Chaotic Vibration Prediction of a Laminated Composite Cantilever Beam Subject to Random Parametric Error

Abstract

1. Introduction

- (1)

- By combining nonlinear dynamic modeling with the RNN data-driven approach, accurate prediction of the chaotic vibration of a LCCB under different levels of RPEs is achieved using the RNN model.

- (2)

- Through numerical validation under different external excitation amplitudes, circular frequencies, and spatial positions, the spatial applicability and generalization capability of the RNN model under RPEs are systematically evaluated.

2. Beam Model Establish

3. Introduction of RPEs

4. RNN Data-Driven Model Establishment

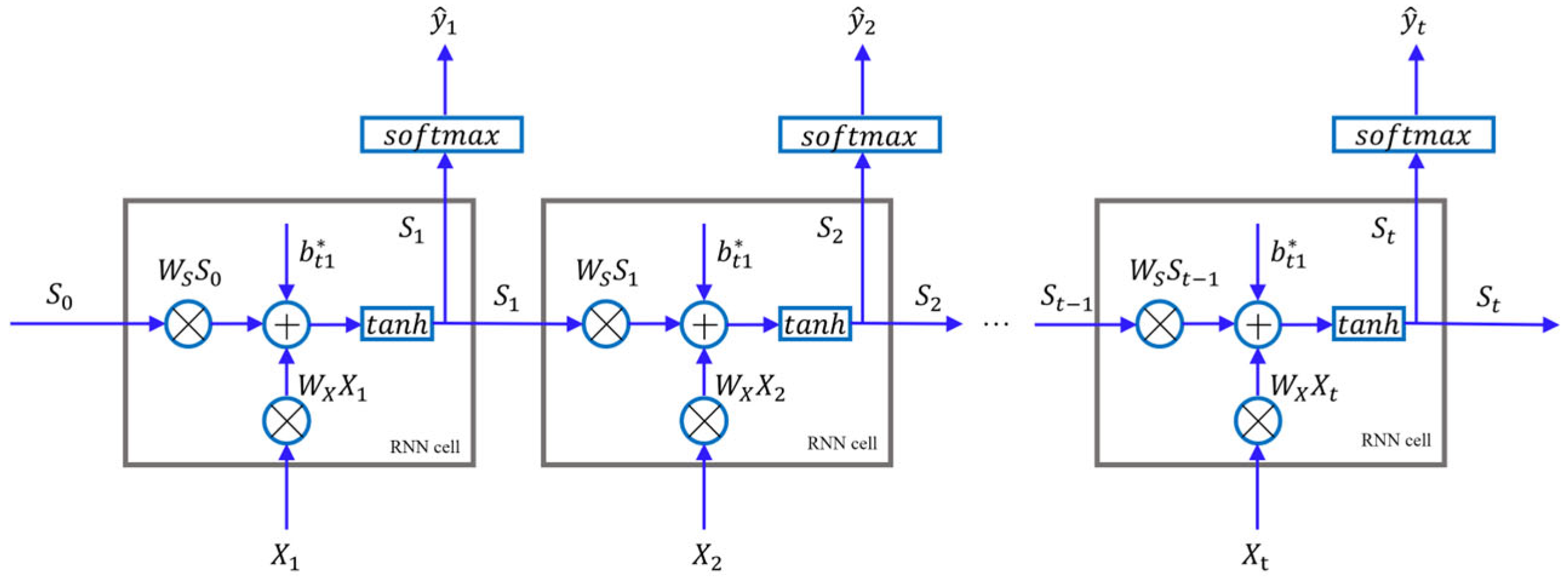

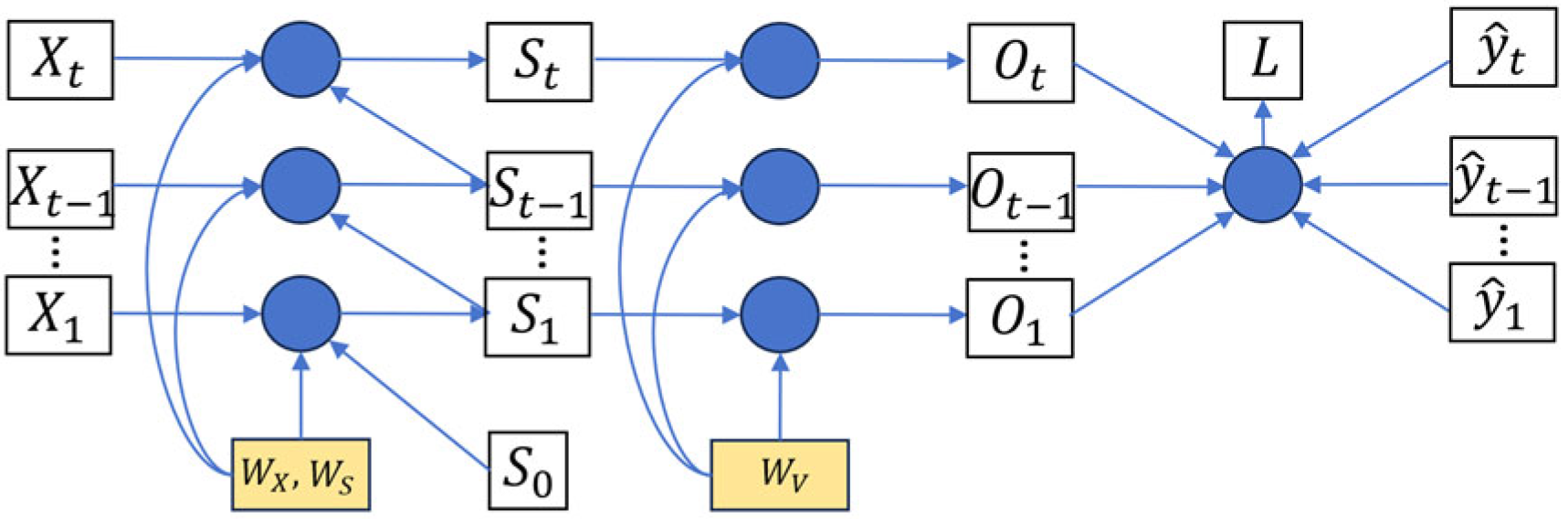

4.1. RNN Model Introduction

4.2. The Main Steps to Establish the Data-Driven Model of RNN

4.3. Loss Evaluation

5. Numerical Simulations

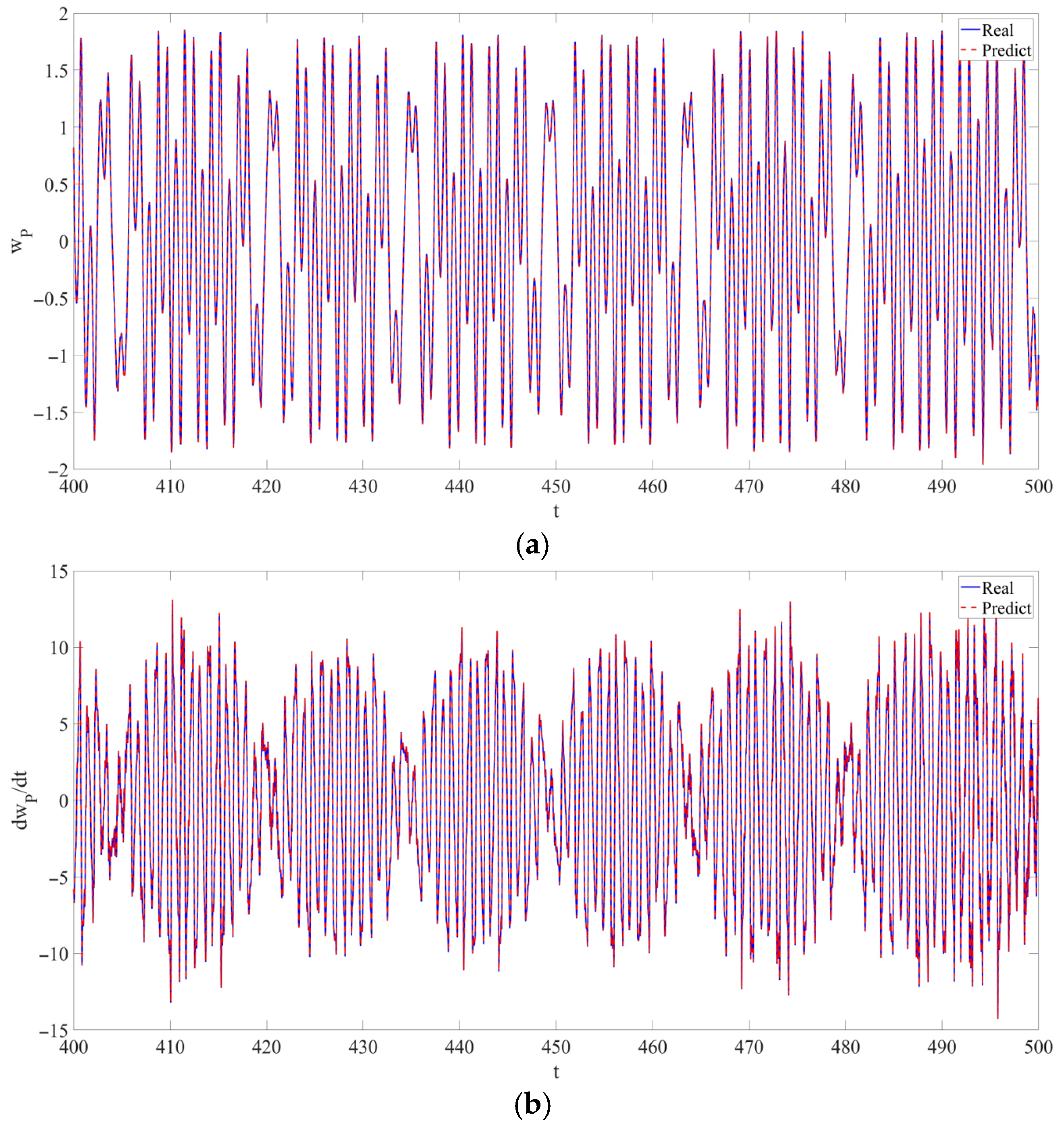

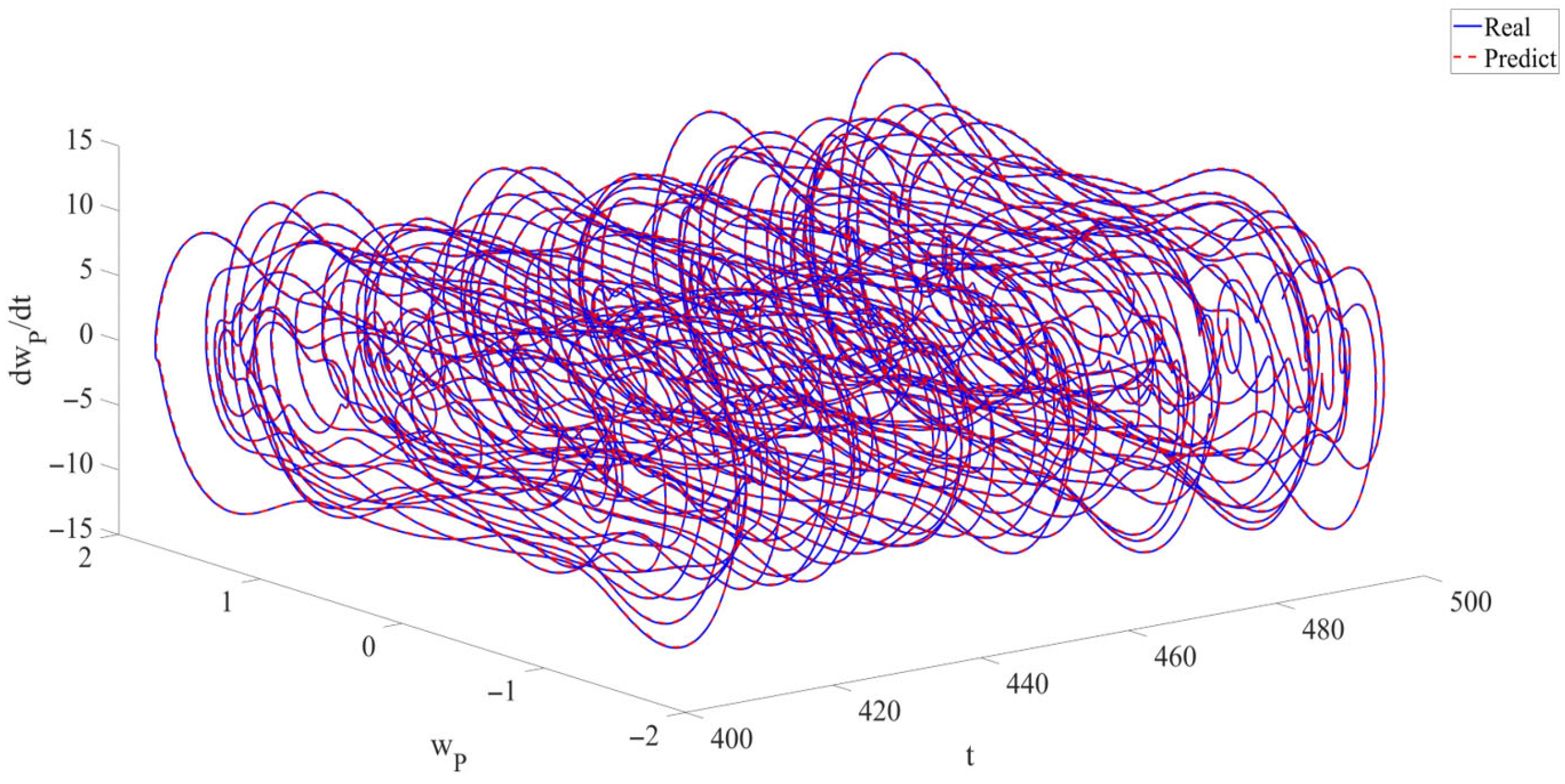

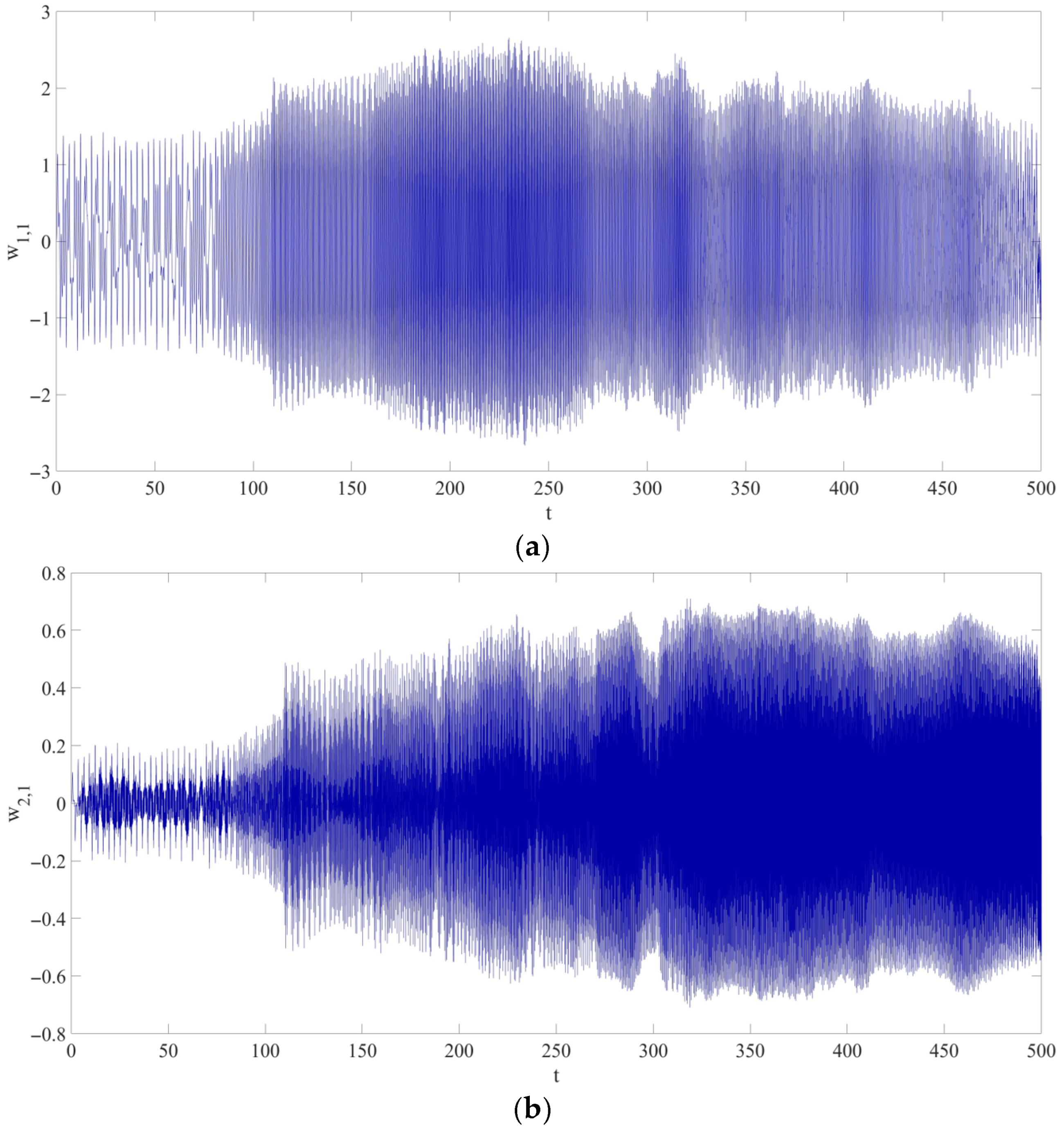

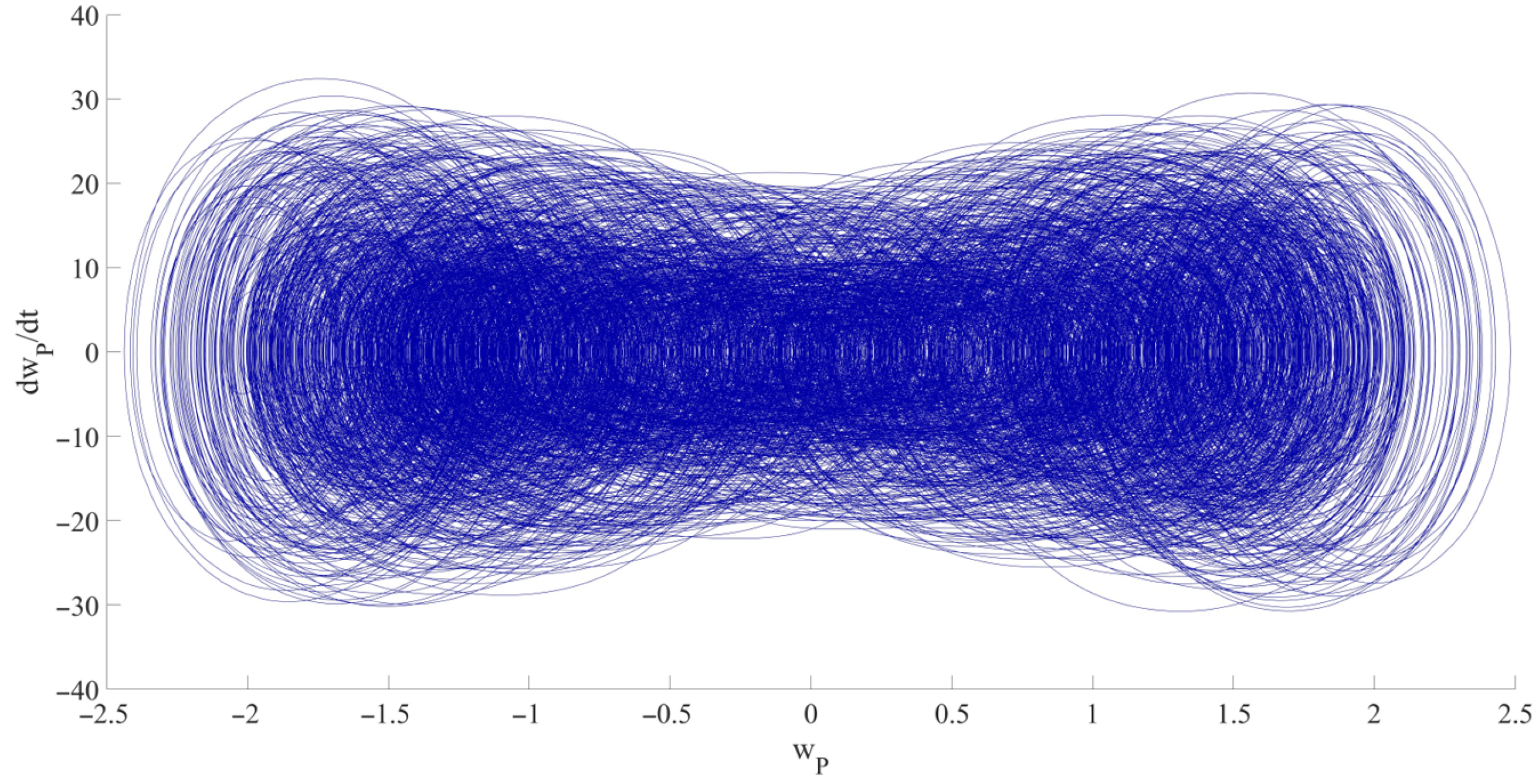

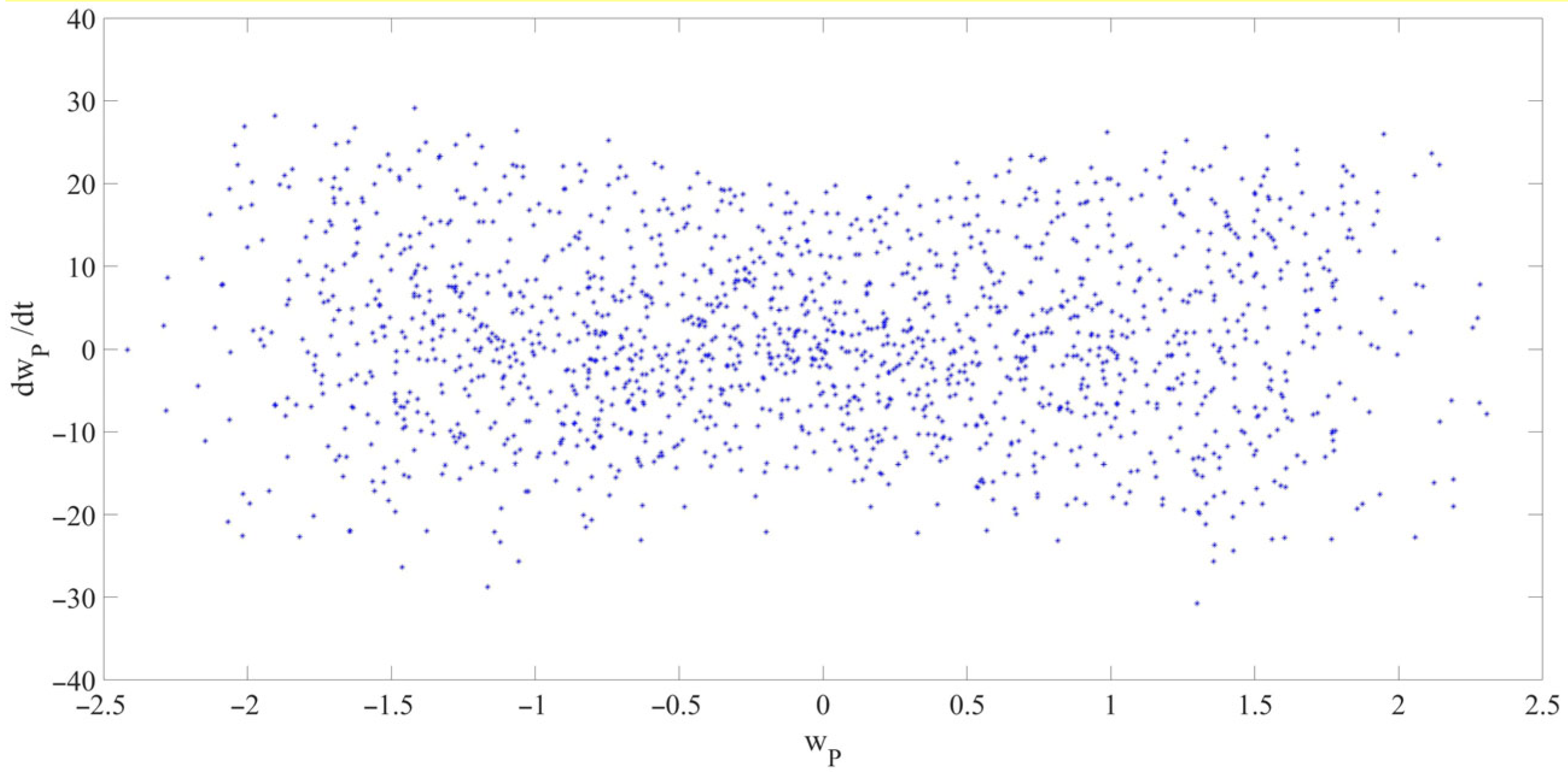

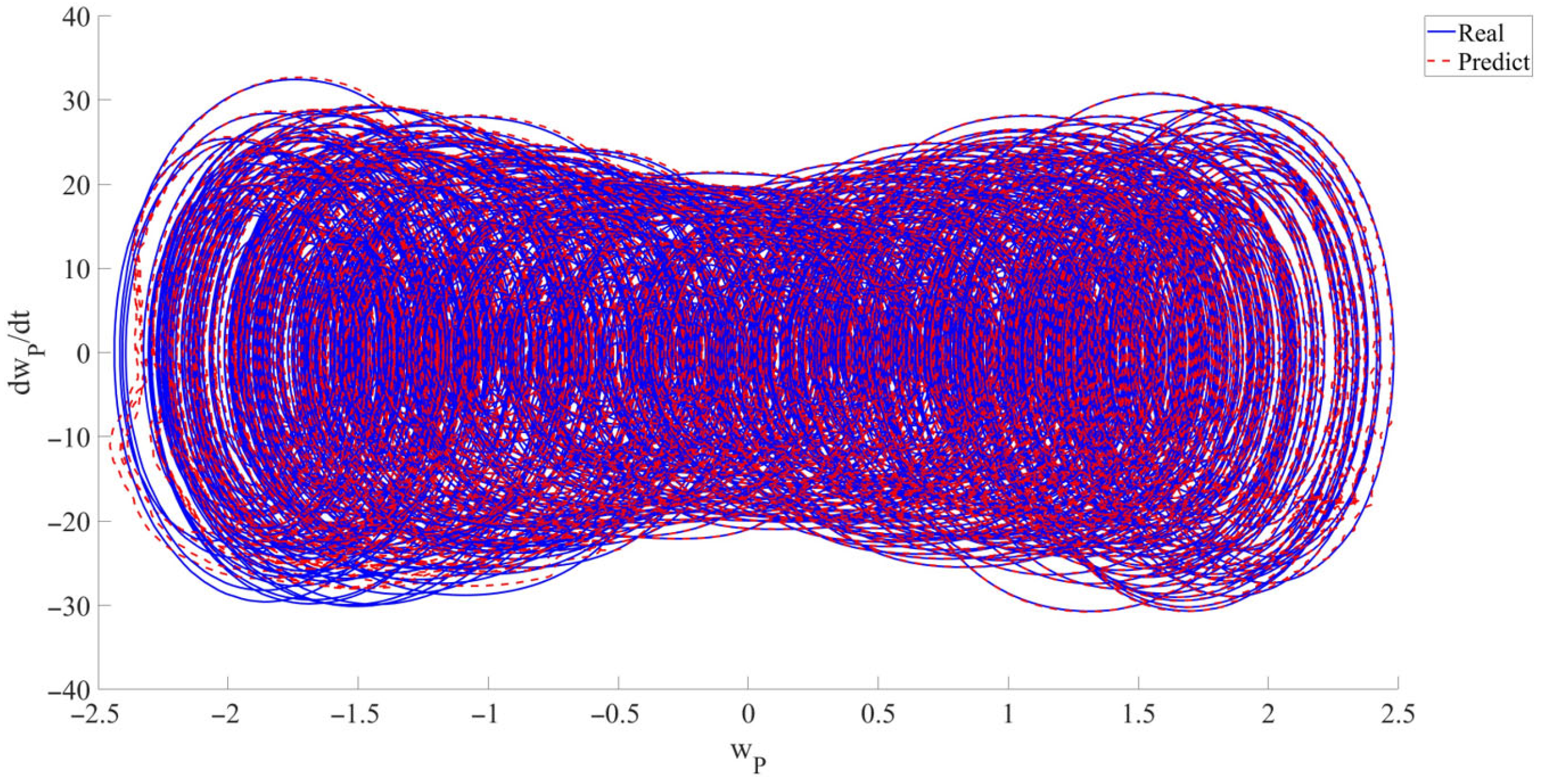

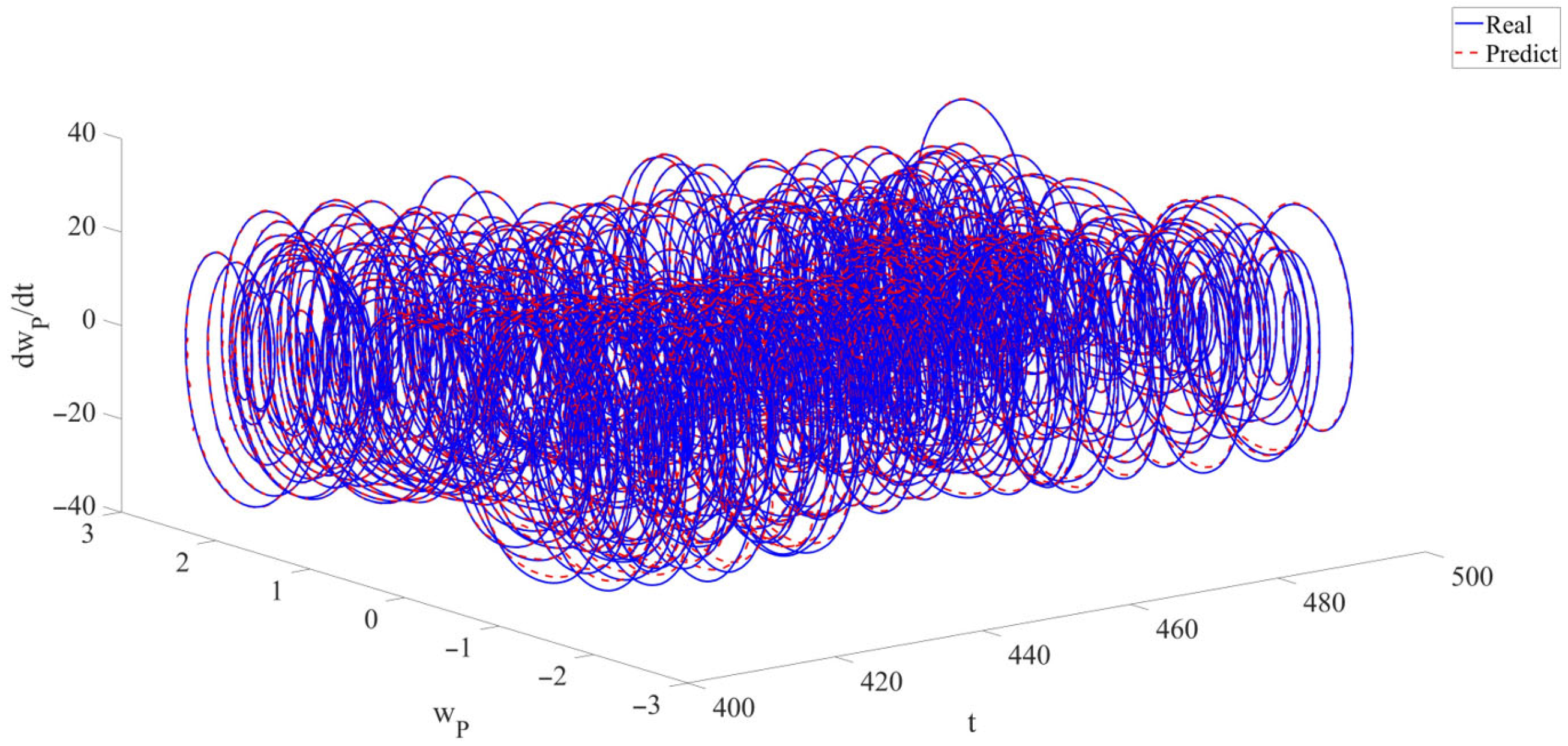

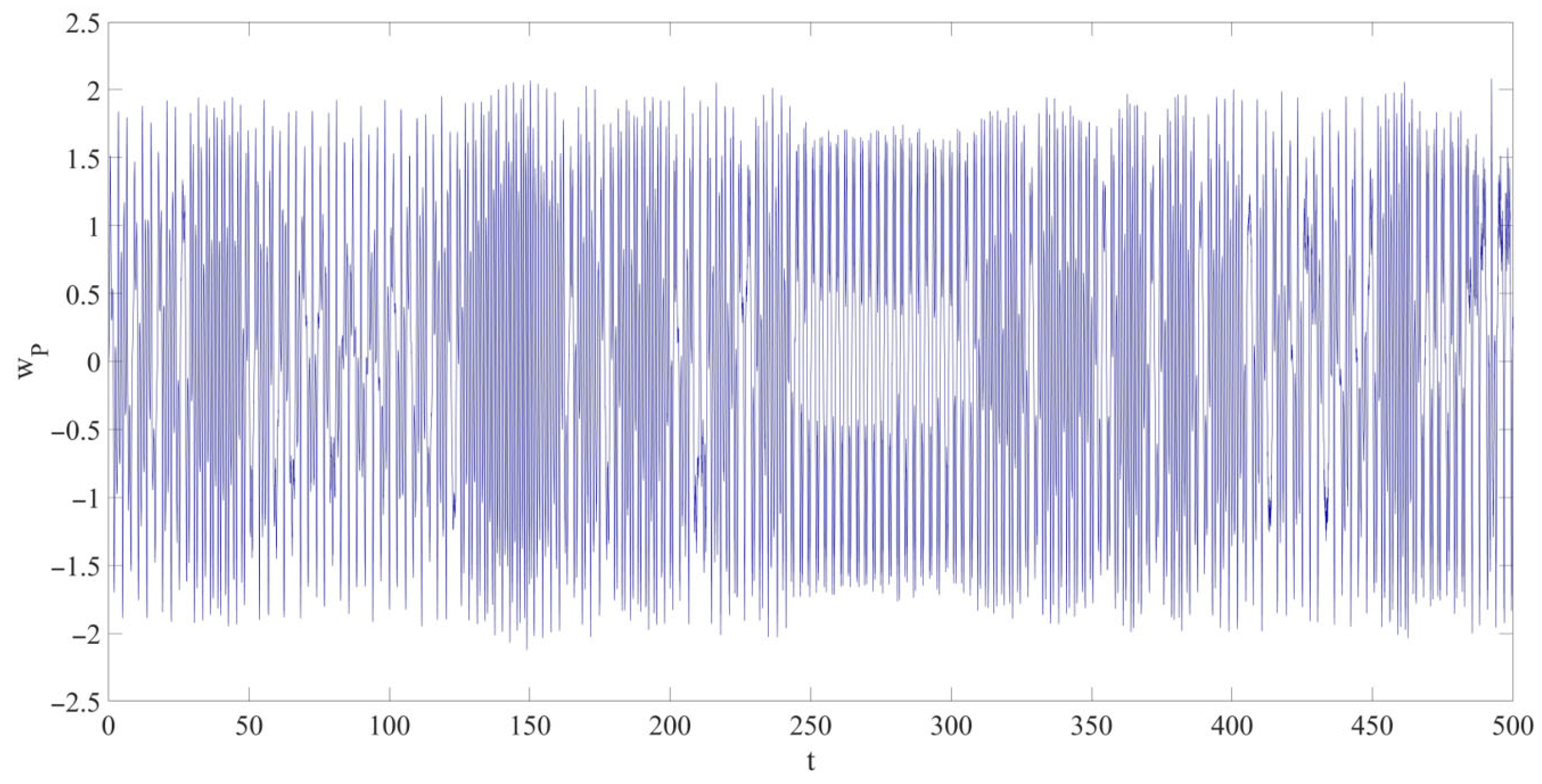

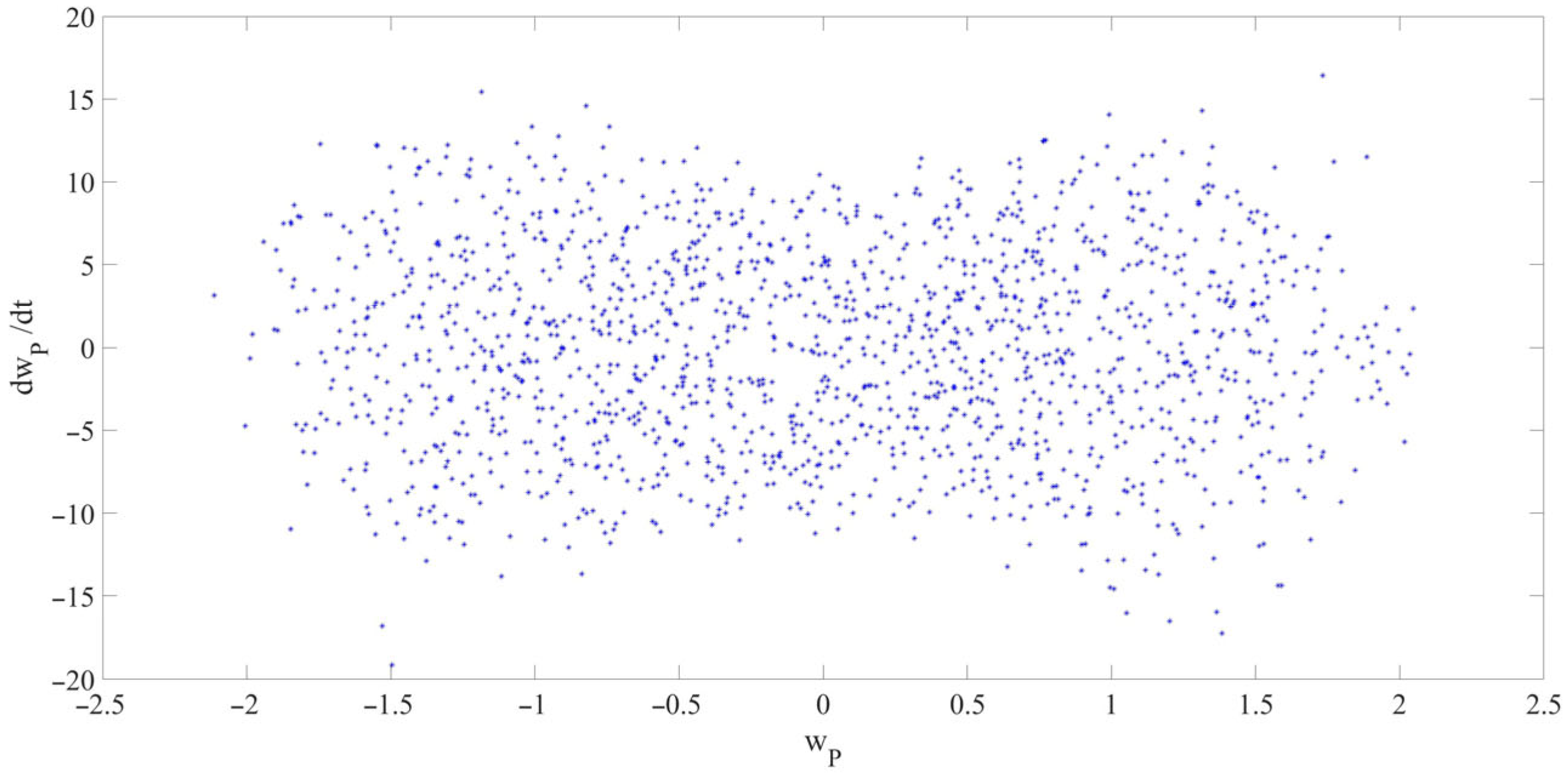

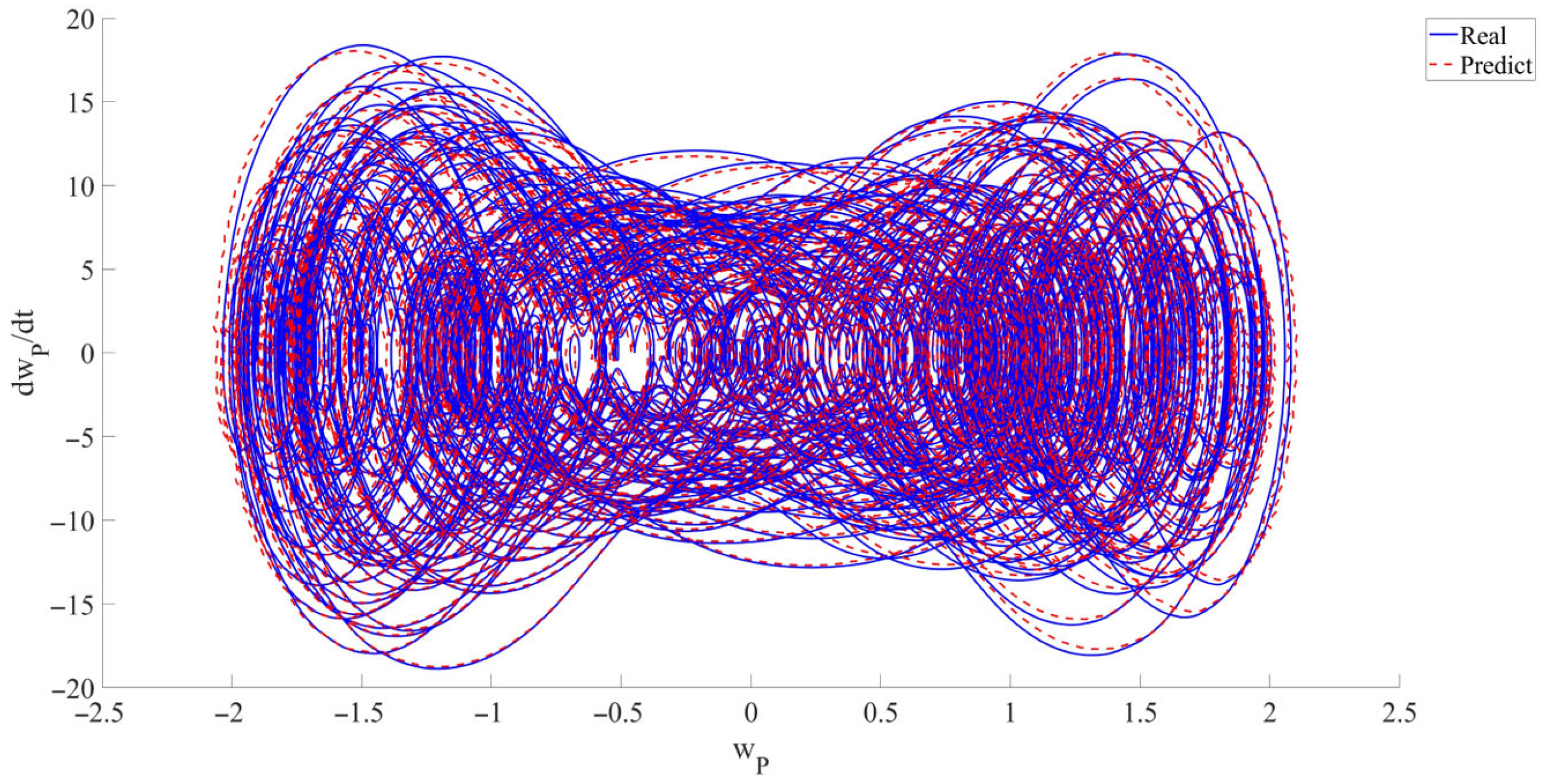

5.1. Case 1

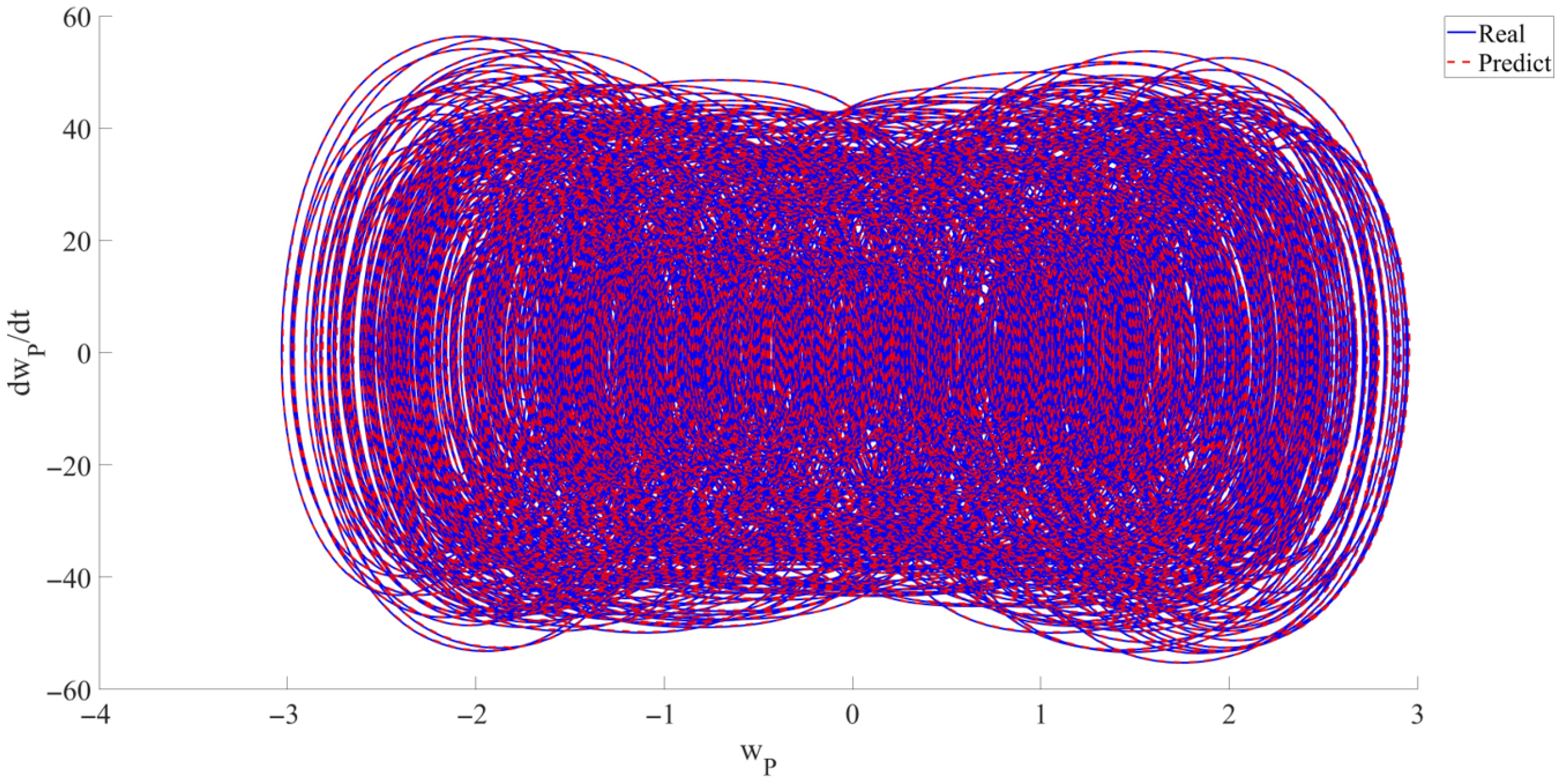

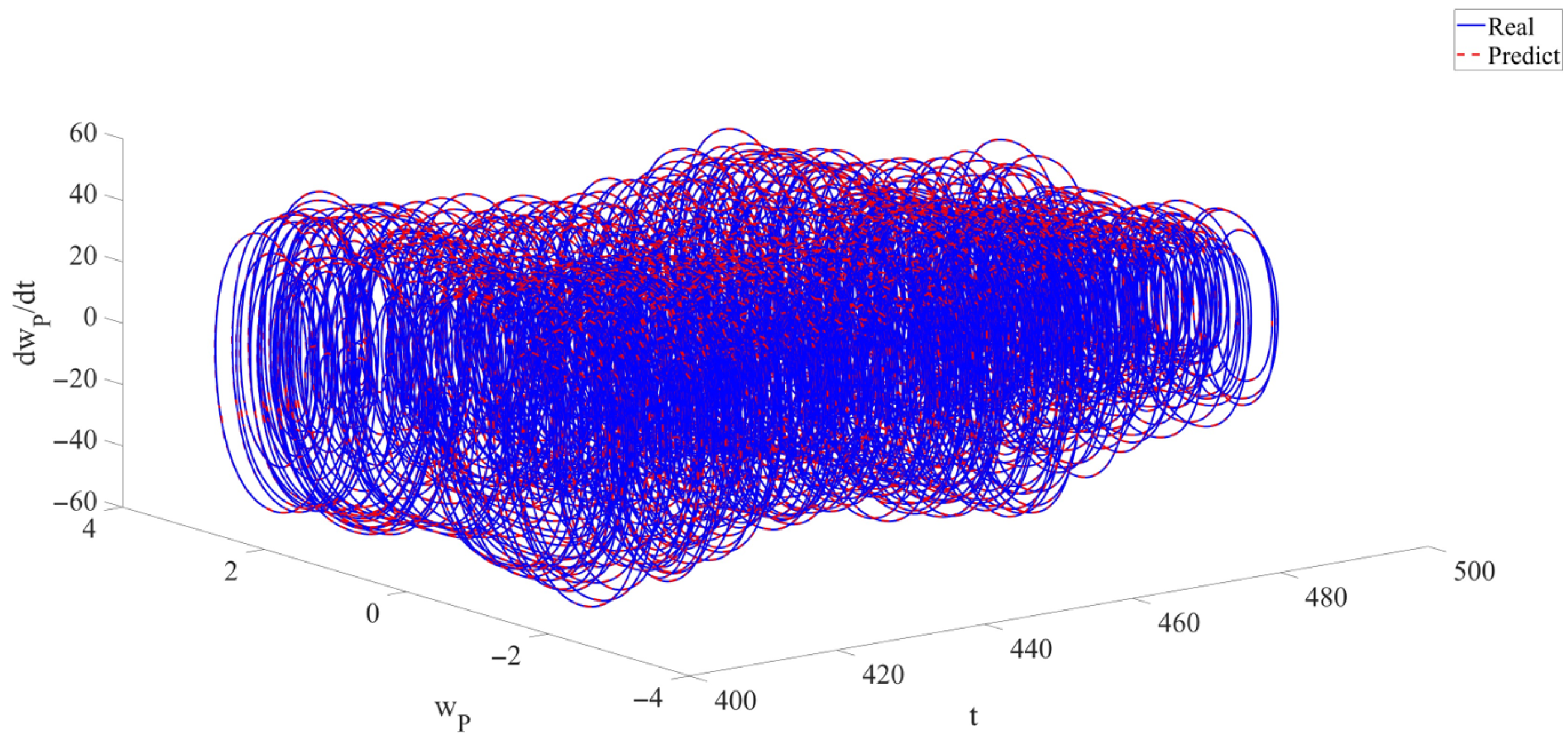

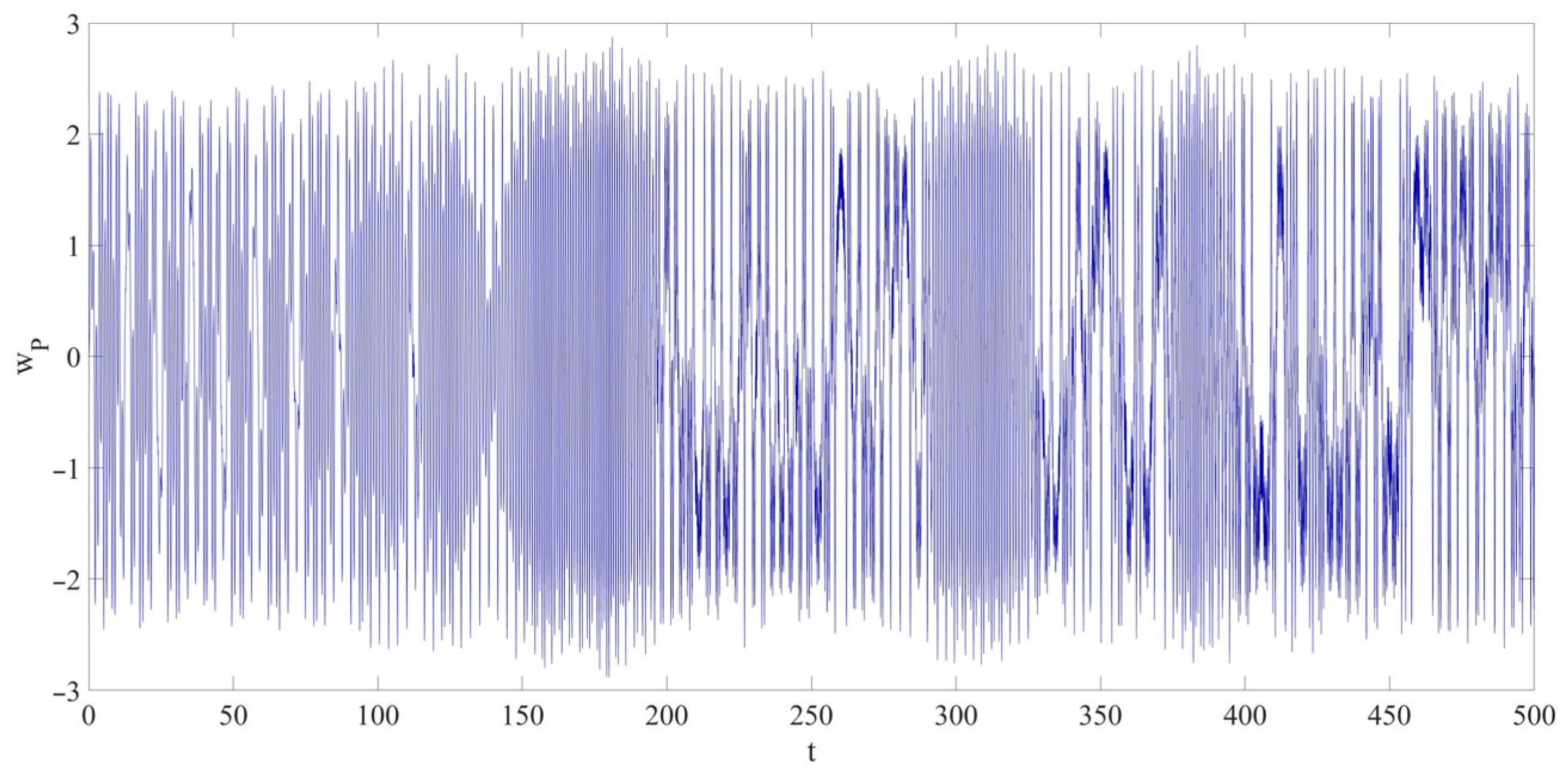

5.2. Case 2

5.3. Case 3

5.4. Case 4

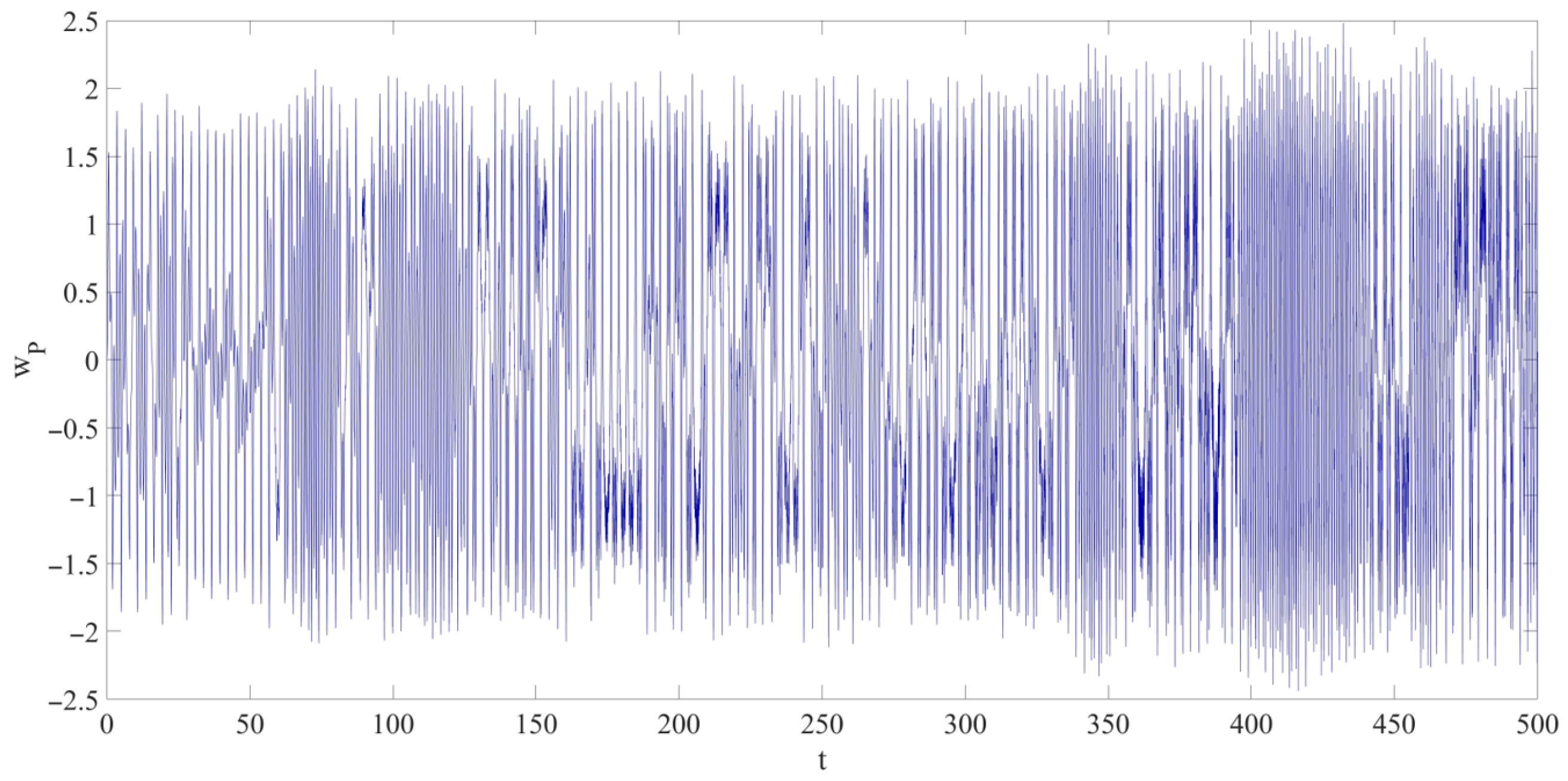

5.5. Spatial Applicability and Generalization

6. Conclusions

- (a)

- A nonlinear dynamic model of the LCCB considering RPEs was successfully developed. The results indicate that RPEs significantly affect the amplitude of chaotic vibrations in the LCCB system. Comparative analysis under four RPE conditions (Cases 1–4) shows that RPEs may lead to increasing, stable, or decreasing trends in vibration amplitude. Specifically, compared to Case 1, Case 2 exhibits an increase in the chaotic vibration amplitude; Case 3 shows that the amplitude remains almost unchanged; and Case 4 demonstrates a decrease in the chaotic vibration amplitude.

- (b)

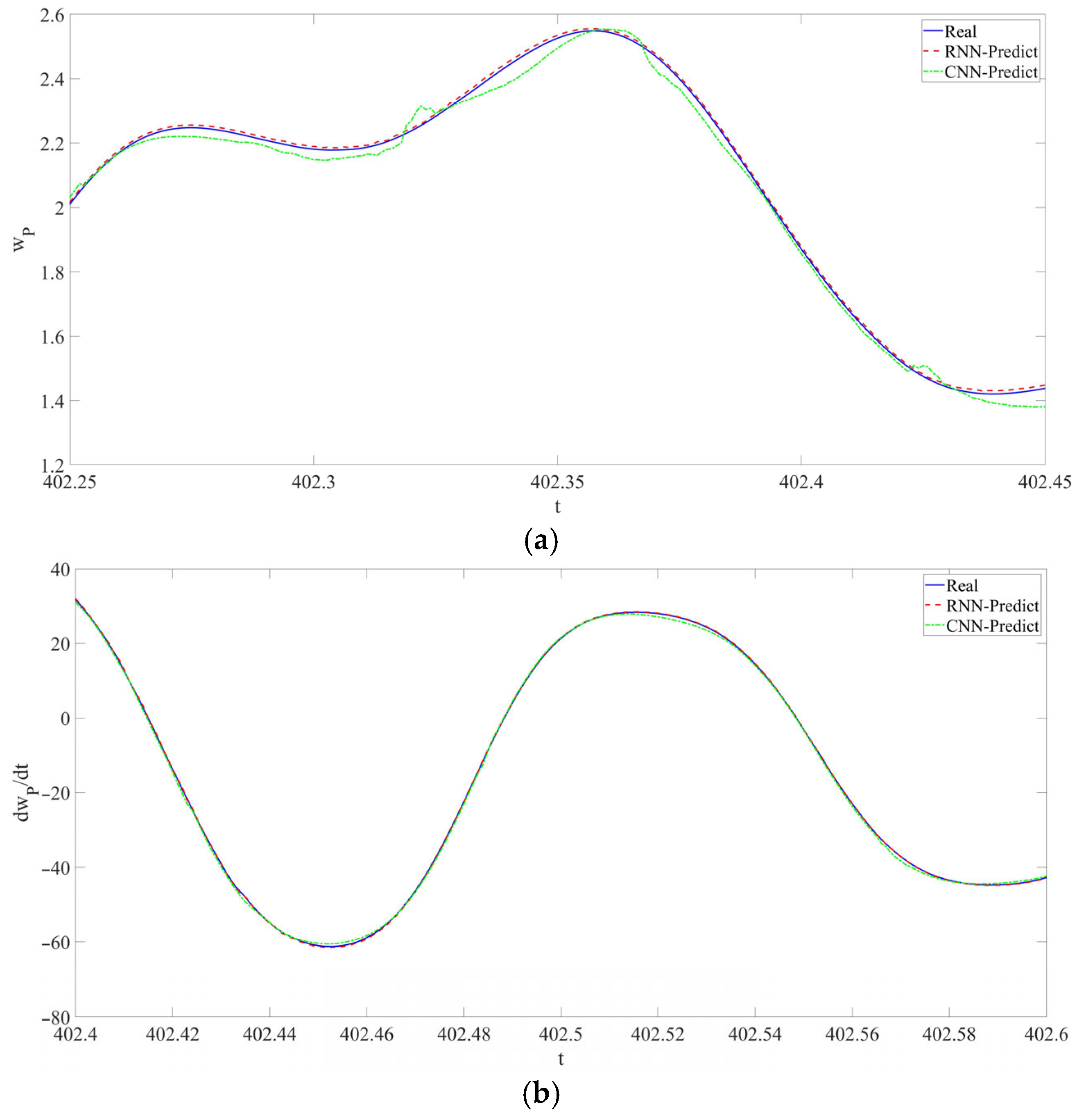

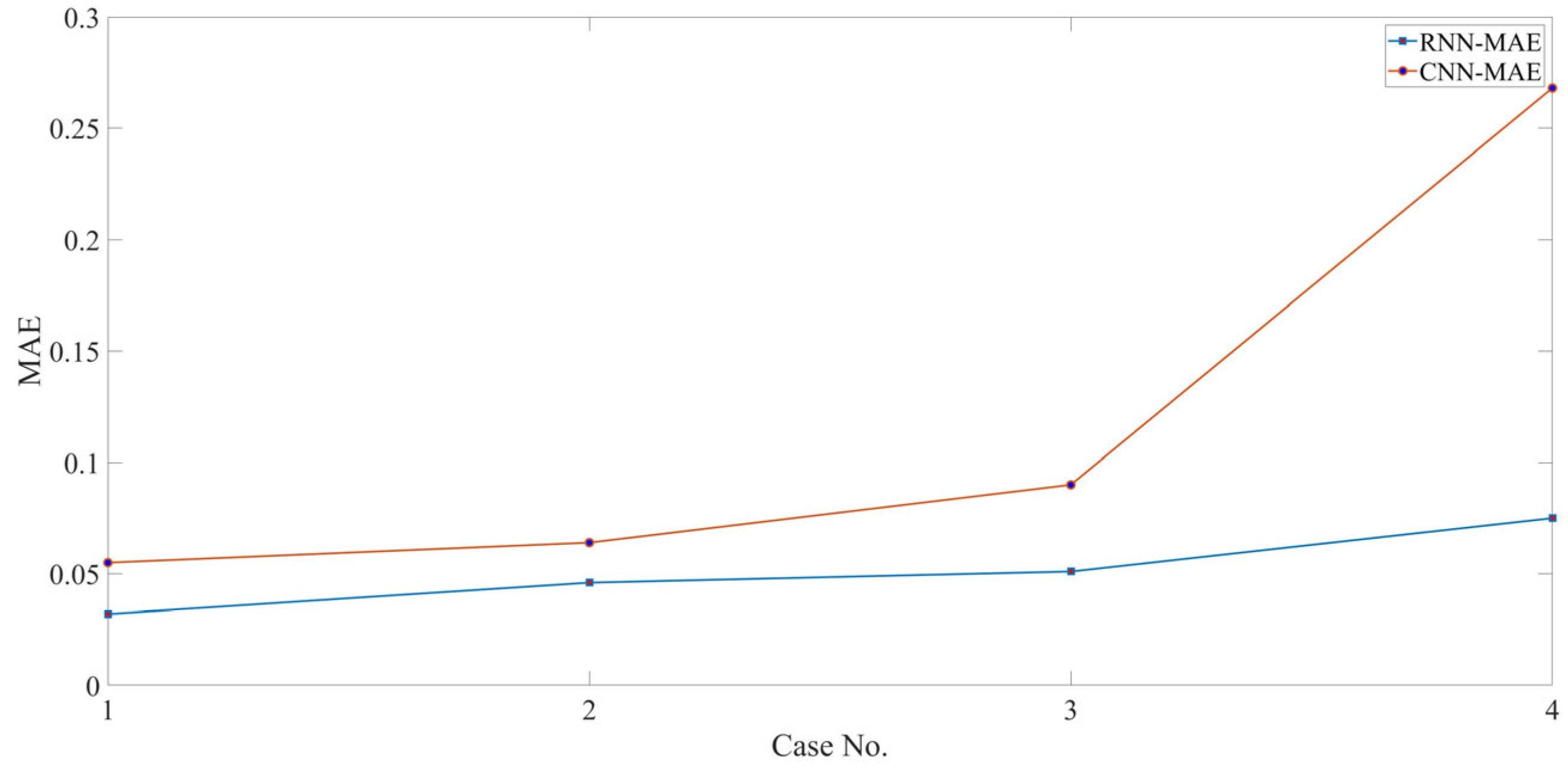

- In this research, for the first time, RPEs are introduced into the modeling of the LCCB to demonstrate the accuracy and robustness of RNN in predicting the chaotic vibrations of the LCCB. Across varying levels of RPEs, the predicted results remain highly consistent with the real data. The prediction curves almost completely overlap the real curves. The model’s predictive capability is quantitatively evaluated using metrics such as , , and . Using the CNN model as a baseline, the performance of the RNN data-driven model is evaluated. The results reveal that the CNN model exhibits a certain phase lag in capturing the response details of chaotic vibrations, whereas the RNN model maintains high accuracy in predicting response variations. In addition, the RNN model outperforms the CNN model in terms of both and . The predictive analysis demonstrates that the RNN data-driven model maintains high prediction accuracy and strong stability in predicting the chaotic vibrations of the LCCB subjected to RPEs.

- (c)

- The prediction results at the free end of the LCCB indicate that the RNN model maintains high prediction accuracy under spatial position variations, demonstrating its spatial applicability. Furthermore, when the external excitation amplitude and circular frequency change, the RNN model can still accurately capture the chaotic vibrations of the LCCB, confirming both its robustness and generalization performance. This study provides a data-driven approach for predicting the chaotic vibrations of complex laminated composite structures and shows engineering applications in structural health monitoring, vibration control, and nonlinear dynamic analysis under complex environmental conditions.

7. Future Development

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Zhang, W.; Sun, L.; Yang, X.D.; Jia, P. Nonlinear dynamic behaviors of a deploying-and-retreating wing with varying velocity. J. Sound Vib. 2013, 332, 6785–6797. [Google Scholar] [CrossRef]

- Ding, Z.; Liao, M.; Xiao, N.; Li, X. Numerical analysis of the seismic response of tunnel composite lining structures across an active fault. Adv. Mater. Sci. Eng. 2021, 2021, 1518763. [Google Scholar] [CrossRef]

- Aldaz-Saca, N.H.; Gregori, S.; Gil, J.; Tur, M.; Fuenmayor, F.J. Cantilever modelling in the railway catenary shape-finding problem. Eng. Struct. 2024, 316, 118557. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, X.; Lu, Z.; Meng, X. IWOA-RNN: An improved whale optimization algorithm with recurrent neural networks for traffic flow prediction. Alex. Eng. J. 2025, 117, 563–576. [Google Scholar] [CrossRef]

- Ahuja, M.; Saini, S. Enhancing short-term chaotic wind speed time-series prediction using hybrid approach with multiple data sets. Nonlinear Dyn. 2024, 112, 18031–18053. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, F.; Yao, M. Global bifurcations and chaotic dynamics in nonlinear nonplanar oscillations of a parametrically excited cantilever beam. Nonlinear Dyn. 2005, 40, 251–279. [Google Scholar] [CrossRef]

- Bouadjadja, S.; Tati, A.; Guerira, B. Analytical and experimental investigations on large deflection analysis of composite cantilever beams. Mech. Adv. Mater. Struct. 2020, 29, 118–126. [Google Scholar] [CrossRef]

- Preethi, K.; Raghu, P.; Rajagopal, A.; Reddy, J.N. Nonlocal nonlinear bending and free vibration analysis of a rotating laminated nano cantilever beam. Mech. Adv. Mater. Struct. 2017, 25, 439–450. [Google Scholar] [CrossRef]

- Van Viet, N.; Zaki, W.; Umer, R. Bending theory for laminated composite cantilever beams with multiple embedded shape memory alloy layers. J. Intell. Mater. Syst. Struct. 2019, 30, 1549–1568. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, B.; Cao, D.; Sun, L. Influence of nonlinear terms on dynamical behavior of graphene reinforced laminated composite plates. Appl. Math. Model. 2020, 78, 169–184. [Google Scholar] [CrossRef]

- Jun, L.; Xiaobin, L.; Hongxing, H. Free vibration analysis of third-order shear deformable composite beams using dynamic stiffness method. Arch. Appl. Mech. 2009, 79, 1083–1098. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, M.H.; Guo, X.Y. Nonlinear responses of a symmetric cross-ply composite laminated cantilever rectangular plate under in-plane and moment excitations. Compos. Struct. 2013, 100, 554–565. [Google Scholar] [CrossRef]

- Zhang, W.; Zhao, M.H.; Guo, X.Y. Nonlinear transverse vibrations of angle-ply laminated composite piezoelectric cantilever plate with four-modes subjected to in-plane and out-of-plane excitations. Eng. Struct. 2019, 198, 109501. [Google Scholar] [CrossRef]

- Guo, X.; Jiang, P.; Cao, D. Influence of piezoelectric performance on nonlinear dynamic characteristics of MFC shells. Complexity 2019, 2019, 1970248. [Google Scholar] [CrossRef]

- Amabili, M.; Ferrari, G.; Ghayesh, M.H.; Hameury, C.; Zamal, H.H. Nonlinear vibrations and viscoelasticity of a self-healing composite cantilever beam: Theory and experiments. Compos. Struct. 2022, 294, 115741. [Google Scholar] [CrossRef]

- Liu, H.; Qu, Y.; Xie, F.; Meng, G. Vortex-induced vibration of large deformable underwater composite beams based on a nonlinear higher-order shear deformation zig-zag theory. Ocean. Eng. 2022, 250, 111000. [Google Scholar] [CrossRef]

- Liu, Y. Nonlinear dynamic analysis of an axially moving composite laminated cantilever beam. J. Vib. Eng. Technol. 2023, 11, 3307–3319. [Google Scholar] [CrossRef]

- Liu, X.; Sun, L. Chaotic vibration control of a composite cantilever beam. Sci. Rep. 2023, 13, 17946. [Google Scholar] [CrossRef]

- Kuo, C.L. Design of an adaptive fuzzy sliding-mode controller for chaos synchronization. Int. J. Nonlinear Sci. Numer. Simul. 2007, 8, 631–636. [Google Scholar] [CrossRef]

- Shirazi, M.J.; Shirazi, M.J.; Vatankhah, R.; Boroushaki, M.; Salarieh, H.; Alasty, A. Application of particle swarm optimization in chaos synchronization in noisy environment in presence of unknown parameter uncertainty. Commun. Nonlinear Sci. Numer. Simul. 2012, 17, 742–753. [Google Scholar] [CrossRef]

- Nozaki, R.; Balthazar, J.M.; Tusset, A.M.; de Pontes, B.R., Jr.; Bueno, Á.M. Nonlinear control system applied to atomic force microscope including parametric errors. J. Control. Autom. Electr. Syst. 2013, 24, 223–231. [Google Scholar] [CrossRef]

- Balthazar, J.M.; Tusset, A.M.; Bueno, A.M. TM-AFM nonlinear motion control with robustness analysis to parametric errors in the control signal determination. J. Theor. Appl. Mech. 2014, 52, 93–106. [Google Scholar]

- Peruzzi, N.J.; Chavarette, F.R.; Balthazar, J.M.; Tusset, A.M.; Perticarrari, A.L.P.M.; Brasil, R.M.F.L. The dynamic behavior of a parametrically excited time-periodic MEMS taking into account parametric errors. J. Vib. Control 2015, 22, 4101–4110. [Google Scholar] [CrossRef]

- Vahidi-Moghaddam, A.; Rajaei, A.; Vatankhah, R.; Hairi-Yazdi, M.R. Terminal sliding mode control with non-symmetric input saturation for vibration suppression of electrostatically actuated nanobeams in the presence of Casimir force. Appl. Math. Model. 2018, 60, 416–434. [Google Scholar] [CrossRef]

- Youssef, M.; Ayman, E.B. Sliding mode control of directly excited structural dynamic model of twin-tailed fighter aircraft. J. Frankl. Inst. 2021, 358, 9721–9740. [Google Scholar] [CrossRef]

- Hao, Y.; Gao, M.; Gong, J. Parametric random vibration analysis of an axially moving laminated shape memory alloy beam based on monte carlo simulation. Materials 2022, 15, 562. [Google Scholar] [CrossRef]

- Sun, L.; Li, X.D.; Liu, X. Control of large amplitude limit cycle of a multi-dimensional nonlinear dynamic system of a composite cantilever beam. Sci. Rep. 2024, 14, 10771. [Google Scholar] [CrossRef]

- Qi, C.; Gao, F.; Li, H.-X.; Zhao, X.; Deng, L. A neural network-based distributed parameter model identification approach for microcantilever. Proc. IMechE Part C J. Mech. Eng. Sci. 2016, 230, 3663–3676. [Google Scholar] [CrossRef]

- Teng, Q.; Zhang, L. Data driven nonlinear dynamical systems identification using multi-step CLDNN. AIP Adv. 2019, 9, 085311. [Google Scholar] [CrossRef]

- Cestnik, R.; Abel, M. Inferring the dynamics of oscillatory systems using recurrent neural networks. Chaos 2019, 29, 063128. [Google Scholar] [CrossRef]

- Huang, B.; Zheng, H.; Guo, X.; Yang, Y.; Liu, X. A novel model based on DA-RNN network and skip gated recurrent neural Network for periodic time series forecasting. Sustainability 2022, 14, 326. [Google Scholar] [CrossRef]

- Sangiorgio, M.; Dercole, F.; Guariso, G. Forecasting of noisy chaotic systems with deep neural networks. Chaos Solitons Fractals 2021, 153, 111570. [Google Scholar] [CrossRef]

- Dudukcu, H.V.; Taskiran, M.; Taskiran, Z.G.C.; Yildirim, T. Temporal convolutional networks with RNN approach for chaotic time series prediction. Appl. Soft Comput. 2023, 133, 109945. [Google Scholar] [CrossRef]

- Uribarri, G.; Mindlin, G.B. Dynamical time series embeddings in recurrent neural networks. Chaos Solitons Fractals 2022, 154, 111612. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, L.; Yao, M. Chaotic time series prediction of nonlinear systems based on various neural network models. Chaos Solitons Fractals 2023, 175, 113971. [Google Scholar] [CrossRef]

- Moorthy, V.; Marappan, K. Free vibration analysis and prediction modeling of delaminated tapered FRP composite plates. J. Mech. Eng. Sci. 2022, 237, 2227–2244. [Google Scholar] [CrossRef]

- Wang, L.; Dai, L.; Sun, L. ConvLSTM-based spatiotemporal and temporal processing models for chaotic vibration prediction of a microbeam. Commun. Nonlinear Sci. Numer. Simul. 2025, 140, 108411. [Google Scholar] [CrossRef]

- Reddy, J.N. Mechanics of Laminated Composite Plates and Shells: Theory and Analysis; Taylor & Francis: Oxfordshire, UK, 2003. [Google Scholar]

| Physical Meaning | Main Parameters | |

|---|---|---|

| Linear damping | ||

| Linear stiffness | ||

| Cubic nonlinear stiffness | ||

| External excitation |

| Cases | Dynamic Phenomena | |||

|---|---|---|---|---|

| Case 1 | 4500 | 0% | Chaotic | |

| Case 2 | 4500 | 4% | Chaotic | |

| Case 3 | 4500 | 8% | Chaotic | |

| Case 4 | 4500 | 10% | Chaotic |

| Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| 0.999938334582534 | 0.999984548634328 | 0.999900810476744 | 0.999494832355506 | |

| 0.032 | 0.046 | 0.051 | 0.075 | |

| 0.06 | 0.089 | 0.096 | 0.140 | |

| 0.003 | 0.003 | 0.006 | 0.011 | |

| 0.044 | 0.093 | 0.099 | 0.121 | |

| 0.062 | 0.132 | 0.140 | 0.171 | |

| 0.004 | 0.004 | 0.007 | 0.014 |

| Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| 0.999646 | 0.999965 | 0.999461 | 0.993126 | |

| 0.055 | 0.064 | 0.09 | 0.268 | |

| 0.098 | 0.12 | 0.163 | 0.47 | |

| 0.013 | 0.007 | 0.016 | 0.066 | |

| 0.09 | 0.112 | 0.162 | 0.39 | |

| 0.126 | 0.159 | 0.228 | 0.546 | |

| 0.016 | 0.009 | 0.028 | 0.072 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Li, X.; Liu, X. Chaotic Vibration Prediction of a Laminated Composite Cantilever Beam Subject to Random Parametric Error. J. Compos. Sci. 2025, 9, 442. https://doi.org/10.3390/jcs9080442

Sun L, Li X, Liu X. Chaotic Vibration Prediction of a Laminated Composite Cantilever Beam Subject to Random Parametric Error. Journal of Composites Science. 2025; 9(8):442. https://doi.org/10.3390/jcs9080442

Chicago/Turabian StyleSun, Lin, Xudong Li, and Xiaopei Liu. 2025. "Chaotic Vibration Prediction of a Laminated Composite Cantilever Beam Subject to Random Parametric Error" Journal of Composites Science 9, no. 8: 442. https://doi.org/10.3390/jcs9080442

APA StyleSun, L., Li, X., & Liu, X. (2025). Chaotic Vibration Prediction of a Laminated Composite Cantilever Beam Subject to Random Parametric Error. Journal of Composites Science, 9(8), 442. https://doi.org/10.3390/jcs9080442