Replacing Glass with Basalt in the Vacuum Infusion Process of Vinyl Ester Composite Laminates: Effect on the Mechanical Performance and Life Cycle Assessment (LCA) †

Abstract

1. Introduction

2. Theoretical Background

3. Materials and Methods

3.1. Specimens Preparation

- Layering of the Composite: The individual layers of glass or basalt fibres are carefully arranged in the desired lamination sequence. For this study, the sequence consisted of alternating orientations of fabric layers to optimize mechanical properties.

- Vacuum Infusion: A vacuum bag is placed over the laminate stack, and resin is introduced into the system under vacuum. The resin permeates through the fibre layers, bonding them together and ensuring uniform resin distribution across the panel. The infusion process took place at room temperature, allowing for full resin penetration through the core and adequate adhesion between layers.

3.2. Experimental Tests

3.3. Thermal Analysis Methodology

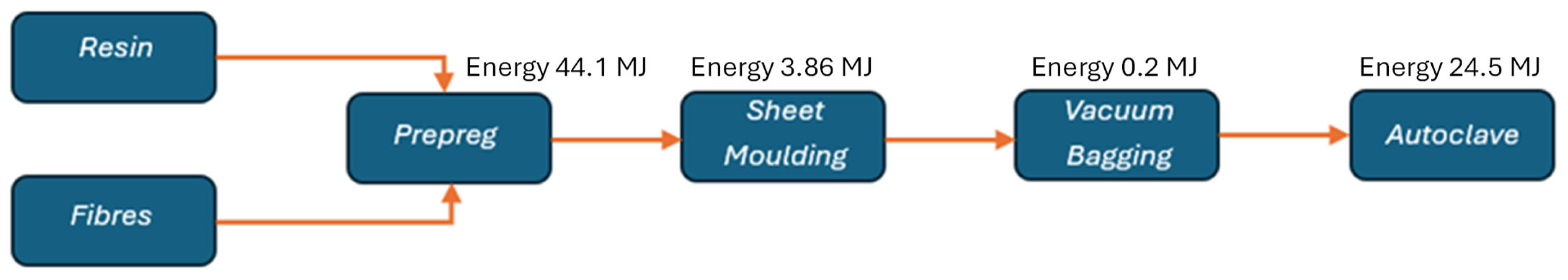

3.4. LCA Goal and Scope Definition

3.5. Life Cycle Inventory

4. Results

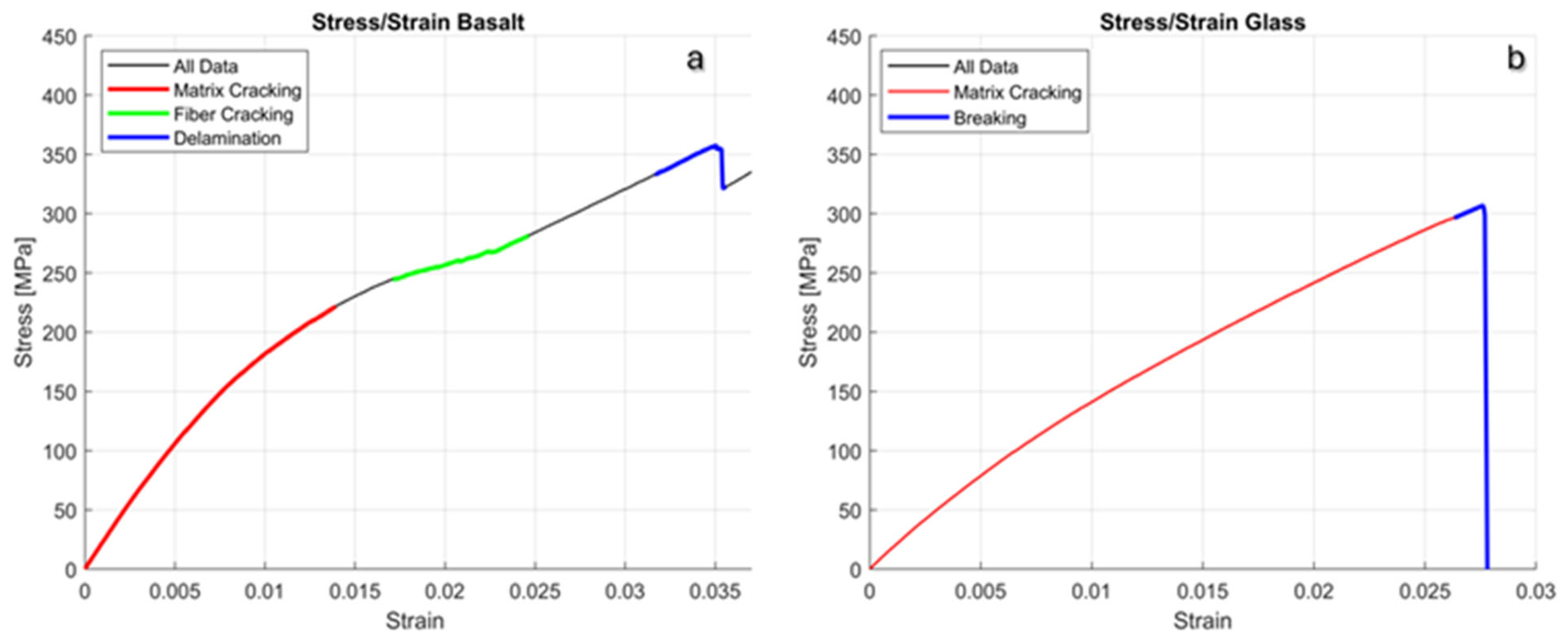

4.1. Static Characterization

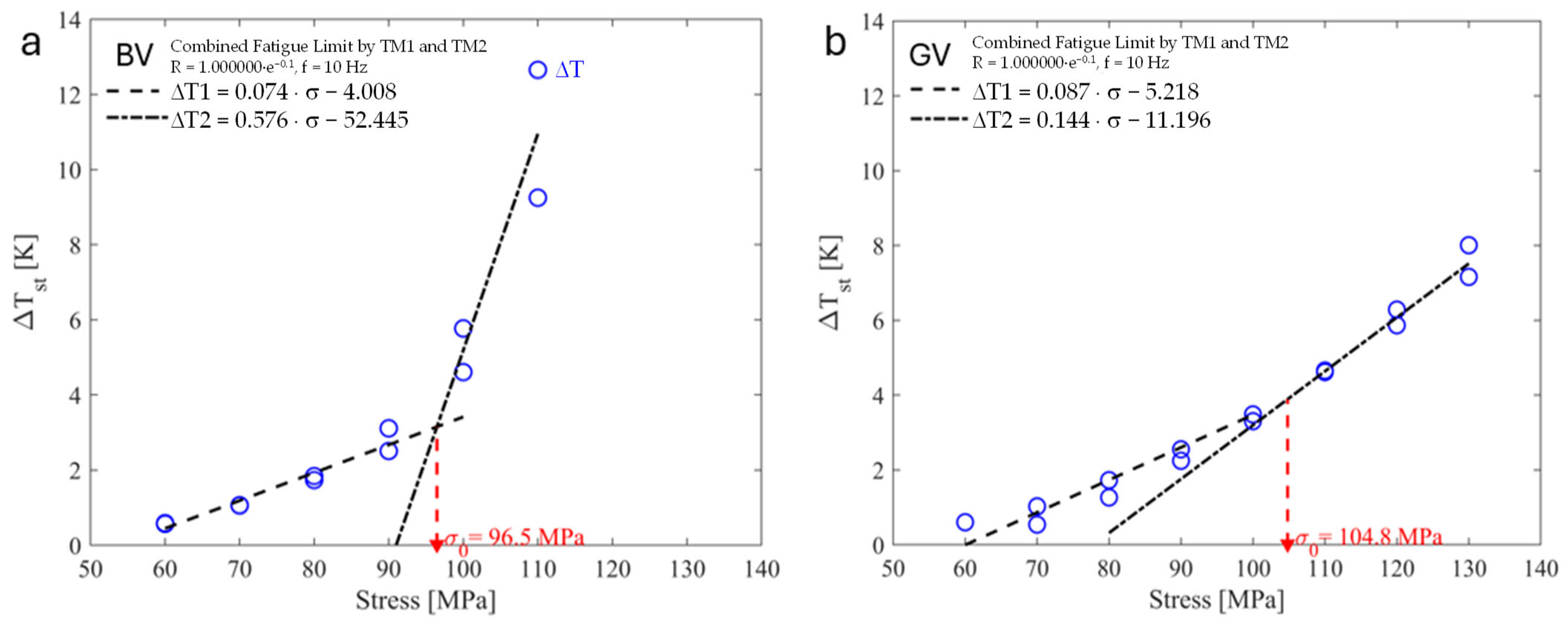

4.2. Fatigue Characterization

4.3. Tensile Failure Analysis

4.4. Life Cycle Impact Assessment

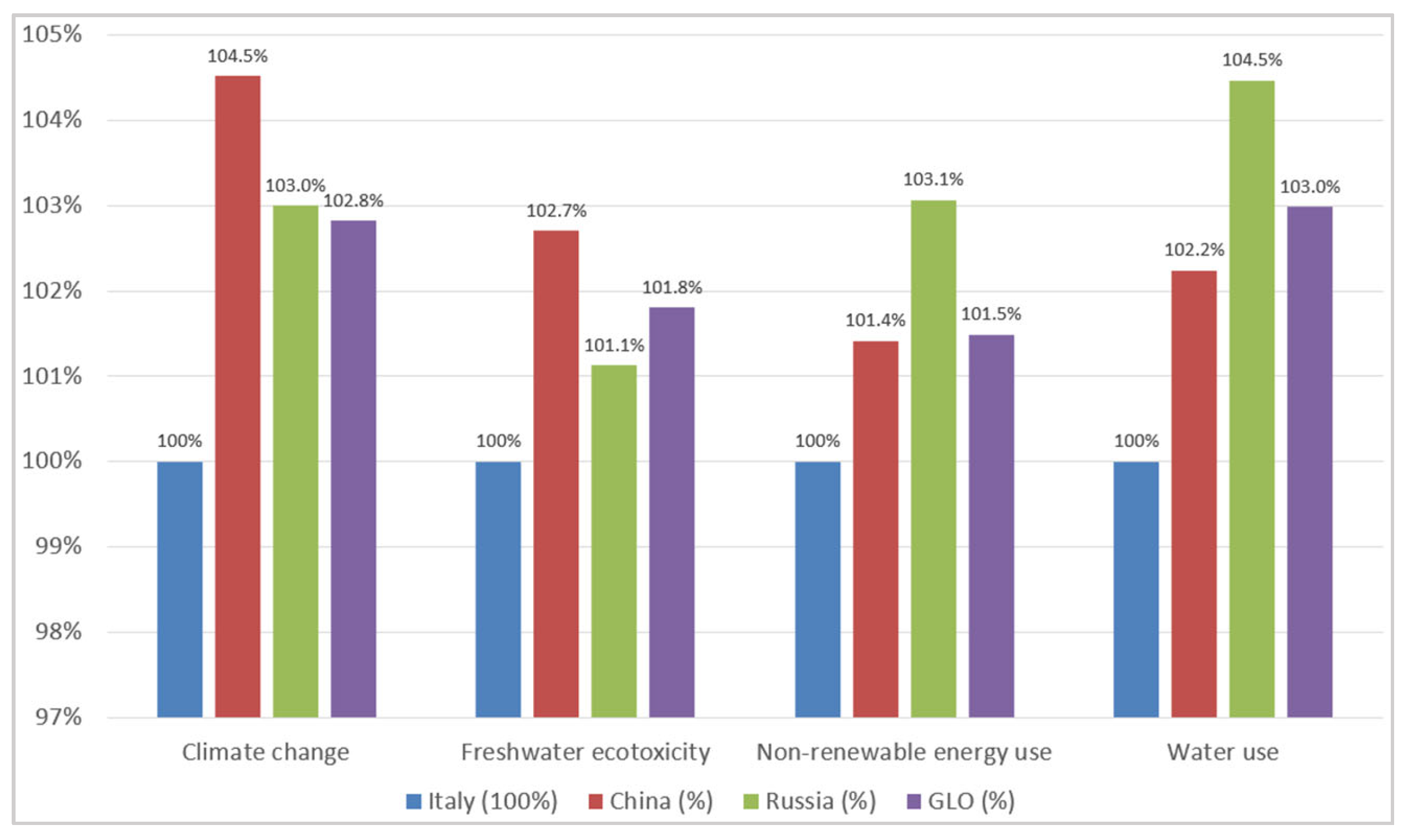

4.5. Geographical Sensitivity Analysis

5. Conclusions

- Basalt fibres exhibit advantageous failure behaviour, offering extended operational lifespans and greater design flexibility.

- The thermal and fatigue analyses further demonstrate the resilience of BFRCs under static and dynamic loads, reinforcing their suitability for demanding industrial applications.

- The results of LCA emphasize the reduced environmental footprint of basalt fibres, including lower greenhouse gas emissions, resource depletion, and toxic substance releases.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Vassilopoulos, A.P. The history of fiber-reinforced polymer composite laminate fatigue. Int. J. Fatigue 2020, 134, 105512. [Google Scholar] [CrossRef]

- Siengchin, S. A review on lightweight materials for defence applications: Present and future developments. Def. Technol. 2023, 24, 1–17. [Google Scholar] [CrossRef]

- Alshahrani, H.; Sebaey, T.A.; Awd Allah, M.M.; Abd El-baky, M.A. Jute-basalt reinforced epoxy hybrid composites for lightweight structural automotive applications. J. Compos. Mater. 2023, 57, 1315–1330. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A review on basalt fibre and its composites. Compos. B Eng. 2015, 74, 74–94. [Google Scholar] [CrossRef]

- Srikavi, A.; Mekala, M. Characterization of Sunn hemp fibers as a substitute for synthetic fibers in composites and various applications. Ind. Crops Prod. 2023, 192, 116135. [Google Scholar] [CrossRef]

- Anand, P.B.; Nagaraja, S.; Jayaram, N.; Sreenivasa, S.P.; Almakayeel, N.; Khan, T.M.Y.; Kumar, R.; Kumar, R.; Ammarullah, M.I. Kenaf fiber and hemp fiber multi-walled carbon nanotube filler-reinforced epoxy-based hybrid composites for biomedical applications: Morphological and mechanical characterization. J. Compos. Sci. 2023, 7, 324. [Google Scholar] [CrossRef]

- Malik, K.; Ahmad, F.; Yunus, N.A.; Gunister, E.; Ali, S.; Raza, A. Physical and mechanical properties of kenaf/flax hybrid composites. J. Appl. Polym. Sci. 2023, 140, e53421. [Google Scholar] [CrossRef]

- Ahmed, J.P.S.; Sudarsan, S.; Parthiban, E.; Trofimov, E.; Sridhar, B. Exploration of mechanical properties of hemp fiber/flax fiber reinforced composites based on biopolymer and epoxy resin. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Prieto, M.I.; Atanes-Sánchez, E. Fire-resistant performance of new sustainable waste-lightened composites with glass and basalt fibres reinforcement. Constr. Build. Mater. 2024, 411, 134620. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Basalt fibers: An environmentally acceptable and sustainable green material for polymer composites. Constr. Build. Mater. 2024, 436, 136834. [Google Scholar] [CrossRef]

- Pavliukevich, Y.; Papko, L.; Trusova, E.; Uvarov, A. Optimization of the basalt glass composition for the continuous fiber production. Chem. Chem. Eng. 2024, 2022, 2. [Google Scholar] [CrossRef]

- Yorseng, K.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Towards green composites: Bioepoxy composites reinforced with bamboo/basalt/carbon fabrics. J. Clean. Prod. 2022, 363, 132314. [Google Scholar] [CrossRef]

- Pareek, K.; Saha, P.; Saha, P. Basalt Fiber and Its Composites: An Overview. In Proceedings of the National Conference on Advances in Structural Technologies (CoAST-2019), Assam, India, 1–3 February 2019; pp. 53–62. [Google Scholar]

- Nagaraju, S.B.; Priya, H.C.; Girijappa, Y.G.T.; Puttegowda, M. Lightweight and sustainable materials for aerospace applications. In Lightweight and Sustainable Composite Materials; Elsevier: Amsterdam, The Netherlands, 2023; pp. 157–178. [Google Scholar]

- Balaji, K.V.; Shirvanimoghaddam, K.; Rajan, G.S.; Ellis, A.V.; Naebe, M. Surface treatment of Basalt fiber for use in automotive composites. Mater. Today Chem. 2020, 17, 100334. [Google Scholar]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; Pemberton, R.; Summerscales, J. Developments and Industrial Applications of Basalt Fibre Reinforced Composite Materials. J. Compos. Sci. 2022, 6, 367. [Google Scholar] [CrossRef]

- Fiore, V.; Di Bella, G.; Valenza, A. Glass-basalt/epoxy hybrid composites for marine applications. Mater. Des. 2011, 32, 2091–2099. [Google Scholar] [CrossRef]

- Liu, J.; Chen, M.; Yang, J.; Wu, Z. Study on Mechanical Properties of Basalt Fibers Superior to E-glass Fibers. J. Nat. Fibers 2022, 19, 882–894. [Google Scholar] [CrossRef]

- Vashıshtha, A.; Sharma, D. Mechanical Performance of Basalt and Glass Woven Composites TT—Mechanical Performance of Basalt and Glass Woven Composites. Tekst. Ve Mühendis 2024, 31, 88–98. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Agrawal, M. A comparative study of static and fatigue performance of glass and basalt fiber reinforced epoxy composites. Polym. Compos. 2024, 45, 3551–3565. [Google Scholar] [CrossRef]

- Cucinotta, F.; Raffaele, M.; Salmeri, F. A Well-to-Wheel Comparative Life Cycle Assessment Between Full Electric and Traditional Petrol Engines in the European Context. In Advances on Mechanics, Design Engineering and Manufacturing III, Proceedings of the International Joint Conference on Mechanics, Design Engineering & Advanced Manufacturing, JCM 2020, Aix-en-Provence, France, 2–4 June 2020; Springer: Berlin/Heidelberg, Germany, 2021; pp. 188–193. [Google Scholar]

- Cucinotta, F.; Barberi, E.; Salmeri, F. A Review on Navigating Sustainable Naval Design: LCA and Innovations in Energy and Fuel Choices. J. Mar. Sci. Eng. 2024, 12, 520. [Google Scholar] [CrossRef]

- Keiser, D.; Schnoor, L.H.; Pupkes, B.; Freitag, M. Life cycle assessment in aviation: A systematic literature review of applications, methodological approaches and challenges. J. Air Transp. Manag. 2023, 110, 102418. [Google Scholar] [CrossRef]

- Curti, G.; La Rosa, G.; Orlando, M.; Risitano, A. Analisi tramite infrarosso termico della temperatura limite in prove di fatica. Proc. XIV Convegno Naz. AIAS 1986, 211–220. [Google Scholar]

- La Rosa, G.; Risitano, A. Thermographic methodology for rapid determination of the fatigue limit of materials and mechanical components. Int. J. Fatigue 2000, 22, 65–73. [Google Scholar] [CrossRef]

- Williams, P.; Liakat, M.; Khonsari, M.M.; Kabir, O.M. A thermographic method for remaining fatigue life prediction of welded joints. Mater. Des. 2013, 51, 916–923. [Google Scholar] [CrossRef]

- Colombo, C.; Vergani, L.; Burman, M. Static and fatigue characterisation of new basalt fibre reinforced composites. Compos. Struct. 2012, 94, 1165–1174. [Google Scholar] [CrossRef]

- Crisafulli, D.; Fintová, S.; Santonocito, D.; D’Andrea, D. Microstructural characterization and mechanical behaviour of laser powder Bed Fusion stainless steel 316L. Theor. Appl. Fract. Mech. 2024, 131, 104343. [Google Scholar] [CrossRef]

- Risitano, A.; Risitano, G. Determining fatigue limits with thermal analysis of static traction tests. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 631–639. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- ISO EN. 14044; Environmental Management, Life Cycle Assessment, Requirements and Guidelines. DIN Deutsches Institut für Normung e. V.: Berlin, Germany, 2006.

- Fořt, J.; Kočí, J.; Černý, R. Environmental efficiency aspects of basalt fibers reinforcement in concrete mixtures. Energies 2021, 14, 7736. [Google Scholar] [CrossRef]

- Ramachandran, K.; Gnanasagaran, C.L.; Vekariya, A. Life cycle assessment of carbon fiber and bio-fiber composites prepared via vacuum bagging technique. J. Manuf. Process 2023, 89, 124–131. [Google Scholar] [CrossRef]

- Scalici, T.; Pitarresi, G.; Badagliacco, D.; Fiore, V.; Valenza, A. Mechanical properties of basalt fiber reinforced composites manufactured with different vacuum assisted impregnation techniques. Compos. B Eng. 2016, 104, 35–43. [Google Scholar] [CrossRef]

- Talabari, A.A.; Alaei, M.H.; Shalian, H.R. Experimental Investigation of Tensile Properties in a Glass/Epoxy Sample Manufactured by Vacuum Infusion, Vacuum Bag and Hand Layup Process. J. Compos. Adv. Mater./Rev. Compos. Matériaux Avancés 2019, 29, 179–182. [Google Scholar] [CrossRef]

- Totaro, M.; Risitano, G.; Di Bella, G.; Crisafulli, D.; D’Andrea, D. A Comparative Study on Mechanical Properties and Failure Mechanisms in Basalt and Glass Fibre Reinforced Composites. Procedia Struct. Integr. 2024, 66, 205–211. [Google Scholar] [CrossRef]

- Fazio, S.; Biganzoli, F.; De Lv Zampori, L.; Sala, S.; Diaconu, E. Supporting Information to the Characterisation Factors of Recommended EF Life Cycle Impact Assessment Methods; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- World Health Organization. INFOSAN Activity Report 2018/2019; Food & Agriculture Org.: Rome, Italy, 2020. [Google Scholar]

| Product Specification upon Delivery | ||

|---|---|---|

| Viscosity | mPa × s | 130–170 |

| Gel time (range 25–35 °C) | min | 65–75 |

| Curing time (range 25–peak) | min | 89–95 |

| Properties of Cast Unfilled Resin | ||

| Hardness | Barcol | 40 |

| Tensile strength | MPa | 78 |

| Tensile modulus | GPa | 3 |

| Elongation at break | % | 3.4 |

| Flexural strength | MPa | 150 |

| Flexural modulus | GPa | 3.5 |

| Heat deflection temperature | °C | 107 |

| Impact resistance (unnotched sample) | kJ/m2 | 15 |

| Basalt | Glass | |

|---|---|---|

| Tensile modulus [GPa] | 89 | 76 |

| Density [g/cm3] | 2.03 | 1.89 |

| Basalt | Glass | |

|---|---|---|

| Static tensile tests | 5 | 5 |

| Stepwise fatigue tests | 2 | 2 |

| Input | Quantity |

|---|---|

| Water | 0.748 kg |

| Basalt rock | 1.4 kg |

| Lubricating oil | 0.0021 kg |

| Silicone | 0.004 kg |

| Electricity | 1.2 kWh |

| Natral gas | 12.5 Mj |

| Diesel | 0.0124 L |

| BFRC | GFRC | Percentage Increase (%) | |

|---|---|---|---|

| Ultimate tensile strength (Mpa) | 374 ± 20.2 | 295 ± 4.7 | +26.7% |

| BFRC | GFRC | |

|---|---|---|

| Stress Limit performed with STM (MPa) | 99.9 ± 6.45 | 101.7 ± 5.24 |

| Fatigue Limit performed with RTM (MPa) | 96.5 ± 0.2 | 104.8 ± 0.8 |

| Impact Category | Results | Unit |

|---|---|---|

| Acidification | 2.75 × 10−3 | mol H+-Eq |

| Climate change | 6.67 × 10−1 | kg CO2-Eq |

| Climate change: biogenic | 2.29 × 10−3 | kg CO2-Eq |

| Climate change: fossil | 6.64 × 10−1 | kg CO2-Eq |

| Climate change: land use and land use change | 1.77 × 10−4 | kg CO2-Eq |

| Ecotoxicity: freshwater | 4.89 × 100 | CTUe |

| Ecotoxicity: freshwater, inorganics | 2.52 × 100 | CTUe |

| Ecotoxicity: freshwater, organics | 2.37 × 100 | CTUe |

| Energy resources: non-renewable | 1.12 × 101 | MJ, net calorific value |

| Eutrophication: freshwater | 1.45 × 10−4 | kg P-Eq |

| Eutrophication: marine | 4.36 × 10−4 | kg N-Eq |

| Eutrophication: terrestrial | 4.71 × 10−3 | mol N-Eq |

| Human toxicity: carcinogenic | 3.49 × 10−9 | CTUh |

| Human toxicity: carcinogenic, inorganics | 8.54 × 10−11 | CTUh |

| Human toxicity: carcinogenic, organics | 3.40 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic | 7.79 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic, inorganics | 7.29 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic, organics | 4.96 × 10−10 | CTUh |

| Ionizing radiation: human health | 6.57 × 10−2 | kBq U235-Eq |

| Land use | 3.50 × 100 | dimensionless |

| Material resources: metals/minerals | 7.47 × 10−6 | kg Sb-Eq |

| Ozone depletion | 2.32 × 10−8 | kg CFC-11-Eq |

| Particulate matter formation | 1.71 × 10−8 | disease incidence |

| Photochemical oxidant formation: human health | 2.02 × 10−3 | kg NMVOC-Eq |

| Water use | 3.23 × 10−1 | m3 world Eq deprived |

| Impact Category | Results | Unit |

|---|---|---|

| Acidification | 3.75 × 10−3 | mol H+-Eq |

| Climate change | 8.12 × 10−1 | kg CO2-Eq |

| Climate change: biogenic | 2.31 × 10−3 | kg CO2-Eq |

| Climate change: fossil | 8.09 × 10−1 | kg CO2-Eq |

| Climate change: land use and land use change | 2.96 × 10−4 | kg CO2-Eq |

| Ecotoxicity: freshwater | 6.89 × 100 | CTUe |

| Ecotoxicity: freshwater, inorganics | 3.50 × 100 | CTUe |

| Ecotoxicity: freshwater, organics | 3.39 × 100 | CTUe |

| Energy resources: non-renewable | 1.35 × 101 | MJ, net calorific value |

| Eutrophication: freshwater | 1.89 × 10−4 | kg P-Eq |

| Eutrophication: marine | 6.31 × 10−4 | kg N-Eq |

| Eutrophication: terrestrial | 6.71 × 10−3 | mol N-Eq |

| Human toxicity: carcinogenic | 4.90 × 10−9 | CTUh |

| Human toxicity: carcinogenic, inorganics | 1.56 × 10−10 | CTUh |

| Human toxicity: carcinogenic, organics | 4.75 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic | 1.36 × 10−8 | CTUh |

| Human toxicity: non-carcinogenic, inorganics | 1.30 × 10−8 | CTUh |

| Human toxicity: non-carcinogenic, organics | 6.30 × 10−10 | CTUh |

| Ionizing radiation: human health | 7.89 × 10−2 | kBq U235-Eq |

| Land use | 3.90 × 100 | dimensionless |

| Material resources: metals/minerals | 1.92 × 10−5 | kg Sb-Eq |

| Ozone depletion | 1.85 × 10−8 | kg CFC-11-Eq |

| Particulate matter formation | 2.56 × 10−8 | disease incidence |

| Photochemical oxidant formation: human health | 2.78 × 10−3 | kg NMVOC-Eq |

| Water use | 3.91 × 10−1 | m3 world Eq deprived |

| Impact Category | Italy | China | Russia | Glo | Unit |

|---|---|---|---|---|---|

| Acidification | 2.75 × 10−3 | 2.90 × 10−3 | 2.80 × 10−3 | 2.82 × 10−3 | mol H+-Eq |

| Climate change | 6.67 × 10−1 | 6.97 × 10−1 | 6.87 × 10−1 | 6.85 × 10−1 | kg CO2-Eq |

| Climate change: biogenic | 2.29 × 10−3 | 2.03 × 10−3 | 2.04 × 10−3 | 2.05 × 10−3 | kg CO2-Eq |

| Climate change: fossil | 6.64 × 10−1 | 6.95 × 10−1 | 6.84 × 10−1 | 6.83 × 10−1 | kg CO2-Eq |

| Climate change: land use and land use change | 1.77 × 10−4 | 1.92 × 10−4 | 3.00 × 10−4 | 2.24 × 10−4 | kg CO2-Eq |

| Ecotoxicity: freshwater | 4.89 × 100 | 5.02 × 100 | 4.94 × 100 | 4.98 × 100 | CTUe |

| Ecotoxicity: freshwater, inorganics | 2.52 × 100 | 2.62 × 100 | 2.54 × 100 | 2.58 × 100 | CTUe |

| Ecotoxicity: freshwater, organics | 2.37 × 100 | 2.40 × 100 | 2.40 × 100 | 2.40 × 100 | CTUe |

| Energy resources: non-renewable | 1.12 × 101 | 1.14 × 101 | 1.16 × 101 | 1.14 × 101 | MJ, net calorific value |

| Eutrophication: freshwater | 1.45 × 10−4 | 1.49 × 10−4 | 1.60 × 10−4 | 1.56 × 10−4 | kg P-Eq |

| Eutrophication: marine | 4.36 × 10−4 | 4.75 × 10−4 | 4.49 × 10−4 | 4.57 × 10−4 | kg N-Eq |

| Eutrophication: terrestrial | 4.71 × 10−3 | 5.07 × 10−3 | 4.76 × 10−3 | 4.86 × 10−3 | mol N-Eq |

| Human toxicity: carcinogenic | 3.49 × 10−9 | 3.59 × 10−9 | 3.61 × 10−9 | 3.59 × 10−9 | CTUh |

| Human toxicity: carcinogenic, inorganics | 8.54 × 10−11 | 8.63 × 10−11 | 8.60 × 10−11 | 8.63 × 10−11 | CTUh |

| Human toxicity: carcinogenic, organics | 3.40 × 10−9 | 3.50 × 10−9 | 3.52 × 10−9 | 3.50 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic | 7.79 × 10−9 | 8.07 × 10−9 | 7.98 × 10−9 | 8.03 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic, inorganics | 7.29 × 10−9 | 7.55 × 10−9 | 7.47 × 10−9 | 7.52 × 10−9 | CTUh |

| Human toxicity: non-carcinogenic, organics | 4.96 × 10−10 | 5.13 × 10−10 | 5.08 × 10−10 | 5.08 × 10−10 | CTUh |

| Ionizing radiation: human health | 6.57 × 10−2 | 6.49 × 10−2 | 7.43 × 10−2 | 6.77 × 10−2 | kBq U235-Eq |

| Land use | 3.50 × 100 | 3.48 × 100 | 3.40 × 100 | 3.46 × 100 | dimensionless |

| Material resources: metals/minerals | 7.47 × 10−6 | 7.66 × 10−6 | 7.66 × 10−6 | 7.66 × 10−6 | kg Sb-Eq |

| Ozone depletion | 2.32 × 10−8 | 1.56 × 10−8 | 1.67 × 10−8 | 1.58 × 10−8 | kg CFC-11-Eq |

| Particulate matter formation | 1.71 × 10−8 | 2.02 × 10−8 | 1.72 × 10−8 | 1.83 × 10−8 | disease incidence |

| Photochemical oxidant formation: human health | 2.02 × 10−3 | 2.17 × 10−3 | 2.12 × 10−3 | 2.13 × 10−3 | kg NMVOC-Eq |

| Water use | 3.23 × 10−1 | 3.31 × 10−1 | 3.38 × 10−1 | 3.33 × 10−1 | m3 world Eq deprived |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Andrea, D.; Salmeri, F.; Di Bella, G.; Totaro, M.; Risitano, G. Replacing Glass with Basalt in the Vacuum Infusion Process of Vinyl Ester Composite Laminates: Effect on the Mechanical Performance and Life Cycle Assessment (LCA). J. Compos. Sci. 2025, 9, 308. https://doi.org/10.3390/jcs9060308

D’Andrea D, Salmeri F, Di Bella G, Totaro M, Risitano G. Replacing Glass with Basalt in the Vacuum Infusion Process of Vinyl Ester Composite Laminates: Effect on the Mechanical Performance and Life Cycle Assessment (LCA). Journal of Composites Science. 2025; 9(6):308. https://doi.org/10.3390/jcs9060308

Chicago/Turabian StyleD’Andrea, Danilo, Fabio Salmeri, Guido Di Bella, Martina Totaro, and Giacomo Risitano. 2025. "Replacing Glass with Basalt in the Vacuum Infusion Process of Vinyl Ester Composite Laminates: Effect on the Mechanical Performance and Life Cycle Assessment (LCA)" Journal of Composites Science 9, no. 6: 308. https://doi.org/10.3390/jcs9060308

APA StyleD’Andrea, D., Salmeri, F., Di Bella, G., Totaro, M., & Risitano, G. (2025). Replacing Glass with Basalt in the Vacuum Infusion Process of Vinyl Ester Composite Laminates: Effect on the Mechanical Performance and Life Cycle Assessment (LCA). Journal of Composites Science, 9(6), 308. https://doi.org/10.3390/jcs9060308