Multi-Objective Optimisation of Hybrid Banana/Sisal/Red Mud Composites Using Taguchi–Grey Relational Analysis

Abstract

1. Introduction

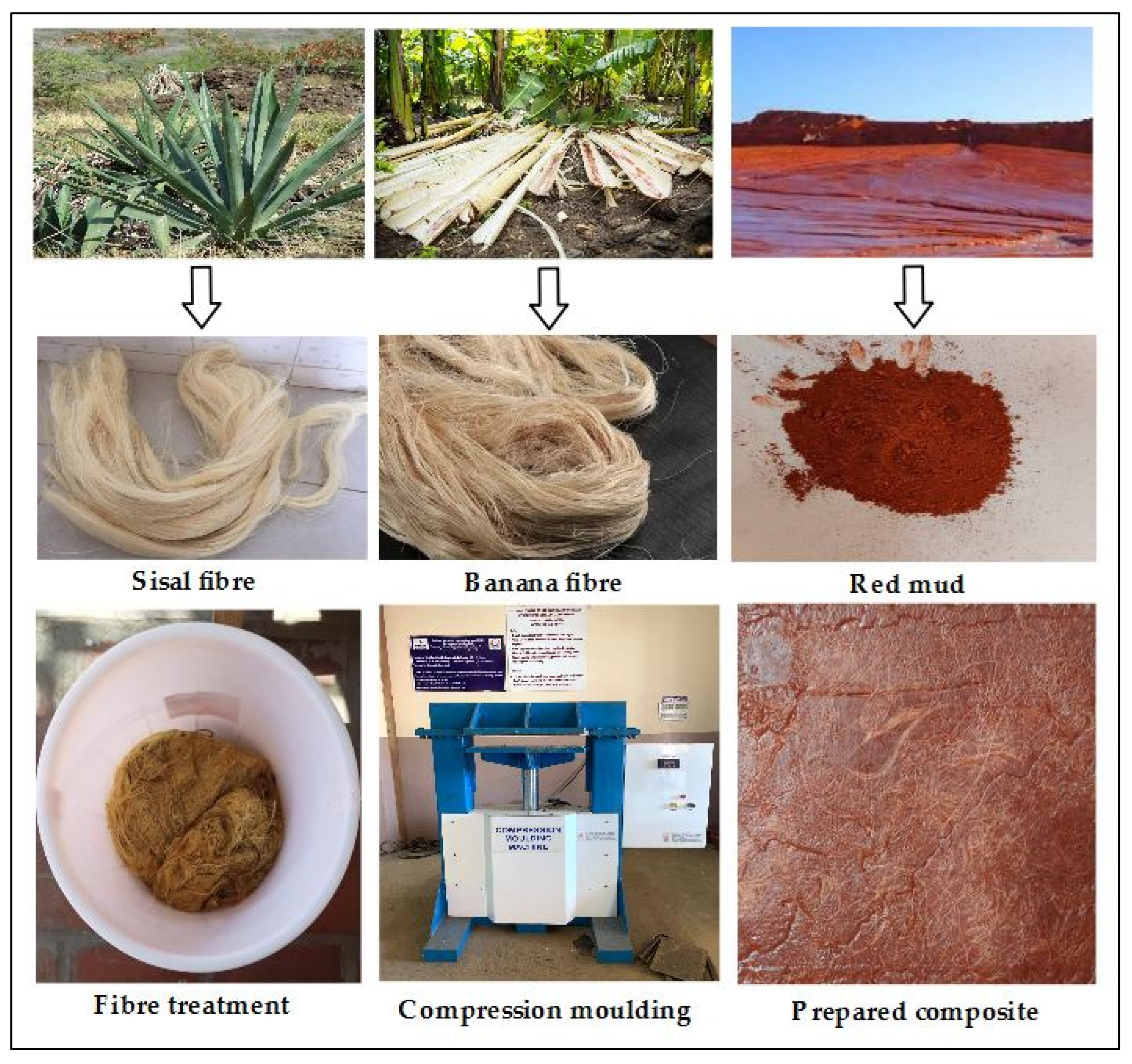

2. Materials and Methods

2.1. Materials

2.2. Fibre Treatment

2.3. Composite Fabrication

2.4. Testing

2.5. Optimising Results with GRA

2.6. Ratio of Signal to Noise

2.7. Normalised S/N Ratio

2.8. Grey Relational Coefficients and Its Grades

3. Results and Discussion

3.1. Impact Strength

3.2. Flexural Strength

3.3. Tensile Strength

3.4. Shear Strength

3.5. Hardness

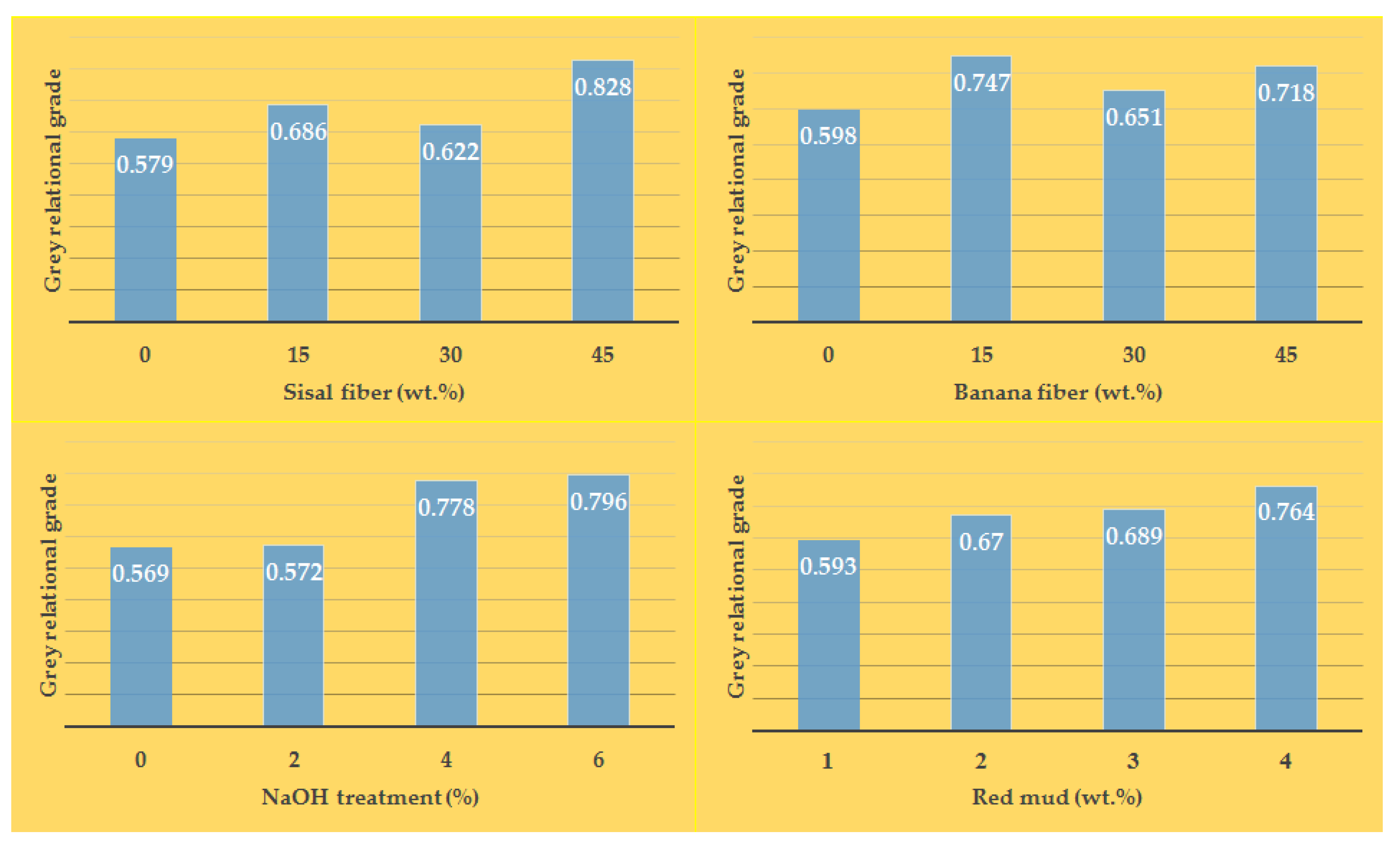

3.6. Response Table for SN Ratio for Mechanical Properties

3.7. ANOVA for Mechanical Properties

3.8. Response of Sisal Fibre- and Banana Fibre-Reinforced Hybrid Composites

3.9. Microstructural Analysis of Sisal-Banana Fibre Hybrid Composites

3.10. Sustainability and Cleaner Production Perspective

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rasu, K.; Veerabathiran, A. Characterization of Bauxite Residue Filled Sisal/Glass Fiber Reinforced Hybrid Composites for Structural Applications. Mater. Test. 2024, 66, 1911–1919. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Uthayakumar, M.; Arumugaprabu, V. Development and Sustainability of Industrial Waste-Based Red Mud Hybrid Composites. J. Clean. Prod. 2019, 230, 862–868. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Wang, J.; Msigwa, G.; Osman, A.I.; Fawzy, S.; Rooney, D.W.; Yap, P.-S. Circular Economy Strategies for Combating Climate Change and Other Environmental Issues. Environ. Chem. Lett. 2023, 21, 55–80. [Google Scholar] [CrossRef]

- Niu, A.; Lin, C. Trends in Research on Characterization, Treatment and Valorization of Hazardous Red Mud: A Systematic Review. J. Environ. Manage. 2024, 351, 119660. [Google Scholar] [CrossRef] [PubMed]

- Mandala, R.; Prasad, B.A.; Akella, S. Enhancing the Mechanical Properties of 3D-Printed Polylactic Acid through Pellet Additive Manufacturing: A Grey Relational Analysis Based on Entropy Weights. Int. J. Lightweight Mater. Manuf. 2025, 8, 331–340. [Google Scholar] [CrossRef]

- Tamilvendan, D.; Ravikumar, A.R.; Thirumalai, R. Parametric Optimization in Drilling of Sisal–Glass Reinforced Epoxy Composites Using Taguchi Grey Relational Analysis Method. Trans. Can. Soc. Mech. Eng. 2024, 48, 469–476. [Google Scholar] [CrossRef]

- Poyyathappan, K.; Kumar, A.G.; Venkatesan, K.; Rajaram, S. Optimization of Drilling Parameters for Alkali–Silane-Treated Areca Fiber–Epoxy Composites Using the Taguchi–Grey Relational Method. Polym. Bull. 2025. [Google Scholar] [CrossRef]

- Thangaraj, S.; kumar, A.R.; Vigneshwaran, M.; Muthuraj, M.; Shenbagaraj, R.; Girimurugan, R. Distinctive Study on Banana/Sisal Fiber Hybrid Composites Filled with Nano Marble Dust Particles. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Anbalagan, K.; Sarala, R.; Subramanian, S.; Yokesh, N.; Saravanan, N. Some Studies on Banana and Sisal Fibers-Based Hybrid Composites. Mater. Today Proc. 2023, 90, 140–144. [Google Scholar] [CrossRef]

- Kumari, N.; Paswan, M.; Prasad, K. Effect of Sawdust Addition on the Mechanical and Water Absorption Properties of Banana-Sisal/Epoxy Natural Fiber Composites. Mater. Today Proc. 2022, 49, 1719–1722. [Google Scholar] [CrossRef]

- Karthikeyan, R.; Pradeep, V.P. Investigation of Mechanical Behaviour on Natural Hybrid Fiber (Sisal/Banana) Reinforced with Epoxy Resin. Mater. Today Proc. 2022, 62, 2310–2314. [Google Scholar] [CrossRef]

- Devi, R.C.; Girimurugan, R.; Nanthakumar, S.; Rajasekaran, P.; Ahammad, S.K.H.; Gnanaraj, S.J.P. Experimental Study of Mechanical Properties of Sisal/Banana Fiber Hybrid Sandwich Composite. Mater. Today Proc. 2022, 68, 1793–1799. [Google Scholar] [CrossRef]

- Siva, R.; Kesavaram, B.; Martin, J.J.; Mathiselvan, G.; Navas, K.B.; Sangeetha, M. Mechanical Behavior of Sisal and Banana Fiber Reinforced Hybrid Epoxy Composites. Mater. Today Proc. 2021, 44, 3692–3696. [Google Scholar] [CrossRef]

- Gupta, U.S.; Dharkar, A.; Dhamarikar, M.; Kumrawat, A.; Giri, N.; Chauhan, A.R.S.; Giri, A.; Tiwari, S.; Namdeo, R. Investigation on Effects of Fiber Loading of Mechanical Properties of Banana/Sisal Hybrid Composite. Mater. Today Proc. 2021, 45, 7829–7837. [Google Scholar] [CrossRef]

- Rasu, K.; Veerabathiran, A. Performance of High Strength Natural Fiber Reinforced Hybrid Composites for Structural Engineering Applications. Mater. Test. 2025, 67, 553–560. [Google Scholar] [CrossRef]

- Karthick, R.; Anbumalar, V.; Vigneshkumar, M.; Samuel Gemsprim, M.; Venkatesh, R.; Dheenathayalan, P.; Selwin, M. Influence of Glass Fiber Hybridization on Flexural and Water Absorption Behaviour of Banana Fiber Reinforced Epoxy Composites. Mater. Today Proc. 2023. [CrossRef]

- Veerabathiran, A.; Palanichamy, R.; Rasu, K. Effect of Chitosan on Mechanical and Thermal Properties of Novel Aloe Vera Fiber Reinforced Composites. Mater. Test. 2024, 66, 867–875. [Google Scholar] [CrossRef]

- Rasu, K.; Veerabathiran, A. Influence of Betel Nut Fiber Hybridization on Properties of Novel Aloevera Fiber-Reinforced Vinyl Ester Composites. Mater. Test. 2024, 66, 1475–1482. [Google Scholar] [CrossRef]

- Karthick, R.; Adithya, K.; Hariharaprasath, C.; Abhishek, V. Evaluation of Mechanical Behavior of Banana Fibre Reinforced Hybrid Epoxy Composites. Mater. Today Proc. 2018, 5, 12814–12820. [Google Scholar] [CrossRef]

- Maurya, H.O.; Kumar, G.; Prasad, L.; Bisaria, H. Thermo-Mechanical and Viscoelastic Behavior of Microwave-Processed Sisal and Banana Hybrid Composite Laminates. J. Mater. Sci. 2024, 59, 20283–20303. [Google Scholar] [CrossRef]

- Rasu, K.; Veerabathiran, A. Effect of Red Mud on Mechanical and Thermal Properties of Agave Sisalana/Glass Fiber–Reinforced Hybrid Composites. Mater. Test. 2023, 65, 1879–1889. [Google Scholar] [CrossRef]

- Siva, R.; Reddy, S.; Aditya, K.; Sangeetha, M.; Karthik, N.; Joy, N. Investigation of Mechanical Properties of Different Arrangement on Sisal/Kenaf/Aloe Vera Hybrid Composites. Mater. Today Proc. 2021, 44, 3557–3563. [Google Scholar] [CrossRef]

- Ganesan, V.; Shanmugam, V.; Alagumalai, V.; Kaliyamoorthy, B.; Das, O.; Misra, M. Optimisation of Mechanical Behaviour of Calotropis Gigantea and Prosopis Juliflora Natural Fibre-Based Hybrid Composites by Using Taguchi-Grey Relational Analysis. Compos. Part C 2024, 13, 100433. [Google Scholar] [CrossRef]

- Bollino, F.; Giannella, V.; Armentani, E.; Sepe, R. Mechanical Behavior of Chemically-Treated Hemp Fibers Reinforced Composites Subjected to Moisture Absorption. J. Mater. Res. Technol. 2023, 22, 762–775. [Google Scholar] [CrossRef]

- Arumuga prabu, V.; Uthayakumar, M.; Manikandan, V.; Rajini, N.; Jeyaraj, P. Influence of Redmud on the Mechanical, Damping and Chemical Resistance Properties of Banana/Polyester Hybrid Composites. Mater. Des. 2014, 64, 270–279. [Google Scholar] [CrossRef]

- Radoor, S.; Karayil, J.; Rangappa, S.M.; Siengchin, S.; Parameswaranpillai, J. A Review on the Extraction of Pineapple, Sisal and Abaca Fibers and Their Use as Reinforcement in Polymer Matrix. Express Polym. Lett. 2020, 14, 309–335. [Google Scholar] [CrossRef]

- Balasubramaniam, S.; Ramalingam, R.; Rasu, K. Friction and Wear Behavior of Alkali-Treated Corn Husk Fiber Reinforced Polyester Composites. Mater. Test. 2025, 67, 543–552. [Google Scholar] [CrossRef]

- Rasu, K.; Veerabathiran, A. Tribological Behaviour of Industrial Waste Based Agave Sisalana/Glass Fiber Reinforced Hybrid Composites for Marine Applications. Mater. Test. 2023, 65, 593–602. [Google Scholar] [CrossRef]

| Process Parameters | Symbols | Levels | |||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | ||

| Sisal fibre (wt.%) | A | 0 | 15 | 30 | 45 |

| Banana fibre (wt.%) | B | 0 | 15 | 30 | 45 |

| NaOH concentration (%) | C | 0 | 2 | 4 | 6 |

| Red mud (wt.%) | D | 1 | 2 | 3 | 4 |

| Exp. No. | Sisal Fibre (wt.%) | Banana Fibre (wt.%) | NaOH Treatment (%) | Red Mud (wt.%) | Impact Strength (J) | Flexural Strength (MPa) | Tensile Strength (MPa) | Shear Strength (Mpa) | Hardness |

|---|---|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 0 | 1 | 1.98 | 47.58 | 26.81 | 16.1 | 57.14 |

| 2 | 0 | 15 | 2 | 2 | 3.86 | 64.25 | 45.68 | 27.39 | 77.51 |

| 3 | 0 | 30 | 4 | 3 | 4.19 | 69.38 | 50.28 | 30.12 | 83.62 |

| 4 | 0 | 45 | 6 | 4 | 5.01 | 71.58 | 56.81 | 34.01 | 59.19 |

| 5 | 15 | 0 | 2 | 3 | 2.98 | 51.25 | 31.53 | 18.86 | 61.05 |

| 6 | 15 | 15 | 0 | 4 | 4.96 | 70.28 | 54.53 | 32.54 | 84.43 |

| 7 | 15 | 30 | 6 | 1 | 6.16 | 60.27 | 61.57 | 36.57 | 72.23 |

| 8 | 15 | 45 | 4 | 2 | 5.58 | 70.89 | 58.92 | 35.21 | 85.71 |

| 9 | 30 | 0 | 4 | 4 | 6.13 | 61.58 | 63.53 | 38.21 | 73.19 |

| 10 | 30 | 15 | 6 | 3 | 6.57 | 63.57 | 65.52 | 39.13 | 76.82 |

| 11 | 30 | 30 | 0 | 2 | 2.08 | 49.87 | 29.98 | 17.28 | 59.48 |

| 12 | 30 | 45 | 2 | 1 | 3.57 | 63.51 | 34.59 | 20.52 | 76.12 |

| 13 | 45 | 0 | 6 | 2 | 5.52 | 72.58 | 60.51 | 36.12 | 87.01 |

| 14 | 45 | 15 | 4 | 1 | 6.08 | 63.51 | 62.95 | 37.66 | 76.12 |

| 15 | 45 | 30 | 2 | 4 | 4.58 | 71.82 | 56.21 | 33.37 | 86.81 |

| 16 | 45 | 45 | 0 | 3 | 4.05 | 72.19 | 58.53 | 35.21 | 86.26 |

| Exp. No. | S/N Ratio | Normalised S/N Ratio | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Impact Strength (J) | Flexural Strength (MPa) | Tensile Strength (MPa) | Shear Strength (Mpa) | Hardness | Impact Strength (J) | Flexural Strength (MPa) | Tensile Strength (MPa) | Shear Strength (Mpa) | Hardness | |

| 1 | 5.933 | 33.548 | 28.566 | 24.137 | 35.139 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| 2 | 11.732 | 36.157 | 33.195 | 28.752 | 37.787 | 0.557 | 0.711 | 0.596 | 0.598 | 0.725 |

| 3 | 12.444 | 36.825 | 34.028 | 29.577 | 38.446 | 0.625 | 0.893 | 0.704 | 0.705 | 0.905 |

| 4 | 13.997 | 37.096 | 35.088 | 30.632 | 35.445 | 0.774 | 0.967 | 0.840 | 0.842 | 0.084 |

| 5 | 9.484 | 34.194 | 29.974 | 25.511 | 35.714 | 0.341 | 0.176 | 0.181 | 0.178 | 0.157 |

| 6 | 13.910 | 36.937 | 34.733 | 30.248 | 38.530 | 0.766 | 0.924 | 0.795 | 0.792 | 0.928 |

| 7 | 15.792 | 35.602 | 35.787 | 31.262 | 37.174 | 0.946 | 0.560 | 0.930 | 0.924 | 0.557 |

| 8 | 14.933 | 37.012 | 35.405 | 30.933 | 38.661 | 0.864 | 0.944 | 0.881 | 0.881 | 0.964 |

| 9 | 15.749 | 35.789 | 36.060 | 31.644 | 37.289 | 0.942 | 0.611 | 0.965 | 0.973 | 0.589 |

| 10 | 16.351 | 36.065 | 36.327 | 31.850 | 37.709 | 1.000 | 0.686 | 1.000 | 1.000 | 0.704 |

| 11 | 6.361 | 33.957 | 29.537 | 24.751 | 35.487 | 0.041 | 0.111 | 0.125 | 0.080 | 0.095 |

| 12 | 11.053 | 36.057 | 30.779 | 26.244 | 37.630 | 0.491 | 0.684 | 0.285 | 0.273 | 0.682 |

| 13 | 14.839 | 37.216 | 35.637 | 31.155 | 38.791 | 0.855 | 1.000 | 0.911 | 0.910 | 1.000 |

| 14 | 15.678 | 36.057 | 35.980 | 31.518 | 37.630 | 0.935 | 0.684 | 0.955 | 0.957 | 0.682 |

| 15 | 13.217 | 37.125 | 34.996 | 30.467 | 38.771 | 0.699 | 0.975 | 0.828 | 0.821 | 0.995 |

| 16 | 12.149 | 37.170 | 35.348 | 30.933 | 38.716 | 0.597 | 0.987 | 0.874 | 0.881 | 0.979 |

| Mechanical Properties | Composition | 1 | 2 | 3 | 4 | Delta | Rank |

|---|---|---|---|---|---|---|---|

| Impact strength (MPa) | Sisal fibre (wt.%) | 11.027 | 13.53 | 12.379 | 13.971 | 2.944 | 2 |

| Banana fibre (wt.%) | 11.501 | 14.418 | 11.954 | 13.033 | 2.916 | 3 | |

| NaOH treatment (%) | 9.588 | 11.372 | 14.701 | 15.245 | 5.656 | 1 | |

| Red mud (wt.%) | 12.114 | 11.966 | 12.607 | 14.218 | 2.252 | 4 | |

| Flexural strength (MPa) | Sisal fibre (wt.%) | 35.91 | 35.94 | 35.47 | 36.89 | 1.43 | 2 |

| Banana fibre (wt.%) | 35.19 | 36.3 | 35.88 | 36.83 | 1.65 | 1 | |

| NaOH treatment (%) | 35.4 | 35.88 | 36.42 | 36.49 | 1.09 | 4 | |

| Red mud (wt.%) | 35.32 | 36.09 | 36.06 | 36.74 | 1.42 | 3 | |

| Tensile strength (MPa) | Sisal fibre (wt.%) | 32.72 | 33.97 | 33.18 | 35.49 | 2.77 | 2 |

| Banana fibre (wt.%) | 32.56 | 35.06 | 33.59 | 34.16 | 2.5 | 3 | |

| NaOH treatment (%) | 32.05 | 32.24 | 35.37 | 35.71 | 3.66 | 1 | |

| Red mud (wt.%) | 32.78 | 33.44 | 33.92 | 35.22 | 2.44 | 4 | |

| Shear strength (MPa) | Sisal fibre (wt.%) | 30.63 | 31.83 | 30.96 | 33.3 | 2.67 | 2 |

| Banana fibre (wt.%) | 30.51 | 32.84 | 31.41 | 31.97 | 2.33 | 3 | |

| NaOH treatment (%) | 30.04 | 30.3 | 33.13 | 33.25 | 3.22 | 1 | |

| Red mud (wt.%) | 30.66 | 31.35 | 31.83 | 32.89 | 2.23 | 4 | |

| Hardness | Sisal fibre (wt.%) | 36.7 | 37.52 | 37.03 | 38.48 | 1.77 | 1 |

| Banana fibre (wt.%) | 36.73 | 37.91 | 37.47 | 37.61 | 1.18 | 2 | |

| NaOH treatment (%) | 36.97 | 37.48 | 38.01 | 37.28 | 1.04 | 3 | |

| Red mud (wt.%) | 36.89 | 37.68 | 37.65 | 37.51 | 0.79 | 4 |

| Mechanical Properties | Composition | DF | Seq SS | Adj SS | Adj MS | F | p |

|---|---|---|---|---|---|---|---|

| Impact strength (MPa) | Sisal fibre (wt.%) | 3 | 20.82 | 20.82 | 6.939 | 1.62 | 0.351 |

| Banana fibre (wt.%) | 3 | 20.21 | 20.21 | 6.736 | 1.57 | 0.360 | |

| NaOH treatment (%) | 3 | 87.69 | 87.69 | 29.231 | 6.82 | 0.075 | |

| Red mud (wt.%) | 3 | 12.77 | 12.77 | 4.257 | 0.99 | 0.502 | |

| Residual error | 3 | 12.85 | 12.85 | 4.284 | - | - | |

| Total | 15 | 154.34 | - | - | - | - | |

| Flexural strength (MPa) | Sisal fibre (wt.%) | 3 | 4.330 | 4.330 | 1.443 | 1.03 | 0.492 |

| Banana fibre (wt.%) | 3 | 5.813 | 5.813 | 1.938 | 1.38 | 0.400 | |

| NaOH treatment (%) | 3 | 3.127 | 3.127 | 1.042 | 0.74 | 0.595 | |

| Red mud (wt.%) | 3 | 4.046 | 4.046 | 1.349 | 0.96 | 0.514 | |

| Residual error | 3 | 4.224 | 4.224 | 1.408 | - | - | |

| Total | 15 | 21.539 | - | - | - | - | |

| Tensile strength (MPa) | Sisal fibre (wt.%) | 3 | 17.75 | 17.75 | 5.918 | 1.47 | 0.379 |

| Banana fibre (wt.%) | 3 | 13.16 | 13.16 | 4.385 | 1.09 | 0.472 | |

| NaOH treatment (%) | 3 | 46.50 | 46.50 | 15.499 | 3.86 | 0.148 | |

| Red mud (wt.%) | 3 | 12.78 | 12.78 | 4.258 | 1.06 | 0.481 | |

| Residual error | 3 | 12.05 | 12.05 | 4.015 | - | - | |

| Total | 15 | 102.23 | - | - | - | - | |

| Shear strength (MPa) | Sisal fibre (wt.%) | 3 | 17.96 | 17.96 | 5.986 | 1.38 | 0.398 |

| Banana fibre (wt.%) | 3 | 13.21 | 13.21 | 4.402 | 1.02 | 0.494 | |

| NaOH treatment (%) | 3 | 47.66 | 47.66 | 15.885 | 3.68 | 0.157 | |

| Red mud (wt.%) | 3 | 13.18 | 13.18 | 4.394 | 1.02 | 0.495 | |

| Residual error | 3 | 12.97 | 12.97 | 4.322 | - | - | |

| Total | 15 | 104.97 | - | - | - | - | |

| Hardness | Sisal fibre (wt.%) | 3 | 7.169 | 7.169 | 2.3896 | 0.64 | 0.640 |

| Banana fibre (wt.%) | 3 | 3.020 | 3.020 | 1.0065 | 0.27 | 0.846 | |

| NaOH treatment (%) | 3 | 2.281 | 2.281 | 0.7603 | 0.20 | 0.889 | |

| Red mud (wt.%) | 3 | 1.618 | 1.618 | 0.5392 | 0.14 | 0.927 | |

| Residual error | 3 | 11.257 | 11.257 | 3.7523 | - | - | |

| Total | 15 | 25.344 | - | - | - | - |

| Exp. No. | Impact Strength (J) | Flexural Strength (MPa) | Tensile Strength (MPa) | Shear Strength (Mpa) | Hardness | Grade | Rank |

|---|---|---|---|---|---|---|---|

| 1 | 0.333 | 0.333 | 0.333 | 0.333 | 0.333 | 0.333 | 16 |

| 2 | 0.530 | 0.634 | 0.553 | 0.555 | 0.645 | 0.583 | 12 |

| 3 | 0.571 | 0.824 | 0.628 | 0.629 | 0.841 | 0.699 | 11 |

| 4 | 0.689 | 0.938 | 0.758 | 0.760 | 0.353 | 0.700 | 10 |

| 5 | 0.431 | 0.378 | 0.379 | 0.378 | 0.372 | 0.388 | 14 |

| 6 | 0.681 | 0.868 | 0.709 | 0.707 | 0.875 | 0.768 | 8 |

| 7 | 0.903 | 0.532 | 0.878 | 0.868 | 0.530 | 0.742 | 9 |

| 8 | 0.786 | 0.900 | 0.808 | 0.808 | 0.933 | 0.847 | 3 |

| 9 | 0.896 | 0.562 | 0.935 | 0.949 | 0.549 | 0.778 | 7 |

| 10 | 1.000 | 0.614 | 1.000 | 1.000 | 0.628 | 0.848 | 2 |

| 11 | 0.343 | 0.360 | 0.364 | 0.352 | 0.356 | 0.355 | 15 |

| 12 | 0.496 | 0.613 | 0.412 | 0.408 | 0.611 | 0.508 | 13 |

| 13 | 0.775 | 1.000 | 0.849 | 0.847 | 1.000 | 0.894 | 1 |

| 14 | 0.886 | 0.613 | 0.918 | 0.921 | 0.611 | 0.790 | 6 |

| 15 | 0.624 | 0.953 | 0.745 | 0.736 | 0.989 | 0.809 | 5 |

| 16 | 0.553 | 0.975 | 0.798 | 0.808 | 0.960 | 0.819 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rasu, K.; Shanmugam, V.; Davim, J.P. Multi-Objective Optimisation of Hybrid Banana/Sisal/Red Mud Composites Using Taguchi–Grey Relational Analysis. J. Compos. Sci. 2025, 9, 357. https://doi.org/10.3390/jcs9070357

Rasu K, Shanmugam V, Davim JP. Multi-Objective Optimisation of Hybrid Banana/Sisal/Red Mud Composites Using Taguchi–Grey Relational Analysis. Journal of Composites Science. 2025; 9(7):357. https://doi.org/10.3390/jcs9070357

Chicago/Turabian StyleRasu, Karthick, Vigneshwaran Shanmugam, and Joao Paulo Davim. 2025. "Multi-Objective Optimisation of Hybrid Banana/Sisal/Red Mud Composites Using Taguchi–Grey Relational Analysis" Journal of Composites Science 9, no. 7: 357. https://doi.org/10.3390/jcs9070357

APA StyleRasu, K., Shanmugam, V., & Davim, J. P. (2025). Multi-Objective Optimisation of Hybrid Banana/Sisal/Red Mud Composites Using Taguchi–Grey Relational Analysis. Journal of Composites Science, 9(7), 357. https://doi.org/10.3390/jcs9070357