Status of Pure Electric Vehicle Power Train Technology and Future Prospects

Abstract

1. Introduction

2. Methodology

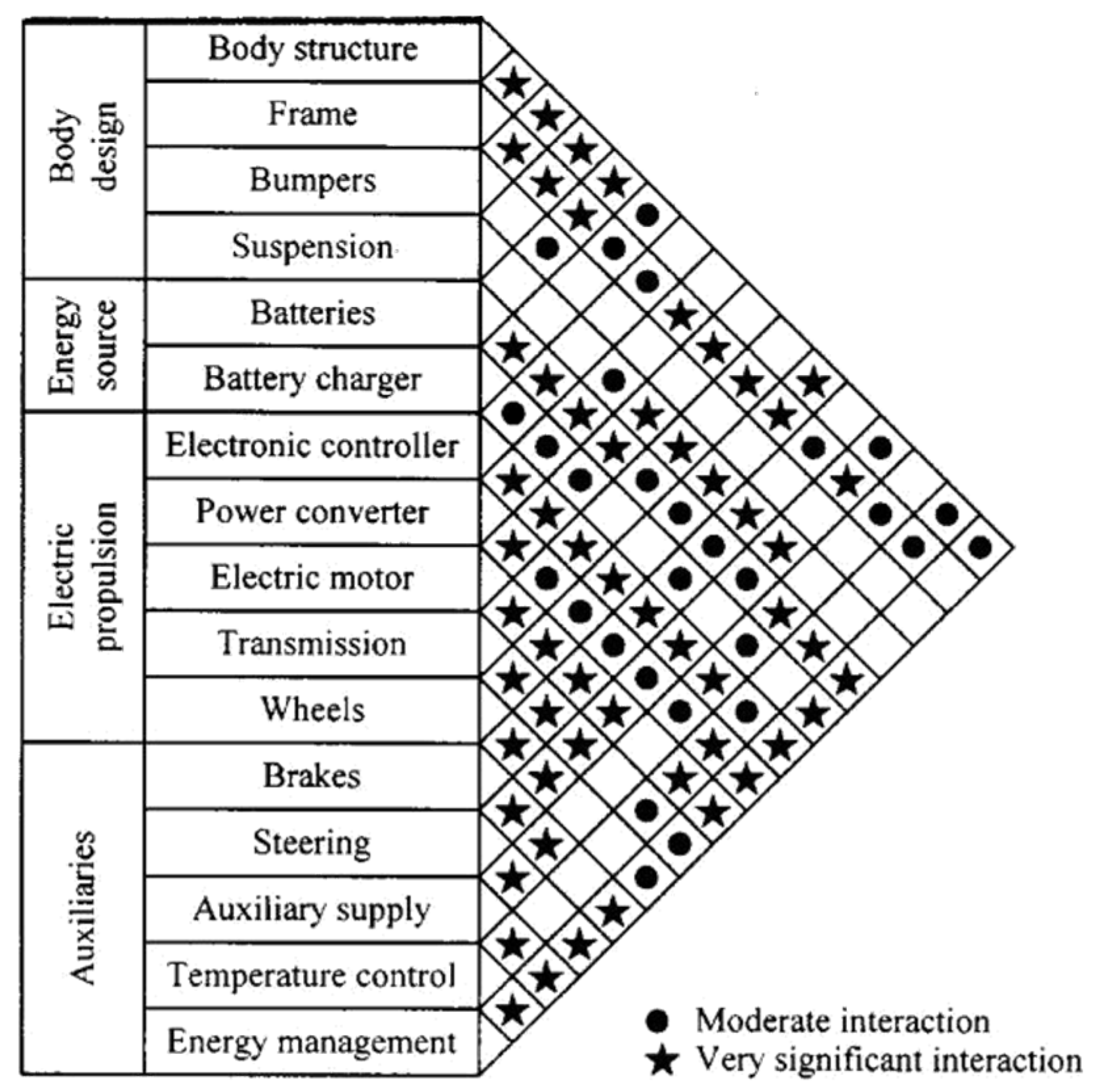

3. Electric Vehicle Powertrain Architecture

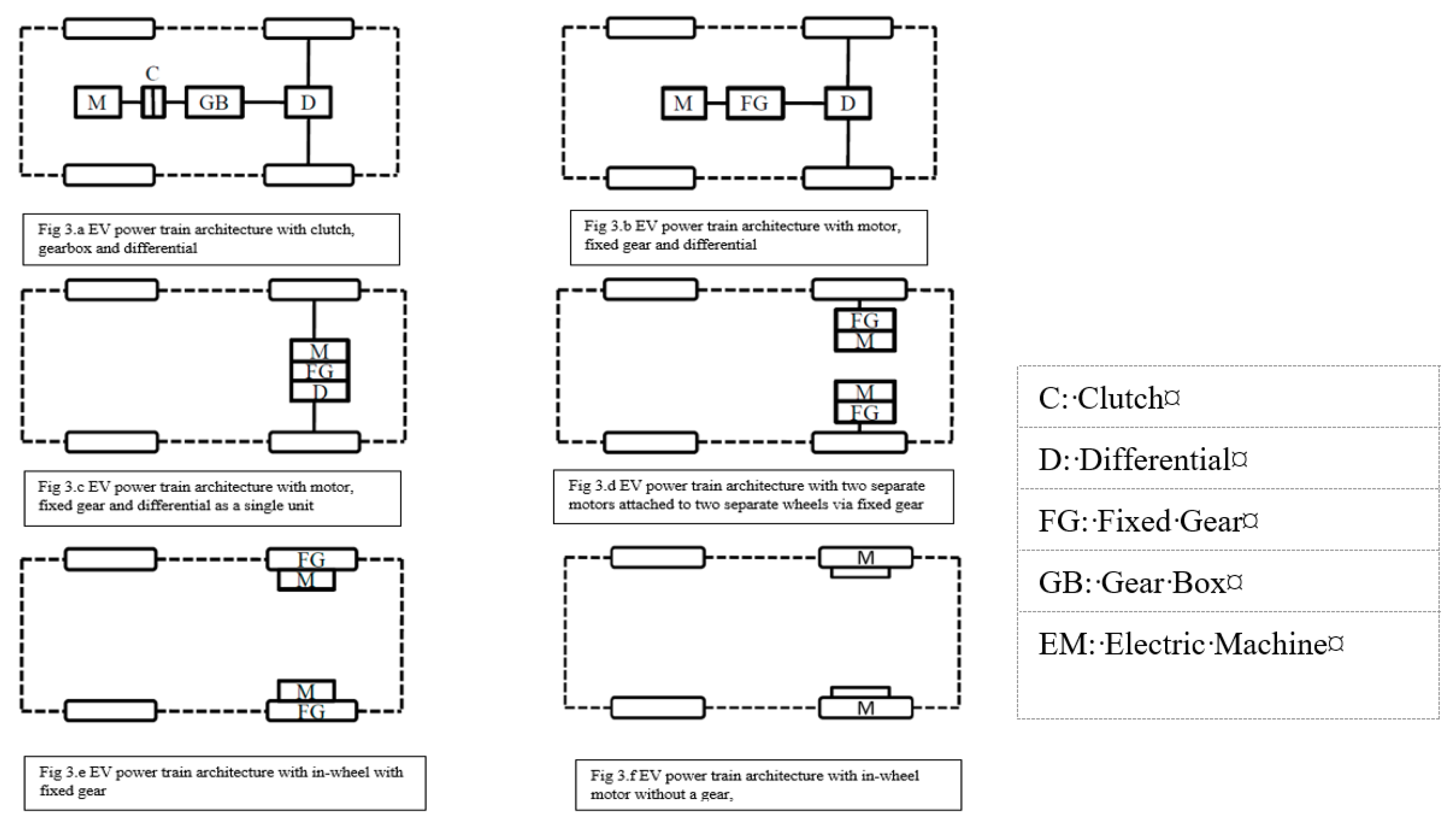

Pure Electric Vehicle Architecture

- Figure 3a presents an electric motor architecture system which has an electric motor, a clutch (C), a gearbox, and a differential (D). The clutch engages or disengages the power flow from electric motor to the wheels like it does in internal combustion engine powered vehicles. The wheels have low speed with high torque in the lower gears and low torque with high-speed in the higher gears. This architecture setup was mostly used in conversion of ICE powered vehicles to EVs utilizing the existing components.

- Figure 3b presents a single electric motor architecture with fixed gear. The advantage of this architecture is that the transmission weight is reduced as transmission and clutch have been omitted. Some vehicle conversion using electric machine without transmission system utilize this configuration.

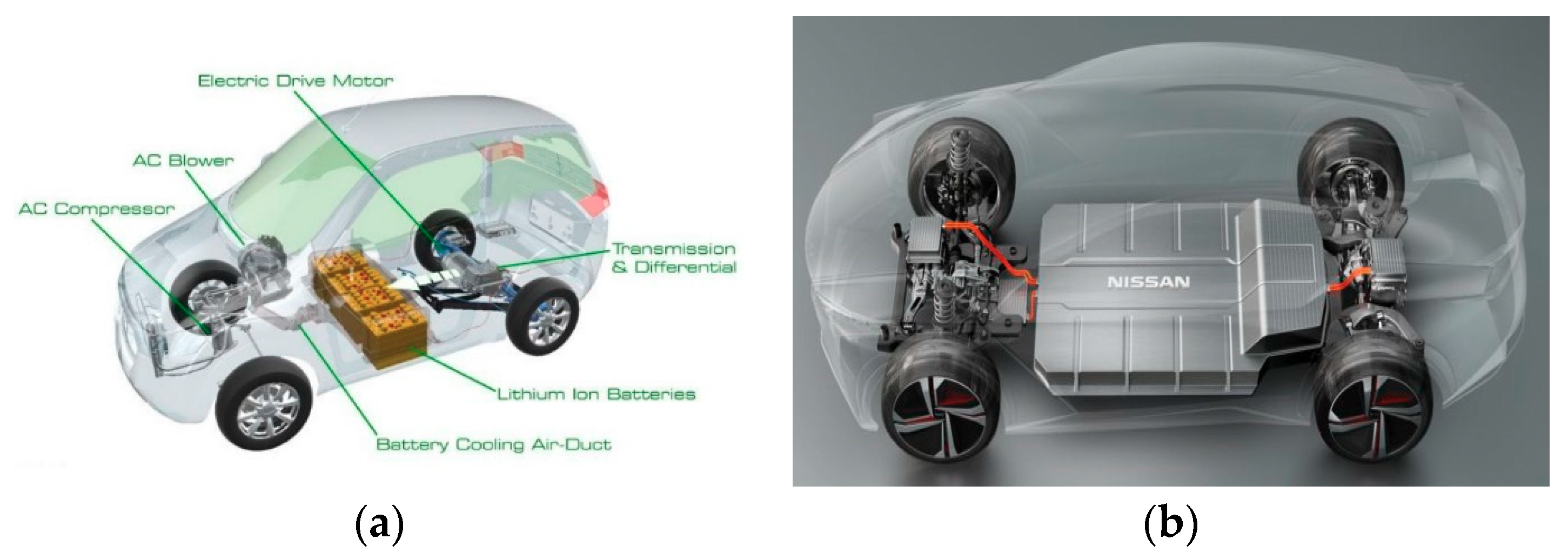

- Figure 3c presents an EV architecture using one electric motor. It is an EM with rear wheel drive architecture with fixed gearing and differential integrated into a single assembly, and has been preferred by most of the electric vehicle manufactures at present scenario. Figure 4a shows similar rear wheel drive system used by Mahindra electric e20.

- Figure 3d presents a dual-motor architecture. In this configuration, the differential action can be electronically controlled provided by two electric motors that operates at different speeds. In this dual-motor architecture, the driving wheels are derived separately by two separate electric motors separately via fixed gearing.

- Figure 3e shows an architecture with a fixed planetary gearing system employed to reduce the motor speed to the desired wheel speed. This architecture is called an in-wheel drive system and the planetary gearing in this system offers the advantages of a high-speed reduction ratio along with an inline arrangement of input and output shafts [55,60].

- Figure 3f presents an EV architecture without a mechanical gear system. A low-speed outer-rotor electric motor has been installed inside the wheels. The gearless arrangement with outer rotor mounted directly on the wheel rim makes equivalent speed control of the electric motor with the wheel speed and, hence, speed of the vehicle [64,65,66,67].

4. Electric Propulsion

4.1. Electric Machines and Drives

4.2. Brushed DC Motor Drive

4.2.1. Brushed DC Drive Control

4.2.2. Application of DC Motor in Electric Vehicles

4.3. Permanent Magnet Brushless DC Motor

- high-energy PMs, light weight, and lower volume providing higher power density offering higher efficiency due to the absence of copper loss;

- better heat dissipation and cooling;

- higher reliability due to lower heating and lower manufacturing defects.

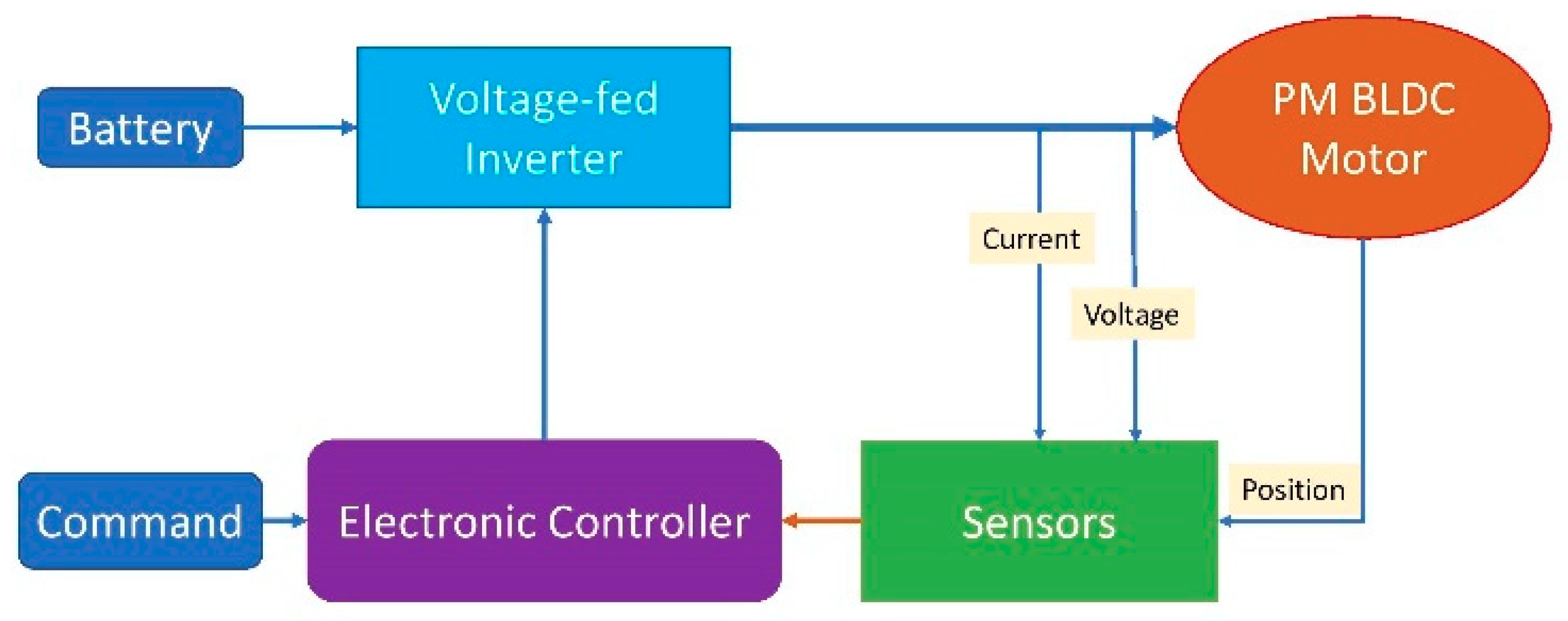

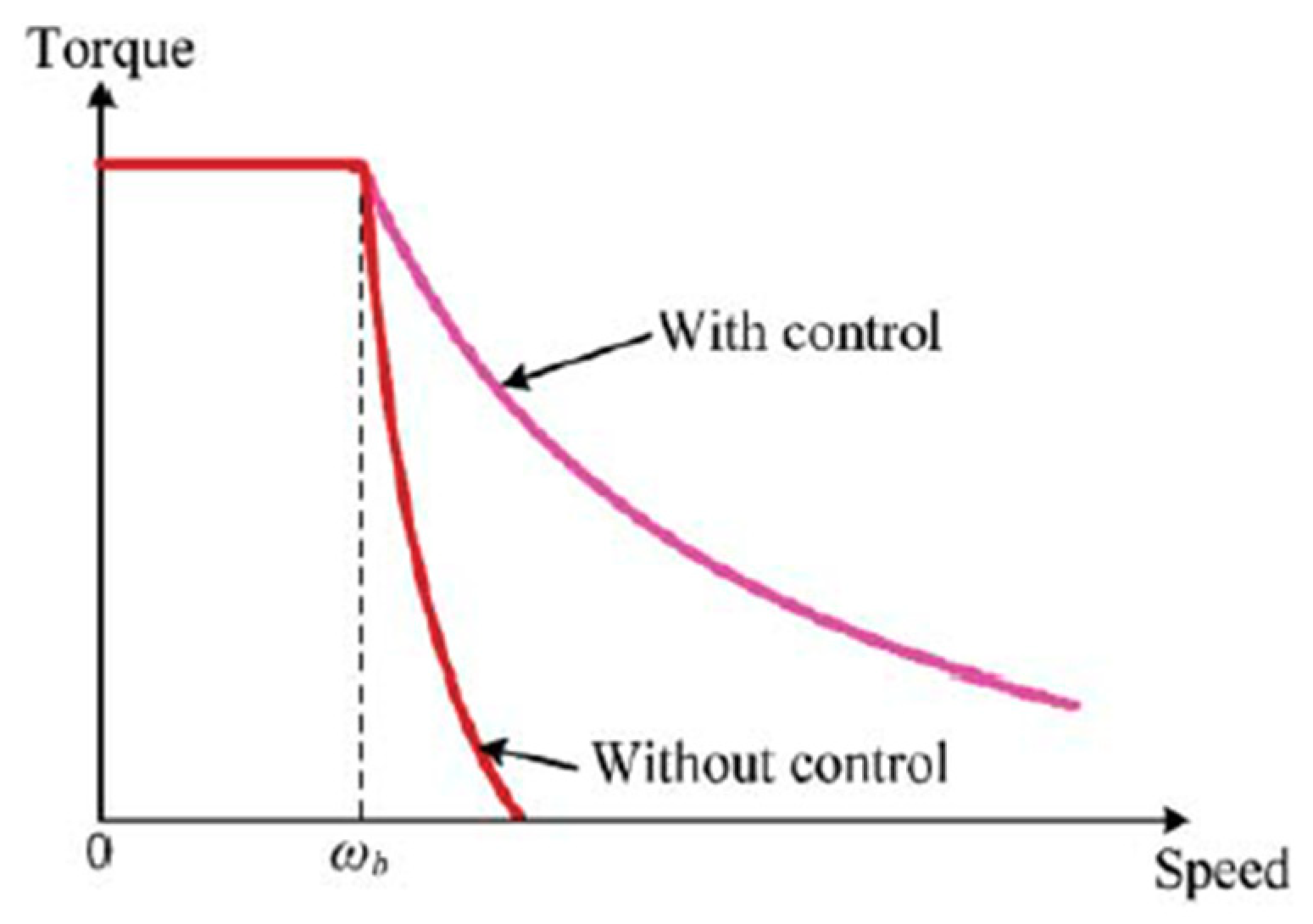

4.3.1. PM Brushless DC Motor Control

4.3.2. Application of PM BLDC Motor in Electric Vehicle

Out-Runner Type BLDC Motor

In-Runner Type BLDC Motor

4.3.3. Permanent Magnet Synchronous Motor (PMSM)

- efficiency is higher compared to brushless DC motors,

- absence of torque ripple when the motor is commutated,

- better performance with the higher torque,

- reliable and less noisy,

- performance is high in both higher and lower speed of operation,

- easy to control due to lower inertia of the rotor,

- heat dissipation is efficient,

- smaller in size.

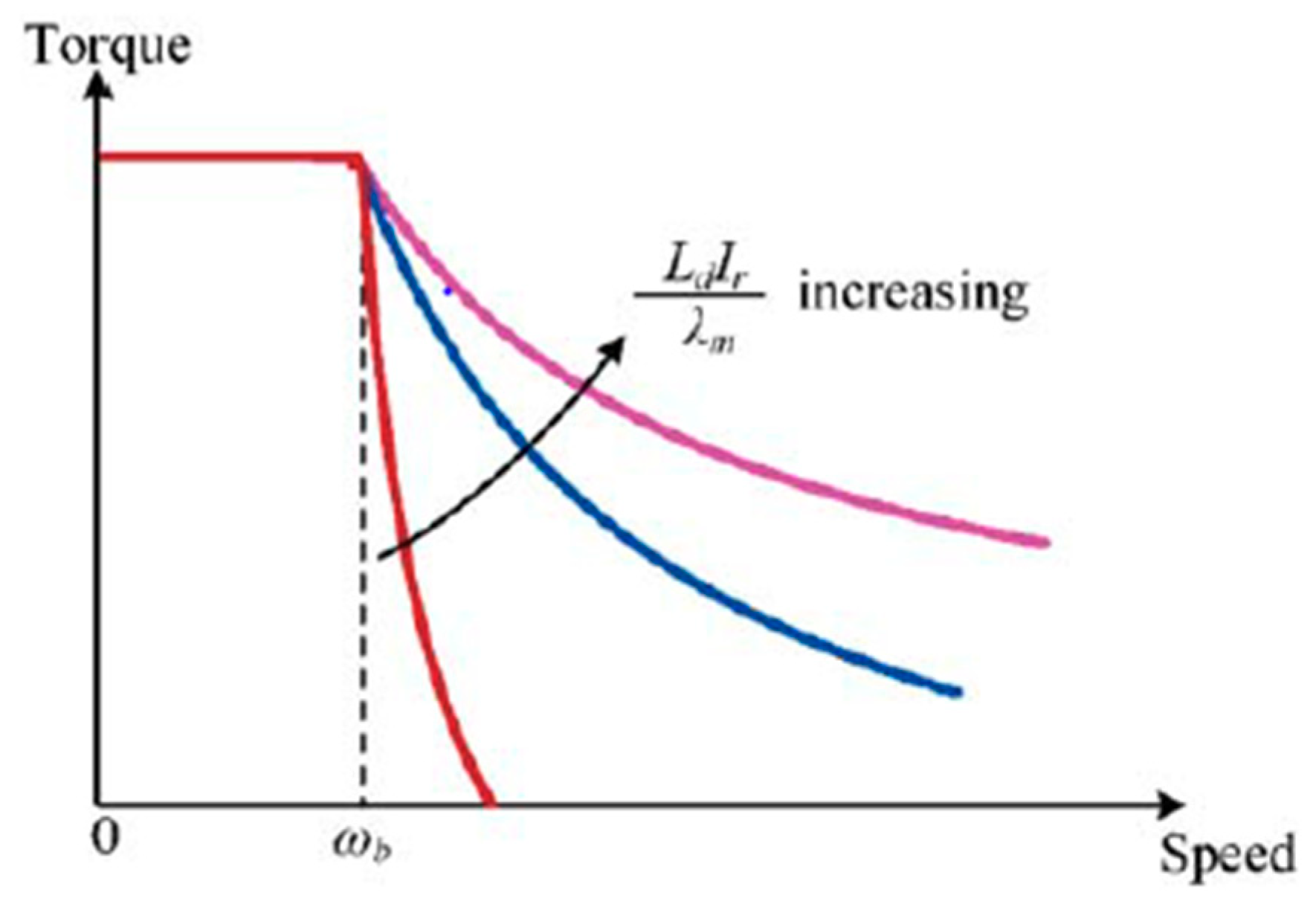

4.4. PMSM Motor Control

- (a)

- Field-Oriented Control (FOC)

- (b)

- Flux-Weakening Control (FWC)

- (c)

- Position Sensorless Control (PSC)

Application of PMSM Drive in Electric Vehicles

4.5. Induction Motor System

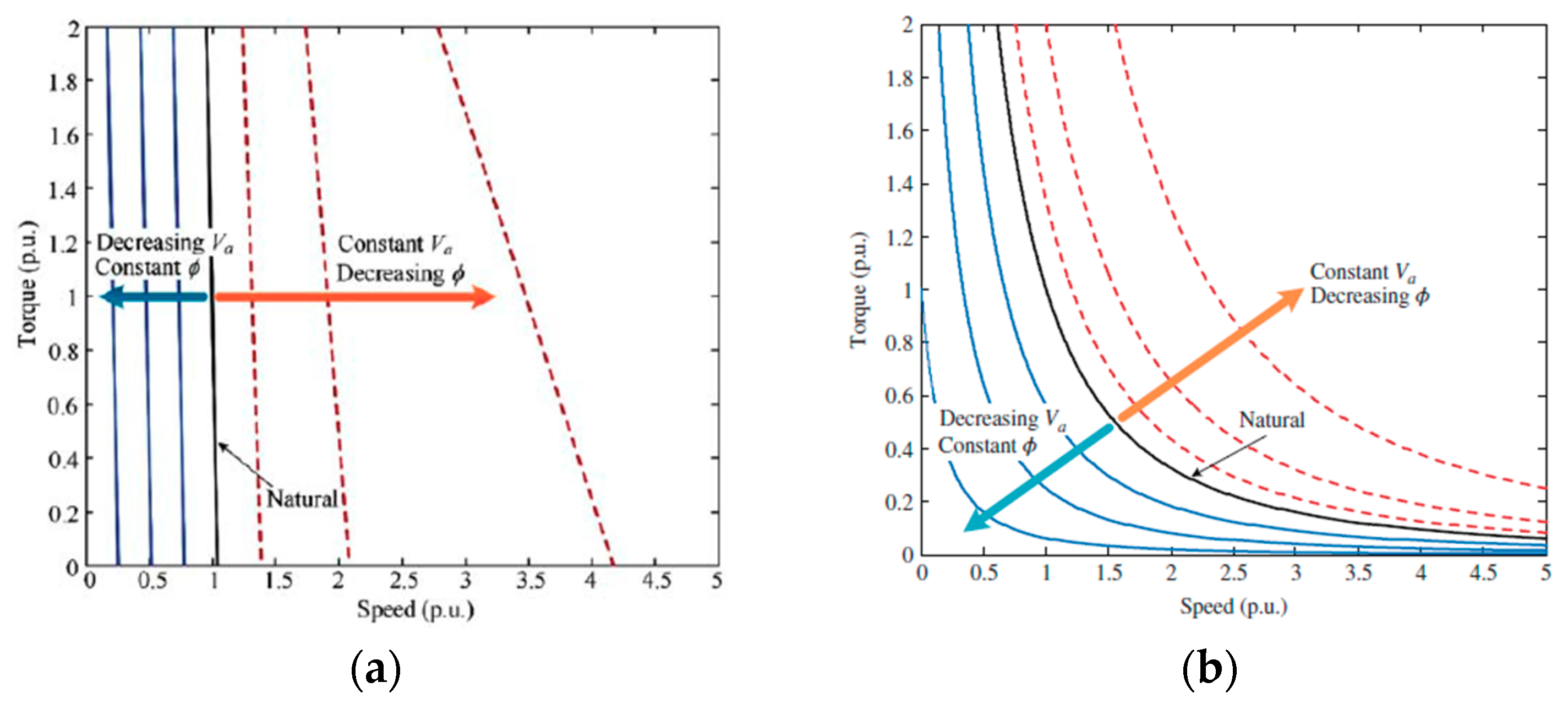

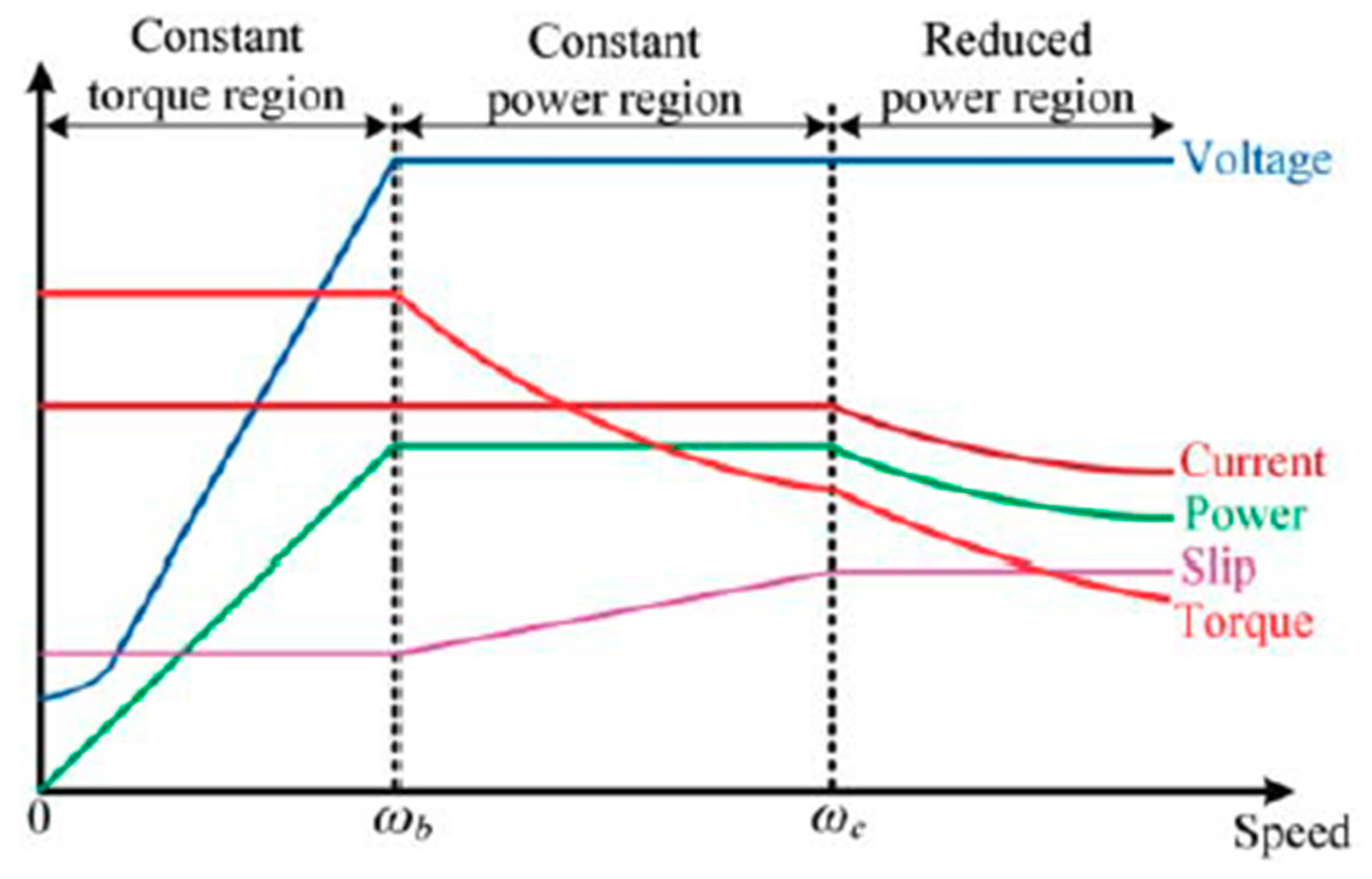

Induction Motor Control

- (a)

- Variable-Voltage Variable-Frequency (VVVF) Control

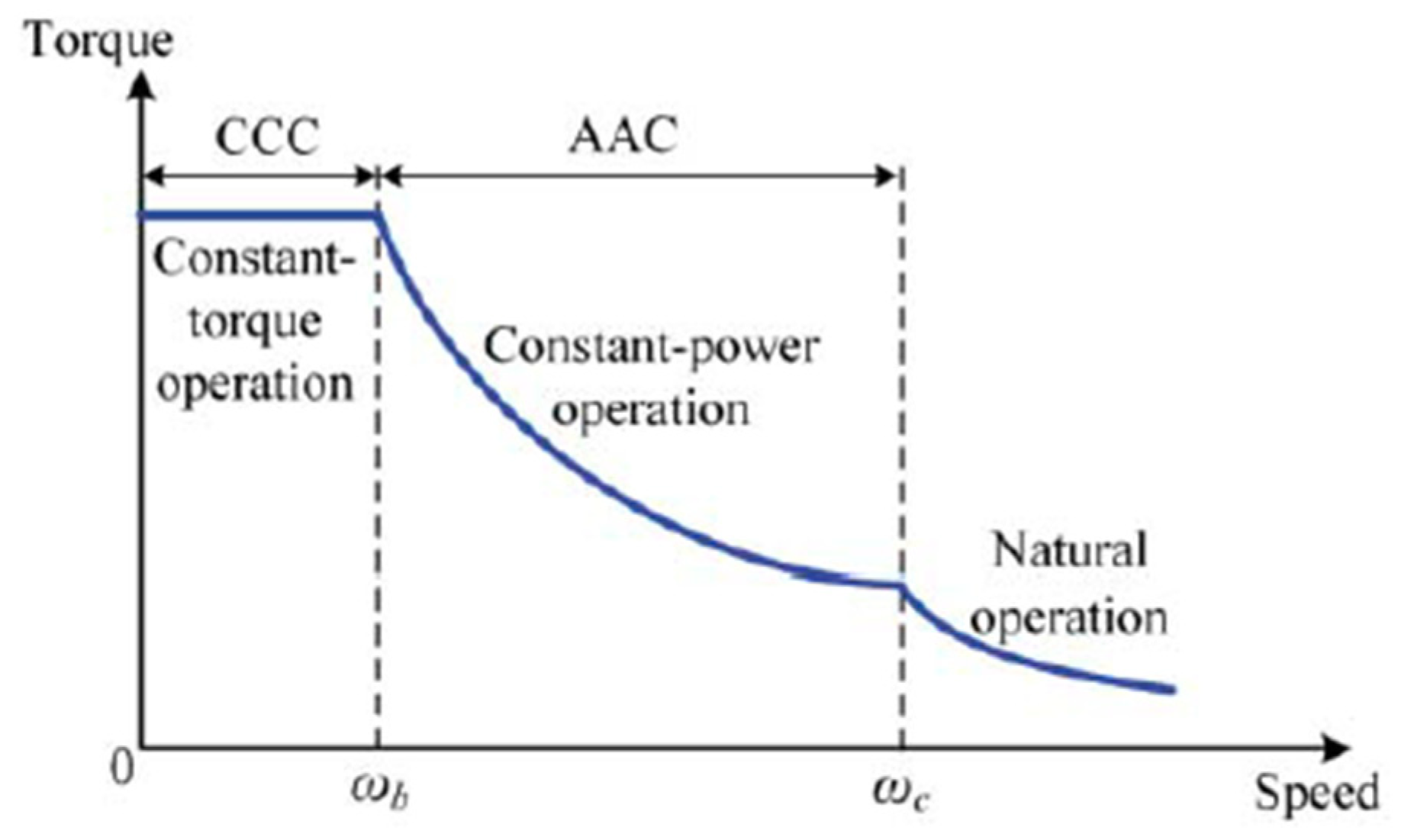

- Below the rated speed, the motor delivers rated torque in constant torque region.

- The slip is increased gradually to the maximum value at constant-power region with constant stator current and the motor runs with the rated power.

- The slip remains constant in the reduced power region where there is decrement in stator current and the torque capability declines with the square of the speed.

- (b)

- Field-Oriented Control (FOC)

- The direct FOC, also known by the direct vector control, identifies the rotor flux linkage instantaneously by measuring the air-gap flux from stator voltage or current.

- The indirect FOC, also known as indirect vector control, has been widely used in the induction motor drive for driving the EVs. This technique does not need to identify the rotor flux linkage.

- (c)

- Direct Torque Control (DTC)

4.6. Switch Reluctance Motor

SRM Control System

- (a)

- Planetary-Geared SR Motor Drive

- (b)

- Outer-Rotor In-Wheel SR Motor Drive

4.7. Comparison of Existing EV Drives

4.8. Stator Permanent Magnet Motor

- Doubly-salient permanent magnet (DSPM) machine

- Flux-reversal permanent magnet (FRPM) machine

- Flux-switching permanent magnet FSPM machine

- Hybrid-excited permanent magnet (HEPM)

- Flux-mnemonic permanent magnet (FMPM)

Potential Application in Electric Vehicle

- Absence of PMs in the rotor, thus avoiding the problem of mounting them on the high-speed rotor and hence to withstand the high centrifugal force.

- All PMs are located in the stator, with cooling arrangement and proving the thermal instability.

4.9. Advance Magnetless Motor

- Synchronous reluctance (SynR)

- Doubly-salient DC (DSDC)

- Flux-switching DC (FSDC)

- Vernier reluctance (VR)

- Doubly-fed Vernier reluctance (DFVR)

Potential Application of Advance Magnetless Motor

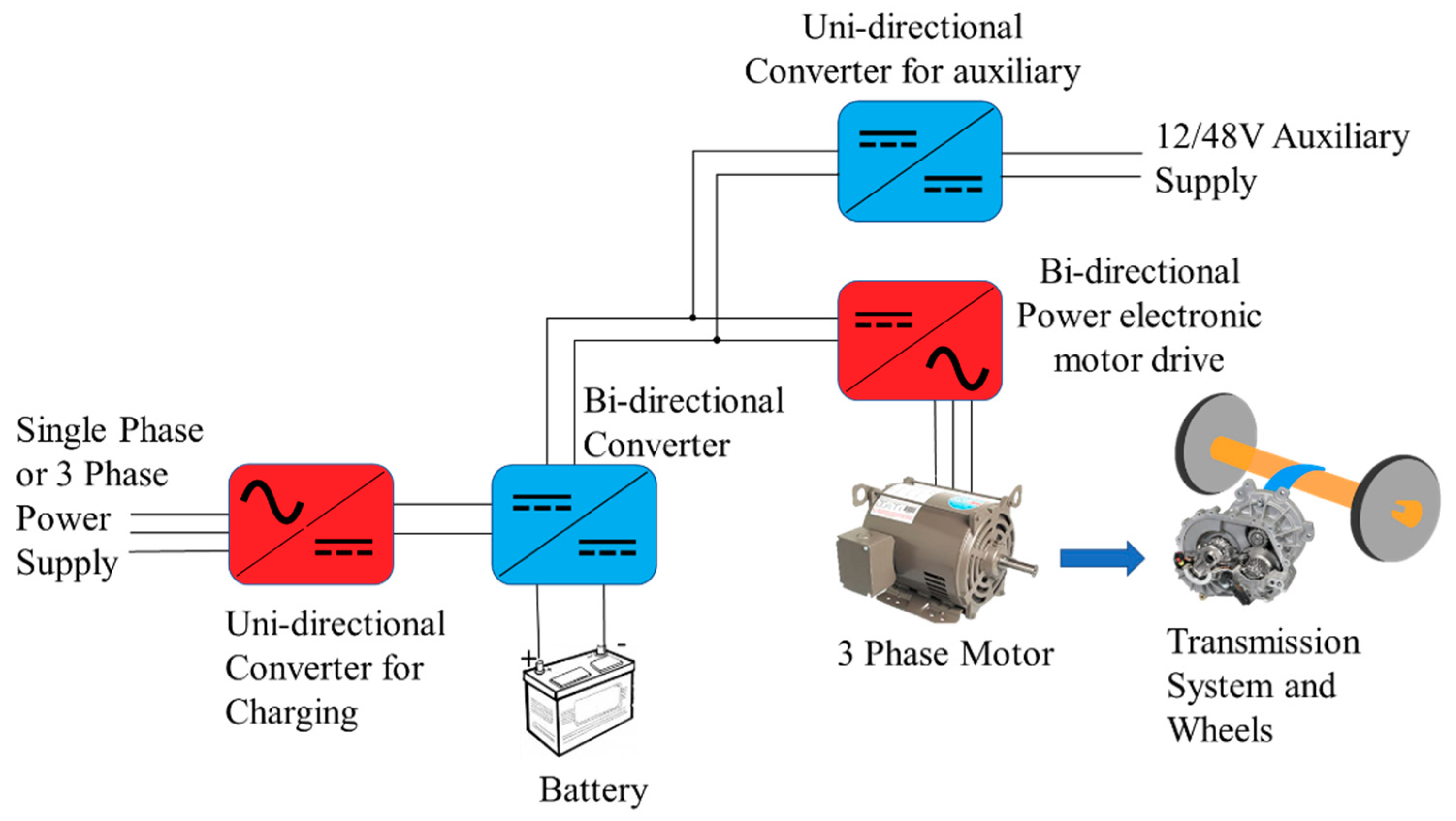

5. Power Electronics

6. Transmission System

6.1. Multi-Motor Drive Transmission System

6.2. In-Wheel Drive

7. EV Power Train Optimization with Performance Consideration

7.1. Dynamic Performance

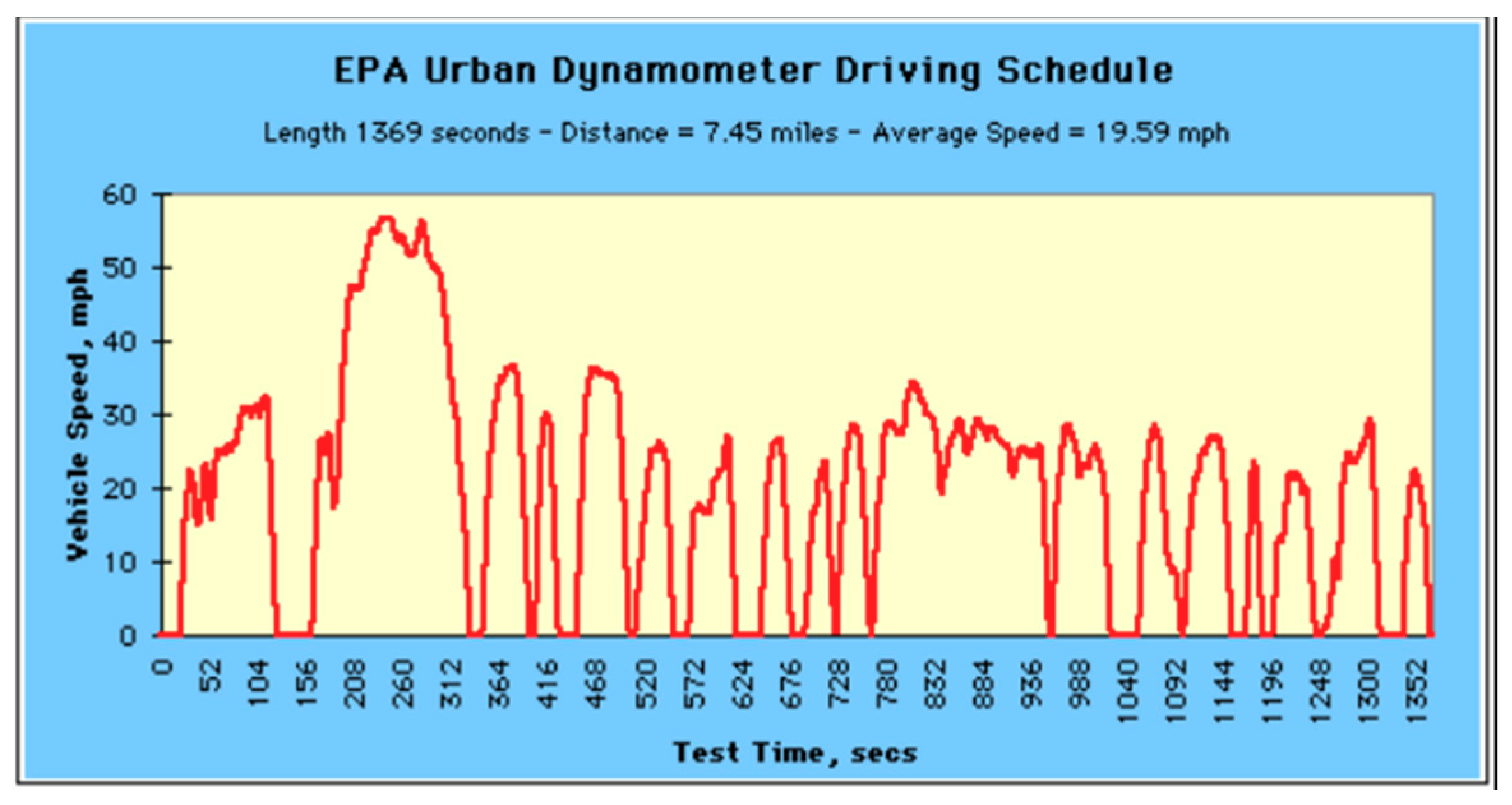

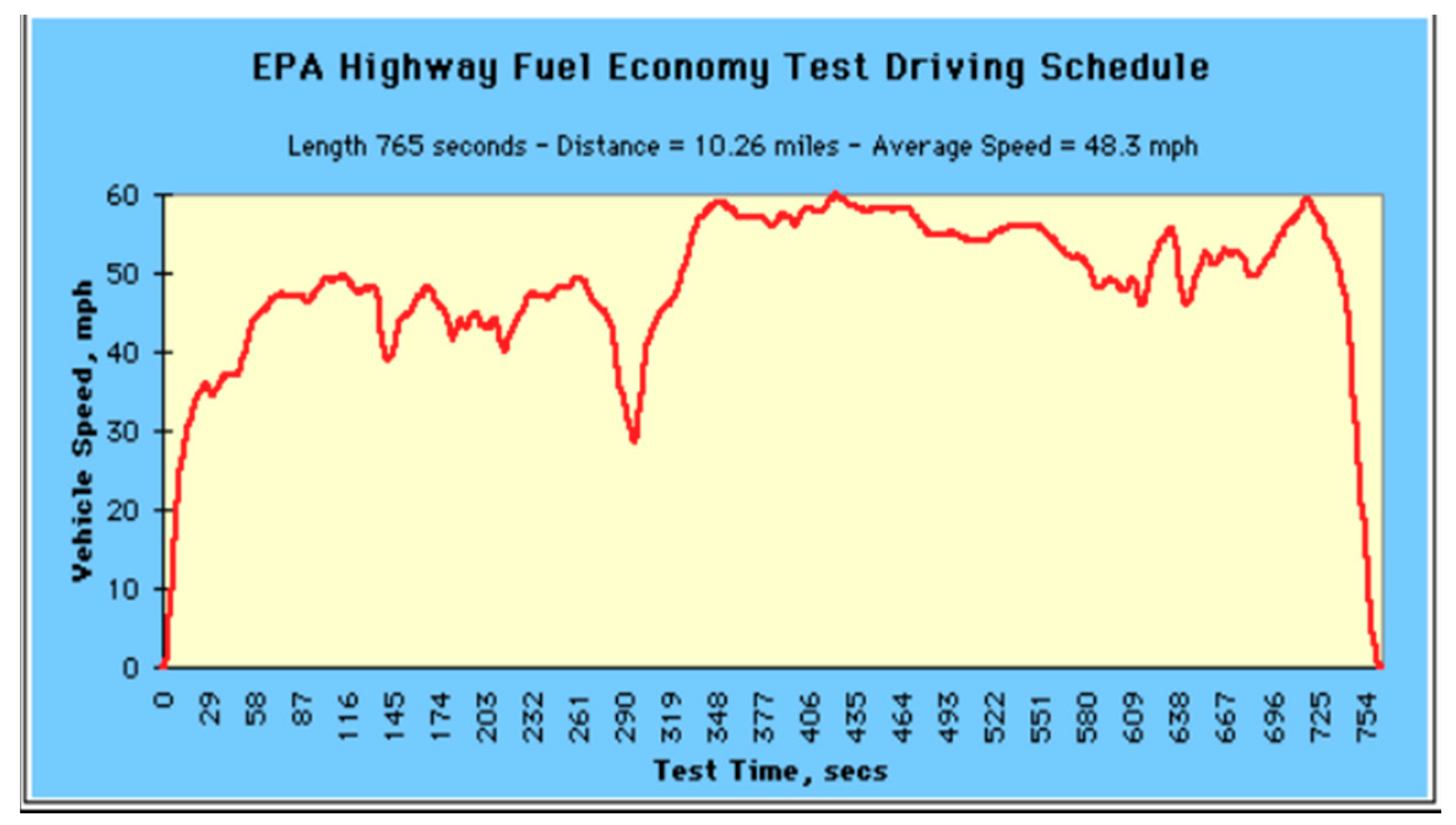

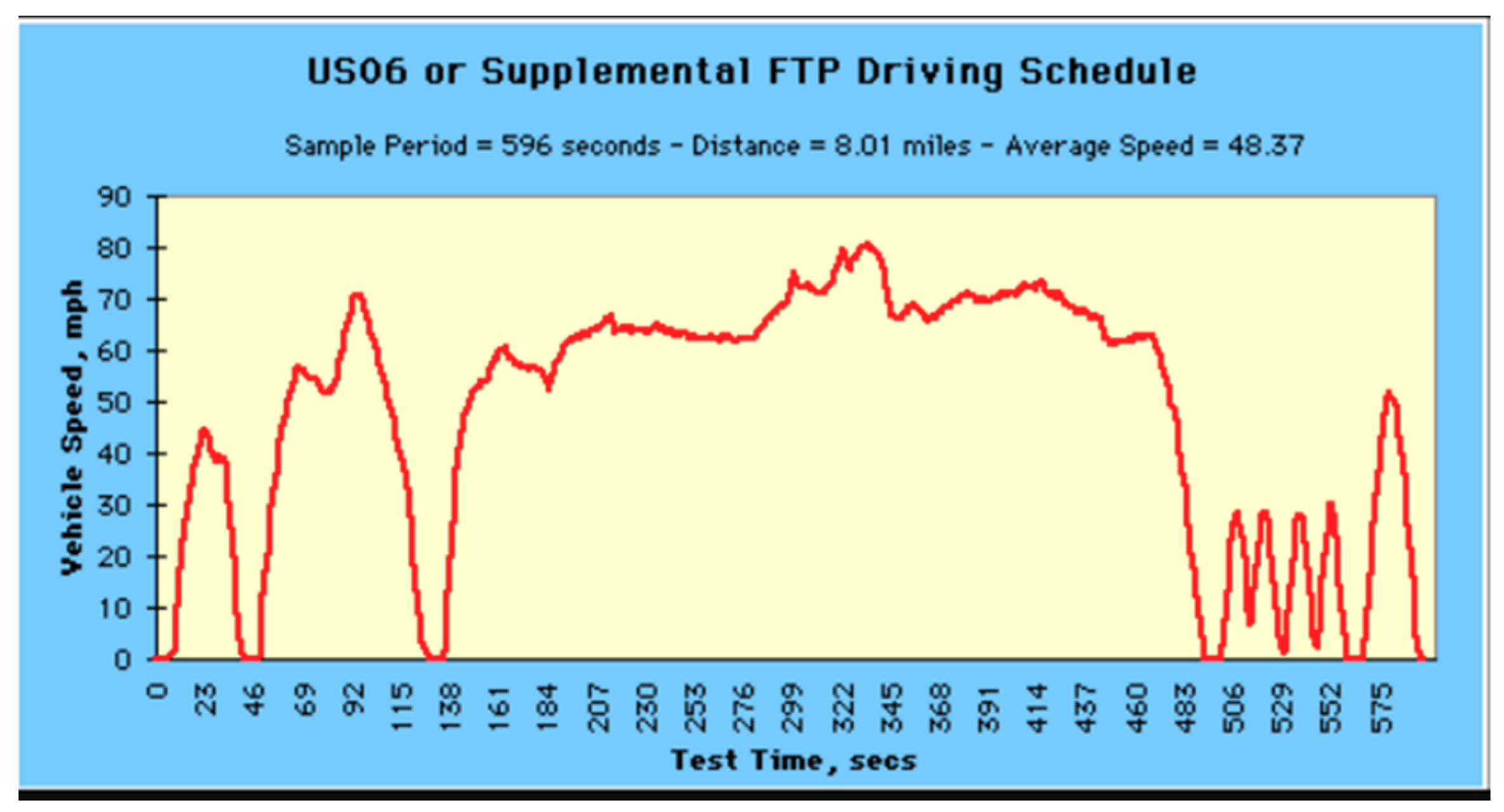

7.2. Drive Cycle

7.3. Performance Parameters

8. Future of Power Train System in Electric Vehicles

9. Discussion

- Different configurations are available for the drive train architecture in EVs. EVs can have front wheel drive, rear wheel drive, single motor drive, dual motor drive, or even all-wheel drive. In-wheel drive vehicles offer distinct advantages such as avoiding transmission as a major one. Different configuration of drive trains has not commercially penetrated now, but they do have scopes for use in future EVs.

- Varieties of electric machines of different designs and configurations can be employed for use in EVs. Induction motors, permanent magnet synchronous motors, and synchronous reluctance motors are the eminent machines to propel EVs. Induction motors have been mostly used by present electric vehicles like Tesla and Mahindra Electric, while PMSM is currently being widely used with brands like Hyundai, Kia, BYD, etc. The next few years will be interesting to see the battle between induction and PMSM motors in electric drive trains.

- Power electronics have developed to a great extent and different control systems have been produced and adopted for driving motors, managing energy, and charging the batteries. With increased penetration of new EV drive systems, energy sources, and charging technologies in the future, there will be greater oppostunities for more efficient control mechanisms.

- Drive train optimization has been a trend for research. Consequently, efficient drive components could be developed. Different simulation tools have been in use for this approach for the design and optimization of the drive train, control unit, and sizing battery pack as well. Recently, multi speed transmission systems, especially two-speed transmission systems for EVs have been a hot topic, although major EV manufacturers are still using single speed fixed gear. In-wheel drive systems and their different configurations have been explained in order to avoid mechanical transmission systems. Most of the research has pointed the positive results with two-speed transmission systems when compared with fixed gear transmissions, as they can minimize the size of the drive train unit as well as increase the efficiency and advantages of in-wheel drive systems. Both of these systems may be in use in future EVs, but a lot of research and experiments in the real world might need to be undertaken as it adds weight and complexity to drive units, as well as adding control complexity to in-wheel drive systems.

10. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Karki, A.; Shrestha, B.P.; Tuladhar, D.; Basnet, S.; Phuyal, S.; Baral, B. Parameters Matching for Electric Vehicle Conversion. In Proceedings of the 2019 IEEE Transportation Electrification Conference (ITEC-India), Bengaluru, India, 17–19 December 2019; pp. 1–5. [Google Scholar] [CrossRef]

- Yu, J.; Wang, J.; Liang, G.; Li, D. Pure electric vehicle driving system parameter matching in motor higher efficiency interval. In Proceedings of the 2012 International Conference on Systems and Informatics (ICSAI2012), Yantai, China, 19–20 May 2012; pp. 594–597. [Google Scholar] [CrossRef]

- Guo, X.; Fu, L.; Ji, M.; Lang, J.; Chen, D.; Cheng, S. Scenario analysis to vehicular emission reduction in Beijing-Tianjin-Hebei (BTH) region, China. Environ. Pollut. 2016, 216, 470–479. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Wang, R.; Zhou, Y.; Lin, B.; Fu, L.; He, K.; Hao, J. On-Road Vehicle Emission Control in Beijing: Past, Present, and Future. Environ. Sci. Technol. 2011, 45, 147–153. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zhang, S.; Hao, J.; Liu, H.; Wu, X.; Hu, J.; Walsh, M.P.; Wallington, T.J.; Zhang, K.M.; Stevanovic, S. On-road vehicle emissions and their control in China: A review and outlook. Sci. Total Environ. 2017, 574, 332–349. [Google Scholar] [CrossRef]

- Netz, B.; Davidson, O.; Bosch, P.; Dave, R.; Meyer, L. Climate Change 2007: Mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change. Summary for Policymakers; Cambridge University Press: Cambridge, UK, 2007. [Google Scholar]

- Kathuria, V. Impact of CNG on vehicular pollution in Delhi: A note. Transp. Res. Part D Transp. Environ. 2004, 9, 409–417. [Google Scholar] [CrossRef]

- Faiz, A.; Ale, B.B.; Nagarkoti, R.K. The role of inspection and maintenance in controlling vehicular emissions in Kathmandu valley, Nepal. Atmos. Environ. 2006, 40, 5967–5975. [Google Scholar] [CrossRef]

- Raux, C. The use of transferable permits in transport policy. Transp. Res. Part D Transp. Environ. 2004, 9, 185–197. [Google Scholar] [CrossRef]

- Das, B.; Bhave, P.V.; Puppala, S.P.; Byanju, R.M. A global perspective of vehicular emission control policy and practices: An interface with kathmandu valley case, nepal. J. Inst. Sci. Technol. 2018, 23, 76–80. [Google Scholar] [CrossRef]

- Neeft, J.P.; Makkee, M.; Moulijn, J.A. Diesel particulate emission control. Fuel Process. Technol. 1996, 47, 1–69. [Google Scholar] [CrossRef]

- Chapman, L. Transport and climate change: A review. J. Transp. Geogr. 2007, 15, 354–367. [Google Scholar] [CrossRef]

- Kirchstetter, T.W.; Harley, R.A.; Kreisberg, N.M.; Stolzenburg, M.R.; Hering, S.V. On-road measurement of fine particle and nitrogen oxide emissions from light-and heavy-duty motor vehicles. Atmos. Environ. 1999, 33, 2955–2968. [Google Scholar] [CrossRef]

- Shrestha, R.M.; Kim Oanh, N.; Shrestha, R.; Rupakheti, M.; Rajbhandari, S.; Permadi, D.; Kanabkaew, T.; Iyngararasan, M. Atmospheric Brown Clouds: Emission Inventory Manual; United Nations Environment Programme: Nairobi, Kenya, 2013. [Google Scholar]

- Zhang, Y.; Stedman, D.H.; Bishop, G.A.; Guenther, P.L.; Beaton, S.P. Worldwide on-road vehicle exhaust emissions study by remote sensing. Environ. Sci. Technol. 1995, 29, 2286–2294. [Google Scholar] [CrossRef] [PubMed]

- Andwari, A.M.; Pesiridis, A.; Rajoo, S.; Martinez-Botas, R.; Esfahanian, V. A review of Battery Electric Vehicle technology and readiness levels. Renew. Sustain. Energy Rev. 2017, 78, 414–430. [Google Scholar] [CrossRef]

- McKinsey, A. Portfolio of Power-Trains for Europe: A Fact-Based Analysis; Tech. Rep.; McKinsey & Company: New York, NY, USA, 2010. [Google Scholar]

- Poullikkas, A. Sustainable options for electric vehicle technologies. Renew. Sustain. Energy Rev. 2015, 41, 1277–1287. [Google Scholar] [CrossRef]

- Wager, G.; Whale, J.; Braunl, T. Driving electric vehicles at highway speeds: The effect of higher driving speeds on energy consumption and driving range for electric vehicles in Australia. Renew. Sustain. Energy Rev. 2016, 63, 158–165. [Google Scholar] [CrossRef]

- Shafie-Khah, M.; Neyestani, N.; Damavandi, M.; Gil, F.; Catalão, J. Economic and technical aspects of plug-in electric vehicles in electricity markets. Renew. Sustain. Energy Rev. 2016, 53, 1168–1177. [Google Scholar] [CrossRef]

- Brasil, D. Provides for the New Stage of the Vehicle Emission Control Program-PROCONVE 20; Resolution No. 315; International Council on Clean Transportation: Washington DC, USA, 2002. [Google Scholar]

- Steinberg, I.; Nasdal, R.; Kurtzke, A. GETRAG 6HDT451:“Mild-Hybrid Including Wet-Running Dual-Clutch”. In Proceedings of the Vehicle Transmissions 2011, Friedrichshafen, Germany, 7–8 July 2011. [Google Scholar]

- Naunheimer, H.; Bertsche, B.; Ryborz, J.; Novak, W. Matching Engine and Transmission. In Automotive Transmissions; Springer: Berlin/Heidelberg, Germany, 2011; pp. 115–139. [Google Scholar]

- Yong, J.Y.; Ramachandaramurthy, V.K.; Tan, K.M.; Mithulananthan, N. A review on the state-of-the-art technologies of electric vehicle, its impacts and prospects. Renew. Sustain. Energy Rev. 2015, 49, 365–385. [Google Scholar] [CrossRef]

- Rana, L.B.; Shrestha, A.; Phuyal, S.; Mali, B.; Lakhe, O.; Maskey, R.K. Design and Performance Evaluation of Series Hybrid Electric Vehicle using Backward Model. J. Eng. 2020, 14, 1–10. [Google Scholar]

- Amjad, S.; Neelakrishnan, S.; Rudramoorthy, R. Review of design considerations and technological challenges for successful development and deployment of plug-in hybrid electric vehicles. Renew. Sustain. Energy Rev. 2010, 14, 1104–1110. [Google Scholar] [CrossRef]

- Shareef, H.; Islam, M.M.; Mohamed, A. A review of the stage-of-the-art charging technologies, placement methodologies, and impacts of electric vehicles. Renew. Sustain. Energy Rev. 2016, 64, 403–420. [Google Scholar] [CrossRef]

- Isobe, F.; Itakura, Y.; Osumi, Y.; Li, G. One Motor Type Electric Vehicle Drive System. Available online: https://www.ntnglobal.com/en/news/new_products/news201100027.html (accessed on 13 August 2020).

- Al-Alawi, B.M.; Bradley, T.H. Review of hybrid, plug-in hybrid, and electric vehicle market modeling studies. Renew. Sustain. Energy Rev. 2013, 21, 190–203. [Google Scholar] [CrossRef]

- Arora, S.; Shen, W.; Kapoor, A. Review of mechanical design and strategic placement technique of a robust battery pack for electric vehicles. Renew. Sustain. Energy Rev. 2016, 60, 1319–1331. [Google Scholar] [CrossRef]

- Hannan, M.; Hoque, M.; Mohamed, A.; Ayob, A. Review of energy storage systems for electric vehicle applications: Issues and challenges. Renew. Sustain. Energy Rev. 2017, 69, 771–789. [Google Scholar] [CrossRef]

- Tie, S.F.; Tan, C.W. A review of energy sources and energy management system in electric vehicles. Renew. Sustain. Energy Rev. 2013, 20, 82–102. [Google Scholar] [CrossRef]

- Peng, M.; Liu, L.; Jiang, C. A review on the economic dispatch and risk management of the large-scale plug-in electric vehicles (PHEVs)-penetrated power systems. Renew. Sustain. Energy Rev. 2012, 16, 1508–1515. [Google Scholar] [CrossRef]

- Phuyal, S.; Bista, D.; Bista, R. Challenges, Opportunities and Future Directions of Smart Manufacturing: A State of Art Review. Sustain. Futures 2020, 2, 100023. [Google Scholar] [CrossRef]

- Phuyal, S.; Izykowski, J.; Bista, D.; Bista, R. Internet of Things in Power Industry: Current Scenario of Nepal. In Proceedings of the International Symposium on Current Research in Hydropower Technologies (CRHT’IX), Dhulikhel, Nepal, 9 April 2019. [Google Scholar]

- Daniele, C. Limousine rivoluzionaria. Auto Des. 2001, 127, 64–67. [Google Scholar]

- Kawakami, K.; Kakizaki, Y.; Shimizu, H.; Norek, J.; Melotti, L. Design concept of high performance electric vehicle “KAZ”. Bull. Jpn. Soc. Sci. Des. 2003, 49, 27–36. [Google Scholar]

- Chan, C. The state of the art of electric and hybrid vehicles. Proc. IEEE 2002, 90, 247–275. [Google Scholar] [CrossRef]

- Fenton, J. Handbook of Vehicle Design Analysis; Professional Engineering Publication: London, UK, 1996. [Google Scholar]

- Shimizu, H.; Harada, J.; Bland, C. The role of optimized vehicle design and power semiconductor devices to improve the performance of an electric vehicle. In Proceedings of the International Symposium on Power Semiconductor Devices and IC’s (ISPSD’95), Yokohama, Japan, 23–25 May 1995; pp. 8–12. [Google Scholar] [CrossRef]

- van Gogh, D.; Shimizu, H. Concept of ‘KAZ’The Start of a New Generation in Car Design. In Proceedings of the 18th International Electric Vehicle Symposium, Berlin, Germany, 20–24 October 2011; pp. 190–191. [Google Scholar]

- Shrestha, A.; Phuyal, S.; Shrestha, P.; Mali, B.; Rana, L.B. Comparative Analysis of Regenerative Power and Fuel Consumption of Hybrid Electric Vehicle. J. Asian Electr. Veh. 2018, 16, 1799–1809. [Google Scholar] [CrossRef]

- Anderson, C.D.; Anderson, J. Electric and Hybrid Cars: A History; McFarland and Company Inc.: Jefferson, NC, USA, 2010; ISBN 978-0-7864-3301-8. [Google Scholar]

- Prem, A.; Bastien, C.; Dickison, M. Multidisciplinary Design Optimisation Strategies for Lightweight Vehicle Structures. Available online: https://core.ac.uk/download/pdf/231744324.pdf (accessed on 13 August 2020).

- Happian-Smith, J. An Introduction to Modern Vehicle Design; Reed Educational and Professional Publishing Ltd.: Oxford, UK, 2002. [Google Scholar]

- Grunditz, E.A.; Thiringer, T. Performance analysis of current BEVs based on a comprehensive review of specifications. IEEE Trans. Transp. Electrif. 2016, 2, 270–289. [Google Scholar] [CrossRef]

- Sae, S. Electric Vehicle and Plug in Hybrid Electric Vehicle Conductive Charge Coupler; SAE International: Warrendale, PA, USA, January 2010. [Google Scholar]

- Yilmaz, M.; Krein, P.T. Review of battery charger topologies, charging power levels, and infrastructure for plug-in electric and hybrid vehicles. IEEE Trans. Power Electron. 2012, 28, 2151–2169. [Google Scholar] [CrossRef]

- Suarez, C.; Martinez, W. Fast and Ultra-Fast Charging for Battery Electric Vehicles–A Review. In Proceedings of the 2019 IEEE Energy Conversion Congress and Exposition (ECCE), Baltimore, MD, USA, 29 September–3 October 2019; pp. 569–575. [Google Scholar] [CrossRef]

- Ronanki, D.; Kelkar, A.; Williamson, S.S. Extreme Fast Charging Technology—Prospects to Enhance Sustainable Electric Transportation. Energies 2019, 12, 3721. [Google Scholar] [CrossRef]

- Yilmaz, M. Limitations/capabilities of electric machine technologies and modeling approaches for electric motor design and analysis in plug-in electric vehicle applications. Renew. Sustain. Energy Rev. 2015, 52, 80–99. [Google Scholar] [CrossRef]

- Ashique, R.H.; Salam, Z.; Aziz, M.J.B.A.; Bhatti, A.R. Integrated photovoltaic-grid dc fast charging system for electric vehicle: A review of the architecture and control. Renew. Sustain. Energy Rev. 2017, 69, 1243–1257. [Google Scholar] [CrossRef]

- Kumar, M.S.; Revankar, S.T. Development scheme and key technology of an electric vehicle: An overview. Renew. Sustain. Energy Rev. 2017, 70, 1266–1285. [Google Scholar] [CrossRef]

- Weiss, M.; Patel, M.K.; Junginger, M.; Perujo, A.; Bonnel, P.; van Grootveld, G. On the electrification of road transport-Learning rates and price forecasts for hybrid-electric and battery-electric vehicles. Energy Policy 2012, 48, 374–393. [Google Scholar] [CrossRef]

- Ehsani, M.; Gao, Y.; Longo, S.; Ebrahimi, K. Modern Electric, Hybrid Electric, and Fuel Cell Vehicles; CRC Press: Boca Raton, FL, USA, 2018. [Google Scholar]

- Gao, Y.; Maghbelli, H.; Ehsani, M.; Frazier, G.; Kajs, J.; Bayne, S. Investigation of Proper Motor Drive Characteristics for Military Vehicle Propulsion; SAE International: Warrendale, PA, USA, 2003. [Google Scholar]

- Anderson, C.; Pettit, E. The Effects of APU Characteristics on the Design of Hybrid Control Strategies for Hybrid Electric Vehicles; SAE International: Warrendale, PA, USA, 1995. [Google Scholar]

- Fenton, J.; Hodkinson, R. Lightweight Electric/hybrid Vehicle Design; Elsevier: Amsterdam, The Netherlands, 2001. [Google Scholar]

- Zhang, L.; Li, L.; Qi, B.; Song, J. Configuration Analysis and Performance Comparison of Drive Systems for Pure Electric Vehicle; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- Husain, I. Electric and Hybrid Electric Vehicles: Design Fundamentals; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Lee, C.H.T.; Chau, K.T.; Liu, C.; Chan, C.C. Overview of magnetless brushless machines. IET Electr. Power Appl. 2017, 12, 1117–1125. [Google Scholar] [CrossRef]

- Un-Noor, F.; Padmanaban, S.; Mihet-Popa, L.; Mollah, M.N.; Hossain, E. A comprehensive study of key electric vehicle (EV) components, technologies, challenges, impacts, and future direction of development. Energies 2017, 10, 1217. [Google Scholar] [CrossRef]

- Nasar, S.A.; Unnewehr, L.E. Electromechanics and Electric Machines; John Wiley & Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Tahami, F.; Kazemi, R.; Farhanghi, S. A novel driver assist stability system for all-wheel-drive electric vehicles. IEEE Trans. Veh. Technol. 2003, 52, 683–692. [Google Scholar] [CrossRef]

- Lampic, G.; Slivnik, T.; Detela, A. Holistic approach in developing propulsion for urban electric vehicles. In Proceedings of the 2005 IEEE Vehicle Power and Propulsion Conference, Chicago, IL, USA, 7 September 2005; p. 5. [Google Scholar] [CrossRef]

- Heim, R.; Hanselka, H.; El Dsoki, C. Technical potential of in-wheel motors for Electric Vehicles. ATZ Worldw. 2012, 114, 4–9. [Google Scholar] [CrossRef]

- Fraser, A. In-wheel electric motors. In Proceedings of the 10th International CTI Symposium, 9–12 May 2016; pp. 12–23. [Google Scholar]

- Biček, M.; Gotovac, G.; Miljavec, D.; Zupan, S. Mechanical failure mode causes of in-wheel motors. Stroj. Vestn. J. Mech. Eng. 2015, 61, 74–85. [Google Scholar] [CrossRef]

- Chan, C.; Chau, K. Modern Electric Vehicle Technology; Oxford University Press: Oxford, UK, 2011; ISBN 019-850-416-0. [Google Scholar]

- Lebeau, K.; Van Mierlo, J.; Lebeau, P.; Mairesse, O.; Macharis, C. The market potential for plug-in hybrid and battery electric vehicles in Flanders: A choice-based conjoint analysis. Transp. Res. Part D Transp. Environ. 2012, 17, 592–597. [Google Scholar] [CrossRef]

- Cheng, M.; Sun, L.; Buja, G.; Song, L. Advanced electrical machines and machine-based systems for electric and hybrid vehicles. Energies 2015, 8, 9541–9564. [Google Scholar] [CrossRef]

- Chau, K. Electric motor drives for battery, hybrid and fuel cell vehicles. In Electric Vehicles: Technology, Research and Development; Nova Science: Hauppauge, NY, USA, 2009. [Google Scholar]

- Zhu, Z.-Q.; Howe, D. Electrical machines and drives for electric, hybrid, and fuel cell vehicles. Proc. IEEE 2007, 95, 746–765. [Google Scholar] [CrossRef]

- Chan, C.C.; Chau, K. An overview of power electronics in electric vehicles. IEEE Trans. Ind. Electron. 1997, 44, 3–13. [Google Scholar] [CrossRef]

- Rajashekara, K. Present status and future trends in electric vehicle propulsion technologies. IEEE J. Emerg. Sel. Top. Power Electron. 2013, 1, 3–10. [Google Scholar] [CrossRef]

- TW, C. Four-quadrant zero-current-transition converter-fed DC motor drives for electric propulsion. J. Asian Electr. Veh. 2006, 4, 911–917. [Google Scholar]

- Cornell, E.; Guess, R.; Turnbull, F. Advanced motor developments for electric vehicles. IEEE Trans. Veh. Technol. 1977, 26, 128–134. [Google Scholar] [CrossRef]

- Chau, K. Electric Vehicle Machines and Drives: Design, Analysis and Application; John Wiley & Sons: Hoboken, NJ, USA, 2015. [Google Scholar]

- Hayes, J.G.; Goodarzi, G.A. Electric Powertrain; John Wiley and Sons Ltd.: Hoboken, NJ, USA, 2018; ISBN 9781119063667. [Google Scholar]

- Unnewehr, L.E.; Nasar, S.A. Electric Vehicle Technology; The National Academies of Sciences, Engineering, and Medicine: Washington DC, USA, 1982; p. 232. [Google Scholar]

- Vas, P. Electrical Machines and Drives: A Space-Vector Theory Approach; Oxford University Press: New York, NY, USA, 1992. [Google Scholar]

- Dubey, G.K. Power Semiconductor Controlled Drives; Prentice Hall Publications: Englewood Cliffs, NJ, USA, 1989. [Google Scholar]

- Xue, X.; Cheng, K.; Cheung, N. Selection of electric motor drives for electric vehicles. In Proceedings of the 2008 Australasian Universities Power Engineering Conference, Sydney, Australia, 14–17 December 2008; pp. 1–6. [Google Scholar]

- Hua, G.; Lee, F.C. Soft-switching techniques in PWM converters. IEEE Trans. Ind. Electron. 1995, 42, 595–603. [Google Scholar] [CrossRef]

- Say, M.G.; Taylor, E.O. Direct Current Machines; Pitman: London, UK, 1986. [Google Scholar]

- Cody, J. Regenerative Braking Control for a BLDC Motor in Electric Vehicle Applications. Bachelor’s Thesis, University of South Australia, School of Electrical and Information Engineering, Adelaide, Australia, 2008. [Google Scholar]

- Emadi, A. Handbook of Automotive Power Electronics and Motor Drives; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Su, G.-J.; McKeever, J.W.; Samons, K.S. Design of a PM brushless motor drive for hybrid electrical vehicle application. In Proceedings of the PCIM 2000 Conference, Boston, MA, USA, 1–5 October 2000. [Google Scholar]

- Cody, J.; Göl, Ö.; Nedic, Z.; Nafalski, A.; Mohtar, A. Regenerative Braking in an Electric Vehicle. Available online: http://www.komel.katowice.pl/zeszyty.html (accessed on 13 August 2020).

- Rahman, K.M.; Ehsani, M. Performance analysis of electric motor drives for electric and hybrid electric vehicle applications. In Proceedings of the Power Electronics in Transportation, Dearborn, MI, USA, 24–25 October 1996; pp. 49–56. [Google Scholar] [CrossRef]

- Chan, C.; Xia, W.; Jiang, J.; Chan, K.; Zhu, M. Permanent magnet brushless drives. IEEE Ind. Appl. Mag. 1998, 4, 16–22. [Google Scholar] [CrossRef]

- Safi, S.; Acarnley, P.; Jack, A. Analysis and simulation of the high-speed torque performance of brushless DC motor drives. IEE Proc. Electr. Power Appl. 1995, 142, 191–200. [Google Scholar] [CrossRef]

- Krishnan, R. Permanent Magnet Synchronous and Brushless DC Motor Drives; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Miller, T. Permanent Magnet and Reluctance Motor Drives; Oxford Science Publications: Oxford, UK, 1989. [Google Scholar]

- Gieras, J.F. Permanent Magnet Motor Technology: Design and Applications; CRC Press: Boca Raton, FL, USA, 2002. [Google Scholar]

- Sebastiangordon, T.; Slemon, G.R. Operating limits of inverter-driven permanent magnet motor drives. IEEE Trans. Ind. Appl. 1987, 327–333. [Google Scholar] [CrossRef]

- Chin, Y.; Soulard, J. A permanent magnet synchronous motor for traction applications of electric vehicles. In Proceedings of the IEEE International Electric Machines and Drives Conference (IEMDC’03), Madison, WI, USA, 1–4 June 2003; pp. 1035–1041. [Google Scholar] [CrossRef]

- Magnussen, F. On Design and Analysis of Synchronous Permanent Magnet Machines for Field-Weakening Operation in Hybrid Electric Vehicles; Elektrotekniska System, Royal Institute of Technology: Stockholm, Sweden, 2004. [Google Scholar]

- Kommula, B.N.; Kota, V.R. Direct instantaneous torque control of Brushless DC motor using firefly Algorithm based fractional order PID controller. J. King Saud Univ. Eng. Sci. 2020, 32, 133–140. [Google Scholar] [CrossRef]

- Yamada, K.; Watanabe, K.; Kodama, T.; Matsuda, I.; Kobayashi, T. An efficiency maximizing induction motor drive system for transmissionless electric vehicle. In Proceedings of the 13th International Electric Vehicle Symp, Osaka, Japan, 13–16 October 1996; pp. 529–536. [Google Scholar]

- Boglietti, A.; Ferraris, P.; Lazzari, M.; Profumo, F. A new design criteria for spindles induction motors controlled by field oriented technique. Electr. Mach. Power Syst. 1993, 21, 171–182. [Google Scholar] [CrossRef]

- Bose, B.K. Power Electronics and Motor Drives: Advances and Trends; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- Divan, D.M. The resonant DC link converter-a new concept in static power conversion. IEEE Trans. Ind. Appl. 1989, 25, 317–325. [Google Scholar] [CrossRef]

- Cheng, S.; Li, C.; Gong, H. Research on induction motor for mini electric vehicles. Energy Procedia 2012, 17, 249–257. [Google Scholar] [CrossRef]

- Nanda, G.; Kar, N.C. A survey and comparison of characteristics of motor drives used in electric vehicles. In Proceedings of the 2006 Canadian Conference on Electrical and Computer Engineering, Ottawa, ON, Canada, 7–10 May 2006; pp. 811–814. [Google Scholar] [CrossRef]

- Tabbache, B.; Kheloui, A.; Benbouzid, M. Design and control of the induction motor propulsion of an electric vehicle. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Bohari, A.A.; Utomo, W.M.; Haron, Z.A.; Zin, N.M.; Sim, S.; Ariff, R.M. Improved FOC of induction motor with online neural network. WSEAS Trans. Power Syst. 2014, 9, 136–142. [Google Scholar]

- Abbasian, M.; Moallem, M.; Fahimi, B. Double-stator switched reluctance machines (DSSRM): Fundamentals and magnetic force analysis. IEEE Trans. Energy Convers. 2010, 25, 589–597. [Google Scholar] [CrossRef]

- Cameron, D.E.; Lang, J.H.; Umans, S.D. The origin and reduction of acoustic noise in doubly salient variable-reluctance motors. IEEE Trans. Ind. Appl. 1992, 28, 1250–1255. [Google Scholar] [CrossRef]

- Gallegos-Lopez, G.; Kjaer, P.C.; Miller, T.; White, G. Simulation study of resonant DC link inverter for current-controlled switched reluctance motors. In Proceedings of the Second International Conference on Power Electronics and Drive Systems, Singapore, 17–20 November 2003; pp. 757–761. [Google Scholar] [CrossRef]

- Husain, I.; Ehsani, M. Torque ripple minimization in switched reluctance motor drives by PWM current control. IEEE Trans. Power Electron. 1996, 11, 83–88. [Google Scholar] [CrossRef]

- Krishnan, R. Switched Reluctance Motor Drives: Modeling, Simulation, Analysis, Design, and Applications; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Miller, T.J.E. Switched Reluctance Motors and Their Control; Magna Physics Publishing and Clarendon Press: Oxford, UK, 1993. [Google Scholar]

- Lin, W.-M.; Hong, C.-M.; Chen, C.-H.; Chien, H.-C. Implementation of a DSP-based hybrid sensor for switched reluctance motor converter. Int. J. Energy Environ. 2010, 1, 841–860. [Google Scholar]

- Sun, X.; Diao, K.; Yang, Z.; Lei, G.; Guo, Y.; Zhu, J. Direct Torque Control Based on a Fast Modeling Method for a Segmented-Rotor Switched Reluctance Motor in HEV Application. IEEE J. Emerg. Sel. Top. Power Electron. 2019. [Google Scholar] [CrossRef]

- Kachapornkul, S.; Jitkreeyarn, P.; Somsiri, P.; Tungpimolrut, K.; Chiba, A.; Fukao, T. A design of 15 kW switched reluctance motor for electric vehicle applications. In Proceedings of the 2007 International Conference on Electrical Machines and Systems (ICEMS), Seoul, South Korea, 24–27 November 2007; pp. 1690–1693. [Google Scholar]

- Cruickshank, A.; Anderson, A.; Menzies, R. Theory and performance of reluctance motors with axially laminated anisotropic rotors. Proc. Inst. Electr. Eng. 1971, 118, 887–894. [Google Scholar] [CrossRef]

- Lawrenson, P.J.; Gupta, S. Developments in the performance and theory of segmental-rotor reluctance motors. Proc. Inst. Electr. Eng. 1967, 114, 645–653. [Google Scholar] [CrossRef]

- Lee, C.H.; Chau, K.; Chan, C.; Liu, C.; Ching, T.W. Development of Axial-Field Flux-Switching DC In-Wheel Motor Drive for Electric Vehicles. In Proceedings of the 20th International Conference on Electrical Engineering, Jeju, South Korea, 20–21 November 2014; pp. 1591–1596. [Google Scholar]

- Lee, C.H.; Chau, K.; Liu, C.; Lin, F. Design and analysis of a magnetless flux-switching DC-excited machine for wind power generation. J. Int. Counc. Electr. Eng. 2014, 4, 80–87. [Google Scholar] [CrossRef]

- Profumo, F.; Zhang, Z.; Tenconi, A. Axial flux machines drives: A new viable solution for electric cars. IEEE Trans. Ind. Electron. 1997, 44, 39–45. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.-S.; McPhee, J. A survey of mathematics-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef]

- Mokrani, Z.; Rekioua, D.; Rekioua, T. Modeling, control and power management of hybrid photovoltaic fuel cells with battery bank supplying electric vehicle. Int. J. Hydrog. Energy 2014, 39, 15178–15187. [Google Scholar] [CrossRef]

- Wang, H.; Song, X.; Saltsman, B.; Hu, H. Comparative Studies of Drivetrain Systems for Electric Vehicles; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Holdstock, T. Investigation into Multiple-Speed Transmissions for Electric Vehicles. Ph.D Thesis, University of Surrey, Guildford, UK, 2015. [Google Scholar]

- Bottiglione, F.; De Pinto, S.; Mantriota, G.; Sorniotti, A. Energy consumption of a battery electric vehicle with infinitely variable transmission. Energies 2014, 7, 8317–8337. [Google Scholar] [CrossRef]

- Spanoudakis, P.; Tsourveloudis, N.C. On the efficiency of a prototype Continuous Variable Transmission system. In Proceedings of the 21st Mediterranean Conference on Control and Automation, Chania, Greece, 25–28 June 2013; pp. 290–295. [Google Scholar] [CrossRef]

- Mantriota, G. Fuel consumption of a vehicle with power split CVT system. Int. J. Veh. Des. 2005, 37, 327–342. [Google Scholar] [CrossRef]

- Zhang, Z.; Zuo, C.; Hao, W.; Zuo, Y.; Zhao, X.; Zhang, M. Three-speed transmission system for purely electric vehicles. Int. J. Automot. Technol. 2013, 14, 773–778. [Google Scholar] [CrossRef]

- Da-Tong, Q.; Bao-Hua, Z.; Ming-Hui, H.; Jian-jun, H.; Xi, W. Parameters Design of Powertrain System of Electric Vehicle with Two-Speed Gearbox; Journal of Chongqing University: Shapingba District, China, 2015. [Google Scholar]

- Spanoudakis, P.; Tsourveloudis, N. Prototype variable transmission system for electric vehicles: Energy consumption issues. Int. J. Automot. Technol. 2015, 16, 525–537. [Google Scholar] [CrossRef]

- Yin, Y.; Yin, X.; Luo, W.; Sun, H. Comparison Research of Electric Vehicles Equipped with Fixed Ratio Gearbox and Two-Speed Gearbox. Int. J. Recent Adv. Mech. Eng. (IJMECH) 2017, 6, 2. [Google Scholar] [CrossRef]

- Gao, B.; Liang, Q.; Xiang, Y.; Guo, L.; Chen, H. Gear ratio optimization and shift control of 2-speed I-AMT in electric vehicle. Mech. Syst. Signal Process. 2015, 50, 615–631. [Google Scholar] [CrossRef]

- Sorniotti, A.; Pilone, G.L.; Viotto, F.; Bertolotto, S.; Everitt, M.; Barnes, R.; Morrish, I. A novel seamless 2-speed transmission system for electric vehicles: Principles and simulation results. SAE Int. J. Engines 2011, 4, 2671–2685. [Google Scholar] [CrossRef]

- Spanoudakis, P.; Tsourveloudis, N.; Koumartzakis, G.; Krahtoudis, A.; Karpouzis, T.; Tsinaris, I. Evaluation of a 2-speed transmission on electric vehicle’s energy consumption. In Proceedings of the 2014 IEEE International Electric Vehicle Conference (IEVC), Florence, Italy, 17–19 December 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Elmarakbi, A.; Ren, Q.; Trimble, R. Modelling and analyzing electric vehicles with geared transmission systems: Enhancement of energy consumption and performance. Int. J. Eng. Res. Technol. 2013, 2, 1215–1254. [Google Scholar]

- Sorniotti, A.; Subramanyan, S.; Turner, A.; Cavallino, C.; Viotto, F.; Bertolotto, S. Selection of the optimal gearbox layout for an electric vehicle. SAE Int. J. Engines 2011, 4, 1267–1280. [Google Scholar] [CrossRef]

- Lukic, S.M.; Emado, A. Modeling of electric machines for automotive applications using efficiency maps. In Proceedings of the Electrical Insulation Conference and Electrical Manufacturing and Coil Winding Technology Conference, Indianapolis, Indiana, USA, 25 September 2003; pp. 543–550. [Google Scholar] [CrossRef]

- Liang, Q.; Tang, N.; Gao, B.; Chen, H. Optimal planning of the clutch slipping control for gear shift of 2-speed electric vehicle. In Proceedings of the 26th Chinese Control and Decision Conference (2014 CCDC), Changsha, China, 31 May–22 June 2014; pp. 1538–1543. [Google Scholar] [CrossRef]

- Di Nicola, F.; Sorniotti, A.; Holdstock, T.; Viotto, F.; Bertolotto, S. Optimization of a multiple-speed transmission for downsizing the motor of a fully electric vehicle. SAE Int. J. Altern. Powertrains 2012, 1, 134–143. [Google Scholar] [CrossRef]

- Walker, P.; Zhu, B.; Zhang, N. Powertrain dynamics and control of a two speed dual clutch transmission for electric vehicles. Mech. Syst. Signal Process. 2017, 85, 1–15. [Google Scholar] [CrossRef]

- Sorniotti, A.; Boscolo, M.; Turner, A.; Cavallino, C. Optimization of a multi-speed electric axle as a function of the electric motor properties. In Proceedings of the 2010 IEEE Vehicle Power and Propulsion Conference, Lille, France, 1–3 September 2010; pp. 1–6. [Google Scholar] [CrossRef]

- Zhou, X.; Walker, P.; Zhang, N.; Zhu, B.; Ding, F. The influence of transmission ratios selection on electric vehicle motor performance. In Proceedings of the International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; pp. 289–296. [Google Scholar] [CrossRef]

- Husain, I. Solutions Manual for Electric and Hybrid Vehicles; CRC Press: Boca Raton, FL, USA, 2003. [Google Scholar]

- Fujimoto, H.; Saito, T.; Tsumasaka, A. Motion Control and Road Condition Estimation of Electric Vehicles with two in-wheel Motors. In Proceedings of the 2004 IEEE International Conference on Control Applications, Taipei, Taiwan, 2–4 September 2004; Volume 2, pp. 1266–1271. [Google Scholar] [CrossRef]

- Gang, W. State and Development of Electric Cars in China. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-ZHBY200302014.htm (accessed on 13 August 2020).

- Fenzhu, J.; Feng, G.; Rong, Z. Parameter design for driving line of power train and study on driving range of EVS. J. Liaoning Tech. Univ. 2006, 25, 426–428. [Google Scholar]

- Zhou, M.; Zhao, L.; Zhang, Y.; Gao, Z.; Pei, R. Pure electric vehicle power-train parameters matching based on vehicle performance. Int. J. Control Autom. 2015, 8, 53–62. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, G.; Yang, X.; Zhou, C. The Electric Vehicle Power Design and The Matching Characteristics Analysis of The Transmission System. Telkomnika Indones. J. Electr. Eng. 2013, 11, 6352–6357. [Google Scholar] [CrossRef]

- Zhu, Z.; Yin, C.; Zhang, J.-W. Genetic Algorithm Based Optimization of Electric Vehicle Powertrain Parameters. Available online: http://en.cnki.com.cn/Article_en/CJFDTotal-SHJT200411030.htm (accessed on 13 August 2020).

- Kang, H.; Dandan, Z. Study on Driving Motor of Pure Electric Vehicles Based on Urban Road Conditions. In Proceedings of the 2013 International Conference on Communication Systems and Network Technologies, Gwalior, India, 4–6 July 2013; pp. 839–842. [Google Scholar] [CrossRef]

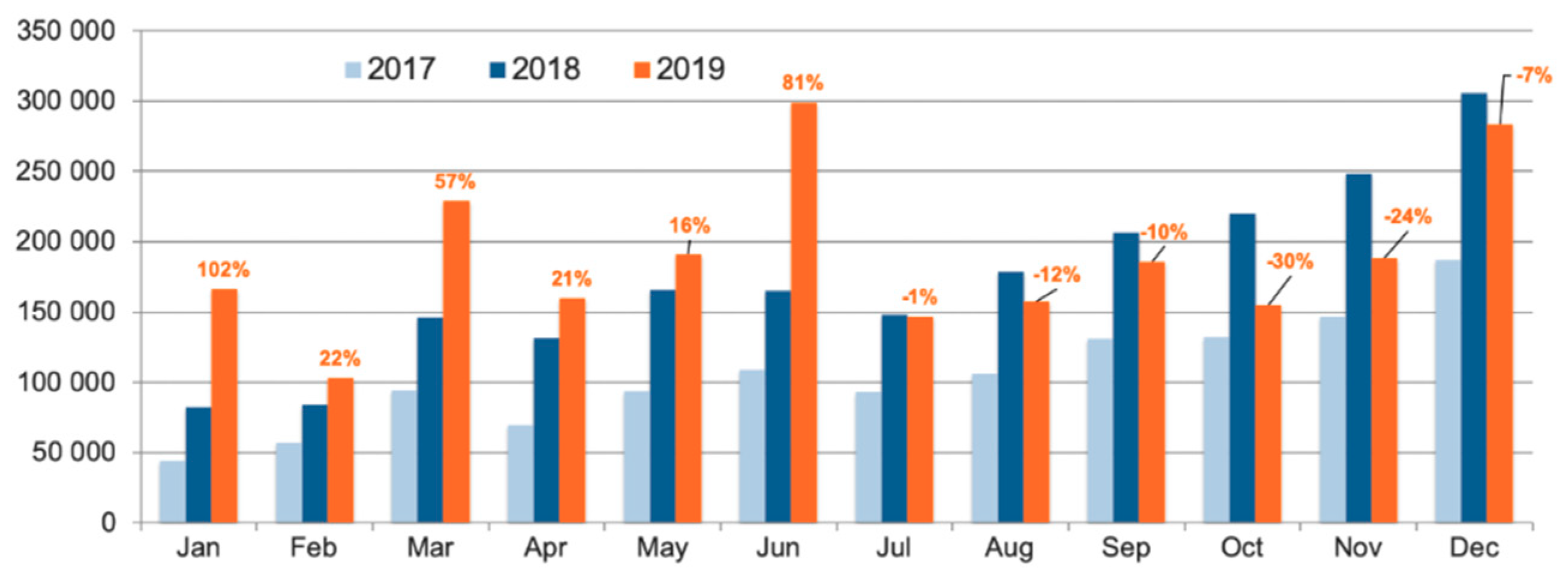

- Irle, R. Global EV Sales for 2018–Final Results. Available online: https://www.ev-volumes.com (accessed on 7 July 2020).

- Kane, M. Global EV Sales For 2019 Now In: Tesla Model 3 Totally Dominated. Available online: https://insideevs.com/news/396177/global-ev-sales-december-2019/ (accessed on 7 July 2020).

| Factors | DC | Induction | SR | PMSM | PM BLDC |

|---|---|---|---|---|---|

| Power density | 2 | 3 | 3.5 | 4.5 | 5 |

| Efficiency | 2 | 3 | 3.5 | 4.5 | 5 |

| Controllability | 5 | 4 | 3 | 4 | 4 |

| Reliability | 3 | 5 | 5 | 4 | 4 |

| Maturity | 5 | 5 | 4 | 5 | 4 |

| Cost level | 4 | 5 | 4 | 3 | 3 |

| Noise level | 3 | 5 | 2 | 5 | 5 |

| Maintenance | 1 | 5 | 5 | 5 | 5 |

| Total | 25 | 35 | 30 | 35 | 35 |

| Drives Types | BEV Models |

|---|---|

| DC | Panda Elettra from FIat, Citroen berlingo Electrique, reva G-Wiz DC, three-wheeled tempos |

| SR | Chloride Lucas, converted General Motor prototype, small pick-up prototytpe |

| Induction | GM EV1, BMW Mini E, Tesla Roadster, Reva G-Wiz I, Mahindra Electric- E20 series, Verito, etc. |

| PMSM | Nissan leaf, Mitsubishi i-MiEV Focus Electric, Citroen C-Zero, Peugeot iOn ED, BYD e6, Hyundai-Kona and Ioniq, KIA Soul EV and Niro, MG ZS EV, etc. |

| PM BLDC | Smart fortwo ED, three-wheel electric tuk-tuks, and some of Chinese electric cars. |

| Test Parameter | SAE J227a Schedule | ||

|---|---|---|---|

| B | C | D | |

| Max. Speed, km/h (mi/hr) | 32 | 48 | 72 |

| Acceleration time, ta (s) | 19 | 18 | 28 |

| Cruise time, tcr (s) | 19 | 20 | 50 |

| Coast time, tco (s) | 4 | 8 | 10 |

| Brake time, tbr (s) | 5 | 9 | 9 |

| Idle Time, Ti (s) | 25 | 25 | 25 |

| Total time (s) | 72 | 80 | 122 |

| Approximate no. of cycles per mile | 4–5 | 3 | 1 |

| Basic Vehicle Parameters | Vehicle Performance Indicator | Electric Machines Basic Parameters |

|---|---|---|

| CURB weight (kg) | Power performance parameters like | Rated power |

| Gross weight (kg) | Maximum Speed (km/h) | Peak power |

| Wheelbase (mm) | (0~50 km/h) Acceleration time (s) | Rated speed |

| Wheel rolling radius (mm) | Maximum climbable gradient (%) | Maximum speed |

| Frontal area (m2) | Endurance mileage (km) | Tared torque |

| Transmission rfficiency | Max. torque | |

| Drag coefficient | ||

| Rolling resistance coefficient |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karki, A.; Phuyal, S.; Tuladhar, D.; Basnet, S.; Shrestha, B.P. Status of Pure Electric Vehicle Power Train Technology and Future Prospects. Appl. Syst. Innov. 2020, 3, 35. https://doi.org/10.3390/asi3030035

Karki A, Phuyal S, Tuladhar D, Basnet S, Shrestha BP. Status of Pure Electric Vehicle Power Train Technology and Future Prospects. Applied System Innovation. 2020; 3(3):35. https://doi.org/10.3390/asi3030035

Chicago/Turabian StyleKarki, Abhisek, Sudip Phuyal, Daniel Tuladhar, Subarna Basnet, and Bim Prasad Shrestha. 2020. "Status of Pure Electric Vehicle Power Train Technology and Future Prospects" Applied System Innovation 3, no. 3: 35. https://doi.org/10.3390/asi3030035

APA StyleKarki, A., Phuyal, S., Tuladhar, D., Basnet, S., & Shrestha, B. P. (2020). Status of Pure Electric Vehicle Power Train Technology and Future Prospects. Applied System Innovation, 3(3), 35. https://doi.org/10.3390/asi3030035