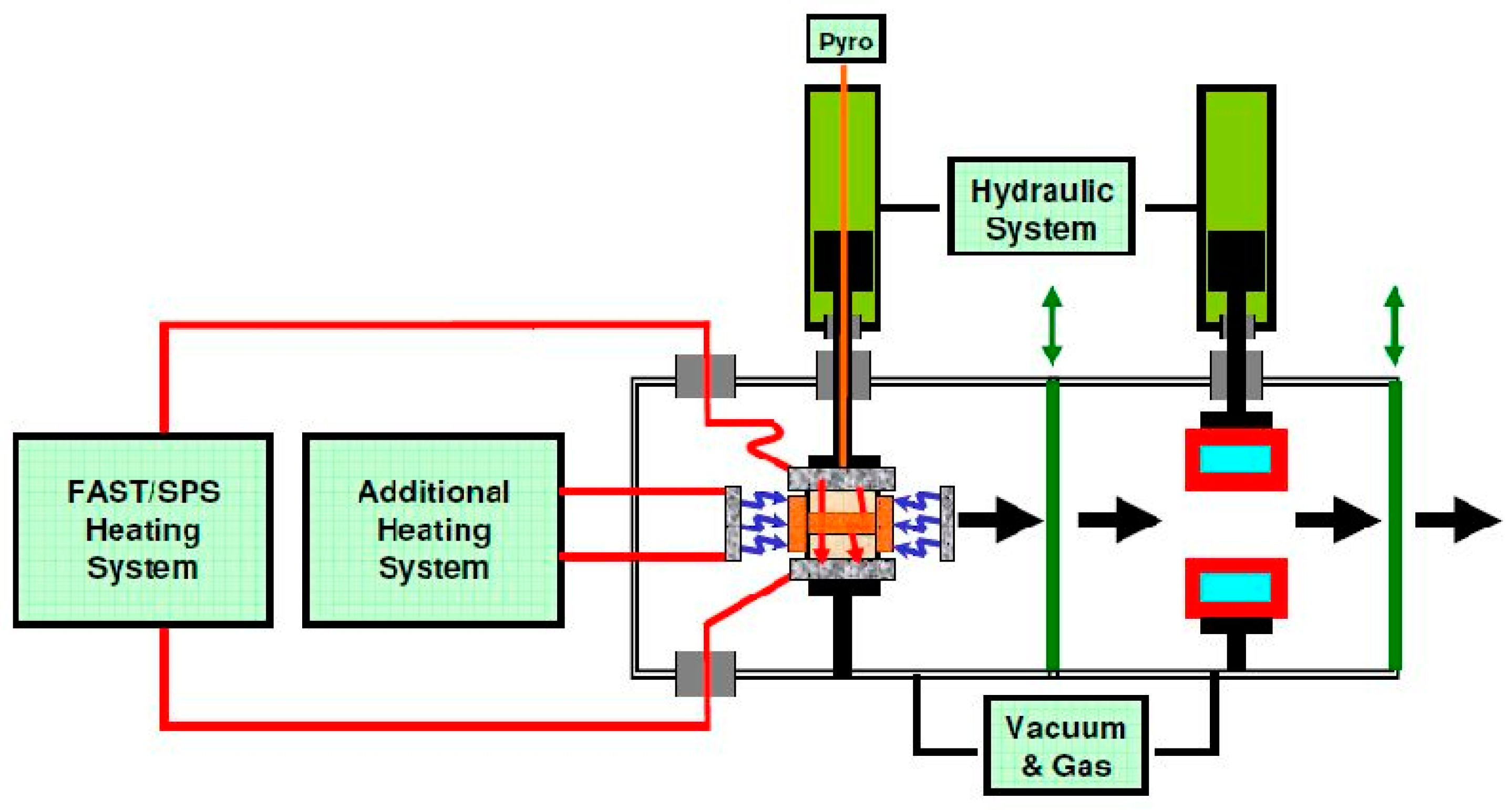

5. Batch vs. Continuous Process Scale-Up of SPS

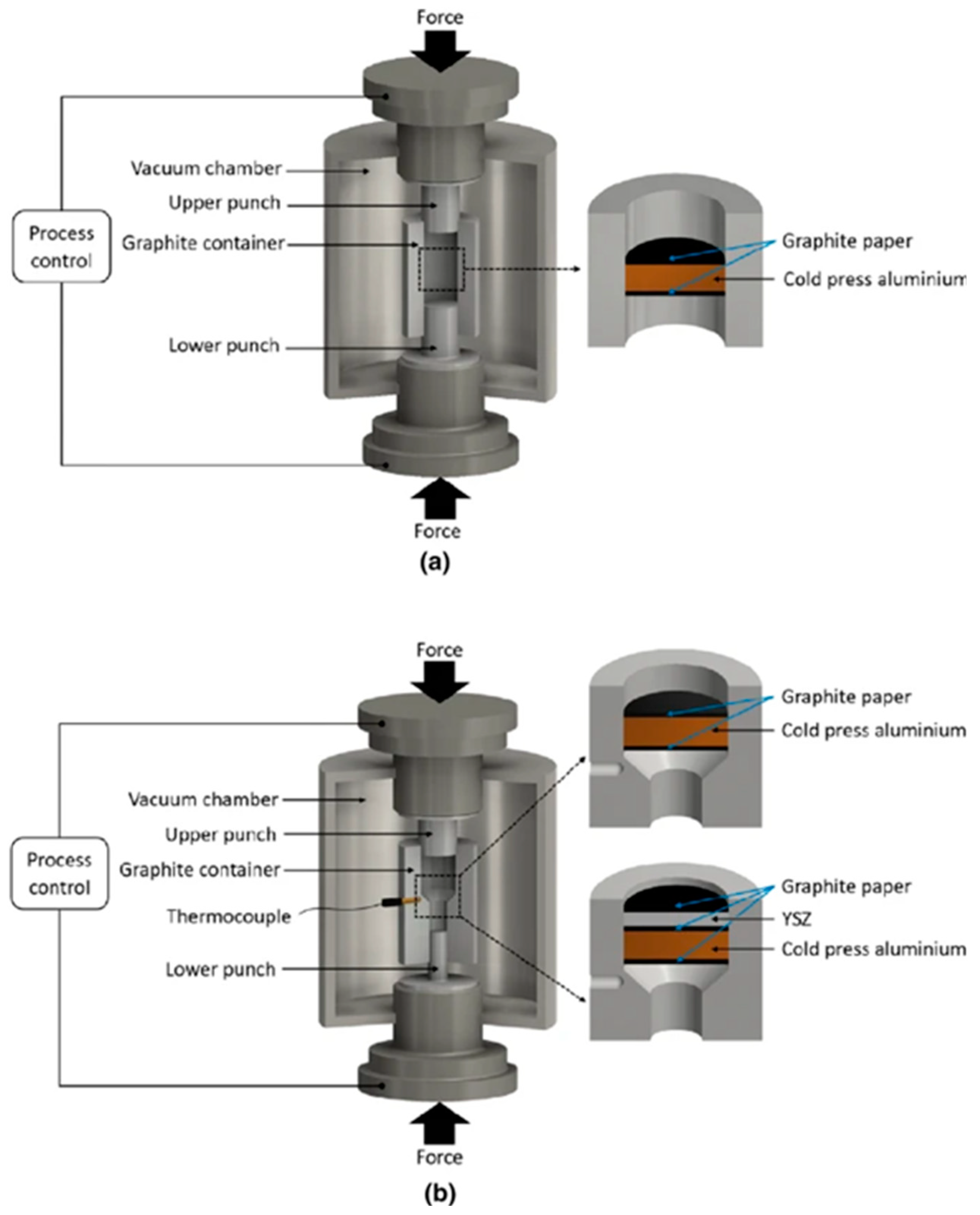

6. Polymer Processing via SPS

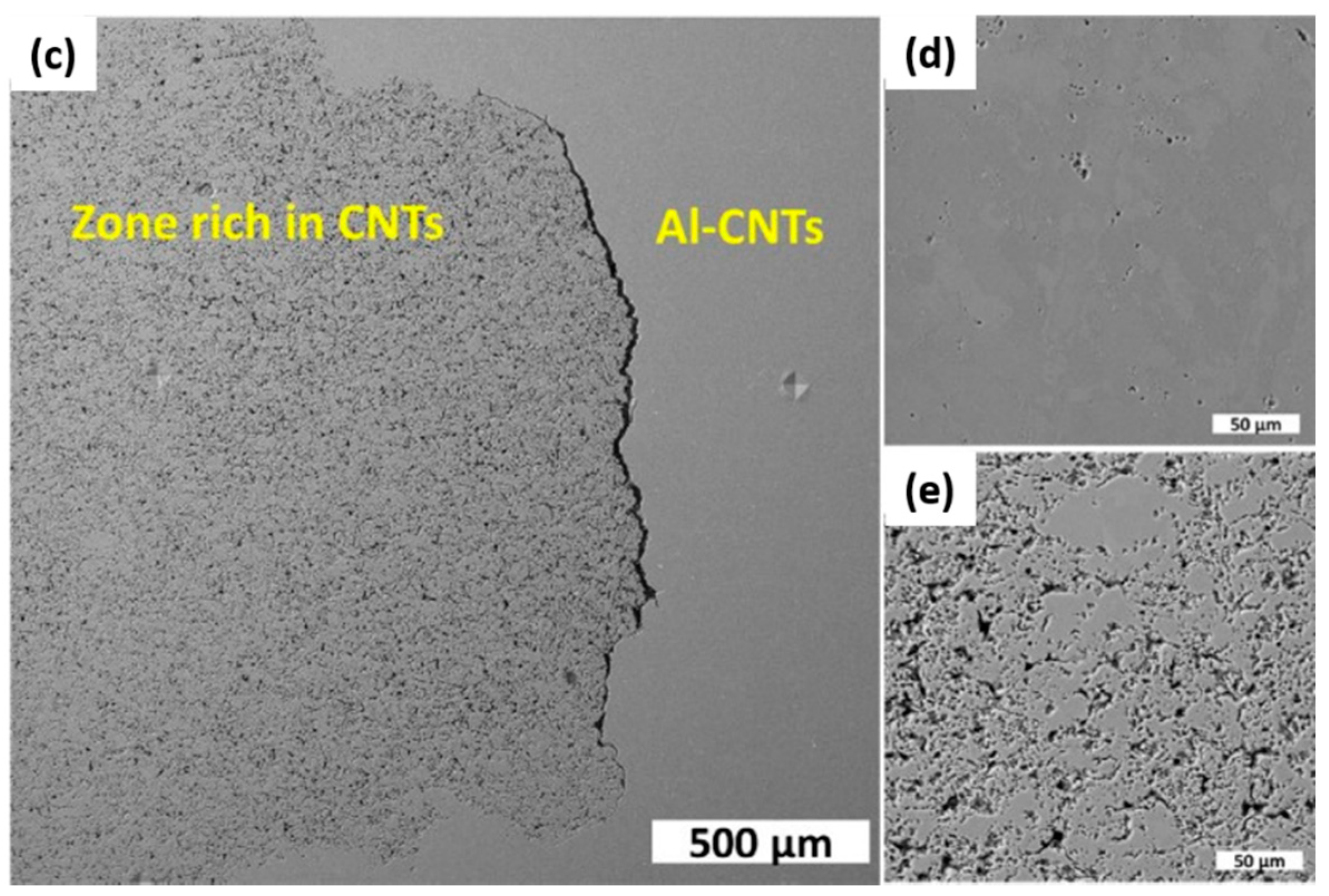

7. Pressureless and Cold-SPS

- Retained grain growth for enhanced mechanical properties;

- Production of a highly porous structure with controlled pore shape, size, and geometry;

- Consolidation of the green body within a short time.

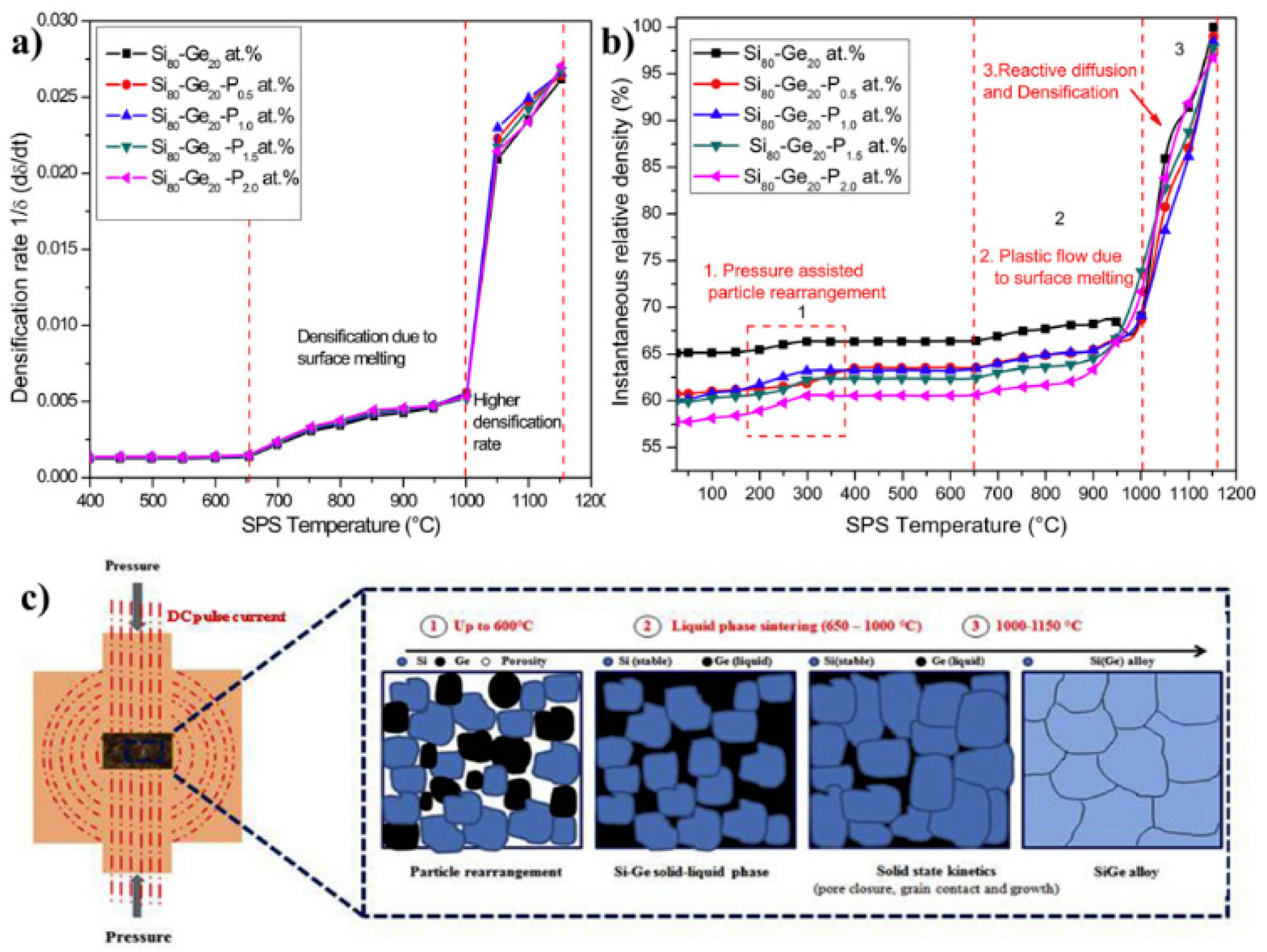

8. Liquid Phase Sintering by SPS

9. Rapid Cooling After SPS

10. Extrusion by SPS

- What is the effect of combined deformation and electric current activation on the recovery and recrystallization behavior of extruding materials?

- What is the effect of current density, extrusion speed, and extrusion ratio on the activation energy for extrusion, deformation mechanisms, extrusion pressure requirements, and resulting microstructures?

- Given that SPE will have different heat generation and dissipation sources (e.g., Joule heating, frictional heating, deformation heating, heat losses to the tooling, and decreased Joule heating during the process due to loss of resistance through consolidation), what would be the temperature distribution within a spark plasma-extruded/extruding sample? Furthermore, how does it affect the microstructure?

11. Summary

Funding

Acknowledgments

Conflicts of Interest

References

- Alaniz, J.; Dupuy, A.; Kodera, Y.; Garay, J. Effects of applied pressure on the densification rates in current-activated pressure-assisted densification (CAPAD) of nanocrystalline materials. Scr. Mater. 2014, 92, 7–10. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Blum, I.D.; Wu, C.-I.; Hogan, T.P.; Seidman, D.N.; Dravid, V.P.; Kanatzidis, M.G. High-performance bulk thermoelectrics with all-scale hierarchical architectures. Nature 2012, 489, 414–418. [Google Scholar] [CrossRef] [PubMed]

- Cramer, C.L.; McMurray, J.W.; Lance, M.J.; Lowden, R.A. Reaction-bond composite synthesis of SiC-TiB2 by spark plasma sintering/field-assisted sintering technology (SPS/FAST). J. Eur. Ceram. Soc. 2020, 40, 988–995. [Google Scholar] [CrossRef]

- Garay, J. Current-activated, pressure-assisted densification of materials. Annu. Rev. Mater. Res. 2010, 40, 445–468. [Google Scholar] [CrossRef]

- Hui, G.; Chuan-Bin, W.; Qiang, S.; Lian-Meng, Z. Preparation of La2NiMnO6 double-perovskite ceramics by plasma activated sintering. J. Inorg. Mater. 2019, 34, 541–545. [Google Scholar]

- Liu, Y.; Liebenberg, D. Electromagnetic radio frequency heating in the pulsed electric current sintering (PECS) process. MRS Commun. 2017, 7, 266–271. [Google Scholar] [CrossRef]

- Peigney, A. Tougher ceramics with nanotubes. Nat. Mater. 2003, 2, 15–16. [Google Scholar] [CrossRef]

- Tan, Z.; Wang, L.; Xue, Y.; Zhang, P.; Cao, T.; Cheng, X. High-entropy alloy particle reinforced Al-based amorphous alloy composite with ultrahigh strength prepared by spark plasma sintering. Mater. Des. 2016, 109, 219–226. [Google Scholar] [CrossRef]

- El-Atwani, O.; Quach, D.V.; Efe, M.; Cantwell, P.R.; Heim, B.; Schultz, B.; Stach, E.A.; Groza, J.R.; Allain, J.P. Multimodal grain size distribution and high hardness in fine grained tungsten fabricated by spark plasma sintering. Mater. Sci. Eng. A 2011, 528, 5670–5677. [Google Scholar] [CrossRef]

- Guillon, O.; Gonzalez-Julian, J.; Dargatz, B.; Kessel, T.; Schierning, G.; Räthel, J.; Herrmann, M. Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments. Adv. Eng. Mater. 2014, 16, 830–849. [Google Scholar] [CrossRef]

- Hu, Z.-Y.; Zhang, Z.-H.; Cheng, X.-W.; Wang, F.-C.; Zhang, Y.-F.; Li, S.-L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Kelly, J.P.; Graeve, O.A. Spark Plasma Sintering as an Approach to Manufacture Bulk Materials: Feasibility and Cost Savings. JOM 2015, 67, 29–33. [Google Scholar] [CrossRef]

- Musa, C.; Licheri, R.; Locci, A.M.; Orrù, R.; Cao, G.; Rodriguez, M.A.; Jaworska, L. Energy efficiency during conventional and novel sintering processes: The case of Ti–Al2O3–TiC composites. J. Clean. Prod. 2009, 17, 877–882. [Google Scholar] [CrossRef]

- Dudina, D.V.; Mukherjee, A.K. Reactive spark plasma sintering: Successes and challenges of nanomaterial synthesis. J. Nanomater. 2013, 2013, 625218. [Google Scholar] [CrossRef]

- Nguyen, V.-H.; Asl, M.S.; Mahaseni, Z.H.; Germi, M.D.; Delbari, S.A.; Van Le, Q.; Ahmadi, Z.; Shokouhimehr, M.; Namini, A.S.; Mohammadi, M. Role of co-addition of BN and SiC on microstructure of TiB2-based composites densified by SPS method. Ceram. Int. 2020, 46, 25341–25350. [Google Scholar] [CrossRef]

- Gild, J.; Kaufmann, K.; Vecchio, K.; Luo, J. Reactive flash spark plasma sintering of high-entropy ultrahigh temperature ceramics. Scr. Mater. 2019, 170, 106–110. [Google Scholar] [CrossRef]

- Nisar, A.; Zhang, C.; Boesl, B.; Agarwal, A. A perspective on challenges and opportunities in developing high entropy-ultra high temperature ceramics. Ceram. Int. 2020, 46, 25845–25853. [Google Scholar] [CrossRef]

- Liu, W.; Naka, M. In situ joining of dissimilar nanocrystalline materials by spark plasma sintering. Scr. Mater. 2003, 48, 1225–1230. [Google Scholar] [CrossRef]

- Matsubara, T.; Shibutani, T.; Uenishi, K.; Kobayashi, K.F. Fabrication of TiB2 reinforced Al3Ti composite layer on Ti substrate by reactive-pulsed electric current sintering. Mater. Sci. Eng. A 2002, 329, 84–91. [Google Scholar] [CrossRef]

- Mulukutla, M.; Singh, A.; Harimkar, S.P. Spark plasma sintering for multi-scale surface engineering of materials. JOM 2010, 62, 65–71. [Google Scholar] [CrossRef]

- Singh, A.; Bakshi, S.R.; Virzi, D.A.; Keshri, A.K.; Agarwal, A.; Harimkar, S.P. In-situ synthesis of TiC/SiC/Ti3SiC2 composite coatings by spark plasma sintering. Surf. Coat. Technol. 2011, 205, 3840–3846. [Google Scholar] [CrossRef]

- Munir, Z. Synthesis and densification of nanomaterials by mechanical and field activation. J. Mater. Synth. Process. 2000, 8, 189–196. [Google Scholar] [CrossRef]

- Anselmi-Tamburini, U.; Munir, Z.A.; Kodera, Y.; Imai, T.; Ohyanagi, M. Influence of synthesis temperature on the defect structure of boron carbide: Experimental and modeling studies. J. Am. Ceram. Soc. 2005, 88, 1382–1387. [Google Scholar] [CrossRef]

- Dudina, D.V.; Mali, V.I.; Anisimov, A.G.; Bulina, N.V.; Korchagin, M.A.; Lomovsky, O.I.; Bataev, I.A.; Bataev, V.A. Ti 3 SiC 2-Cu composites by mechanical milling and Spark Plasma Sintering: Possible microstructure formation scenarios. Met. Mater. Int. 2013, 19, 1235–1241. [Google Scholar] [CrossRef]

- Hocquet, S.; Dupont, V.; Cambier, F.; Ludewig, F.; Vandewalle, N. Densification of complex shape ceramics parts by SPS. J. Eur. Ceram. Soc. 2020, 40, 2586–2596. [Google Scholar] [CrossRef]

- Cai, K.; Román-Manso, B.; Smay, J.E.; Zhou, J.; Osendi, M.I.; Belmonte, M.; Miranzo, P. Geometrically Complex Silicon Carbide Structures Fabricated by Robocasting. J. Am. Ceram. Soc. 2012, 95, 2660–2666. [Google Scholar] [CrossRef]

- Duoss, E.B.; Twardowski, M.; Lewis, J.A. Sol-Gel Inks for Direct-Write Assembly of Functional Oxides. Adv. Mater. 2007, 19, 3485–3489. [Google Scholar] [CrossRef]

- Voisin, T.; Monchoux, J.-P.; Durand, L.; Karnatak, N.; Thomas, M.; Couret, A. An Innovative Way to Produce γ-TiAl Blades: Spark Plasma Sintering. Adv. Eng. Mater. 2015, 17, 1408–1413. [Google Scholar] [CrossRef]

- Manière, C.; Nigito, E.; Durand, L.; Weibel, A.; Beynet, Y.; Estournes, C. Spark plasma sintering and complex shapes: The deformed interfaces approach. Powder Technol. 2017, 320, 340–345. [Google Scholar] [CrossRef]

- Manière, C.; Torresani, E.; Olevsky, E.A. Simultaneous spark plasma sintering of multiple complex shapes. Materials 2019, 12, 557. [Google Scholar] [CrossRef]

- Bakhtiari Argesi, F.; Shamsipur, A.; Mirsalehi, S.E. Dissimilar Joining of Pure Copper to Aluminum Alloy via Friction Stir Welding. Acta Metall. Sin. 2018, 31, 1183–1196. [Google Scholar] [CrossRef]

- Dong, H.; Yu, Y.; Jin, X.; Tian, X.; He, W.; Ma, W. Microstructure and mechanical properties of SiC-SiC joints joined by spark plasma sintering. Ceram. Int. 2016, 42, 14463–14468. [Google Scholar] [CrossRef]

- Pinc, W.R.; Di Prima, M.; Walker, L.S.; Wing, Z.N.; Corral, E.L. Spark plasma joining of ZrB2–SiC composites using zirconium–boron reactive filler layers. J. Am. Ceram. Soc. 2011, 94, 3825–3832. [Google Scholar] [CrossRef]

- Yu, Y.; Dong, H.; Ma, B.; Ren, Q.; Ma, W. Effect of different filler materials on the microstructure and mechanical properties of SiCSiC joints joined by spark plasma sintering. J. Alloys Compd. 2017, 708, 373–379. [Google Scholar] [CrossRef]

- Okuni, T.; Miyamoto, Y.; Abe, H.; Naito, M. Joining of silicon carbide and graphite by spark plasma sintering. Ceram. Int. 2014, 40, 1359–1363. [Google Scholar] [CrossRef]

- Rizzo, S.; Grasso, S.; Salvo, M.; Casalegno, V.; Reece, M.J.; Ferraris, M. Joining of C/SiC composites by spark plasma sintering technique. J. Eur. Ceram. Soc. 2014, 34, 903–913. [Google Scholar] [CrossRef]

- Zhou, X.; Liu, J.; Zou, S.; Xu, K.; Chang, K.; Li, P.; Huang, F.; Huang, Z.; Huang, Q. Almost seamless joining of SiC using an in-situ reaction transition phase of Y3Si2C2. J. Eur. Ceram. Soc. 2020, 40, 259–266. [Google Scholar] [CrossRef]

- Miriyev, A.; Stern, A.; Tuval, E.; Kalabukhov, S.; Hooper, Z.; Frage, N. Titanium to steel joining by spark plasma sintering (SPS) technology. J. Mater. Process. Technol. 2013, 213, 161–166. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, D.; He, Z.-Y.; Chen, X.-C. Progress in joining ceramics to metals. J. Iron Steel Res. Int. 2006, 13, 1–5. [Google Scholar] [CrossRef]

- Schwertz, M.; Lemonnier, S.; Barraud, E.; Carradò, A.; Vallat, M.-F.; Nardin, M. Spark plasma sintering technology applied to polymer-based composites for structural light weighting. Powder Metall. 2015, 58, 87–90. [Google Scholar] [CrossRef]

- Liu, L.; Ye, F.; Zhou, Y.; Zhang, Z.; Hou, Q. Fast bonding α-SiAlON ceramics by spark plasma sintering. J. Eur. Ceram. Soc. 2010, 30, 2683–2689. [Google Scholar] [CrossRef]

- Grasso, S.; Tatarko, P.; Rizzo, S.; Porwal, H.; Hu, C.; Katoh, Y.; Salvo, M.; Reece, M.J.; Ferraris, M. Joining of β-SiC by spark plasma sintering. J. Eur. Ceram. Soc. 2014, 34, 1681–1686. [Google Scholar] [CrossRef]

- Tatarko, P.; Chlup, Z.; Mahajan, A.; Casalegno, V.; Saunders, T.G.; Dlouhý, I.; Reece, M.J. High temperature properties of the monolithic CVD β-SiC materials joined with a pre-sintered MAX phase Ti3SiC2 interlayer via solid-state diffusion bonding. J. Eur. Ceram. Soc. 2017, 37, 1205–1216. [Google Scholar] [CrossRef]

- Koyanagi, T.; Katoh, Y.; Hinoki, T.; Henager, C.; Ferraris, M.; Grasso, S. Progress in development of SiC-based joints resistant to neutron irradiation. J. Eur. Ceram. Soc. 2020, 40, 1023–1034. [Google Scholar] [CrossRef]

- Koyanagi, T.; Katoh, Y.; Kiggans, J.; Hinoki, T.; Khalifa, H.; Deck, C.; Back, C. Irradiation resistance of silicon carbide joint at light water reactor–relevant temperature. J. Nucl. Mater. 2017, 488, 150–159. [Google Scholar] [CrossRef]

- Ferreres, X.R.; Gazder, A.; Manettas, A.; Aminorroaya Yamini, S. Solid-state bonding of bulk PbTe to nickel electrode for thermoelectric modules. ACS Appl. Energy Mater. 2018, 1, 348–354. [Google Scholar] [CrossRef]

- Dudina, D.V.; Bokhonov, B.B.; Olevsky, E.A. Fabrication of porous materials by spark plasma sintering: A review. Materials 2019, 12, 541. [Google Scholar] [CrossRef]

- Hussein, M.A.; Shahzad, H.K.; Patel, F.; Atieh, M.A.; Al-Aqeeli, N.; Baroud, T.N.; Laoui, T. Porous Al2O3-CNT Nanocomposite Membrane Produced by Spark Plasma Sintering with Tailored Microstructure and Properties for Water Treatment. Nanomaterials 2020, 10, 845. [Google Scholar] [CrossRef]

- Andersen, O.; Waag, U.; Schneider, L.; Stephani, G.; Kieback, B. Novel metallic hollow sphere structures: Processing and properties. In Proceedings of the 1st International Conference on Metal Foams and Porous Metal Structures (MetFoam´99), Breme, Germany, 14–16 June 1999; pp. 14–16. [Google Scholar]

- Hurysz, K.; Clark, J.; Nagel, A.; Hardwicke, C.; Lee, K.; Cochran, J.; Sanders, T. Steel and titanium hollow sphere foams. MRS Online Proc. Libr. Arch. 1998, 521. [Google Scholar] [CrossRef]

- Sazegaran, H.; Kiani-Rashid, A.R.; Khaki, J.V. Effects of sphere size on the microstructure and mechanical properties of ductile iron–steel hollow sphere syntactic foams. Int. J. Miner. Metall. Mater. 2016, 23, 676–682. [Google Scholar] [CrossRef]

- Khor, K.A.; Yu, L.G.; Andersen, O.; Stephani, G. Effect of spark plasma sintering (SPS) on the microstructure and mechanical properties of randomly packed hollow sphere (RHS) cell wall. Mater. Sci. Eng. A 2003, 356, 130–135. [Google Scholar] [CrossRef]

- Hakamada, M.; Yamada, Y.; Nomura, T.; Chen, Y.; Kusuda, H.; Mabuchi, M. Fabrication of porous aluminum by spacer method consisting of spark plasma sintering and sodium chloride dissolution. Mater. Trans. 2005, 46, 2624–2628. [Google Scholar] [CrossRef]

- Yamanoglu, R.; Gulsoy, N.; Olevsky, E.; Gulsoy, H. Production of porous Ti5Al2. 5Fe alloy via pressureless spark plasma sintering. J. Alloys Compd. 2016, 680, 654–658. [Google Scholar] [CrossRef]

- Nicula, R.; Lüthen, F.; Stir, M.; Nebe, B.; Burkel, E. Spark plasma sintering synthesis of porous nanocrystalline titanium alloys for biomedical applications. Biomol. Eng. 2007, 24, 564–567. [Google Scholar] [CrossRef] [PubMed]

- Xie, G.; Fukuhara, M.; Louzguine-Luzgin, D.V.; Inoue, A. Ultrasonic characteristics of porous Zr55Cu30Al10Ni5 bulk metallic glass fabricated by spark plasma sintering. Intermetallics 2010, 18, 2014–2018. [Google Scholar] [CrossRef]

- Akhtar, F.; Vasiliev, P.O.; Bergström, L. Hierarchically porous ceramics from diatomite powders by pulsed current processing. J. Am. Ceram. Soc. 2009, 92, 338–343. [Google Scholar] [CrossRef]

- Stingaciu, M.; Zhu, B.; Singh, M.; Johnsson, M. Single-component fuel cells fabricated by spark plasma sintering. RSC Adv. 2012, 2, 12140–12143. [Google Scholar] [CrossRef]

- Ning, H.; Mastrorillo, G.D.; Grasso, S.; Du, B.; Mori, T.; Hu, C.; Xu, Y.; Simpson, K.; Maizza, G.; Reece, M.J. Enhanced thermoelectric performance of porous magnesium tin silicide prepared using pressure-less spark plasma sintering. J. Mater. Chem. A 2015, 3, 17426–17432. [Google Scholar] [CrossRef]

- Vasylkiv, O. Growing Larger: Scaling up during Spark Plasma Sintering of High—Temperature Ceramics. In Proceedings of the Electric Field Assisted Sintering and Related Phenomena Far from Equilibrium, Tomar, Portugal, 6–11 March 2016. [Google Scholar]

- Hennicke, J.; Kessel, T.; Raethel, J. Enhancements on Fast Sintering Systems Promote Transfer from the Lab to Industrial Applications. In Advanced Processing and Manufacturing Technologies for Nanostructured and Multifunctional Materials III; The American Ceramic Society: Daytona Beach, FL, USA, 2017; pp. 11–20. [Google Scholar]

- Hennicke, J.; Kessel, H.; Kessel, T.; Neeß, H. High-Throughput Serial Production Line for Hot Pressing of Large Area Ceramic Components; The Advanced Materials Show: Birmingham, UK, 2019. [Google Scholar]

- Suárez, M.; Fernández, A.; Menéndez, J.; Torrecillas, R.; Kessel, H.; Hennicke, J.; Kirchner, R.; Kessel, T. Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials. Sinter. Appl. 2013, 13, 319–342. [Google Scholar]

- Manière, C.; Durand, L.; Weibel, A.; Chevallier, G.; Estournès, C. A sacrificial material approach for spark plasma sintering of complex shapes. Scr. Mater. 2016, 124, 126–128. [Google Scholar] [CrossRef]

- Adesina, O.T.; Sadiku, E.R.; Jamiru, T.; Ogunbiyi, O.F.; Adesina, O.S. Thermal properties of spark plasma-sintered polylactide/graphene composites. Mater. Chem. Phys. 2020, 242, 122545. [Google Scholar] [CrossRef]

- Sébileau, J.C.; Lemonnier, S.; Barraud, E.; Vallat, M.F.; Carradò, A.; Nardin, M. Consolidation by spark plasma sintering (SPS) of polyetheretherketone. J. Appl. Polym. Sci. 2017, 134, 44911. [Google Scholar] [CrossRef]

- Wool, R.P.; Yuan, B.L.; McGarel, O. Welding of polymer interfaces. Polym. Eng. Sci. 1989, 29, 1340–1367. [Google Scholar] [CrossRef]

- Blaiszik, B.J.; Kramer, S.L.; Olugebefola, S.C.; Moore, J.S.; Sottos, N.R.; White, S.R. Self-healing polymers and composites. Annu. Rev. Mater. Res. 2010, 40, 179–211. [Google Scholar] [CrossRef]

- Omori, M.; Okubo, A.; Kang, G.; Hirai, T. Preparation and properties of polyimide/Cu functionally graded material. In Proceedings of the 4th International Symposium on Functionally Graded Materials, Tsukuba, Japan, 21–24 October 1996; Elsevier Science: Tsukuba, Japan, 1997; pp. 767–772. [Google Scholar]

- Ojalvo, C.; Moreno, R.; Guiberteau, F.; Ortiz, A.L. Pressureless ultrafast sintering of near-net-shaped superhard isotropic B4C/rGO composites with Ti-Al additives. J. Eur. Ceram. Soc. 2020, 40, 4354–4360. [Google Scholar] [CrossRef]

- Giuntini, D.; Wei, X.; Maximenko, A.L.; Wei, L.; Ilyina, A.M.; Olevsky, E.A. Initial stage of free pressureless spark-plasma sintering of vanadium carbide: Determination of surface diffusion parameters. Int. J. Refract. Met. Hard Mater. 2013, 41, 501–506. [Google Scholar] [CrossRef]

- Yamanoglu, R. Pressureless Spark Plasma Sintering: A Perspective from Conventional Sintering to Accelerated Sintering Without Pressure. Powder Metall. Met. Ceram. 2019, 57, 513–525. [Google Scholar] [CrossRef]

- Guo, J.; Berbano, S.S.; Guo, H.; Baker, A.L.; Lanagan, M.T.; Randall, C.A. Cold sintering process of composites: Bridging the processing temperature gap of ceramic and polymer materials. Adv. Funct. Mater. 2016, 26, 7115–7121. [Google Scholar] [CrossRef]

- Guo, H.; Baker, A.; Guo, J.; Randall, C.A. Cold sintering process: A novel technique for low-temperature ceramic processing of ferroelectrics. J. Am. Ceram. Soc. 2016, 99, 3489–3507. [Google Scholar] [CrossRef]

- Guo, H.; Baker, A.; Guo, J.; Randall, C.A. Protocol for ultralow-temperature ceramic sintering: An integration of nanotechnology and the cold sintering process. ACS Nano 2016, 10, 10606–10614. [Google Scholar] [CrossRef]

- Grossin, D.; Rollin-Martinet, S.; Estournès, C.; Rossignol, F.; Champion, E.; Combes, C.; Rey, C.; Geoffroy, C.; Drouet, C. Biomimetic apatite sintered at very low temperature by spark plasma sintering: Physico-chemistry and microstructure aspects. Acta Biomater. 2010, 6, 577–585. [Google Scholar] [CrossRef] [PubMed]

- Yao, T.; Scott, S.; Xin, G.; Lu, F.; Lian, J. Dense Iodoapatite ceramics consolidated by low-temperature spark plasma sintering. J. Am. Ceram. Soc. 2015, 98, 3733–3739. [Google Scholar] [CrossRef]

- De Beauvoir, T.H.; Sangregorio, A.; Cornu, I.; Elissalde, C.; Josse, M. Cool-SPS: An opportunity for low temperature sintering of thermodynamically fragile materials. J. Mater. Chem. C 2018, 6, 2229–2233. [Google Scholar] [CrossRef]

- Ojalvo, C.; Guiberteau, F.; Ortiz, A.L. Fabricating toughened super-hard B4C composites at lower temperature by transient liquid-phase assisted spark plasma sintering with MoSi2 additives. J. Eur. Ceram. Soc. 2019, 39, 2862–2873. [Google Scholar] [CrossRef]

- Ji, W.; Todd, R.I.; Wang, W.; Wang, H.; Zhang, J.; Fu, Z. Transient liquid phase spark plasma sintering of B4C-based ceramics using Ti-Al intermetallics as sintering aid. J. Eur. Ceram. Soc. 2016, 36, 2419–2426. [Google Scholar] [CrossRef]

- Ortiz, A.L.; Candelario, V.M.; Moreno, R.; Guiberteau, F. Near-net shape manufacture of B4C–Co and ZrC–Co composites by slip casting and pressureless sintering. J. Eur. Ceram. Soc. 2017, 37, 4577–4584. [Google Scholar] [CrossRef]

- German, R.M.; Suri, P.; Park, S.J. Review: Liquid phase sintering. J. Mater. Sci 2009, 44, 1–39. [Google Scholar] [CrossRef]

- Liang, H.; Yao, X.; Huang, Z.; Zeng, Y.; Su, B. Effect of sintering techniques on the microstructure of liquid-phase-sintered SiC ceramics. J. Eur. Ceram. Soc. 2016, 36, 1863–1871. [Google Scholar] [CrossRef]

- Murugasami, R.; Vivekanandhan, P.; Kumaran, S.; Kumar, R.S.; Tharakan, T.J. Thermoelectric power factor performance of silicon-germanium alloy doped with phosphorus prepared by spark plasma assisted transient liquid phase sintering. Scr. Mater. 2018, 143, 35–39. [Google Scholar] [CrossRef]

- Thakur, S.N.; Newkirk, J.W.; Fillari, G.B.; Murphy, T.F.; Narasimhan, K. Mechanical properties of sinter-hardened steels. Int. J. Powder Metall. 2004, 40, 45–54. [Google Scholar]

- Dlapka, M.; Danninger, H.; Gierl, C.; Lindqvist, B. Sinter hardening—A special heat treatment for powder metallurgy precision parts. HTM J. Heat Treat. Mater. 2012, 67, 223. [Google Scholar] [CrossRef]

- Zhang, F.; Reich, M.; Kessler, O.; Burkel, E. The potential of rapid cooling spark plasma sintering for metallic materials. Mater. Today 2013, 16, 192–197. [Google Scholar] [CrossRef]

- Hallett, R.; Cox, J.R.; Morsi, K. Novel Spark Plasma Extrusion of Titanium Above and Below the β-Transus: Effect on Microstructure and Properties. Metall. Mater. Trans. B 2020, 51, 1363–1369. [Google Scholar] [CrossRef]

- Novitskaya, E.; Esquivel-Castro, T.; Dieguez-Trejo, G.; Kritsuk, A.; Cahill, J.; Díaz-de-la-Torre, S.; Graeve, O. Current assisted extrusion of metallic alloys: Insight into microstructure formation and mechanical properties. Mater. Sci. Eng. A 2018, 717, 62–67. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A.; Borah, P.; Lanka, S.; Sayed, A.; Taher, M. Properties of single and dual matrix aluminum–carbon nanotube composites processed via spark plasma extrusion (SPE). Mater. Sci. Eng. A 2010, 527, 5686–5690. [Google Scholar] [CrossRef]

- Morsi, K.; Esawi, A.; Lanka, S.; Sayed, A.; Taher, M. Spark plasma extrusion (SPE) of ball-milled aluminum and carbon nanotube reinforced aluminum composite powders. Compos. Part A Appl. Sci. Manuf. 2010, 41, 322–326. [Google Scholar] [CrossRef]

- Čelko, L.; Menelaou, M.; Casas-Luna, M.; Horynová, M.; Musálek, T.; Remešová, M.; Diaz-De-La-Torre, S.; Morsi, K.; Kaiser, J. Spark Plasma Extrusion and the Thermal Barrier Concept. Metall. Mater. Trans. B 2019, 50, 656–665. [Google Scholar] [CrossRef]

- Morsi, K.; El-Desouky, A.; Johnson, B.; Mar, A.; Lanka, S. Spark plasma extrusion (SPE): Prospects and potential. Scr. Mater. 2009, 61, 395–398. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nisar, A.; Zhang, C.; Boesl, B.; Agarwal, A. Unconventional Materials Processing Using Spark Plasma Sintering. Ceramics 2021, 4, 20-39. https://doi.org/10.3390/ceramics4010003

Nisar A, Zhang C, Boesl B, Agarwal A. Unconventional Materials Processing Using Spark Plasma Sintering. Ceramics. 2021; 4(1):20-39. https://doi.org/10.3390/ceramics4010003

Chicago/Turabian StyleNisar, Ambreen, Cheng Zhang, Benjamin Boesl, and Arvind Agarwal. 2021. "Unconventional Materials Processing Using Spark Plasma Sintering" Ceramics 4, no. 1: 20-39. https://doi.org/10.3390/ceramics4010003

APA StyleNisar, A., Zhang, C., Boesl, B., & Agarwal, A. (2021). Unconventional Materials Processing Using Spark Plasma Sintering. Ceramics, 4(1), 20-39. https://doi.org/10.3390/ceramics4010003