Feasibility Assessment of Hydrophobic Surface Creation via Digital Light Processing: Influence of Texture Geometry, Composition, and Resin Type

Abstract

1. Introduction

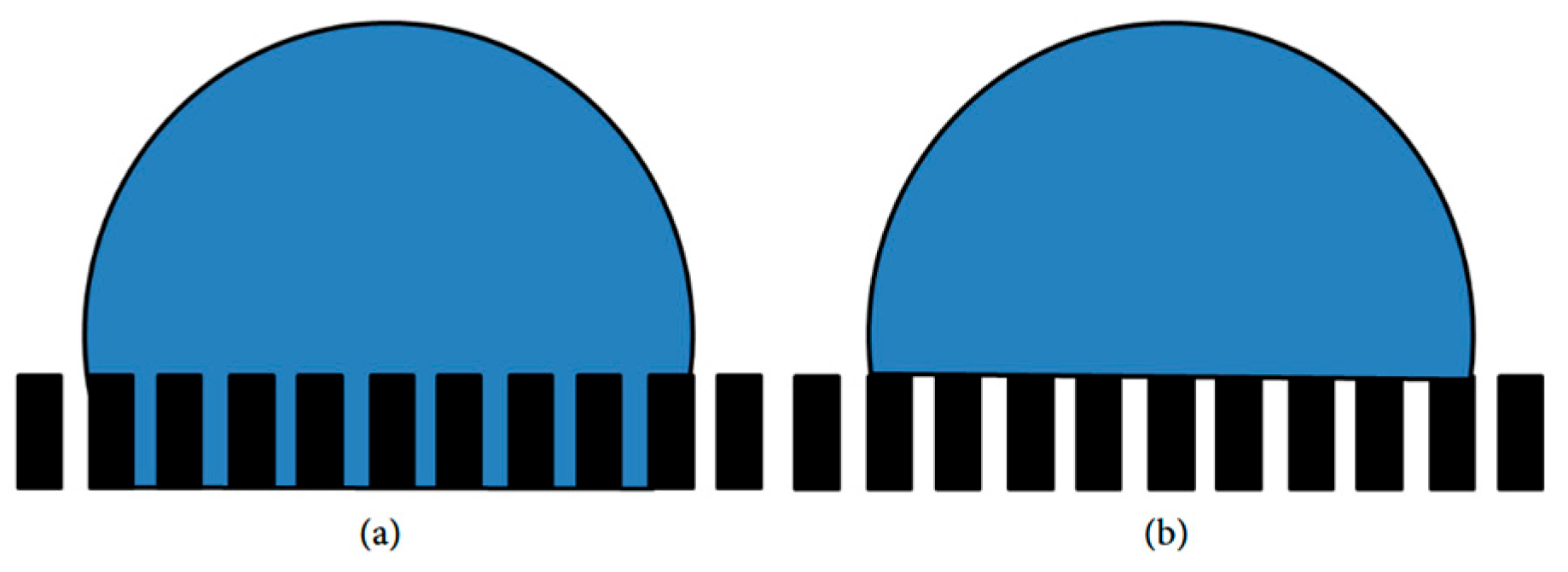

Fundamentals of Surface Wettability

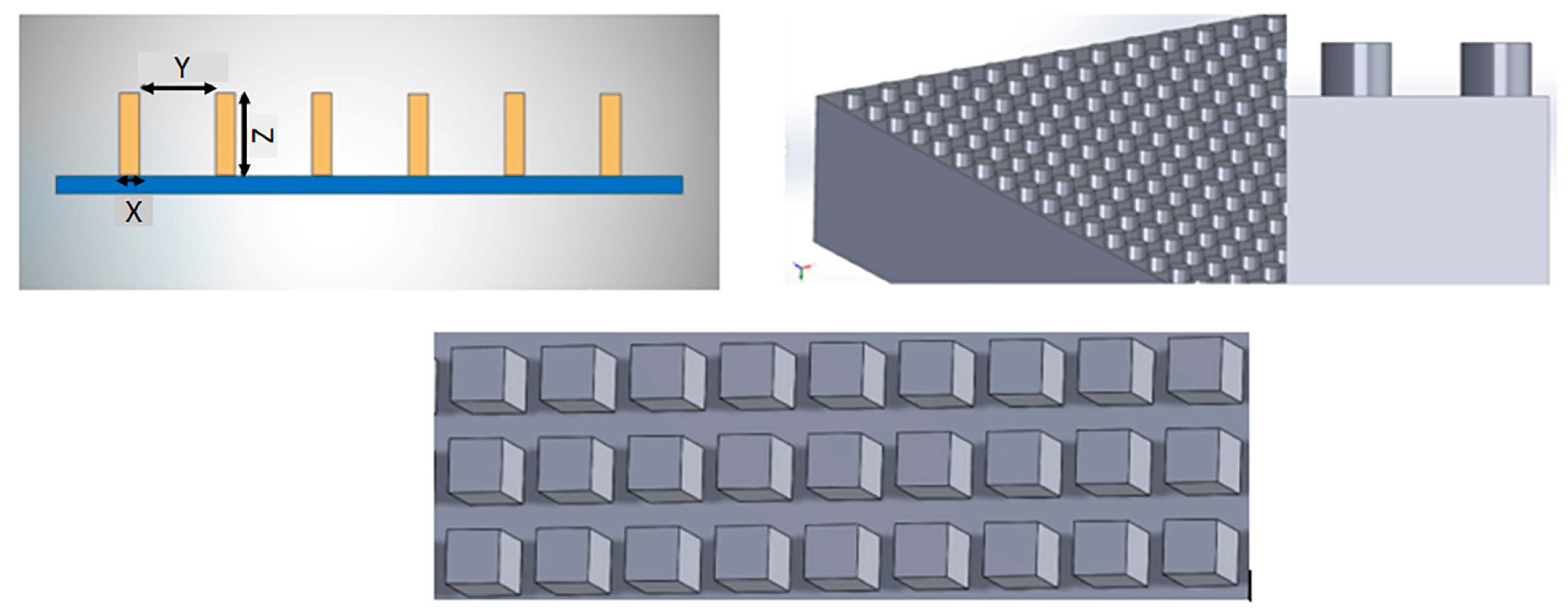

2. Materials and Methods

3. Results

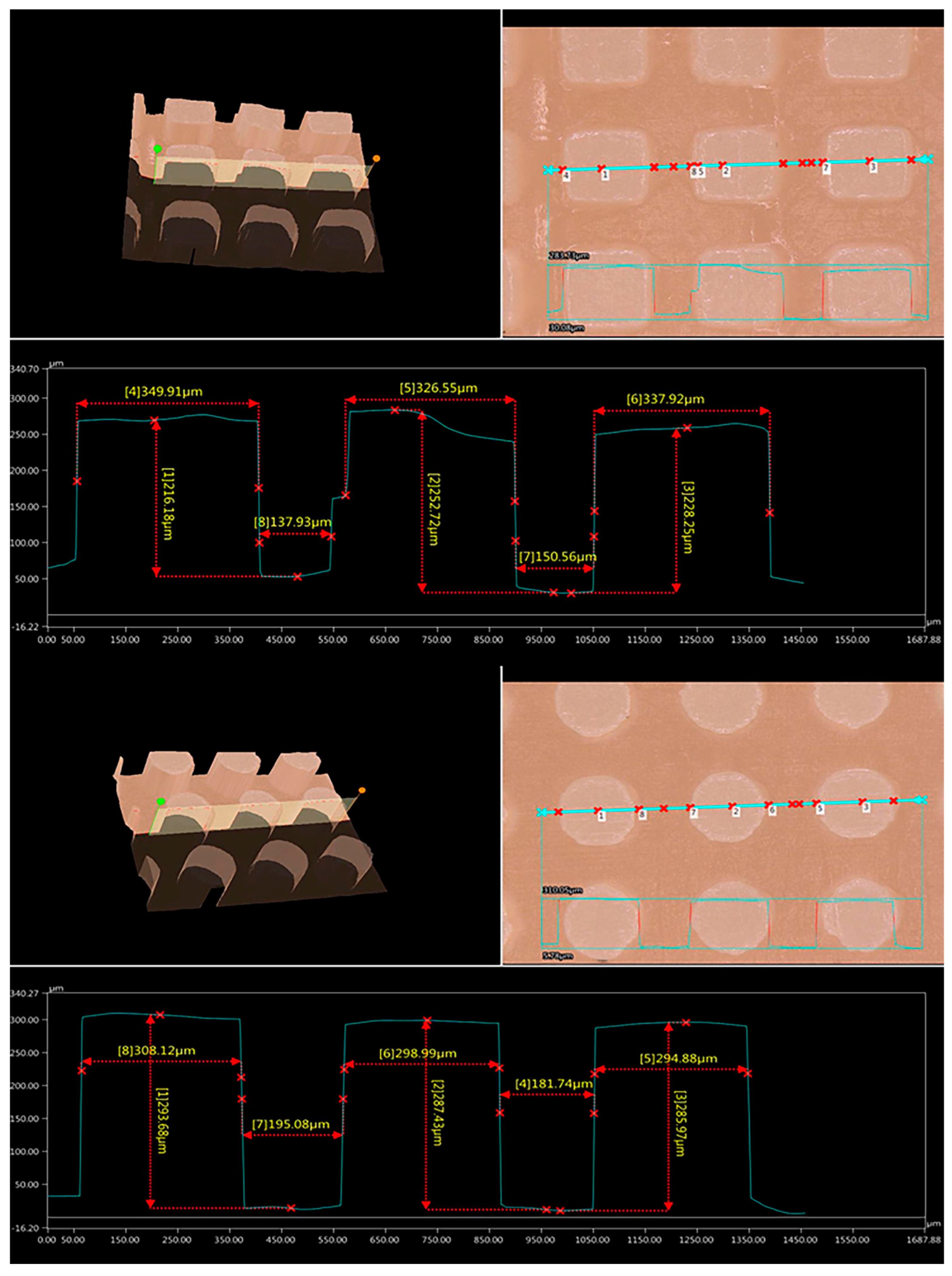

3.1. Printing Accuracy Analysis

3.2. The Effect of Resin Type

3.3. The Effect of Geometry on Hydrophobicity

3.4. The Effects of Dimensions on Hydrophobicity

3.5. The Effect of Height

3.6. The Effect of Distance

3.7. Hydrophobic Agent Percentage

4. Discussion

5. Conclusions

- The Water-Washable resin showed the highest contact angle (90.38°), representing a 26% increase compared to TR300 (71.77°), and a 15.4% increase compared to the Speed resin (78.3°). This highlights the critical role of intrinsic material properties in enhancing surface hydrophobicity.

- Square microstructures outperformed cylindrical ones of the same size. For the 300 µm × 300 µm × 200 µm design, the square pattern achieved a contact angle of 106.08°, compared to 99.62° for the cylindrical counterpart—a 6.5% increase due to improved air trapping and edge sharpness.

- Increasing the square structure’s width from 300 µm to 460 µm raised the contact angle from 106.08° to 128.36°, marking a 21% improvement in hydrophobicity due to better air retention.

- Raising the pillar height from 350 µm to 521 µm resulted in a contact angle increase from 116.4° to 133.6°, corresponding to a 14.7% enhancement; this was attributed to the larger volume for air pockets and reduced solid–liquid contact.

- In the square textures, increasing the spacing from 150 µm to 258 µm led to a drop in contact angle from 106.08° to 86.84° (18.1% decrease). Similarly, for cylindrical textures, the angle dropped from 99.6° to 69.6° (30.1% decrease), confirming that excessive spacing reduces hydrophobic performance by enabling the Wenzel state.

- Applying 1 wt.% HFS coating raised the contact angle from 85.1° to 113.1°, representing a 32.9% increase. Further increases to 2 wt.% and 3 wt.% yielded 120.4° and 123.4°, respectively, indicating diminishing improvements beyond 1 wt.% due to surface saturation.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DLP | Digital Light Processing |

| SHB | Superhydrophobic |

| CAH | Contact Angle Hysteresis |

| TR300 | A Type of Photopolymer Resin |

| Speed | A Type of Photopolymer Resin |

| HFS | Hydrophobic Fluoro-Silane |

| MSLA | Masked Stereolithography |

| RPM | Revolutions per Minute |

| VHX | A Type of Digital Microscope (KEYENCE VHX-5000) |

| µm | Micrometer |

| wt.% | Weight percent |

| UV | Ultraviolet |

References

- Falde, E.J.; Yohe, S.T.; Colson, Y.L.; Grinstaff, M.W. Superhydrophobic Materials for Biomedical Applications. Biomaterials 2016, 104, 87–103. [Google Scholar] [CrossRef]

- Jeong, C. A Study on Functional Hydrophobic Stainless Steel 316L Using Single-Step Anodization and a Self-Assembled Monolayer Coating to Improve Corrosion Resistance. Coatings 2022, 12, 395. [Google Scholar] [CrossRef]

- Bai, M.; Kazi, H.; Zhang, X.; Liu, J.; Hussain, T. Robust Hydrophobic Surfaces from Suspension HVOF Thermal Sprayed Rare-Earth Oxide Ceramics Coatings. Sci. Rep. 2018, 8, 6973. [Google Scholar] [CrossRef]

- Farzam, M.; Beitollahpoor, M.; Solomon, S.E.; Ashbaugh, H.S.; Pesika, N.S. Advances in the Fabrication and Characterization of Superhydrophobic Surfaces Inspired by the Lotus Leaf. Biomimetics 2022, 7, 196. [Google Scholar] [CrossRef]

- Antonov, D.V.; Islamova, A.G.; Strizhak, P.A. Hydrophilic and Hydrophobic Surfaces: Features of Interaction with Liquid Drops. Materials 2023, 16, 5932. [Google Scholar] [CrossRef]

- Jokinen, V.; Kankuri, E.; Hoshian, S.; Franssila, S.; Ras, R.H.A. Superhydrophobic Blood-Repellent Surfaces. Adv. Mater. 2018, 30, 1705104. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Zhang, Z.; Wu, C.; Su, K.; Kan, X. Biomimetic Superhydrophobic Materials through 3D Printing: Progress and Challenges. Micromachines 2023, 14, 1216. [Google Scholar] [CrossRef]

- Young, B.R.; Pitt, W.G.; Cooper, S.L. Protein Adsorption on Polymeric Biomaterials: II. Adsorption Kinetics. J. Colloid Interface Sci. 1988, 125, 246–260. [Google Scholar] [CrossRef]

- Schmidt, D.R.; Waldeck, H.; Kao, W.J. Protein Adsorption to Biomaterials. In Biological Interactions on Materials Surfaces: Understanding and Controlling Protein, Cell, and Tissue Responses; Puleo, D.A., Bizios, R., Eds.; Springer: New York, NY, USA, 2009; pp. 1–18. ISBN 978-0-387-98161-1. [Google Scholar]

- Non-Fouling Surfaces—Buddy Ratner Biomaterials Group. Available online: https://sites.uw.edu/biomaterialsgroup/research/non-fouling-surfaces/?utm_source=chatgpt.com (accessed on 5 February 2025).

- Ballester-Beltrán, J.; Rico, P.; Moratal, D.; Song, W.; Mano, J.F.; Salmerón-Sánchez, M. Role of Superhydrophobicity in the Biological Activity of Fibronectin at the Cell–Material Interface. Soft Matter 2011, 7, 10803. [Google Scholar] [CrossRef]

- Shadpour, H.; Sims, C.E.; Thresher, R.J.; Allbritton, N.L. Sorting and Expansion of Murine Embryonic Stem Cell Colonies Using Micropallet Arrays. Cytometry A 2009, 75A, 121–129. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Gao, P.; Han, S.; Kao, R.Y.T.; Wu, S.; Liu, X.; Qian, S.; Chu, P.K.; Cheung, K.M.C.; Yeung, K.W.K. A Tailored Positively-Charged Hydrophobic Surface Reduces the Risk of Implant Associated Infections. Acta Biomater. 2020, 114, 421–430. [Google Scholar] [CrossRef]

- Kang, J.-W.; Jeon, J.; Lee, J.-Y.; Jeon, J.-H.; Hong, J. Surface-Wetting Characteristics of DLP-Based 3D Printing Outcomes under Various Printing Conditions for Microfluidic Device Fabrication. Micromachines 2023, 15, 61. [Google Scholar] [CrossRef]

- Rodič, P.; Kovač, N.; Kralj, S.; Jereb, S.; Golobič, I.; Može, M.; Milošev, I. Anti-Corrosion and Anti-Icing Properties of Superhydrophobic Laser-Textured Aluminum Surfaces. Surf. Coat. Technol. 2024, 494, 131325. [Google Scholar] [CrossRef]

- A., K.S.; P., D.; G., D.; J., N.; G.S., H.; S., A.S.; K., J.; R., M. Super-Hydrophobicity: Mechanism, Fabrication and Its Application in Medical Implants to Prevent Biomaterial Associated Infections. J. Ind. Eng. Chem. 2020, 92, 1–17. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Z.; Yang, J.; Yue, Y.; Zhang, H. A Review of Recent Advances in Superhydrophobic Surfaces and Their Applications in Drag Reduction and Heat Transfer. Nanomaterials 2021, 12, 44. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the Sacred Lotus, or Escape from Contamination in Biological Surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Atwah, A.A.; Almutairi, M.D.; He, F.; Khan, M.A. Influence of Printing Parameters on Self-Cleaning Properties of 3D Printed Polymeric Fabrics. Polymers 2022, 14, 3128. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Jiang, S.; Wang, Z.; Liang, P.; Fan, W.; Zhuo, K.; Xu, G. Fabrication of Durable Superhydrophobic Surface for Versatile Oil/Water Separation Based on HDTMS Modified PPy/ZnO. Nanomaterials 2022, 12, 2510. [Google Scholar] [CrossRef] [PubMed]

- Kaur, G.; Marmur, A.; Magdassi, S. Fabrication of Superhydrophobic 3D Objects by Digital Light Processing. Addit. Manuf. 2020, 36, 101669. [Google Scholar] [CrossRef]

- Efremov, A.N.; Stanganello, E.; Welle, A.; Scholpp, S.; Levkin, P.A. Micropatterned Superhydrophobic Structures for the Simultaneous Culture of Multiple Cell Types and the Study of Cell-Cell Communication. Biomaterials 2013, 34, 1757–1763. [Google Scholar] [CrossRef]

- Duda, T.; Raghavan, L.V. 3D Metal Printing Technology. IFAC-Pap. 2016, 49, 103–110. [Google Scholar] [CrossRef]

- Chaudhary, R.; Fabbri, P.; Leoni, E.; Mazzanti, F.; Akbari, R.; Antonini, C. Additive Manufacturing by Digital Light Processing: A Review. Prog. Addit. Manuf. 2023, 8, 331–351. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S. Additive Manufacturing: Recent Trends, Applications and Future Outlooks. Prog. Addit. Manuf. 2022, 7, 261–287. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer International Publishing: Cham, Switzerland, 2021; ISBN 978-3-030-56126-0. [Google Scholar]

- Han, Y.; Liu, Y.; Kaneko, M.; Uchikoba, F. Profile Characterization and Temperature Effect on the Wettability of Microstructured Surfaces. J. Surf. Eng. Mater. Adv. Technol. 2018, 8, 83–94. [Google Scholar] [CrossRef]

- Tadmor, R.; Das, R.; Gulec, S.; Liu, J.; N’guessan, H.E.; Shah, M.; Wasnik, P.S.; Yadav, S.B. Solid–Liquid Work of Adhesion. Langmuir 2017, 33, 3594–3600. [Google Scholar] [CrossRef]

- Liu, M.; Wang, S.; Wei, Z.; Song, Y.; Jiang, L. Bioinspired Design of a Superoleophobic and Low Adhesive Water/Solid Interface. Adv. Mater. 2009, 21, 665–669. [Google Scholar] [CrossRef]

- Feng, L.; Li, S.; Li, Y.; Li, H.; Zhang, L.; Zhai, J.; Song, Y.; Liu, B.; Jiang, L.; Zhu, D. Super-Hydrophobic Surfaces: From Natural to Artificial. Adv. Mater. 2002, 14, 1857–1860. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surfaces to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Wang, J.; Do-Quang, M.; Cannon, J.J.; Yue, F.; Suzuki, Y.; Amberg, G.; Shiomi, J. Surface Structure Determines Dynamic Wetting. Sci. Rep. 2015, 5, 8474. [Google Scholar] [CrossRef]

- Hashim, J.; Looney, L.; Hashmi, M.S.J. The Wettability of SiC Particles by Molten Aluminium Alloy. J. Mater. Process. Technol. 2001, 119, 324–328. [Google Scholar] [CrossRef]

- Zhang, T.; Wang, J.; Chen, L.; Zhai, J.; Song, Y.; Jiang, L. High-Temperature Wetting Transition on Micro- and Nanostructured Surfaces. Angew. Chem. Int. Ed. 2011, 50, 5311–5314. [Google Scholar] [CrossRef] [PubMed]

- Young, T. III. An Essay on the Cohesion of Fluids. Philos. Trans. R. Soc. Lond. 1805, 95, 65–87. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Della Volpe, C.; Hołysz, L.; Marmur, A.; Siboni, S. Contact Angles: History of over 200 Years of Open Questions. Surf. Innov. 2020, 8, 3–27. [Google Scholar] [CrossRef]

- TR300 Ultra-High Temp 3D Printing Resin. Available online: https://phrozen3d.com/products/tr300-ultra-high-temp-resin (accessed on 15 February 2025).

- Phrozen Speed 3D Printing Resin. Available online: https://phrozen3d.com/products/speed-resin (accessed on 15 February 2025).

- Phrozen Water-Washable Dental Model Resin. Available online: https://3dpartnershop.com (accessed on 14 August 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abo Shawish, S.M.; Barmouz, M.; Azarhoushang, B. Feasibility Assessment of Hydrophobic Surface Creation via Digital Light Processing: Influence of Texture Geometry, Composition, and Resin Type. J. Compos. Sci. 2025, 9, 447. https://doi.org/10.3390/jcs9080447

Abo Shawish SM, Barmouz M, Azarhoushang B. Feasibility Assessment of Hydrophobic Surface Creation via Digital Light Processing: Influence of Texture Geometry, Composition, and Resin Type. Journal of Composites Science. 2025; 9(8):447. https://doi.org/10.3390/jcs9080447

Chicago/Turabian StyleAbo Shawish, Saher Mohammed, Mohsen Barmouz, and Bahman Azarhoushang. 2025. "Feasibility Assessment of Hydrophobic Surface Creation via Digital Light Processing: Influence of Texture Geometry, Composition, and Resin Type" Journal of Composites Science 9, no. 8: 447. https://doi.org/10.3390/jcs9080447

APA StyleAbo Shawish, S. M., Barmouz, M., & Azarhoushang, B. (2025). Feasibility Assessment of Hydrophobic Surface Creation via Digital Light Processing: Influence of Texture Geometry, Composition, and Resin Type. Journal of Composites Science, 9(8), 447. https://doi.org/10.3390/jcs9080447