Sustainable Acrylic Thermoplastic Composites via Vacuum-Assisted Resin Infusion Molding: Evaluation and Comparison of Fabrics and Recycled Non-Woven Carbon Fiber as Reinforcement

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Samples Preparation

2.2.1. Neat PMMA Sheets

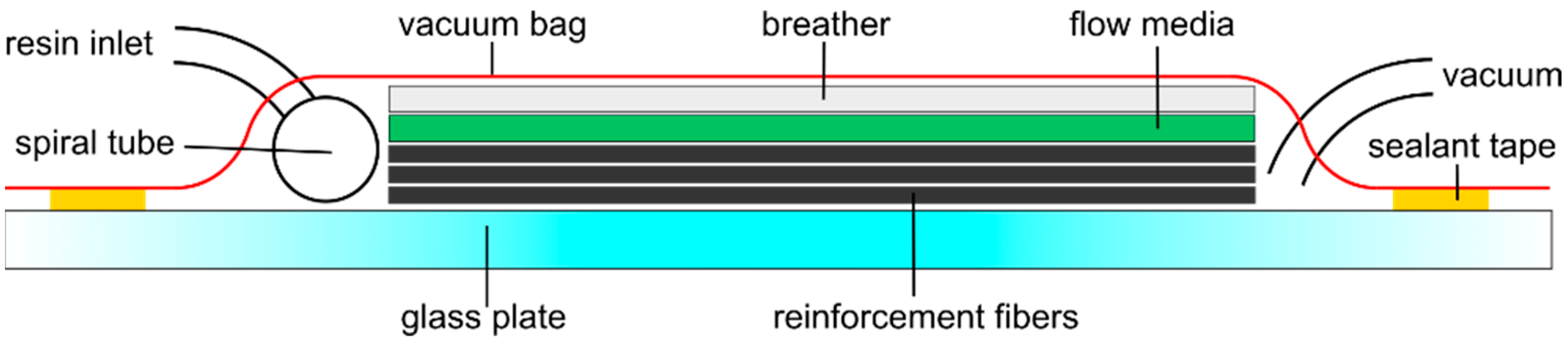

2.2.2. Composite Manufacturing

2.3. Characterization

2.3.1. Flexural Testing

2.3.2. Dynamic Mechanical Analysis (DMA)

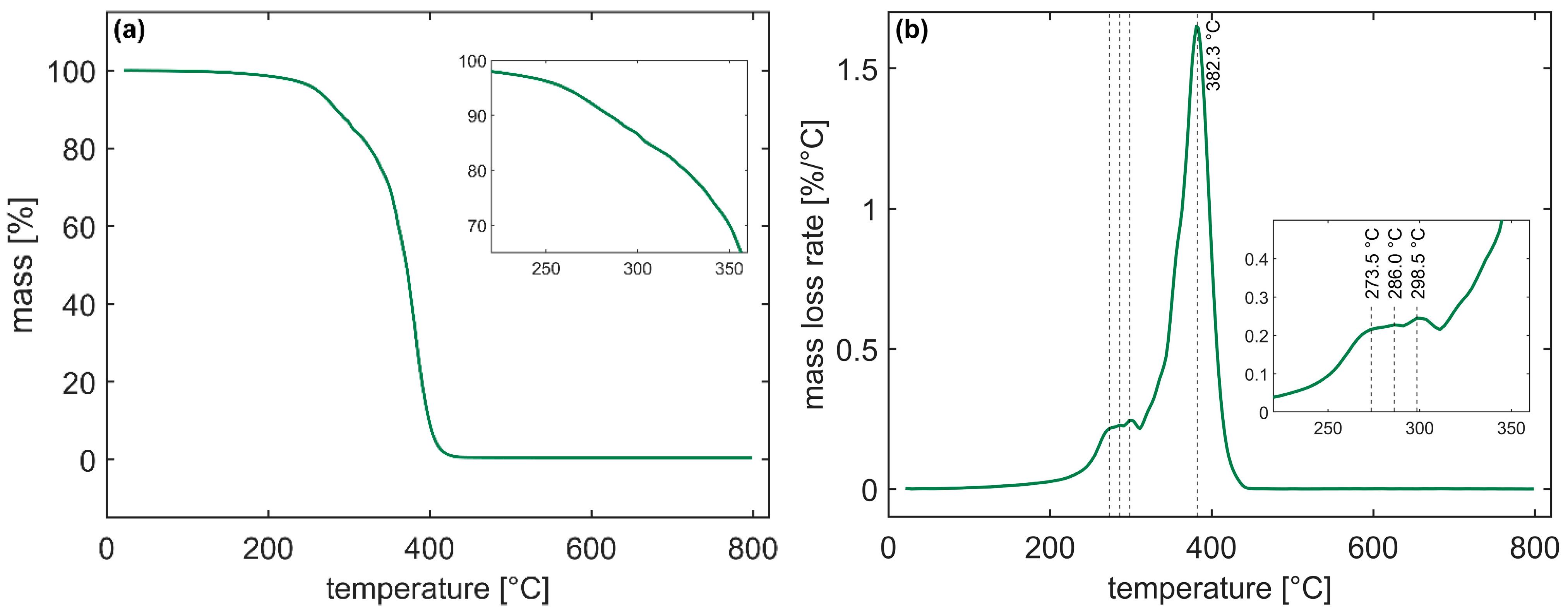

2.3.3. Thermal Analysis

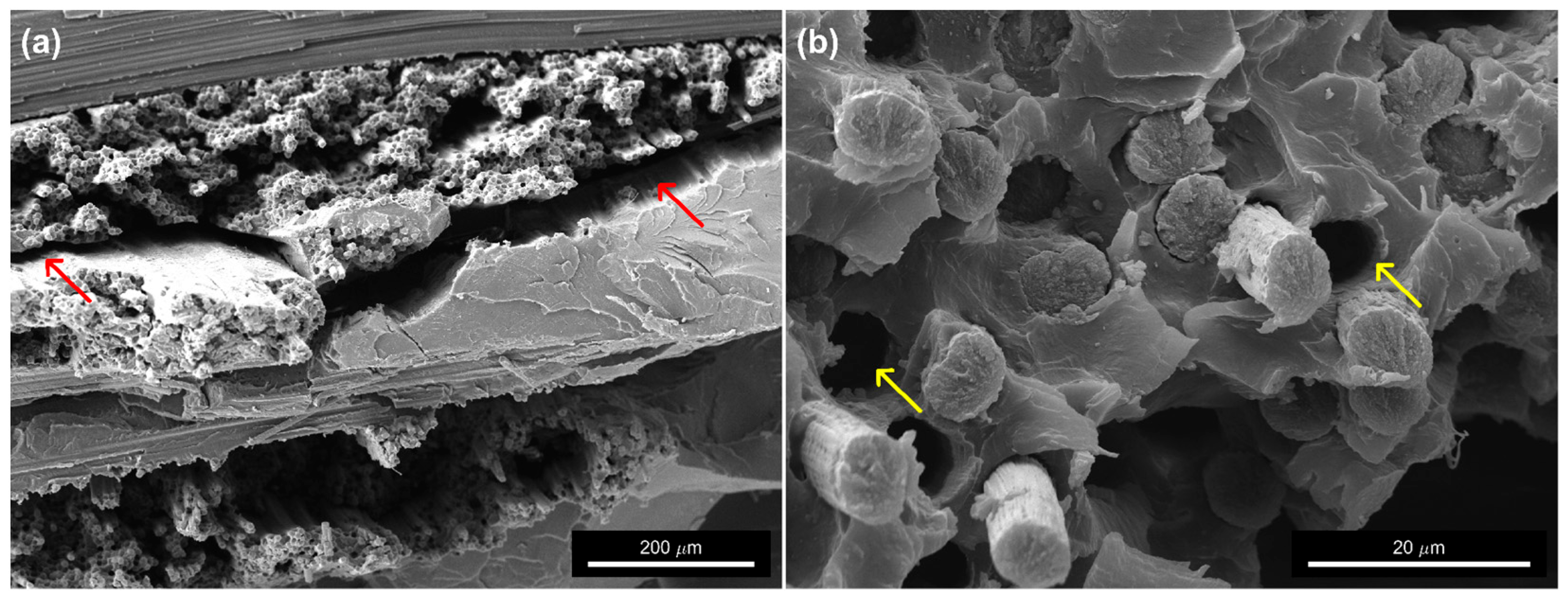

2.3.4. Fractography

2.3.5. Tensile Tests on Dry Non-Woven Fabric

2.3.6. Resin Burn-Off

3. Results and Discussion

3.1. Neat Resins

3.1.1. Flexural Properties

3.1.2. Thermal and Dynamic Mechanical Analysis of Optimized Formulation

3.2. Woven and Non-Woven Fabric Composites

4. Conclusions and Future Perspectives

- Optimal mechanical performance of the resin was achieved with 3 wt.% initiator concentration. Post-curing at 80 °C reduced performance, likely due to the specific composition of the initiator system.

- Woven vCF composites demonstrated mechanical properties comparable to values reported in the literature, despite a lower fiber volume fraction, suggesting that further optimization of the resin infusion process and fiber–matrix interfacial adhesion could enhance performance.

- Non-woven rCF composites exhibited approximately 20% of the mechanical performance of their virgin counterparts. Despite the reduced properties, the use of rCF presents a promising route for the development of sustainable composite materials. While their mechanical performance limits their adoption to semi-structural applications, the environmental benefit—through carbon fiber recycling—along with the cost-effectiveness and scalability of the processing technique make them highly attractive. These features are particularly relevant to the automotive industry, which has shown strong interest in lightweight, sustainable solutions for flooring, paneling, and interior components. Moreover, further reduction in porosity through thermal treatments is feasible due to the thermoplastic nature of the resin.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- De, B.; Bera, M.; Bhattacharjee, D.; Ray, B.C.; Mukherjee, S. A Comprehensive Review on Fiber-Reinforced Polymer Composites: Raw Materials to Applications, Recycling, and Waste Management. Prog. Mater. Sci. 2024, 146, 101326. [Google Scholar] [CrossRef]

- Tayebi, S.T.; Sambucci, M.; Valente, M. Waste Management of Wind Turbine Blades: A Comprehensive Review on Available Recycling Technologies with A Focus on Overcoming Potential Environmental Hazards Caused by Microplastic Production. Sustainability 2024, 16, 4517. [Google Scholar] [CrossRef]

- Mishnaevsky, L. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124. [Google Scholar] [CrossRef] [PubMed]

- Butenegro, J.A.; Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent Progress in Carbon Fiber Reinforced Polymers Recycling: A Review of Recycling Methods and Reuse of Carbon Fibers. Materials 2021, 14, 6401. [Google Scholar] [CrossRef]

- Bel Haj Frej, H.; Léger, R.; Perrin, D.; Ienny, P.; Gérard, P.; Devaux, J.-F. Recovery and Reuse of Carbon Fibre and Acrylic Resin from Thermoplastic Composites Used in Marine Application. Resour. Conserv. Recycl. 2021, 173, 105705. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling Glass Fiber Thermoplastic Composites from Wind Turbine Blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Meyer zu Reckendorf, I.; Sahki, A.; Perrin, D.; Lacoste, C.; Bergeret, A.; Ohayon, A.; Morand, K. Chemical Recycling of Vacuum-Infused Thermoplastic Acrylate-Based Composites Reinforced by Basalt Fabrics. Polymers 2022, 14, 1083. [Google Scholar] [CrossRef] [PubMed]

- Pimenta, S.; Pinho, S.T. The Effect of Recycling on the Mechanical Response of Carbon Fibres and Their Composites. Compos. Struct. 2012, 94, 3669–3684. [Google Scholar] [CrossRef]

- Aravindan, P.; Becagli, F.; Longana, M.L.; Blok, L.G.; Pozegic, T.R.; Huntley, S.J.; Rendall, T.; Hamerton, I. Remanufacturing of Woven Carbon Fibre Fabric Production Waste into High Performance Aligned Discontinuous Fibre Composites. J. Compos. Sci. 2020, 4, 68. [Google Scholar] [CrossRef]

- Paulsen, E.B.; Enevoldsen, P. A Multidisciplinary Review of Recycling Methods for End-of-Life Wind Turbine Blades. Energies 2021, 14, 4247. [Google Scholar] [CrossRef]

- Job, S.; Leeke, G.; Mativenga, P.; Oliveux, G.; Pickering, S.; Shuaib, N. Composites Recycling—Where Are We Now? Composites UK. 2016. Available online: https://compositesuk.co.uk/wp-content/uploads/2021/10/Recycling-Report-2016-Light-Background.pdf (accessed on 14 August 2025).

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.-J.; Kuiper, P.; de Wit, H. Recycling of Composite Materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Pakdel, E.; Kashi, S.; Varley, R.; Wang, X. Recent Progress in Recycling Carbon Fibre Reinforced Composites and Dry Carbon Fibre Wastes. Resour. Conserv. Recycl. 2021, 166, 105340. [Google Scholar] [CrossRef]

- Tse, B.; Yu, X.; Gong, H.; Soutis, C. Flexural Properties of Wet-Laid Hybrid Nonwoven Recycled Carbon and Flax Fibre Composites in Poly-Lactic Acid Matrix. Aerospace 2018, 5, 120. [Google Scholar] [CrossRef]

- Barnett, P.R.; Ghossein, H.K. A Review of Recent Developments in Composites Made of Recycled Carbon Fiber Textiles. Textiles 2021, 1, 433–465. [Google Scholar] [CrossRef]

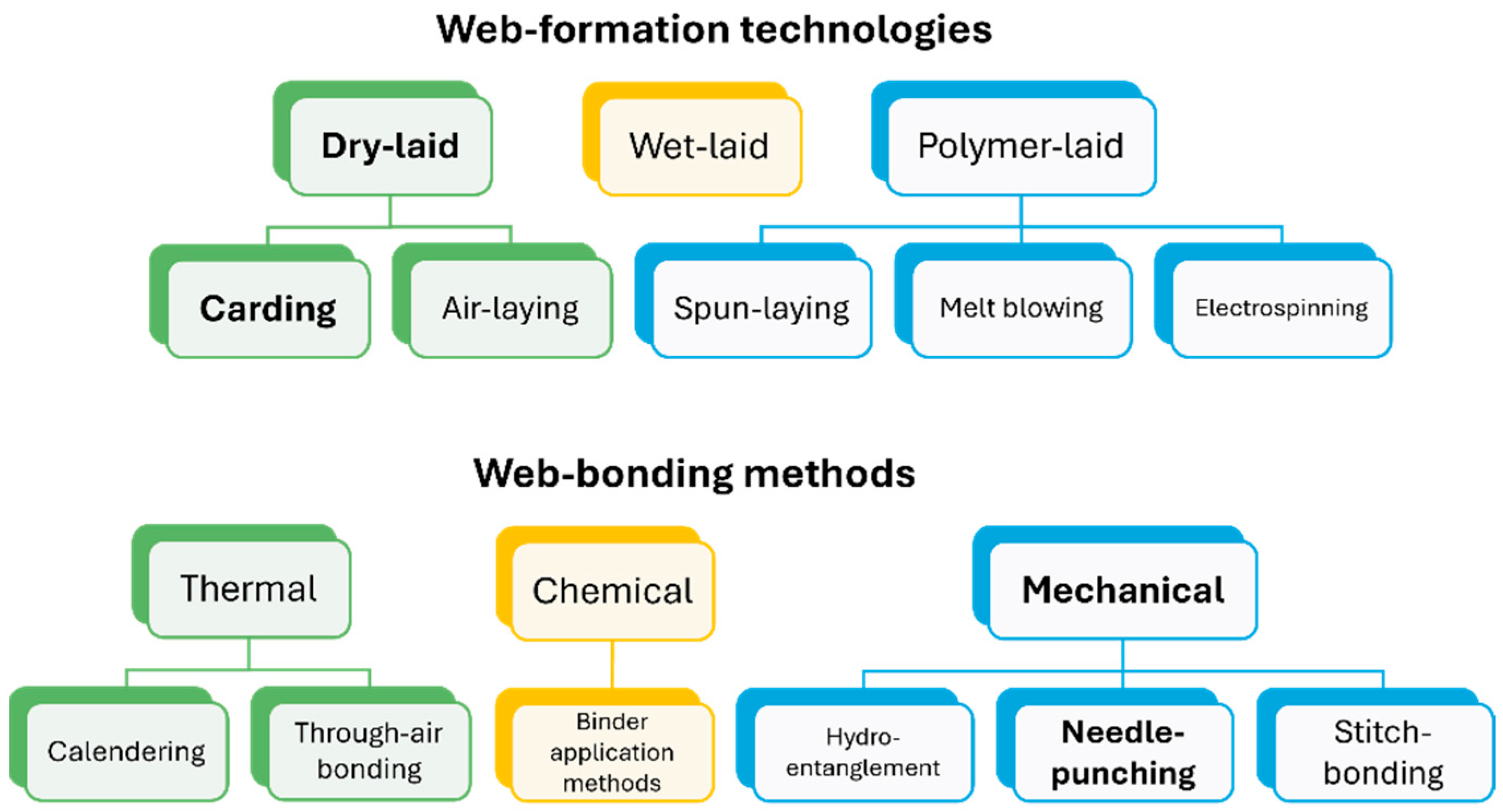

- Raghvendra, K.; Sravanthi, L. Fabrication Techniques of Micro/Nano Fibres Based Nonwoven Composites: A Review. Mod. Chem. Appl. 2017, 05, 1–11. [Google Scholar] [CrossRef]

- Yilmaz, K.B.; Sabuncuoglu, B.; Yildirim, B.; Silberschmidt, V.V. A Brief Review on the Mechanical Behavior of Nonwoven Fabrics. J. Eng. Fibers Fabr. 2020, 15, 1558925020970197. [Google Scholar] [CrossRef]

- Patnaik, P.K.; Swain, P.T.R.; Mishra, S.K.; Purohit, A.; Biswas, S. Recent Developments on Characterization of Needle-Punched Nonwoven Fabric Reinforced Polymer Composites—A Review. Mater. Today Proc. 2020, 26, 466–470. [Google Scholar] [CrossRef]

- Devine, M.; Bajpai, A.; Ó Brádaigh, C.M.; Ray, D. ‘Resin Welding’: A Novel Route to Joining Acrylic Composite Components at Room Temperature. Compos. Part B Eng. 2024, 272, 111212. [Google Scholar] [CrossRef]

- Sacchetti, F.; Grouve, W.J.B.; Warnet, L.L.; Villegas, I.F. Effect of Resin-Rich Bond Line Thickness and Fibre Migration on the Toughness of Unidirectional Carbon/PEEK Joints. Compos. Part Appl. Sci. Manuf. 2018, 109, 197–206. [Google Scholar] [CrossRef]

- Stavrov, D.; Bersee, H.E.N. Resistance Welding of Thermoplastic Composites-an Overview. Compos. Part Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Bernet, N.; Michaud, V.; Bourban, P.-E.; Månson, J.-A.E. Commingled Yarn Composites for Rapid Processing of Complex Shapes. Compos. Part Appl. Sci. Manuf. 2001, 32, 1613–1626. [Google Scholar] [CrossRef]

- Mitschang, P.; Blinzler, M.; Wöginger, A. Processing Technologies for Continuous Fibre Reinforced Thermoplastics with Novel Polymer Blends. Compos. Sci. Technol. 2003, 63, 2099–2110. [Google Scholar] [CrossRef]

- Qiao, Y.; Fring, L.D.; Pallaka, M.R.; Simmons, K.L. A Review of the Fabrication Methods and Mechanical Behavior of Continuous Thermoplastic Polymer Fiber–Thermoplastic Polymer Matrix Composites. Polym. Compos. 2023, 44, 694–733. [Google Scholar] [CrossRef]

- Bodaghi, M.; Park, C.H.; Krawczak, P. Reactive Processing of Acrylic-Based Thermoplastic Composites: A Mini-Review. Front. Mater. 2022, 9, 931338. [Google Scholar] [CrossRef]

- van Rijswijk, K.; Bersee, H.E.N. Reactive Processing of Textile Fiber-Reinforced Thermoplastic Composites—An Overview. Compos. Part Appl. Sci. Manuf. 2007, 38, 666–681. [Google Scholar] [CrossRef]

- Qin, Y.; Summerscales, J.; Graham-Jones, J.; Meng, M.; Pemberton, R. Monomer Selection for In Situ Polymerization Infusion Manufacture of Natural-Fiber Reinforced Thermoplastic-Matrix Marine Composites. Polymers 2020, 12, 2928. [Google Scholar] [CrossRef]

- Valente, M.; Rossitti, I.; Biblioteca, I.; Sambucci, M. Thermoplastic Composite Materials Approach for More Circular Components: From Monomer to In Situ Polymerization, a Review. J. Compos. Sci. 2022, 6, 132. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Optimizing Polymer Infusion Process for Thin Ply Textile Composites with Novel Matrix System. Materials 2017, 10, 293. [Google Scholar] [CrossRef] [PubMed]

- Obande, W.; Ó Brádaigh, C.M.; Ray, D. Continuous Fibre-Reinforced Thermoplastic Acrylic-Matrix Composites Prepared by Liquid Resin Infusion—A Review. Compos. Part B Eng. 2021, 215, 108771. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, P.; Xian, G. Continuous Fiber Reinforced Thermoplastic Composite Pultrusion with in Situ Polymerizable Methyl Methacrylate: A Review. Polym. Compos. 2023, 44, 4345–4369. [Google Scholar] [CrossRef]

- Shen, Y.; Du, W.; Sui, X.; Liu, X.; Tang, B.Z.; Yang, J. Green Manufacturing Process Design for Infusible Acrylic Resin Composites: A Data-Guided Life Cycle Management Model Incorporating Material-Process-Property-Energy-Emission Relationships. Compos. Part Appl. Sci. Manuf. 2024, 181, 108146. [Google Scholar] [CrossRef]

- Feraboli, P.; Kawakami, H.; Wade, B.; Gasco, F.; DeOto, L.; Masini, A. Recyclability and Reutilization of Carbon Fiber Fabric/Epoxy Composites. J. Compos. Mater. 2012, 46, 1459–1473. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J. On Recycled Carbon Fibre Composites Manufactured through a Liquid Composite Moulding Process. J. Reinf. Plast. Compos. 2016, 35, 533–540. [Google Scholar] [CrossRef]

- Cider|Circular Product Design for Automotive Components Made from Recycled and Sustainable Composite Material. Available online: https://www.igcv.fraunhofer.de/en/research/reference_projects/sustainable_circular_product_design_composites_cider.html (accessed on 14 August 2025).

- Elium® 158 O TDS. Available online: http://www.arkema.com (accessed on 14 August 2025).

- Benzoclean 40 LLV TDS. Available online: https://www.rsm-web.com/wp-content/uploads/2018/10/TDS-BENZOCLEAN-40-LLV-Rev.-1.0-05_2016-ENG.pdf (accessed on 14 August 2025).

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D4065-20; Standard Practice for Plastics: Dynamic Mechanical Properties: Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D3171-22; Standard Test Methods for Constituent Content of Composite Materials. ASTM International: West Conshohocken, PA, USA, 2022.

- Raponi, O.d.A.; Barbosa, L.C.M.; de Souza, B.R.; Ancelotti Junior, A.C. Study of the Influence of Initiator Content in the Polymerization Reaction of a Thermoplastic Liquid Resin for Advanced Composite Manufacturing. Adv. Polym. Technol. 2018, 37, 3579–3587. [Google Scholar] [CrossRef]

- de Andrade Raponi, O.; Righetti de Souza, B.; Miranda Barbosa, L.C.; Ancelotti Junior, A.C. Thermal, Rheological, and Dielectric Analyses of the Polymerization Reaction of a Liquid Thermoplastic Resin for Infusion Manufacturing of Composite Materials. Polym. Test. 2018, 71, 32–37. [Google Scholar] [CrossRef]

- Charlier, Q.; Fontanier, J.-C.; Lortie, F.; Pascault, J.-P.; Gerard, J.-F. Rheokinetic Study of Acrylic Reactive Mixtures Dedicated to Fast Processing of Fiber-Reinforced Thermoplastic Composites. J. Appl. Polym. Sci. 2019, 136, 47391. [Google Scholar] [CrossRef]

- O’neil, G.A.; Wisnudel, M.B.; Torkelson, J.M. Gel Effect in Free Radical Polymerization: Model Discrimination of Its Cause. AIChE J. 1998, 44, 1226–1231. [Google Scholar] [CrossRef]

- Hutchinson, J.M. Determination of the Glass Transition Temperature: Methods Correlation and Structural Heterogeneity. J. Therm. Anal. Calorim. 2009, 98, 579–589. [Google Scholar] [CrossRef]

- Kashiwagi, T.; Inaba, A.; Brown, J.E.; Hatada, K.; Kitayama, T.; Masuda, E. Effects of Weak Linkages on the Thermal and Oxidative Degradation of Poly(Methyl Methacrylates). Macromolecules 1986, 19, 2160–2168. [Google Scholar] [CrossRef]

- Manring, L.E. Thermal Degradation of Saturated Poly(Methyl Methacrylate). Macromolecules 1988, 21, 528–530. [Google Scholar] [CrossRef]

- Manring, L.E. Thermal Degradation of Poly(Methyl Methacrylate). 2. Vinyl-Terminated Polymer. Macromolecules 1989, 22, 2673–2677. [Google Scholar] [CrossRef]

- Manring, L.E.; Sogah, D.Y.; Cohen, G.M. Thermal Degradation of Poly(Methyl Methacrylate). 3. Polymer with Head-to-Head Linkages. Macromolecules 1989, 22, 4652–4654. [Google Scholar] [CrossRef]

- Manring, L.E. Thermal Degradation of Poly(Methyl Methacrylate). 4. Random Side-Group Scission. Macromolecules 1991, 24, 3304–3309. [Google Scholar] [CrossRef]

- Holland, B.J.; Hay, J.N. The Effect of Polymerisation Conditions on the Kinetics and Mechanisms of Thermal Degradation of PMMA. Polym. Degrad. Stab. 2002, 77, 435–439. [Google Scholar] [CrossRef]

- Gao, Z.; Kaneko, T.; Hou, D.; Nakada, M. Kinetics of Thermal Degradation of Poly(Methyl Methacrylate) Studied with the Assistance of the Fractional Conversion at the Maximum Reaction Rate. Polym. Degrad. Stab. 2004, 84, 399–403. [Google Scholar] [CrossRef]

- Galgano, A.; Branca, C.; Di Blasi, C.; Vollaro, P.; Milella, E. Modeling the Ignition of Poly(Methyl Methacrylate)/Carbon Nanotube Nanocomposites. Polym. Degrad. Stab. 2017, 144, 344–353. [Google Scholar] [CrossRef]

- Saladino, M.L.; Motaung, T.E.; Luyt, A.S.; Spinella, A.; Nasillo, G.; Caponetti, E. The Effect of Silica Nanoparticles on the Morphology, Mechanical Properties and Thermal Degradation Kinetics of PMMA. Polym. Degrad. Stab. 2012, 97, 452–459. [Google Scholar] [CrossRef]

- Gałka, P.; Kowalonek, J.; Kaczmarek, H. Thermogravimetric Analysis of Thermal Stability of Poly(Methyl Methacrylate) Films Modified with Photoinitiators. J. Therm. Anal. Calorim. 2014, 115, 1387–1394. [Google Scholar] [CrossRef]

- Porras, J.; Morales, M.A.; Hernandez, C.; Maranon, A.; Michaud, V.; Porras, A. Development of a Sustainable Thermoplastic Composite Material Using Manicaria Saccifera Fabric and Elium® Resin. J. Nat. Fibers 2025, 22, 2462977. [Google Scholar] [CrossRef]

- Rieger, J. The Glass Transition Temperature Tg of Polymers—Comparison of the Values from Differential Thermal Analysis (DTA, DSC) and Dynamic Mechanical Measurements (Torsion Pendulum). Polym. Test. 2001, 20, 199–204. [Google Scholar] [CrossRef]

- Ehrenstein, G.W.; Riedel, G.; Trawiel, P. Dynamic Mechanical Analysis (DMA). In Thermal Analysis of Plastics; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2004; pp. 236–299. [Google Scholar]

- Dong, S.; Gauvin, R. Application of Dynamic Mechanical Analysis for the Study of the Interfacial Region in Carbon Fiber/Epoxy Composite Materials. Polym. Compos. 1993, 14, 414–420. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Perrotey, P.; Joshi, S.C. Enhanced Vibration Damping and Dynamic Mechanical Characteristics of Composites with Novel Pseudo-Thermoset Matrix System. Compos. Struct. 2017, 179, 502–513. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A.; Pegoretti, A. Dynamic-Mechanical Response of Carbon Fiber Laminates with a Reactive Thermoplastic Resin Containing Phase Change Microcapsules. Mech. Time-Depend. Mater. 2020, 24, 395–418. [Google Scholar] [CrossRef]

- Palmieri, B.; Petriccione, A.; De Tommaso, G.; Giordano, M.; Martone, A. An Efficient Thermal Cure Profile for Thick Parts Made by Reactive Processing of Acrylic Thermoplastic Composites. J. Compos. Sci. 2021, 5, 229. [Google Scholar] [CrossRef]

- Genna, S.; Papa, I.; Trovalusci, F. Mechanical Behavior of Recycled Carbon Fiber Epoxy and Vinylester Composites Produced by Resin Infusion with Flexible Tooling Technology (RIFT). J. Compos. Mater. 2023, 57, 4025–4033. [Google Scholar] [CrossRef]

- Khan, T.; Ali, M.A.; Irfan, M.S.; Cantwell, W.J.; Rehan, U. Visualizing Pseudo-Ductility in Carbon/Glass Fiber Hybrid Composites Manufactured Using Infusible Thermoplastic Elium® Resin. Polym. Compos. 2023, 44, 1859–1876. [Google Scholar] [CrossRef]

- Fredi, G.; Dorigato, A.; Pegoretti, A. Novel Reactive Thermoplastic Resin as a Matrix for Laminates Containing Phase Change Microcapsules. Polym. Compos. 2019, 40, 3711–3724. [Google Scholar] [CrossRef]

- Bhudolia, S.K.; Joshi, S.C.; Bert, A.; Yi Di, B.; Makam, R.; Gohel, G. Flexural Characteristics of Novel Carbon Methylmethacrylate Composites. Compos. Commun. 2019, 13, 129–133. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Pothnis, J.R.; Portela, A.; Gujjala, R.; Ma, H.; O’Higgins, R.M. Flexural and Interlaminar Shear Response of Novel Methylmethacrylate Composites Reinforced with High-Performance Fibres. Polym. Test. 2024, 140, 108578. [Google Scholar] [CrossRef]

- Pini, T.; Caimmi, F.; Briatico-Vangosa, F.; Frassine, R.; Rink, M. Fracture Initiation and Propagation in Unidirectional CF Composites Based on Thermoplastic Acrylic Resins. Eng. Fract. Mech. 2017, 184, 51–58. [Google Scholar] [CrossRef]

- Pini, T.; Briatico-Vangosa, F.; Frassine, R.; Rink, M. Matrix Toughness Transfer and Fibre Bridging Laws in Acrylic Resin Based CF Composites. Eng. Fract. Mech. 2018, 203, 115–125. [Google Scholar] [CrossRef]

- Kang, T.J.; Lee, S.H. Characterization of Reinforcing Web Structures in Needle Punched Nonwoven Composites. J. Compos. Mater. 1999, 33, 2116–2132. [Google Scholar] [CrossRef]

- Manis, F.; Stegschuster, G.; Wölling, J.; Schlichter, S. Influences on Textile and Mechanical Properties of Recycled Carbon Fiber Nonwovens Produced by Carding. J. Compos. Sci. 2021, 5, 209. [Google Scholar] [CrossRef]

- Smoleń, J.; Olesik, P.; Jała, J.; Adamcio, A.; Kurtyka, K.; Godzierz, M.; Kozera, R.; Kozioł, M.; Boczkowska, A. The Use of Carbon Fibers Recovered by Pyrolysis from End-of-Life Wind Turbine Blades in Epoxy-Based Composite Panels. Polymers 2022, 14, 2925. [Google Scholar] [CrossRef] [PubMed]

| Label | BPO Content [wt.%] | Reinforcement Type | Post-Curing |

|---|---|---|---|

| E2 | 2 | - | - |

| E3 | 3 | - | - |

| E4 | 4 | - | - |

| E3_PC | 3 | - | 2 h at 80 °C |

| E3_CF | 3 | 10 plies of CF fabric (160 g/m2) | - |

| E3_NW | 3 | 3 plies of non-woven CF fabric (200 g/m2) | - |

| Label | Method | [%] | [%] | [%] |

|---|---|---|---|---|

| E3_CF | Fabric areal density | 42.8 | 54.6 | 2.6 |

| E3_NW | Fabric areal density | 11.3 | 72.9 | 15.8 |

| Resin burn-off | 14.1 | 71.8 | 14.1 |

| Label | [°C] | [-] |

|---|---|---|

| E3 | 92.6 | 0.32 |

| E3_CF | 101.3 | 0.85 |

| E3_NW_R | 106.0 | 0.49 |

| Source | Elium® Grade | [-] | [MPa] | [GPa] | [MPa] | [GPa] |

|---|---|---|---|---|---|---|

| E3_CF | 158O | 0.43 | 618 | 36 | 1444 | 84 |

| E3_NW_T | 158O | 0.14 | 113 | 8 | 799 | 57 |

| E3_NW_R | 158O | 0.14 | 107 | 6 | 764 | 43 |

| Khan et al. [64] | 188O | 0.77 | 658 | 50 | 856 | 65 |

| Fredi et al. [65] | 150 | 0.57 | 469 | 38 | 827 | 67 |

| Budholia et al. [66] | 280 | 0.58 | 813 | 51 | 1395 | 88 |

| Bandaru et al. [67] | 180 | 0.54 | 465 | 40 | 869 | 75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taherinezhad Tayebi, S.; Pini, T.; Caruso, B.; Sambucci, M.; Bavasso, I.; Sarasini, F.; Tirillò, J.; Valente, M. Sustainable Acrylic Thermoplastic Composites via Vacuum-Assisted Resin Infusion Molding: Evaluation and Comparison of Fabrics and Recycled Non-Woven Carbon Fiber as Reinforcement. J. Compos. Sci. 2025, 9, 441. https://doi.org/10.3390/jcs9080441

Taherinezhad Tayebi S, Pini T, Caruso B, Sambucci M, Bavasso I, Sarasini F, Tirillò J, Valente M. Sustainable Acrylic Thermoplastic Composites via Vacuum-Assisted Resin Infusion Molding: Evaluation and Comparison of Fabrics and Recycled Non-Woven Carbon Fiber as Reinforcement. Journal of Composites Science. 2025; 9(8):441. https://doi.org/10.3390/jcs9080441

Chicago/Turabian StyleTaherinezhad Tayebi, Sara, Tommaso Pini, Bruno Caruso, Matteo Sambucci, Irene Bavasso, Fabrizio Sarasini, Jacopo Tirillò, and Marco Valente. 2025. "Sustainable Acrylic Thermoplastic Composites via Vacuum-Assisted Resin Infusion Molding: Evaluation and Comparison of Fabrics and Recycled Non-Woven Carbon Fiber as Reinforcement" Journal of Composites Science 9, no. 8: 441. https://doi.org/10.3390/jcs9080441

APA StyleTaherinezhad Tayebi, S., Pini, T., Caruso, B., Sambucci, M., Bavasso, I., Sarasini, F., Tirillò, J., & Valente, M. (2025). Sustainable Acrylic Thermoplastic Composites via Vacuum-Assisted Resin Infusion Molding: Evaluation and Comparison of Fabrics and Recycled Non-Woven Carbon Fiber as Reinforcement. Journal of Composites Science, 9(8), 441. https://doi.org/10.3390/jcs9080441