Abstract

Introducing and compacting lignocellulosic biomass in aluminum structures, though recommendable in terms of higher sustainability, the potential use of agro-waste and significant weight reduction, still represents a challenge. This is due to the variability of biomass performance and to its limited compatibility with the metal. Another question may concern possible moisture penetration in the structure, which may reduce environmental resistance and result in local degradation, such as wear or even corrosion. Despite these limitations, this hybridization enjoys increasing success. Two forms are possibly available for this: introduction into metal matrix composites (MMCs), normally in the form of char from biomass combustion, or laminate reinforcement as the core for fiber metal laminates (FMLs). These two cases are treated alongside each other in this review, first because they may represent two combined options for recycling the same biomass into high-profile structures, aimed primarily at the aerospace industry. Moreover, as discussed above, the effect on the aluminum alloy can be compared and the forces to which they are subjected might be of a similar type, most particularly in terms of their hardness and impact. Both cases considered, MMCs and FMLs involved over time many lignocellulosic residues, starting from the most classical bast species, i.e., flax, hemp, sisal, kenaf, etc., and extending also to less diffuse ones, especially in view of the introduction of biomass as secondary, or residual, raw materials.

1. Introduction

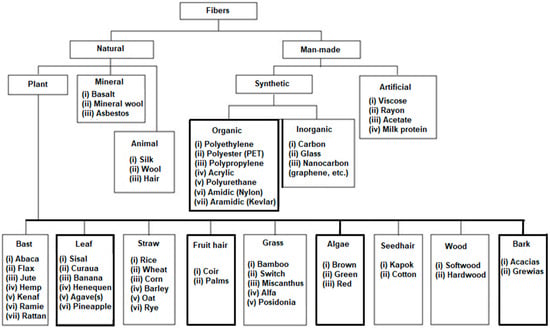

1.1. Biomass Use in Aluminum-Based Materials

In widely diffused structures, such as aircraft and automobiles, the introduction of bio-based materials results in decreased resource depletion for material production together with some energy saving due to their reduced weight [1,2]. More recently, the very large availability of biomass that can potentially be used in these materials makes this task easier to realize. On the other hand, the endless variety of biological species and cultivars, together with their different origins and the inherent variability of their properties, does pose some questions concerning the effect of their introduction in the specific case of aluminum alloys [3]. To offer an initial indication, the fibers that are used in polymer composites, among which are the biomass ones that can be potentially included in FMLs (as received) and in MMCs (in the form of ashes), as will discussed further down, are reported in Figure 1. In the first of the two situations considered in this work, a typical filler for metal matrix composites is a ceramic in the form of fibers, whiskers or particles, and the typical outcome to be expected is an increase in hardness, wear resistance and impact performance [4]. In contrast, in the case of fiber metal laminates, biomass is supposed to replace the polymer composite as the core filler and expectations would mainly concern static compression or, again, the various forms of impact loading [5]. The drive towards introducing more raw materials from biomass into both MMCs and FMLs also suggests that the materials and the issues experimented in both fields for their coupling with the relevant aluminum alloys could be similar. It would also be possible that the biomass from the same species and from the same production system could be used in MMCs in the form of ash [6] and in FMLs in the form of core fibers [7], such as in the case of hemp. It is significant that in the automotive industry, hemp was the first agricultural production system to be involved in this, in terms not only of materials, but even for the production of hemp fuel [8].

Figure 1.

Fibers used in composites.

This would therefore possibly involve an exchange of competencies between the two types of materials, also considering they are mainly used in the same sectors of application. There have been some suggestions that polymer composites, including FMLs as kind of “nobilitated” ones, could substitute MMCs in their possible diffusion in the automotive industry, mainly due to their lower cost [9]. This would be predicted to come despite their lower properties, e.g., in terms of machining, and for the need to prevent delamination. In this sense, the introduction of biomass is suggested to possibly modify the situation in favor of MMCs by making the performance/price ratio more favorable.

1.2. Metal Matrix Composites

Traditionally, metal matrix composites (MMCs) have been thought of as materials formed by a low-density metal (aluminum, magnesium and sometimes titanium) reinforced with some ceramic filler, such as alumina (Al2O3), carbides or nitrides, which enhance, in particular, abrasion resistance and hardness [10]. For their fabrication, various processes have been employed over time, which are nonetheless connected with metallurgical developments [11]. Issues related to MMC fabrication include wettability, low densification, particle agglomeration and undesired chemical interactions between the matrix and reinforcements [12]. In practice, the three principal routes for production are based on casting, powder metallurgy and more recently, additive manufacturing [13]. Although the initial objective in the fabrication of aluminum alloy MMCs (abbreviated also as AMCs) is to obtain an improvement in the hardness of the matrix without affecting (as much as possible) ductility, it is obvious that the selection of the process for MMC manufacturing does significantly modify all the characteristics of the initial material. In many cases, this modification is profound and does largely exceed the amount of filler introduced. As an example, in [14], stir casting a 6082 Al alloy including a total 15% by weight of mixed silicon carbide and graphite produced an increase in Vickers hardness from 49.5 to 85, with open porosities passing from 0.39% to 1.2%, due to impurities, as well as an improvement in tensile strength (from 161 to 187 MPa) substantially aligned to the filler content.

In an attempt to achieve a more sustainable approach, and in a parallel sense to what was experimented on natural fiber composites using a polymer matrix [15], lignocellulosic fibers have also been introduced, which contribute to the wealth of reinforcements experimented upon in the production of MMCs [16]. Conversely, this operation can be thought of as one of the potential hybridization procedures applied on natural fiber composites, which are exhaustively exposed in [17].

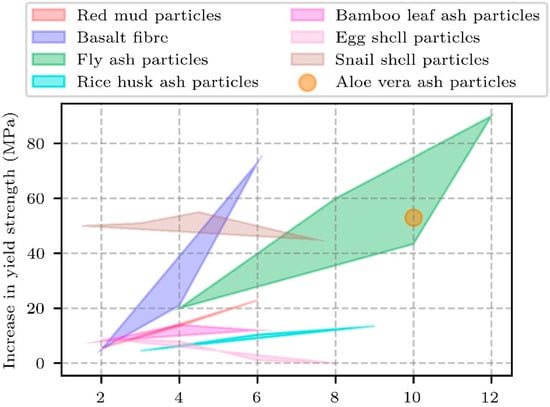

Delving into greater detail, the study by Seetharaman et al. does mention, beyond the introduction of basalt fibers and some industrial waste, such as red mud, or agricultural refuse, such as rice husk ash, eggshells and snail shells, incinerated lignocellulosic material, based on coconut shells, bamboo fibers and sugarcane [18]. Data on the improvement in compressive stiffness with respect to the amount of filler introduced are reported in Figure 2. These data clearly indicate that the effect obtained, provided the distribution of the filler was uniform, may largely exceed the amount introduced. Casting methods proposed for the fabrication of hybrid MMCs include either melt processing, through stir casting, or forcing it in various ways, which include mechanical load, the use of gas or vacuum pressure and ultrasound. In some cases, different methods are also combined, such as in squeeze casting, where mechanical stirring is then supplemented by the application of pressure [19].

Figure 2.

Increase in yield strength vs. filler weight (%) in MMCs [18].

The use of ashes as a filler from the pyrolysis of lignocellulosic biomass might also be beneficial in a more limited sense than on stiffness improvement, e.g., acting on hardness and abrasion resistance [20]. Some applications in this sense were attempted also on MMCs, using, for example, bagasse ash from sugarcane production, in the understanding that the convenience is enhanced and the environmental impact of this operation is reduced in the presence of a large production system, such as one based on glucose extraction [21]. Other examples concerned the use of rice husk as a reinforcement, which represents an abundant waste from this production system (over 20% of rice is directly husked during production) [22]. The compression and hardness properties of rice husk ash are able to compete with silica-based ceramics due to the presence of 91.5% SiO2 in it [23]. A further work concerned the introduction of coconut rice together with eggshells into an aluminum metal matrix, which was tested against acid rain (0.4 molar solution of sulphuric acid) [24] to assess its potential application in wind turbine blades [25]. It is suggested that corrosion patterns have a relation with processing methods applied for the fabrication of the composites. In particular, in liquid methods, such as stir casting, where the incorporation of reinforcement particles in the molten or semi-solid aluminum matrix occurs through a stirring process, some void creation during the wetting of the plant-derived particles by the matrix can occur. Calcination normally minimizes the relevant risk of porosity creation, which can be reduced to virtually zero by specific agents, such as magnesium carbonate [26]. In any case, research on alkali lignocellulosic fiber treatment offers a large number of possible alternatives, each one of these with specific effects other than those obtained with sodium hydroxide [27]. On the other hand, degassing additives, e.g., hexachloroethane (C2Cl6), can also contribute to this effect, being added to the molten metal during stir casting [28]. Despite all the aforementioned issues, the introduction of natural fiber-obtained materials in various forms into MMCs represents a promising alternative to the use of expensive synthetic ceramics for controlling wear and hardness [29].

1.3. Fiber Metal Laminates

Fiber metal laminates (FMLs), of initial interest for the aerospace industry, include aluminum sheets, normally surface-treated, to serve as the skin for a composite. Of course, the alloy series that are more frequently used are those more connected with use in aircraft structures, such as 2024 T3 or 6061 series aircraft [30,31]. In contrast, the composite core is typically made of epoxy resin with carbon fiber reinforcement (CARALL), which is preferred as it shows very limited environmental degradation [32], and is also hybridized with glass [33], aramid fiber (ARALL) [34] or glass fiber (GLARE), often investigated for their impact properties [35]. The relevant complexity of the obtained materials suggested attention towards their machining using different methods with attention over the possible onset of core delamination [36]. Aluminum skins can be flat and continuous, or else present other dispositions, which all deal with a more substantial weight reduction and possibly with a lower number of pieces to compose the whole structure. One solution is, for example, splicing, which allows the junction of larger skins with no excessive technological issues [37]. Another approach involves the use of perforated aluminum sheets, where the holes’ dimension can also control damage progression, such as reported in [38] in a study that used a carbon fiber composite core. Further weight reduction with an easier compaction process is achieved by the use of aluminum meshes, also in view of their preparation for their introduction in larger structures, such as concrete or masonry walls [39,40]. Expanded aluminum meshes also provide other properties, such as the suppression of deflagration when in combination with soft cores, most typically polymer foams [41]. The initial interest for the development and use of FMLs experimented in the aerospace industry gradually expanded to other sectors. This applies so far mainly to the automotive field, where obviously other considerations are of paramount importance, such as crashworthiness and falling weight impact properties [42].

Hybridization is a widely used approach when it comes to the introduction of lignocellulosic biomass, preferably in the form of fiber or textile structures, into materials [43]. It provides a cautious and sensible route towards investigating the prospected properties of the modified material, while indicating a reasonable level of substitution for the synthetic component [44]. This results, for example, in the control of some properties, such as impact performance [45]. In practice, the number of lignocellulosic (or, less frequently, protein-based) fibers that can be introduced in composites is countless; however, a non-exhaustive list is offered, e.g., in [46], dividing fibers by their plant origin (bast, grass/straw, leaf, fruit, seed, bark, etc.) or their animal derivation. Epoxy resins can be still considered the most used matrix for natural fiber composites for their reliability, relative constancy of properties, easy manufacturing and complete hydrophobicity [47,48]. Furthermore, the introduction of bio-based content into epoxies is gradually rising in recent developments [49] and, beyond that, more recyclable epoxy products are continuously being synthesized [50,51]. It is worth noting also that some Al alloys are particularly consolidated in their use in FMLs, such as 2024 T3, so that their processing and surface treatment do not in themselves impede the experimentation of novel fibers as the core reinforcement [52]. The application of epoxies into natural fiber composites makes them particularly desirable for their use as the core of fiber metal laminates, for example, with flax, which also offers remarkable fire resistance, as reported in [53]. However, one of the first studies on FMLs also including lignocellulosic fiber used a self-reinforced polypropylene composite with hemp fibers [54]. A particular issue that arises in the introduction of lignocellulosic fibers is that the ingress of moisture and water due to the presence of hydrophilic components might also generate some corrosion issues, which in a sense also affects the sustainability balance [55]. The introduction of a variety of different natural fiber composites to form the core of FMLs led to another study on ecodesign to try to assess the environmental impact of their production [56]. This research demonstrated their consistent superiority in the use of a barely sanded series 1 (1200-H14) aluminum alloy, with the use of a castor oil biopolymer as resin and untreated coir fibers. These results appear to counterbalance the idea that more refined lignocellulosic fibers would need to be used, though obviously the aforementioned alloy does not comply with the requirements of some industry standards, e.g., aeronautical ones, though it is suitable for some work, such as forging [57].

This review is structured as starting from the challenges owed to the hybridization of lignocellulosic (generically defined as “biomass”) materials in aluminum alloys in the form of fiber metal laminates, normally in fiber or fabric format into a resin, most frequently using epoxy resins. Some studies also exist on a similar hybridization: FMLs with titanium alloy skins in [58] were combined with Kevlar and jute fibers and in [59] with basalt and flax fibers. However, this work, recognizing the perduring centrality of aluminum alloys in both MMCs and FMLs, as per aerospace and automotive industry requirements, decided to concentrate only on these. In Section 2, the introduction of lignocellulosic materials, normally in a combusted form, namely ashes, into MMCs, is considered, and their potential for the replacement of ceramics as regards particularly hardness and wear control is discussed. In the case that biomass is introduced in its as-received state, in other words at ambient temperature, such as in FMLs, the presence of hydrophilic elements in the hybrids does change its relationship with the environment. This is discussed in Section 3, after which the variety of lignocellulosic fibers introduced is broadly presented, and the mechanical, physical and chemical properties obtained by this hybridization operation are discussed. Often, an intermediate approach is also applied, which includes both lignocellulosic and other fibers, including especially glass, carbon and basalt, and obviously combines the properties of both types of fibers in a possibly tailored context. Finally, Section 4 reasons on the perspectives of this application in fields different from aerospace and aims at predicting future developments and on the perduring competition between MMCs and FMLs, which is altered by the role of biomass, yet often involves natural materials obtained from the same production system. This will especially consider the increasingly large amounts of secondary raw matter based on biomass and the need for their upcycling, which can be particularly significant in high-profile and expensive materials, such as is the case for these hybrids.

2. Properties of Aluminum MMCs (AMCs) Including Lignocellulosic Fibers

2.1. AMCs Manufactured via Liquid Methods Including Generic Biomass Ashes

In AMCs, as exposed above, biomass is normally introduced in its combusted form since most of the production methods for these materials occur via the application of high temperature to produce alloy melting and casting, application of reinforcement by stirring or even application of a pressure, such as in squeeze casting or pressure infiltration. For an improved sustainability profile, agricultural waste and bio-ashes need to be applied in light and durable components, which also offers more significance to their recycling [60]. The origin of these fillers can be from a large number of vegetable species, woody and herbaceous, e.g., wheat or sugarcane straw, rice husk or palm oil clinker, typically mostly originating from large production systems [61].

Biomass ashes are predominantly rich in silica with variable levels of crystallinity, being more or less quartz-like [62], and sometimes also in alumina [63], and also contain carbon and various sulfates, phosphates, carbonates and oxide, as well as a large variety of other elements. A comprehensive study at its time aimed at the substitution of coal with biomass and indicated as major elements (other than obviously C, O, H and N) Ca, K, Si, Mg, Al, S, Fe, P, Cl and Na, in addition to Mn, Ti and others in traces [64]. More profound studies would classify biomass ashes into various groups according to the presence of the following elements, respectively: Si–Al–Fe–Na–Ti, Ca–Mg–Mn and K–P–S–Cl [65]. Ashes of the first group appear closer to reproducing the characteristics of the commonly used ceramics for reinforcement in MMCs, namely alumina and silica. Previous reviews explicitly report their potential comparison with other industrial carbonate-based fillers, such as eggshells, or others directly derived from the aluminum industry, such as red mud [66].

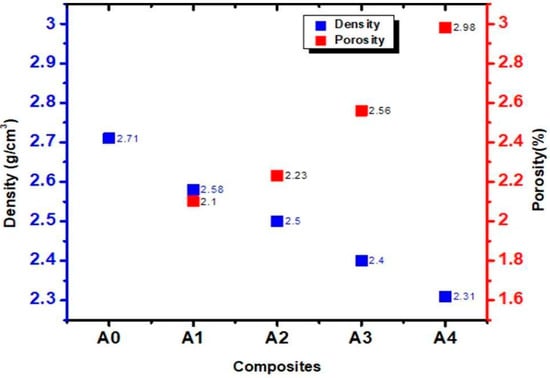

In particular, an important source of bio-silica is rice husk, which is widely used also in polymers as a filler and rheology controller for the replacement of calcium carbonate, and starts in the as-received state from a bare 15–17% SiO2 content [67]. In its combusted state, rice husk has been used in amounts of up to 7–9% to increase the hardness without affecting the ductility of a stir-cast 7075 aluminum alloy MMC, reaching a value of 162.4 HV [68]. This result was over 50% higher than what was obtained in [69], adding up to 15% fused silica in a stir-cast 2024 aluminum alloy. Adopting once more a two-phase stir casting process, aluminum powder was mixed with ashes from rice husk, cassava peel or coconut shells, up to 15% in weight, or 5% of each. The density and porosity data obtained in each of the cases are reported in Figure 3. The results demonstrated that the latter samples had a largely higher impact and tensile strength, suggesting that the tailored mix of various agricultural residues into an aluminum matrix could be a route to be followed [65]. Introducing the same residues, yet using a 6063 alloy in a compo-casting process, hence at only a 20% solid fraction and a slightly lower temperature, the tribological properties of AMCs were also assessed, demonstrating that they outperformed the same amount of alumina in the composite [70]. A closer hardness (155 HV) to the one reported in [68] was obtained using up to 7% of lemon grass ashes in a compo-casting process, which ensured the effective dispersion of particles and therefore a suitable blocking of the dislocation movement in the AMC, again in a 6061 alloy [71].

Figure 3.

Density and porosity of various MMCs: A0 Al-alloy; A1 Al-alloy + 15 wt.% coconut shell ash (CSA); A2 Al-alloy + 5 wt.% CSA + 5 wt.% rice hull ash (RHA) + 5 wt.% cassava peel ash (CPA); A3 Al-alloy + 15 wt.% CPA; A4 Al-alloy + 15 wt.% RHA [69].

As shown above and starting from the concept of property control, traditional composites based on aluminum matrices and alumina particles were developed by the combined addition of various biomass ashes, namely bean pod, cassava peel and coconut husk agro-waste, in a total amount of 10%, as described in [72]. The target of this study’s examination was to reach a higher wear resistance for aluminum alloy 6063 in the understanding that provided that porosity is controlled, a constant relationship between shear and compressive strength is ensured with a potential control of corrosion too in some combinations of fillers.

On the other hand, another trend was offered by filling an aluminum alloy using carbon-based nanoparticles, such as those originated from graphene [73]. It is worth noting that nanoparticles from agro-waste are diffusing in fields that span from remediation to the production of biofuel, though one of the most sustainable and valuable fields is their use as fillers [74]. From biomass ashes, the development of nanoparticle-reinforced AMCs has also been proposed using liquid methods for their production: a classical application involves their synthesis from eggshell powder in combination with other ceramics, such as silicon carbides. This was performed in [75] on a 2014 alloy. The highest reduction in wear, from 15 × 10−5 to 9.5 × 10−5, was obtained by introducing 6.5% carbonized eggshell with the addition of 11% silicon carbide. The comparison of silicon carbide with rice husk ashes in a double-stir-cast A356 aluminum alloy (Al-Si-Mg) composite was attempted in [76], though at a micrometric dimension (25 μm). However, ashes from vegetable origin have also, though rarely, been used to produce nanoparticles for their introduction in AMCs. In particular, by double stir casting in a 2009 alloy, bean pod ashes were calcined, and then nanoparticles were produced using a sol–gel method down to a dimension of 55 nm [77].

2.2. AMCs Including Seed Waste

A component of biomass that has recently received a great deal of attention for its introduction in materials as natural hardeners is seeds [78], which also derive from the sector of agricultural and food waste and are often over-produced, so that they remain unused [79]. The production of AMCs using powder metallurgy allowed the integration of seeds, such as in the case of date palms, which were compared with natural dolomite. After being ground to a size between 53 and 80 microns, date palm seeds were calcined so as to avoid problems of flame development in the oven, and they offered ultimately in the composite a hardness performance exceeding that of natural dolomite for an optimal tenor of 7.5% (HRV hardness equal to 50 against 48.3 for dolomite-filled AMCs) [80]. Also, the use of palm kernel (internal and edible part of the seed) was proposed in an aluminum alloy recycled from an automotive engine block. The kernel was ground down after roasting in a furnace to an average size of 106 microns and added to an amount of up to 15% either pre-treated (1 M solution of NaOH at 50 °C for 4 h) or untreated. However, the effect of treatment on performance did not demonstrate consistency [81].

Another seed whose use in the form of char was experimented in AMCs is neem (Azadirachta indica). Neem fiber enjoyed some success in the field of polymer composites [82], proving particularly suitable to combination with other fibers [83], also when introduced in the form of as-received seeds [84]. In [85], in a stir-cast 6061 alloy AMC, the composite with 7.5% neem seed ash showed the lowest wear rate (375 × 10−3 mm3/m), though Vickers hardness investigations indicated a large variability, exceeding ±10% for the empirical units, according to the indentation point selected. This suggests once again that a more accurate control of particle dispersion would lead to even further improvements in the composite’s performance. Further studies were attempted using Al alloys with significant amounts of silicon. In particular, one study involved mango (Mangifera indica) seed ash inserted to up to 20% tenor in an Al-Si-M g alloy with intended use as a motorcycle wheel hub. The maximum hardness obtained was quite deceiving, though, amounting to 43.2 HV for a 15% addition [86]. Also, in an Al-Si-Fe alloy, breadfruit (Artocarpus camansi) seed ash considerably rich in alumina (approximately 35%) was introduced in an amount of up to 12 wt.% in a stir-cast composite, resorting to a very good and steady improvement in hardness, largely exceeding the filler tenor (from 65 to 85 HRB for a 12 wt.% filler) [87]. Different breadfruit parts, including the peel fiber [88], leaf [89] and again seed shell ashes, lasted in combination with up to 25% Momordica angustisepala leaf fibers [90], have also been used in polymer composites as fillers, which indicates also in this case the presence of some production waste from the system, though perhaps not extensive, as in other cases. However, in polyethylene, these fillers stimulated fragmentation and ultimately oxo-degradation. The objectives in MMCs are going to principally involve hardness improvement, though not to the level achieved by ceramic fillers.

A further example of seed elements that have been occasionally proposed for AMCs, yet belong to a potentially important production system, are castor seed shells [91]. These were used in an Al-Si-Mg alloy in an amount equal to 12 wt.%. The results obtained indicated a 25% increase in tensile strength and an over 40% increase in hardness. It is also worth considering that castor oil has a paramount importance in materials for the manufacturing of bio-thermosetting resins [92] and in energy production in biofuels [93], which can be quite obviously related to the availability of seed shells and/or oil cake.

2.3. Brake Pads by AMCs and Biomass: A Case Study

Powder metallurgy is particularly suitable to introduce scraps, or general production waste, into MMCs; an example of this process is reported in [94], where powders of iron, nickel and Ni3Fe intermetallics were recovered from ferrous scrap by a hydrometallurgical process and added with alumina in a composite. Since the process does not necessarily require very high temperatures, it also allows the introduction of biomass in its as-received form in AMCs. In particular, brake pads, in the post-asbestos revolution, need to be resistant to wear and friction, yet on the other side, they need to be consumed gradually and consistently. For this application, metal matrix composites are particularly suitable and used as substitutes for graphite-filled cast iron pads [95]. Moreover, the use of biomass waste in brake pads, namely in the substitution of carbonaceous components, is recently recommended [96]. This leads to a reduction in carbon emissions and generally in related pollution [97]. Of course, for the purpose to be attained, the biomass material needs to be sufficiently abrasion-resistant. This was the case for coir fibers, which were introduced in amounts of up to 15% in brake pads, by compacting and sintering them using an aluminum powder with a number of other ceramic particles, such as silicon carbide, alumina, zirconia and graphite, together with phenolic resin [98]. In another case, rice husk was employed in a smaller amount (2%) as the complement to silicon carbide (5 to 20%) into a 2024 aluminum alloy, stir casting these into the composite. Obviously, the effect was limited, and the main detrimental effects on mechanical (not friction) performance were observed in increasing silicon carbide from 15 to 20% [99]. Rice husk has been proposed for coupling with fillers other than silicon carbide in the field of the automotive industry; examples are fly ash, sugarcane bagasse and alumina, as reported in [100]. This review confirms the absolute predominance of stir casting as a production method in this case. Despite this, not always is success expected. For example, locust bean pod ash, added up to 25% into A356 Al-Si 7-Mg 0.3 alloy for automotive brake rotor, offered some improvement in hardness (from 25.9 to 40.5 HRB) and even more considerably reduced the wear rate (from 0.0896 to 0.0492 mm3/N·m). However, the modification to the grain structure via filler addition offers expectations about the repeatability and predictability of the results, which were not totally fulfilled [101].

It is fair to say though that the research over brake pad materials from biomass goes well beyond the field of AMCs, and extends to using thermosetting resins as binders, which may suggest that some candidates may be proposed in the near future. Some studies are mentioned here about various fillers successfully monitored in brake testing, such as silanized garlic stalk (Allium sativum) fiber with synthetic barite [102]. The types of biomass used in this respect are countless. Limitations were highlighted as regards the brake efficiency for coir fibers in combination with wood particles, which can only be possibly applied with judicious control of the final composition, for small vehicles [103]. This could be due to the variable porosity of these materials, which could possibly worsen in a prospected introduction into metal matrix composites. More punctual studies have been carried out on the effect of rice husk [104] and hemp hurds [105], investigating granulometry and distribution in the matrix.

3. Properties of Aluminum FMLs Including Lignocellulosic Fibers

3.1. General Considerations on Water Absorption and Environmental Degradation

One of the typical tests that is performed on natural fiber composites, due to the need to better elucidate their interaction with the environment, is hygrothermal conditioning, whose first consequence is water absorption, thus reducing the material’s stiffness [106]. Moreover, the inherent hydrophilicity of lignocellulosic fibers leads to their poor interfacial adhesion with hydrophobic polymer matrices, such as epoxies, for water penetration along the fibers, using as additional routes the processing voids in the resin [107,108]. Lignocellulosic fibers are normally treated with the idea of reducing water retention and absorption, and a large number of studies have reported the effect of various chemicals on the surface characteristics of the fibers as far as wettability is concerned [109,110,111,112]. Moreover, investigations are available on whether the addition of other components in the composite, such as carbon nanotubes (CNTs), would modify their properties, in the understanding that moisture effect would also be linked with other characteristics, such as, for example, sound absorption [113]. Other aspects were also clarified, which are deeply affected by the presence of moisture. This is the case for machining, where the hygrothermal effect may lead to extensive fibrillation and to a reduction in interfacial strength between the fibers and matrix [114]. The connection between moisture content and distribution with fatigue and the aspect of S-N curves was also recently explored in birch–polyethylene composites, of course investigated through aging in normal environmental conditions [115].

In particular, when combining lignocellulosic fibers with aluminum alloys in an FML structure, the pressure of environmental degradation becomes obviously significant due to the potential damage obtained by the moisture effect [116]. The uncontrolled introduction of biomass is also deemed to affect the bridging effect between the skin and core, which makes FMLs particularly effective in fatigue [117]. To try to address this issue, a warm compression method (80 °C) was found to be able to reduce water absorption in the specific case of kenaf/epoxy laminates, with respect to the cold compression method (27 °C) applied to a 2024 T3 aluminum alloy [118]. Kenaf also proved valuable in FMLs in a hybrid combination with pineapple fibers, very diffused most recently in natural fiber composites [119,120], where up to 50 wt.% reinforcement was able to be introduced in a flatwise and edgewise combination, though with some penalties in terms of excessive water absorption [121]. It is worth noting that hot molding the composites, even with complex stacking sequences, including hemp, bamboo and basalt in a diamond micro-expanded mesh (DMEM), resulted in a high void content, in practice never inferior to 20%. As a result, depending on the layup structure, a water absorption at saturation between 7 and 9% was measured [122]. An obvious modification aimed at reducing the incidence of water absorption is the addition of some ceramic powder into natural fiber FMLs. Using nanosilica, for example, the fabrication of fiber metal laminates with unusual, yet abundant, waste lignocellulosic fibers, such as okra (Abelmoschus esculentus) [123], was also possible [124]. This was specifically proposed, due to their significantly long fatigue life, for steam turbine applications. Another possibility for natural moisture-reducing materials is nanoclay (montmorillonite), experimented in [125] using a jute/epoxy core. Montmorillonite has also been experimented on in other FMLs based on a basalt/jute hybrid core with different stacking sequences, in which case the ability of intercalating and exfoliating attributed to nanoclay proves, to a point, other than reduced water absorption, the ability to improve the flexural and impact properties of FMLs. This occurs in this specific case up to a 1.5% nanoclay content, with limited differences among the different jute/basalt stacking sequences in flexural properties, though for impact the addition of more jute layers proved detrimental [126].

3.2. Mechanical and Impact Properties

In Table 1, a number of studies that led to the assessment of mechanical properties, which will be discussed later on, are reported. Whenever not specified, the resin used in the core composite is intended to be epoxy.

Table 1.

Some studies of aluminum alloy FMLs with lignocellulosic fibers.

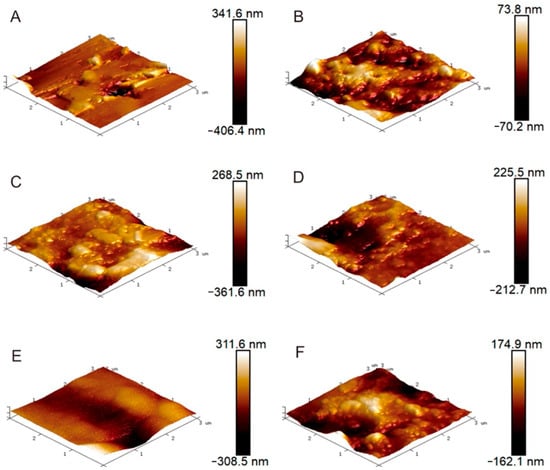

To improve the bonding in the composite, typically alkali treatment using sodium hydroxide (NaOH) is used to modify the surface of lignocellulosic fibers in the core; this is applied, for example, in [127,128] on flax fibers. This is the most followed procedure, which can be tailored to act on some different parameters, such as the concentration, time and temperature of alkali treatment, which improve mechanical properties by reducing water absorption [141], as applied in [142] onto fique, pineapple and flax. In [139], to offer an example, a 5% NaOH solution was used on kenaf, although the dependance of the effect of solution used over the species of fibers was not negligible at all. In other cases, such as in [131], combining treatment solutions proved effective, including for aluminum alloy mechanical polishing, alkaline treatment and etching by sulfuric acid–ferric sulfate treatment, while flax fibers were treated via the application of a silane coupling agent. Also, a more complex stacking sequence solution was attempted, namely Al/Flax 0°/Flax 90°/Al/Flax 90°/Flax 0°/Al, with 22% fiber content and 18% Al weight. An atomic force microscopy (AFM) study on the variation in the roughness of Al alloy with treatments was carried out, and the results are shown in Figure 4. This suggests the degree of adaptability of the alloy in being stacked into a complex FML environment.

Figure 4.

Three-dimensional atomic force microscope (AFM) roughness images of the Al alloy with different surface treatments: (A) untreated, (B) mechanically polished, (C) mechanically polished and alkali-treated, (D) mechanical polishing, alkali-treated and silanized, (E) etched, and (F) etched and silanized [131].

In order to assess the performance of the core, hence measuring the mechanical properties of composites including lignocellulosic fibers, most typically tensile, flexural and impact (Charpy or Izod), reference is made to tests performed on polymer composites, and specific tests need to be carried out to measure the bonding strength of the metal skin with the composite core. In particular, T-peel tests were performed in [132], which allowed the measurement of the interlaminar shear strength at the skin–core interface. These results are comparable with those obtained in other studies, namely [143] on GLAREs and [144] on carbon prepreg FMLs, where the effect of the so-called “kissing defects” was also explored.

The machining performance of FMLs with flax and sisal fiber, with only thin foils of aluminum (24 microns thickness) as skins, so as to exaggerate the effect of drilling holes of various dimensions, was examined in [132]. For comparison, the considerations made in [114] can be taken as a reference. Further information can be obtained in [145], based on FMLs with glass fibers. In this case, hole diameter deviation (HDD) was measured with respect to the velocity of entrance of the drill. At 400 and 600 mm/min transversal speeds, an average deviation equal to 2.8% was measured at the hole entrance and an average of 2.13% at the hole exit, whereas when increasing the speed at 1000 mm/min, both increased to 5% at the hole entrance and 4% at the hole exit. In [128], the highest circularity error was measured at a 2000 revolutions/min for a 20 mm drill, and was equal to 3.3%. This can appear promising in terms of comparison, though it needs to be noticed that the amount of lignocellulosic fibers introduced in the composite is limited, being around 9% for woven flax and just below 7% for woven sisal.

For the predicted applications of FMLs, the different types of impact testing, in terms of unidimensional ones, i.e., Charpy/Izod, bidimensional (falling weight impact), are considered for evaluation. In [133], ballistic impact studies offered the indication for the projectile impact energy of the material as being equal to 8.31 J/mm for CRALE 6 (6 Al layers and 5 coir fabric layers) and 9.95 J/mm for the thicker CRALE 12 (12 Al layers +11 coir fabric layer). To compare these data, some studies on the ballistic impact properties of GLAREs are available, in particular with epoxy resin [146] or polypropylene [147]. It is worth mentioning that in a comparison between the effect of using epoxy and polyester resin in coir fiber AMLs [134], interestingly enough, flexural properties were higher for the former, while impact performance was much more promising for the latter.

Further considerations on the control of mechanical properties are given by the importance revealed in some cases of the effect of the fiber content (10 to 40 wt.% oil palm fibers) on these [137]. Moreover, they are also offered, due to the increasingly frequent disposal of biomass waste into materials, to the use of unusual plant fibers into the composite core, which is the case for those from Hibiscus tiliaceus bark [138]. The use of less-diffuse fibers is a well-recognized and distinct practice in natural fiber composites, especially due to the need for their added-value disposal into materials [148]. As regards bark, this has normally been discarded for employment into material until very recent times. However, the local large availability of particular species has brought to the need for the characterization of these materials, as is reported in [149] in view of their insertion into polymer composites, although it has to be recognized that their use in FMLs represents an increase in value on the path of upcycling.

3.3. Properties of Aluminum FMLs Including Lignocellulosic Fibers Layered with Other Fibers

A distinctly more cautious approach regards the possibility to add lignocellulosic fibers to traditional ones in hybrid composite laminates. Some examples are given in Table 2 below [150,151,152,153,154,155,156,157]. Also, in this case, whenever not specified, the resin used in the core composite is epoxy. Excluding some exceptions, such as the phormium in [151], a leaf fiber that had some interest in the composites for its similarity with agave fibers and the use of poly(vinyl butyrate) (PVB), a biodegradable polymer, in [157]. The latter may appear rather incongruous for materials such as FMLs, yet it was more compatible with jute fibers in that specific case. Moreover, as was also noticed for the MMCs, the control of the stacking sequence, easily achievable with hand layup, appears essential to tailor the properties of the composites.

Table 2.

Some studies of aluminum alloy hybrid FMLs with lignocellulosic and other fibers.

A single study on a hybrid with bamboo (B) and glass (GF)/carbon fiber (CF) was executed, intended at increasing damping by replacing a central aluminum (Al) (undeclared series) sheet by bamboo, passing therefore from Al/CF/Al/CF/Al to Al/CF/B/CF/Al to Al/GF/B/GF/Al, with a significant drop in acceleration [158].

4. Comparing Further Developments for Introduction of Biomass in MMCs and FMLs

4.1. The Perceived Rationale for Introducing Lignocellulosic Biomass into Aluminum Hybrid Composites

Introducing lignocellulosic biomass into high-profile materials, such as those based on aluminum alloys, can offer an advantage not only in economic terms but also as a matter of sustainability, especially in cases where they can be considered the waste or possibly undesired by-products of a production system. It needs to be noticed that as far as the duration of service of these materials is concerned, this way to recycle biomass can be considered closer to a real circular economy approach than other applications, which are albeit successful but involve a limited time of use before being discarded with no possibility for further recycling. This is the case, for example, for the use of biomass for water remediation with metal ion removal [159], as well as for the production of active carbons [160].

Concerning aluminum hybrid composites, a definition that includes both types of materials presented in this work, the assortment of fillers aimed at improving their performance in various senses, especially including hardness and wear resistance, is countless; a quite exhaustive list is presented in [161]. However, the presence of a substantial production system that produces waste is recognized as often being important for the selection of the relevant biomass for introduction into the hybrid. Some examples are discussed, such as ashes from rice husk, bamboo leaf, coconut shell microparticles, corn cob and carbonized maize stalk particulates [162,163]. Another species of great interest in polymer composites and limited interest in metal hybrids is hemp, which interestingly led, in [164], to an inversion of the concept for FMLs by layering it with external sheets of hemp and an aluminum core in view of its application to reduce electromagnetic interference issues. In general terms, the quantity of biomass available for this purpose, which has been very lightly exploited so far, would suggest, namely in the case of MMCs and supposing, as it has been the case in the greatest majority of cases, that it will be used as ashes, would need to establish a relation between ash composition and the function of the specific MMC to be fabricated. In the long run, out of this purpose, it would even result in a futile exercise inserting biomass waste in a material matrix. With this idea, a reasonably comprehensive plan of applications for MMCs, most of which are AMCs, is presented in [165]. If this is the case also for FMLs, the application of new biomass species can be possibly attempted, even in the presence of considerable dimensional variability, such as occurred in [166] for grass of the Cynodon species.

What can be noticed in particular about biomass-filled MMCs and FMLs is that the aluminum alloys used for production show some superpositions, in particular as regards series 2024 and 6061, which appear to be popular in both cases. This can be attributed to the common aim towards aerospace applications, where both series find diffuse use [167]. In the case of MMCs, however, a large space is also given to Si-loaded alloys, possibly for the need to decrease wear and to better host ceramic particles, which are typical fillers for these materials. Concerning ceramic fillers, biomass particles engage in real competition with these, often coexisting in the same materials. This is true for MMCs, but also for FMLs, where a diffuse presence is that of nanosilica in the composite core [168]. The question of biogenic ceramic fillers is now central to experimentation on sustainable composite materials, involving considerations for achieving constant granulometry and quasi-spherical particles, able to guarantee an effective and sound interface with the matrix [159,160,161,162,163,164,165,166,167,168,169,170]. Examples are given in AMCs, namely hydroxyapatite from milkfish (Chanos chanos) bones [171], bone powder from slaughtering [172] and calcium carbonate from seashells [173,174].

As for processing, the absolute predominance of the stir casting method for MMCs when coming to the introduction of biomass ashes is observed [175]. Powder metallurgy is less popular, though it could, in principle, also allow the introduction of dried biomass powders, rather than ashes, which would avoid the impact of the calcination process. However, even for small amounts of dried biomass, room-temperature powder compaction, coupled with hot extrusion at 500 °C [176], would lead to substantial risks of flame development (unless possibly specific fire-retardant treatments were applied on the biomass powders). Despite all these limitations, it can be considered that the use of biomass in MMCs and FMLs broadens their field of application beyond aerospace and improves their sustainability. This would especially occur whenever a correct synergy among the different reinforcements and fillers is achieved by opportunely tailoring quantities, granulometry (not excluding the use of nanoparticles) and ultimately targeted properties [177].

4.2. How the Balance Between FMLs and MMCs Is Altered by Lignocellulosic Biomass

As from the initial assumptions of this work, the introduction of biomass alters the relation between FMLs and MMCs, which are two ways of using aluminum alloys going beyond their limitations. Some very basic considerations are reported in Table 3 to pave the way for more to-the-point and case-by-case discussion. Most generally, the success of FMLs is ensured by an effective bonding between the skins and the core, which, unlike the case of the cellular sandwich structure, is a prevalently solid one [178]. In contrast, MMCs work optimally whenever the ceramic (or in any case harder) particles, or more rarely short fibers [179], provide a good interface with the matrix [180]. The production of MMCs involves higher inherent complexity, linked to its requirements to attain temperatures where the aluminum phase can be liquid, namely in some of the most popular processes, such as stir casting, or to reach very high pressures, as in powder metallurgy. In the case of stir casting, other factors are also of significant importance in ensuring material uniformity, namely stirring velocity and time, as well as preheating time [181].

Table 3.

Compared enhancement of properties by the introduction of biomass.

The general effect obtained by the introduction of biomass is the increase in the presence of voids: internal porosities in biochar and seeds used as the reinforcement of MMCs, and inherent voids, such as lumens and lacunae [182], in the vegetable structure for fibers employed in FMLs. In both cases, this results in some decrease in the material’s density, rather negligible in most cases for MMCs for the limited amount of particles introduced and the small percentage of porosity in biochar, which is presently in search of surface engineering to increase its effectiveness also in terms of other uses, such as, e.g., for active carbons [183]. The porosity of seeds and their introduction under pressure (powder metallurgy) into MMCs would vary even more depending on the species; however, its effect may be less negligible, so that some of these, e.g., poppy seeds, have even been used as templates for the development of porous ceramics [184].

As discussed before, the use of liquid processes for the production of MMCs including biomass has been preferred so far. It is worth noting that the composition of ashes is easily determinable, and they are normally not further affected by the typical processing temperatures of aluminum alloys at the liquid stage. In contrast, the effect of pressure as required by powder metallurgy has been only limitedly elucidated so far, and the only available information is on wood pellets intended for use in energy generation and barely intended to measure their compression strength [185].

In the case of FMLs, using biomass as a part or the whole reinforcement does considerably reduce their weight and cost, especially if it sourced from the residue of some other agro-industrial process, and, depending on the regularity of the geometry of the fibers, it can be introduced in amounts comparable to what achieved in the case of synthetic fibers, such as carbon, glass or aramid [186]. Concerning both structural repeatability and the improvement in the properties, a significant factor is given by the optimization of fiber treatment, which is an essential driver for the development of materials including lignocellulosic raw matter, especially when relatively novel fibers are used [187]. One of the caveats that can be observed nonetheless when employing biomass is that its relative geometrical complexity would impede in principle the fabrication of FMLs with alternate layers of metal and composite in contrast to those with a simpler skin–core structure. This objection, though in principle valid, has not impeded so far the fabrication of very tailored and multiform structures, including a variety of metal forms, natural fibers and ceramic nanoparticles. For example, in [188], a structure was proposed that included, specifically, pineapple, nanosilica and a conductive copper mesh between aluminum sheets. It was aimed at aeronautical applications. It is fair to say though that these possibilities would depend on the specific lignocellulosic fiber introduced and on its processing/treatment.

4.3. Predicted Future Developments

The amount of biomass available in the world from various agricultural operations, going from wood production to cropping, and recently including also the consideration of periodic operations such as pruning/forest maintenance, is continuously growing. Considerations of the increasing carbon footprint and climate change would suggest avoiding as much as possible its disposal by energy recovery and, when this is finished, to offer another use to ashes that is not being tossed into the landfill.

Both MMCs and FMLs will carry on being optimal candidates for this process since they include either ceramic particles or synthetic fibers, which are costly and are increasingly substituted from biomass products that are increasingly diffusing, such as biochar and lignocellulosic fibers. This process also has a positive effect on reducing resource depletion, as this has been realized in many other fields (e.g., considering the use as rheology modifiers in polymers of calcium carbonate from eggshells, calcinated or not [189]). Other factors can be considered that will bring together MMCs and FMLs: the discussions over the enhanced use of biochar, as well as its processability and machinability, in selected processes, namely stir casting [190], singularly and in combination with ceramic particles, e.g., from metal oxides [191].

To conclude, biomass (and especially secondary biomass from other processes) is gradually and steadily making its way through all materials. This occurs especially when complex and even contrasting exigences are addressed, which may include wear resistance, light weight, mechanical/impact resistance and renewability, in fields such as the automotive or aerospace industry [192]. There is some urgency therefore to recognize and formalize a definition of “biomass-loaded materials”, of which MMCs and FMLs are two examples, as this review eagerly attempted to demonstrate.

Author Contributions

Conceptualization: C.S. and C.F.; methodology, C.F. and C.S.; investigation, C.S. and C.F.; writing-original draft, C.F. and C.S.; writing-review and editing, C.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AMCs | Aluminum Metal Composites |

| ARALL | Aramid-Reinforced Aluminum Laminate |

| CARALL | Carbon-Reinforced Aluminum Laminate |

| CPAs | Cassava Peel Ashes |

| CRALE | Coir-Reinforced Aluminum Laminate Epoxy |

| CSAs | Coconut Shell Ashes |

| DMEM | Diamond Micro-Expanded Mesh |

| FLARE | Flax-Reinforced Aluminum Laminate |

| FMLs | Fiber Metal Laminates |

| GLARE | Glass-Reinforced Aluminum Laminate |

| HRB | Rockwell B Hardness |

| HRV | Block Rockwell (Rockwell V) Hardness |

| HV | Vickers Hardness |

| PVB | Poly(vinyl butyral) |

| RHAs | Rice Hull Ashes |

| VARTM | Vacuum-Assisted Resin Transfer Molding |

References

- Rahman, M.Z.; Rahman, M.; Mahbub, T.; Ashiquzzaman, M.; Sagadevan, S.; Hoque, M.E. Advanced biopolymers for automobile and aviation engineering applications. J. Polym. Res. 2023, 30, 106. [Google Scholar] [CrossRef]

- Svidler, R.; Rinberg, R. Bio-based hybrid cabin door of ultralight helicopter with variable-axis fiber design. CEAS Aer. J. 2023, 14, 115–125. [Google Scholar] [CrossRef]

- Allah, M.M.A.; Hegazy, D.A.; Alshahrani, H.; Sebaey, T.A.; El-baky, M.A.A. Fiber metal laminates based on natural/synthesis fiber composite for vehicles industry: An experimental comparative study. Fib. Polym. 2023, 24, 2877–2889. [Google Scholar] [CrossRef]

- Casati, R.; Vedani, M. Metal matrix composites reinforced by nano-particles—A review. Metals 2014, 4, 65–83. [Google Scholar] [CrossRef]

- Hussain, M.; Imad, A. Natural fiber metal laminate and its joining. In Natural Fibers to Composites: Process, Properties, Structures; Nawab, Y., Shaker, K., Imad, A., Saouab, A., Eds.; Springer: Berlin, Germany, 2022; pp. 149–172. [Google Scholar]

- Palanivendhan, M.; Chandradass, J. Experimental investigation on mechanical and wear behavior of agro waste ash based metal matrix composite. Mater. Today Proc. 2021, 45, 6580–6589. [Google Scholar] [CrossRef]

- Xiao, H.; Sultan, M.T.H.; Shahar, F.S.; Gaff, M.; Hui, D. Recent developments in the mechanical properties of hybrid fiber metal laminates in the automotive industry: A review. Rev. Adv. Mater. Sci. 2023, 62, 20220328. [Google Scholar] [CrossRef]

- Marsh, G. Next step for automotive materials. Mater. Today 2003, 6, 36–43. [Google Scholar] [CrossRef]

- Gebrehiwet, L.; Abate, E.; Negussie, Y.; Teklehaymanot, T.; Abeselom, E. Application of composite materials in aerospace & automotive industry. Int. J. Adv. Eng. Manag. (IJAEM) 2023, 5, 697–723. [Google Scholar]

- Sharma, D.K.; Mahant, D.; Upadhyay, G. Manufacturing of metal matrix composites: A state of review. Mater. Today Proc. 2020, 26, 506–519. [Google Scholar] [CrossRef]

- Singh, L.; Singh, B.; Saxena, K.K. Manufacturing techniques for metal matrix composites (MMC): An overview. Adv. Mater. Proc. Technol. 2020, 6, 441–457. [Google Scholar] [CrossRef]

- Mussatto, A.; Ahad, I.U.; Mousavian, R.T.; Delaure, Y.; Brabazon, D. Advanced production routes for metal matrix composites. Eng. Rep. 2021, 3, e12330. [Google Scholar] [CrossRef]

- Sharma, S.K.; Saxena, K.K.; Salem, K.H.; Mohammed, K.A.; Singh, R.; Prakash, C. Effects of various fabrication techniques on the mechanical characteristics of metal matrix composites: A review. Adv. Mater. Proc. Technol. 2024, 10, 277–294. [Google Scholar] [CrossRef]

- Sharma, P.; Dabra, V.; Sharma, S.; Khanduja, D.; Sharma, N.; Sharma, R.; Saini, K. Microstructure and properties of AA6082/(SiC+ graphite) hybrid composites. Refractor. Ind. Ceram. 2019, 59, 471–477. [Google Scholar] [CrossRef]

- Bahl, S. Fiber reinforced metal matrix composites-a review. Mater. Today Proc. 2021, 39, 317–323. [Google Scholar] [CrossRef]

- Samuel, A.A.; Arudi, I.S.; Markus, S.; Adeleke, A.A.; Ogedengbe, T.; Jesuloluwa, S.; Aladejana, M.; Jahswill, O.O.; Chijioke, S.L.; Adeyelu, A.E. Metal matrix reinforcements-fabrication, applications, and properties: A review. In Proceedings of the 2023 2nd International Conference on Multidisciplinary Engineering and Applied Science (ICMEAS), Abuja, Nigeria, 1–3 November 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Vinayagamoorthy, R. Trends and Challenges on the Development of Hybridized Natural Fiber Composites. J. Nat. Fib. 2020, 17, 1757–1774. [Google Scholar]

- Seetharaman, S.; Subramanian, J.; Singh, R.A.; Wong, W.L.E.; Nai, M.L.S.; Gupta, M. Mechanical properties of sustainable metal matrix composites: A review on the role of green reinforcements and processing methods. Technologies 2022, 10, 32. [Google Scholar] [CrossRef]

- Baliarsingh, S.S.; Tripathy, A.G.; Sahoo, B.P.; Das, D.; Behera, R.R.; Satpathy, M.P.; Kumar, R. Comprehensive review on fabrication methods of metal matrix composites and a case study on squeeze casting. Adv. Mater. Process. Technol. 2024, 10, 2862–2885. [Google Scholar] [CrossRef]

- Butola, R.; Malhotra, A.; Yadav, M.; Singari, R.; Murtaza, Q.; Chandra, P. Experimental Studies on Mechanical Properties of Metal Matrix Composites Reinforced with Natural Fibres Ashes; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2019. [Google Scholar]

- Lancaster, L.; Lung, M.H.; Sujan, D. Utilization of agro-industrial waste in metal matrix composites: Towards sustainability. Proceedings of World Academy of Science, Engineering and Technology, Zürich, Switzerland, 14–15 January 2013; p. 1136. [Google Scholar]

- Dixit, P.; Suhane, A. Aluminum metal matrix composites reinforced with rice husk ash: A review. Mater. Today Proc. 2022, 62, 4194–4201. [Google Scholar] [CrossRef]

- Yadav, A.K.; Pandey, K.M.; Dey, A. Aluminium metal matrix composite with rice husk as reinforcement: A review. Mater. Today Proc. 2018, 5, 20130–20137. [Google Scholar] [CrossRef]

- Okokpujie, I.P.; Tartibu, L. Corrosion behaviour of coconut rice and eggshell reinforced aluminium metal matrix composites in 0.4 M H2SO4. Adv. Mater. Proc. Technol. 2024, 10, 2983–2997. [Google Scholar]

- Okokpujie, I.P.; Tartibu, L.K.; Babaremu, K.; Akinfaye, C.; Ogundipe, A.T.; Akinlabi, E.T. Study of the corrosion, electrical, and mechanical properties of aluminium metal composite reinforced with coconut rice and eggshell for wind turbine blade development. Clean. Eng. Technol. 2023, 13, 100627. [Google Scholar] [CrossRef]

- Siva, R.; Valarmathi, T.N.; Palanikumar, K. Effects of magnesium carbonate concentration and lignin presence on properties of natural cellulosic Cissus quadrangularis fiber composites. Int. J. Biol. Macromol. 2020, 164, 3611–3620. [Google Scholar] [CrossRef] [PubMed]

- Sari, N.H.; Sari, S.; Sutaryono, Y.A.; Khan, M.A. A review: Fracture structure of natural fiber surface after treatment with various alkali chemicals. J. Fib. Polym. Compos. 2024, 3, 158–180. [Google Scholar]

- Sarada, B.N.; Murthy, P.S.; Ugrasen, G.J. Hardness and wear characteristics of hybrid aluminium metal matrix composites produced by stir casting technique. Mater. Today Proc. 2015, 2, 2878–2885. [Google Scholar] [CrossRef]

- Aliyu, I.; Sapuan, S.M.; Zainudin, E.S.; Mohamed Yusoff, M.Z.; Yahaya, R.; Aiza Jaafar, C.N. An overview of mechanical and corrosion properties of aluminium matrix composites reinforced with plant based natural fibres. Phys. Sci. Rev. 2024, 9, 357–386. [Google Scholar] [CrossRef]

- Venkataravanappa, R.Y.; Lakshmikanthan, A.; Kapilan, N.; Chandrashekarappa, M.P.G.; Der, O.; Ercetin, A. Physico-mechanical property evaluation and morphology study of moisture-treated hemp–banana natural-fiber-reinforced green composites. J. Compos. Sci. 2023, 7, 266. [Google Scholar] [CrossRef]

- Costa, R.D.; Sales-Contini, R.C.; Silva, F.J.; Sebbe, N.; Jesus, A.M. A critical review on fiber metal laminates (FML): From manufacturing to sustainable processing. Metals 2023, 13, 638. [Google Scholar] [CrossRef]

- Botelho, E.C.; Almeida, R.S.; Pardini, L.C.; Rezende, M.C. Influence of hygrothermal conditioning on the elastic properties of Carall laminates. Appl. Compos. Mater. 2019, 14, 209–222. [Google Scholar] [CrossRef]

- Dadej, K.; Bienias, J.; Surowska, B. On the effect of glass and carbon fiber hybridization in fiber metal laminates: Analytical, numerical and experimental investigation. Comp. Struct. 2019, 220, 250–260. [Google Scholar] [CrossRef]

- Vogelesang, L.B.; Gunnink, J.W. ARALL: A materials challenge for the next generation of aircraft. Mater. Des. 1986, 7, 287–300. [Google Scholar] [CrossRef]

- Moriniere, F.D.; Alderliesten, R.C.; Benedictus, R. Low-velocity impact energy partition in GLARE. Mech. Mater. 2013, 66, 59–68. [Google Scholar] [CrossRef]

- Doğan, M.A.; Yazman, Ş.; Gemi, L.; Yildiz, M.; Yapici, A. A review on drilling of FML stacks with conventional and unconventional processing methods under different conditions. Compos. Struct. 2022, 297, 115913. [Google Scholar] [CrossRef]

- Asundi, A.; Choi, A.Y. Fiber metal laminates: An advanced material for future aircraft. J. Mater. Process. Technol. 1997, 63, 384–394. [Google Scholar] [CrossRef]

- Ucan, H.; Apmann, H.; Graßl, G.; Krombholz, C.; Fortkamp, K.; Nieberl, D.; Schmick, F.; Nguyen, C.; Akin, D. Production technologies for lightweight structures made from fibre–metal laminates in aircraft fuselages. CEAS Aeronaut. J. 2019, 10, 479–489. [Google Scholar] [CrossRef]

- Chen, J.F.; Morozov, E.V.; Shankar, K. Progressive failure analysis of perforated aluminium/CFRP fibre metal laminates using a combined elastoplastic damage model and including delamination effects. Compos. Struct. 2014, 114, 64–79. [Google Scholar] [CrossRef]

- Iernutan, R.A.; Babota, F.; Istoan, R. Carbon fibre reinforced aluminium mesh composite materials. Procedia Manuf. 2019, 32, 901–907. [Google Scholar] [CrossRef]

- Zalosh, R. Deflagration suppression using expanded metal mesh and polymer foams. J. Loss Prev. Process Ind. 2007, 20, 659–663. [Google Scholar] [CrossRef]

- Mansor, M.A.; Ahmad, Z.; Abdullah, M.R. Crashworthiness capability of thin-walled fibre metal laminate tubes under axial crushing. Eng. Struct. 2020, 252, 113660. [Google Scholar] [CrossRef]

- Prem Kumar, R.; Muthukrishnan, M.; Felix Sahayaraj, A. Effect of hybridization on natural fiber reinforced polymer composite materials–A review. Polym. Compos. 2023, 44, 4459–4479. [Google Scholar] [CrossRef]

- Karikalan, L.; Chandrasekran, M.; Ramasubramanian, S.; Baskar, S. Hybridization of composites using natural and synthetic fibers for automotive application. Int. J. Sci. Res. Sci. Technol. 2017, 7, 916–920. [Google Scholar]

- Santulli, C. Impact properties of glass/plant fibre hybrid laminates. J. Mater. Sci. 2007, 42, 3699–3707. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Boonyasopon, P.; Rangappa, S.M.; Khan, A.; Siengchin, S. Recent developments and challenges in natural fiber composites: A review. Polym. Compos. 2022, 43, 2545–2561. [Google Scholar] [CrossRef]

- Mittal, V.; Saini, R.; Sinha, S. Natural fiber-mediated epoxy composites–a review. Compos. Part B Eng. 2016, 99, 425–435. [Google Scholar] [CrossRef]

- Parbin, S.; Waghmare, N.K.; Singh, S.K.; Khan, S. Mechanical properties of natural fiber reinforced epoxy composites: A review. Proc. Comp. Sci. 2019, 152, 375–379. [Google Scholar] [CrossRef]

- Capretti, M.; Giammaria, V.; Santulli, C.; Boria, S.; Del Bianco, G. Use of bio-epoxies and their effect on the performance of polymer composites: A critical review. Polymers 2023, 15, 4733. [Google Scholar] [CrossRef]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J. A review on the potential and limitations of recyclable thermosets for structural applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Feng, Y.; Zhang, Z.; Yue, D.; Belko, V.O.; Maksimenko, S.A.; Deng, J.; Sun, Y.; Yang, Z.; Fu, Q.; Liu, B.; et al. Recent progress in degradation and recycling of epoxy resin. J. Mater. Res. Technol. 2024, 32, 2891–2912. [Google Scholar] [CrossRef]

- Santos, A.L.; Nakazato, R.Z.; Schmeer, S.; Botelho, E.C. Influence of anodization of aluminum 2024 T3 for application in aluminum/Cf/epoxy laminate. Compos. B Eng. 2020, 184, 107718. [Google Scholar] [CrossRef]

- Mohammed, I. Fire Properties of Hybrid Composites. J. Technol. Innov. Energy 2022, 1, 4–8. [Google Scholar] [CrossRef]

- Santulli, C.; Kuan, H.T.; Sarasini, F.; De Rosa, I.M.; Cantwell, W.J. Damage characterisation on PP-hemp/aluminium fibre–metal laminates using acoustic emission. J. Compos. Mater. 2013, 47, 2265–2274. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M.; Shahroze, R.M. Fabrication of Fibre Metal Laminate with Flax and Sugar Palm Fibre based Epoxy Composite and Evaluation of their Fatigue Properties. J. Polym. Mater. 2018, 35, 463. [Google Scholar] [CrossRef]

- Caggiano, M.; Saffioti, M.R.; Rotella, G. Fiber Metal Laminates: The Role of the Metal Surface and Sustainability Aspects. J. Compos. Sci. 2025, 9, 35. [Google Scholar] [CrossRef]

- Adeosun, S.O.; Oyetunji, A.; Akpan, E.I. Strength and ductility of forged 1200 aluminum alloy reinforced with steel particles. Niger. J. Technol. 2015, 34, 710–715. [Google Scholar] [CrossRef]

- Naveen, M.R.; Kamaraj, L.; Ponnarengan, H. Adhesion strength and mechanical properties of nanoclay modified hybrid kevlar/jute-epoxy fiber metal laminate. Polym. Compos. 2024, 45, 9936–9947. [Google Scholar] [CrossRef]

- Kirubakaran, R.; Kaliyamoorthy, R.; Munusamy, R.; Annamalai, B. Mechanical and vibration behavior of surface-modified titanium sheet interleaved with woven basalt/flax fiber metal laminates. Polym. Compos. 2023, 44, 8442–8453. [Google Scholar] [CrossRef]

- Peter, P.I.; Adekunle, A.A. A review of ceramic/bio-based hybrid reinforced aluminium matrix composites. Cogent Eng. 2020, 7, 1727167. [Google Scholar] [CrossRef]

- Bahrami, A.; Soltani, N.; Pech-Canul, M.I.; Gutiérrez, C.A. Development of metal-matrix composites from industrial/agricultural waste materials and their derivatives. Crit. Rev. Environ. Sci. Technol. 2016, 46, 143–208. [Google Scholar] [CrossRef]

- Niu, Y.; Du, W.; Tan, H.; Xu, W.; Liu, Y.; Xiong, Y.; Hui, S. Further study on biomass ash characteristics at elevated ashing temperatures: The evolution of K, Cl, S and the ash fusion characteristics. Bioresour. Technol. 2013, 129, 642–645. [Google Scholar] [CrossRef]

- Lei, Z.; Pavia, S. Geopolymer based on biomass ash from agricultural residues. Constr. Build. Mater. 2024, 441, 137471. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash: Part 2. Potential utilisation, technological and ecological advantages and challenges. Fuel 2013, 105, 19–39. [Google Scholar] [CrossRef]

- Kandpal, B.C.; Johri, N.; Kumar, N.; Srivastava, A. Effect of industrial/agricultural waste materials as reinforcement on properties of metal matrix composites. Mater. Today Proc. 2021, 46, 10736–10740. [Google Scholar] [CrossRef]

- Arjmandi, R.; Hassan, A.; Majeed, K.; Zakaria, Z. Rice husk filled polymer composites. Int. J. Polym. Sci. 2015, 2015, 501471. [Google Scholar] [CrossRef]

- Periasamy, K.; Prathap, P.; Arunnath, A.; Madhu, S. Exploring the effect of bio-silica on the mechanical, microstructural, and corrosion properties of aluminium metal matrix composites. Proc. Inst. Mech. Eng. E. J. Proc. Mech. Eng. 2024. [Google Scholar] [CrossRef]

- Osunmakinde, L.; Asafa, T.B.; Agboola, P.O.; Durowoju, M.O. Development of aluminum composite reinforced with selected agricultural residues. Discov. Mater. 2023, 3, 33. [Google Scholar] [CrossRef]

- Magesh, M.; Baruch, L.J.; Oliver, D.G. Microstructure and hardness of aluminium alloy-fused silica particulate composite. Int. J. Innov. Res. Adv. Eng. (IJIRAE) 2014, 1, 199–204. [Google Scholar]

- Jose, J.; Christy, T.V.; Peter, P.E.; Feby, J.A.; George, A.J.; Joseph, J.; Chandra, R.G.; Benjie, N.M. Manufacture and characterization of a novel agro-waste based low cost metal matrix composite (MMC) by compocasting. Mater. Res. Express 2018, 5, 066530. [Google Scholar] [CrossRef]

- Ben, F.; Olubambi, P.A. Investigating the tribological behavior of bioinspired surfaces in agro-waste and alumina reinforced AA6063 matrix composites. Vacuum 2024, 230, 113687. [Google Scholar] [CrossRef]

- Tazari, H.; Siadati, M.H. Synthesis and mechanical properties of aluminum alloy 5083/SiCnp nanocomposites. J. Alloys Compd. 2017, 729, 960–969. [Google Scholar] [CrossRef]

- Kaur, N. An innovative outlook on utilization of agro waste in fabrication of functional nanoparticles for industrial and biological applications: A review. Talanta 2024, 267, 125114. [Google Scholar] [CrossRef]

- Dwivedi, S.P.; Sharma, S.; Mishra, R.K. Tribological behavior of a newly developed AA2014/waste eggshell/SiC hybrid green metal matrix composite at optimum parameters. Green. Proc. Synth. 2018, 7, 48–60. [Google Scholar] [CrossRef]

- Prasad, D.S.; Shoba, C.; Ramanaiah, N. Investigations on mechanical properties of aluminum hybrid composites. J. Mater. Res. Technol. 2014, 3, 79–85. [Google Scholar] [CrossRef]

- Aigbodion, V.S. Bean pod ash nanoparticles a promising reinforcement for aluminium matrix biocomposites. J. Mater. Res. Technol. 2019, 8, 6011–6020. [Google Scholar] [CrossRef]

- Fragassa, C.; Vannucchi de Camargo, F.; Santulli, C. Sustainable biocomposites: Harnessing the potential of waste seed-based fillers in eco-friendly materials. Sustainability 2024, 16, 1526. [Google Scholar] [CrossRef]

- Economou, F.; Papamichael, I.; Rodríguez-Espinosa, T.; Voukkali, I.; Pérez-Gimeno, A.; Zorpas, A.A.; Navarro-Pedreño, J. The Impact of Food Overproduction on Soil: Perspectives and Future Trends. In Planet Earth: Scientific Proposals to Solve Urgent Issues; Nunez-Delgado, A., Ed.; Springer International Publishing: Cham, Switzerland, 2024; pp. 263–292. [Google Scholar]

- Abdulrazaq, A.A.; Ahmed, S.; Mahdi, F.M. Agricultural waste and natural dolomite for green production of aluminum composites. Clean. Eng. Technol. 2023, 12, 100588. [Google Scholar] [CrossRef]

- Oladele, I.O.; Okoro, A.M. The effect of palm kernel shell ash on the mechanical properties of as-cast aluminium alloy matrix composites. Leonardo J. Sci. 2016, 28, 15–30. [Google Scholar]

- Ramesh, M.; Deepa, C.; Aswin, U.S.; Eashwar, H.; Mahadevan, B.; Murugan, D. Effect of alkalization on mechanical and moisture absorption properties of Azadirachta indica (neem tree) fiber reinforced green composites. Trans. Indian Inst. Metals 2017, 70, 187–199. [Google Scholar] [CrossRef]

- Binu Kumar, V.J.; Bensam Raj, J.; Karuppasamy, R.; Thanigaivelan, R. Influence of chemical treatment and moisture absorption on tensile behavior of neem/banana fibers reinforced hybrid composites: An experimental investigation. J. Nat. Fib. 2022, 19, 3051–3062. [Google Scholar] [CrossRef]

- Babu, B.; Bensam Raj, J.; Jeya Raj, R.; Roshan Xavier, X. Investigation on the mechanical properties of natural composites made with Indian almond fiber and neem seed particulates. Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci. 2023, 237, 3908–3915. [Google Scholar] [CrossRef]

- Jannet, S.; Raja, R.; Arumugaprabu, V.; Kumar, G.V.; Vigneshwaran, S.; Sreekanth, P.R.; Naresh, K. Effect of neem seed biochar on the mechanical and wear properties of aluminum metal matrix composites fabricated using stir casting. Mater. Today Proc. 2022, 56, 1507–1512. [Google Scholar] [CrossRef]

- Ochuokpa, E.O.; Sumaila, D.S.; Adebisi, A. Development of aluminium based mango seed Mangifera indica shell ash (MSSA) particulate metal matrix composite. Int. J. Eng. Mater. Manuf. 2021, 6, 176–186. [Google Scholar]

- Atuanya, C.U.; Ibhadode, A.O.A.; Dagwa, I.M. Effects of breadfruit seed hull ash on the microstructures and properties of Al–Si–Fe alloy/breadfruit seed hull ash particulate composites. Results Phys. 2012, 2, 142–149. [Google Scholar] [CrossRef]

- Government, R.M.; Okeke, E.T.; Oladimeji, A.T.; Ani, A.K.; Onukwuli, O.D.; Odera, R.S. Effect of using different chemically modified breadfruit peel fiber in the reinforcement of LDPE composite. Mater. Test. 2021, 63, 286–292. [Google Scholar] [CrossRef]

- Satoto, R.; Rohmah, S.; Suhandi, A. Physical and mechanical of breadfruit leaves-polyethylene composites. IOP Conf. Ser. Earth Environ. Sci. 2017, 60, 012011. [Google Scholar] [CrossRef]

- Ezechukwu, V.C.; Nwobi-Okoye, C.C.; Atanmo, P.N.; Aigbodion, V.S. Wear Performance of Value-Addition Epoxy/Breadfruit Seed Shell Ash Particles and Functionalized Momordica Angustisepala Fiber Hybrid Composites. J. Compos. Adv. Mater. 2020, 30, 195. [Google Scholar] [CrossRef]

- Dara, J.E.; Omenyi, S.N.; Nwigbo, S.C. Potentials of castor seed shell as a reinforcement in aluminum matrix composite development. UNIZIK J. Eng. Appl. Sci. 2021, 19, 400–408. [Google Scholar]

- Duran, A.J.F.P.; Lyra, G.P.; Campos Filho, L.E.; Martins, R.H.B.; Bueno, C.; Rossignolo, J.A.; Fiorelli, J. The Use of Castor Oil Resin on Particleboards: A Systematic Performance Review and Life Cycle Assessment. Sustainability 2025, 17, 3609. [Google Scholar] [CrossRef]

- Abel, S.; Jule, L.T.; Gudata, L.; Nagaraj, N.; Shanmugam, R.; Dwarampudi, L.P.; Stalin, B.; Ramaswamy, K. Preparation and characterization analysis of biofuel derived through seed extracts of Ricinus communis (castor oil plant). Sci. Rep. 2022, 12, 11021. [Google Scholar] [CrossRef]

- Karayannis, V.G.; Moutsatsou, A.K. Fabrication of MMCs from metal and alloy powders produced from scrap. J. Mater. Proc. Technol. 2006, 171, 295–300. [Google Scholar] [CrossRef]

- Anggono, A.D.; Faishal, A.; Aditya, E.B. An analytical study of metal matrix composite materials for railway brake pad applications. Int. J. Adv. Technol. Eng. Explor. 2024, 11, 1325. [Google Scholar]

- Dirisu, J.O.; Okokpujie, I.P.; Joseph, O.O.; Oyedepo, S.O.; Falodun, O.; Tartibu, L.K.; Shehu, F.D. Sustainable Biocomposites Materials for Automotive Brake Pad Application: An Overview. J. Renew. Mater. 2024, 12, 485–511. [Google Scholar] [CrossRef]

- Lyu, Y.; Olofsson, U. On black carbon emission from automotive disc brakes. J. Aerosol Sci. 2020, 148, 105610. [Google Scholar] [CrossRef]

- Maleque, M.A.; Atiqah, A.; Talib, R.J.; Zahurin, H. New natural fibre reinforced aluminium composite for automotive brake pad. Int. J. Mech. Mater. Eng. 2012, 7, 166–170. [Google Scholar]

- Moulleswaran, S.K.; Gopal, E.; Ramesh, K.P.M.; Ravikumar, M.; Sakthivel, R. Structural and thermal study of aluminum hybrid composite alloy reinforced with silicon carbide and rice husk ash for automobile brake drum. Ann. Fac. Eng. Hunedoara 2017, 15, 31–39. [Google Scholar]

- Yekinni, A.A.; Durowoju, M.O.; Agunsoye, J.O.; Mudashiru, L.O.; Animashaun, L.A.; Sogunro, O.D. Automotive application of hybrid composites of aluminium alloy matrix: A review of rice husk ash based reinforcements. Int. J. Compos. Mater. 2019, 9, 44–52. [Google Scholar]

- Bawa, M.A.; Umaru, O.B.; Abur, B.T.; Salako, I.; Jatau, J.S. Effect of locust bean pod ash on the hardness and wear rate of heat treated A356 alloy metal matrix composite for production of automobile brake rotor. Int. J. Res. Publ. 2020, 57, 36–43. [Google Scholar] [CrossRef]

- Kumar, V.V.; Dhanalakshmi, S.; Raghunathan, V.; Ayyappan, V.; Sanjay, M.R.; Siengchin, S. Characterization of Allium sativum stalk-based biomass for automotive brake pad applications. Biomass Convers. Biorefin. 2024, 15, 9215–9228. [Google Scholar] [CrossRef]

- Pinca-Bretotean, C.; Josan, A.; Sharma, A.K. Composites based on sustainable biomass fiber for automotive brake pads. Mater. Plast. 2024, 61, 24–33. [Google Scholar] [CrossRef]

- Anggraeni, S.; Anshar, A.N.; Maulana, A.; Nurazizah, S.; Nurjihan, Z.; Putri, S.R.; Nandiyanto, A.B.D. Mechanical properties of sawdust and rice husk brake pads with variation of composition and particle size. J. Eng. Sci. Technol. 2022, 17, 2390–2401. [Google Scholar]

- Kunaroop, N.; Rimdusit, S.; Mora, P.; Hiziroglu, S.; Jubsilp, C. Carbonized hemp hurd powder for eco-friendly polybenzoxazine composite brake material: Excellent friction property and high mechanical performance. Arab. J. Chem. 2024, 17, 105769. [Google Scholar] [CrossRef]

- Braga, G.G.; Giusti, G.; dos Santos, J.C.; Silva, D.A.L.; Christoforo, A.L.; Panzera, T.H.; Scarpa, F. Life cycle assessment of fibre metal laminates: An ecodesign approach. Compos. C 2024, 13, 100435. [Google Scholar] [CrossRef]

- Papa, I.; Formisano, A.; Lopresto, V.; Cimino, F.; Vitiello, L.; Russo, P. Water ageing effects on the mechanical properties of flax fibre fabric/polypropylene composite laminates. J. Compos. Mater. 2020, 54, 3481–3489. [Google Scholar] [CrossRef]

- Tian, F.; Zhong, Z.; Pan, Y. Modeling of natural fiber reinforced composites under hygrothermal ageing. Compos. Struct. 2018, 200, 144–152. [Google Scholar] [CrossRef]

- dos Santos, J.C.; de Oliveira, L.A.; Panzera, T.H.; Remillat, C.D.; Farrow, I.; Placet, V.; Scarpa, F. Ageing of autoclaved epoxy/flax composites: Effects on water absorption, porosity and flexural behaviour. Compos. B Eng. 2020, 202, 108380. [Google Scholar] [CrossRef]