Influence of Laminated Expanded Clay Proportion on Mortar Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Portland Cement

2.2. Aggregates

2.3. Preparation of Formulations

2.4. Mortar Characterization

2.5. Data Processing and Analysis

3. Results

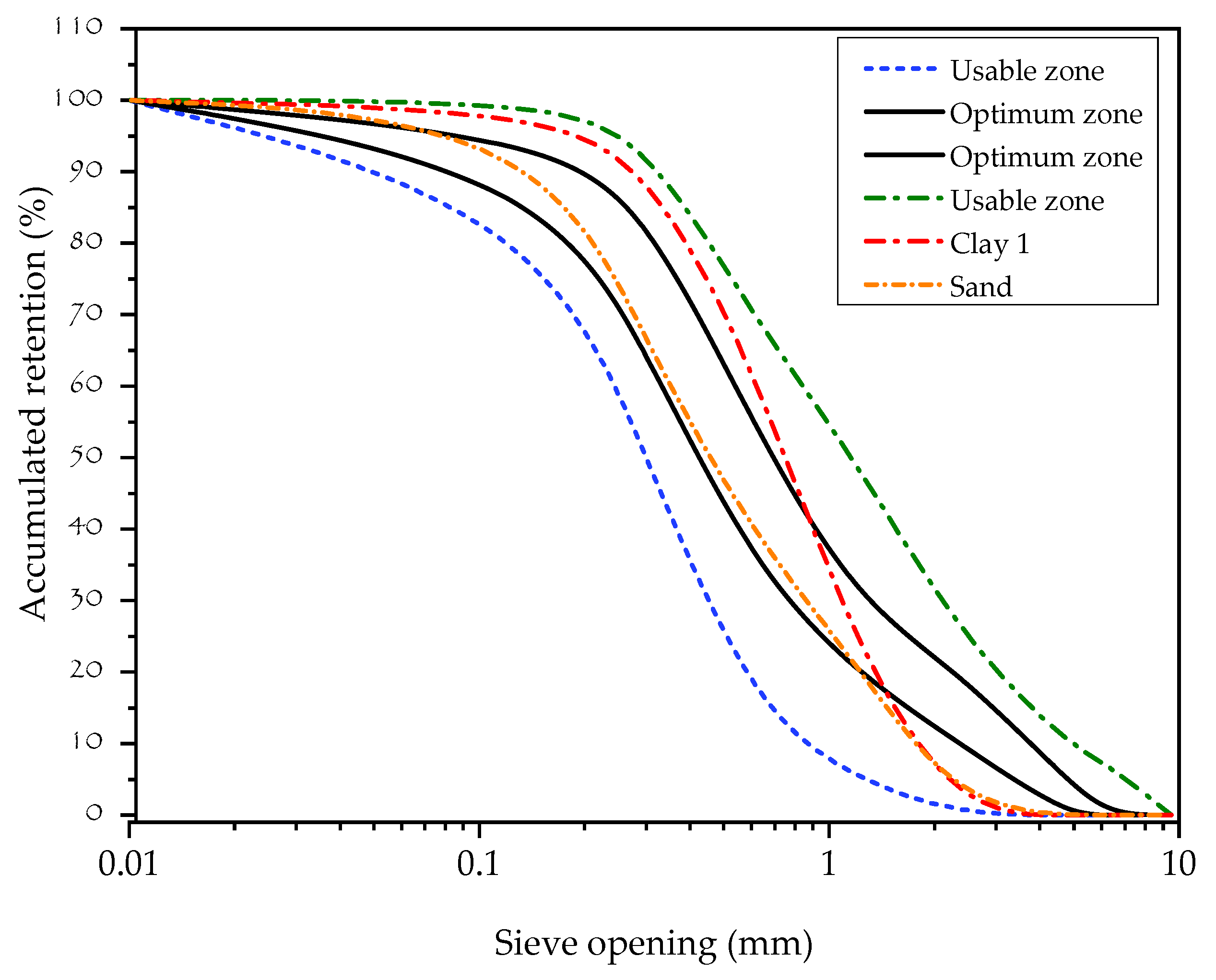

3.1. Characterization of Raw Materials

3.2. Characterization of Mortars in the Fresh State

3.2.1. Consistency Index

3.2.2. Fresh Mass Density

3.3. Characterization of Mortars in the Hardened State

3.3.1. Real Specific Mass

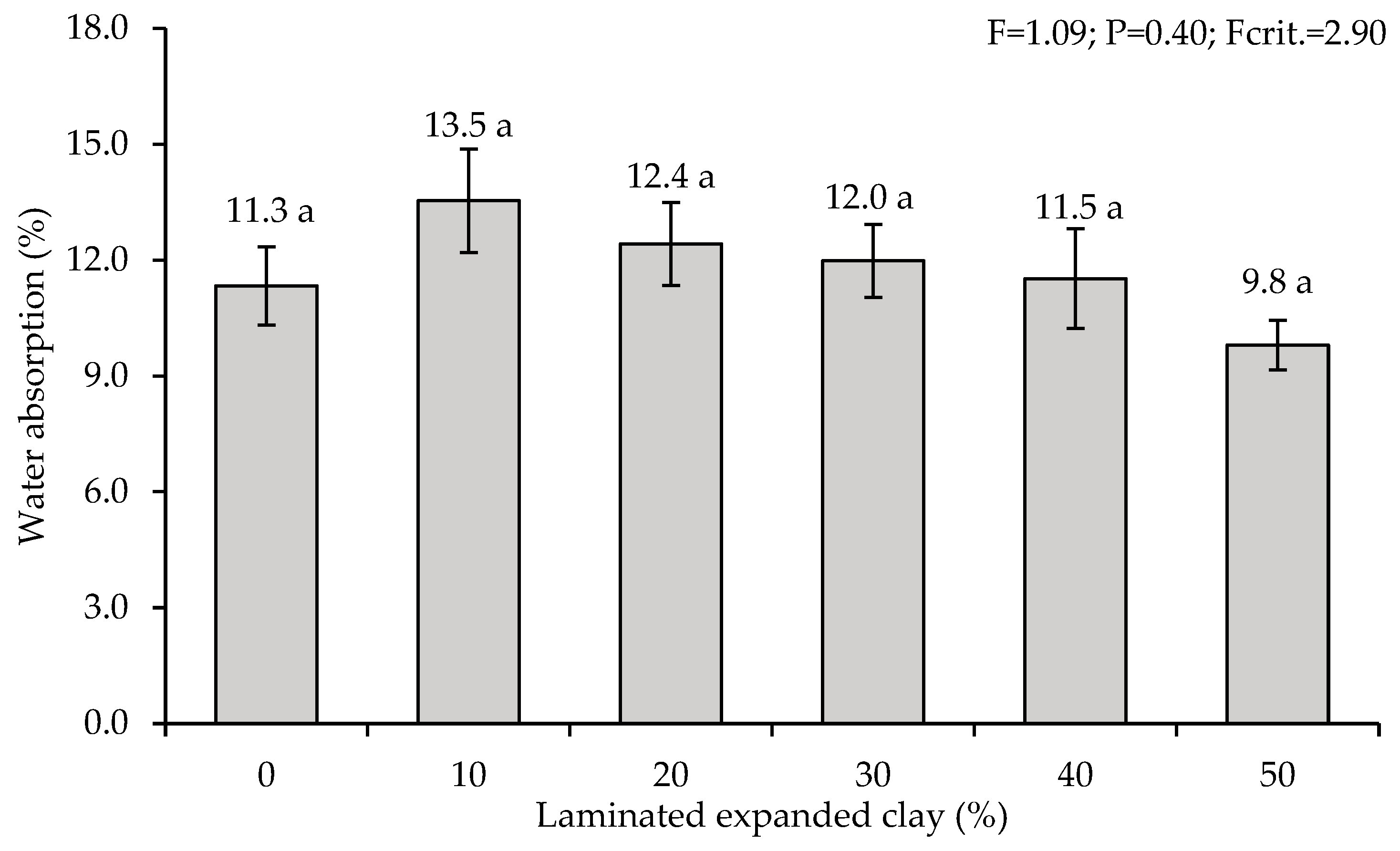

3.3.2. Water Absorption

3.3.3. Water Absorption by Capillarity

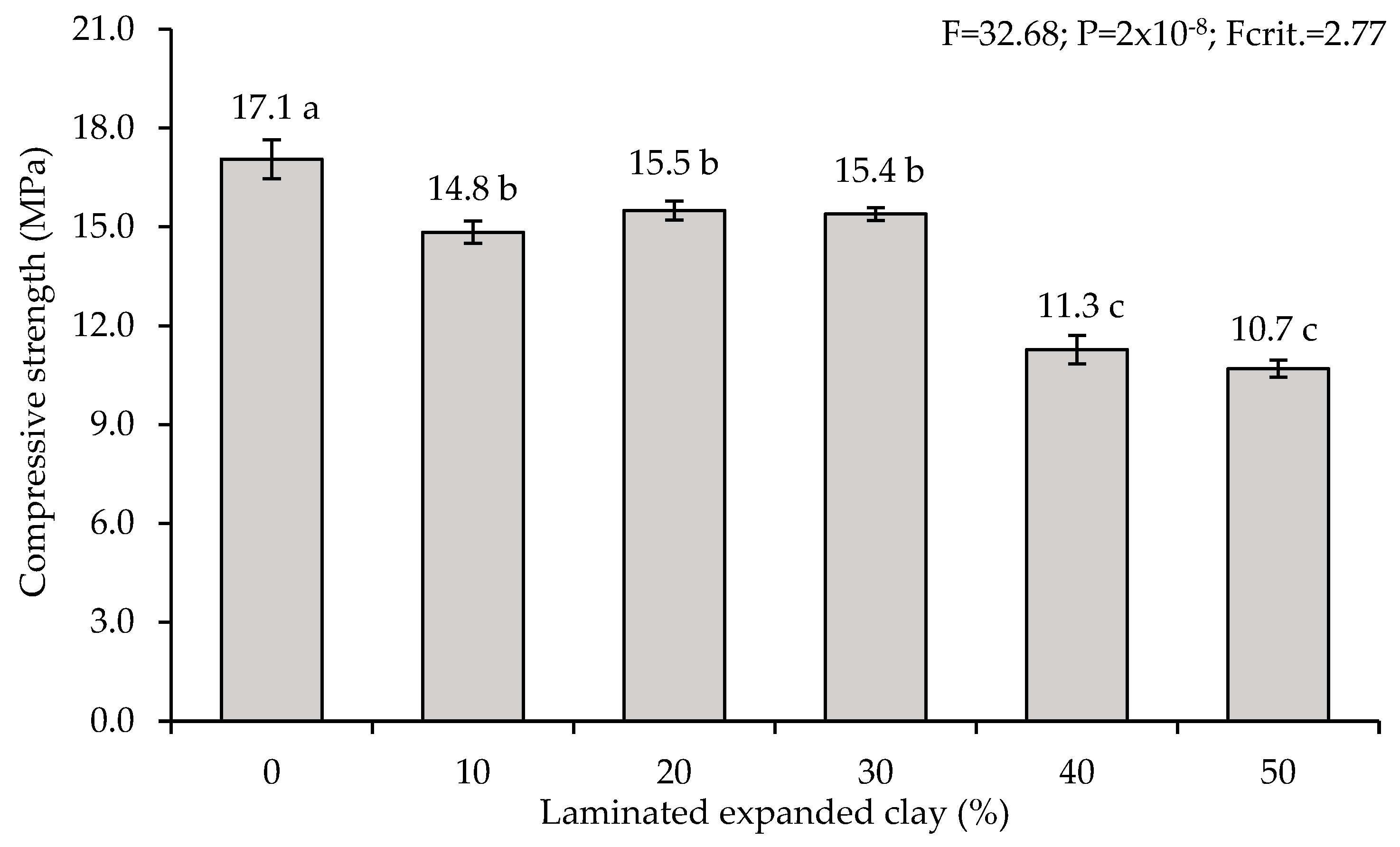

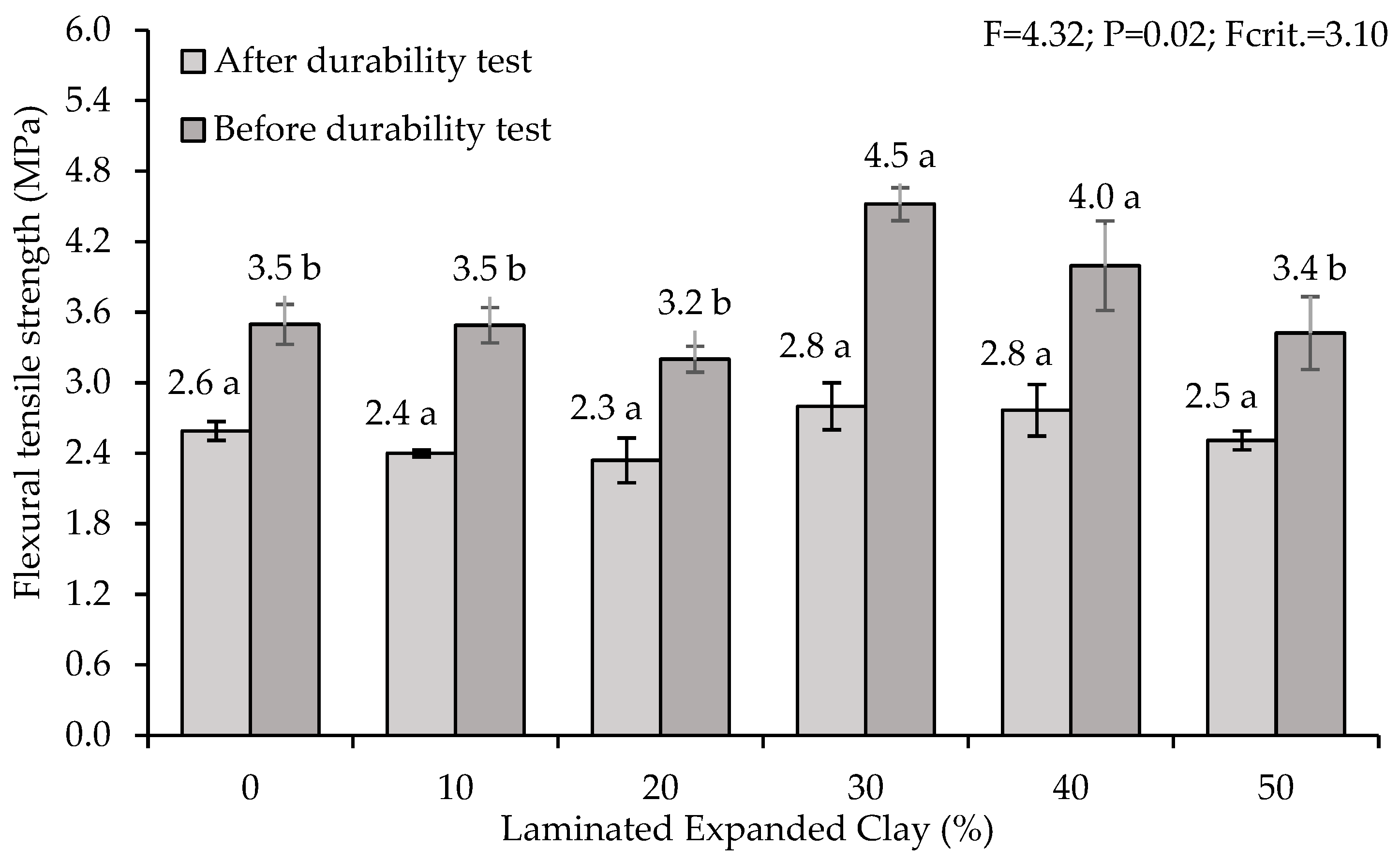

3.3.4. Compressive and Tensile Strengths in Bending

3.3.5. Tensile Strength of Adhesion

3.3.6. Durability

3.3.7. Coefficient of the Constructive Quality (CCQ)

4. Discussion

4.1. Raw Materials

4.2. Physical Characterization of Mortars

4.3. Mechanical Characterization of Mortars

4.4. Durability and Coefficient of the Constructive Quality

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salgueiro, T.; SamaGaio, A.; Gonçalves, M.; Figueiredo, A.; Labrincha, J.; Silva, L. Incorporation of Phase Change Materials in an Expanded Clay Containing Mortar for Indoor Thermal Regulation of Buildings. J. Energy Storage 2021, 36, 102385. [Google Scholar] [CrossRef]

- Fontes, A.É.M.S.; Cabral, K.C.; Souza, W.R.M.; Martinelli, A.E.; Fontes, K.E.S. Análise Mecânica e Térmica de Argamassas de Revestimento com Peças Parciais do Agregado por Argila Expandida. Ambiente Construído 2022, 22, 299–311. [Google Scholar] [CrossRef]

- Becker, A.R.; Silva, C.T.O.; Lintz, R.C.C.; Gachet, L.A. Estudo das Propriedades Mecânicas, Acústicas e Microestruturais de Argamassas Leves Produzidas com Argila Expandida. Mater. Today Proc. 2022, 65, 1222–1229. [Google Scholar] [CrossRef]

- Ruiperez, A.M.; Rodriguez, A.; Gonzalez, S.G.; Calderon, V. Lightweight Masonry Mortars Made with Expanded Clay and Recycled Aggregates. Constr. Build. Mater. 2016, 118, 139–145. [Google Scholar] [CrossRef]

- Gündüz, L.; Kalkan, Ş.O. A Technical Evaluation on Determining Thermal Comfort Parametric Properties of Different-Originated Expanded and Exfoliated Aggregates. Arab. J. Geosci. 2019, 12, 119. [Google Scholar] [CrossRef]

- Ortega, J.M.; Branco, F.G.; Pereira, L.; Marques, L. Resistência à Entrada de Cloretos, Microestrutura e Propriedades Mecânicas de Argamassas Leves com Cortiça Natural e Argila Expandida Preparada com Cimentos Mistos Sustentáveis. J. Mar. Sci. Eng. 2022, 10, 1174. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 11579: Cimento Portland—Determinação do Índice de Finura por Meio da Peneira 75 μm (nº 200); ABNT: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16606: Cimento Portland—Determinação da Pasta de Consistência Normal; ABNT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16607: Cimento Portland—Determinação dos Tempos de Pega; ABNT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16605: Cimento Portland e Outros Materiais em Pó—Determinação da Massa Específica; ABNT: Rio de Janeiro, Brazil, 2017. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 11582: Cimento Portland—Determinação da Expansibilidade Le Chatelier; ABNT: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 17054: Agregados: Determinação da Composição Granulométrica; ABNT: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16972: Agregados—Determinação da Massa Unitária e do Índice de Vazios; ABNT: Rio de Janeiro, Brazil, 2021. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16916: Agregado Miúdo—Determinação da Densidade e da Absorção de Água*; ABNT: Rio de Janeiro, Brazil, 2021. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 7215: Determinação da Resistência à Resistência de Corpos de Prova Cilíndricos; ABNT: Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13276: Argamassa para Assentamento e Revestimento de Paredes e Tetos—Determinação do Índice de Consistência; ABNT: Rio de Janeiro, Brazil, 2016. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13278: Argamassa para Assentamento e Revestimento de Paredes e Tetos—Determinação do Teor de Ar Incorporado; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 9778: Argamassa e Concretos Suportados—Determinação da Captação de Água, Índice de Vazios e Massa Específica; ABNT: Rio de Janeiro, Brazil, 2009. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13279: Argamassa para Assentamento e Revestimento de Paredes e Tetos—Determinação da Resistência à Tração na Flexão e à Elasticidade; ABNT: Rio de Janeiro, Brazil, 2005. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 9779: Argamassas e Concretos Suportáveis—Determinação da Absorção de Água por Capilaridade; ABNT: Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13528-2: Revestimento de Paredes de Argamassas Inorgânicas—Determinação da Resistência de Aderência à Tração; ABNT: Rio de Janeiro, Brazil, 2019. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13583: Cimento Portland—Determinação da Variação Dimensional de Barras de Argamassa de Cimento Portland Expostas à Solução de Sulfato de Sódio; ABNT: Rio de Janeiro, Brazil, 2014. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 16697: Cimento Portland—Requisitos; ABNT: Rio de Janeiro, Brazil, 2018. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 7211: Agregados para Concreto—Requisitos; ABNT: Rio de Janeiro, Brazil, 2022. [Google Scholar]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 12655: Concreto de Cimento Portland—Preparação, Controle, Coleta e Acesso—Procedimento; ABNT: Rio de Janeiro, Brazil, 2015. [Google Scholar]

- CINEXPAN. Ficha Técnica. Available online: https://www.cinexpan.com.br/argila-expandida-1506-cinexpan.html (accessed on 1 August 2024).

- Rossignolo, J.A. Concreto Leve Estrutural: Produção, Propriedades, Microestrutura e Aplicações, 1st ed.; Pini: São Paulo, Brazil, 2009. [Google Scholar]

- Silva, A.C.G.; Becker, A.R.; Silva, C.T.O.; Marçula, S.C.; Pereira, L.S.; Gachet, L.A.; Gomes, A.E.; Lintz, R.C.C. Comparison of the Properties of Mortars Containing Expanded Clay, Vermiculite, and Rubber Residue. Cerâmica 2023, 69, 325–331. [Google Scholar] [CrossRef]

- Moravia, W.G.; Oliveira, C.A.S.; Gumieri, A.G.; Vasconcelos, W.L. Microstructural Evaluation of Expanded Clay to be Used as Lightweight Aggregate in Structural Concrete. Cerâmica 2006, 52, 193–199. [Google Scholar] [CrossRef]

- Malaiskiene, J.; Skripkiunas, G.; Vaiciene, M.; Karpova, E. The Influence of Aggregate Type on W/C Ratio on the Strength and Other Properties of Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2017, 251, 012025. [Google Scholar] [CrossRef]

- Associação Brasileira de Normas Técnicas (ABNT). NBR 13281: Argamassas Inorgânicas—Requisitos e Métodos de Ensaio. Parte 1: Argamassa para Revestimento de Paredes e Tetos; ABNT: Rio de Janeiro, Brazil, 2023. [Google Scholar]

- Souto, B.C.C. Estudo da Influência do Fator Água/Cimento na Confeção de Compósitos Cimentícios com Argila Expandida e Seus Impactos na Microestrutura. Master’s Thesis, Universidade Federal da Paraíba, João Pessoa, Brazil, 2022. [Google Scholar]

- Ozkiliç, Y.O.; Karalar, M.; Aksoylu, C.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban, E.M.; Azevedo, A.R. Shear Performance of Reinforced Expansive Concrete Beams Utilizing Aluminium Waste. J. Mater. Res. Technol. 2023, 24, 5433–5448. [Google Scholar] [CrossRef]

- Vaiciene, M.; Malaiskiene, J.; Kizinievic, O. Possibilities of Plastic Waste Application in Expanded Clay Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 032009. [Google Scholar] [CrossRef]

- Borja, E.V. Efeito da Adição de Argila Expandida e Adições Minerais na Formulação de Concretos Estruturais Leves Autoadensáveis. Ph.D. Thesis, Universidade Federal do Rio Grande do Norte, Natal, Brazil, 2011. [Google Scholar]

- Angelin, A.F. Concreto Nível Estrutural—Desempenho Físico, Térmico, Mecânico e Microestruturais. Master’s Thesis, Universidade Estadual de Campinas, Limeira, Brazil, 2014. [Google Scholar]

- Cintra, C.L.D.; Paiva, A.E.M.; Baldo, J.B. Masonry Mortars Containing Expanded Vermiculite and Rubber Aggregates from Recycled Tires—Relevant Properties. Cerâmica 2014, 60, 69–76. [Google Scholar] [CrossRef]

- Koksal, F.; Gencel, O.; Kaya, M. Combined Effect of Silica Fume and Expanded Vermiculite on Properties of Lightweight Mortars at Ambient and Elevated Temperatures. Constr. Build. Mater. 2015, 88, 175–187. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Lu, Z.; Li, Z. Paraffin/Expanded Vermiculite Composite Phase Change Material as Aggregate for Developing Lightweight Thermal Energy Storage Cement-Based Composites. Appl. Energy 2015, 160, 358–367. [Google Scholar] [CrossRef]

- Barros, I.M.S. Análise Térmica e Mecânica de Argamassas de Revestimento com Adição de Vermiculita Expandida em Substituições ao Agregado. Master’s Thesis, Universidade Federal do Rio Grande do Norte, Natal, Brazil, 2018. [Google Scholar]

- Kasinikota, P.; Tripura, D.D. Evaluation of Compressed Stabilized Earth Block Properties Using Crushed Brick Waste. Constr. Build. Mater. 2021, 280, 122520. [Google Scholar] [CrossRef]

- Bouikni, A.; Bali, A. Durability properties of concrete containing 50% and 65% slag. Constr. Build. Mater. 2009, 23, 2836–2845. [Google Scholar] [CrossRef]

| Identification | C:A | Water | Adittive | Sand | Clay |

|---|---|---|---|---|---|

| ---------------------- Ratio -------------------- | --------------- % --------------- | ||||

| Ae0 | 1:3 | 0.5 | 0.3 | 100 | 0 |

| Ae10 | 1:3 | 0.5 | 0.3 | 90 | 10 |

| Ae20 | 1:3 | 0.5 | 0.3 | 80 | 20 |

| Ae30 | 1:3 | 0.5 | 0.3 | 70 | 30 |

| Ae40 | 1:3 | 0.5 | 0.3 | 60 | 40 |

| Ae50 | 1:3 | 0.5 | 0.3 | 50 | 50 |

| Characteristics | Results | Regulatory Requirements * |

|---|---|---|

| Fineness Index (%) | 0.82 | ≤6.0 |

| Normal Consistency (% water) | 30.30 | - |

| Start of Setting (min) | 160.00 | ≥60 |

| Specific mass (g cm−3) | 3.18 | - |

| Le Chatelier Expansibility (mm) | 4.00 | ≤5.0 |

| Specific Surface Area (cm2 g−1) | 4186 | - |

| Characteristics | Sand | Expanded Clay |

|---|---|---|

| Fineness modulus | 2.24 | 2.96 |

| Maximum diameter (mm) | 2.36 | 2.36 |

| Specific mass (g cm−3) | 2.50 | 1.43 |

| Water absorption (%) | 0.50 | 5.13 |

| Unit mass in loose state (kg m−3) | 1593 | 936 |

| Unit mass in compacted state (kg m−3) | 1688 | 943 |

| Chemical Compound | Percentage (%) |

|---|---|

| SiO2 | 59.13 |

| Al2O3 | 18.63 |

| FeO3 | 8.48 |

| K2O | 5.31 |

| MgO | 3.56 |

| CaO | 1.98 |

| TiO2 | 0.82 |

| Na2O | 0.58 |

| P2O5 | 0.36 |

| SO3 | 0.11 |

| WO3 | 0.11 |

| BaO | 0.10 |

| MnO | 0.09 |

| ZrO2 | 0.03 |

| Cl | 0.02 |

| Cr2O3 | 0.02 |

| ZnO | 0.02 |

| SrO | 0.01 |

| Y2O3 | 0.01 |

| NiO | 0.01 |

| Calcination loss | 0.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almeida, V.G.d.O.; Farias, K.R.; Souza, V.A.; Melo, F.M.C.d.; Oliveira, H.A.d.; Pimenta, A.S.; Khan, S.; Melo, R.R.d. Influence of Laminated Expanded Clay Proportion on Mortar Properties. J. Compos. Sci. 2025, 9, 309. https://doi.org/10.3390/jcs9060309

Almeida VGdO, Farias KR, Souza VA, Melo FMCd, Oliveira HAd, Pimenta AS, Khan S, Melo RRd. Influence of Laminated Expanded Clay Proportion on Mortar Properties. Journal of Composites Science. 2025; 9(6):309. https://doi.org/10.3390/jcs9060309

Chicago/Turabian StyleAlmeida, Vanessa Gentil de Oliveira, Karolaine Rodrigues Farias, Veluza Anchieta Souza, Fernanda Martins Cavalcante de Melo, Herbet Alves de Oliveira, Alexandre Santos Pimenta, Sabir Khan, and Rafael Rodolfo de Melo. 2025. "Influence of Laminated Expanded Clay Proportion on Mortar Properties" Journal of Composites Science 9, no. 6: 309. https://doi.org/10.3390/jcs9060309

APA StyleAlmeida, V. G. d. O., Farias, K. R., Souza, V. A., Melo, F. M. C. d., Oliveira, H. A. d., Pimenta, A. S., Khan, S., & Melo, R. R. d. (2025). Influence of Laminated Expanded Clay Proportion on Mortar Properties. Journal of Composites Science, 9(6), 309. https://doi.org/10.3390/jcs9060309