Bond Behavior Between Fabric-Reinforced Cementitious Matrix (FRCM) Composites and Different Substrates: An Experimental Investigation

Abstract

1. Introduction

2. Mechanical Properties of Materials

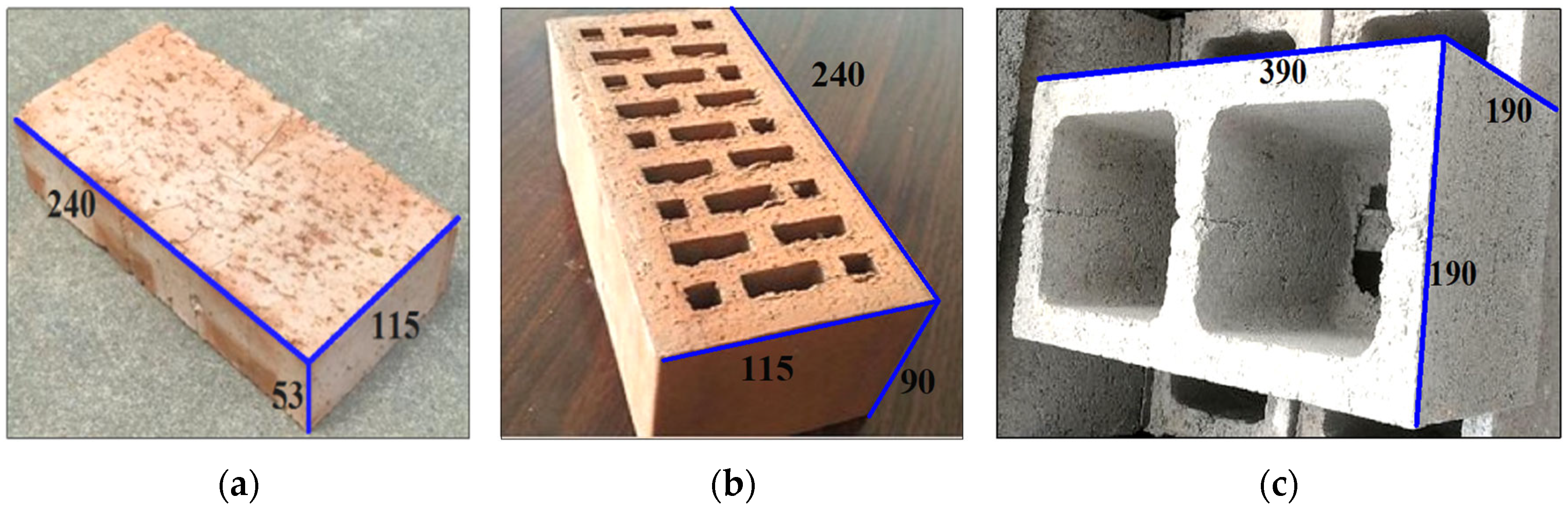

2.1. Mechanical Characteristics of Brick-Based Materials

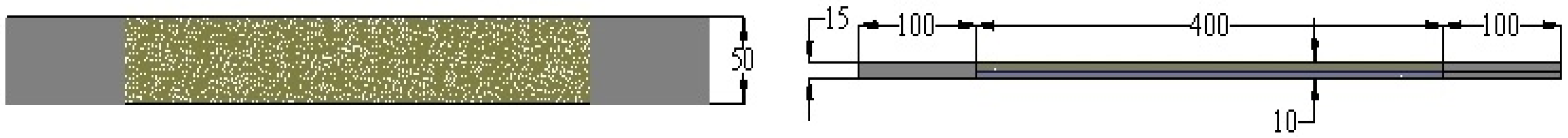

2.2. Mechanical Properties of Fabric–Matrix Composites

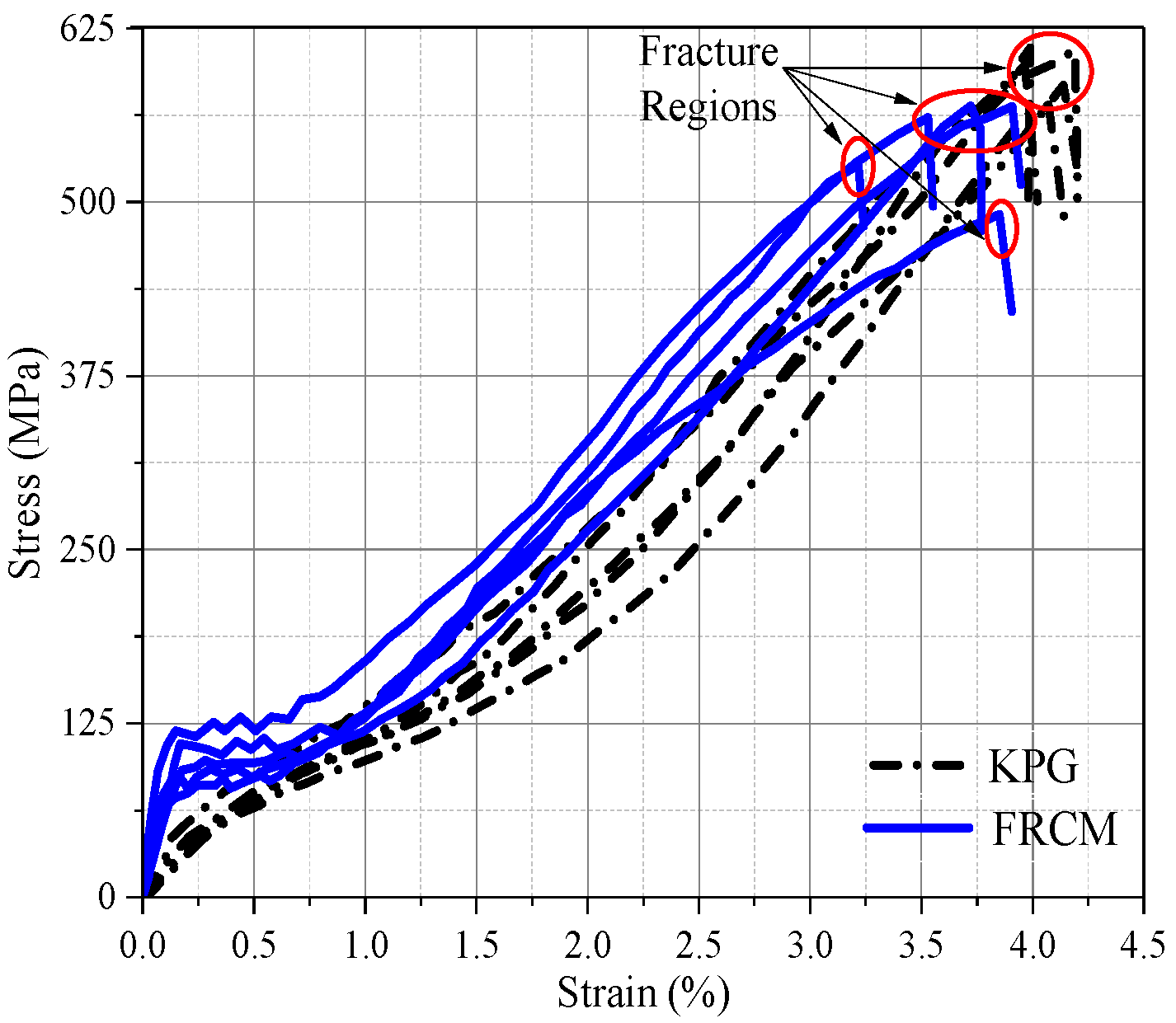

3. Tensile Performance of Fabric and Reinforcement Systems

3.1. Tensile Properties of KPG Fabric

3.2. Tensile Performance of FRCM Strengthening System

3.3. Crack Evolution in FRCM Strengthening System

3.4. Stress–Strain Responses of Fabric and Strengthening System

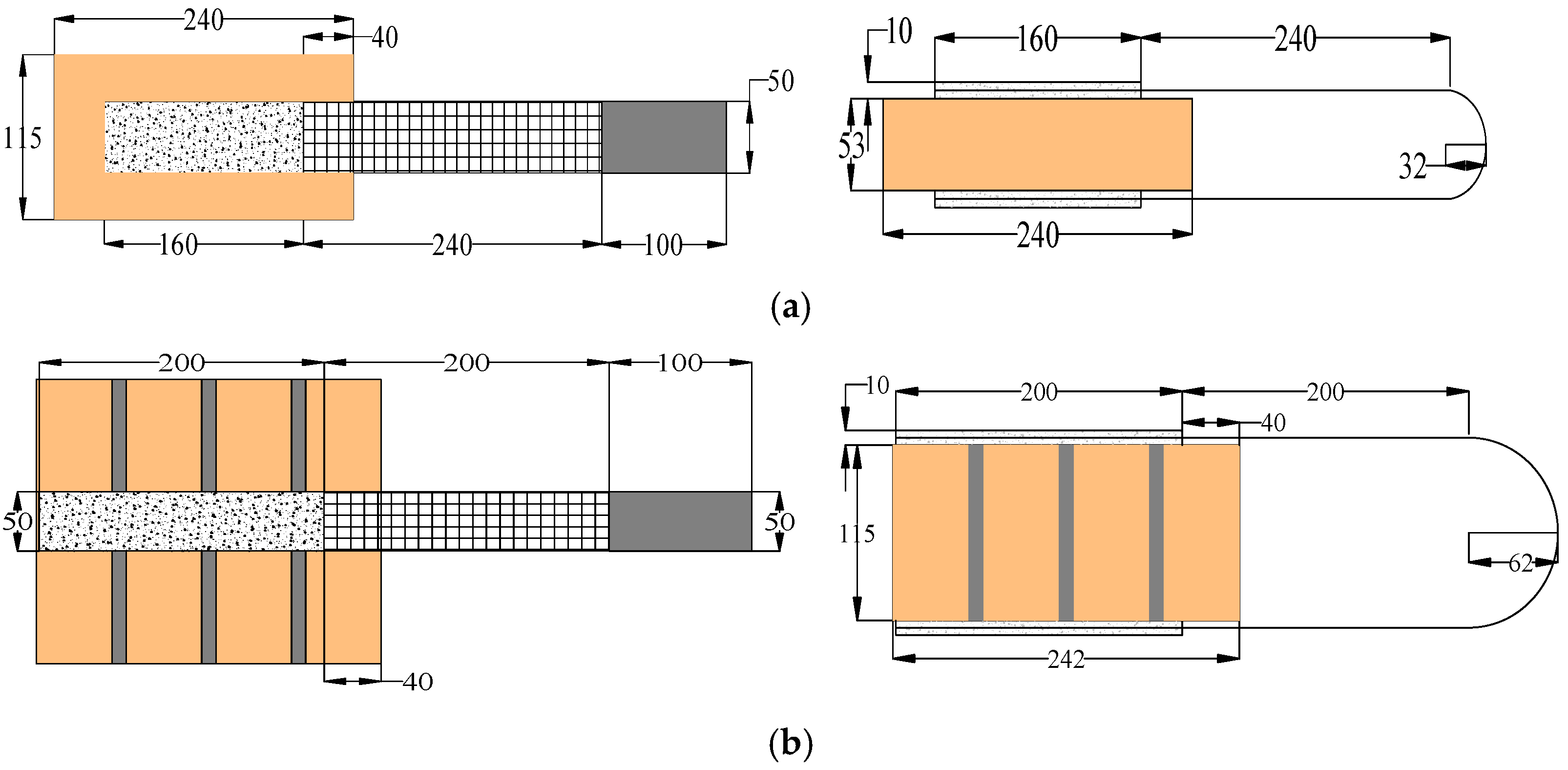

4. Experimental Design Details

4.1. Specimen Design

4.2. Specimen Nomenclature Convention

4.3. Specimen Fabrication

4.4. Test Setup

4.5. Instrumentation and Loading Protocol

5. Analysis and Discussion of Bond Performance Test Results

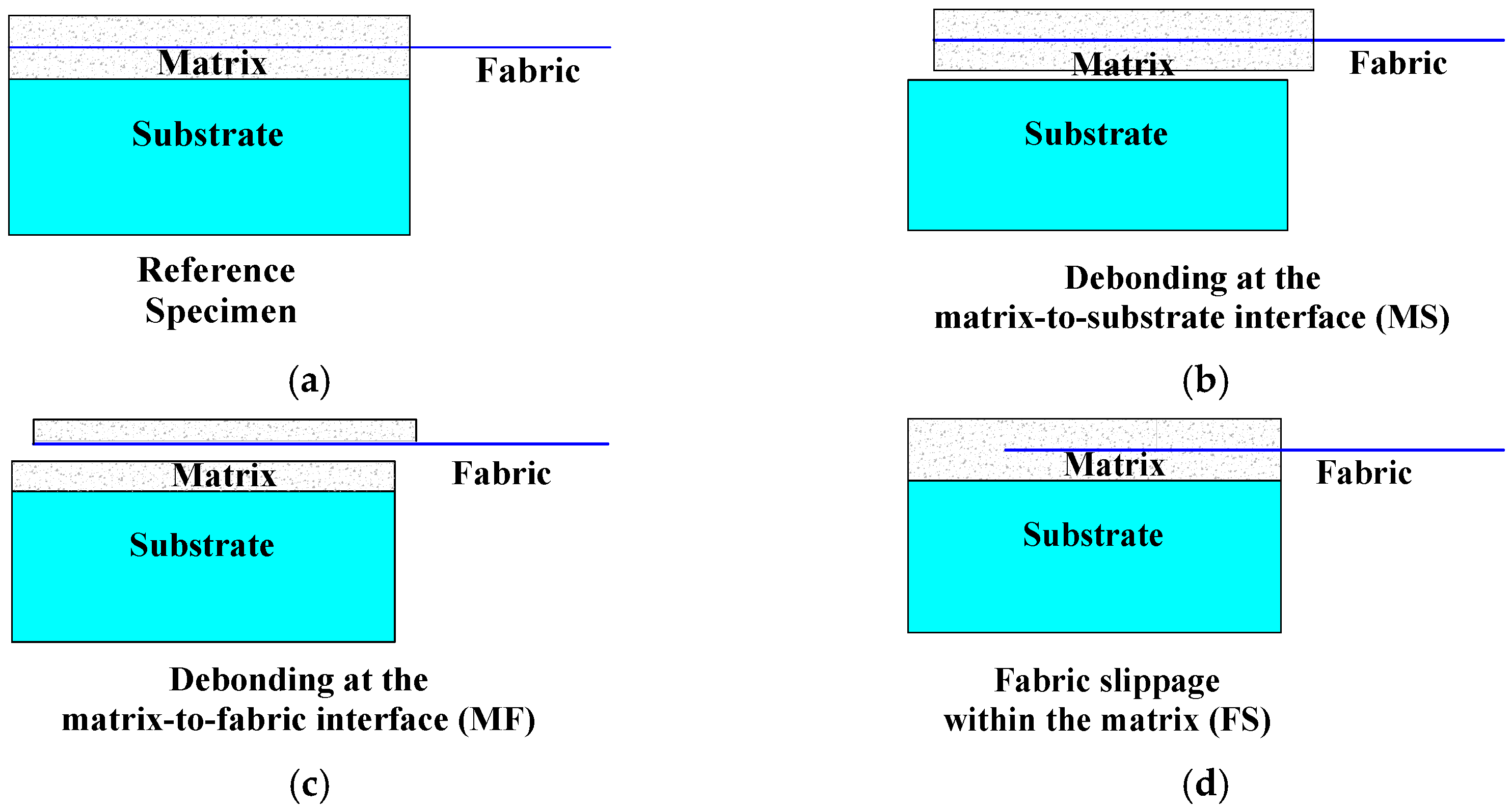

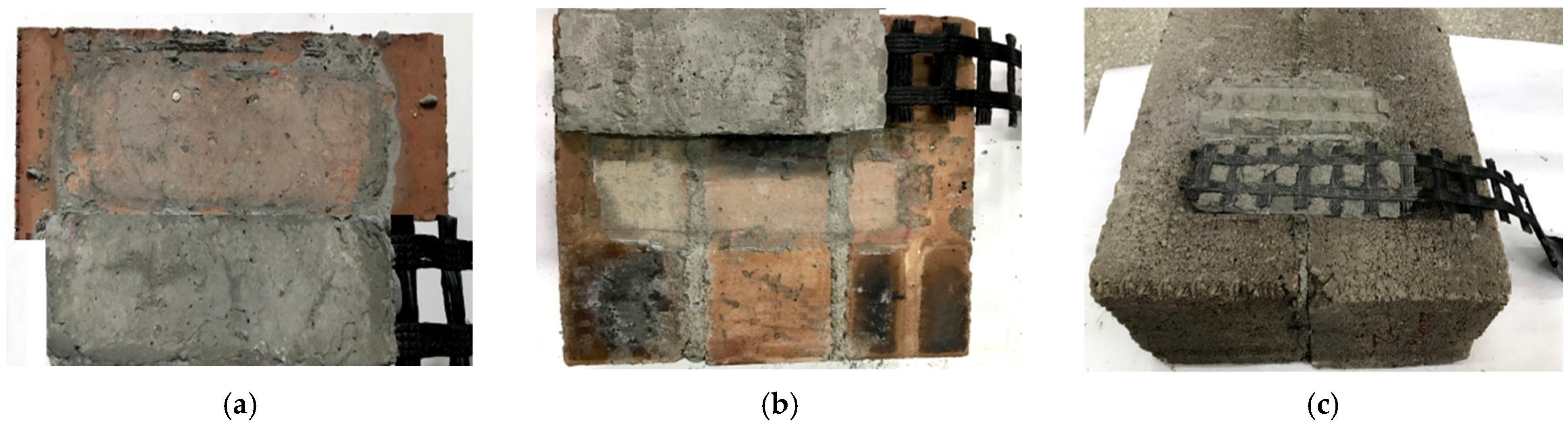

5.1. Characterization of Debonding Failure Modes

5.2. Global Load-Slip Behavior

5.3. Failure Load

5.4. Peak Stress Analysis

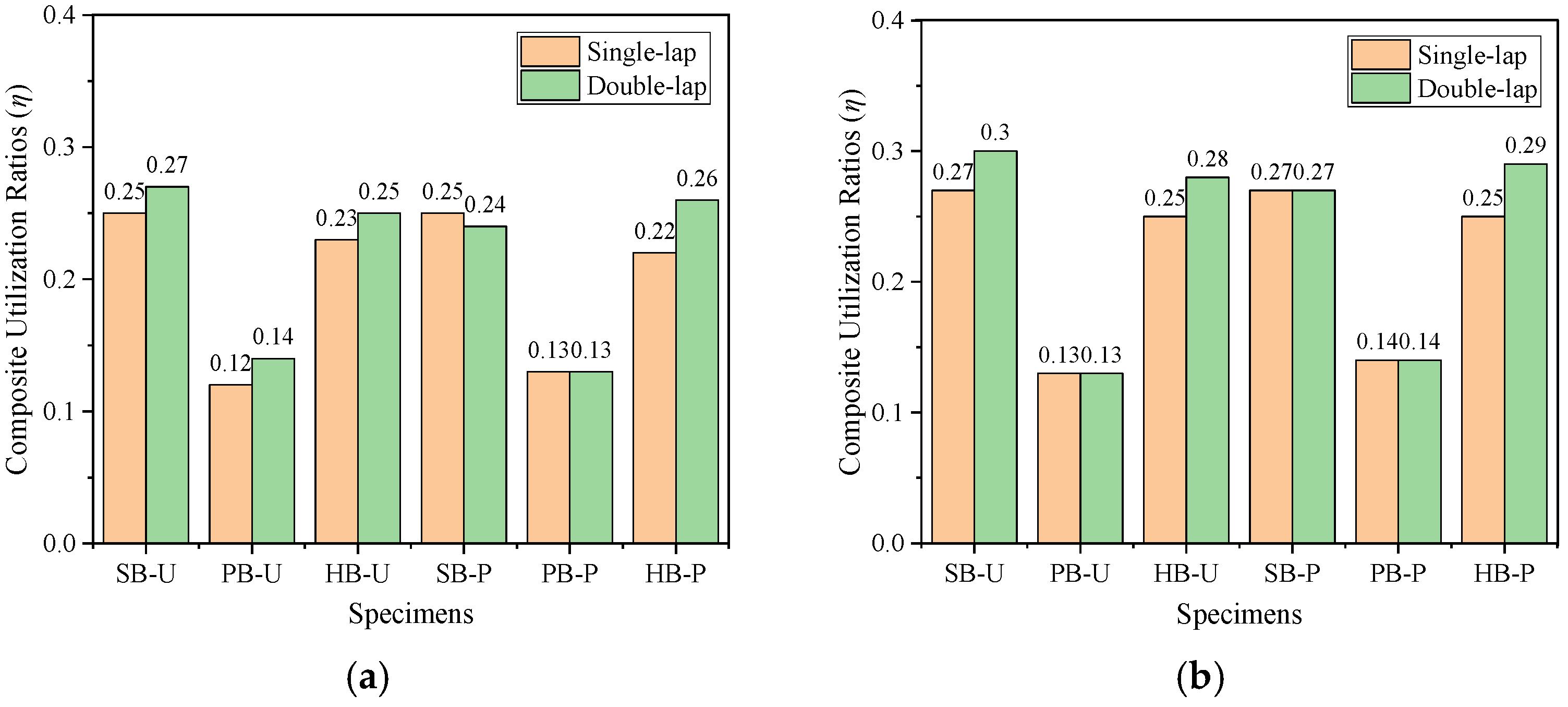

5.5. Composite Utilization Ratio

6. Conclusions

- (1)

- The FRCM strengthening system exhibited three distinct failure phases: uncracked, crack development, and rupture. Throughout all loading stages, the system demonstrated superior strength and stiffness compared to the fabric alone, despite their similar peak stress values.

- (2)

- Test setup (single-lap vs. double-lap) showed negligible influence on debonding failure modes. Specimens predominantly failed through either interfacial debonding or fabric slippage, with the transition between these modes governed by fabric–matrix interlock quality.

- (3)

- The presence of mortar joints significantly affected load-slip response curves, particularly in prism specimens, which exhibited more pronounced curve fluctuations compared to brick units across all loading conditions.

- (4)

- Both loading configurations produced comparable failure loads with low experimental variability, confirming the reliability of the designed test apparatus. Peak stresses showed strong dependence on debonding failure modes.

- (5)

- The FRCM system achieved 12–30% utilization efficiency for both fabric and composite system capacities. This constrained performance resulted from (i) dominant failure mode characteristics; and (ii) potential overdesign of fabric tensile capacity (requiring further verification).

- (6)

- Through comprehensive comparative analysis, concrete hollow blocks can achieve higher bonding performance and reasonable debonding failure modes in the renovation and repair process of actual engineering, and should be recommended as the most suitable substrate material. In addition, FRCM composite materials showed similar peak stress and failure modes in single-lap and double-lap tests. For areas where simultaneous construction of both sides of the wall is not possible, only the exterior wall can be used for construction, which can cooperate with the deformation of the brick substrate without generating additional stiffness.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2010.

- Bagheri, B.; Lee, J.-H.; Kim, H.-G.; Oh, S.-H. Experimental Evaluation of the Seismic Performance of Retrofitted Masonry Walls. Compos. Struct. 2020, 240, 111997. [Google Scholar] [CrossRef]

- Marcari, G.; Manfredi, G.; Prota, A.; Pecce, M. In-Plane Shear Performance of Masonry Panels Strengthened with FRP. Compos. Part B Eng. 2007, 38, 887–901. [Google Scholar] [CrossRef]

- Zhou, D.; Lei, Z.; Wang, J. In-Plane Behavior of Seismically Damaged Masonry Walls Repaired with External BFRP. Compos. Struct. 2013, 102, 9–19. [Google Scholar] [CrossRef]

- Babatunde, S.A. Review of Strengthening Techniques for Masonry Using Fiber Reinforced Polymers. Compos. Struct. 2017, 161, 246–255. [Google Scholar] [CrossRef]

- NR-DT 200/2006; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures. Materials, RC and PC Structures, Masonry Structures. National Research Council, Rome-CNR: Rome, Italy, 2006.

- Tetta, Z.C.; Bournas, D.A. TRM vs FRP Jacketing in Shear Strengthening of Concrete Members Subjected to High Temperatures. Compos. Part B Eng. 2016, 106, 190–205. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. Bond between TRM versus FRP Composites and Concrete at High Temperatures. Compos. Part B Eng. 2017, 127, 150–165. [Google Scholar] [CrossRef]

- Raoof, S.M.; Bournas, D.A. TRM versus FRP in Flexural Strengthening of RC Beams: Behaviour at High Temperatures. Constr. Build. Mater. 2017, 154, 424–437. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Karlos, K.; Papathanasiou, M. Textile-Reinforced Mortar (TRM) versus FRP as Strengthening Material of URM Walls: In-Plane Cyclic Loading. Mater. Struct. 2007, 40, 1081–1097. [Google Scholar] [CrossRef]

- Papanicolaou, C.G.; Triantafillou, T.C.; Papathanasiou, M.; Karlos, K. Textile Reinforced Mortar (TRM) versus FRP as Strengthening Material of URM Walls: Out-of-Plane Cyclic Loading. Mater. Struct. 2007, 41, 143–157. [Google Scholar] [CrossRef]

- De Felice, G.; De Santis, S.; Garmendia, L.; Ghiassi, B.; Larrinaga, P.; Lourenço, P.B.; Oliveira, D.V.; Paolacci, F.; Papanicolaou, C.G. Mortar-Based Systems for Externally Bonded Strengthening of Masonry. Mater. Struct. 2014, 47, 2021–2037. [Google Scholar] [CrossRef]

- Razavizadeh, A.; Ghiassi, B.; Oliveira, D.V. Bond Behavior of SRG-Strengthened Masonry Units: Testing and Numerical Modeling. Constr. Build. Mater. 2014, 64, 387–397. [Google Scholar] [CrossRef]

- Kouris, L.A.S.; Triantafillou, T.C. State-of-the-Art on Strengthening of Masonry Structures with Textile Reinforced Mortar (TRM). Constr. Build. Mater. 2018, 188, 1221–1233. [Google Scholar] [CrossRef]

- Oliveira, D.V.; Basilio, I.; Lourenço, P.B. Experimental Bond Behavior of FRP Sheets Glued on Brick Masonry. J. Compos. Constr. 2011, 15, 32–41. [Google Scholar] [CrossRef]

- Mazzotti, C.; Savoia, M.; Ferracuti, B. A New Single-Shear Set-up for Stable Debonding of FRP–Concrete Joints. Constr. Build. Mater. 2009, 23, 1529–1537. [Google Scholar] [CrossRef]

- Ombres, L.; Mancuso, N.; Mazzuca, S.; Verre, S. Bond between Carbon Fabric-Reinforced Cementitious Matrix and Masonry Substrate. J. Mater. Civ. Eng. 2019, 31, 04018356. [Google Scholar] [CrossRef]

- Bui, T.-L.; Si Larbi, A.; Reboul, N.; Ferrier, E. Shear Behaviour of Masonry Walls Strengthened by External Bonded FRP and TRC. Compos. Struct. 2015, 132, 923–932. [Google Scholar] [CrossRef]

- De Santis, S.; de Felice, G. Tensile Behaviour of Mortar-Based Composites for Externally Bonded Reinforcement Systems. Compos. Part B Eng. 2015, 68, 401–413. [Google Scholar] [CrossRef]

- Shiping, Y.; Boxue, W.; Chenxue, Z.; Shuang, L. Bond Performance between Textile Reinforced Concrete (TRC) and Brick Masonry under Conventional Environment. Structures 2022, 36, 392–403. [Google Scholar] [CrossRef]

- Bilotta, A.; Ceroni, F.; Nigro, E.; Pecce, M. Experimental Tests on FRCM Strengthening Systems for Tuff Masonry Elements. Constr. Build. Mater. 2017, 138, 114–133. [Google Scholar] [CrossRef]

- Augenti, N.; Parisi, F.; Prota, A.; Manfredi, G. In-Plane Lateral Response of a Full-Scale Masonry Subassemblage with and without an Inorganic Matrix-Grid Strengthening System. J. Compos. Constr. 2011, 15, 578–590. [Google Scholar] [CrossRef]

- Balsamo, A.; Iovinella, I.; Di Ludovico, M.; Prota, A. Masonry Reinforcement with IMG Composites: Experimental Investigation. Key Eng. Mater. 2014, 624, 275–282. [Google Scholar] [CrossRef]

- Giamundo, V.; Lignola, G.P.; Maddaloni, G.; Balsamo, A.; Prota, A.; Manfredi, G. Experimental Investigation of the Seismic Performances of IMG Reinforcement on Curved Masonry Elements. Compos. Part B Eng. 2015, 70, 53–63. [Google Scholar] [CrossRef]

- Garmendia, L.; Larrinaga, P.; García, D.; Marcos, I. Textile-Reinforced Mortar as Strengthening Material for Masonry Arches. Int. J. Arch. Herit. 2014, 8, 627–648. [Google Scholar] [CrossRef]

- Ismail, N.; Ingham, J.M. In-Plane and out-of-Plane Testing of Unreinforced Masonry Walls Strengthened Using Polymer Textile Reinforced Mortar. Eng. Struct. 2016, 118, 167–177. [Google Scholar] [CrossRef]

- Giaretton, M.; Dizhur, D.; Garbin, E.; Ingham, J.M.; Da Porto, F. In-Plane Strengthening of Clay Brick and Block Masonry Walls Using Textile-Reinforced Mortar. J. Compos. Constr. 2018, 22, 04018028. [Google Scholar] [CrossRef]

- Donnini, J.; Maracchini, G.; Lenci, S.; Corinaldesi, V.; Quagliarini, E. TRM reinforced tuff and fired clay brick masonry: Experimental and analytical investigation on their in-plane and out-of-plane behavior. Constr. Build. Mater. 2021, 272, 121643. [Google Scholar] [CrossRef]

- De Santis, S.; Hadad, H.A.; De Caso, Y.; Basalo, F.; De Felice, G.; Nanni, A. Acceptance Criteria for Tensile Characterization of Fabric-Reinforced Cementitious Matrix Systems for Concrete and Masonry Repair. J. Compos. Constr. 2018, 22, 04018048. [Google Scholar] [CrossRef]

- Babaeidarabad, S.; Nanni, A. In-Plane Behavior of Unreinforced Masonry Walls Strengthened with Fabric- Reinforced Cementitious Matrix (FRCM). In SP-299: Fiber Reinforced Concrete for Sustainable Structures; American Concrete Institute: Farmington Hills, MI, USA, 2015. [Google Scholar]

- Alecci, V.; Focacci, F.; Rovero, L.; Stipo, G.; De Stefano, M. Extrados Strengthening of Brick Masonry Arches with PBO–FRCM Composites: Experimental and Analytical Investigations. Compos. Struct. 2016, 149, 184–196. [Google Scholar] [CrossRef]

- Alecci, V.; Focacci, F.; Rovero, L.; Stipo, G.; De Stefano, M. Intrados Strengthening of Brick Masonry Arches with Different FRCM Composites: Experimental and Analytical Investigations. Compos. Struct. 2017, 176, 898–909. [Google Scholar] [CrossRef]

- Grande, E.; Imbimbo, M.; Sacco, E. Investigation on the Bond Behavior of Clay Bricks Reinforced with SRP and SRG Strengthening Systems. Mater. Struct. 2015, 48, 3755–3770. [Google Scholar] [CrossRef]

- De Santis, S.; Casadei, P.; De Canio, G.; De Felice, G.; Malena, M.; Mongelli, M.; Roselli, I. Seismic Performance of Masonry Walls Retrofitted with Steel Reinforced Grout. Earthq. Eng. Struct. Dyn. 2016, 45, 229–251. [Google Scholar] [CrossRef]

- De Santis, S.; Ceroni, F.; De Felice, G.; Fagone, M.; Ghiassi, B.; Kwiecień, A.; Lignola, G.P.; Morganti, M.; Santandrea, M.; Valluzzi, M.R.; et al. Round Robin Test on Tensile and Bond Behaviour of Steel Reinforced Grout Systems. Compos. Part B Eng. 2017, 127, 100–120. [Google Scholar] [CrossRef]

- Wang, X.; Lam, C.C.; Iu, V.P.; Kou, K.P. Experimental and Analytical Investigation of Steel Reinforced Grout (SRG) Strengthened Masonry Panels. Key Eng. Mater. 2017, 747, 226–233. [Google Scholar] [CrossRef]

- Ekenel, M.; Basalo, F.D.C.Y.; Nanni, A. Acceptance Criteria for Concrete and Masonry Strengthening Using Fabric-Reinforced Cementitious Matrix (FRCM) and Steel Reinforced Grout (SRG) Composites. In Proceedings of the ACI Convention, 2017. [Google Scholar]

- Wang, X.; Lam, C.C.; Iu, V.P. Bond Behaviour of Steel-TRM Composites for Strengthening Masonry Elements: Experimental Testing and Numerical Modelling. Constr. Build. Mater. 2020, 253, 119157. [Google Scholar] [CrossRef]

- D’Antino, T.; Sneed, L.H.; Carloni, C.; Pellegrino, C. Influence of the Substrate Characteristics on the Bond Behavior of PBO FRCM-Concrete Joints. Constr. Build. Mater. 2015, 101, 838–850. [Google Scholar] [CrossRef]

- Subramaniam, K.V.; Carloni, C.; Nobile, L. Width Effect in the Interface Fracture during Shear Debonding of FRP Sheets from Concrete. Eng. Fract. Mech. 2007, 74, 578–594. [Google Scholar] [CrossRef]

- Dalalbashi, A.; Ghiassi, B.; Oliveira, D.V.; Freitas, A. Fiber-to-Mortar Bond Behavior in TRM Composites: Effect of Embedded Length and Fiber Configuration. Compos. Part B Eng. 2018, 152, 43–57. [Google Scholar] [CrossRef]

- ICC-ES AC 434; Acceptance Criteria for Masonry and Concrete Strengthening Using Fiber-Reinforced Cementitious Matrix (FRCM) Composite Systems. ICC-Evaluation Service: Whittier, CA, USA, 2013.

- ACI 549.4R-13; Guide to Design and Construction of Externally Bonded Fabric-Reinforced Cementitious Matrix (FRCM) Systems for Repair and Strengthening Concrete and Masonry Structures. American Concrete Institute: Farmington Hills, MI, USA, 2013.

- Sneed, L.H.; D’Antino, T.; Carloni, C.; Pellegrino, C. A Comparison of the Bond Behavior of PBO-FRCM Composites Determined by Double-Lap and Single-Lap Shear Tests. Cem. Concr. Compos. 2015, 64, 37–48. [Google Scholar] [CrossRef]

- Alecci, V.; Barducci, S.; Stefano, M.D.; Galassi, S.; Luciano, R.; Rovero, L.; Stipo, G. Reliability of Different Test Setups and Influence of Mortar Mixture on the Fabric-Reinforced Cementitious Matrix-to-Brick Bond Response. J. Test. Eval. 2021, 49, 4476–4495. [Google Scholar] [CrossRef]

- Barducci, S.; Alecci, V.; De Stefano, M.; Misseri, G.; Rovero, L.; Stipo, G. Experimental and Analytical Investigations on Bond Behavior of Basalt-FRCM Systems. J. Compos. Constr. 2020, 24, 04019055. [Google Scholar] [CrossRef]

- D’Antino, T.; Carloni, C.; Sneed, L.H.; Pellegrino, C. Matrix–Fiber Bond Behavior in PBO FRCM Composites: A Fracture Mechanics Approach. Eng. Fract. Mech. 2014, 117, 94–111. [Google Scholar] [CrossRef]

- GB/T 2542–2012; Test Methods for Wall Bricks. Standardization Administration of China: Beijing, China, 2012.

- GB/T 4111-2013; Test Methods for the Concrete Block and Brick. China Architecture & Building Press: Beijing, China, 2013.

- Ma, P.; Xin, R.; Yao, J. Assessment of Failure Mode and Seismic Performance of Damaged Masonry Structures Retrofitted with Grout-Injected Ferrocement Overlay Reinforcement (GFOR). Constr. Build. Mater. 2021, 305, 124778. [Google Scholar] [CrossRef]

- Zhou, F.; Chen, X.; Du, Y. Study on In-Plane Shear Behavior of CTRM Plate. J. Hunan Univ. Nat. Sci. 2021, 48, 39–46. Available online: https://www.cnki.com.cn/Article/CJFDTotal-HNDX202105005.htm (accessed on 1 July 2025).

- JGJ/T 223–2010; Technical Specification for Application of Ready-Mixed Mortar. Standardization Administration of China: Beijing, China, 2011.

- Valluzzi, M.R.; Oliveira, D.V.; Caratelli, A.; Castori, G.; Corradi, M.; de Felice, G.; Garbin, E.; Garcia, D.; Garmendia, L.; Grande, E.; et al. Round Robin Test for Composite-to-Brick Shear Bond Characterization. Mater. Struct. 2012, 45, 1761–1791. [Google Scholar] [CrossRef]

- GB/T 3362-2017; Test Methods for Tensile Properties of Carbon Fiber Multifilament. Standardization Administration of China: Beijing, China, 2017.

- RILEM. Technical Committee 232-TDT (Wolfgang Brameshuber) Recommendation of RILEM TC 232-TDT: Test Methods and Design of Textile Reinforced Concrete. Mater. Struct. 2016, 49, 4923–4927. [Google Scholar] [CrossRef]

- CEN EN 1015-2; Methods of Test for Mortar for Masonry—Part 2: Bulk Sampling of Mortars and Preparation of Test Mortars. European Committee for Standarization: Brussels, Belgium, 1998.

- CEN EN 196-1; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standarization: Brussels, Belgium, 2005.

- Leone, M.; Aiello, M.A.; Balsamo, A.; Carozzi, F.G.; Ceroni, F.; Corradi, M.; Gams, M.; Garbin, E.; Gattesco, N.; Krajewski, P.; et al. Glass Fabric Reinforced Cementitious Matrix: Tensile Properties and Bond Performance on Masonry Substrate. Compos. Part B Eng. 2017, 127, 196–214. [Google Scholar] [CrossRef]

- Carozzi, F.G.; Bellini, A.; D’Antino, T.; de Felice, G.; Focacci, F.; Hojdys, Ł.; Laghi, L.; Lanoye, E.; Micelli, F.; Panizza, M.; et al. Experimental Investigation of Tensile and Bond Properties of Carbon-FRCM Composites for Strengthening Masonry Elements. Compos. Part B Eng. 2017, 128, 100–119. [Google Scholar] [CrossRef]

- Olivito, R.S.; Codispoti, R.; Cevallos, O.A. Bond Behavior of Flax-FRCM and PBO-FRCM Composites Applied on Clay Bricks: Experimental and Theoretical Study. Compos. Struct. 2016, 146, 221–231. [Google Scholar] [CrossRef]

- Grande, E.; Imbimbo, M.; Sacco, E. Bond Behaviour of CFRP Laminates Glued on Clay Bricks: Experimental and Numerical Study. Compos. Part B Eng. 2011, 42, 330–340. [Google Scholar] [CrossRef]

- Bellini, A.; Aiello, M.A.; Bencardino, F.; de Carvalho Bello, C.B.; Castori, G.; Cecchi, A.; Ceroni, F.; Corradi, M.; D’Antino, T.; De Santis, S.; et al. Influence of Different Set-up Parameters on the Bond Behavior of FRCM Composites. Constr. Build. Mater. 2021, 308, 124964. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; De Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Prota, A.; et al. Performance Assessment of Basalt FRCM for Retrofit Applications on Masonry. Compos. Part B Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Ma, P.; Xin, R.; Yao, J. An Investigation of Bond Behavior between Composite Materials (CFRP, GWMM, KPGC) and Substrates (Brick and Concrete) for Strengthening Existing Masonry Structures. Constr. Build. Mater. 2023, 409, 134019. [Google Scholar] [CrossRef]

- Ascione, L.; de Felice, G.; De Santis, S. A Qualification Method for Externally Bonded Fibre Reinforced Cementitious Matrix (FRCM) Strengthening Systems. Compos. Part B Eng. 2015, 78, 497–506. [Google Scholar] [CrossRef]

| Category | Dimensions (mm) | Compressive Strength | Testing Standard | |

|---|---|---|---|---|

| Length × Width × Height | Mean (MPa) | (CoV) | ||

| SB | 240 × 115 × 53 | 14.38 | 0.18 | GB/T 2542-2012 [48] |

| PB | 240 × 115 × 90 | 12.87 | 0.13 | GB/T 2542-2012 [48] |

| HB | 390 × 190 × 190 | 3.13 | 0.15 | GB/T 4111-2013 [49] |

| Matrix | Cement | Fine Sand | Water | Fly Ash | Silica Fume | Superplasticizer |

|---|---|---|---|---|---|---|

| Cementitious matrix | 1 | 1.5 | 0.35 | 0.12 | 0.06 | 0.01 |

| Matrix | Compressive Strength | Elastic Modulus | Testing Standard | ||

|---|---|---|---|---|---|

| Mean (MPa) | (CoV) | Mean (MPa) | (CoV) | ||

| Cementitious matrix | 25.73 | 0.11 | 3855 | 0.13 | JGJ/T 223-2010 [52] |

| Fabric | σ (MPa) | ε (%) | E (GPa) | n |

|---|---|---|---|---|

| KPG | 596.54 (0.11) | 4.07 (0.07) | 18.13 (0.12) | 8 |

| Strengthening System | Pre-Cracking Phase | Post-Cracking Phase | Fabric-Dominated Phase | ||||||

|---|---|---|---|---|---|---|---|---|---|

| σI (Mpa) | εI (%) | EI (Gpa) | σII (Mpa) | εII (%) | EII (Gpa) | σIII (Mpa) | εIII (%) | EIII (Gpa) | |

| FRCM | 88.24 | 0.13 | 67.34 | 148.74 | 1.13 | 6.22 | 543.33 | 3.65 | 15.66 |

| (0.16) | (0.11) | (0.29) | (0.17) | (0.21) | (0.10) | (0.07) | (0.08) | (0.13) | |

| Specimens | Failure Load | Failure Displacement | Peak Stress | Composite Utilization Ratio | Debonding Failure Modes | |

|---|---|---|---|---|---|---|

| (N) | (mm) | (MPa) | VS Fabric | VS System | ||

| SB-U-S | 5700.14 | 4.06 | 146.80 | 0.25 | 0.27 | FS |

| PB-U-S | 3170.06 | 1.93 | 69.64 | 0.12 | 0.13 | MS |

| HB-U-S | 4998.62 | 3.74 | 135.16 | 0.23 | 0.25 | FS |

| SB-P-S | 4861.60 | 4.05 | 146.26 | 0.25 | 0.27 | MF + FS |

| PB-P-S | 3741.09 | 2.04 | 73.69 | 0.13 | 0.14 | MS |

| HB-P-S | 5038.55 | 3.71 | 133.91 | 0.22 | 0.25 | MF + FS |

| SB-U-D | 5817.63 | 4.32 | 155.95 | 0.27 | 0.30 | FS |

| PB-U-D | 2796.51 | 1.96 | 70.94 | 0.14 | 0.13 | MS |

| HB-U-D | 5873.61 | 4.12 | 148.85 | 0.25 | 0.28 | FS |

| SB-P-D | 4934.71 | 3.99 | 144.11 | 0.24 | 0.27 | MF + FS |

| PB-P-D | 3060.18 | 2.06 | 74.33 | 0.13 | 0.14 | MS |

| HB-P-D | 4999.76 | 4.14 | 149.48 | 0.26 | 0.29 | MF + FS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, P.; Yuan, S.; Jia, S. Bond Behavior Between Fabric-Reinforced Cementitious Matrix (FRCM) Composites and Different Substrates: An Experimental Investigation. J. Compos. Sci. 2025, 9, 407. https://doi.org/10.3390/jcs9080407

Ma P, Yuan S, Jia S. Bond Behavior Between Fabric-Reinforced Cementitious Matrix (FRCM) Composites and Different Substrates: An Experimental Investigation. Journal of Composites Science. 2025; 9(8):407. https://doi.org/10.3390/jcs9080407

Chicago/Turabian StyleMa, Pengfei, Shangke Yuan, and Shuming Jia. 2025. "Bond Behavior Between Fabric-Reinforced Cementitious Matrix (FRCM) Composites and Different Substrates: An Experimental Investigation" Journal of Composites Science 9, no. 8: 407. https://doi.org/10.3390/jcs9080407

APA StyleMa, P., Yuan, S., & Jia, S. (2025). Bond Behavior Between Fabric-Reinforced Cementitious Matrix (FRCM) Composites and Different Substrates: An Experimental Investigation. Journal of Composites Science, 9(8), 407. https://doi.org/10.3390/jcs9080407