Comprehensive Overview on the Computational, Experimental, Numerical, and Theoretical Assessments of Silica Aerogel Composites

Abstract

1. Introduction

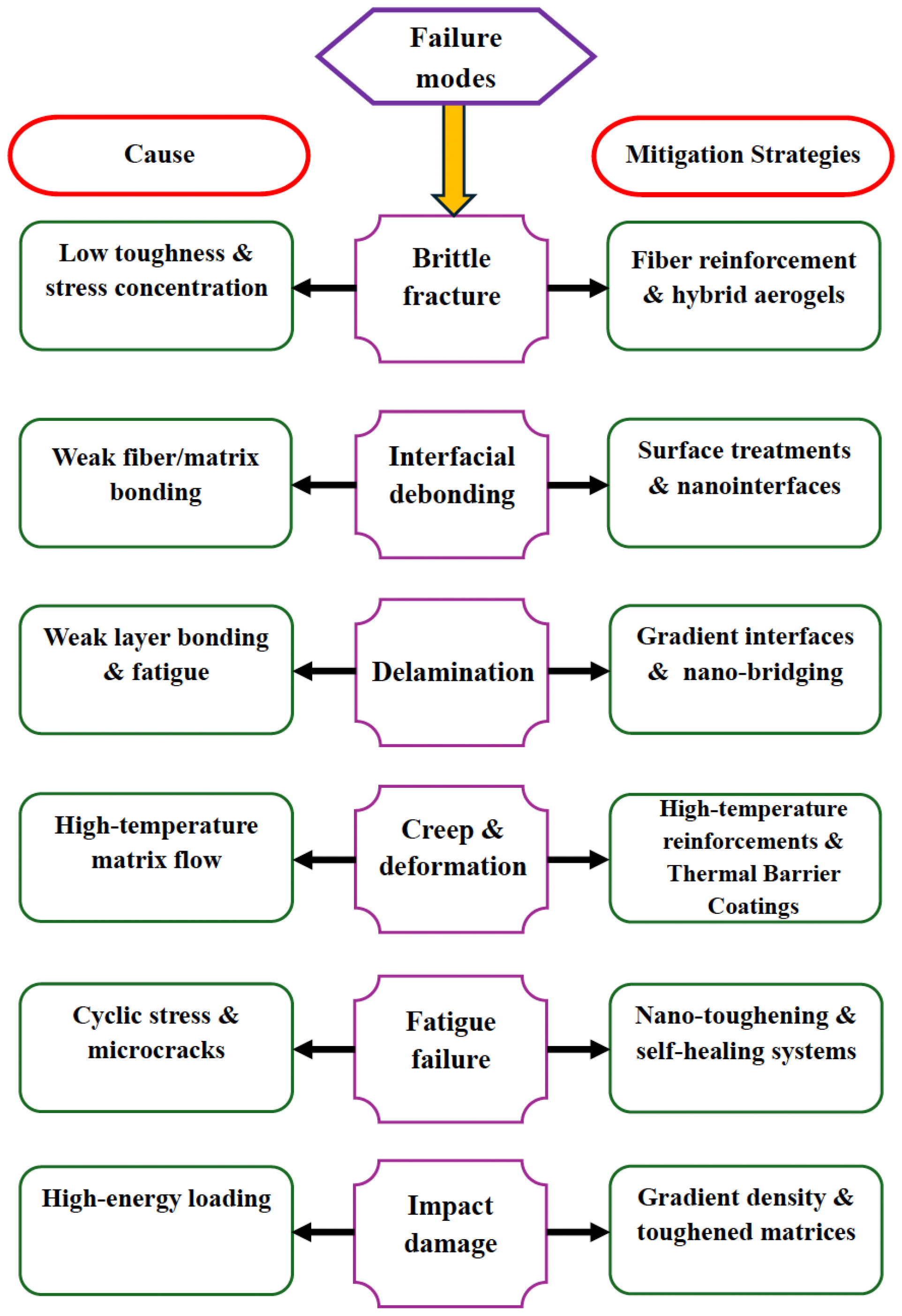

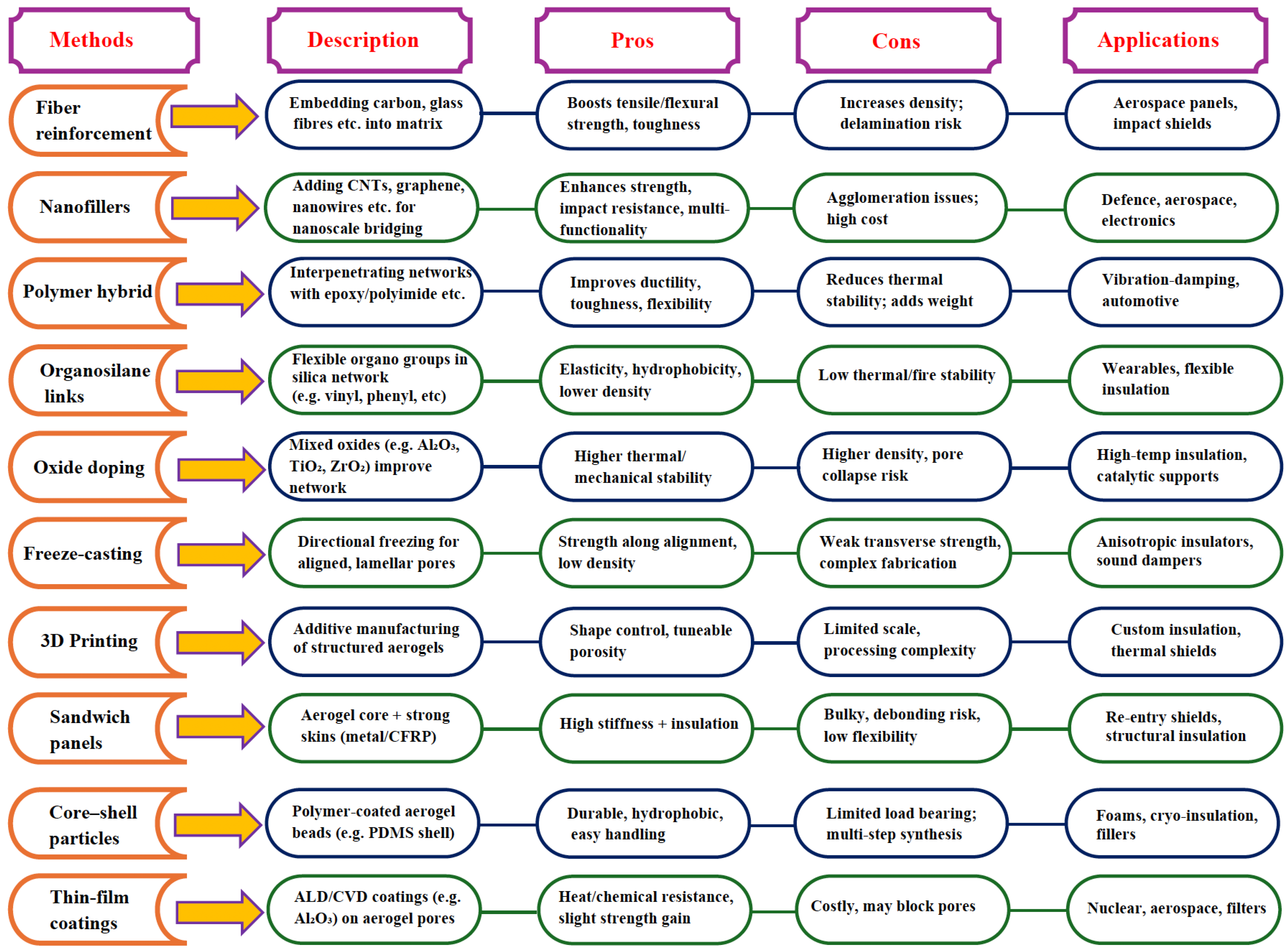

2. Mechanical Characterization

2.1. Recent Advancements and Current Research Trends

2.2. Future Directions

| Author and Year | Tests | Reinforcement | Composite Formulation | Processing Method | Standards | Application | Key Insights |

|---|---|---|---|---|---|---|---|

| Zhao C. et al. [2015] [31] |

| Particle-reinforced | Granular silica aerogel | One-shot free-rise polymer-foam process |

| Thermal insulation, fire prevention | Compressive strength of composites increased by 136%, and specific strength improved by 92.2% using polyethylene glycol (PEG) 600 as polyol. |

| Ji X. et al. [2019] [76] |

| Matrix- and fiber-reinforced | Alumina plain-woven fiber and silica aerogel matrix | Impregnation, sintering, and ambient pressure drying (APD) |

| Integrated thermal protection system (ITPS) | The longitudinal tensile modulus and strength decrease with the off-axis angle. The fracture strain increases, leading to accelerated damage progression under biaxial tension and shear stress. |

| Zhu P. et al. [2019] [78] |

| Matrix- and particle-reinforced | Cement and silica fume (matrix) and silica aerogel granulates (particle) | Two-step mixing, dry and wet mixing | Non-load bearing thermal insulation layers of buildings | Silica aerogel enhances frost and water resistance, freeze-thaw performance, and dry shrinkage in composites due to its strong hydrophobicity. | |

| Zolfaghari S. et al. [2019] [13] |

| Matrix- and particle-reinforced | Polypropylene (PP) matrix and silica aerogel (SiA) particles | Melt mixing and compression molding | Thermal barrier fields | Increasing the SiA content reduced tensile strength, elongation, and impact strength but enhanced hardness and friction coefficient, as well as improved the PP’s frictional properties. | |

| Aragón-Gutierrez A. et al. [2020] [5] |

| Matrix- and particle-reinforced | Silica aerogel powder, polylactic acid (PLA) matrix, and acetyl-tributyl citrate (ATBC) as plasticizer | Melt extrusion, compression molding, plasticization |

| Sustainable bionanocomposites for food packaging solutions | Low SiA content (0.5–1 wt.%) and slightly improved elongation at break, while 3 wt.% enhances the modulus but reduces elongation, maintaining sufficient flexibility for packaging. |

| Albooyeh A. et al. [2020] [85] |

| Matrix- and particle-reinforced | SiA nanoparticles and epoxy matrix | Mixing, degassing, pouring, and curing | Used in advanced composite materials for enhanced performance | Addition of 4 wt.% of SiA nanoparticles to the epoxy matrix significantly improves its mechanical properties, including the tensile, flexural, and compressive moduli, as well as its ductility, toughness, hardness, and vibration absorption. | |

| Ismail F. I. et al. [2021] [91] |

| Matrix-, particle-, and fiber-reinforced | High-density polyethylene (HDPE) (matrix), silica aerogel (partilces), and kapok fiber | Hot pressing technique | Recommended for energy-efficient building roof constructions | Incorporating 3 wt.% silica aerogel, along with HDPE and kapok fiber, enhances the mechanical properties of composite insulation boards, achieving improved tensile and flexural strength with excellent thermal insulation performance. | |

| Aminoroaya A. et al. [2021] [92] |

| Particle-reinforced | Silica aerogel modified with -trimethoxysilyl propyl methacrylate (SiA-MPS) and silica aerogel modified with trimethylchlorosilane (SiATMCS). | Two-step sol gel, surface modification, and ambient pressure drying (APD) | Dental composite formulation | Mesoporous silica aerogel fillers enhance filler–matrix interlocking, improve flexural properties, exhibit water resistance, and enable stable, high-performance dental composites with -MPS modification. | |

| Adhikary S. K. et al. [2021] [53] |

| Matrix- and fiber-reinforced | Ordinary portland cement (matrix) polycarboxylate (superplasticise) multi-walled carbon nanotubes | Ultrasonication-assisted dispersion and manual mixing |

| High-strength lightweight concrete | The addition of 0.6 wt% CNTs to aerogel-based lightweight concrete improves compressive strength by 41% and effectively reduces separation gaps by filling voids. |

| Kim J. H. et al. [2021] [96] |

| Matrix- and particle-reinforced | Polyurethane foam (matrix) and silica aerogel particles. | Homogenization, high-speed mixing, and free foaming |

| Liquefied natural gas (LNG) insulation systems used in cryogenic environments | Polyurethane foam-silica aerogel (1 wt.%) enhances the compressive strength and elastic modulus, but higher aerogel content reduces uniformity, weakening mechanical performance due to pore formation on the surface. |

| Selver E. et al. [2021] [27] |

| Matrix-, fiber-, and particle-reinforced | Woven glass fabric (satin weave) (primary) and silica aerogels (secondary) into the epoxy resin matrix. | Multi-step ultrasonic-assisted and vacuum-degassed mixing process |

| Applicable for producing composites with enhanced mechanical properties and thermal insulation | Composites exhibited improved flexural strength, modulus, and energy absorption with ductility trade-offs. |

| An L. et al. [2021] [19] |

| Fiber-reinforced | Aramid fibers and ceramic aerogel | In situ cross-linking reaction and ambient pressure drying (APD) |

| Low-cost wearable textile for harsh environments | The low density and high compressive strength of the composite depend on cross-linked interfacial interactions, ensuring performance in extreme temperature conditions. |

| Zhang Z. et al. [2022] [98] |

| Matrix-, particle-, and fiber-reinforced | Polyvinyl alcohol (PVA) fibers, SiO2 particles, and aerogel and cement matrix | Ultrasonic dispersion, planetary mixing, and molding | Reduced thermal conductivity ductile cement-based composite (RTCDCC) material enables durable, insulated building materials | The incorporation of silane enhances the mechanical properties of cementitious composites by improving bonding and increasing both flexural compressive strength. However, it also delays early hydration and contributes to the formation of additional microcracks in the specimens. | |

| Wang G. et al. [2023] [100] |

| Matrix-, particle-, and fiber-reinforced | SiO2, chopped glass fiber, modified glass fiber, and styrene–butadiene rubber (matrix) | Mechanical mixing, surface modification, and vulcanization |

| Thermal insulation | The addition of modified glass fiber improves tensile strength, cross-linking density, and interface bonding with the rubber matrix, enhancing mechanical properties and amplifying the strain behavior in composites. |

| Zhu Z. et al. [2024] [11] |

| Matrix- and fiber-reinforced | Multi-walled carbon nanotubes (MWCNTs) in silica aerogel matrix | Sol-gel, freeze drying, and ultrasonic dispersion |

| Cost-effective CNTs/silica aerogel for industrial use | Uniform CNT dispersion enhances mechanical properties below 4 wt.%, but agglomeration above 6 wt.% reduces them. |

3. Thermal Characterization

3.1. Recent Advancements and Current Research Trends

3.2. Future Directions

| Author and Year | Tests | Reinforcement | Reinforcing Material | Processing Method | Standards | Application | Key Insights |

|---|---|---|---|---|---|---|---|

| Wang X. et al. [2014] [119] |

| Particle-reinforced | Titanium dioxide (TiO2) | Sol-gel and APD |

| Removal of organic pollutants | Increasing the heating rate is favorable for the crystallization of TiO2. |

| Eskandari N. et al. [2016] [120] |

| Matrix- and particle-reinforced | Silica aerogel (particles) and unplasticized polyvinyl chloride (UPVC) (matrix) | Two step sol-gel process, melt mixing, and hot pressing | Drainage pipes and window profiles in buildings | SiA significantly reduces UPVC’s TC, improving insulation for energy-efficient windows and buildings. | |

| Li C. et al. [2016] [10] |

| Fiber-reinforced | Glass fiber (GF) film | Sol-gel and APD |

| Fire resistance and flexible composites | The fire hazards of the GF/aerogel composites decrease with an increase in the S value (where S is the H2O: TEOS molar ratio). |

| Li Z. et al. [2016] [15] |

| Matrix- and fiber-reinforced | Aramid fiber (AF) (Kevlar-49) and silica aerogel (matrix) | Sol-gel and APD |

| Piping heat insulation | AF/aerogels exhibit ultra-low thermal conductivity and stability, making them ideal for heat insulation applications. |

| Lee K. J. et al. [2017] [22] |

| Fiber-reinforced | Polyethylene (PE) fiber blankets | Impregnation technique (using silica aerogel slurries) and APD | Super-insulation material | The composite’s thermal conductivity values were approximately 20% lower than those of bare PE and PE nonwoven fabrics without silica aerogel powders. | |

| Ye X. et al. [2019] [20] |

| Matrix- and particle-reinforced | Silicon carbide (SiC) coating-reinforced carbon foam (CF) | Sol-gel, pyrolysis, CVD, and APD |

| Thermal insulation | Obtained SiC/CF-aerogel possessed a superior high temperature insulation property than CF and SiC/CF. |

| Shang L. et al. [2019] [21] |

| Fiber-reinforced | Anti-infrared radiation silica fibers | Sol-gel and supercritical CO2 drying |

| Aerospace insulation material (thermal protection structures) | Composite was stable under sustained durations in a high-temperature oxygen environment of 250 °C. |

| Liu Y. et al. [2020] [7] |

| Fiber-reinforced | Polyester fiber felt (support) and silica aerogel (filling medium) | Sol-gel and APD | Building insulation (even in humid areas) | Compounding fiber felt with aerogel reduces voids, lowering water vapor transmission and improving thermal insulation. | |

| Krzemińska S. et al. [2020] [68] |

| Fiber-reinforced | Aramid fibers (Kermel® meta-aramid fibers, 98% content) and conductive fiber (2% content) | Coating technique | Protective clothing fabric to improve its heat resistance | Aerogel coatings improved thermal resistance and reduced conductivity, but aerogel fragmentation during coating processing compromises insulation. | |

| Yang H. and Ye F. [2022] [130] |

| Particle-reinforced | Si3N4 (primary) and TiO2 (additional) | Sol-gel and APD |

| High-temperature wave permeable insulation material | At higher TiO2 contents, the thermal diffusivity and TC of the composites decrease, while an excessive increase is unsuitable for wave-transmitting applications. |

| Wang X. et al. [2023] [131] |

| Particle-reinforced | Montmorillonite (MMT) | Two-step acid-base catalyzed sol-gel process and APD |

| Thermal insulation | MMT/SiA exhibit reduced TC, lower heat release rate, and improved thermal stability, enhancing thermal insulation and reducing fire hazards with increasing MMT content. |

| Pantaleo S. et al. [2024] [132] |

| Matrix- and particle-reinforced | Silica aerogel granulates (particle), acrylic copolymer emulsion, styrene-acrylic copolymer emulsion, vinyl acetate, ethylene, and acrylate emulsion (matrix) | Hand mixing and stirring |

| Housing refurbishing | The composites maintain low TC and exhibit minimal moisture absorption, optimizing energy efficiency in housing applications. |

| Yu D. et al. [2024] [133] |

| Fiber- and particle-reinforced | Alkali-free glass fiber (GF) and silicon carbide (SiC) particles | Sol gel and super-critical drying | Architectural insulation | Composite exhibits excellent thermal insulation and improves thermal shock resistance with SiC. | |

| Zhang T. et al. [2024] [136] |

| Fiber-reinforced | Ceramic (aluminum silicate) fiber felt (CF) | Sol-gel method with supercritical CO2 drying | Thermal insulation in lithium-ion batteries | Flexible silica aerogel composites exhibit excellent thermal stability, low thermal conductivity, and strong thermal shock resistance, making them ideal for high-temperature insulation applications. | |

| Liu M. at al. [2024] [139] |

| Fiber- and particle-reinforced | Aerogel-supported carbon fiber and silicon carbide (SiC) | Single-step sol-gel impregnation and super critical drying CO2 | Thermal insulation (high temperature and thermal-force coupling conditions) | Composite exhibits excellent thermal insulation, maintains stability under extreme conditions, resists thermal stress, and effectively prevents thermal runaway propagation in high-energy systems. |

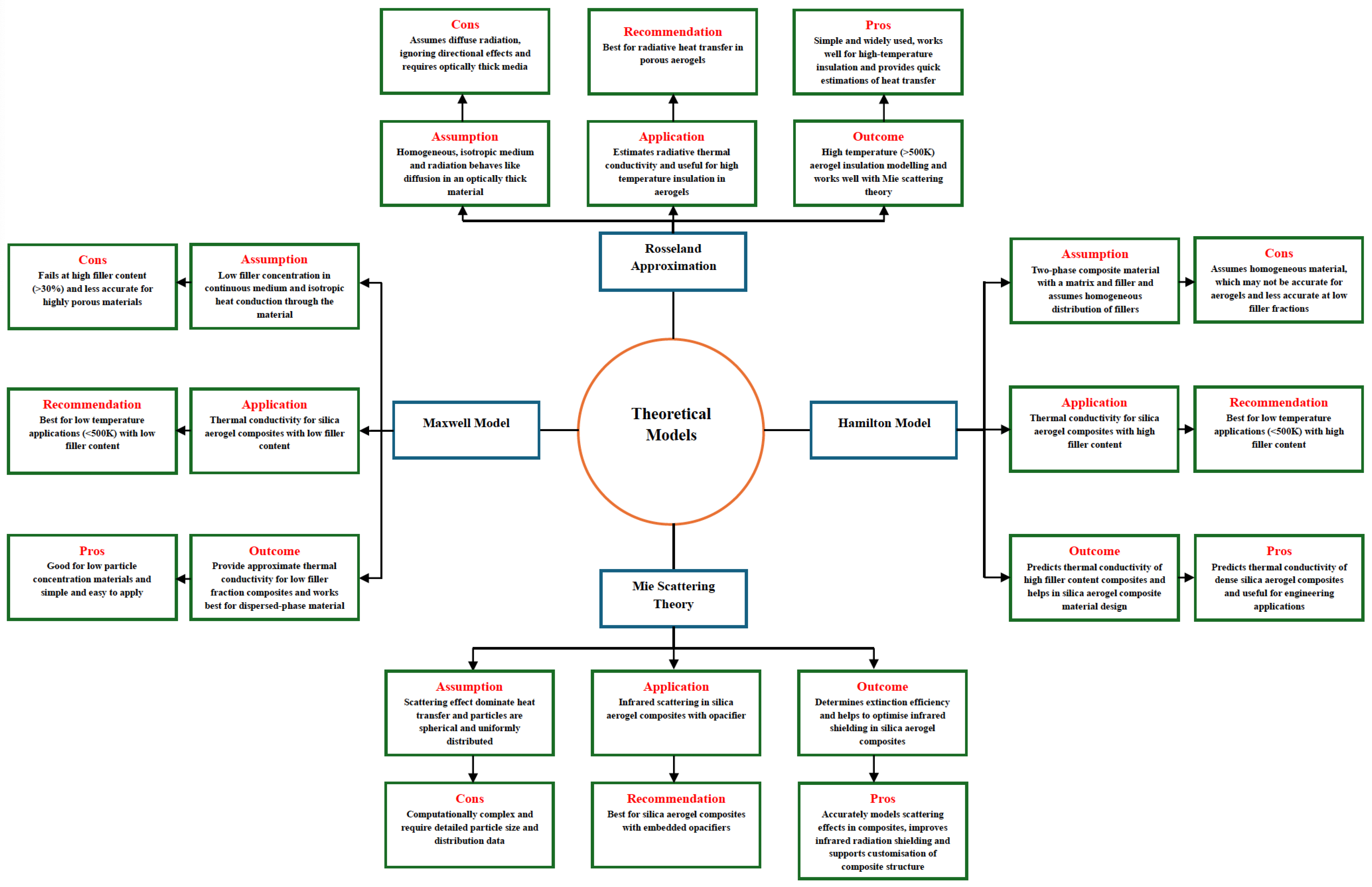

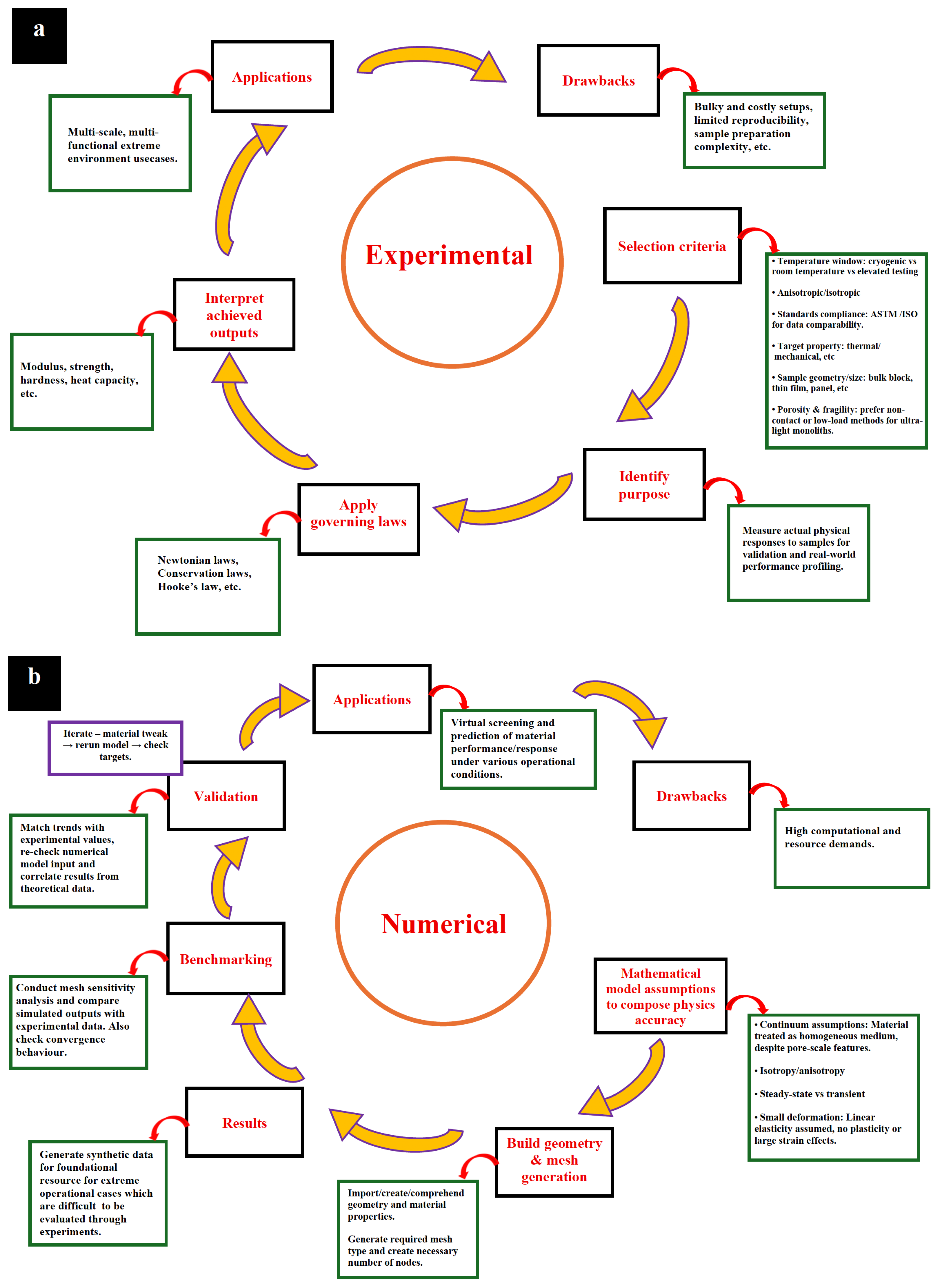

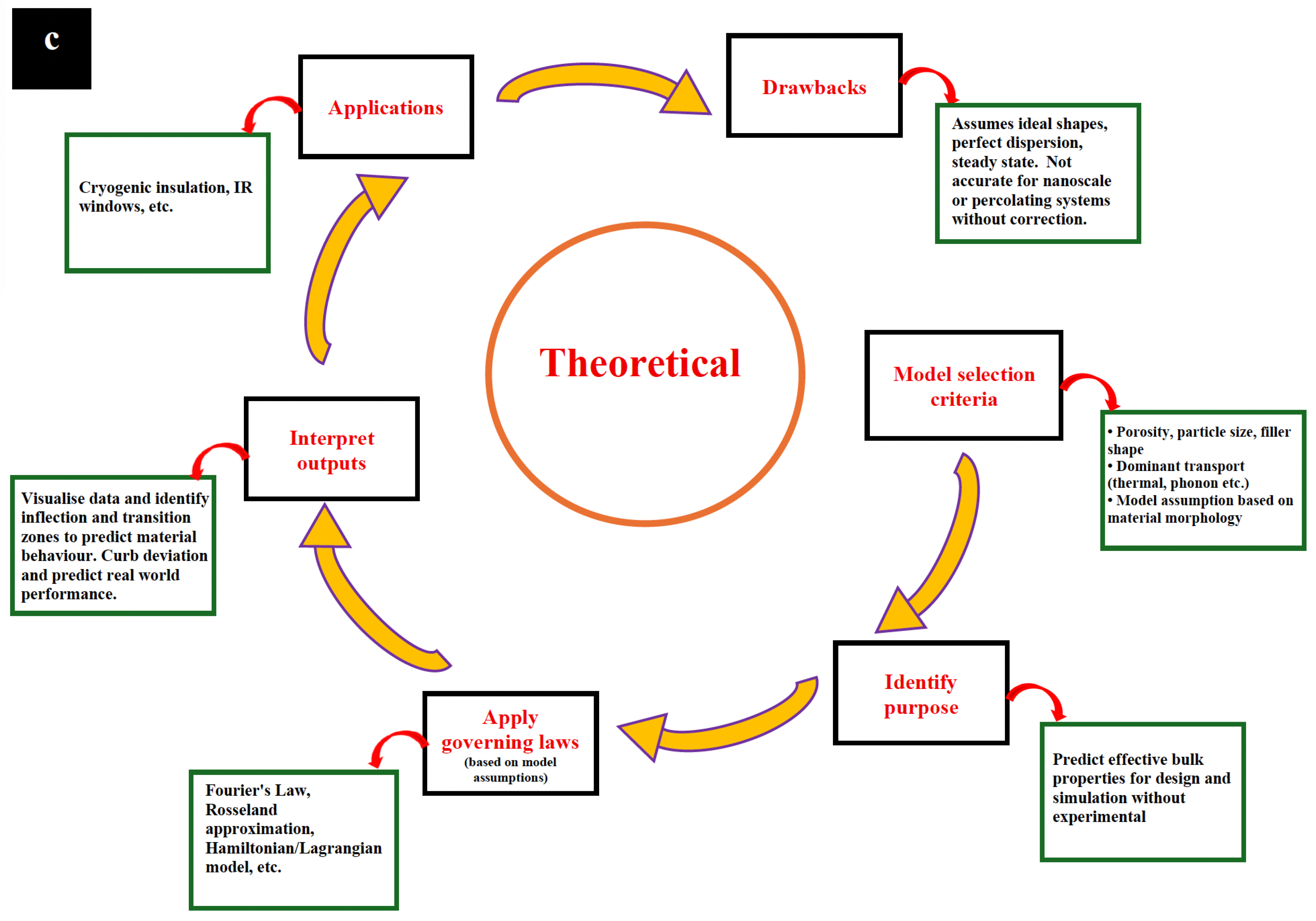

4. Theoretical and Numerical-Based Frameworks

4.1. Recent Advancements and Current Research Trends

4.2. Future Directions

| Author and Year | Objective | Reinforcement | Characteristics Studied | Relations and Equations | Temperature | Application | Key Insights |

|---|---|---|---|---|---|---|---|

| Zhao J. J. et al. [2012] [145] | A numerical study that investigated the effective thermal conductivity of fiber-loaded composites employed a randomly parameterized 2D fiber distribution to simulate a realistic material structure, integrating heat conduction and radiation models. | Silica aerogel fiber-reinforced |

|

| High temperature | High-temperature thermal insulation applications | Effective thermal conductivity depends upon the fiber-length-to-diameter ratio, the inclination angle, and the fiber volume fraction. |

| Wang X. D. et al. [2013] [152] | Theoretical method with four sub-models to evaluate radiative characteristics and propose an optimized gradient design for temperature-dependent opacifier properties. | SiC-, TiO2-, ZrO-2, coal ash-, carbon black-, and Al2O3-particle-reinforced |

|

| High temperature (1300 K) | High-temperature application | SiC performs best at high temperatures; opacifier diameter affects radiative characteristics. |

| Hoseini A. et al. [2015] [151] | Comparison, accounting for conduction and radiation, of the theoretical and experimental thermal conductivity of composites, which were modeled using a unit cell with cylindrical fibers. | Cryogel Z- and thermal wrap fiber-reinforced |

|

| −20 °C–80 °C | Thermal insulation systems | The effective thermal conductivity of Cryogel Z is less than thermal wrap; high porosity, small pore sizes, and large surface area are key to low thermal conductivity in aerogel blankets. |

| Dai Y. J. et al. [2017] [154] | To validate a theoretical model using a spherical hollow cube structure to predict and optimize SiA composites thermal conductivity under varying conditions. | SiO2 (fiber), SiC, TiO2 and C (opacifiers) are fiber- and particle-reinforced. |

|

| Room temperature–1000 K | Thermal insulation applications | SiC demonstrates the best overall performance, while a fiber diameter of approximately 4 μm and temperature-dependent optimal fiber concentrations effectively minimize thermal conductivity. |

| Liu H. et al. [2022] [155] | To study the effective thermal conductivity of fiber-reinforced composites through theoretical models, focusing on randomly distributed fibers and optimizing their diameter, inclination, and mass fraction for high-temperature insulation. | Silica aerogel fiber-reinforced |

|

| 600–1400 K | High-temperature thermal insulation application | Effective thermal conductivity of fiber-reinforced composites depends on the fiber alignment (where a perpendicular angle minimizes), diameter, and mass fraction, optimizing thermal insulation across 600–1400 K. |

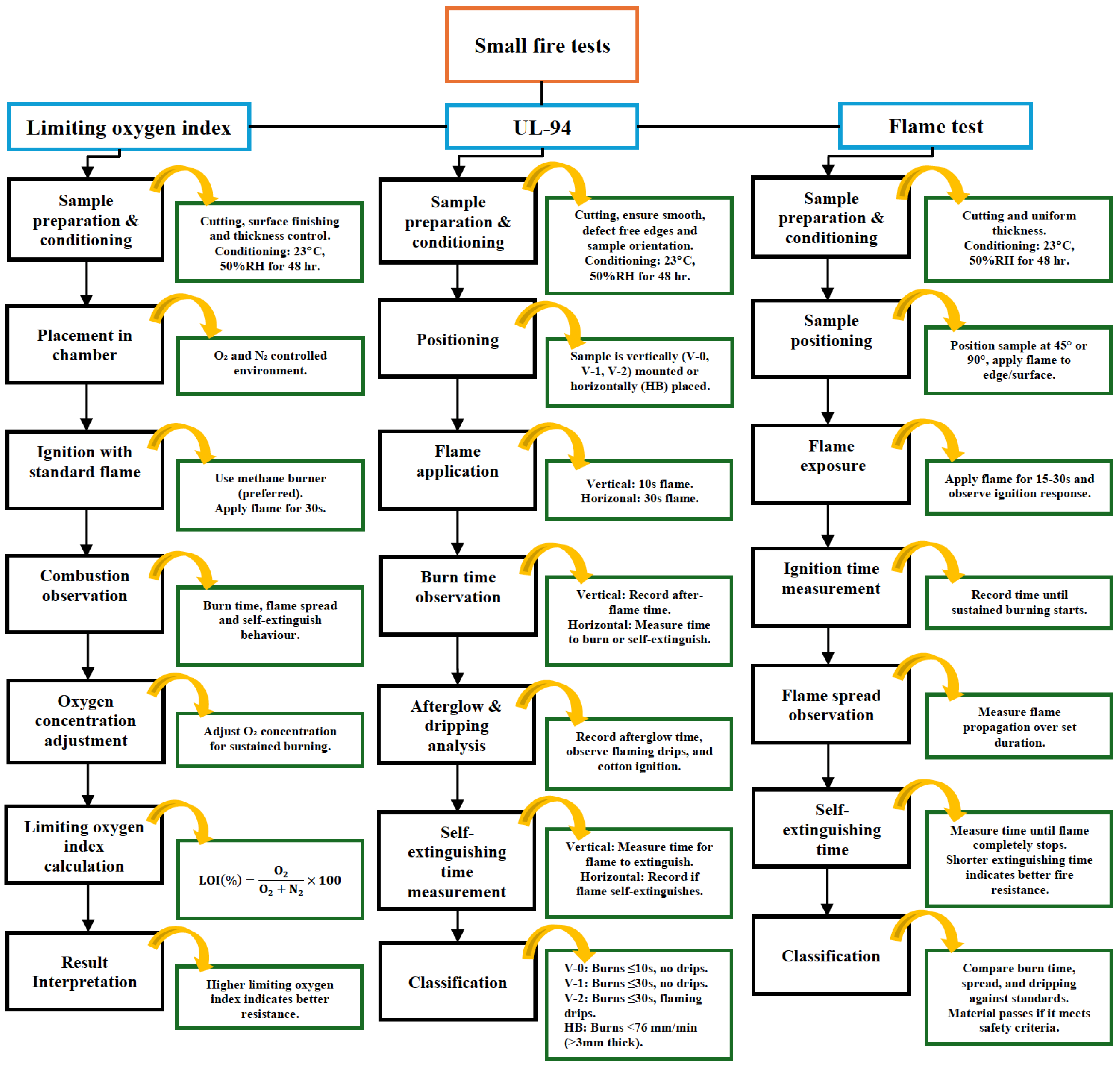

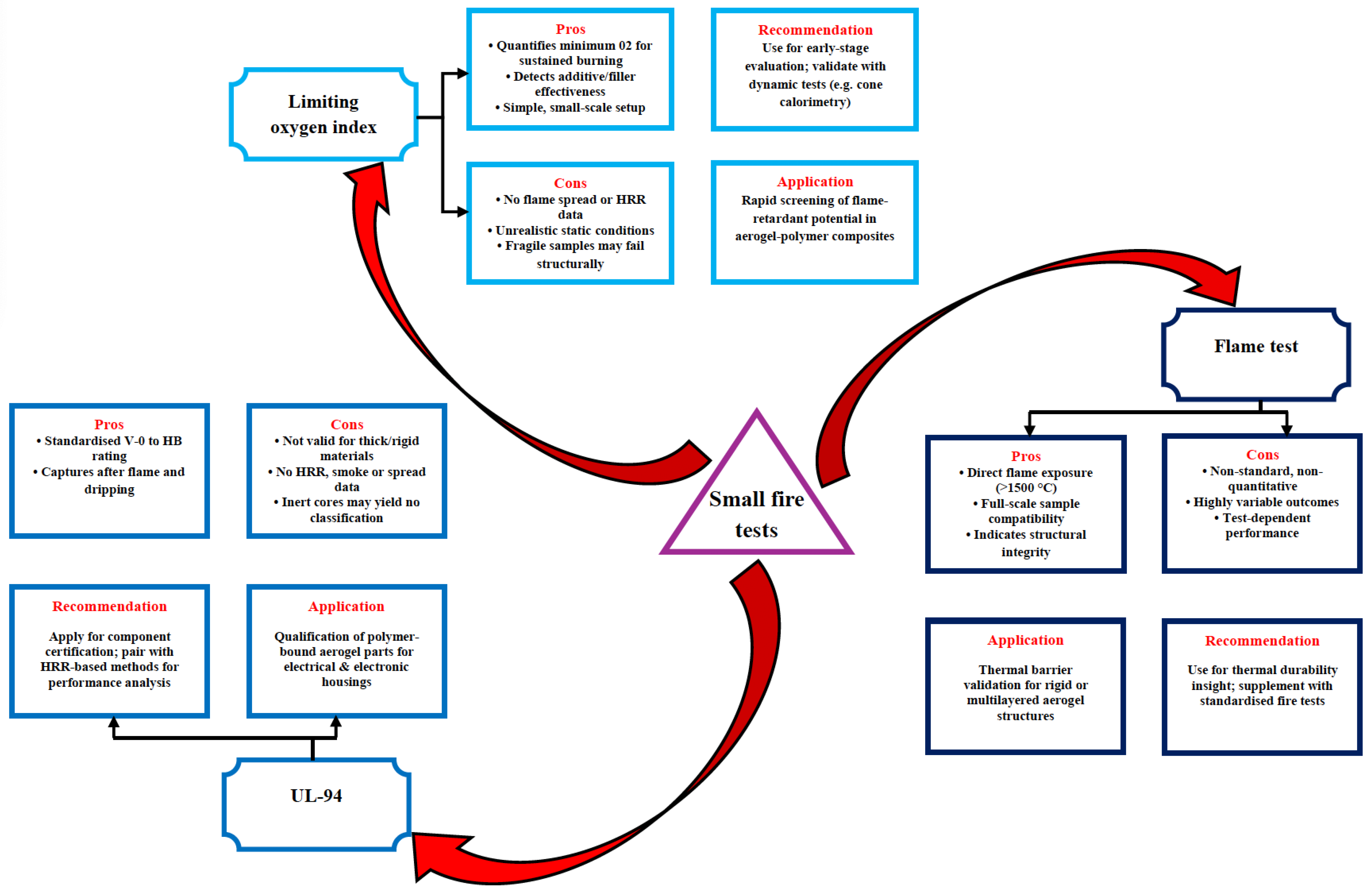

5. Radiation and Flammability Assessments

5.1. Recent Advancements and Current Research Trends

5.2. Future Directions

| Author and Year | Tests | Reinforcement | Reinforcing Material | Processing Method | Standards | Application | Key Insights |

|---|---|---|---|---|---|---|---|

| Motahari S. et al. [2015] [30] |

| Matrix- and particle-reinforced | Polypropylene (PP) (matrix) and silica aerogel (particles) | Melt compounding method | Thermoplastic composites for automotive, aerospace, and building industries | Adding SiA to PP increased the thermal decomposition temperature by 24–34 °C, and this was attributed to the protective char layer and its physical cross-linking. | |

| Rocha H. et al. [2019] [8] |

| Fiber-reinforced | Inorganic quartz fiber and inorganic polyethylene terephthalate (PET)-based fibers | Sol-gel and APD | Martian environment | Thermal insulation remained unaffected by thermal cycling or environmental exposure, demonstrating aerogel’s resilience to martian temperature variations. | |

| Almeida C. M. et al. [2021] [156] |

| Fiber-reinforced | Kevlar pulp (KP), aramid felt (PAF), and aramid fibers | Sol-gel and APD | Suitable for shape adaption and vibration applications (such as launch pad rockets and thermal protection systems) | Elongated aramid fiber-reinforced SiA nanocomposites offer superior flexibility, vibration damping, and thermal stability, ideal for space applications. | |

| Xi S. et al. [2023] [18] |

| Matrix- and particle-reinforced | Polyimide (PI) matrix, inorganic silica aerogel powders (ISAp), and polyvinylpolymethylsiloxane aerogel powders (PAp) | ISAp was created using sol-gel, while PAp was formed by radical polymerization. Both were dried through supercritical CO2 drying. |

| Space environment | PI-I40 shows resistance to electron irradiation, moderate sensitivity to proton and UV irradiation, and stability after thermal cycling. ISAp enhances thermal stability and fire resistance but reduces moisture resistance, while PAp improves moisture resistance but weakens thermal stability and fire resistance. Combined, they reduce thermal conductivity, ensuring strong insulation. |

| Ni L. et al. [2024] [158] |

| Particle-reinforced | Polyimide foam (PIF) and silica aerogel (SiA) powders | Microwave-assisted foaming and thermal imidization treatment | Aerospace, precision electronics, and transportation | Carbonized PIF/SiA foams demonstrate superior mechanical and EMI shielding performance over the original PIF/SiA composite foam. The latter shows exceptional infrared stealth performance, indicating potential for extended service life. |

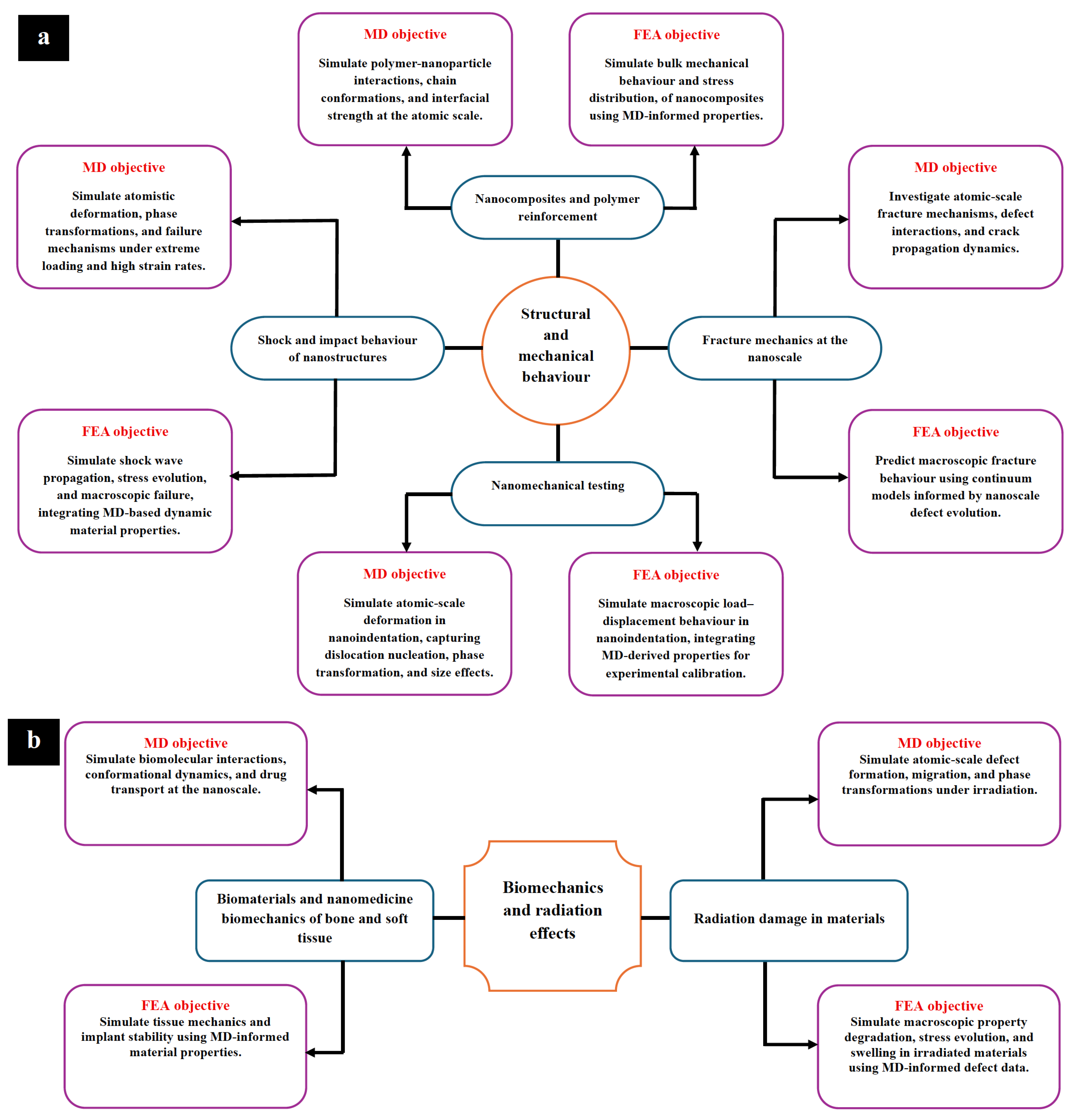

6. Computational Studies

6.1. Recent Advancements and Current Research Trends

6.1.1. Continuum Mechanics and Nanoscale Simulations

6.1.2. Other Simulation Models

6.2. Future Directions

6.2.1. Continuum Mechanics

6.2.2. MD Simulations

| Author and Year | Type | Model Objective | Model Details | Characteristics Studied | Relations and Equations | Temperature(s) | Key Insights |

|---|---|---|---|---|---|---|---|

| Patil S. P. et al. [2019] [34] | MD | This paper investigates the mechanical behavior of glass fiber-reinforced silica aerogel nanocomposites using MD simulations with LAMMPS and OVITO, where the focus is on the tensile strength, elastic modulus, and compressive properties. | Model construction

|

|

|

| The simulation showed that the tensile strength increased from 0.2 GPa to 0.442 GPa. It established a linear modulus–density relationship and improved compressive resistance, confirming enhanced mechanical performance at 300 K. |

| Patil S. P. et al. [2020] [35] | MD | This study explored the mechanical properties of silica aerogel nanocomposites reinforced with glass fibers, graphene sheets, and CNTs through MD simulations using LAMMPS and OVITO. | Model construction

|

|

| Silica aerogel formation

| Carbon-based nanocomposites improve tensile strength by 8–9× and elastic modulus by 9.5–11.5×. Crack penetration reduces fracture strength by 15–20%. |

| Mishra R. et al. [2021] [177] | FEA | This study investigated, comparing heat transfer with stagnant air under sub-zero conditions, the thermal insulation of aerogel-based nonwoven fabrics using FEM simulations (ANSYS and COMSOL) and experiments. | Modeling

|

|

|

| Aerogel outperforms air as an insulator at all temperatures. Computational models predicted conductivity with <10% error in comparison to experimental results. |

| Xiao J. et al. [2023] [181] | MD | The objective is to investigate the pyrolysis behavior of siliconoxycarbide-modified phenolic resin (SiOC-PR) nanocomposites using reactive force field (ReaxFF) MD simulations via LAMMPS, as well as analyzing gaseous product evolution, reaction pathways, and thermal stability improvements. | Simulation box

|

|

|

| ReaxFF MD simulations revealed that SiOC-PR undergoes five-stage pyrolysis, where SiOC enhances oxidation resistance, regulates gaseous product evolution, and stabilizes phenolic fragments by Si-O-Si interactions. |

| Zhang W. et al. [2023] [33] | MD | This study investigates the effect of carbon doping (1–10%) on the mechanical properties of paraffin-reinforced silica aerogel (PRSA) when using MD simulations with LAMMPS, Avogadro, and Packmol. | Modeling

|

|

|

| MD simulations show that carbon doping (3%) enhances PRSA’s mechanical properties, increasing the ultimate strength and Young’s modulus, while equilibrium is achieved at 300 K after 2 ns. |

| Maximiano P. and Simões P. N. [2023] [182] | MD | This study investigated, focusing on the aggregation, adsorption, oxidation effects, and structural organization at the nanoscale, silica aerogel–CNT interactions using GROMACS [199,200] MD simulations. | Boundary conditions

|

|

|

| Silica–CNT interactions vary by oxidation, affecting aggregation and adsorption. Van der Waals forces direct the structure, especially in octamer systems. H-bonds enhance ordered layers in oxidized CNTs. |

| Karimipour A. et al. [2024] [183] | MD | This study investigated, analyzing Young’s modulus, ultimate strength, stress–strain behavior, and atomic interactions, the temperature-dependent mechanical behavior of tricalcium phosphate/chitosan/silica aerogels nanocomposites (TCS-NCs) using MD simulations via LAMMPS, Avogadro, and Packmol. | Simulation box

|

|

|

| MD simulations revealed that increasing temperature influences TCS-NC’s mechanical properties, with the Young’s modulus peaking at 320 K and the ultimate strength decreasing as the temperature rises from 300 to 350 K. |

| Zhu C. Y. et al. [2024] [153] | FEM | This study investigated the impact of the opacifier protrusion shape, number, and volume on extinction properties, as well as the radiative thermal conductivity, when using COMSOL-based finite element method (FEM) simulations, thereby optimizing silica aerogel insulation for high-temperature applications. | Boundary conditions

|

|

|

| The study used COMSOL to show that cylindrical protrusions (optimal at 12) significantly enhance the extinction properties, reducing the radiative thermal conductivity of silica aerogels by 22.6% at 1300 K. |

| Fu W. et al. [2024] [175] | FEA | This study numerically simulated the heat transfer on silica composite phase change material (CPCM) using ANSYS Fluent | Simulation model

|

|

|

| Numerical simulations showed that 20 wt% CPCM with an 80 mm thickness optimized thermal insulation, reducing peak temperature by 9.87 K with a delay time of 198,000 s and an attenuation factor of 6.6. |

| Zhang X. et al. [2024] [32] | MD | This study investigated the thermal conductivity of composite aerogels using non-equilibrium molecular dynamics (NEMD) simulations across varying content, temperature, and strains using LAMMPS and OVITO. | Boundary conditions

|

|

|

| MD simulations showed that adding makes the nanoporous structure stronger, reducing thermal conductivity, while a slight increase occurs under elevated temperature and compression strain conditions. |

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Satha, H.; Atamnia, K.; Despetis, F. Effect of drying processes on the texture of silica gels. J. Biomater. Nanobiotechnol. 2013, 4, 17. [Google Scholar] [CrossRef]

- Tewari, P.; Hunt, A.; Lofftus, K. Advances in production of transparent silica aerogels for window glazings. In Aerogels: Proceedings of the First International Symposium, Würzburg, Fed. Rep. of Germany September 23–25, 1985; Springer: Berlin/Heidelberg, Germany, 1986; pp. 31–37. [Google Scholar] [CrossRef]

- Kistler, S.S. Coherent expanded aerogels and jellies. Nature 1931, 127, 741. [Google Scholar] [CrossRef]

- Hüsing, N.; Schubert, U. Aerogels—Airy materials: Chemistry, structure, and properties. Angew. Chem. Int. Ed. Engl. 1998, 37, 22–45. [Google Scholar] [CrossRef]

- Aragón-Gutierrez, A.; Arrieta, M.P.; López-González, M.; Fernández-García, M.; López, D. Hybrid biocomposites based on poly (lactic acid) and silica aerogel for food packaging applications. Materials 2020, 13, 4910. [Google Scholar] [CrossRef]

- Jo, M.G.; Kim, N.G.; Kim, H.J. Fabrication of Sn (IV) porphyrin-Imbedded Silica Aerogel Composite. J. Compos. Sci. 2023, 7, 401. [Google Scholar] [CrossRef]

- Liu, Y.; Wu, H.; Zhang, Y.; Yang, J.; He, F. Structure characteristics and hygrothermal performance of silica aerogel composites for building thermal insulation in humid areas. Energy Build. 2020, 228, 110452. [Google Scholar] [CrossRef]

- Rocha, H.; Lafont, U.; Semprimoschnig, C. Environmental testing and characterization of fibre reinforced silica aerogel materials for Mars exploration. Acta Astronaut. 2019, 165, 9–16. [Google Scholar] [CrossRef]

- Leventis, N.; Sotiriou-Leventis, C.; Zhang, G.; Rawashdeh, A.M.M. Nanoengineering strong silica aerogels. Nano Lett. 2002, 2, 957–960. [Google Scholar] [CrossRef]

- Li, C.; Cheng, X.; Li, Z.; Pan, Y.; Huang, Y.; Gong, L. Mechanical, thermal and flammability properties of glass fiber film/silica aerogel composites. J. Non-Cryst. Solids 2017, 457, 52–59. [Google Scholar] [CrossRef]

- Zhu, Z.; Zhang, H.; Ma, Y.; Yang, Z.; Chen, Z.; Zhang, H. Preparing high-quality monolithic carbon nanotubes reinforced silica aerogel composites based on a vacuum freeze-drying method. Eng. Sci. 2024, 31, 1149. [Google Scholar] [CrossRef]

- An, L.; Wang, J.; Petit, D.; Armstrong, J.N.; Li, C.; Hu, Y.; Huang, Y.; Shao, Z.; Ren, S. A scalable crosslinked fiberglass-aerogel thermal insulation composite. Appl. Mater. Today 2020, 21, 100843. [Google Scholar] [CrossRef]

- Zolfaghari, S.; Paydayesh, A.; Jafari, M. Mechanical and thermal properties of polypropylene/silica aerogel composites. J. Macromol. Sci. Part B Phys. 2019, 58, 305–316. [Google Scholar] [CrossRef]

- Zhao, S.; Siqueira, G.; Drdova, S.; Norris, D.; Ubert, C.; Bonnin, A.; Galmarini, S.; Ganobjak, M.; Pan, Z.; Brunner, S.; et al. Additive manufacturing of silica aerogels. Nature 2020, 584, 387–392. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Cheng, X.; He, S.; Shi, X.; Gong, L.; Zhang, H. Aramid fibers reinforced silica aerogel composites with low thermal conductivity and improved mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 84, 316–325. [Google Scholar] [CrossRef]

- Shafi, S.; Navik, R.; Ding, X.; Zhao, Y. Improved heat insulation and mechanical properties of silica aerogel/glass fiber composite by impregnating silica gel. J. Non-Cryst. Solids 2019, 503, 78–83. [Google Scholar] [CrossRef]

- Hasan, M.A.; Rashmi, S.; Esther, A.C.M.; Bhavanisankar, P.Y.; Sherikar, B.N.; Sridhara, N.; Dey, A. Evaluations of silica aerogel-based flexible blanket as passive thermal control element for spacecraft applications. J. Mater. Eng. Perform. 2018, 27, 1265–1273. [Google Scholar] [CrossRef]

- Xi, S.; Wang, Y.; Zhang, X.; Cao, K.; Su, J.; Shen, J.; Wang, X. Fire-resistant polyimide-silica aerogel composite aerogels with low shrinkage, low density and high hydrophobicity for aerospace applications. Polym. Test 2023, 129, 108259. [Google Scholar] [CrossRef]

- An, L.; Liang, B.; Guo, Z.; Wang, J.; Li, C.; Huang, Y.; Hu, Y.; Li, Z.; Armstrong, J.N.; Zhou, C.; et al. Wearable aramid–ceramic aerogel composite for harsh environment. Adv. Eng. Mater. 2021, 23, 2001169. [Google Scholar] [CrossRef]

- Ye, X.; Chen, Z.; Ai, S.; Hou, B.; Zhang, J.; Zhou, Q.; Wang, F.; Liu, H.; Cui, S. Microstructure characterization and thermal performance of reticulated SiC skeleton reinforced silica aerogel composites. Compos. B Eng. 2019, 177, 107409. [Google Scholar] [CrossRef]

- Shang, L.; Lyu, Y.; Han, W. Microstructure and thermal insulation property of silica composite aerogel. Materials 2019, 12, 993. [Google Scholar] [CrossRef]

- Lee, K.J.; Choe, Y.J.; Kim, Y.H.; Lee, J.K.; Hwang, H.J. Fabrication of silica aerogel composite blankets from an aqueous silica aerogel slurry. Ceram. Int. 2018, 44, 2204–2208. [Google Scholar] [CrossRef]

- Rezaei, E.; Moghaddas, J. Thermal conductivities of silica aerogel composite insulating material. Adv. Mater. Lett. 2016, 7, 296–301. [Google Scholar] [CrossRef]

- Wong, J.C.; Kaymak, H.; Tingaut, P.; Brunner, S.; Koebel, M.M. Mechanical and thermal properties of nanofibrillated cellulose reinforced silica aerogel composites. Microporous Mesoporous Mater. 2015, 217, 150–158. [Google Scholar] [CrossRef]

- Yang, H.; Ye, F.; Liu, Q.; Gao, Y. Microstructure and properties of the Si3N4/silica aerogel composites fabricated by the sol–gel method via ambient pressure drying. Mater. Des. 2015, 85, 438–443. [Google Scholar] [CrossRef]

- Hung, W.C.; Horng, R.S.; Shia, R.E. Investigation of thermal insulation performance of glass/carbon fiber-reinforced silica aerogel composites. J. Solgel Sci. Technol. 2021, 97, 414–421. [Google Scholar] [CrossRef]

- Selver, E.; Öztaş, B.; Uçar, M.; Uçar, N.; Baydoğan, M.; Altay, P.; Geygel, B. Mechanical and thermal properties of glass/epoxy composites filled with silica aerogels. Plast. Rubber Compos. 2021, 50, 371–383. [Google Scholar] [CrossRef]

- Moner-Girona, M.; Martínez, E.; Esteve, J.; Roig, A.; Solanas, R.; Molins, E. Micromechanical properties of carbon–silica aerogel composites. Appl. Phys. A 2002, 74, 119–122. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Feng, J.; Jiang, Y.; Li, L.; Hu, Y.; Feng, J. Fabrication of flexible silica aerogel composite blankets from an aqueous fumed silica-based slurry. Sci. China Mater. 2024, 67, 1332–1339. [Google Scholar] [CrossRef]

- Motahari, S.; Motlagh, G.H.; Moharramzadeh, A. Thermal and flammability properties of polypropylene/silica aerogel composites. J. Macromol. Sci. Part B Phys. 2015, 54, 1081–1091. [Google Scholar] [CrossRef]

- Zhao, C.; Yan, Y.; Hu, Z.; Li, L.; Fan, X. Preparation and characterization of granular silica aerogel/polyisocyanurate rigid foam composites. Constr. Build. Mater. 2015, 93, 309–316. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, F.; Wang, J.; Qi, Z. Experimental and molecular dynamics studies on thermal insulation at high-temperature of SiO2/Al2O3 composite aerogel. J. Mol. Struct. 2024, 1315, 138858. [Google Scholar] [CrossRef]

- Zhang, W.; Jasim, D.J.; Alizadeh, A.a.; Nasajpour-Esfahani, N.; Hekmatifar, M.; Sabetvand, R.; Salahshour, S.; Toghraie, D. A numerical study of carbon doping effect on paraffin-reinforced silica aerogel mechanical properties: A molecular dynamics approach. J. Mol. Liq. 2023, 392, 123543. [Google Scholar] [CrossRef]

- Patil, S.P.; Shendye, P.; Markert, B. Mechanical properties and behavior of glass fiber-reinforced silica aerogel nanocomposites: Insights from all-atom simulations. Scr. Mater. 2020, 177, 65–68. [Google Scholar] [CrossRef]

- Patil, S.P.; Shendye, P.; Markert, B. Molecular dynamics simulations of silica aerogel nanocomposites reinforced by glass fibers, graphene sheets and carbon nanotubes: A comparison study on mechanical properties. Compos. B Eng. 2020, 190, 107884. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Silva, R.F.; Durães, L. Advances in carbon nanostructure–silica aerogel composites: A review. J. Mater. Chem. A 2018, 6, 1340–1369. [Google Scholar] [CrossRef]

- Kaya, G.G.; Deveci, H. Synergistic effects of silica aerogels/xerogels on properties of polymer composites: A review. J. Ind. Eng. Chem. 2020, 89, 13–27. [Google Scholar] [CrossRef]

- Lee, K.Y.; Mahadik, D.B.; Parale, V.G.; Park, H.H. Composites of silica aerogels with organics: A review of synthesis and mechanical properties. J. Korean Ceram. Soc. 2020, 57, 1–23. [Google Scholar] [CrossRef]

- Akhter, F.; Soomro, S.A.; Inglezakis, V.J. Silica aerogels; a review of synthesis, applications and fabrication of hybrid composites. J. Porous Mater. 2021, 28, 1387–1400. [Google Scholar] [CrossRef]

- Mazrouei-Sebdani, Z.; Begum, H.; Schoenwald, S.; Horoshenkov, K.V.; Malfait, W.J. A review on silica aerogel-based materials for acoustic applications. J. Non-Cryst. Solids 2021, 562, 120770. [Google Scholar] [CrossRef]

- Woignier, T.; Primera, J.; Alaoui, A.; Dieudonne, P.; Duffours, L.; Beurroies, I.; Calas-Etienne, S.; Despestis, F.; Faivre, A.; Etienne, P. Fractal structure in silica and composites aerogels. Gels 2020, 7, 1. [Google Scholar] [CrossRef] [PubMed]

- Linhares, T.; de Amorim, M.T.P.; Durães, L. Silica aerogel composites with embedded fibres: A review on their preparation, properties and applications. J. Mater. Chem. A 2019, 7, 22768–22802. [Google Scholar] [CrossRef]

- Fu, Z.; Corker, J.; Papathanasiou, T.; Wang, Y.; Zhou, Y.; Madyan, O.A.; Liao, F.; Fan, M. Critical review on the thermal conductivity modelling of silica aerogel composites. J. Build. Eng. 2022, 57, 104814. [Google Scholar] [CrossRef]

- Jadhav, S.; Sarawade, P. Recent advances and prospective of reinforced silica aerogel Nanocomposites and their applications. Eur. Polym. J. 2024, 206, 112766. [Google Scholar] [CrossRef]

- Niculescu, A.G.; Tudorache, D.I.; Bocioagă, M.; Mihaiescu, D.E.; Hadibarata, T.; Grumezescu, A.M. An updated overview of silica aerogel-based nanomaterials. Nanomaterials 2024, 14, 469. [Google Scholar] [CrossRef]

- Lamy-Mendes, A.; Pontinha, A.D.R.; Alves, P.; Santos, P.; Durães, L. Progress in silica aerogel-containing materials for buildings’ thermal insulation. Constr. Build. Mater. 2021, 286, 122815. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Vashchuk, A.; Klapiszewski, Ł. Research development in silica aerogel incorporated cementitious composites—A review. Polymers 2022, 14, 1456. [Google Scholar] [CrossRef]

- Maximiano, P.; Durães, L.; Simões, P. Overview of multiscale molecular modeling and simulation of silica aerogels. Ind. Eng. Chem. Res. 2019, 58, 18905–18929. [Google Scholar] [CrossRef]

- Patil, S.P.; Heider, Y. A review on brittle fracture nanomechanics by all-atom simulations. Nanomaterials 2019, 9, 1050. [Google Scholar] [CrossRef]

- Maghsoudi, K.; Motahari, S. Mechanical, thermal, and hydrophobic properties of silica aerogel–epoxy composites. J. Appl. Polym. Sci. 2018, 135, 45706. [Google Scholar] [CrossRef]

- Li, J.; Lei, Y.; Xu, D.; Liu, F.; Li, J.; Sun, A.; Guo, J.; Xu, G. Improved mechanical and thermal insulation properties of monolithic attapulgite nanofiber/silica aerogel composites dried at ambient pressure. J. Sol-Gel Sci. Technol. 2017, 82, 702–711. [Google Scholar] [CrossRef]

- Adhikary, S.K.; Rudžionis, Ž.; Tučkutė, S.; Ashish, D.K. Effects of carbon nanotubes on expanded glass and silica aerogel based lightweight concrete. Sci. Rep. 2021, 11, 2104. [Google Scholar] [CrossRef] [PubMed]

- Schwan, M.; Rößler, M.; Milow, B.; Ratke, L. From fragile to resilient insulation: Synthesis and characterization of aramid-honeycomb reinforced silica aerogel composite materials. Gels 2015, 2, 1. [Google Scholar] [CrossRef] [PubMed]

- Ślosarczyk, A. Carbon fiber—Silica aerogel composite with enhanced structural and mechanical properties based on water glass and ambient pressure drying. Nanomaterials 2021, 11, 258. [Google Scholar] [CrossRef]

- Merillas, B.; Lamy-Mendes, A.; Villafañe, F.; Durães, L.; Rodríguez-Pérez, M.Á. Silica-based aerogel composites reinforced with reticulated polyurethane foams: Thermal and mechanical properties. Gels 2022, 8, 392. [Google Scholar] [CrossRef]

- Yang, X.; Sun, Y.; Shi, D.; Liu, J. Experimental investigation on mechanical properties of a fiber-reinforced silica aerogel composite. Mater. Sci. Eng. A 2011, 528, 4830–4836. [Google Scholar] [CrossRef]

- Lyu, S.; Yang, X.; Shi, D.; Qi, H.; Jing, X.; Li, S. Effect of high temperature on compression property and deformation recovery of ceramic fiber reinforced silica aerogel composites. Sci. China Technol. Sci. 2017, 60, 1681–1691. [Google Scholar] [CrossRef]

- Wang, K.; Yang, L. Investigation of fibre-modified silica aerogel composites. Int. J. Mater. Res. 2024, 115, 687–699. [Google Scholar] [CrossRef]

- Shafi, S.; Tian, J.; Navik, R.; Gai, Y.; Ding, X.; Zhao, Y. Fume silica improves the insulating and mechanical performance of silica aerogel/glass fiber composite. J. Supercrit. Fluids 2019, 148, 9–15. [Google Scholar] [CrossRef]

- Abazari, M.S.; Entezari, M.H. Enhance the loss of sound transmission of glass using a thin polyester/silica aerogel composite as a new sound insulation. J. Build. Eng. 2024, 90, 109437. [Google Scholar] [CrossRef]

- Chen, Y.; Klima, K.; Brouwers, H.; Yu, Q. Effect of silica aerogel on thermal insulation and acoustic absorption of geopolymer foam composites: The role of aerogel particle size. Compos. B Eng. 2022, 242, 110048. [Google Scholar] [CrossRef]

- Tan, V.; Berg, F.; Maleki, H. Diatom-inspired silicification process for development of green flexible silica composite aerogels. Sci. Rep. 2024, 14, 6973. [Google Scholar] [CrossRef] [PubMed]

- Renjith, P.; Sarathchandran, C.; Chandramohanakumar, N.; Sekkar, V. Silica aerogel composite with inherent superparamagnetic property: A pragmatic and ecofriendly approach for oil spill clean-up under harsh conditions. Mater. Today Sustain. 2023, 24, 100498. [Google Scholar] [CrossRef]

- Liu, P.; Gao, H.; Chen, X.; Chen, D.; Lv, J.; Han, M.; Cheng, P.; Wang, G. In situ one-step construction of monolithic silica aerogel-based composite phase change materials for thermal protection. Compos. B Eng. 2020, 195, 108072. [Google Scholar] [CrossRef]

- Lin, D.; Yuen, P.Y.; Liu, Y.; Liu, W.; Liu, N.; Dauskardt, R.H.; Cui, Y. A silica-aerogel-reinforced composite polymer electrolyte with high ionic conductivity and high modulus. Adv. Mater. 2018, 30, 1802661. [Google Scholar] [CrossRef]

- Yi, Z.; Zhang, X.; Yan, L.; Huyan, X.; Zhang, T.; Liu, S.; Guo, A.; Liu, J.; Hou, F. Super-insulated, flexible, and high resilient mullite fiber reinforced silica aerogel composites by interfacial modification with nanoscale mullite whisker. Compos. B Eng. 2022, 230, 109549. [Google Scholar] [CrossRef]

- Krzemińska, S.; Cieślak, M.; Kamińska, I.; Nejman, A. Application of silica aerogel in composites protecting against thermal radiation. Autex Res. J. 2020, 20, 274–287. [Google Scholar] [CrossRef]

- Sachithanadam, M.; Joshi, S.C. High strain recovery with improved mechanical properties of gelatin–silica aerogel composites post-binding treatment. J. Mater. Sci. 2014, 49, 163–179. [Google Scholar] [CrossRef]

- Zhao, S.; Emery, O.; Wohlhauser, A.; Koebel, M.M.; Adlhart, C.; Malfait, W.J. Merging flexibility with superinsulation: Machinable, nanofibrous pullulan-silica aerogel composites. Mater. Des. 2018, 160, 294–302. [Google Scholar] [CrossRef]

- Koriakovtseva, T.A.; Dontsova, A.E.; Nemova, D.V. Mechanical and Thermal Properties of an Energy-Efficient Cement Composite Incorporating Silica Aerogel. Buildings 2024, 14, 1034. [Google Scholar] [CrossRef]

- Shah, S.N.; Mo, K.H.; Yap, S.P.; Radwan, M.K. Effect of micro-sized silica aerogel on the properties of lightweight cement composite. Constr. Build. Mater. 2021, 290, 123229. [Google Scholar] [CrossRef]

- Joshi, S.C.; Manikandan, P.; Jothi, Y. Enhancement studies on manufacturing and properties of novel silica aerogel composites. Gels 2018, 4, 5. [Google Scholar] [CrossRef] [PubMed]

- Linhares, T.; Carneiro, V.H.; Pessoa de Amorim, M.T.; Durães, L. A comparative thermoacoustic insulation study of silica aerogels reinforced with reclaimed textile fibres: Cotton, polyester and wool. Gels 2023, 9, 548. [Google Scholar] [CrossRef] [PubMed]

- GB/T 8813-2008; Plastics—Determination of Heat Distortion Temperature. Standardization Administration of China (SAC): Beijing, China, 2008.

- Ji, X.; Hao, Z.; Su, L.; He, T.; Liu, L. Characterizing the constitutive response of plain-woven fibre reinforced aerogel matrix composites using digital image correlation. Compos. Struct. 2020, 234, 111652. [Google Scholar] [CrossRef]

- ASTM C1359-96; Standard Test Method for Determination of Abrasion Resistance of Dimension Stone Subjected to Foot Traffic Using a Rotary Platform, Double-Head Abraser. ASTM International: West Conshohocken, PA, USA, 1996.

- Zhu, P.; Yu, S.; Cheng, C.; Zhao, S.; Xu, H. Durability of silica aerogel cementitious composites–freeze–thaw resistance, water resistance and drying shrinkage. Adv. Cem. Res. 2020, 32, 527–536. [Google Scholar] [CrossRef]

- JGJ 70-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2009.

- JGJ 51-2002; Technical Specification for Ground Base and Foundation of Buildings. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2002.

- GB/T 17671-1999; Method of Testing Cements—Determination of Strength. Standardization Administration of China (SAC): Beijing, China, 1999.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2010.

- Albooyeh, A.; Bayat, M.; Rafieian, P.; Dadrasi, A.; Khatibi, M.M. Silica aerogel/epoxy nanocomposites: Mechanical, vibrational, and morphological properties. J. Appl. Polym. Sci. 2020, 137, 49338. [Google Scholar] [CrossRef]

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D695-15; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D4065-12; Standard Practice for Plastics: Dynamic Mechanical Properties—Determination and Report of Procedures. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D676-03; Standard Test Method for Identification of Plastics. ASTM International: West Conshohocken, PA, USA, 2011.

- ASTM E756-05; Standard Test Method for Measuring Vibration-Damping Properties of Materials. ASTM International: West Conshohocken, PA, USA, 2010.

- Ismail, F.I.; Farhan, S.A.; Shafiq, N.; Husna, N.; Sharif, M.T.; Affan, S.U.; Veerasenan, A.K. Nano-porous silica-aerogel-incorporated composite materials for thermal-energy-efficient pitched roof in the tropical region. Appl. Sci. 2021, 11, 6081. [Google Scholar] [CrossRef]

- Aminoroaya, A.; Bagheri, R.; Khorasani, S.N.; Talebi, Z.; Derakhshanfar, P.; Neisiany, R.E. Mesoporous silica aerogel reinforced dental composite: Effects of microstructure and surface modification. J. Mech. Behav. Biomed. Mater. 2022, 125, 104947. [Google Scholar] [CrossRef]

- ISO 4049:2009; Dentistry—Polymer-Based Restorative Materials. International Organization for Standardization: Geneva, Switzerland, 2009.

- ISO 6872:2015; Dentistry—Ceramic Materials. International Organization for Standardization: Geneva, Switzerland, 2015.

- BS EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. British Standards Institution: London, UK, 2016.

- Kim, J.H.; Ahn, J.H.; Kim, J.D.; Lee, D.H.; Kim, S.K.; Lee, J.M. Influence of silica-aerogel on mechanical characteristics of polyurethane-based composites: Thermal conductivity and strength. Materials 2021, 14, 1790. [Google Scholar] [CrossRef]

- BKS M ISO 844:2009; Rigid Cellular Plastics—Determination of Compression Properties. Korean Agency for Technology and Standards: Eumseong, Republic of Korea, 2009.

- Zhang, Z.; Li, B.; Wang, Z.; Liu, W.; Liu, X. Development of reduced thermal conductivity ductile cement-based composite material by using silica aerogel and silane. J. Build. Eng. 2023, 65, 105698. [Google Scholar] [CrossRef]

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. Standardization Administration of China (SAC): Beijing, China, 2005.

- Wang, G.; Yu, W.; Zhang, S.; Yang, K.; Liu, W.; Wang, J.; Liu, F. Improved Thermal Insulation and Mechanical Strength of Styrene-Butadiene Rubber through the Combination of Filled Silica Aerogels and Modified Glass Fiber. Materials 2023, 16, 5947. [Google Scholar] [CrossRef] [PubMed]

- GB/T 528-2009; Rubber, Vulcanized or Thermoplastic—Determination of Tensile Stress-Strain Properties. Standardization Administration of China (SAC): Beijing, China, 2009.

- Kang, D.; Jia, S.; Zhao, C.; Ni, Y.; Qi, J.; Kang, Z.; Sui, Y.; Wei, F.; Xiao, B.; Meng, Q. High-temperature resistance performance of silica aerogel composites through fiber reinforcement. Ceram. Int. 2024, 50, 26829–26838. [Google Scholar] [CrossRef]

- Shan, J.; Shan, Y.; Zou, C.; Hong, Y.; Liu, J.; Guo, X. Cost-effective preparation of hydrophobic and thermal-insulating silica aerogels. Nanomaterials 2024, 14, 119. [Google Scholar] [CrossRef] [PubMed]

- Kucharek, M.; MacRae, W.; Yang, L. Investigation of the effects of silica aerogel particles on thermal and mechanical properties of epoxy composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106108. [Google Scholar] [CrossRef]

- Sai, H.; Wang, M.; Miao, C.; Song, Q.; Wang, Y.; Fu, R.; Wang, Y.; Ma, L.; Hao, Y. Robust silica-bacterial cellulose composite aerogel fibers for thermal insulation textile. Gels 2021, 7, 145. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Li, H.; Ji, H.; Sun, X.; He, J. Effect of sepiolite fiber on the structure and properties of the sepiolite/silica aerogel composite. J. Sol-Gel Sci. Technol. 2013, 67, 646–653. [Google Scholar] [CrossRef]

- Lao, J.; Ma, J.; Zhao, Z.; Xia, N.; Liu, J.; Peng, H.; Fang, T.; Fu, W. Preparation and Properties of Na2HPO4·12H2O/Silica Aerogel Composite Phase Change Materials for Building Energy Conservation. Materials 2024, 17, 5350. [Google Scholar] [CrossRef]

- Ren, J.; Zhang, T.; Kong, Y.; Zhao, Z.; Zhu, K.; Zhang, X.; Shen, X. Facile synthesis of phenolic-reinforced silica aerogel composites for thermal insulation under thermal-force coupling conditions. Ceram. Int. 2023, 49, 29820–29828. [Google Scholar] [CrossRef]

- Feng, G.; Li, Z.; Mi, L.; Zheng, J.; Feng, X.; Chen, W. Polypropylene/hydrophobic-silica-aerogel-composite separator induced enhanced safety and low polarization for lithium-ion batteries. J. Power Sources 2018, 376, 177–183. [Google Scholar] [CrossRef]

- Martinez, R.G.; Goiti, E.; Reichenauer, G.; Zhao, S.; Koebel, M.; Barrio, A. Thermal assessment of ambient pressure dried silica aerogel composite boards at laboratory and field scale. Energy Build. 2016, 128, 111–118. [Google Scholar] [CrossRef]

- Mazraeh-Shahi, Z.T.; Shoushtari, A.M.; Bahramian, A.R.; Abdouss, M. Synthesis, structure and thermal protective behavior of silica aerogel/PET nonwoven fiber composite. Fibers Polym. 2014, 15, 2154–2159. [Google Scholar] [CrossRef]

- Zhang, C.; Li, J.; Jiang, J.; Hu, X.; Yang, S.; Wang, K.; Guo, A.; Du, H. Flexible and Compressible Nanostructure-Assembled Aramid Nanofiber/Silica Composites Aerogel. Materials 2024, 17, 1938. [Google Scholar] [CrossRef] [PubMed]

- Perez-Moreno, A.; Reyes-Peces, M.d.l.V.; de Los Santos, D.M.; Pinaglia-Tobaruela, G.; de la Orden, E.; Vilches-Pérez, J.I.; Salido, M.; Piñero, M.; de la Rosa-Fox, N. Hydroxyl groups induce bioactivity in silica/chitosan aerogels designed for bone tissue engineering. In vitro model for the assessment of osteoblasts behavior. Polymers 2020, 12, 2802. [Google Scholar] [CrossRef] [PubMed]

- Laskowski, J.; Milow, B.; Ratke, L. Aerogel–aerogel composites for normal temperature range thermal insulations. J. Non-Cryst. Solids 2016, 441, 42–48. [Google Scholar] [CrossRef]

- Li, Z.; Gong, L.; Cheng, X.; He, S.; Li, C.; Zhang, H. Flexible silica aerogel composites strengthened with aramid fibers and their thermal behavior. Mater. Des. 2016, 99, 349–355. [Google Scholar] [CrossRef]

- Hwang, J.; Kim, Y.; Park, J.; Rie, D. A Study on the Evaluation of Thermal Insulation Performance of Cellulose-Based Silica Aerogel Composite Building Materials. Polymers 2024, 16, 1848. [Google Scholar] [CrossRef]

- Ghica, M.E.; Almeida, C.M.; Fonseca, M.; Portugal, A.; Durães, L. Optimization of polyamide pulp-reinforced silica aerogel composites for thermal protection systems. Polymers 2020, 12, 1278. [Google Scholar] [CrossRef]

- Ge, D.; Yang, L.; Li, Y.; Zhao, J. Hydrophobic and thermal insulation properties of silica aerogel/epoxy composite. J. Non-Cryst. Solids 2009, 355, 2610–2615. [Google Scholar] [CrossRef]

- Wang, X.; Liu, J.; Shi, F.; Liu, S.; Feng, X.; Bao, L. Influences of heat-treatment on the microstructure and properties of silica–titania composite aerogels. J. Porous Mater. 2014, 21, 293–301. [Google Scholar] [CrossRef]

- Eskandari, N.; Motahari, S.; Atoufi, Z.; Hashemi Motlagh, G.; Najafi, M. Thermal, mechanical, and acoustic properties of silica-aerogel/UPVC composites. J. Appl. Polym. Sci. 2017, 134, 44685. [Google Scholar] [CrossRef]

- ASTM D1525-15; Standard Test Method for Vicat Softening Temperature of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C177-13; Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus. ASTM International: West Conshohocken, PA, USA, 2013.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate — Part 1: Heat Release Rate (Cone Calorimeter Method). International Organization for Standardization: Geneva, Switzerland, 2022.

- ASTM C518-17; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus. ASTM International: West Conshohocken, PA, USA, 2017.

- ISO/DIS 8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- GB/T 5480-2017; Glass Fibre—Definition of Terms Related to Woven Fabrics. Standardization Administration of China (SAC): Beijing, China, 2017.

- GB/T 12704.2-2009; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Part 2: Heat Flow Meter Apparatus. Standardization Administration of China (SAC): Beijing, China, 2009.

- EN ISO 6942:2002; Protective Clothing—Protection Against Heat and Fire—Method of Test: Evaluation of Materials and Material Assemblies when Exposed to a Source of Radiant Heat. European Committee for Standardization: Brussels, Belgium, 2002.

- EN ISO 11612:2015; Protective Clothing—Clothing to Protect Against Heat and Flame—Minimum Performance Requirements. European Committee for Standardization: Brussels, Belgium, 2015.

- Yang, H.; Ye, F. Microtexture, microstructure evolution, and thermal insulation properties of Si 3 N 4/silica aerogel composites at high temperatures. RSC Adv. 2022, 12, 12226–12234. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, Q.; Li, M.; Chen, Z.; Cheng, X.; Wu, X.; Li, Z. Insights into the thermal safety of ambient pressure dried hydrophobic montmorillonite/silica aerogel composites. Ceram. Int. 2024, 50, 6135–6145. [Google Scholar] [CrossRef]

- Pantaleo, S.; Gauvin, F.; Schollbach, K.; Brouwers, H. Development of latex/silica aerogel composites for thermal insulation applications. Dev. Built Environ. 2024, 20, 100576. [Google Scholar] [CrossRef]

- Yu, D.; Liu, M.; Xu, F.; Kong, Y.; Shen, X. Structure tailoring and thermal performances of water glass-derived silica aerogel composite with high specific surface area and enhanced thermal stability. J. Non-Cryst. Solids 2024, 630, 122889. [Google Scholar] [CrossRef]

- GB/T 10294-2008; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. Standardization Administration of China (SAC): Beijing, China, 2008.

- ISO 8302:1991; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Guarded Hot Plate Apparatus. International Organization for Standardization: Geneva, Switzerland, 1991.

- Zhang, T.; Yu, D.; Xu, F.; Kong, Y.; Shen, X. Flexible silica aerogel composites for thermal insulation under high-temperature and thermal–force coupling conditions. ACS Appl. Nano Mater. 2024, 7, 6326–6338. [Google Scholar] [CrossRef]

- YB/T 4130-2005; Test Method for Thermal Conductivity of Refractories—Hot Wire Method. Ministry of Industry and Information Technology of the People’s Republic of China: Beijing, China, 2005.

- ASTM C201-93; Standard Test Method for Thermal Conductivity of Refractories by Hot Wire (Platinum Resistance Thermometer Technique). ASTM International: West Conshohocken, PA, USA, 2001.

- Liu, M.; Kong, Y.; Tang, J.; Zhang, B.; Shen, X. Structure and performance evolutions with temperature, stress, and thermal-force coupling of the silica aerogel composite for suppressing thermal runaway propagation of LIBs. Compos. Part A Appl. Sci. Manuf. 2025, 190, 108692. [Google Scholar] [CrossRef]

- GB/T 10295-2008; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Calibrated and Guarded Hot Box. Standardization Administration of China (SAC): Beijing, China, 2008.

- Wei, G.; Liu, Y.; Zhang, X.; Yu, F.; Du, X. Thermal conductivities study on silica aerogel and its composite insulation materials. Int. J. Heat Mass Transf. 2011, 54, 2355–2366. [Google Scholar] [CrossRef]

- Xie, T.; He, Y.L.; Hu, Z.J. Theoretical study on thermal conductivities of silica aerogel composite insulating material. Int. J. Heat Mass Transf. 2013, 58, 540–552. [Google Scholar] [CrossRef]

- Li, D.; Cao, Z.W.; Xie, X.Q.; Chen, X.; He, Y.L. Experiments and numerical study on heat transfer of moist silica aerogel composites at high temperatures. Energy Storage Sav. 2024, 3, 73–86. [Google Scholar] [CrossRef]

- Fang, W.Z.; Zhang, H.; Chen, L.; Tao, W.Q. Numerical predictions of thermal conductivities for the silica aerogel and its composites. Appl. Therm. Eng. 2017, 115, 1277–1286. [Google Scholar] [CrossRef]

- Zhao, J.J.; Duan, Y.Y.; Wang, X.D.; Wang, B.X. Radiative properties and heat transfer characteristics of fiber-loaded silica aerogel composites for thermal insulation. Int. J. Heat Mass Transf. 2012, 55, 5196–5204. [Google Scholar] [CrossRef]

- Xie, T.; He, Y.L. Heat transfer characteristics of silica aerogel composite materials: Structure reconstruction and numerical modeling. Int. J. Heat Mass Transf. 2016, 95, 621–635. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Tian, Y.; Jiao, J.; Wu, X. Thermal insulation performance of silica aerogel composites doped with hollow opacifiers: Theoretical approach. Gels 2022, 8, 295. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Xu, G.; Li, H.; Yuan, P.; Wang, Y.; Liu, Y.; Wu, X.; Li, Z. Design of hollow glass fiber/silica aerogel composites for high-temperature thermal insulation applications. Therm. Sci. Eng. Prog. 2024, 48, 102388. [Google Scholar] [CrossRef]

- Chen, Y.; Li, D.; Xie, X.Q.; Gao, Y.; He, Y.L. Theoretical modeling and experimental validation for the effective thermal conductivity of moist silica aerogel. Int. J. Heat Mass Transf. 2020, 147, 118842. [Google Scholar] [CrossRef]

- Bjurström, H.; Karawacki, E.; Carlsson, B. Thermal conductivity of a microporous particulate medium: Moist silica gel. Int. J. Heat Mass Transf. 1984, 27, 2025–2036. [Google Scholar] [CrossRef]

- Hoseini, A.; McCague, C.; Andisheh-Tadbir, M.; Bahrami, M. Aerogel blankets: From mathematical modeling to material characterization and experimental analysis. Int. J. Heat Mass Transf. 2016, 93, 1124–1131. [Google Scholar] [CrossRef]

- Wang, X.D.; Sun, D.; Duan, Y.Y.; Hu, Z.J. Radiative characteristics of opacifier-loaded silica aerogel composites. J. Non-Cryst. Solids 2013, 375, 31–39. [Google Scholar] [CrossRef]

- Zhu, C.Y.; Li, J.B.; Dai, P.C.; Gong, L. Elevating high-temperature insulation performance of silica aerogels enabled by innovative surface-structured opacifiers. Appl. Therm. Eng. 2024, 255, 123915. [Google Scholar] [CrossRef]

- Dai, Y.J.; Tang, Y.Q.; Fang, W.Z.; Zhang, H.; Tao, W.Q. A theoretical model for the effective thermal conductivity of silica aerogel composites. Appl. Therm. Eng. 2018, 128, 1634–1645. [Google Scholar] [CrossRef]

- Liu, H.; Liu, J.; Tian, Y.; Wu, X.; Li, Z. Investigation of high temperature thermal insulation performance of fiber-reinforced silica aerogel composites. Int. J. Therm. Sci. 2023, 183, 107827. [Google Scholar] [CrossRef]

- Almeida, C.M.; Ghica, M.E.; Ramalho, A.L.; Durães, L. Silica-based aerogel composites reinforced with different aramid fibres for thermal insulation in Space environments. J. Mater. Sci. 2021, 56, 13604–13619. [Google Scholar] [CrossRef]

- Ślosarczyk, A.; Klapiszewski, Ł.; Buchwald, T.; Krawczyk, P.; Kolanowski, Ł.; Lota, G. Carbon fiber and nickel coated carbon fiber–silica aerogel nanocomposite as low-frequency microwave absorbing materials. Materials 2020, 13, 400. [Google Scholar] [CrossRef] [PubMed]

- Ni, L.; Luo, Y.; Shen, L.; Qiu, C.; Yan, L.; Liang, M.; Zhou, S.; Zou, H. Lightweight polyimide/silica aerogel composite foams and their derived carbon foams for excellent flame retardancy, thermal insulation and EMI shielding performance. Polymer 2024, 305, 127158. [Google Scholar] [CrossRef]

- Yang, L.; Ding, Y.; Yang, M.; Wang, Y.; Erişen, D.E.; Chen, Z.; Wu, Q.; Zheng, G. Ultra-light and ultra-low thermal conductivity of elastic silica nanofibrous aerogel with TiO2 opacifier particles as filler. Nanomaterials 2022, 12, 3928. [Google Scholar] [CrossRef]

- Lee, H.; Lee, D.; Cho, J.; Kim, Y.O.; Lim, S.; Youn, S.; Jung, Y.C.; Kim, S.Y.; Seong, D.G. Super-insulating, flame-retardant, and flexible poly (dimethylsiloxane) composites based on silica aerogel. Compos. Part A Appl. Sci. Manuf. 2019, 123, 108–113. [Google Scholar] [CrossRef]

- Bo, G.; Xu, X.; Tian, X.; Wu, J.; Yan, Y. Enhancing the fire safety and smoke safety of bio–based rigid polyurethane foam via inserting a reactive flame retardant containing P@ N and blending silica aerogel powder. Polymers 2021, 13, 2140. [Google Scholar] [CrossRef]

- Motahari, S.; Abolghasemi, A. Silica aerogel–glass fiber composites as fire shield for steel frame structures. J. Mater. Civ. Eng. 2015, 27, 04015008. [Google Scholar] [CrossRef]

- Abd Halim, Z.A.; Ahmad, N.; Yajid, M.A.M.; Hamdan, H. Thermal insulation performance of silicone rubber/silica aerogel composite. Mater. Chem. Phys. 2022, 276, 125359. [Google Scholar] [CrossRef]

- Liu, L.; Li, L.; Hu, Y.; Feng, J.; Jiang, Y.; Feng, J. Effect of Fiber Characteristics on the Structure and Properties of Quartz Fiber Felt Reinforced Silica-Polybenzoxazine Aerogel Composites. Gels 2024, 10, 613. [Google Scholar] [CrossRef]

- Berkefeld, A.; Heyer, M.; Milow, B. Silica aerogel paper honeycomb composites for thermal insulations. J. Sol-Gel Sci. Technol. 2017, 84, 486–495. [Google Scholar] [CrossRef]

- Huang, Y.; He, S.; Chen, G.; Shi, X.; Yang, X.; Dai, H.; Chen, X. Mechanical reinforced fiber needle felt/silica aerogel composite with its flammability. J. Sol-Gel Sci. Technol. 2018, 88, 129–140. [Google Scholar] [CrossRef]

- ASTM D2863-13; Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index). ASTM International: West Conshohocken, PA, USA, 2013.

- ASTM E1354-17; Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter. ASTM International: West Conshohocken, PA, USA, 2017.

- ECSS-Q-ST-70-04C; Space Product Assurance—Thermal Cycling Test for the Screening of Space Materials and Processes. ESA/ESTEC: Noordwijk, The Netherlands, 2008.

- ECSS-Q-ST-70-02C; Thermal Vacuum Outgassing Test for the Screening of Space Materials. ESA/ESTEC: Noordwijk, The Netherlands, 2008.

- ECSS-Q-ST-70; Space Product Assurance—Materials, Mechanical Parts and Processes. European Cooperation for Space Standardization (ECSS): Noordwijk, The Netherlands, 2019.

- GB/T 2406.2-2009; Plastics—Determination of Burning Behaviour by Oxygen Index—Part 2: Ambient-Temperature Test. Standardization Administration of China (SAC): Beijing, China, 2009.

- COMSOL Multiphysics. Introduction to Comsol Multiphysics®. Available online: https://cdn.comsol.com/doc/5.5/IntroductionToCOMSOLMultiphysics.pdf (accessed on 8 June 2025).

- Arshad, A.; Roy, A.; Mallick, T.K.; Tahir, A.A. Shape-stabilized PEGylated silica aerogel-composite as an energy saving building material. Ind. Eng. Chem. Res. 2023, 62, 20236–20250. [Google Scholar] [CrossRef] [PubMed]

- Fu, W.; Lao, J.; Zhou, W.; Chen, L.; Ma, J.; He, Z.; Tan, B.; Zhou, Q. Experimental and numerical investigations on phase change thermal storage foam concrete based on CaCl2·6H2O/silica aerogel composite phase change material. J. Energy Storage 2024, 103, 114371. [Google Scholar] [CrossRef]

- Mei, H.; Li, H.; Jin, Z.; Li, L.; Yang, D.; Liang, C.; Cheng, L.; Zhang, L. 3D-printed SiC lattices integrated with lightweight quartz fiber/silica aerogel sandwich structure for thermal protection system. Chem. Eng. J. 2023, 454, 140408. [Google Scholar] [CrossRef]

- Mishra, R.; Behera, B.; Muller, M.; Petru, M. Finite element modeling based thermodynamic simulation of aerogel embedded nonwoven thermal insulation material. Int. J. Therm. Sci. 2021, 164, 106898. [Google Scholar] [CrossRef]

- Gelb, L.D. Simulating silica aerogels with a coarse-grained flexible model and langevin dynamics. J. Phys. Chem. C 2007, 111, 15792–15802. [Google Scholar] [CrossRef]

- Ferreiro-Rangel, C.A.; Gelb, L.D. Investigation of the bulk modulus of silica aerogel using molecular dynamics simulations of a coarse-grained model. J. Phys. Chem. B 2013, 117, 7095–7105. [Google Scholar] [CrossRef]

- Ferreiro-Rangel, C.A.; Gelb, L.D. Computational study of uniaxial deformations in silica aerogel using a coarse-grained model. J. Phys. Chem. B 2015, 119, 8640–8650. [Google Scholar] [CrossRef]

- Xiao, J.; Zhang, H.; Gao, X.; Wang, H.; Fang, G.; Wang, B.; Hong, C.; Meng, S. Insight into pyrolysis behavior of silicone-phenolic hybrid aerogel through thermal kinetic analysis and ReaxFF MD simulations. Chem. Eng. J. 2023, 458, 141480. [Google Scholar] [CrossRef]

- Maximiano, P.; Simões, P.N. Understanding silica aerogel-carbon nanotube composite structures by molecular simulation. Microporous Mesoporous Mater. 2024, 365, 112886. [Google Scholar] [CrossRef]

- Karimipour, A.; Shahgholi, M.; Attaeyan, A.; Viet, P.; Asiri, S.A.; Alfawaz, K.M.; Alogla, A.F. The effect of initial temperature on the mechanical strength of tricalcium phosphate/Chitosan/Silica aerogels nanocomposites using molecular dynamics simulation. J. Taiwan Inst. Chem. Eng. 2024, 164, 105682. [Google Scholar] [CrossRef]

- Lu, Z.; Yuan, Z.; Liu, Q.; Hu, Z.; Xie, F.; Zhu, M. Multi-scale simulation of the tensile properties of fiber-reinforced silica aerogel composites. Mater. Sci. Eng., A 2015, 625, 278–287. [Google Scholar] [CrossRef]

- Vivekh, P.; Bui, D.; Kumja, M.; Islam, M.; Chua, K. Theoretical performance analysis of silica gel and composite polymer desiccant coated heat exchangers based on a CFD approach. Energy Convers. Manag. 2019, 187, 423–446. [Google Scholar] [CrossRef]

- Nasri, W.; Djebali, R.; Chamkha, A.J.; Bezazi, A.; Mechighel, F.; Reis, P.; Driss, Z. Thermal behavior of mesoporous Aramid fiber reinforced silica aerogel composite for thermal insulation applications: Microscale modeling. J. Appl. Comput. Mech. 2024, 10, 140–151. [Google Scholar]

- Murillo, J.S.R.; Bachlechner, M.E.; Campo, F.A.; Barbero, E.J. Structure and mechanical properties of silica aerogels and xerogels modeled by molecular dynamics simulation. J. Non-Cryst. Solids 2010, 356, 1325–1331. [Google Scholar] [CrossRef]

- Gelb, L.D. Simulation and modeling of aerogels using atomistic and mesoscale methods. In Springer Handbook of Aerogels; Springer: Cham, Switzerland, 2023; pp. 273–288. [Google Scholar] [CrossRef]

- Harper, L.; Qian, C.; Turner, T.; Li, S.; Warrior, N. Representative volume elements for discontinuous carbon fibre composites–Part 1: Boundary conditions. Compos. Sci. Technol. 2012, 72, 225–234. [Google Scholar] [CrossRef]

- Lu, Z.; Yuan, Z.; Liu, Q. 3D numerical simulation for the elastic properties of random fiber composites with a wide range of fiber aspect ratios. Comput. Mater. Sci. 2014, 90, 123–129. [Google Scholar] [CrossRef]

- Luo, Z.; Yang, Z.; Fei, Z.; Li, K. Dissipative particle dynamics simulation of physical process in preparing PI cross-linked silica aerogel. J. Mol. Liq. 2021, 325, 115038. [Google Scholar] [CrossRef]

- Maximiano, P.; Duraes, L.; Simoes, P. Intermolecular interactions in composites of organically-modified silica aerogels and polymers: A molecular simulation study. Microporous Mesoporous Mater. 2021, 314, 110838. [Google Scholar] [CrossRef]

- Gonçalves, W.; Morthomas, J.; Chantrenne, P.; Perez, M.; Foray, G.; Martin, C.L. Elasticity and strength of silica aerogels: A molecular dynamics study on large volumes. Acta Mater. 2018, 145, 165–174. [Google Scholar] [CrossRef]

- Patil, S.P.; Parale, V.G.; Park, H.H.; Markert, B. Molecular dynamics and experimental studies of nanoindentation on nanoporous silica aerogels. Mater. Sci. Eng. A 2019, 742, 344–352. [Google Scholar] [CrossRef]

- Phalippou, J.; Woignier, T.; Rogier, R. Fracture toughness of silica aerogels. J. Phys. Colloq. 1989, 50, C4-191. [Google Scholar] [CrossRef]

- Patil, S.P.; Rege, A.; Itskov, M.; Markert, B. Fracture of silica aerogels: An all-atom simulation study. J. Non-Cryst. Solids 2018, 498, 125–129. [Google Scholar] [CrossRef]

- Patil, S.P.; Shendye, P.; Markert, B. Molecular dynamics investigation of the shock response of silica aerogels. Materialia 2019, 6, 100315. [Google Scholar] [CrossRef]

- Patil, S.P.; Rege, A.; Sagardas; Itskov, M.; Markert, B. Mechanics of nanostructured porous silica aerogel resulting from molecular dynamics simulations. J. Phys. Chem. B 2017, 121, 5660–5668. [Google Scholar] [CrossRef]

- Berendsen, H.J.; van der Spoel, D.; van Drunen, R. GROMACS: A message-passing parallel molecular dynamics implementation. Comput. Phys. Commun. 1995, 91, 43–56. [Google Scholar] [CrossRef]

- Hess, B.; Kutzner, C.; Van Der Spoel, D.; Lindahl, E. GROMACS 4: Algorithms for highly efficient, load-balanced, and scalable molecular simulation. J. Chem. Theory Comput. 2008, 4, 435–447. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kunte, A.A.; Khandelwal, S.; Patil, S.P. Comprehensive Overview on the Computational, Experimental, Numerical, and Theoretical Assessments of Silica Aerogel Composites. J. Compos. Sci. 2025, 9, 306. https://doi.org/10.3390/jcs9060306

Kunte AA, Khandelwal S, Patil SP. Comprehensive Overview on the Computational, Experimental, Numerical, and Theoretical Assessments of Silica Aerogel Composites. Journal of Composites Science. 2025; 9(6):306. https://doi.org/10.3390/jcs9060306

Chicago/Turabian StyleKunte, Aditya Abhijit, Sarthak Khandelwal, and Sandeep P. Patil. 2025. "Comprehensive Overview on the Computational, Experimental, Numerical, and Theoretical Assessments of Silica Aerogel Composites" Journal of Composites Science 9, no. 6: 306. https://doi.org/10.3390/jcs9060306

APA StyleKunte, A. A., Khandelwal, S., & Patil, S. P. (2025). Comprehensive Overview on the Computational, Experimental, Numerical, and Theoretical Assessments of Silica Aerogel Composites. Journal of Composites Science, 9(6), 306. https://doi.org/10.3390/jcs9060306