Reuse of Activated Carbon Filter Waste as Filler in Vulcanized Rubber Composites

Abstract

1. Introduction

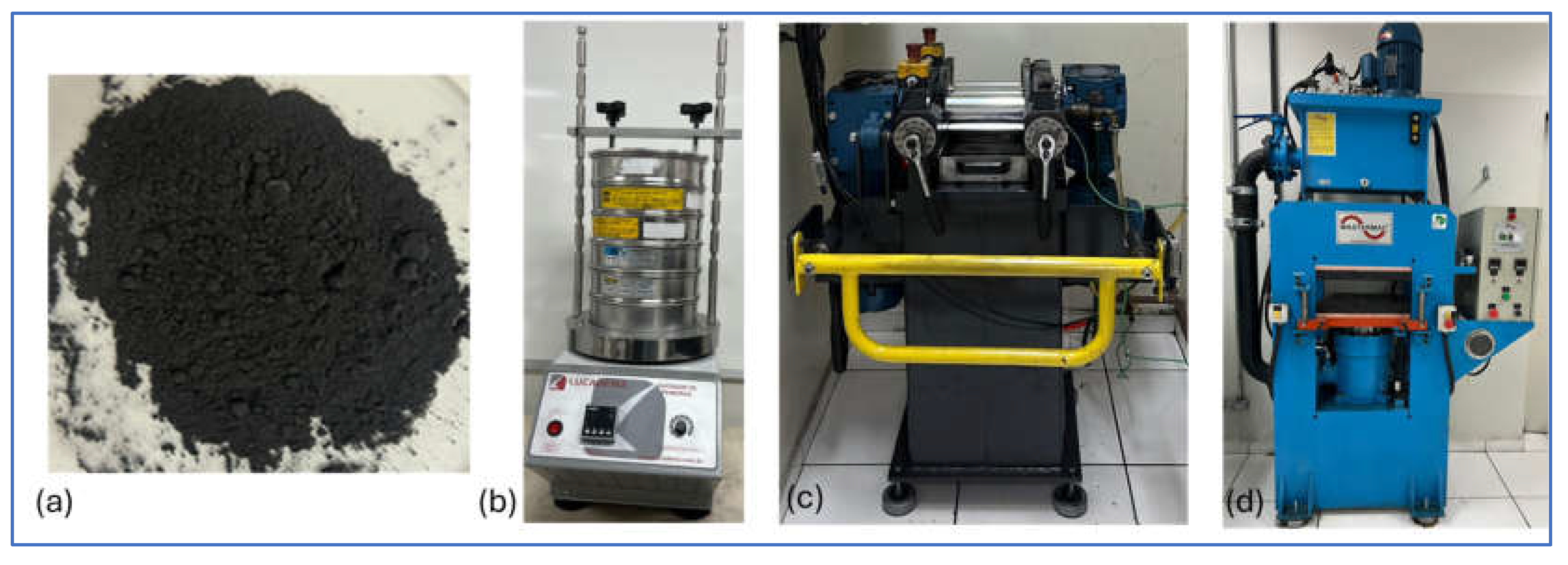

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Engwa, G.A.; Ferdinand, P.U.; Nwalo, F.N.; Unachukwu, M.N. Mechanism and Health Effects of Heavy Metal Toxicity in Humans; IntechOpen: London, UK, 2019. [Google Scholar] [CrossRef]

- Afzal, A.; Mahreen, N. Emerging insights into the impacts of heavy metals exposure on health, reproductive and productive performance of livestock. Front. Pharmacol. 2024, 15, 1375137. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Santhosh, K.; Kamala, K.; Ramasamy, P.; Musthafa, M.S.; Almujri, S.S.; Asdaq, S.M.B.; Sivaperumal, P. Unveiling the silent threat: Heavy metal toxicity devastating impact on aquatic organisms and DNA damage. Mar. Pollut. Bull. 2024, 200, 116139. [Google Scholar] [CrossRef] [PubMed]

- You, R.; Li, H.; Li, X.; Luo, L.; Wang, P.; Xia, H.; Zhou, Y. Ecotoxicological impacts of cadmium on soil microorganisms and earthworms Eisenia foetida: From gene regulation to physiological processes. Front. Environ. Sci. 2024, 12, 1479500. [Google Scholar] [CrossRef]

- Sabio, E.; González, E.; González, J.F.; González-García, C.M.; Ramiro, A.; Gañan, J. Thermal Regeneration of Activated Carbon Saturated with P-Nitrophenol. Carbon 2004, 42, 2285–2293. [Google Scholar] [CrossRef]

- Bunker, B.; Dvorak, B.; Aly Hassan, A. Thermal Regeneration of Activated Carbon Used as an Adsorbent for Hydrogen Sulfide (H2S). Sustainability 2023, 15, 6435. [Google Scholar] [CrossRef]

- Ivancev-Tumbas, I.; Dalmacija, B.; Tamas, Z.; Karlovic, E. Reuse of Biologically Regenerated Activated Carbon for Phenol Removal. Water Res. 1998, 32, 1085–1094. [Google Scholar] [CrossRef]

- El Gamal, M.; Mousa, H.A.; El-Naas, M.H.; Zacharia, R.; Judd, S. Bio-Regeneration of Activated Carbon: A Comprehensive Review. Sep. Purif. Technol. 2018, 197, 345–359. [Google Scholar] [CrossRef]

- Liu, S.; Chen, Z.; Shen, Y.; Chen, H.; Li, Z.; Cai, L.; Yang, H.; Zhu, C.; Shen, J.; Kang, J.; et al. Simultaneous Regeneration of Activated Carbon and Removal of Adsorbed Atrazine by Ozonation Process: From Laboratory Scale to Pilot Studies. Water Res. 2024, 251, 121113. [Google Scholar] [CrossRef]

- Larasati, A.; Fowler, G.D.; Graham, N.J.D. Insights into Chemical Regeneration of Activated Carbon for Water Treatment. J. Environ. Chem. Eng. 2021, 9, 105555. [Google Scholar] [CrossRef]

- Da’na, E.; Awad, A. Regeneration of Spent Activated Carbon Obtained from Home Filtration System and Applying It for Heavy Metals Adsorption. J. Environ. Chem. Eng. 2017, 5, 3091–3099. [Google Scholar] [CrossRef]

- Santos, D.H.S.; Duarte, J.L.S.; Tonholo, J.; Meili, L.; Zanta, C.L.P.S. Saturated Activated Carbon Regeneration by UV-Light, H2O2 and Fenton Reaction. Sep. Purif. Technol. 2020, 250, 117112. [Google Scholar] [CrossRef]

- Yu, H.-Y.; Gupta, S.; Zhou, Z. Removal of Metals and Assimilable Organic Carbon by Activated Carbon and Reverse Osmosis Point-of-Use Water Filtration Systems. Chemosphere 2024, 365, 143251. [Google Scholar] [CrossRef]

- Pedro, N.A.R.; Brígido, B.M.; Badolato, M.I.C.; Antunes, J.L.F.; Oliveira, E. de Avaliação de Filtros Domésticos Comerciais Para Purificação de Águas e Retenção de Contaminantes Inorgânicos. Quim. Nova 1997, 20, 14. [Google Scholar] [CrossRef]

- Sangkarak, S.; Phetrak, A.; Kittipongvises, S.; Kitkaew, D.; Phihusut, D.; Lohwacharin, J. Adsorptive Performance of Activated Carbon Reused from Household Drinking Water Filter for Hexavalent Chromium-Contaminated Water. J. Environ. Manag. 2020, 272, 111085. [Google Scholar] [CrossRef] [PubMed]

- Mishra, S.P.; Ghosh, M.R. Use of Silver Impregnated Activated Carbon (SAC) for Cr(VI) Removal. J. Environ. Chem. Eng. 2020, 8, 103641. [Google Scholar] [CrossRef]

- Szymańska, M.; Nowicki, P. Used Filter Cartridges as Potential Adsorbents of Organic Pollutants. Water 2023, 15, 714. [Google Scholar] [CrossRef]

- Mishra, S.P.; Patra, A.R.; Das, S. Methylene Blue and Malachite Green Removal from Aqueous Solution Using Waste Activated Carbon. Biointerface Res. Appl. Chem. 2020, 11, 7410–7421. [Google Scholar] [CrossRef]

- Marszałek, A.; Puszczało, E. Evaluation of the Use of Regenerated Activated Carbons for the Adsorption of Phenol from a River. J. Water Land Dev. 2024, 93–99. [Google Scholar] [CrossRef]

- Bote, P.P.; Vaze, S.R.; Patil, C.S.; Patil, S.A.; Kolekar, G.B.; Kurkuri, M.D.; Gore, A.H. Reutilization of Carbon from Exhausted Water Filter Cartridges (EWFC) for Decontamination of Water: An Innovative Waste Management Approach. Environ. Technol. Innov. 2021, 24, 102047. [Google Scholar] [CrossRef]

- Bhan, C.; Singh, J.; Sahu, N.; Koduru, J.R. Reutilization of carbon of waste filter cartridge after its surface modification for the fluoride removal from water by continuous flow process. Environ. Sci. Pollut. Res. 2023, 30, 87483–87499. [Google Scholar] [CrossRef]

- Bai, X.; Quan, B.; Kang, C.; Zhang, X.; Zheng, Y.; Song, J.; Xia, T.; Wang, M. Activated Carbon from Tea Residue as Efficient Absorbents for Environmental Pollutant Removal from Wastewater. Biomass Convers. Biorefin. 2023, 13, 13433–13442. [Google Scholar] [CrossRef]

- Lewoyehu, M. Comprehensive Review on Synthesis and Application of Activated Carbon from Agricultural Residues for the Remediation of Venomous Pollutants in Wastewater. J. Anal. Appl. Pyrolysis 2021, 159, 105279. [Google Scholar] [CrossRef]

- Hasanzadeh, V.; Rahmanian, O.; Heidari, M. Cefixime Adsorption onto Activated Carbon Prepared by Dry Thermochemical Activation of Date Fruit Residues. Microchem. J. 2020, 152, 104261. [Google Scholar] [CrossRef]

- Serna-Carrizales, J.C.; Zárate Guzmán, A.I.; Forgionny, A.; Acelas, N.; Pérez, S.; Muñoz-Saldaña, J.; Ocampo-Perez, R. Production of Activated Carbon from Agave Residues and Its Synergistic Application in a Hybrid Adsorption-AOPs System for Effective Removal of Sulfamethazine from Aqueous Solutions. Environ. Res. 2024, 250, 118559. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, X.; Li, X.; Li, W.; Mao, S.; He, S.; Wu, X.; Tang, C.; Yu, J.; Pan, L.; et al. High Efficiency Removal of Ibuprofen in Water Using Activated Carbon Derived from Radix Angelica Dahurica Residue. Environ. Prog. Sustain. Energy 2024, 43, e14318. [Google Scholar] [CrossRef]

- Preglo, A.J.R.; Namata, J.; Caculba, J.; Sanchez, G.; Joyno, C.; Pagalan, E.; Arazo, R.O. Paracetamol Removal from Aqueous Solution Through Activated Carbon from Mango Seeds. Chem. Afr. 2023, 6, 699–710. [Google Scholar] [CrossRef]

- Isinkaralar, K. Multi-Component Volatile Organic Compounds (VOCs) Treatment Nexus: High-Performance of Activated Carbon Derived from Residual Agroforestry Biomass. Int. J. Environ. Sci. Technol. 2024, 21, 925–938. [Google Scholar] [CrossRef]

- Pereira, L.; Castillo, V.; Calero, M.; González-Egido, S.; Martín-Lara, M.Á.; Solís, R.R. Promoting the Circular Economy: Valorization of a Residue from Industrial Char to Activated Carbon with Potential Environmental Applications as Adsorbents. J. Environ. Manag. 2024, 356, 120753. [Google Scholar] [CrossRef]

- Gouaich, I.; Bestani, B.; Bouberka, Z.; Sreńscek-Nazza, J.; Michalkiewicz, B.; Benzekri-Benallou, M.; Boucherdoud, A.; Benderdouche, N. Characterization of a Low-Cost Eucalyptus Camaldulensis Leaves Based Activated Carbon for Pharmaceutical Residues Removal from Aqueous Solutions. Desalination Water Treat. 2023, 296, 19–31. [Google Scholar]

- Han, Q.; Wang, J.; Goodman, B.A.; Xie, J.; Liu, Z. High Adsorption of Methylene Blue by Activated Carbon Prepared from Phosphoric Acid Treated Eucalyptus Residue. Powder Technol. 2020, 366, 239–248. [Google Scholar] [CrossRef]

- Jawad, A.H.; Bardhan, M.; Islam, M.A.; Islam, M.A.; Syed-Hassan, S.S.A.; Surip, S.N.; Alothman, Z.A.; Khan, M.R. Insights into the Modeling, Characterization and Adsorption Performance of Mesoporous Activated Carbon from Corn Cob Residue via Microwave-Assisted H3PO4 Activation. Surf. Interfaces 2020, 21, 100688. [Google Scholar] [CrossRef]

- Sabitov, A.; Atamanov, M.; Doszhanov, O.; Saurykova, K.; Tazhu, K.; Kerimkulova, A.; Orazbayev, A.; Doszhanov, Y. Surface Characteristics of Activated Carbon Sorbents Obtained from Biomass for Cleaning Oil-Contaminated Soils. Molecules 2024, 29, 3786. [Google Scholar] [CrossRef] [PubMed]

- Rustamaji, H.; Prakoso, T.; Devianto, H.; Widiatmoko, P.; Kurnia, K.A. Facile Synthesis of N, S-Modified Activated Carbon from Biomass Residue for Promising Supercapacitor Electrode Applications. Bioresour. Technol. Rep. 2023, 21, 101301. [Google Scholar] [CrossRef]

- Santos, R.J.; Agostini, D.L.S.; Cabrera, F.C.; Budemberg, E.R.; Job, A.E. Recycling Leather Waste: Preparing and Studying on the Microstructure, Mechanical, and Rheological Properties of Leather Waste/Rubber Composite. Polym. Compos. 2015, 36, 2275–2281. [Google Scholar] [CrossRef]

- Gobetti, A.; Cornacchia, G.; Agnelli, S.; Ramini, M.; Ramorino, G. A Novel and Sustainable Rubber Composite Prepared from Electric Arc Furnace Slag as Carbon Black Replacement. Carbon Resour. Convers. 2024, 7, 100230. [Google Scholar] [CrossRef]

- Sittitanadol, I.; Srakeaw, N.L.; Somdee, P.; Chumsamrong, P.; Noyming, S.; Singsang, W.; Prasoetsopha, N. Utilizing Coconut Biochar as a Bioreinforcing Agent in Natural Rubber Composites. Starch Stärke 2025, 77, 168. [Google Scholar] [CrossRef]

- Peterson, S.C.; Chisholm, B.J. Utilizing Pistachio Shell Biochar to Replace Carbon Black in Natural Rubber Composites. J. Compos. Sci. 2024, 8, 482. [Google Scholar] [CrossRef]

- Xuan, Y.Y.; Ridzuan, M.J.M.; Abdul Majid, M.S.; Syayuthi, A.R.A.; Mat, F.; Sapuan, S.M. Wear and Friction Properties of Pineapple Leaf Fibers-reinforced Natural Rubber Composites with the Influence of Multi-walled Carbon Nanotubes. Polym. Compos. 2025, 46, 3208–3227. [Google Scholar] [CrossRef]

- El Mogy, S.A.; El-Wakil, A.A.; Halim, S.F.; Abdel-Hakim, A. Optimization of Nile Rose Role as a Bio-filler for Green Natural Rubber Composites. Polym. Compos. 2024, 45, 17088–17104. [Google Scholar] [CrossRef]

- Xuan, Y.Y.; Ridzuan, M.J.M.; Abdul Majid, M.S.; Rahman, M.T.A.; Yudhanto, F.; Khasri, A.; Ismail, M.S. Influence of Multi-Walled Carbon Nanotubes on Thermal Behaviour and Mechanical Properties of Pineapple Leaf Fibre-Based Natural Rubber Composites. J. Mater. Res. Technol. 2024, 30, 8608–8619. [Google Scholar] [CrossRef]

- Zhang, K.; Zheng, X.; Wang, Q.; Xu, M. Aramid Nanofiber as a Polyfunctional Crosslinker for Epoxidized Natural Rubber with Robust and Recyclable Properties. Polymer 2024, 305, 127195. [Google Scholar] [CrossRef]

- Kamel, N.A.; Shafik, E.S.; Nabil, Y.M.; El Messeih, S.L.A. Production of Eco Composites Based on Natural Rubber and Recycled Sugarcane Bagasse Waste to Be Utilised as a Type of Food Contact. Sci. Rep. 2024, 14, 22996. [Google Scholar] [CrossRef]

- Barrera Torres, G.; Gutierrez Aguilar, C.M.; Lozada, E.R.; Tabares Montoya, M.J.; Ángel Álvarez, B.E.; Sánchez, J.C.; Jaramillo Carvalho, J.A.; Santos, R.J. Application of Post-Industrial Leather Waste for the Development of Sustainable Rubber Composites. Polymers 2025, 17, 190. [Google Scholar] [CrossRef]

- Wetchakama, P.; Sriwongruang, D.; Sae-Oui, P.; Siriwong, C. Characterization and Utilization of Cacao Shell Powder as a Biofiller in Natural Rubber Composite. J. Mater. Res. Technol. 2024, 30, 9130–9139. [Google Scholar] [CrossRef]

- Tilokavichai, V.; Pannarungsee, O.; Luangchuang, P.; Nakaramontri, Y. Effects of Recycled Pol-yethylene on Natural Rubber Composite Blends Filled with Aluminum Trihydroxide and Polyurethane Waste: Mechanical and Dynamic Mechanical Properties, Flammability. Polymers 2024, 16, 1657. [Google Scholar] [CrossRef] [PubMed]

- Öncel, Ş.; Ünügül, T.; Abacı, U.; Karaağaç, B. Coffee Grounds as Sustainable Filler for Bio-based Rubber Composites. Polym. Compos. 2024, 45, 12611–12623. [Google Scholar] [CrossRef]

- Juszkiewicz, A.; Maciejewska, M. Tea Grounds as a Waste Biofiller for Natural Rubber. Materials 2024, 17, 1516. [Google Scholar] [CrossRef]

- Lubura Stošić, J.; Bera, O.; Vukša, T.; Balaban, D.; Vidović, S.; Gavarić, A.; Ostojić, S.B.; Simić, S. Herbal Waste from Filter-Tea Production as Eco-Friendly Ash for Sustainable Natural Rubber Composites. Materials 2025, 18, 204. [Google Scholar] [CrossRef] [PubMed]

- Zhao, M.; Duan, H.; Zhang, S.; Han, L.; ·Peng, K.; Jing, Y.; Lin, G. Effect of low cost mussel inspired poly(catechol/polyamine) modification of waste brick powder followed by grafting of epoxy elastomers on natural rubber composites. Colloid Polym. Sci. 2024, 302, 735–744. [Google Scholar] [CrossRef]

- Naebpetch, W.; Chamnankit, N.; Boonkongkaew, M.; Uthaipan, N.; Indriasari, S.K.; Halim, K.A.A.; Nakaramontri, Y.; Sattayanurak, S. Utilization of waste high calcium oxide fly ash as hybrid activator for vulcanization of natural rubber/carbon black composites: Reducing zinc oxide requirement. Ind. Crops Prod. 2024, 215, 118648. [Google Scholar] [CrossRef]

- Filgueira, M.S.; Pinto, L.F.; Hiranobe, C.T.; Freitas, A.S.M.; Rodrigues, J.S.; Oliveira, A.L.; Ferreira, M.; Kawall, S.A.; Souza, D.S.; Silva, E.A.; et al. Evaluation of the Antioxidant Properties of Black Acacia (Acacia mearnsii) Tannin in Vulcanized Natural Rubber Using Different Vulcanization Systems. Sustainability 2024, 16, 11213. [Google Scholar] [CrossRef]

- Hiranobe, C.T.; Ribeiro, G.D.; Torres, G.B.; Reis, E.A.P.; Cabrera, F.C.; Job, A.E.; Paim, L.L.; Santos, R.J. Cross-Linked Density Determination of Natural Rubber Compounds by Different Analytical Techniques. Mat. Res. 2021, 24 (Suppl. 1), e20210052. [Google Scholar] [CrossRef]

- Lee, B.L. Reinforcement of uncured and cured rubber composites and its relationship to dispersive mixing—an interpretation of cure meter rheographs of carbon black loaded SBR and cispolybutadiene compounds. Rubber Chem. Technol. 1979, 52, 1019–1029. [Google Scholar] [CrossRef]

- Santos, R.J.; Duarte, J.L.S.; Tonholo, J.; Meili, L.; Zanta, C.L.P.S. Evaluation of sugarcane bagasse ash as an alternative filler in natural rubber composites. Polímeros 2014, 24, 37. [Google Scholar] [CrossRef]

- Kim, Y.H.; Park, J.W.; Lee, J.H. Correlation between the crosslink characteristics and mechanical properties of natural rubber compounds with various accelerators and filler contents. Polymers 2020, 12, 2345. [Google Scholar] [CrossRef]

- Sun, C.; Fan, C.; Kan, X.; Ma, Y.; Zhang, X.; Zhao, Y. Enhanced crosslinking performances and carbon black (CB) dispersion in solution styrene butadiene rubber (SSBR) filled with triazine-based graphdiyne (TGDY). Compos. Sci. Technol. 2022, 223, 109438. [Google Scholar] [CrossRef]

| Compounds | Amount (phr) |

|---|---|

| Natural rubber | 100 |

| Zinc oxide | 5 |

| Stearic acid | 2 |

| PEG 4000 1 | 2 |

| Activated carbon filter waste | 5|10|15|20 |

| Sulfur | 1.5 |

| MBTS 2 | 0.7 |

| TMTD 3 | 0.4 |

| Analyte | Result (%) |

|---|---|

| Ca | 0.376 |

| Si | 0.227 |

| S | 0.055 |

| K | 0.031 |

| Fe | 0.020 |

| Ag | 0.017 |

| Zn | 0.012 |

| Cu | 0.012 |

| Br | 0.004 |

| Ti | 0.004 |

| C | 99.242 |

| Composite Samples | MH (dN.m) | ML (dN.m) | ΔM (dN.m) | t90 (min) |

|---|---|---|---|---|

| NRpure | 18.50 | 0.80 | 17.7 | 03.55 |

| NR/AC5phr | 20.20 | 1.10 | 19.1 | 03.55 |

| NR/AC10phr | 22.00 | 1.40 | 20.6 | 03.42 |

| NR/AC15phr | 22.10 | 1.45 | 20.7 | 03.38 |

| NR/AC20phr | 24.00 | 1.50 | 22.5 | 03.35 |

| Composite Samples | Tensile Strength (MPa) at Rupture | Deformation (%) at Rupture |

|---|---|---|

| NRpure | 11.4 ± 1.0 | 382 ± 14 |

| NR/AC5phr | 13.1 ± 0.6 | 385 ± 10 |

| NR/AC10phr | 13.9 ± 1.0 | 331 ± 27 |

| NR/AC15phr | 11.0 ± 1.0 | 306 ± 19 |

| NR/AC20phr | 10.7 ± 0.5 | 234 ± 63 |

| NR/AC10phr (HCl) | 14.1 ± 0.4 | 394 ± 37 |

| NR/CB5phr | 14.4 ± 2.7 | 331 ± 14 |

| NR/CB10phr | 14.9 ± 1.3 | 267 ± 25 |

| NR/CB15phr | 16.2 ± 1.5 | 303 ± 22 |

| NR/CB20phr | 18.4 ±1.6 | 269 ± 34 |

| Composite Samples | Filler Amount (phr) | Volumetric Abrasion Loss (mm3/40 m) | Hardness (Shore A) |

|---|---|---|---|

| NRpure | 0 | 145 ± 1 | 36 ± 1 |

| NR/AC5phr | 5 | 157 ± 8 | 42 ± 1 |

| NR/AC10phr | 10 | 154 ± 20 | 44 ± 1 |

| NR/AC15phr | 15 | 164 ± 14 | 46 ± 1 |

| NR/AC20phr | 20 | 176 ± 16 | 47 ± 1 |

| Composites | Cross-link Density (mol/cm3) | Standard Deviation |

|---|---|---|

| NRpure | 1.43 × 10−4 | ±0.025 × 10−4 |

| NR/AC5 phr | 1.47 × 10−4 | ±0.021 × 10−4 |

| NR/AC10 phr | 1.53 × 10−4 | ±0.036 × 10−4 |

| NR/AC15 phr | 1.44 × 10−4 | ±0.012 × 10−4 |

| NR/AC20 phr | 1.92 × 10−4 | ±0.078 × 10−4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Souza, V.C.; Cardim, H.P.; Hiranobe, C.T.; Cardim, G.P.; Zapelini, I.W.; Paim, L.L.; Santos, G.T.A.; Teixeira, S.R.; da Silva, E.A.; dos Santos, R.J.; et al. Reuse of Activated Carbon Filter Waste as Filler in Vulcanized Rubber Composites. J. Compos. Sci. 2025, 9, 406. https://doi.org/10.3390/jcs9080406

de Souza VC, Cardim HP, Hiranobe CT, Cardim GP, Zapelini IW, Paim LL, Santos GTA, Teixeira SR, da Silva EA, dos Santos RJ, et al. Reuse of Activated Carbon Filter Waste as Filler in Vulcanized Rubber Composites. Journal of Composites Science. 2025; 9(8):406. https://doi.org/10.3390/jcs9080406

Chicago/Turabian Stylede Souza, Viviane Chaves, Henrique Pina Cardim, Carlos Toshiyuki Hiranobe, Guilherme Pina Cardim, Iago William Zapelini, Leonardo Lataro Paim, Gleyson Tadeu Almeida Santos, Silvio Rainho Teixeira, Erivaldo Antônio da Silva, Renivaldo José dos Santos, and et al. 2025. "Reuse of Activated Carbon Filter Waste as Filler in Vulcanized Rubber Composites" Journal of Composites Science 9, no. 8: 406. https://doi.org/10.3390/jcs9080406

APA Stylede Souza, V. C., Cardim, H. P., Hiranobe, C. T., Cardim, G. P., Zapelini, I. W., Paim, L. L., Santos, G. T. A., Teixeira, S. R., da Silva, E. A., dos Santos, R. J., & Cabrera, F. C. (2025). Reuse of Activated Carbon Filter Waste as Filler in Vulcanized Rubber Composites. Journal of Composites Science, 9(8), 406. https://doi.org/10.3390/jcs9080406