Abstract

The food industry is trying to reformulate many of its products to replace functional ingredients that are chemically synthesized or isolated from animal sources (such as meat, fish, eggs, or milk) with ingredients derived from plant or microbial sources. This effort is largely a result of the demand for foods that are better for the environment, human health, and animal welfare. Many new kinds of plant- or microbial-derived proteins are being isolated for potential utilization as functional ingredients by the food industry. A major challenge in this area is the lack of standardized methods to measure and compare the functional performance of proteins under conditions they might be used in food applications. This information is required to select the most appropriate protein for each application. In this article, we discuss the physicochemical principles of emulsifier functionality and then present a series of analytical tests that can be used to quantify the ability of proteins to form and stabilize emulsions. These tests include methods for characterizing the effectiveness of the proteins to promote the formation and stability of the small droplets generated during homogenization, as well as their ability to stabilize the droplets against aggregation under different conditions (e.g., pH, ionic composition, temperature, and shearing). This information should be useful to the food industry when it is trying to identify alternative proteins to replace existing emulsifiers in specific food applications.

1. Introduction

An important trend in the modern food industry is the creation of foods designed to reduce the negative impacts of the food supply on the environment, human health, and animal welfare [,,]. A major thrust in this area is the replacement of animal-derived ingredients (such as those from meat, fish, eggs, or milk), with those from alternative sources (such as plants, algae, and microbes) [,,]. Proteins are one of the most versatile functional ingredients found in foods and so there is a strong focus on finding alternatives to animal proteins [,]. Animal proteins may be naturally present within whole foods (such as meat, fish, eggs, or milk) or they may be isolated and used as functional ingredients (such as gelatin, lysozyme, caseinate, or whey proteins) []. These proteins make important contributions to the desirable physicochemical, textural, and sensory attributes of many foods due to the diverse range of functional attributes, such as emulsification, foaming, thickening, gelling, structure forming, water holding, and oil retention []. Moreover, they contribute to the nutritional content of foods by providing calories and essential amino acids []. Consequently, it is important that any alternative proteins provide the same desirable functional and nutritional attributes as animal proteins. Proteins derived from animals, such as those isolated from milk (casein and whey protein), egg (ovalbumin), and meat (gelatin) are commonly used as emulsifiers in the food industry because they are amphiphilic molecules that can adsorb to oil-water interfaces, reduce the interfacial tension, and protect the oil droplets from aggregation. One of the major challenges in this area is that there are no widely recognized analytical methods available to measure and compare the functional attributes of animal and alternative proteins under conditions where they may be used in real food applications. As a result, it is difficult to select an alternative protein to replace an animal protein in specific food products.

In this article, we propose a series of analytical tests that can be used to characterize the ability of alternative proteins to form and stabilize emulsions. We also propose a standardized format for presenting the data from these tests so that the functional performance of different proteins can be compared under similar conditions. This is important because the ability of proteins to form and stabilize oil-in-water emulsions is critical in many kinds of food products. For instance, proteins can be used as emulsifiers in soft drinks, coffee creamers, dressings, sauces, desserts, and nutritional beverages, as well as in meat, egg, and dairy analogs [,]. Moreover, they can be used as emulsifiers in emulsion-based delivery systems, such as those used to encapsulate, protect, and deliver hydrophobic bioactive agents like oil-soluble vitamins, omega-3 lipids, and nutraceuticals [,].

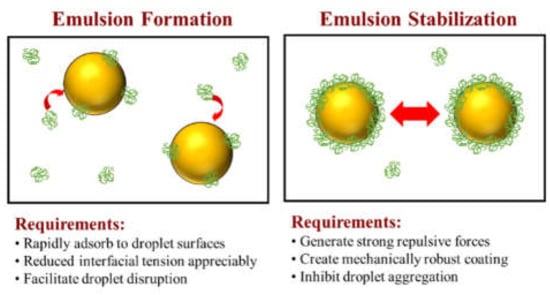

Typically, protein-based emulsifiers must perform two important functions when creating emulsions [,]. First, they should rapidly adsorb to the surfaces of the oil droplets generated during homogenization, thereby forming small protein-coated oil droplets. Second, they should protect the oil droplets from aggregation during food production, storage, distribution, and utilization. In some foods, however, controlled droplet aggregation is desirable because it leads to a highly viscous or gelled product with desirable textural attributes (e.g., desserts, yogurts, and cheeses). Consequently, standardized methods are needed to characterize both the emulsion forming and emulsion stabilizing properties of alternative proteins. This information could then be utilized to select the most appropriate protein for a specific application.

In this article, we begin by discussing the physicochemical principles of emulsifier performance and then present a series of protocols that can be used to characterize the composition and functionality of protein-based ingredients.

2. Physicochemical Principles of Emulsifier Performance

Protein-based emulsifiers should be able to facilitate the formation of emulsions and enhance their stability (Figure 1). In this section, we therefore provide an overview of the physicochemical basis for the ability of emulsifiers to form and stabilize oil-in-water emulsions. This knowledge is important when establishing an appropriate analytical protocol to characterize and compare the performance of different alternative emulsifiers.

Figure 1.

Protein-based emulsifiers play two major functions in the production of emulsion-based foods: facilitate emulsion formation and enhance emulsion stability.

2.1. Formation of Emulsions

2.1.1. Principles of Homogenization

Protein-stabilized emulsions are usually formed by homogenizing oil and water phases using a mechanical device known as a homogenizer [,]. Homogenizers are designed to breakup and intermingle the oil and water phases, as well as to reduce the size of the oil droplets [,]. Proteins are normally dissolved or dispersed in the water phase prior to homogenization because their outer surfaces are predominantly hydrophilic (although they also need to have some exposed hydrophobic groups to make them surface active, but not too many or they will tend to aggregate). Various kinds of homogenizers can be used to form oil-in-water emulsions, including high-shear blenders, colloid mills, high-pressure valve homogenizers (HPVHs), microfluidizers, and sonicators [,,]. Within each of these categories there are different instrument designs, and each type of instrument can be operated differently (e.g., energy intensity, duration, and temperature). This makes it challenging to develop standardized test protocols because different laboratories have access to different homogenizers. Significant advances have been made towards understanding the fundamental transport phenomena govering the mechanisms of droplet formation during homogenization processes, including interfacial tension, inertia, and viscous force effects []. Nevertheless, more research is still required to understand the relative importance of different physical processes in different homogenizers. In the future, it would be advantageous to establish standardized operating conditions for each kind of homogenizer that would make the results comparable with other types of homogenizers.

Most homogenizers can be used to produce oil-in-water emulsions using proteins as emulsifiers. Nevertheless, there are some factors that should be considered when selecting the most appropriate one for a specific application. Proteins can be hydrolyzed, denatured, and/or aggregated within homogenizers as a result of the intense local temperatures and pressures generated, which may adversely impact their ability to form and stabilize emulsions []. This is especially true when emulsions are homogenized at high energy intensities for long times []. Proteins may also become denatured and aggregated during homogenization because they adsorb to oil-water interfaces and undergo conformational changes due to the alteration in their local thermodynamic environment [,,,]. It is therefore important to consider any potential adverse effects of homogenization on protein functionality when selecting an appropriate test for characterizing their ability to form emulsions.

2.1.2. Role of Emulsifier in Emulsion Formation

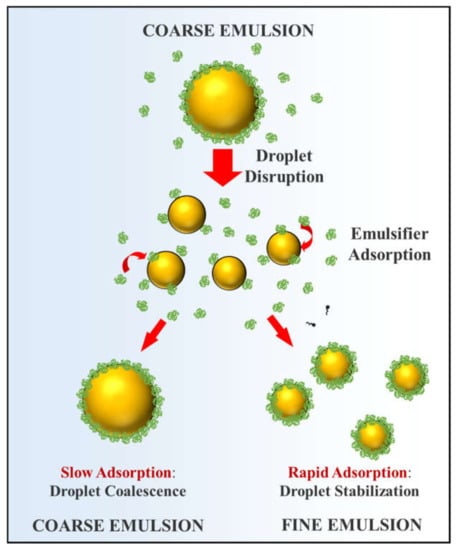

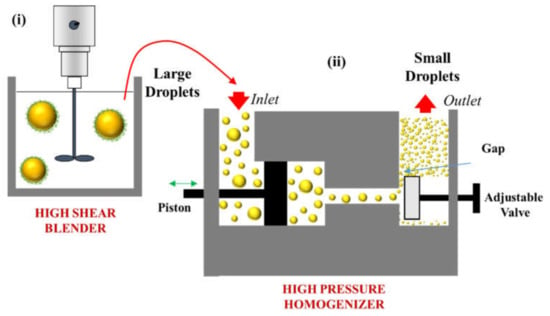

In this section, the impact of the properties of protein-based emulsifiers on the size of the oil droplets produced during homogenization is considered (Figure 2). We use a HPVH as an example as this kind of homogenizer is the most widely used in industry for producing food emulsions (Figure 3). It should be noted, however, that similar physicochemical events occur inside other types of homogenizers during emulsion formation [,].

Figure 2.

Representation of the major physicochemical processes occurring inside a high-energy homogenizer during emulsion formation: droplet disruption; droplet coalescence; emulsifier adsorption; and droplet stabilization. Small droplets tend to be formed when the emulsifier adsorbs more rapidly than droplet collisions occur.

Figure 3.

Simplified diagram of the typical two-step procedure used to produce oil-in-water emulsions using a high-energy method (i) a coarse emulsion is formed using a high-shear mixer; (ii) a fine emulsion is formed by passing the coarse emulsion through a high-pressure valve homogenizer.

Initially, the protein should be dissolved or dispersed in the water phase because the surfaces of most food proteins are predominantly hydrophilic. Ideally, the protein should be completely dissolved in the water phase, as this improves its functional performance. In many cases, however, proteins are not completely soluble in water and so there may be a fraction in a molecular form and another fraction in a particulate form. The ratio of these two fractions in a protein ingredient will impact its ability to form emulsions. For this reason, researchers often centrifuge and/or filter protein dispersions prior to homogenization to remove the insoluble fraction []. Alternatively, the relative amounts of the soluble and insoluble fractions could be measured and reported.

Sometimes, particulate forms of proteins are used to create emulsions []. In this case, protein particles adsorb to the droplet surfaces rather than protein molecules, and the resulting colloidal dispersions are referred to as Pickering emulsions. Typically, the oil droplets produced using protein particles are much bigger than those produced using protein molecules [], which is unsuitable for some applications because they would rapidly cream (e.g., soft drinks, plant-based milks, or nutritional beverages). Conversely, the resistance of protein-coated oil droplets to coalescence is much higher for particle-based than for molecular-based protein emulsifiers [,]. In summary, it is important to characterize the aggregation state of the proteins being tested when forming emulsions.

Typically, the oil phase and protein-containing water phase are then blended using a high-shear blender to form a coarse emulsion (Figure 3), which commonly contains quite large oil droplets (d > 2 μm). After this process, some of the protein will be adsorbed to the surfaces of the oil droplets and some of it will remain in the water phase surrounding them (Figure 2). The coarse emulsion is then poured into the inlet of a HPVH, which uses a pump to force it through a narrow orifice under high pressure (Figure 3). As the emulsion passes through the orifice it experiences a large reduction in pressure, which generates a complex mixture of disruptive stresses, including cavitation, turbulence, and shear stresses, which cause fragmentation of the large oil droplets [,]. The size of the oil droplets generated within the homogenizer depends on the balance between these disruptive stresses and interfacial restoring effects, such as the Laplace pressure [,].

Promotion of Droplet Disruption

The interfacial restoring stresses are a result of the positive free energy associated with the thermodynamically unfavorable contact between oil and water molecules at the droplet surfaces, which arises because of the hydrophobic effect []. As a result, oil droplets have a strong tendency to adopt a spherical shape when dispersed in water because this shape minimizes the contact area between the oil and water phases. To a first approximation, the magnitude of the interfacial restoring effect can be taken to be the Laplace Pressure (ΔPL):

In this equation, γ is the oil-water interfacial tension and d is the diameter of the oil droplets []. Inside a homogenizer, large oil droplets are broken down into smaller ones when the disruptive stresses exceed ΔPL [,,]. Based on Equation (1), one would expect smaller oil droplets to be produced under fixed homogenization conditions when the interfacial tension is lower. This can be achieved by using a more polar oil or by using an emulsifier that can rapidly adsorb to the oil droplet surfaces during homogenization and reduce the interfacial tension by an appreciable amount. In general, the adsorption rate and interfacial tension reduction of proteins depend on their molecular and physicochemical characteristics, such as molar mass, conformation, aggregation state, charge, surface hydrophobicity, as well as environmental conditions such as aqueous phase viscosity and temperature.

The disruptive stresses generated by a homogenizer depend on its design and the operating conditions used (such as homogenization pressure or sonication intensity). If an emulsion is repeatedly exposed to these disruptive stresses (e.g., by continuously passing it through the homogenizer) and there is sufficient emulsifier present, then the size of the droplets will decrease until they reach a certain level where the disruptive stresses balance the interfacial restoring effects. Under these conditions, the droplet size is mainly determined by the disruptive stresses generated by the homogenizer, although emulsifier type does have some effect because it influences the magnitude of the Laplace pressure through the interfacial tension (Equation (1)).

Inhibition of Droplet Coalescence

The size of the oil droplets produced during homogenization also depends on the tendency for coalescence to occur inside the homogenizer [,,,]. When larger oil droplets are broken down into smaller ones there is an increase in the oil-water interfacial area (Figure 2). Consequently, the surfaces of the newly formed oil droplets are not completely covered with emulsifier molecules. The stability of these emulsions to coalescence inside the homogenizer depends on the rate of emulsifier adsorption relatative to the rate of droplet-droplet collisions []. If the oil droplets collide with their neighbors before there is time for their surfaces to be fully covered by emulsifier, then they tend to coalesce with each other, leading to an increase in droplet size [,]. Conversely, if the emulsifiers adsorb so quickly that the droplet surfaces are completely covered before they have a chance to collide with their neighbors, they may be stable to coalescence. Of course, it is also important to use a protein-based emulsifier that generates strong repulsive interactions between the protein-coated oil droplets under the solution conditions employed (e.g., pH, ionic strength, or temperature). Otherwise, droplet aggregation may occur even when the droplet surfaces are completely covered by emulsifier.

Factors Affecting Emulsifier Performance

The rate at which proteins adsorb to oil droplet surfaces during homogenization, their effectiveness at reducing the interfacial tension, and their ability to prevent droplet aggregation all depend on the molecular characteristics of the proteins used. For instance, the size, aggregation state, charge, and surface hydrophobicity of proteins are likely to impact their ability to form and stabilize small droplets during homogenization []. In the remainder of this section, we examine some of the most important factors that are known to impact the ability of protein-based emulsifiers to form small droplets during homogenization.

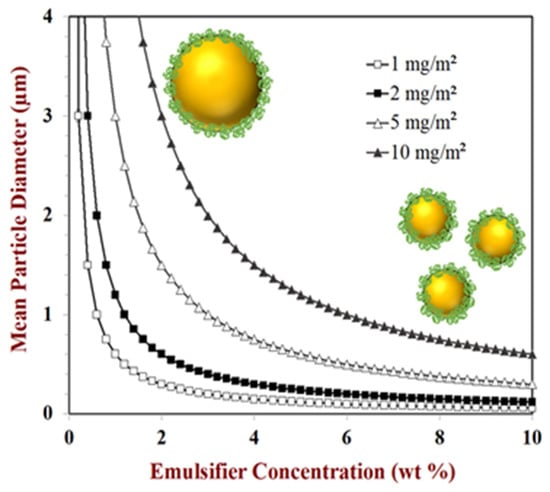

Emulsifier concentration: When forming food emulsions, it is important to include enough emulsifier to cover all the small oil droplets generated within the homogenizer, while not including too much, otherwise there may be an increase in ingredient costs and off-flavors. A solution containing a fixed amount of emulsifier can only cover a certain amount of oil-water interface, which depends on the nature of the emulsifier used. The oil-water interfacial area that needs to be covered is governed by the droplet concentration and size. Typically, the amount of emulsifier required to stabilize the droplets increases with increasing droplet concentration and decreasing droplet size. Assuming that the droplet size is limited by the amount of emulsifier present, the smallest droplet diameter that can be reached during homogenization can be described by the following expression []:

In this equation, dmin is the surface-weighted mean diameter (d32), Γsat is the surface load of the emulsifier when the droplet surfaces are saturated (in kg m−2), φ is the volume fraction of the disperse phase (unitless), and cS is the total concentration of emulsifier in the emulsion (in kg m−3). Equation (2) predicts that the minimum droplet size that can be produced during homogenization decreases as the surface load of the emulsifier and volume fraction of the disperse phase decrease, as well as when the emulsifier concentration increases.

There are several assumptions underlying the derivation of this equation that should be considered when using it. First, it is assumed that the oil droplets generated inside the homogenizer are only stable to aggregation once their surfaces are fully coated with emulsifier. At lower surface concentrations, it is assumed that droplets coalesce with their neighbors when they collide with them. In practice, full coverage of the oil droplet surfaces by an emulsifier may not be required to inhibit droplet coalescence within a homogenization. Even so, it is likely to be close to full coverage. Second, the equation assumes that the size of the droplets produced during homogenization is limited by the emulsifier concentration, rather than by the intensity of the disruptive forces generated by the homogenizer. In some cases, a homogenizer may not be able to generate small droplets because of limitations in its mechanical design, and so adding more emulsifier to the aqueous phase will not reduce the droplet size. Third, the equation assumes that all the emulsifier molecules adsorb to the oil droplet surfaces. In practice, some of them may remain in the aqueous phase (Figure 2). Fourth, it assumes that the emulsifier molecules form a monolayer around the oil droplets. But some emulsifiers are known to form multilayers, especially when used at high concentrations [,]. Multilayer formation may also depend on other factors, such as pH, ionic strength, and temperature, as these affect the tendency for the protein molecules to associate with each other. Consequently, the surface load of an emulsifier may depend on its concentration and the solution conditions used. This phenomenon is important to recognize when comparing the surface loads of different kinds of proteins.

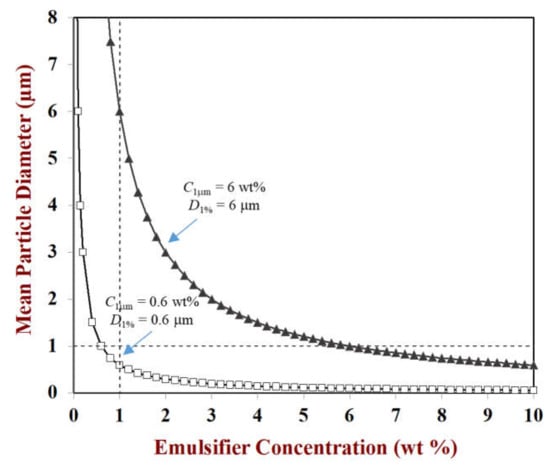

Predictions of the change in droplet diameter with emulsifier concentration for an emulsion with a fixed disperse phase volume fraction (oil content = 10 vol%) are shown in Figure 4 for model protein-based emulsifiers with different surface loads. These predictions indicate that the size of the droplets should decrease with increasing emulsifier concentration and decreasing surface load. Consequently, if one is trying to produce an emulsion with a certain droplet size and concentration, then the amount of emulsifier required will depend on the surface load of the emulsifier: the higher the surface load, the more emulsifier is required. Protein-based emulsifiers vary considerably in their surface loads and so this is an important parameter to compare their effectiveness. There are several reasons that the minimum droplet size predicted by the above equation may not be reached in practice: (i) the emulsifier molecules are unable to adsorb fast enough to the droplet surfaces during homogenization, leading to some droplet coalescence; (ii) a fraction of the emulsifier molecules stay in the aqueous phase and are not adsorbed; (iii) the homogenizer is unable to generate strong enough disruptive forces.

Figure 4.

Under conditions where the droplet size is limited by the amount of emulsifier present (rather than the homogenizer operating conditions), the mean droplet diameter decreases with increasing emulsifier concentration. Here, the mean particle diameter (d32) is plotted against emulsifier concentration for emulsifiers with different surface loads. Predictions were made using Equation (2).

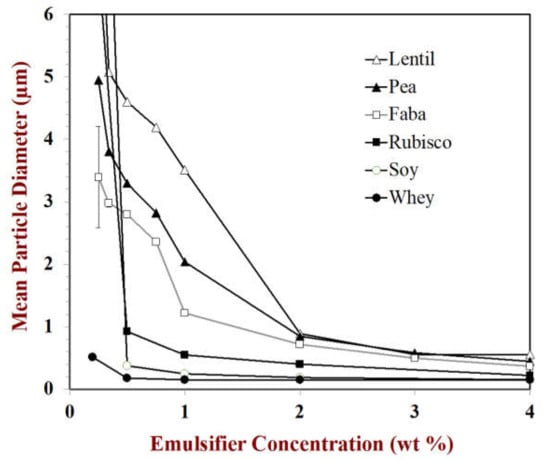

Experimental measurements of the change in droplet size with emulsifier concentration under quite similar homogenization conditions (microfluidization at 10,000 or 12,000 psi with 3 passes) are shown for several proteins in Figure 5. These results clearly show that protein type has a major influence on the size of the oil droplets produced during homogenization, which may partly be due to differences in their surface load, as well as their adsorption kinetics, surface activity, or interfacial tension reduction.

Figure 5.

The effectiveness of different emulsifiers can be compared by plotting the mean particle diameter (d32) versus emulsifier concentration. Data from authors laboratory.

2.1.3. Role of Homogenization Conditions

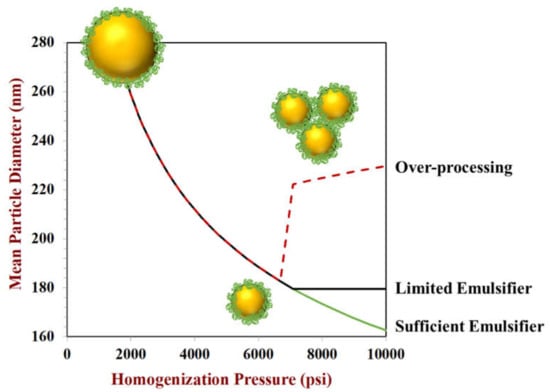

Homogenization conditions also play an important role in determining the size of the oil droplets in emulsions. In particular, the type of homogenizer used, the intensity of the disruptive forces generated, and the duration of homogenization are all important factors [,,]. The disruptive force intensity and duration depend on homogenizer type. For high pressure valve homogenizers and microfluidizers it is mainly governed by the operating pressure and number of passes used, whereas for sonicators it is mainly governed by the power and application time of the high-intensity ultrasonic waves. The droplet size usually decreases with increasing disruptive force intensity and duration, but the nature of this relationship depends on emulsifier type and concentration []. Several potential situations that might occur during high pressure valve homogenization or microfluidization are shown in Figure 6.

Figure 6.

The mean particle diameter usually decreases with increasing homogenization pressure, provided there is sufficient emulsifier present to cover the surfaces of all droplet formed. In some situations, the particle size increases at high homogenization pressures, which is known as over-processing. Predictions were made using Equation (2) for the case of sufficient emulsifier, and modified for the other curves to schematically show the effects of over-processing and limited emulsifier on droplet size.

Sufficient Emulsifier Conditions: When the amount of emulsifier present in the system is always more than enough to cover all the oil droplet surfaces generated during homogenization, then the droplet size continually decreases as the operating pressure is raised. However, once the maximum operating pressure a homogenizer can attain is reached, the droplet size cannot decrease any further. Under sufficient emulsifier conditions, the droplet size is primarily governed by the homogenization pressure and there is typically a linear relationship between the logarithm of the droplet size and the logarithm of the operating pressure. Even so, the size of the droplets produced under these emulsifier conditions also depends somewhat on the nature of the emulsifier used, as well as the physicochemical properties of the oil and water phases. The ease of droplet disruption during homogenization usually increases as the interfacial tension and oil-to-water viscosity ratio decreases [,]. Thus, smaller oil droplets can be produced for emulsifiers that decrease the interfacial tension by a larger amount, and when the viscosity of the oil phase becomes more like that of the water phase. Moreover, the rate at which the emulsifier adsorbs to the oil droplet surfaces during homogenization is important as this governs the interfacial tension decrease during the formation of new oil/water interfaces as droplets are disrupted and their surface areas increase, as well as the resistance of the droplets to coalescence when they collide with their neighbors. If the emulsifier adsorbs too slowly, then the interfacial tension will not be fully decreased before the next droplet fragmentation event occurs and the droplet surfaces will not be fully covered before the next droplet-droplet collision event occurs. Consequently, proteins that adsorb quickly and reduce the interfacial tension by a large amount tend to produce smaller droplets during homogenization [,].

Limited Emulsifier Conditions: When the amount of emulsifier present in the system is insufficient to fully cover all the oil droplet surfaces produced during homogenization, then the droplet size is mainly governed by emulsifier concentration rather than homogenization conditions []. Under these conditions, almost all the emulsifier included in the original system will be adsorbed to the surfaces of the oil droplets. As a result, the size of the droplets cannot be decreased any further because there is not sufficient emulsifier to stabilize the surfaces of any more droplets. In this situation, the homogenizer usually generates many small droplets but many of them coalesce with their neighbors because their surfaces are not fully covered with emulsifier (Figure 2). Droplet coalescence will occur until there is enough emulsifier present to cover all the droplet surfaces. To a first approximation, the smallest droplet size that can be achieved under these conditions can be predicted using Equation (2).

Over-processing: Occasionally, the size of the droplets produced by homogenization initially decreases when the homogenization pressure is raised, but then it increases []. This phenomenon is known as over-processing and is usually a result of droplet aggregation occurring at high pressures, which often arises due to a decrease in the functional performance of the emulsifiers. When homogenizers are operated at high pressures there is often a considerable rise in temperature because of the heat generated due to friction as the fluids move at high speeds. Under these conditions, protein molecules may undergo conformational changes (such as thermal denaturation), which increase their surface hydrophobicity, thereby increasing their tendency to aggregate with each other. As a result, large protein aggregates may be formed that cannot rapidly adsorb to the oil droplet surfaces nor reduce the interfacial tension efficiently. In addition, homogenizing for extended periods can also lead to an increase in droplet size, which may be because the rise in temperature leads to thermal denaturation and aggregation of the proteins or because repeated adsorption/desorption at the oil-water interfaces leads to surface denaturation and aggregation of the proteins []. Consequently, it is important to optimize the homogenization conditions to avoid over-processing effects, as this can reduce product quality, increase costs, and decrease energy efficiency.

In general, homogenization is an extremely complex dynamic process where droplet formation, disruption, and coalescence occur simulataneously due to the action of complex fluid flow and force profiles inside the mechanical device. As a result, it is often difficult to understand the relative importance of the various physical phenomenon occurring to the final droplet size distribution. However, valuable insights into the behavior of droplets can be obtained using microfluidic devices that apply well-defined flow and force profiles to oil and water phases in the presence of emulsifiers. The application and insights of these microfluidic methods have been reviewed in detail recently, and interested readers are referred to these articles [,].

2.2. Stabilization of Emulsions

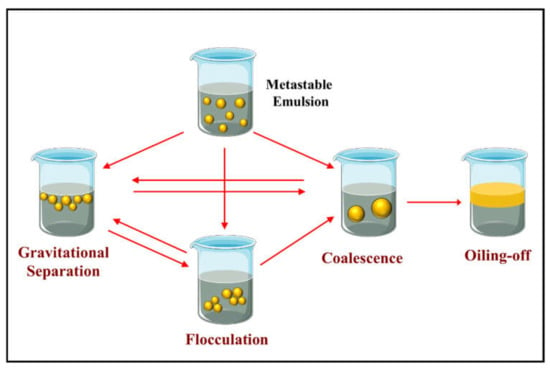

Once small oil droplets have been successfully formed by homogenization, it is usually necessary to ensure they remain stable throughout a food product’s intended lifespan [,,]. For instance, they may be expected to remain stable during the manufacturing process, throughout storage and distribution, and when they are utilized by the consumer. Emulsions may experience various environmental stressors during their lifespan that may promote their deterioration, including changes in solution conditions (e.g., pH and ionic strength), variations in temperature (e.g., chilling, freezing, pasteurization, sterilization, or cooking), changes in environmental conditions (e.g., light and oxygen levels), exposure to mechanical stresses (e.g., flow through a pipe, shearing, and vibrations during transport), and food matrix interactions (e.g., mineral ions, polysaccharides, and polyphenols). Emulsion deterioration may involve one or more physicochemical and biological processes, such as creaming, sedimentation, flocculation, coalescence, partial coalescence, Ostwald ripening, phase inversion, chemical degradation, and microbial contamination. The most important physicochemical mechanisms of emulsion instability are summarized in Figure 7. The susceptibility of protein-stabilized emulsions to these processes depends on their initial composition and microstructure, as well as their history after manufacture. Each emulsion should therefore be designed to remain stable over the conditions it might experience during its lifespan, including alterations in pH, ionic composition, ingredient interactions, temperature, dilution/concentration, mechanical stresses, and water activity. Protein-based emulsifiers vary somewhat in their ability to resist these changes in solution and environmental conditions. Consequently, it is important to select the most appropriate one for the specific food or beverage they are going to be used in. Several mechanisms by which protein-based emulsifiers may impact the physicochemical stability of food emulsions are highlighted here.

Figure 7.

Schematic diagram of different physicochemical mechanisms that protein-stabilized oil-in-water emulsions may become unstable: gravitation separation, flocculation, coalescence, and oiling-off.

2.2.1. Gravitational Separation

Gravitational separation is one of the most common instability mechanisms observed in emulsified foods and beverages, and so manufacturers must carefully design their products to prevent it. The driving force for gravitational separation is the density contrast between the oil droplets and the fluid that surrounds them. For dilute emulsions, the velocity (v) that droplets move upwards is described by Stokes’ Law []:

In this equation, g is the acceleration due to gravity, ρ is the density, d is the diameter of the droplets, η is the shear viscosity, and the subscripts 1 and 2 refer to the fluid surrounding the droplets (the continuous phase) and the droplets (the disperse phase), respectively. The sign of the creaming velocity determines whether the droplets tend to move upwards (+) or downwards (−) and are therefore susceptible to creaming or sedimentation, respectively (Figure 7). Stokes’ law predicts that the creaming velocity should decrease with decreasing density contrast, decreasing droplet size, and increasing continuous phase viscosity. The type of protein-based emulsifier used to formulate an emulsion impacts the rate of gravitational separation in several ways:

Droplet size: The type and concentration of emulsifier used influences the size of the droplets produced during homogenization. The creaming rate is proportional to the droplet diameter squared (Equation (3)). Consequently, the more effective the emulsifier is at reducing the droplet size during emulsion preparation, the stronger the resistance of the emulsion to gravitational separation.

Droplet aggregation state: The nature of the emulsifier used impacts the stability of the oil droplets to aggregation when exposed to different environments (Section 2.2.2). Droplet aggregation increases the particle size, which should increase the rate of creaming (Equation (3)), provided that the droplet concentration is not so high that a particle network is formed that inhibits the movement of the droplets. Consequently, for dilute emulsions, the more effective the emulsifier is at increasing the steric and electrostatic repulsion between the oil droplets, the stronger the resistance of the emulsion to gravitational separation.

Droplet density contrast: The density of oil is usually lower than that of water and so emulsions are susceptible to creaming (Figure 7). In contrast, protein-based emulsifiers are denser than water. Consequently, if the protein coating around the oil droplets makes up an appreciable contribution to the total volume of the particle (droplet + coating), then the overall density of the particle may be closer to that of the water, thereby slowing creaming. This effect only tends to be important in emulsions that contain small droplets (<200 nm) covered by thick interfacial layers (>20 nm) [,].

Aqueous phase rheology: If an emulsion contains a relatively high concentration of non-adsorbed emulsifier and the emulsifier is an effective thickening or gelling agent, then the viscosity of the continuous phase may increase appreciably. As a result, this may lead to a decrease in the rate of gravitational separation. For most globular proteins, this effect is unlikely to be important unless they are used at a high concentration and the system is heated to unfold and aggregate them.

2.2.2. Droplet Aggregation

Another common instability mechanism in oil-in-water emulsions is the tendency for the droplets to aggregate with each other (Figure 7). Several kinds of droplet aggregation may occur, including flocculation, coalescence, and partial coalescence [,,,]. Flocculation occurs when several droplets come together and form a clump, with each of the individual droplets remaining intact [,]. Coalescence occurs when several smaller droplets come into contact and then merge with each other, leading to the generation of a single larger droplet [,]. These large oil droplets may then coalesce with other large oil droplets leading to an oil layer on top of the emulsion, which is usually referred to as oiling-off (Figure 7). Partial coalescence occurs when several partly crystallized oil droplets collide with each other and form a clump []. Typically, a solid fat crystal protruding from one droplet penetrates a liquid oil region in another droplet, thereby forming a link between them. The partly crystalline droplets do not completely merge into each other because of the mechanical resistance generated by the 3D fat crystal network inside them [,]. The type of emulsifier used to create an oil-in-water emulsion can impact the tendency for droplet aggregation to occur in several ways:

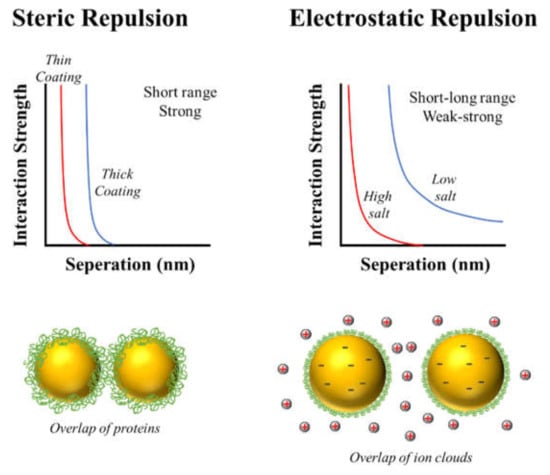

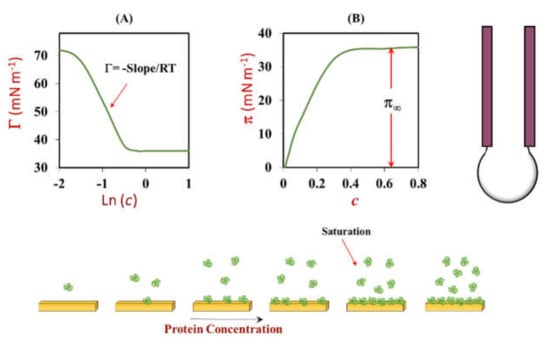

Modulation of colloidal interactions: The nature of the emulsifier that coats the oil droplets plays an important role in determining the attractive and repulsive forces between them []. Emulsifier-coated oil droplets have a propensity to aggregate with each other when the attractive forces dominate, but remain as individual entities when the repulsive forces dominate []. Protein-based emulsifiers can prevent droplet aggregation by generating a combination of electrostatic and steric repulsive forces (Figure 8). Typically, the strength of the electrostatic repulsion depends on the magnitude of the charge on the emulsifier-coated oil droplets, whereas the strength of the steric repulsion depends on the thickness of the interfacial layer (Figure 8). In some situations, protein-based emulsifiers can also promote droplet aggregation by generating attractive forces. For instance, globular proteins often expose non-polar patches to the surrounding water phase after they adsorb to droplet surfaces (“surface denaturation) or after they are heated (“thermal denaturation”), which generates a strong hydrophobic attractive force between the droplets [,]. Consequently, it is important to have analytical tools that can measure these parameters, such as particle electrophoresis and dynamic light scattering, which are described in detail later. At present, there is no well-established method for measuring the surface hydrophobicity of emulsifier-coated oil droplets.

Figure 8.

Protein-based emulsifiers typically stabilize oil droplets against aggregation through a combination of steric and electrostatic repulsive forces. The magnitude and range of these repulsive forces depends on the thickness, packing, and charge of the adsorbed protein molecules.

Modulation of interfacial layer properties: The type, concentration, and interactions of the emulsifier molecules adsorbed to the oil droplet surfaces impact the thickness, rheology, and robustness of the interfacial layer. Some interfacial layers are relatively thin, fragile, and easy to disrupt, whereas others are relatively thick, strong, and difficult to disrupt. The properties of the interfacial layer determine the tendency for droplets to fuse together after they come into contact, which impacts their resistance to coalescence or partial coalescence.

The impact of emulsifiers on some of the most important attractive and repulsive forces that impact the stability of protein-stabilized emulsions are discussed in the remainder of this section.

Electrostatic Interactions

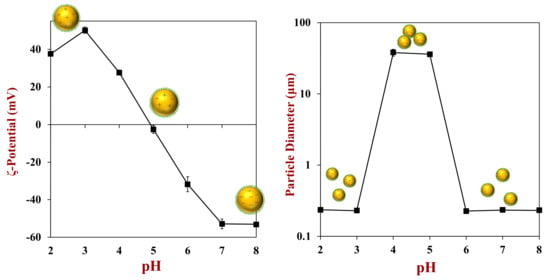

The sign, strength, and range of the electrostatic forces in oil-in-water emulsions depend on the electrical characteristics of the droplet surfaces, as well as the ionic strength of the aqueous phase [,]. For protein-coated oil droplets, the surface charge usually goes from positive to negative as the pH is increased from acidic to basic, with a point of zero charge near the isoelectric point (pI) of the adsorbed protein layer (Figure 9). As a result, the electrostatic repulsion is relatively strong at pH values well below the pI (where all the droplets are strongly positive) and at pH values well above the pI (where all the droplets are strongly negative). Conversely, the electrostatic repulsion is relatively weak at pH values close to the pI (where all the droplets have little charge). Consequently, protein-coated oil droplets are often stable to aggregation at pH values well below and well above the pI but not at pH values near the pI. In general, the magnitude of the droplet charge (weak to strong) at a particular pH depends on the number of ionized groups per unit surface area, which depends on protein type. In particular, the numbers of amino and carboxyl groups on their polypeptide chains are important, as well as the pH of the aqueous phase relative to the pKa value of the ionizable groups. Typically, a protein with more charged groups will be able to generate stronger electrostatic repulsive forces. The electrical characteristics of protein-coated oil droplets are usually quantified by measuring their surface potential (ζ-potential) as a function of pH under controlled solution conditions (such as ionic composition and temperature).

Figure 9.

The electrical charge on protein-coated oil droplets goes from positive at low pH to negative at high pH because of changes in the ionization of the amino acid charge groups. Droplet aggregation tends to occur under conditions where there is not a strong electrostatic repulsion between the droplets, i.e., around the isoelectric point. Data is experimental measurements on whey protein-coated oil droplets prepared in our laboratory.

The strength of the electrostatic interactions between protein-coated oil droplets is usually reduced when salt ions are added to the aqueous phase because of electrostatic screening effects, i.e., the accumulation of oppositely charged counter-ions around the charged groups (Figure 8). Multivalent counter-ions (like Ca2+) are particularly effective at screening electrostatic interactions. In addition, they can promote flocculation at pH values above the pI of the protein-coated oil droplets by acting as cationic salt bridges between the anionic droplet surfaces. Consequently, it is particularly important to consider the ionic composition of the aqueous phase when designing and testing oil-in-water emulsions assembled from proteins.

In general, the greater the ζ-potential of the droplets and the lower the ionic strength of the surrounding aqueous phase, the stronger the electrostatic repulsion between the droplets and the more resistant they are to aggregation. To avoid droplet aggregation, it is therefore usually important that the pH of the food product is far from the pI of the protein-coated oil droplets (usually 2 pH units below or above) and that the ionic strength is relatively low (<100 mM), but this depends on protein type.

Steric Repulsion

The strength and range of the steric repulsive forces acting between emulsifier-coated oil droplets are mainly governed by the structural organization and thickness of the adsorbed emulsifier molecules [,]. To prevent droplet aggregation through steric repulsion alone, the interfacial layer should be thicker than the range of the attractive van der Waals attraction (and hydrophobic) between the droplets, which is typically on the order of tens of nanometers, e.g., around 10 to 50 nm []. Consequently, emulsifiers that form thin layers, like most proteins (a few nanometers thick), are unable to prevent droplet aggregation through steric repulsion alone. In contrast, emulsifiers that form thick layers, like amphiphilic polysaccharides (tens of nanometers thick), are able to prevent droplet aggregation through this mechanism []. For this reason, it is important that protein-coated oil droplets have a high charge to generate a strong electrostatic repulsion. In the absence of this charge, the droplets aggregate because the attractive forces dominate the repulsive ones. However, the thin layer of protein molecules may still be able to inhibit droplet aggregation by generating a strong steric repulsion that stops the oil droplets from merging. Thick interfacial coatings may also inhibit partial coalescence of oil droplets by reducing the ability of the fat crystals in one droplet to penetrate another droplet [,].

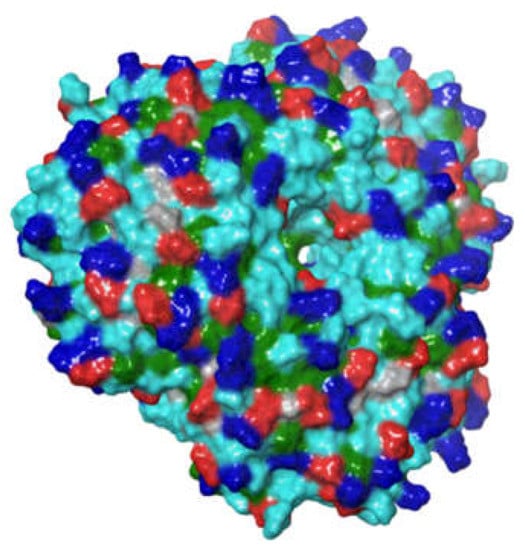

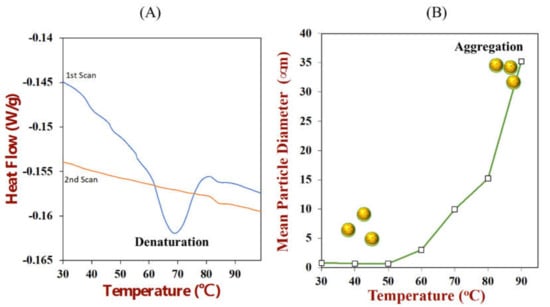

Hydrophobic Interactions

The surfaces of the droplets in most oil-in-water emulsions are predominantly hydrophilic because they are coated by amphiphilic emulsifiers that orientate themselves so that the non-polar groups contact the oil phase, whereas the polar groups contact the water phase. This is especially true for emulsions stabilized by small molecule surfactants that have a distinct hydrophobic tail and a hydrophilic head. At saturation, the surface of the droplets is then covered by the hydrophilic head groups. In contrast, protein-based emulsifiers have highly heterogeneous surfaces with numerous polar and non-polar regions (Figure 10). As a result, there are often non-polar patches facing the water phase after they have adsorbed to an oil-water interface. These non-polar patches lead to an attraction between the emulsifier-coated oil droplets due to the hydrophobic effect, which may cause them to aggregate [,]. The surface hydrophobicity of protein-coated oil droplets may be further increased by surface or thermal denaturation of the adsorbed proteins [,,,]. Surface denaturation occurs because the protein molecule undergoes a molecular rearrangement after adsorbing to the oil-water interface to decrease the number of non-polar groups in contact with water. However, the partial unfolding of globular proteins can sometimes increase the number of non-polar groups that are orientated towards the water phase, thereby increasing the surface hydrophobicity. Heating an emulsion above the thermal denaturation temperature of the adsorbed proteins typically causes a more extensive unfolding of the protein molecules (Figure 11A), which can lead to a large increase in surface hydrophobicity. It is for this reason that many emulsions stabilized by proteins undergo extensive aggregation after heating, especially when the repulsive interactions (such as electrostatic or steric repulsion) are relatively weak (Figure 11B). Hydrophobic interactions are less important for flexible random coil-like proteins, like casein, because they do not unfold upon heating. They are also less important for other kinds of natural emulsifiers such as phospholipids and polysaccharides for the same reason.

Figure 10.

Proteins have highly heterogenous surfaces with cationic, anionic, polar, and non-polar regions exposed to the surrounding environment. The image here is of a soy protein prepared using the Maestro program (Schrodinger) from the crystal structure of soybean proglycinin A1AB1B homotrimer (Protein database 1FXZ). Key: Dark blue is positively charged regions, red is negatively charged regions, and green are hydrophobic regions.

Figure 11.

(A) Differential scanning calorimetry analysis shows that Rubisco protein is irreversibly thermally denatured when heated from between 65 to 75 °C. (B) The droplets in Rubisco-stabilized emulsions aggregate when they are heated above their thermal denaturation temperature because of an increase in surface hydrophobicity when the proteins unfold (data from our laboratory).

Covalent Interactions

Proteins have a diverse range of chemical groups on their surfaces, including sulfhydryl groups in cysteine, amino groups in lysine, and phenyl groups in phenylalanine []. Under appropriate conditions, some of these groups undergo chemical reactions that may alter the performance of the emulsifier. For instance, many proteins contain reactive free sulfhydryl groups (-SH) or disulfide bonds (-S-S-) [,]. Two sulfhydryl groups can react with each other to form a new disulfide bond, whereas a sulfhydryl group and a disulfide bond can undergo interchange reactions that change the location of the disulfide bonds. The formation of disulfide bonds between neighboring proteins adsorbed to the same oil droplet can improve the resistance of emulsions to aggregation by reducing the number of reactive surface groups and by increasing the robustness of the interfacial layer [,]. In contrast, the formation of disulfide bonds between proteins located at the surfaces of different oil droplets can promote irreversible aggregation because the droplets are held tightly together by strong covalent bonds [].

The covalent bonds formed between protein molecules are relatively short-range, which means they only form after the reactive groups come close together. For this reason, they often only occur when other kinds of molecular interactions have brought the proteins into proximity, such as van der Waals, electrostatic, hydrogen bonding, or hydrophobic attraction. For instance, experiments with globular milk proteins (β-lactoglobulin) have shown that disulfide bonds only form between different protein-coated oil droplets when they are flocculated as a result of a weakening of the electrostatic repulsion and hydrophobic attraction between them [,].

Other kinds of chemical reactions may also influence the ability of proteins to function as emulsifiers, including oxidation, hydrolysis, and crosslinking reactions []. The relative importance of these reactions depends on protein type, food matrix composition (such as pH and ion composition), and environmental conditions (such as heat, light, and oxygen). Consequently, it is important when designing appropriate test methods to consider any environmental stresses that may promote chemical changes of a protein-based emulsifier. It is also important to have analytical methods that can provide information about changes in the properties of the proteins due to these interactions, such as changes in their chemical composition, molecular weight, and aggregation state.

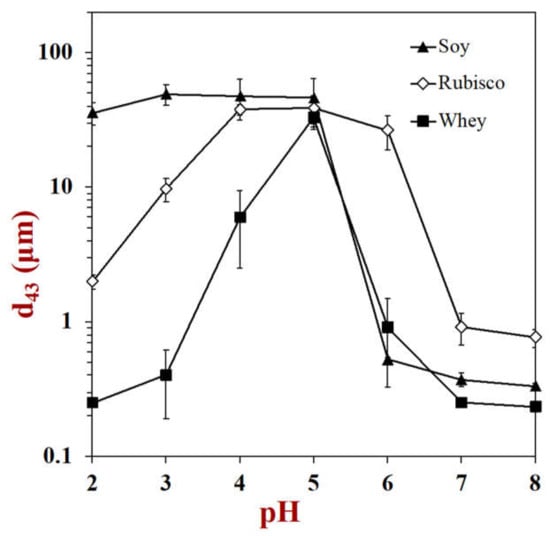

2.2.3. Overall Interactions

In general, any colloidal interaction is characterized by its sign (positive to negative), strength (weak to strong), and range (short to long). The net interaction between two protein-coated droplets can therefore be quite complex, as it is the sum of several different kinds of interactions that vary in these parameters []. For protein-coated oil droplets, the most important colloidal interactions are van der Waals attraction, hydrophobic attraction, steric repulsion, and electrostatic repulsion. However, in some systems other interactions may also be important, such as bridging and depletion flocculation in emulsions containing adsorbing or non-adsorbing biopolymers, respectively. To produce a stable emulsion, it is important that the repulsive interactions (steric and electrostatic) are stronger and longer range than the attractive interactions (van der Waals and hydrophobic). A layer of adsorbed proteins is usually capable of inhibiting flocculation under conditions where there is a strong electrostatic repulsion between the droplets, i.e., pH values far from the isoelectric point and low ionic strengths. In contrast, droplet flocculation often occurs under conditions where the electrostatic interactions are weak (close to the isoelectric point and high ionic strength) because the protein layers are too thin to create a long-range steric repulsion.

Proteins from different sources vary in their molecular dimensions, electrical characteristics, and surface hydrophobicities, which leads to differences in interfacial thickness, packing, charge, and hydrophobicity. As a result, the protein type impacts the colloidal interactions between protein-coated oil droplets, thereby determining their aggregation stability under different conditions. As an example, differences in the pH-stability of oil-in-water emulsions stabilized by different kinds of animal and plant proteins are shown in Figure 12. Ideally, it would be useful to develop structure-function relationships to relate the molecular features of proteins to their functional performance as emulsifiers, but more work is still required in this area.

Figure 12.

The pH stability of protein-coated oil droplets is highly dependent on protein type. This figure shows the change in mean particle diameter with pH for emulsions stabilized by soy, rubisco, and whey protein (data from our laboratory).

2.2.4. Ostwald Ripening

Another cause of instability in some emulsions is Ostwald ripening (OR), which leads to a growth in the average droplet size over time. The origin of this effect is the transfer of oil molecules from the smaller droplets to the larger droplets due to diffusion through the intervening aqueous phase [,,]. This process occurs because the water-solubility of oil molecules is higher around the surfaces of small droplets than large droplets and so there is a concentration gradient in the system. The Ostwald ripening rate, therefore, depends on the solubility of the oil molecules in the aqueous phase. It is relatively slow for oils with a low water-solubility, such as triacylglycerol molecules containing long- or -medium chain fatty acids (like those in corn, sunflower, olive, safflower, vegetable, or coconut oil). In contrast, it can occur relatively quickly in emulsions containing oils that have a relatively high water-solubility, such as flavor or essential oils (like those in lemon, lime, thyme, or clove oil) [,,]. To a first approximation, the increase in droplet size with time due to Ostwald ripening is described by the following expression []:

In this equation, d(0) is the initial droplet diameter, d(t) is the droplet diameter after time t, γ is the oil-water interfacial tension, Vm is the molar volume of the oil molecules, S is the water-solubility of the oil phase, D is the diffusion coefficient of the oil molecules through the aqueous phase, R is the gas constant, and T is the absolute temperature. This equation predicts that the Ostwald ripening rate increases as the water-solubility of the oil molecules increases. Typically, this is the most important factor impacting the Ostwald ripening rate because the water-solubility of oil may vary by orders of magnitude depending on its structure []. However, the above equation also predicts that emulsifier type impacts the growth rate by influencing the interfacial tension. Emulsifier type may also impact Ostwald ripening because it influences the mechanical properties of the interfacial layer. If the interfacial layer is relatively rigid, then it may inhibit the shrinkage or growth of the oil droplets, thereby slowing down Ostwald ripening [,,].

2.3. Desirable Attributes of Protein-Based Emulsifiers

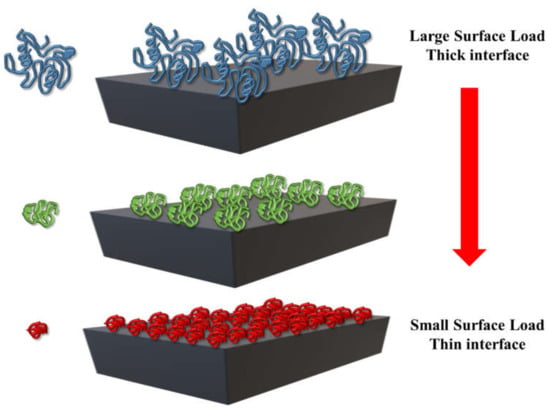

In summary, a protein-based emulsifier should be an amphiphilic molecule that can quickly adsorb to the oil droplet surfaces generated during homogenization. It should then decrease the interfacial tension, which lowers the Laplace pressure and facilitates further droplet breakup, thereby promoting the formation of smaller oil droplets. The protein should also form a protective coating around the oil droplets that inhibits their tendency to aggregate with their neighbors. Moreover, the protein may also provide protection against chemical degradation of the lipids, through a variety of mechanisms (such as steric hindrance, antioxidant activity, and chelation). The amount of emulsifier required to create a stable emulsion with a specific droplet size and concentration depends on its surface load (Γ), which depends on the molecular dimensions and interfacial packing of the proteins (Figure 13).

Figure 13.

The surface load and thickness of a protein layer depends on the molecular dimensions and packing of the proteins at the oil-water interface.

3. Recommended Protocols for Testing and Comparing Emulsifier Performance

At present, there are no standardized methods available to test and compare the functional performance of different emulsifiers. Instead, researchers tend to use different analytical methods and experimental protocols in their studies, which makes it difficult to compare results from different laboratories. Ideally, it would be advantageous to have a set of standardized methods to test and compare the performance of emulsifiers under similar conditions so their suitability for different applications can be established. For this reason, we propose a series of methods that can be used to test the functional performance of protein-based emulsifiers based on the authors decades of experience working in this area.

3.1. Initial Ingredient Properties

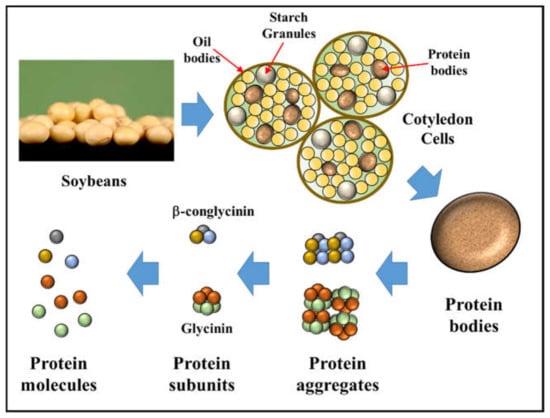

Typically, when working with protein-based emulsifiers they arrive in a powdered form, which must then be dissolved or dispersed in an appropriate aqueous solution prior to emulsion formation. These protein powders are usually isolated from natural materials using a series of different processing steps, which may alter their composition and properties (Figure 14). The nature of the initial powder plays an important role in determining the functional performance of the food proteins, including their emulsifying properties. Consequently, it is usually necessary to carry out an initial analysis of the protein powder prior to using it. In this section, analytical methods for testing the most important physical and chemical properties of protein powders are highlighted.

Figure 14.

Plant proteins are isolated from plant materials, such as soybeans, using various separation and purification processes. The native and aggregation state of the proteins obtained depends on the isolation methods used. The dimensions of the different entities in the schematic diagram are not drawn to scale. Image of soybeans by Amy Wilson, CSIRO (http://www.scienceimage.csiro.au/image/3273 (accessed on 9 February 2022)) (Crea-tive Commons 3.0).

3.1.1. Proximate Analysis

As well as proteins, powdered protein ingredients may also contain several other constituents that can impact their functional performance, including carbohydrates, lipids, minerals, and water. Knowledge of the composition of these ingredients is therefore critical to ensure that they behave as expected. Ingredient manufacturers typically provide a report of the proximate analysis of the proteins they are supplying, such as their protein, carbohydrate, lipid, moisture, and ash content. If this information is not supplied, or one wants to know the precise composition of the ingredient being used, then proximate analysis can be carried out using standardized methods [,]. For instance, the protein content can be determined using Kjeldahl, Dumas, or spectrophotometry methods, the lipid content can be determined using the Soxhlet or other solvent extraction methods, the moisture content can be determined by oven drying or Karl Fischer titration methods, the ash content can be determined using a muffle furnace, and the carbohydrate content can be determined as the difference or using various chemical methods. Alternatively, information about the composition of protein powders can be obtained more quickly using non-destructive infrared spectroscopy methods, which simultaneously measure the protein, moisture, fat, ash, and fiber content []. However, these instruments must be calibrated using powders of known composition before they can be used, which is often done by the instrument supplier. The choice of a particular combinaton of methods to carry out the proximate analysis of a protein ingredient depends on many factors, including their cost, ease of use, availability, sensitivity, and accuracy. Typically, Kjehdalh or Dumas for protein, oven drying for moisture, Soxhlet for fat, muffle furnace for ash, and weight difference for carbohydrate are convenient choices for this purpose.

3.1.2. Protein Composition

Most sources of food proteins contain a mixture of different kinds of protein molecules, e.g., whey protein ingredients contain β-lactoglobulin, α-lactalbumin, bovine serum albumin, immunoglobins, and other proteins. Similarly, most plant protein ingredients contain numerous kinds of proteins []. Each protein fraction has a different molecular structure, physicochemical properties, and functional attributes. Consequently, it is important to know the type and amount of the different protein fractions present. Several analytical methods are available to determine the protein composition of powdered ingredients []. The most common method is sodium dodecyl sulfate-polyacrylamide gel electrophoresis (SDS-PAGE) since it is relatively inexpensive and simple to perform. In this method, the proteins are mainly separated based on their molecular weights. Basically, the protein is mixed with a solution containing SDS and a reducing agent such as dithiothreitol or 2-mercaptoethanol. The reducing agent disrupts any disulfide linkages within or between proteins, which allows individual polypeptide chains to completely unfold. The SDS is an anionic surfactant that binds to the polypeptide chains in the form of micelles, which is driven mainly by the hydrophobic effect. As a result, all protein molecules gain a strong negative charge, which causes them to adopt an extended structure and prevents their aggregation. The number of anionic groups per unit length of the polypeptide chain is quite similar for all protein molecules, so they have a similar linear charge density. The solution of treated proteins is then applied to a polyacrylamide gel, which contains crosslinked polymer molecules and has a particular pore size. Then, an electrical potential is applied across the gel, which causes the negatively charged SDS-coated proteins to move towards the positively charged electrode. The movement of the proteins through the gel is hindered by the porous gel network by an amount that depends on their molecular weight: the larger the protein molecules, the slower they move. After the proteins have been adequately separated, the electric field is switched off, the gel is removed, and then it is stained with a suitable protein label, such as Coomassie blue. The molecular weight of the test proteins can be determined by running another gel under the same conditions with a series of proteins of known molecular weight. Sometimes, the individual proteins can be further characterized by cutting out a spot from the gel and then passing the sample through a mass spectrometer. Alternatively, a plate reader can be used to measure the signal intensity of each peak, which can then be related to protein concentration.

Size exclusion chromatography (SEC) can also be used to separate proteins based on their molecular dimensions [,]. In this case, a protein solution is passed through a column containing beads with defined pore sizes. The small proteins can enter the beads and so their movement through the column is hindered. In contrast, the large proteins cannot enter the beads and so they move through the column more quickly. After separation, the concentration of proteins in each peak can be determined using different kinds of detectors, such as UV-visible, fluorescence, or refractive index detectors []. In some devices, it is possible to carry out multiangle light scattering analysis of the proteins in each peak, which provides direct information about their molecular weight and conformation. Alternatively, a series of proteins of known molecular weight can be passed through the column and the positions of the peaks determined. The molecular weight of an unknown protein can then be determined from the resulting calibration curve. After separation by SEC, detailed information about protein properties can also be obtained by coupling the instrument to a mass spectrometer [].

Other methods are also available that separate and identify proteins based on other molecular characteristics. For instance, isoelectric focusing can be used to separate proteins based on their electrical characteristics, whereas a combination of isoelectric focusing and SDS-PAGE can be used to separate them based on both their charge and molecular weight characteristics.

3.1.3. Protein Solubility

The solubility of proteins plays a major role in determining their functional attributes []. Typically, a protein should be soluble in water to function as a good emulsifier. The solubility of proteins depends on their molecular characteristics, especially the number of charged, polar, and non-polar groups on their surfaces []. It also depends on solution conditions, such as pH, ionic strength, and temperature, as these conditions influence the surface characteristics of proteins, as well as the magnitude and range of electrostatic and hydrophobic interactions. Typically, the water-solubility of a protein increases as the number of polar and charged groups on their surfaces increases and the number of non-polar groups decreases because this strengthens the electrostatic repulsion and weakens the hydrophobic attraction between them. Consequently, it is important to measure the solubility of proteins under different solution and environmental conditions. Typically, the impact of pH and salt content on protein solubility are the most common parameters studied.

The solubility of proteins is usually measured using centrifugation methods [,]. First, a fixed amount of protein powder (e.g., 1 wt%) is dispersed into a solution of known pH and ionic strength at ambient temperature and stirred using a magnitude stirrer (e.g., for 1 h). The pH is then measured and adjusted back to the required value if necessary. The protein dispersion is then stored for a fixed time (e.g., 24 h at 4 °C) to allow any soluble proteins to fully dissolve. It is then removed from the refrigerator and allowed to equilibrate to ambient temperature (e.g., 2 h at 25 °C) before being centrifuged under fixed conditions (e.g., 20,000× g for 30 min) []. The supernatant can then be collected, filtered (No. 1 Whatman filter paper), and the protein content measured using a suitable method. Typically, a micro-Kjeldahl or UV-visible spectrophotometer method (such as the direct, Biuret, BCA, Lowry, Bradford, or dye binding methods) is used for this purpose. For the spectrophotometer method, it is important to develop an appropriate calibration curve or know the extinction coefficient for the protein being analyzed. The solubility can then be calculated:

Here CS is the concentration of the soluble protein in the supernatant and CT is the total protein concentration in the system. If the powdered ingredient is pure protein, then CT is known. Otherwise, CT must be measured, which can sometimes be achieved by using the same colorimetric method as for the supernatant (provided that any insoluble proteins are made soluble by the components in the assay). Typically, the protein solubility should be measured as a function of pH (e.g., from pH 2 to 8 in 1 pH unit increments) and salt concentration (e.g., from 0 to 400 mM in 50 mM increments) to obtain a 2D solubility map. This type of map is useful for specifying the conditions where a protein is soluble and therefore has the functional performance required.

3.1.4. Protein Aggregation State

The proteins in powdered ingredients may be present as individual molecules (monomers), small molecular clusters (dimers, trimers, etc.), or large aggregates depending on their biological origin, the methods used to isolate and purify them, the solution composition (e.g., pH and ionic strength), and the environmental conditions (e.g., temperature) (Figure 14). The aggregation state of proteins influences their functional performance and so it is important to be able to quantify it. Several analytical methods are available for providing this kind of information. Non-denaturing polyacrylamide gel electrophoresis can be used to provide some information about the aggregation state of proteins []. This is like SDS-PAGE but no SDS or reducing agent is added. As a result, the proteins in solution should be present in their original (aggregated) states, rather than as unfolded isolated molecules. A solution of proteins is applied to the polyacrylamide gel and then an electrical potential is applied, which causes the proteins to move through the gel. In this case, the proteins are separated based on their charge, molecular weight, conformation, and aggregation state. Larger protein entities move through the gel slower than smaller ones, which enables information to be obtained about their aggregation state. One limitation of this approach is that some proteins do not enter the gel because they might be too large or do not carry enough charge. Size exclusion chromatography can also be used to separate proteins based on their aggregation state, but in this case the large protein entities move through the column faster than the smaller ones []. Alternatively, light scattering methods can be used to provide insights into the aggregation state of proteins, such as dynamic or static light scattering []. Dynamic light scattering is based on measurements of the diffusion coefficient of protein entities: larger particles move slower than smaller ones. Static light scattering is based on differences in the scattering patterns (intensity versus angle) of different sized protein entities when a laser beam is passed through a dilute sample. However, light scattering is sometimes limited by the sample concentration (too low or too high).For more detailed information about the nature of the aggregates formed, electron microscopy or atomic force microscopy can be used [].

3.1.5. Protein Denaturation

For many applications, it is important that the proteins are in their native state for them to exhibit the required functional attributes, e.g., emulsifying, foaming, and gelling. Globular proteins are often denatured during their isolation and purification, which therefore alters their ability to act as emulsifiers. For this reason, it is usually important to measure whether a protein is in its native or denatured state. Differential scanning calorimetry (DSC) is the most common analytical instrument used for this purpose. In this method, a known amount of protein is usually dispersed within a buffer solution of known pH and ionic composition. Dilute protein solutions (e.g., 10 to 1000 μg/mL or 0.001 to 0.1%) can be analyzed using ultra-sensitive micro-DSC instruments, whereas more concentrated ones (e.g., 5 to 200 mg/mL or 5 to 20%) can be analyzed using conventional DSC instruments. Typically, the protein solution is placed in a sample cell and distilled water (or a buffer solution) is placed in a reference cell. Both cells are then heated together at a controlled rate, and the heat flow required to keep the two cells at the same temperature is measured. Thus, if an exothermic or endothermic transition occurs within the protein solution, a negative or positive heat flow is applied to the sample cell. A DSC scan therefore involves measuring the change in the heat flow (q) versus temperature (Figure 11A), which can be changed into a molar heat capacity versus temperature profile. When the protein is in its native state an endothermic transition is observed around its thermal denaturation temperature. The enthalpy of this transition is proportional to the amount of protein that undergoes the transition. Conversely, no transition is observed when a denatured protein is heated (Figure 11A).

The unfolding of proteins can also be monitored using other methods, such as measuring changes in fluorescence, circular dichroism, or infrared signals with temperature [,,], but these methods are less routinely used for the analysis of food proteins. In summary, the composition, solubility, aggregation state, and denaturation state of proteins should be assessed before characterizing their emulsifying properties.

3.2. Impact of Emulsifier on Emulsion Formation

A good emulsifier should usually be capable of forming emulsions containing small droplets during homogenization. Ideally, the minimum amount of emulsifier required to form these small oil droplets should also be known, because this would reduce ingredient costs by only using the amount required. In this section, we highlight methods that can be used to measure and compare the performance of emulsifiers at forming emulsions. As mentioned earlier, it is often important that a protein is soluble prior to forming an emulsion, or that the fraction of soluble and insoluble protein is known (Role of Emulsifier in Emulsion Formation section). Consequently, it is useful to use standardized conditions to disperse the protein in an aqueous solution, such as mixing time, temperature, and speed, as well as solution conditions (such as pH and ionic strength). It is then important to measure the fraction of soluble and insoluble protein within the resulting solution used to formulate the emulsion.

3.2.1. Emulsifying Capacity

A traditional approach of providing information about the amount of emulsifier required to form a stable emulsion is known as the emulsifying capacity method. The emulsifying capacity is defined as the maximum amount of oil that can be converted into a stable oil-in-water emulsion using a fixed amount of emulsifier under fixed homogenization conditions []. The emulsifying capacity can be measured by placing a fixed mass of aqueous emulsifier solution (e.g., 40 g of 1 wt% protein solution) into a container with fixed dimensions (e.g., a 400 mL glass beaker) and then titrating an oil at a controlled rate (e.g., 1 mL per min) into this solution while continuously blending using a high-shear mixer operating at a fixed speed (e.g., 1600 rpm) []. The mixer will generate oil droplets with a certain size, depending on its design, and rotation speed. As long as there is enough emulsifier present to stabilize the droplets, a stable oil-in-water emulsion will be formed. But once all the protein has been used up, the oil droplets cannot be stabilized any longer, and any additional oil added will separate. The end point can therefore be determined by measuring the appearance of an oil phase on the surface of the emulsion or by measuring the change in electrical conductivity. The electrical conductivity remains relatively high while an oil-in-water emulsion remains in the beaker but decreases steeply when phase inversion to a water-in-oil emulsion occurs []. The volume of oil (VO) required to reach the end point (in mL) can then be determined and the emulsifying capacity (EC) calculated:

Here, mE is the mass of emulsifier used (in g). Thus, the EC value is expressed as mL of oil per gram of emulsifier. This method is very simple to implement and does not require any expensive equipment. However, it is difficult to standardize because the emulsifying capacity depends on the conditions used to carry out the experiment, such as the rate the oil phase is added, the type of mixing device used, the type of container used, the shear rate of the mixer, and the method used to detect the end point []. Several of these factors are important because they influence the size of the oil droplets generated, which influences the size of the surface area that needs to be covered. More emulsifier is needed to cover smaller droplets because they have a greater surface area. Nevertheless, the method is useful for comparing different kinds of proteins under similar conditions in one set of experiments. However, we would highly recommend measuring the surface load (see next section), rather than the emulsifying capacity when comparing proteins because it is less dependent on the conditions used.

3.2.2. Surface Load

Definition

The surface load of an emulsifier provides a more reliable method of quantifying the amount of emulsifier required to form a particular emulsion []. The surface load (ΓS) is defined as the mass of emulsifier per unit surface area of emulsion at saturation (e.g., mg m−2). It can be calculated using the following expression:

Here, CA is the concentration of emulsifier adsorbed to the droplet surfaces, expressed as mass per unit volume of emulsion (mg m−3), φ is the disperse volume fraction, and d32 is the surface-weighted mean droplet diameter (m):

Here, ni and di are the number and diameter of the droplets in the ith size category of the measured particle size distribution. This value is often reported by static light scattering instruments designed to measure particle size. The above equations show that the concentration of emulsifier required to create an emulsion with a fixed droplet concentration (φ) and size (d32) increases as the surface load of the emulsifier increases. For most proteins, the surface load varies from around 1 to 10 mg m−2, with larger individual proteins or aggregated proteins having higher values. In the remainder of this section, we highlight methods for estimating the surface load of a protein using theoretical calculations or experimental measurements.

Theoretical Calculations

An estimate of the surface load of a globular protein can be obtained by assuming they are monodisperse spheres that are closely (hexagonal) packed at the oil-water interface:

Here, m and S are the mass and cross-sectional area of an individual protein molecule, and φS is the fraction of the surface covered by spheres at maximum packing (around 0.91, i.e., 91%). Assuming they are spherical, the mass and the cross-sectional area of the protein molecules would be m = 4πr3ρP/3 and S = πr2, respectively. Here, r and ρP (≈ 1500 kg m−3) are the radius and density of the protein molecules. Substituting these values in Equation (9) gives:

An expression for the radius of the proteins can be obtained by rearranging the following equation: m = MW/NA = 4πr3ρP/3, where MW is the molecular weight of the protein and NA is Avogadro’s number. Substituting this value in Equation (10) gives:

When the molecular weight is expressed in kg mol−3, the surface load (in mg m−2) can be estimated using the following simple expression:

As an example, for β-lactoglobulin (MW = 18 kg mol−3), bovine serum albumin (MW = 66.4 kg mol−3) and pea legumin hexamer (MW = 350 kg mol−3) the calculated surface loads are 3.0, 4.7, and 8.2 mg m−2, respectively. These values are in the range of those reported for globular proteins [,]. These predictions suggest that considerably more (2.7-fold) pea protein would be required to form an emulsion than whey protein, which is consistent with our own experimental measurements (Figure 5), and with those of other researchers [,]. In practice, the actual values may be smaller or larger than the predicted values because the proteins are not spherical, the interface may not be fully covered with proteins, or multilayers may form.

Experimental Determination

There are several ways of measuring the surface load of emulsifiers. In this section, we highlight three methods that can be utilized for this purpose.